Efficient feed production line

A production line and feed technology, which is applied in the field of high-efficiency feed production lines, can solve the problems of large loss, material pollution, and inconvenient flexible feed production, and achieve the effects of reducing pollution and loss, saving floor space, and facilitating flexible production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

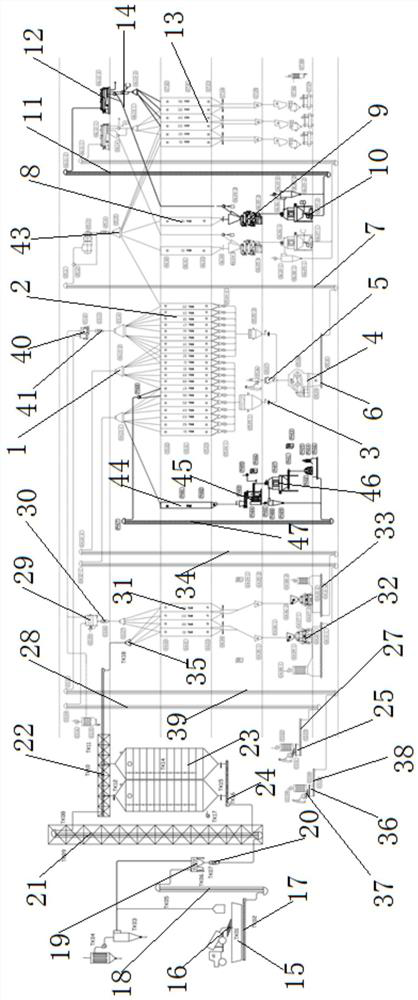

[0022] Such as figure 1 As shown, a high-efficiency feed production line includes a car incoming material conveying impurity removal mechanism, a cake conveying impurity removing mechanism and a powder conveying impurity removing mechanism, an automobile incoming material conveying impurity removing mechanism and a cake conveying impurity removing mechanism The discharge ends are all connected to the feed port of the crushing mechanism, and the discharge ports of the crushing mechanism and the powder conveying and removing mechanism are connected to the first distributor 1, and the feed through the first distributor 1 and the batching bin 2 The outlet of the batching bin 2 is provided with a screw feeder, the screw feeder is connected with the mixer 4 through the electronic scale 3, the mixer 4 is provided with a small material inlet 5, and the output of the mixer 4 The mouth is connected with the mixing elevator 7 through the third screw conveyor 6, and the outlet of the mixi...

Embodiment 2

[0025] This embodiment is basically the same as Embodiment 1, the difference is: as figure 1 As shown, the automobile incoming material conveying impurity removal mechanism includes a first discharge pit 15, a first grid screen 16 is fixed on the upper end of the first discharge pit 15, and a fan is arranged above the first discharge pit 15 for suction. Dust removal, the bottom of the first unloading pit 15 is fixed with a first buried scraper conveyor 17, and the outlet of the first buried scraper conveyor 17 is connected with a first bucket elevator in sequence along the conveying direction of the incoming materials of the automobile 18. The first chute, the first cylinder initial cleaning screen 19, the first permanent magnet cylinder 20, the second bucket elevator 21, the discharge scraper conveyor 22, and the outlet of the discharge scraper conveyor 22 Connect with the feed port of the vertical cylinder warehouse 23 and the crushing mechanism respectively, and the lower e...

Embodiment 3

[0031] This embodiment is basically the same as Embodiment 1 or 2, the difference is: as figure 1 As shown, the powder conveying and removing mechanism includes a third discharge pit 36, a third grid screen 37 is fixed on the upper end of the third discharge pit 36, and a second pulse dust collector is arranged above the third discharge pit 36 The third buried scraper conveyor 38 is fixed on the bottom of the third unloading pit 36, and the discharge port of the third buried scraper conveyor 38 is sequentially connected with a third The bucket elevator 39, the third chute, the third cylinder preliminary cleaning screen 40 and the third permanent magnet cylinder 41, the third permanent magnet cylinder 41 is connected with the feeding port of the first distributor 1.

[0032] After being preliminarily screened by the third grid sieve 37, the powder raw materials enter the third unloading pit 36 after removing relatively large debris, and are transported to the third bucket ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com