Impurity separation and screening device for producing carbon black

A technology for separation, screening and impurities, applied in the chemical industry, can solve the problem of impurity removal and purification, and achieve the effects of prolonging service life, simple and convenient collection, and improving product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

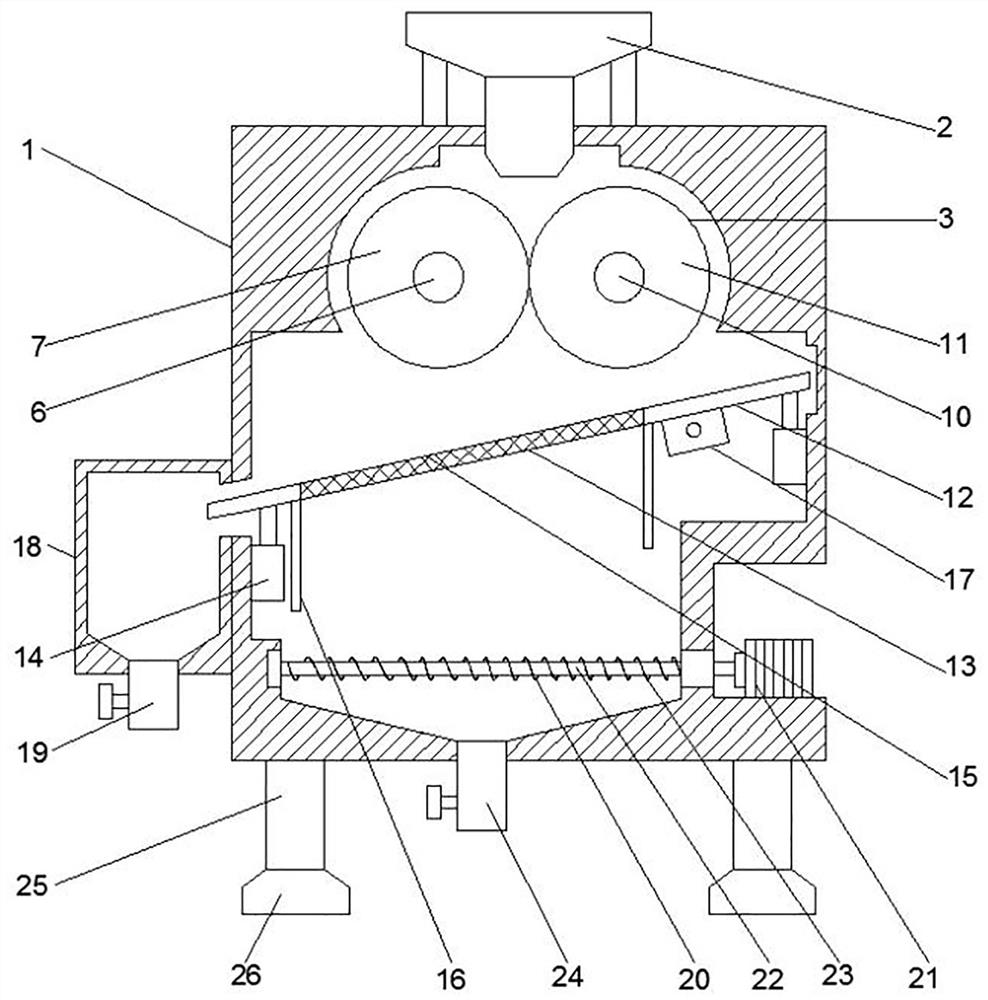

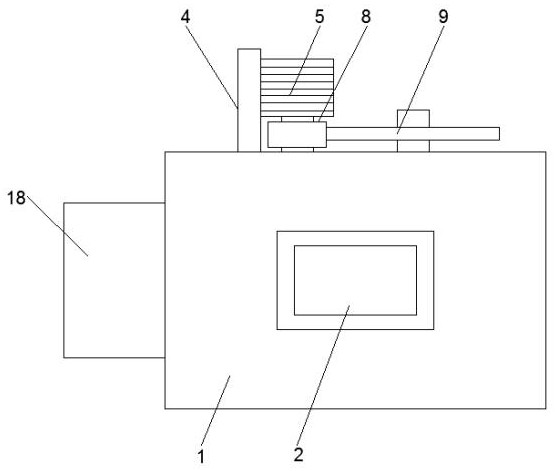

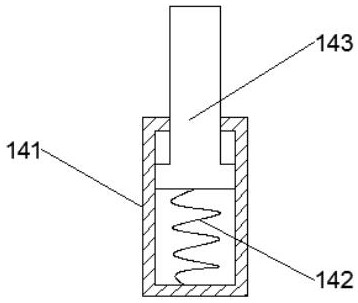

[0023] Below in conjunction with accompanying drawing, the present invention is further explained and illustrated;

[0024] Such as Figure 1~3 , an impurity separation and screening device for producing carbon black, comprising a box body 1, a feed hopper 2 is fixed in the middle of the upper end of the box body 1, and the inside of the box body 1 is located below the feed hopper 2 from top to bottom The grinding mechanism 3, the screening mechanism 12 and the impurity separation mechanism 20 are sequentially; the feeding hopper 2 is funnel-shaped, and the left and right sides are fixedly connected to the top surface of the box body 1 through support rods; The lower end of the supporting leg 25 is equipped with a foot 26; the inner bottom of the box body 1 is set as a V-shaped structure with a slope, and the bottom of the slope is provided with a discharge pipe 2 24;

[0025] Wherein, the grinding mechanism 3 includes a grinding motor 5, two grinding wheels, and driving and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com