Spindle-shaped material tail removing machine

A spindle-shaped material technology, applied in solid separation, separation of solids from solids with airflow, metal processing, etc., can solve the problems of difficult to ensure hygiene and safety, different thickness of tail removal, low efficiency, etc., to save labor , Avoid external pollution and reduce energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

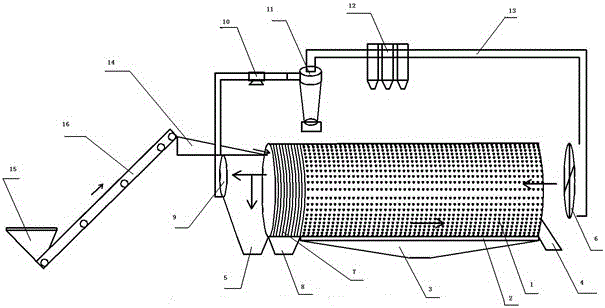

[0011] Embodiment 1: a kind of spindle-shaped material tailing machine, as figure 1 , comprising a feeding mechanism, an impurity removal and screening mechanism, a tail removal mechanism and a dust removal mechanism; The tail receiving hopper 3 at the bottom of the tail removal scraper 2 is connected with the discharge hopper 4 at the end of the mesh tail removal drum 1 . Utilize heterophylla heterophylla with large head and small tail, when the tail passes through the layout with holes, the small tail will be randomly inserted into the hole, and then scraped off by the tail scraper 2 to separate the tail, and the broken tail will fall into the tail receiving hopper 3 , to remove the tail material is sent to the discharge hopper 4 through the corresponding deflector.

[0012] The impurity removal and screening mechanism includes an impurity removal hopper 5, an impurity removal blower 6 positioned at the end of the mesh tail removal drum 1, a longitudinal strip drum screen 7...

Embodiment 2

[0014] Embodiment 2: a kind of spindle-shaped material tailing machine, as figure 1 As shown, it includes a feeding mechanism, an impurity removal and screening mechanism, a tail removal mechanism and a dust removal mechanism; the tail removal mechanism includes a mesh tail removal drum, and the mesh of the mesh tail removal drum is 0.25cm. All the other are identical with embodiment 1.

Embodiment 3

[0015] Embodiment 3: a kind of spindle-shaped material tailing machine, as figure 1 As shown, it includes a feeding mechanism, an impurity removal and screening mechanism, a tail removal mechanism and a dust removal mechanism; the tail removal mechanism includes a mesh tail removal drum, and the mesh of the mesh tail removal drum is 0.3cm. All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com