Test bed and method for testing high-frequency mechanical characteristic of tire

A technology of mechanical properties and test bench, which is applied in the direction of automobile tire testing, etc., can solve the problems that affect the research, cannot guarantee the high stiffness of the test simulated road surface, the uniformity of stiffness, and the error of test data, so as to improve the accuracy and novel and unique loading method , Reduce the difficulty and cost of design and manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

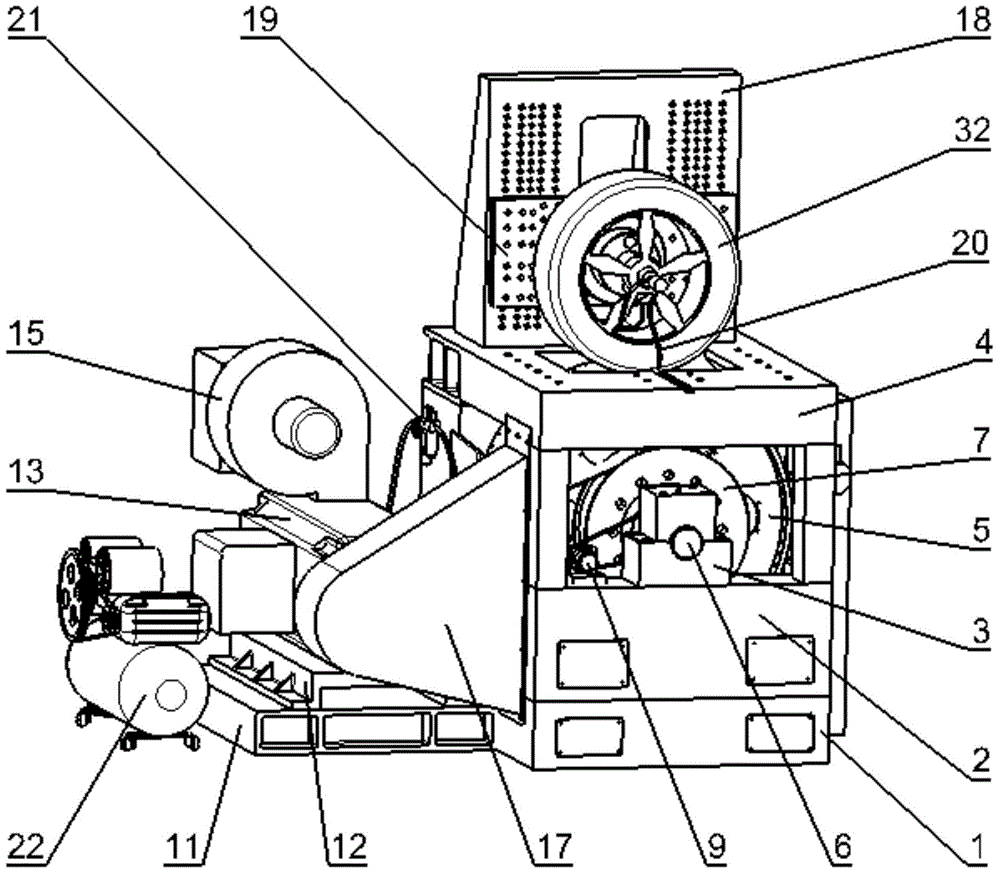

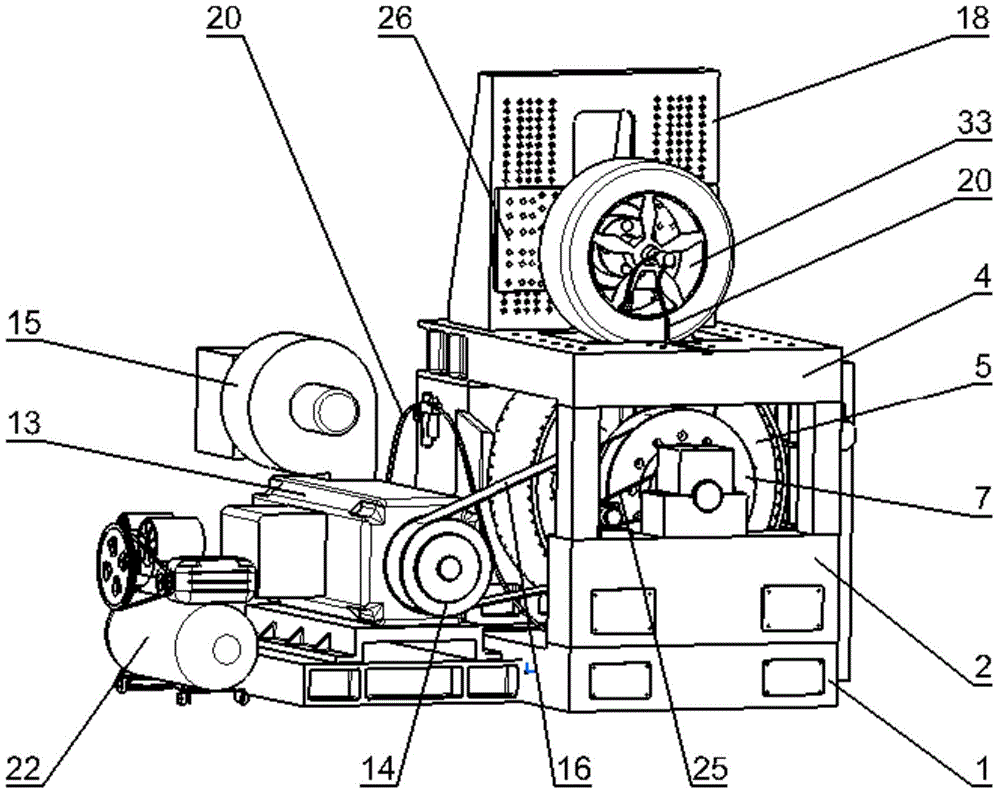

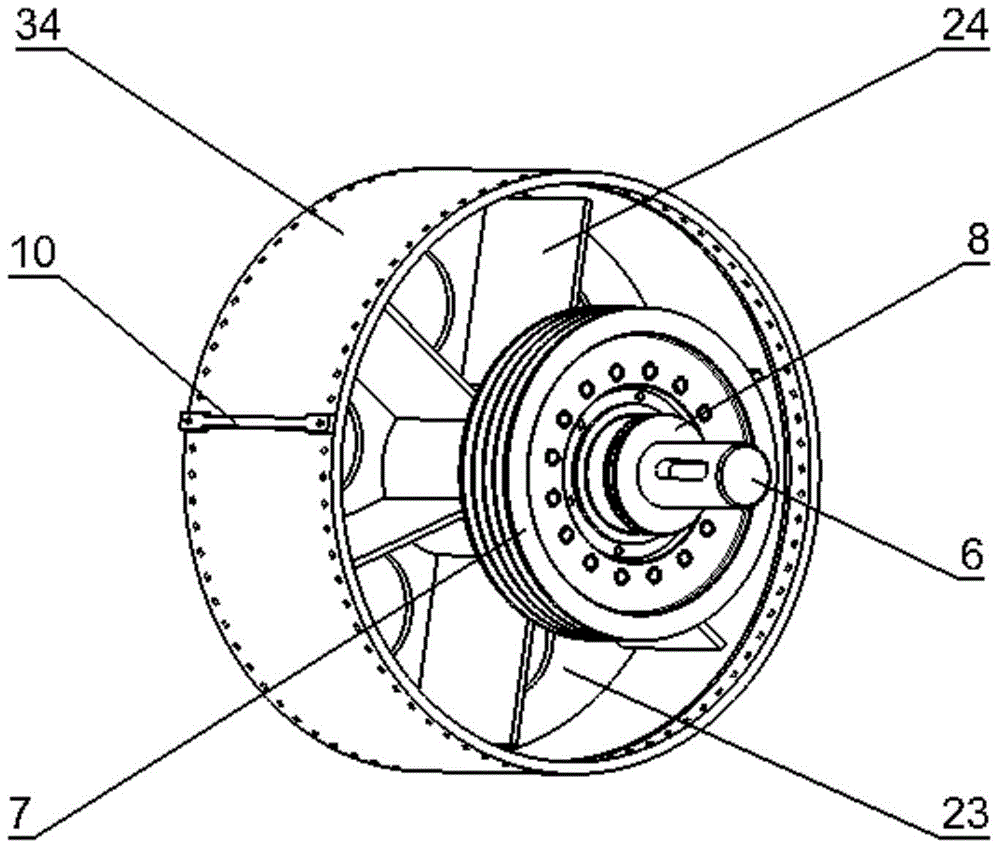

[0034] attached by figure 1 , 2 As shown, the test bench includes a simulated road surface frame assembly composed of a bottom plate 1, a lower box body 2, a shaft seat 3, and an upper box body 4, and a high-rigidity drum 5, a main shaft 6, a driven pulley 7, and a synchronous The simulated road surface assembly composed of pulley 8, speed measuring assembly 9 and road surface bump 10, the driving mechanism assembly composed of motor base 11, motor plate 12, servo motor 13, driving pulley 14 and blower 15, driving pulley 14 The transmission toothed belt 16 and the wheel cover 17 between the driven pulley 7, the tire positioning mechanism assembly composed of the positioning bracket 18 and the mounting plate assembly 19, and the tire positioning mechanism assembly composed of the air pipe 20, the tire pressure control valve 21 and the air pump 22. Tire inflation and deflation mechanism assembly. The lower box body 2 of the simulated road rack assembly is fixedly connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com