Multi-cascade phononic crystal vibration isolator

A phononic crystal and vibration isolator technology, which is applied in the field of rail transit, can solve the problems of small damping of spring bearings, short service life of rubber bearings, low-frequency vibration amplification, etc., to achieve convenient replacement, improve vibration isolation effect, and optimize design structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

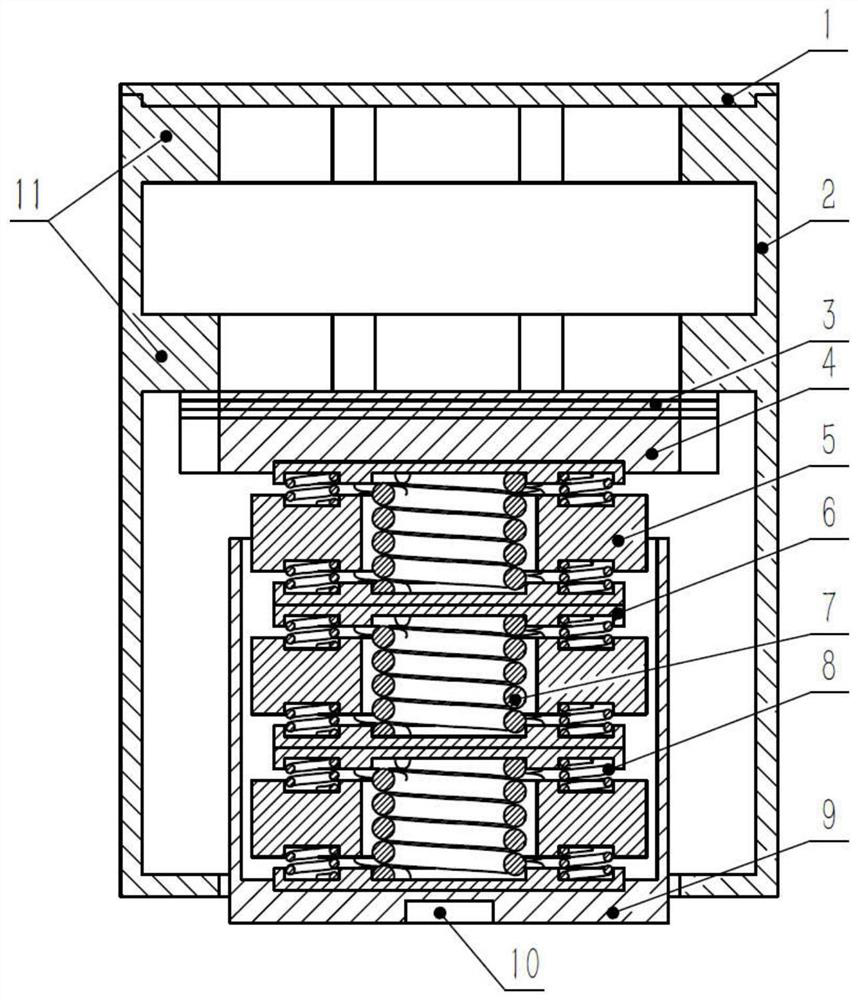

[0035] Such as figure 1 As shown, this embodiment is a multi-cascaded phononic crystal isolator, the multi-cascaded phononic crystal isolator is a cylindrical structure, including a vibration isolator outer cylinder, a multi-cascaded phononic crystal The main structure of the vibration isolator and the structure of the inner cylinder of the vibration isolator. The inner cylinder structure of the vibration isolator includes a bearing top plate 4 and an inner cylinder 9; the main structure of the multi-cascade phononic crystal vibration isolator includes a main mass element 5, a secondary mass element 6, a central stiffness element 7, and a circumferential elastic element 8.

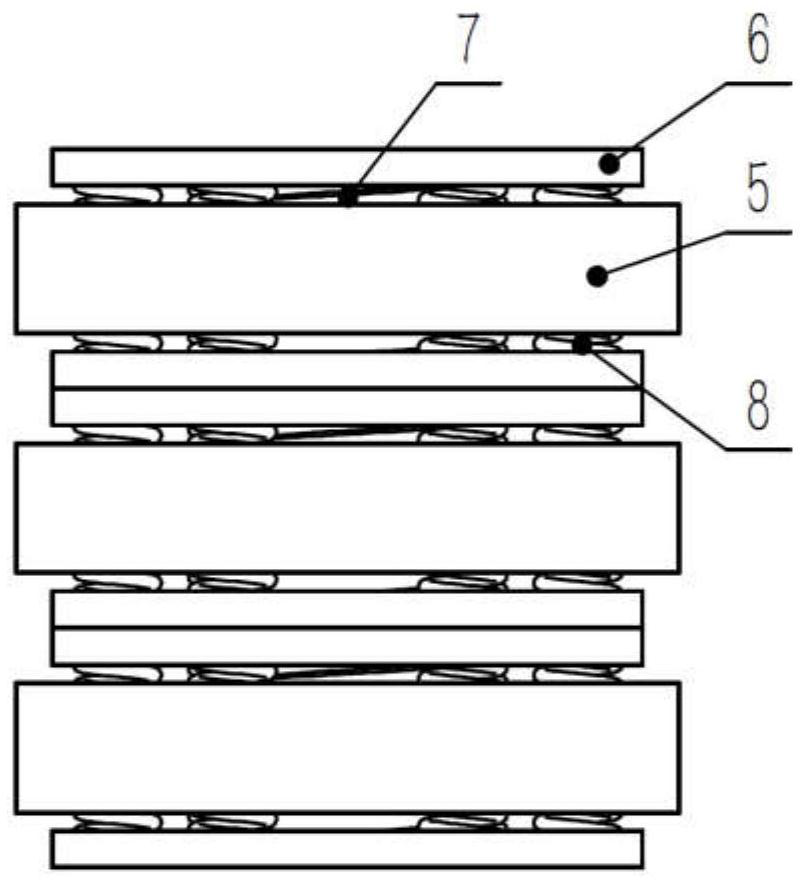

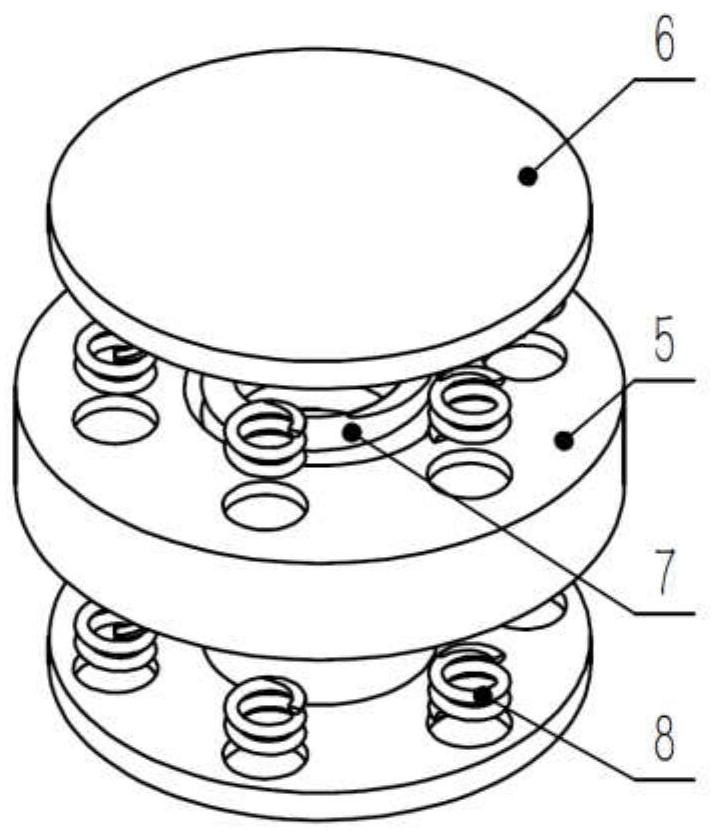

[0036] The main structure of the multi-cascaded phononic crystal vibration isolator ( figure 2 ) is placed in the inner cylinder 9, composed of several phononic crystal cells ( image 3 ), each cell is composed of a mass element and an elastic element; the mass element is a cylindrical or hollow cylind...

Embodiment 2

[0045] This embodiment is a multi-cascaded phononic crystal vibration isolator with a phononic crystal substructure, and its basic structure is consistent with that described in Embodiment 1. In particular, this embodiment redesigns the structure of the main mass element in Embodiment 1, such as Figure 7 As shown, a phononic crystal substructure with 3 periods is provided on the solid part of the main mass element 5, and 2 to 4 periods can also be provided as required. The substructure cells are composed of metal layers (such as steel layers) and non-metal layers (such as Rubber layers) are alternately superimposed, forming a primary and secondary cascade system with the main structure of the phononic crystal, and have a certain degree of vibration reduction effect on both high-frequency and low-frequency bands.

Embodiment 3

[0047] This embodiment is a multi-cascade phononic crystal vibration isolator whose elastic element is a polymer material, and its basic structure is similar to that described in Embodiment 1. In particular, in this embodiment, the central rigid element 7 is a cylindrical structure, and the circumferential elastic element 8 is a hollow cylindrical structure. The central stiffness element 7 is preferably a hard polymer material (such as a synthetic resin material), and the circumferential elastic element 8 is preferably a soft polymer material (such as a rubber material). For the schematic diagram of the main structure of the phononic crystal in this embodiment, please refer to Figure 8 , Figure 9 .

[0048]

[0049] The invention is an assembled structure, and the outer cylinder of the vibration isolator is embedded in the floating plate to form a main vibration system. Arrange the limit device on the base corresponding to the central axis of the outer cylinder, put the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com