Patents

Literature

78results about How to "Achieve vibration isolation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vibrator of beam type linear ultrasonic motor using bending vibration modes

ActiveCN101626203AImprove mechanical output capabilityImprove performancePiezoelectric/electrostriction/magnetostriction machinesEngineeringControl theory

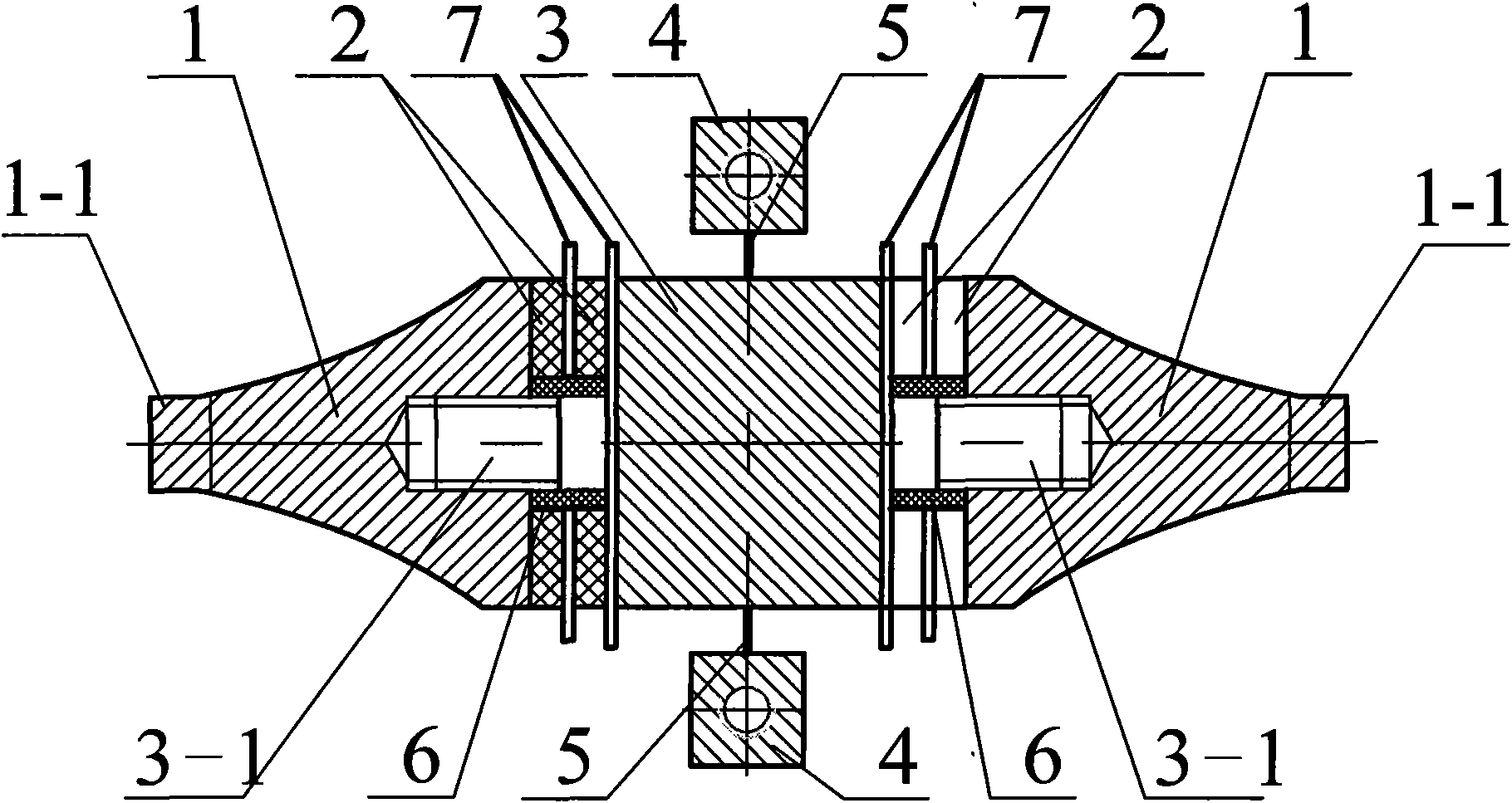

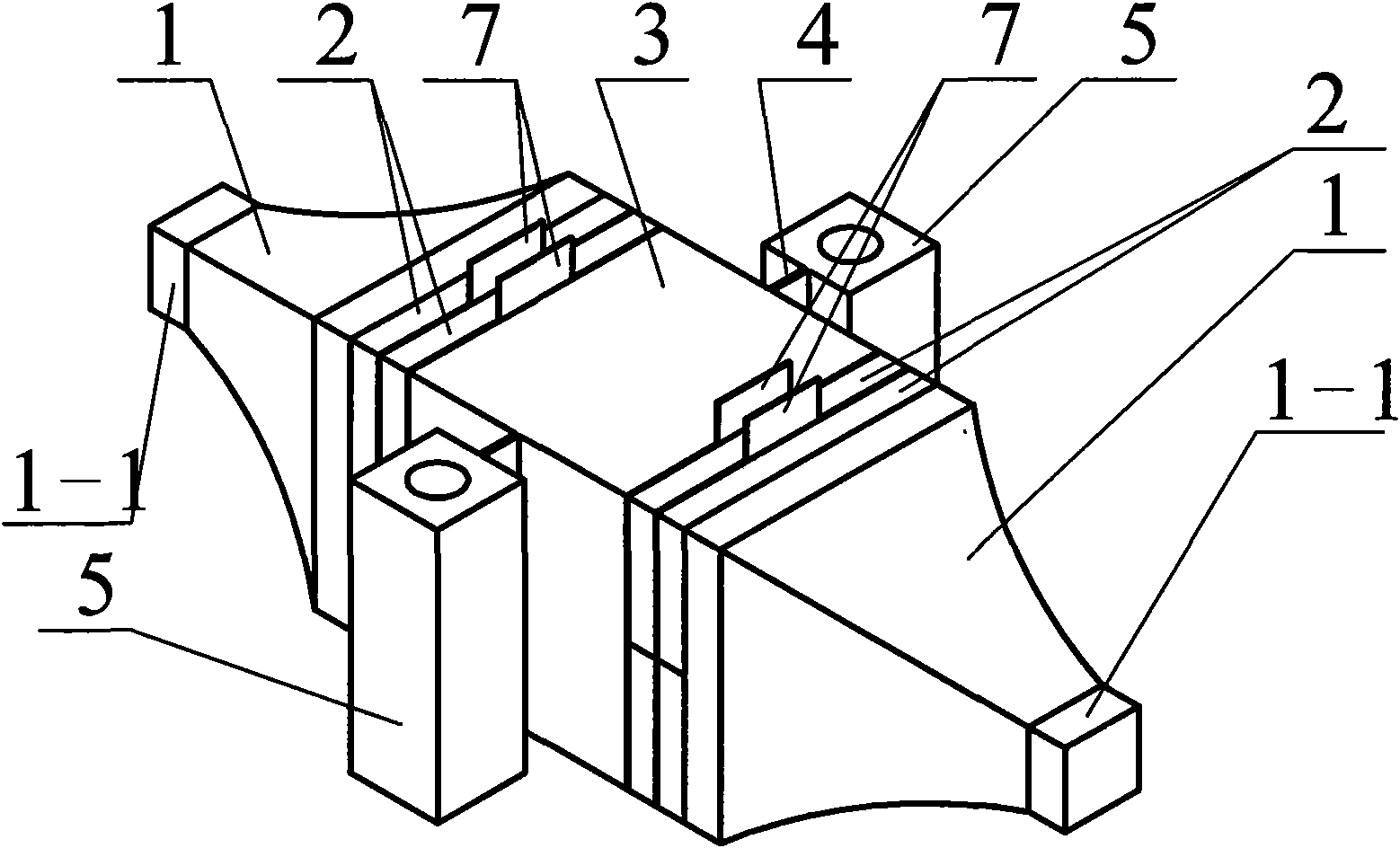

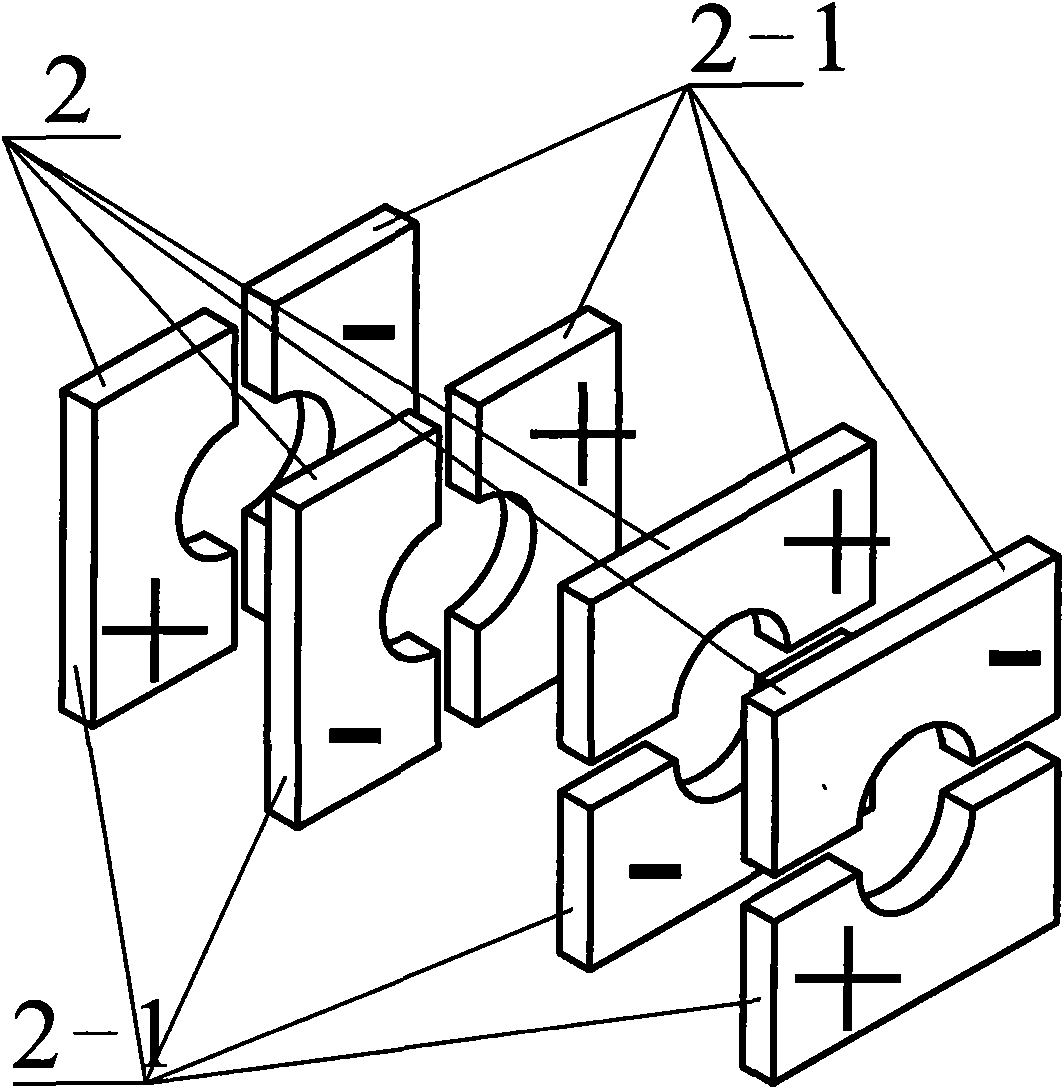

A vibrator of a beam type linear ultrasonic motor using bending vibration modes belongs to the technical field of piezoelectric ultrasonic motors and is used for the piezoelectric ultrasonic motors. The vibrator solves the problem that the mechanical output capabilities of the ultrasonic motors are restricted because of low tensile strength and low electromechanical coupling efficiency of ceramic materials in the prior art. The vibrator comprises two driving pads, two end covers, two insulating sleeves, two pairs of piezoelectric ceramics with polarization directions being thickness directions, a flange, two thin-walled beams and mounting bases; wherein, studs extend out from the end faces of the flange along the axis of the flange; each stud is sleeved with a pair of piezoelectric ceramics; an end cover is screwed at the overhanging end of each stud; the tail end of each end cover is provided with a driving pad; each piezoelectric ceramic is composed of two symmetrical half piezoelectric ceramics which are combined after being split; the polarization directions of the two half piezoelectric ceramics are opposite; the splitting lines of the two pairs of piezoelectric ceramics at both sides of the flange are vertical to each other; the polarization directions of the piezoelectric ceramics in each pair are opposite.

Owner:HARBIN INST OF TECH

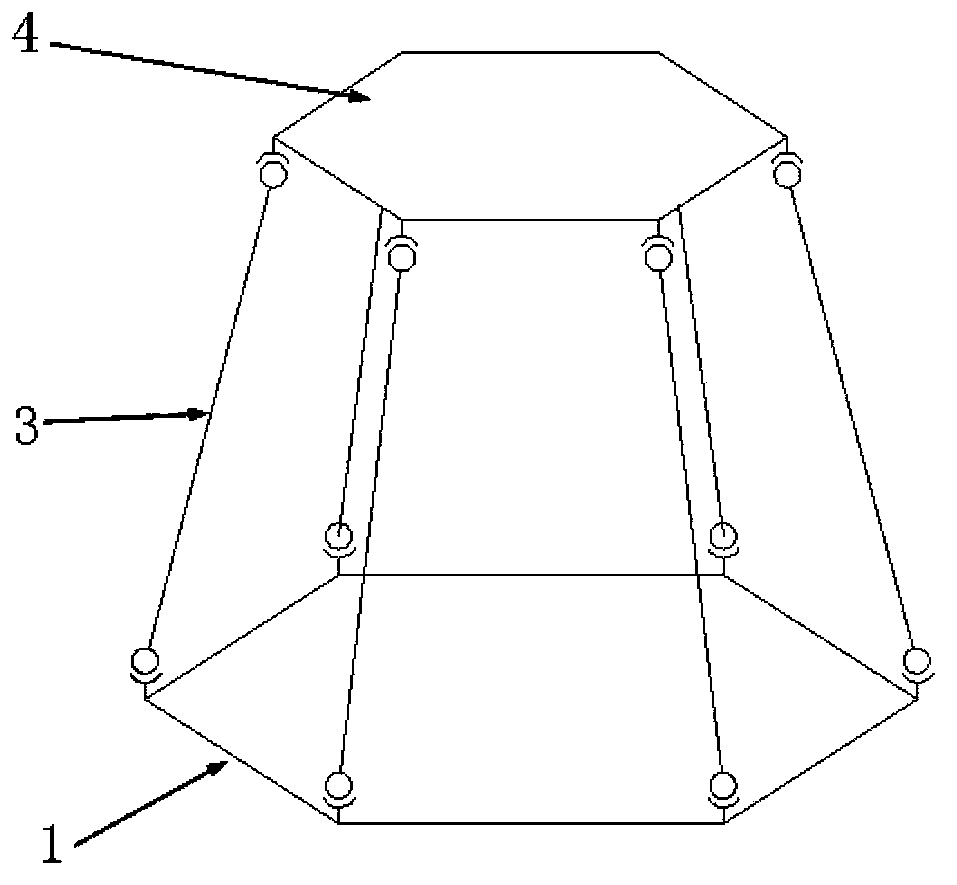

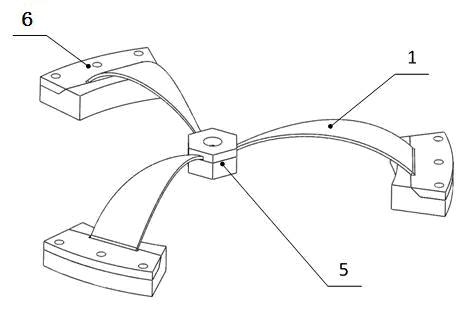

Six-degree-of-freedom active vibration isolation device

InactiveCN103438142AAchieve vibration isolationRealize the positioning functionNon-rotating vibration suppressionUltrasound attenuationIsoetes triquetra

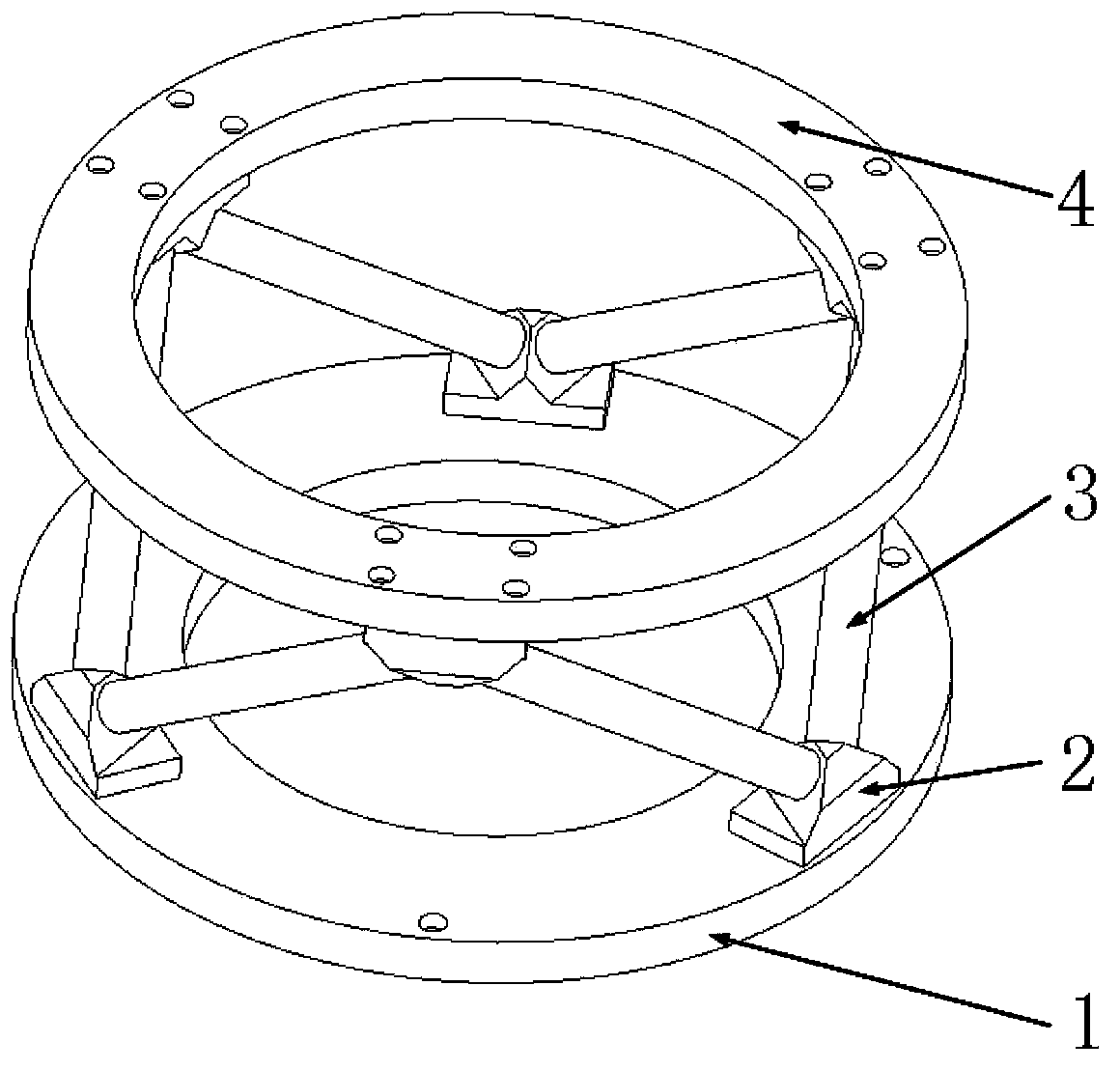

The invention discloses a six-degree-of-freedom active vibration isolation device, which has the six-degree-of-freedom vibration isolation and positioning functions. The device comprises a lower platform, an upper platform and six support legs, wherein the six support legs are respectively connected with the upper platform and the lower platform through fixing blocks to form a Stewart parallel mechanism, the positions of the three fixing blocks on the lower platform are arranged in an equilateral triangle shape, the positions of the three fixing blocks on the upper platform are also arranged in an equilateral triangle shape, the six support legs are same in the structure, two adjacent support legs are mutually vertical with each other, each support leg comprises an active executer and an air spring which are formed into a parallel structure, and each air spring is used as a passive vibration isolation part. The device has the advantages that the combined method of active vibration isolation and passive vibration isolation is adopted, the ultra-low inherent frequency is realized, and the vibration with frequency exceeding the inherent frequency is effectively isolated; the good attenuation on the six-degree-of-freedom vibration is realized, and the precise positioning of six degrees of freedom is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Parameter selection method adopting onboard control moment gyroscope group vibration-isolating platform

InactiveCN102778891AOvercome wasteAchieve vibration isolationAttitude controlSpacecraft attitude controlEngineering

The invention relates to a parameter selection method adopting an onboard control moment gyroscope group vibration-isolating platform and belongs to the field of the attitude control and the vibration and shaking control of a spacecraft. (1) an idea of the cube vibration-isolating platform is adopted, the cube vibration-isolating platform is arranged between a configuration consisting of a plurality of control moment gyroscopes and a satellite body and the high frequency vibration caused by a plurality of control moment gyroscopes is isolated to the greatest extent; and (2) by reasonably selecting parameters of the onboard control moment gyroscope group vibration-isolating platform, the problem of effectiveness loss of other onboard systems, which is caused after the vibration-isolating platform is applied on a satellite, is avoided.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Encapsulating structure of distributed feedback (DFB) fiber laser

InactiveCN102035125AHighly integratedImprove performanceLaser constructional detailsActive medium shape and constructionFiber disk laserEngineering

The invention discloses an encapsulating structure of a distributed feedback (DFB) fiber laser. The encapsulating structure comprises a rectangular base, an outer encapsulating layer, a sound insulating board, an inner encapsulating layer and strip-shaped piezoelectric ceramic, wherein the outer encapsulating layer is an inwardly-concave rectangle and is buckled on the base so as to form an accommodating space between the base and the outer encapsulating layer; two opposite side walls of the outer encapsulating layer are concentrically provided with two first circular holes; the sound insulating board is attached to an inner wall between the base and the outer encapsulating layer and provided with two second circular holes corresponding to the two circular holes on the outer encapsulating layer; the inner encapsulating layer is a hollow rectangular shell fixed on the sound insulating board on the base and provided with two third circular holes corresponding to the two circular holes on the sound insulating board; the strip-shaped piezoelectric ceramic is fixed on the bottom surface of the inner encapsulating layer on the sound insulating board on the base; the DFB fiber laser is fixed on the upper two sides of the strip-shaped piezoelectric ceramic by bonding; and the two ends of the DFB fiber laser pass through the first, second and third circular holes.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

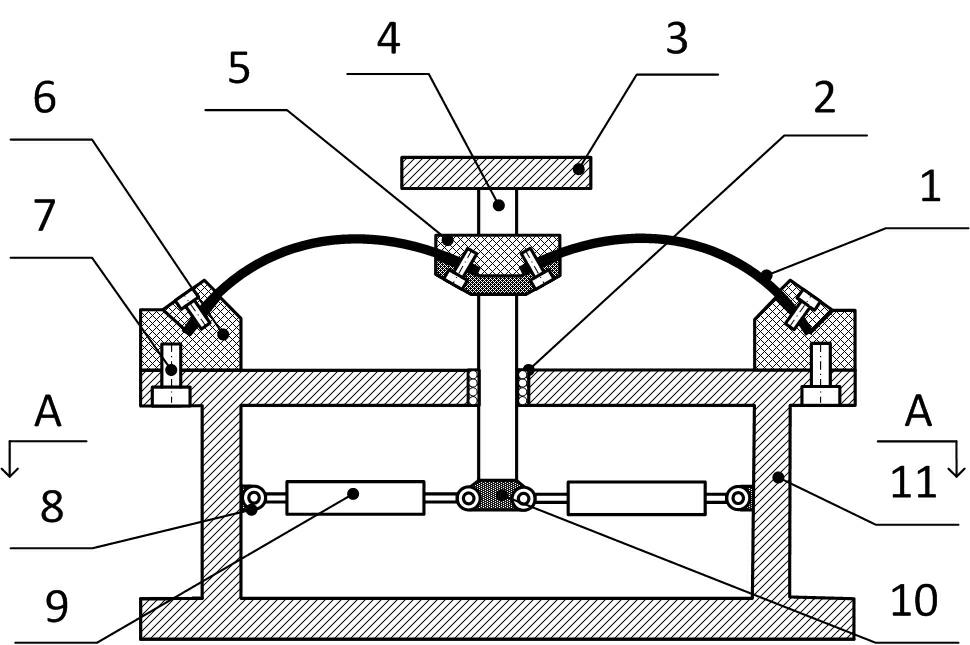

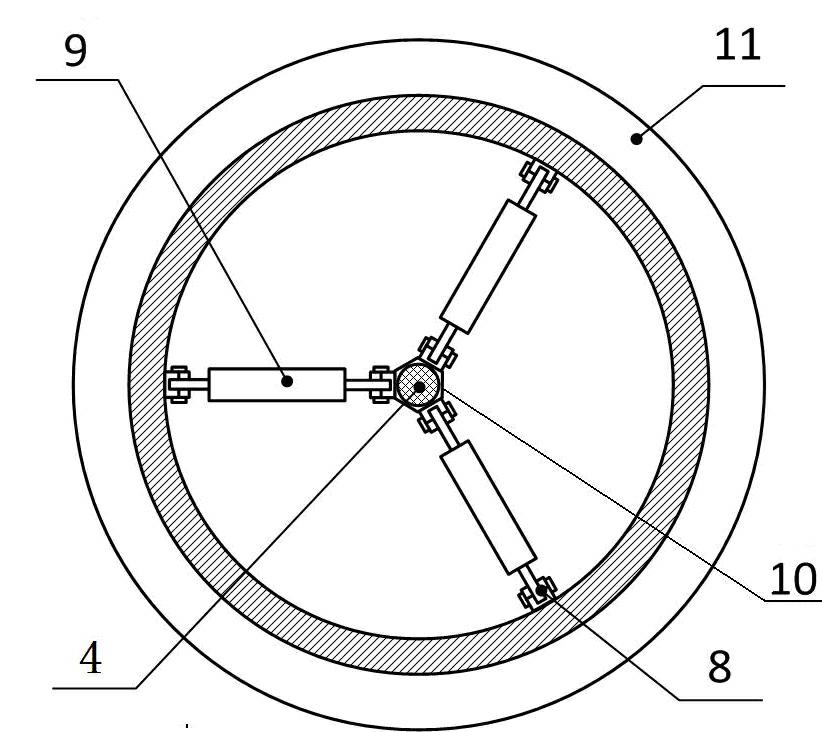

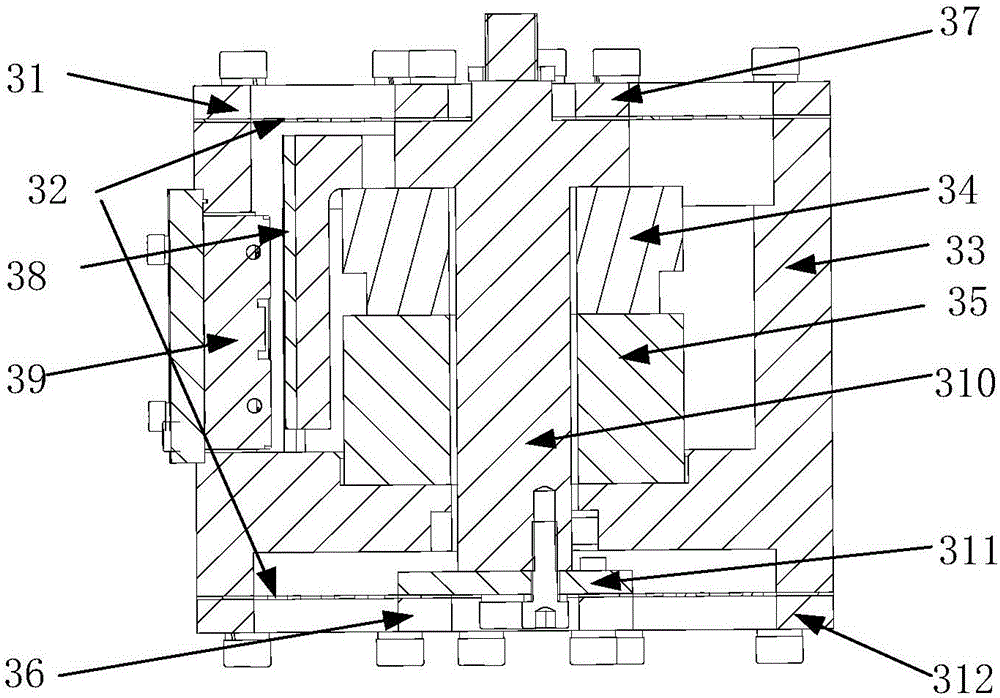

Passive low-frequency vibration isolator

InactiveCN102518741AImprove static stiffnessAchieve low frequency and even ultra-low frequency vibration isolationSpringsNon-rotating vibration suppressionLow frequency vibrationEngineering

The invention relates to a passive low-frequency vibration isolator, which comprises an enclosed cylindrical base, wherein the top of the enclosed cylindrical base is provided with a through hole, and the inner side wall of the enclosed cylindrical base is uniformly provided and movably connected with cylinder bodies of three dampers; a center connecting rod is inserted into the through hole in the base, and the lower end of the center connecting rod is moveably connected with piston rods of the three dampers; the top of the base is uniformly provided with three mounting fixtures; the upper part of the center connecting rod is provided with a hexagonal center clamping piece which is uniformly provided and connected with one ends of three flat springs; the other ends of the three flat springs are connected with the three mounting fixtures respectively; and the top of the center connecting rod is provided with a bearing table. The passive low-frequency vibration isolator has obvious high static stiffness and low dynamic stiffness, reduces initial isolation frequency, can realize low-frequency vibration isolation and ultralow-frequency vibration isolation, has high static bearing capacity and reduces deformation; meanwhile, by optimizing the damping structure, the vibration isolator can automatically adjust damp according to working conditions to achieve effects of inhibiting resonance and resisting impact.

Owner:UNIV OF SCI & TECH OF CHINA

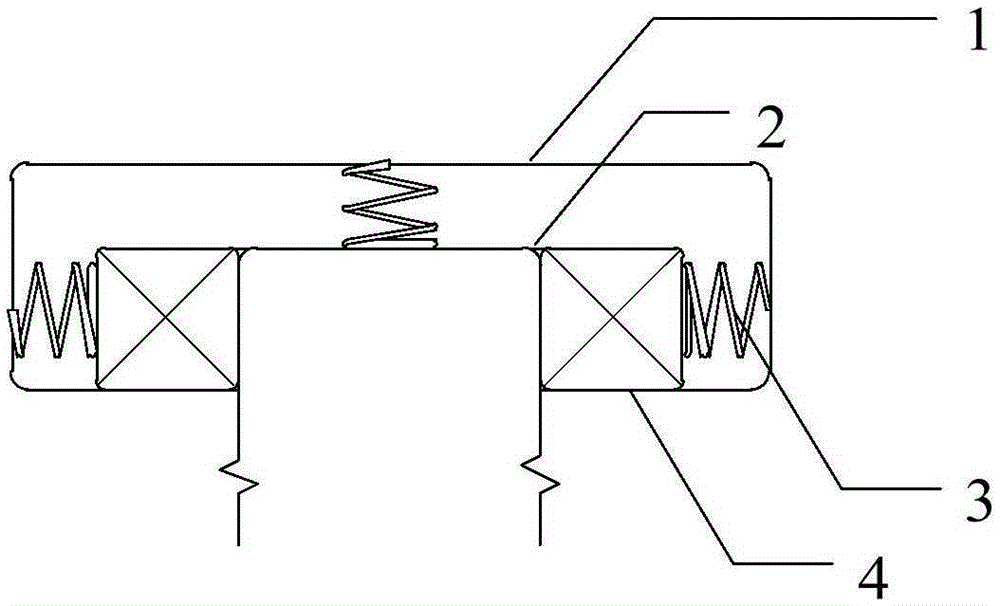

Apparatus and method of improving spacecraft attitude stability

The invention relates to an apparatus and method of improving spacecraft attitude stability, belonging to the spacecraft attitude dynamics and vibration inhibition field. The framework bearing of each SGCMG is provided with a vibration isolation element; each vibration isolation element includes a plurality of metal springs respectively in connection with the internal wall and the external wall of the vibration isolation element through spherical hinges. The internal wall of the vibration isolation element sleeves the framework bearing of an SGCMG so as to be in connection with the framework bearing of the SGCMG; the external wall of the vibration isolation element is directly in fixed connection with a satellite body. The vibration isolation elements can effectively solve the vibration problem of an SGCMG, and possess a decoupling characteristic so as to effectively and rapidly realize the parameter design of vibration isolation elements; in addition, the vibration isolation elements can greatly improve satellite attitude stability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

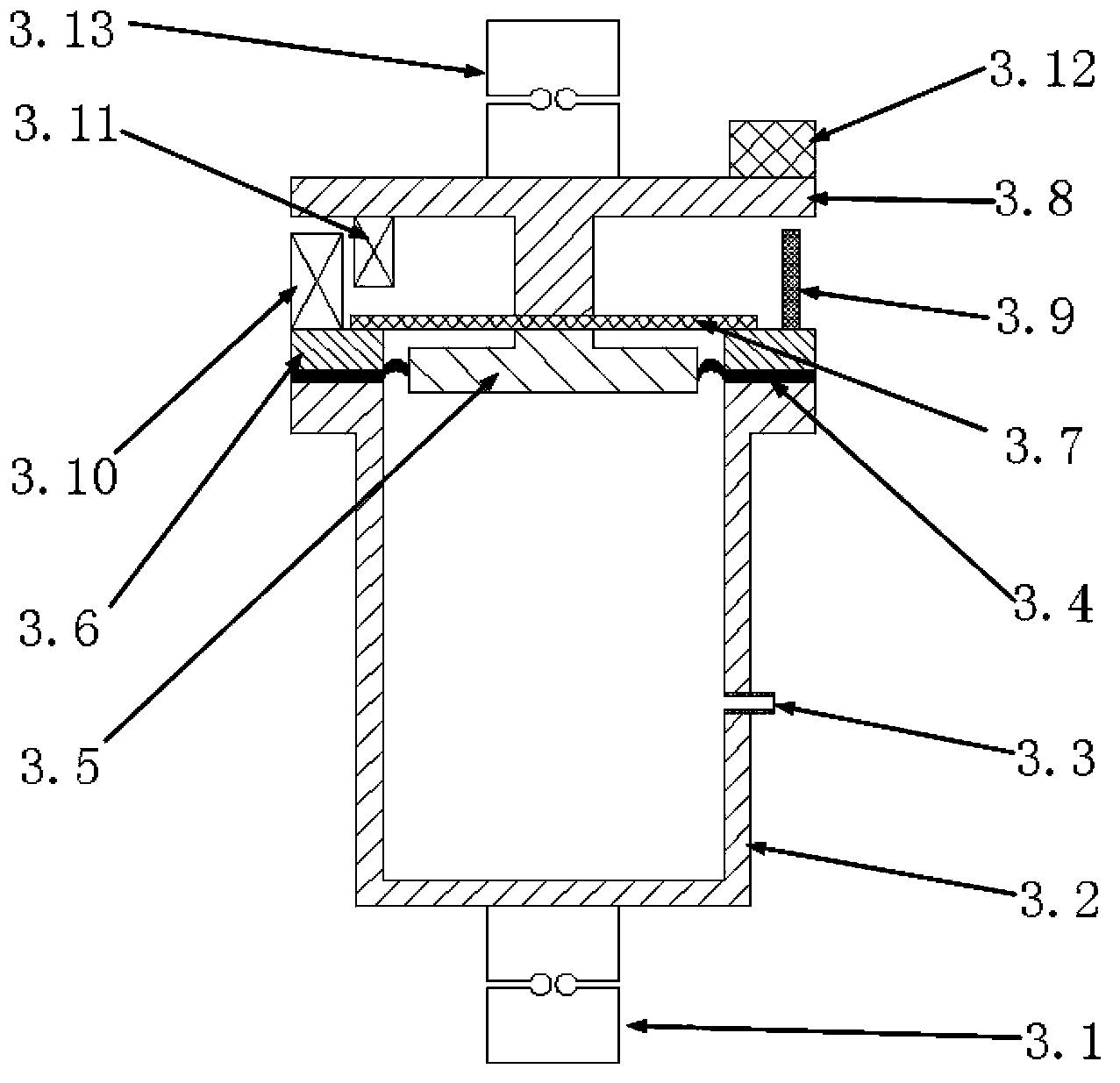

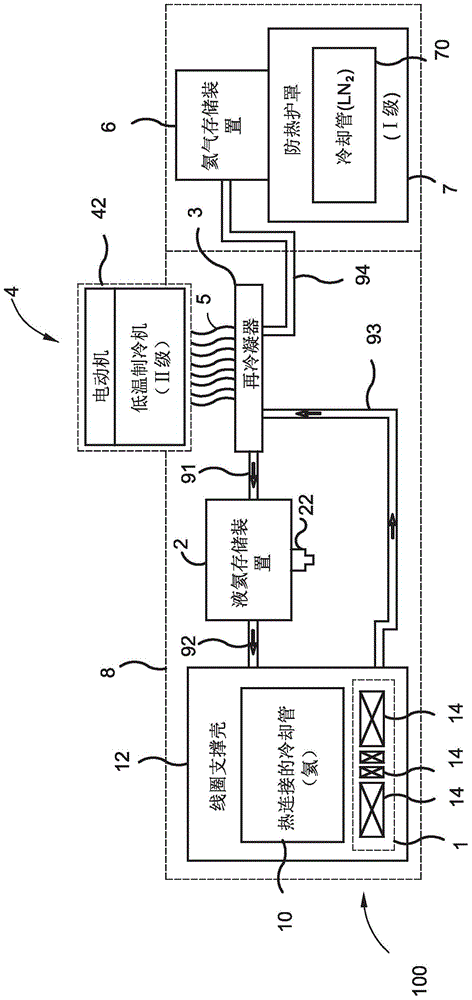

Superconducting magnet cooling system

InactiveCN106298152AAchieve vibration isolationMagnetic measurementsRefrigeration componentsSuperconducting CoilsEngineering

The invention discloses a superconducting magnet cooling system comprising a superconducting magnet, a liquid coolant container used for cooling the liquid coolant, a heat exchanger unit fluid-connected with the liquid coolant container, a low temperature refrigerating machine carrying out heat exchange with the heat exchanger, and a flexible connecting device; the flexible connecting device has high thermal conductivity, and is in hot link with the low temperature refrigerating machine and heat exchanger unit, thus providing vibration isolation between the low temperature refrigerating machine and the heat exchanger unit, so the vibrations of the low temperature refrigerating machine cannot be transferred onto the superconducting magnet.

Owner:GENERAL ELECTRIC CO

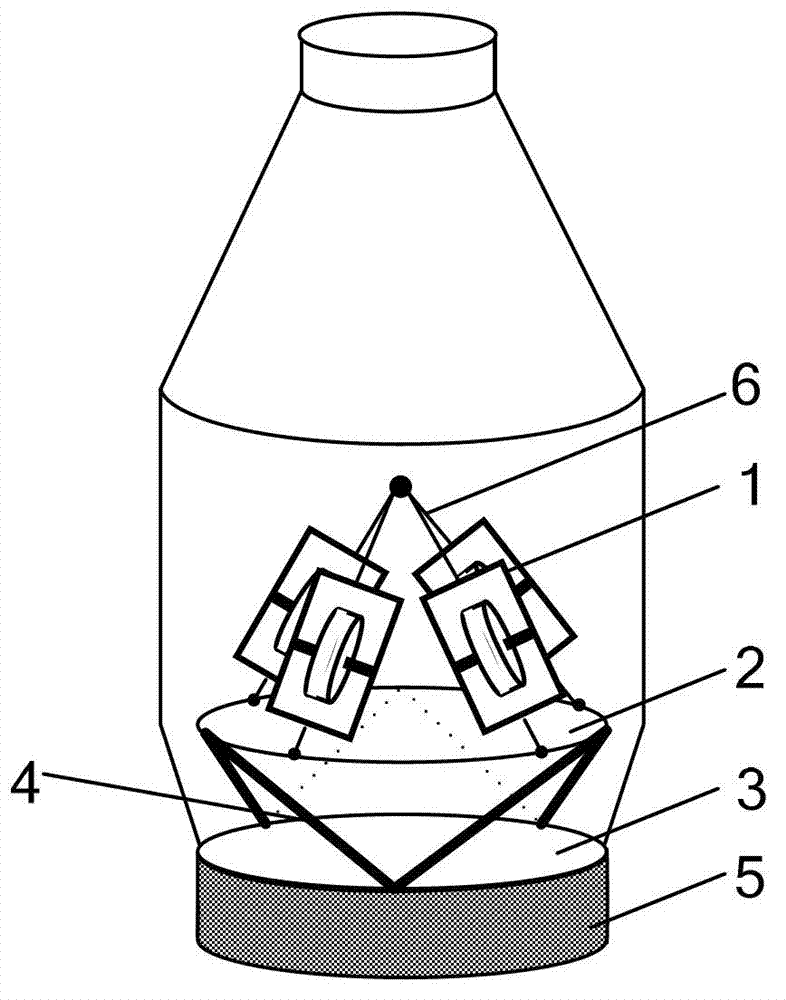

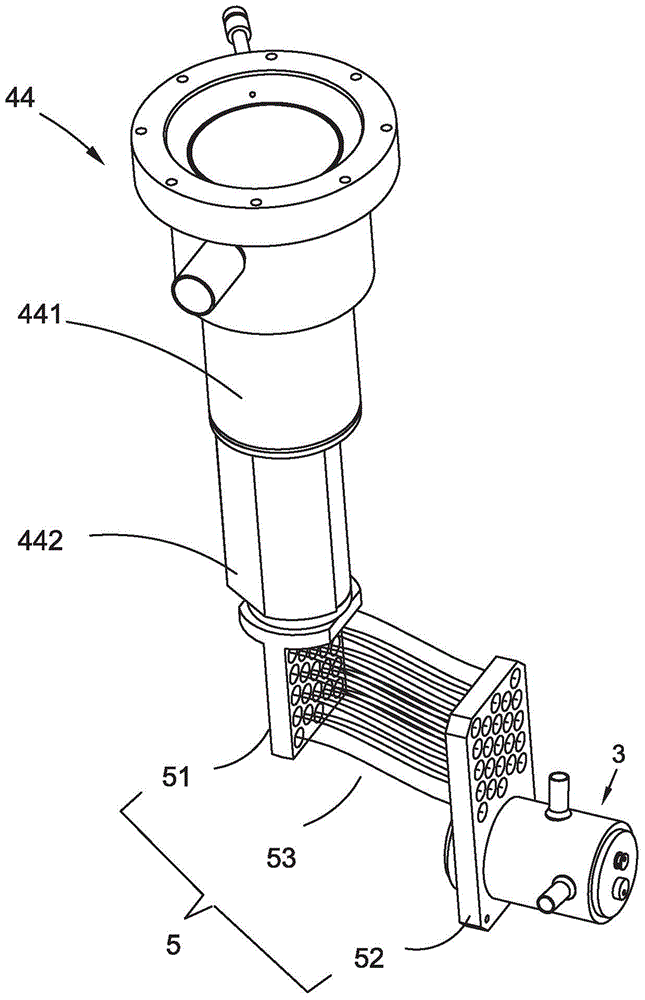

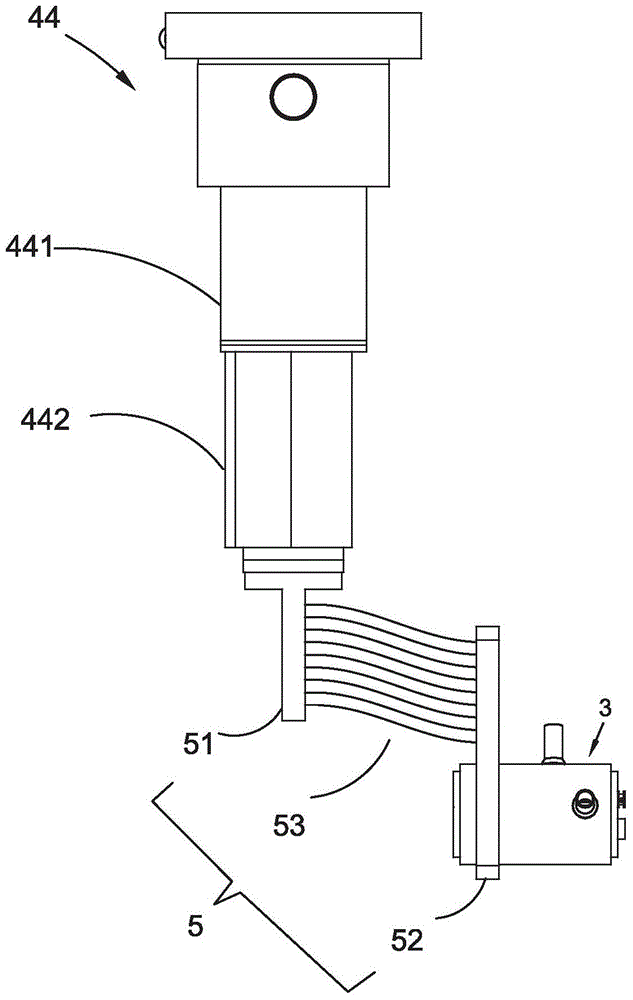

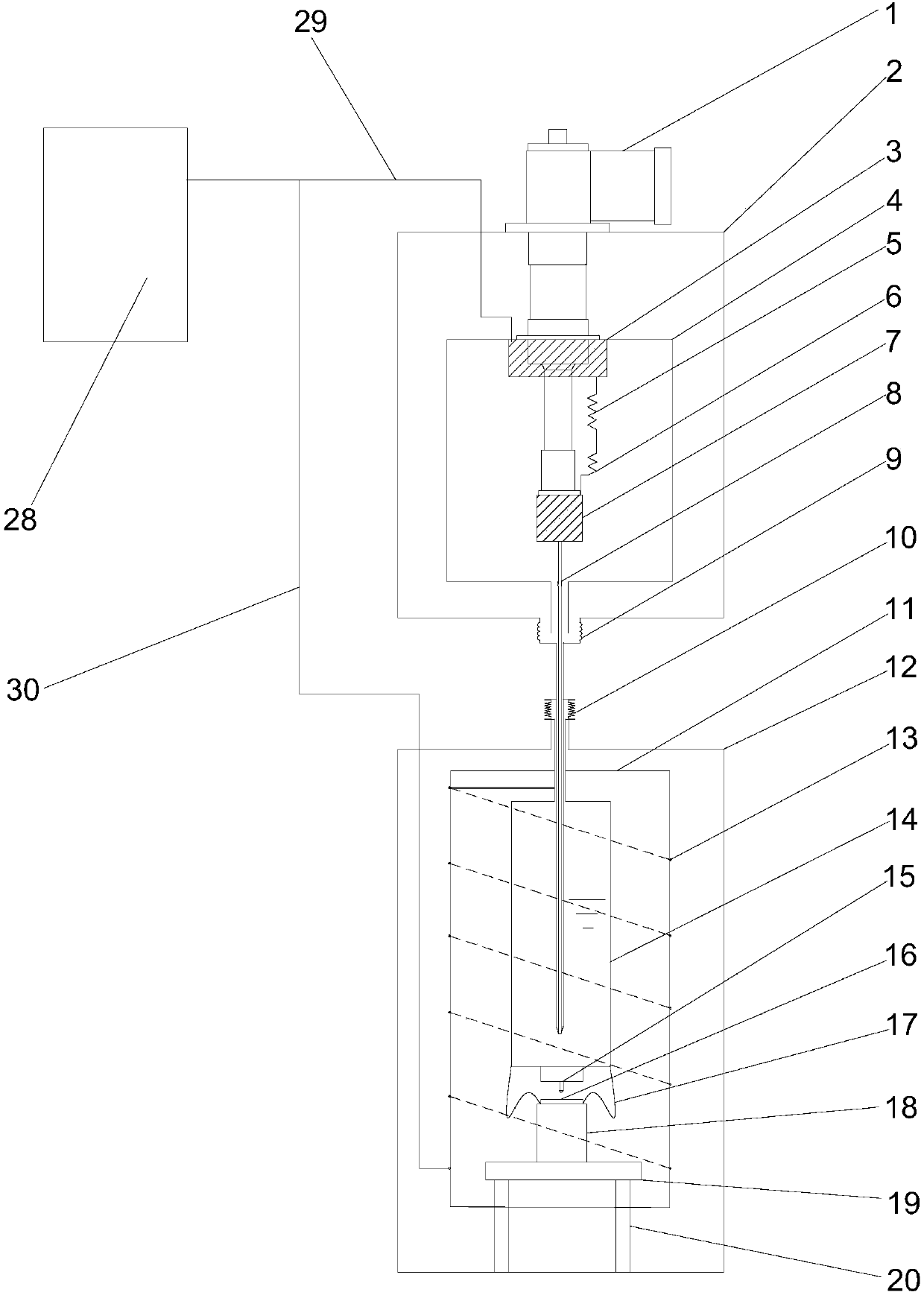

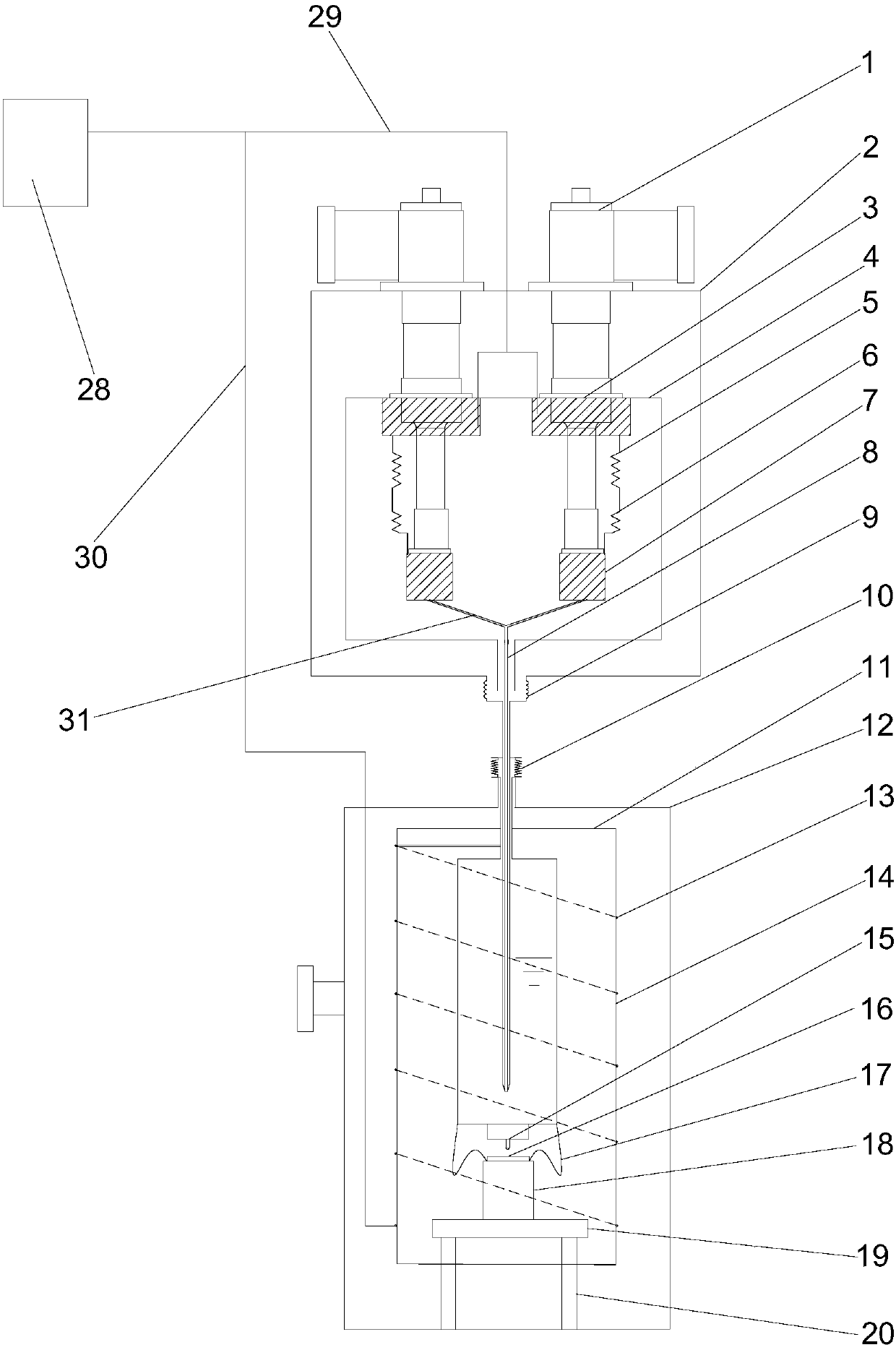

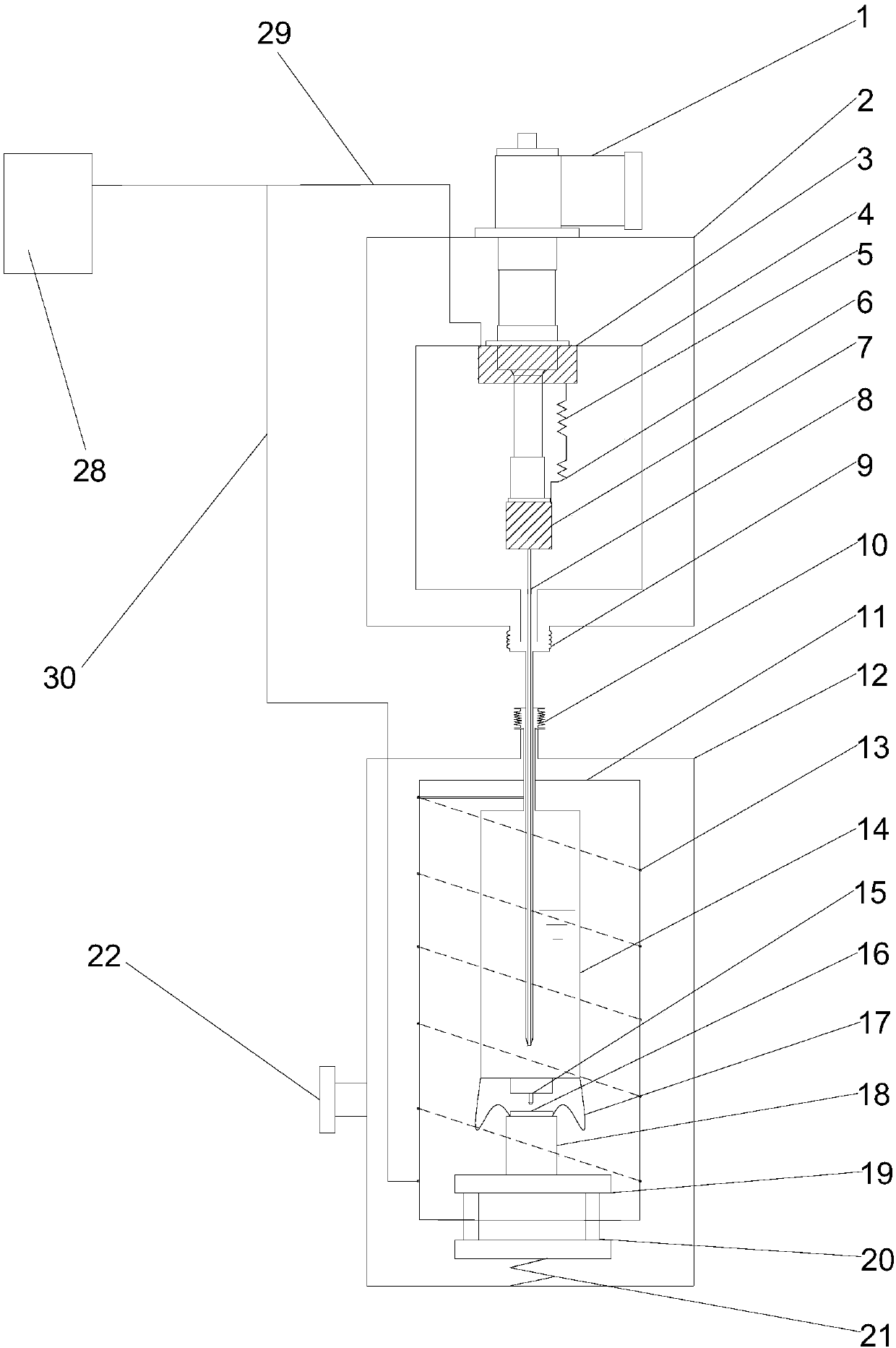

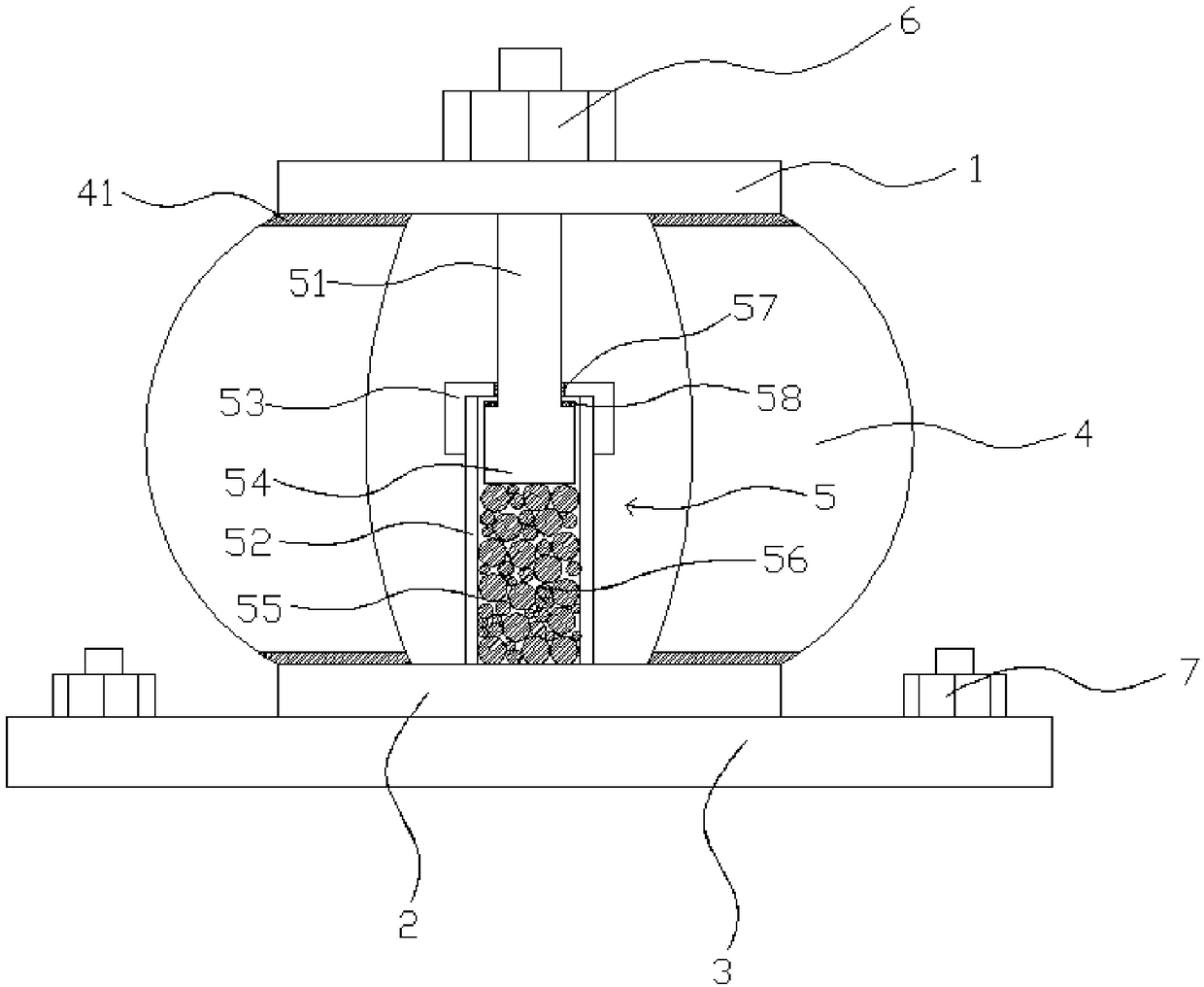

Ultralow-temperature and ultralow-vibration friction testing device

InactiveCN107560958AAchieve vibration isolationLow costInvestigating abrasion/wear resistanceCold shieldEngineering

The invention discloses an ultralow-temperature and ultralow-vibration friction testing device, which comprises a helium liquefying mechanism, a friction mechanism and a storage tank, wherein the helium liquefying mechanism comprises a first vacuum hood and a first cold shield arranged in the first vacuum hood; a refrigerator penetrates through the first vacuum hood; a first-level heat exchanger and a second-level heat exchanger connected with a liquid conveying pipe are arranged on the refrigerator; the first-level heat exchanger and the second-level heat exchanger are positioned in the firstcold shield; the friction mechanism comprises a second vacuum hood, a second cold shield and an insulating bracket; the second cold shield and the insulating bracket are arranged in the second vacuumhood; the second vacuum hood is connected below the first vacuum hood; a liquid helium cavity is formed in the second cold shield; an exit of the liquid conveying pipe is formed in the liquid heliumcavity; an upper sample support is arranged on the outer bottom wall of the second cold shield; a movable displacement platform is arranged on the insulating bracket; a lower sample support is arranged on the displacement platform; the upper sample support and the lower sample support face each other up and down; the storage tank is connected with the first-level heat exchanger through a gas supplementing pipe and connected with the liquid helium cavity through a gas return pipe. According to the invention, a friction test of a sample can be realized in an environment with ultrahigh vacuum degree and ultralow temperature.

Owner:TSINGHUA UNIV

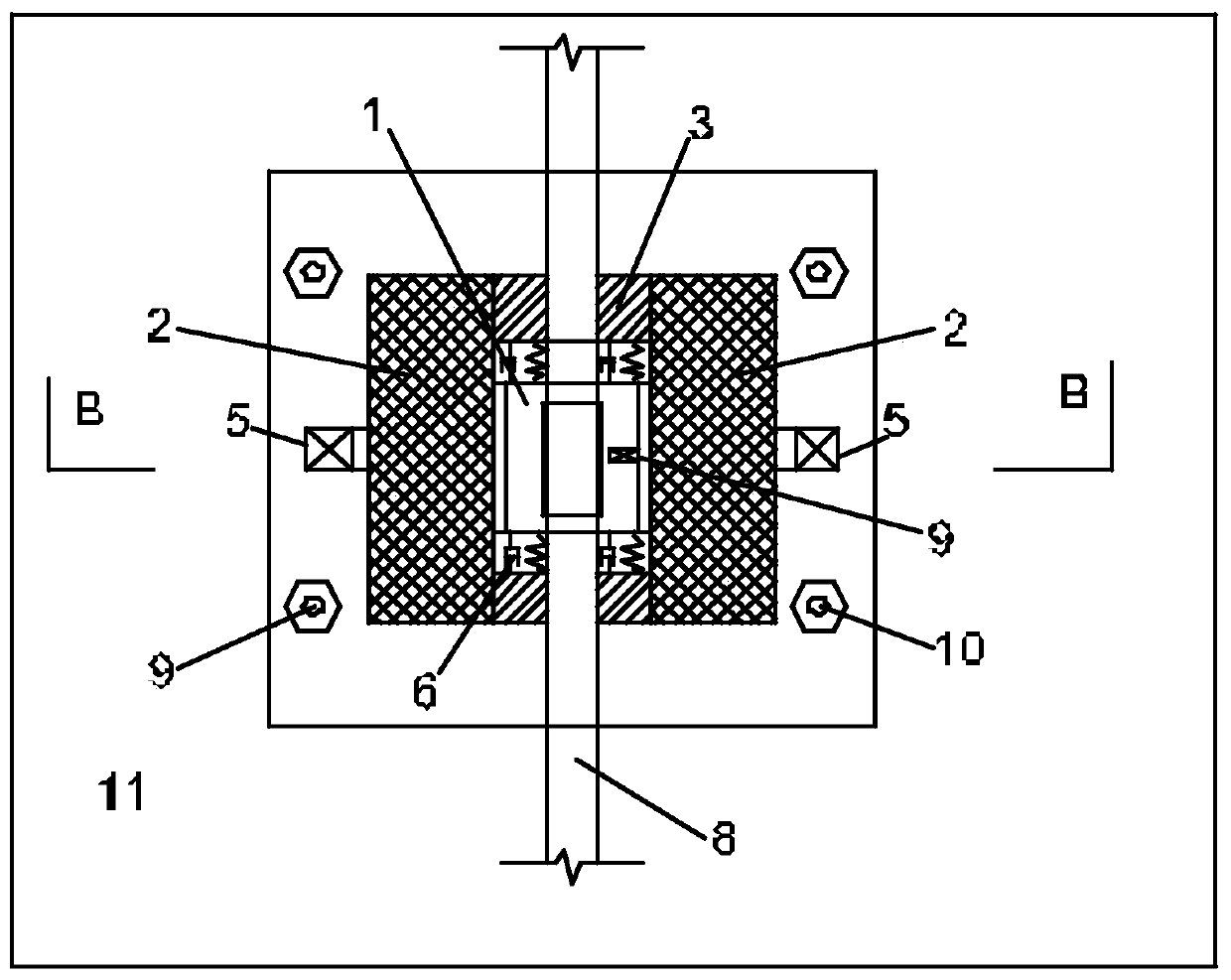

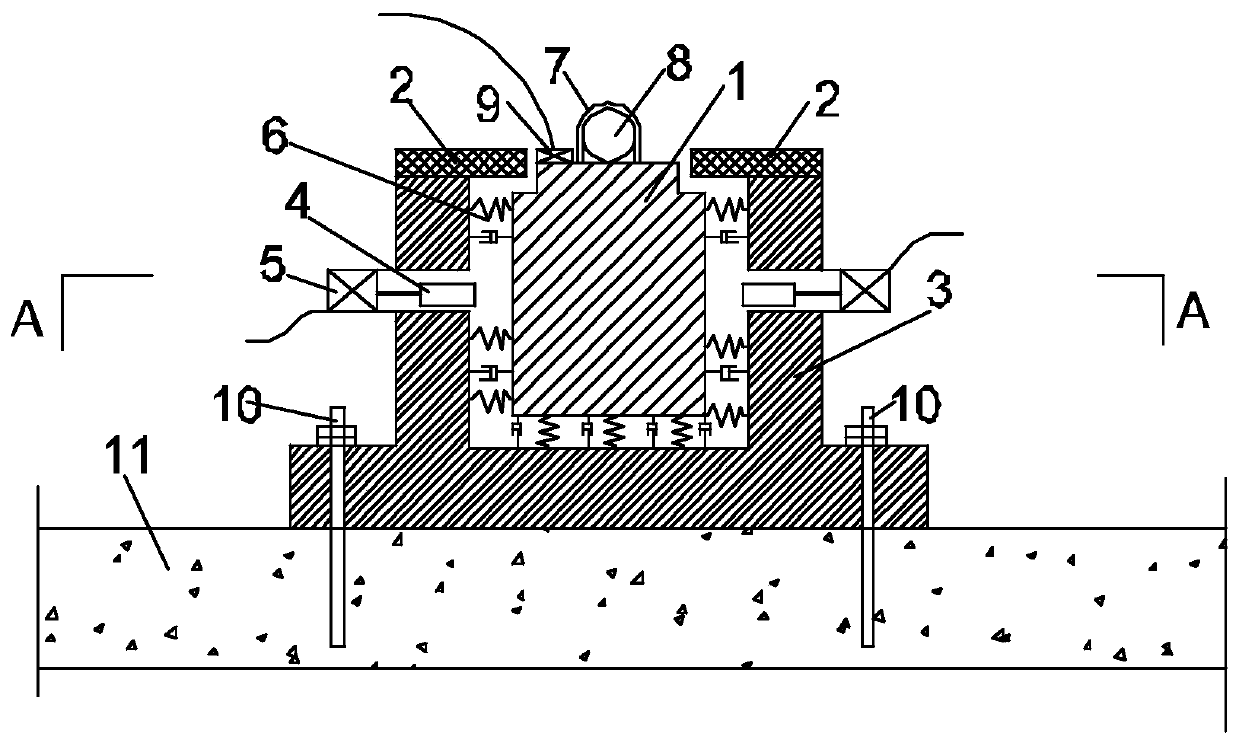

Particle damping rubber vibration isolator of engine

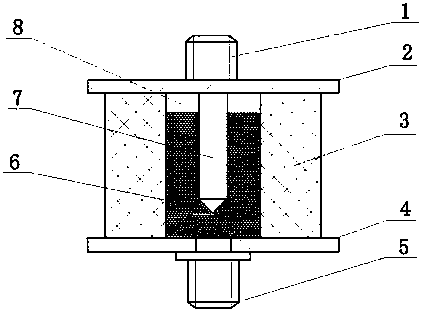

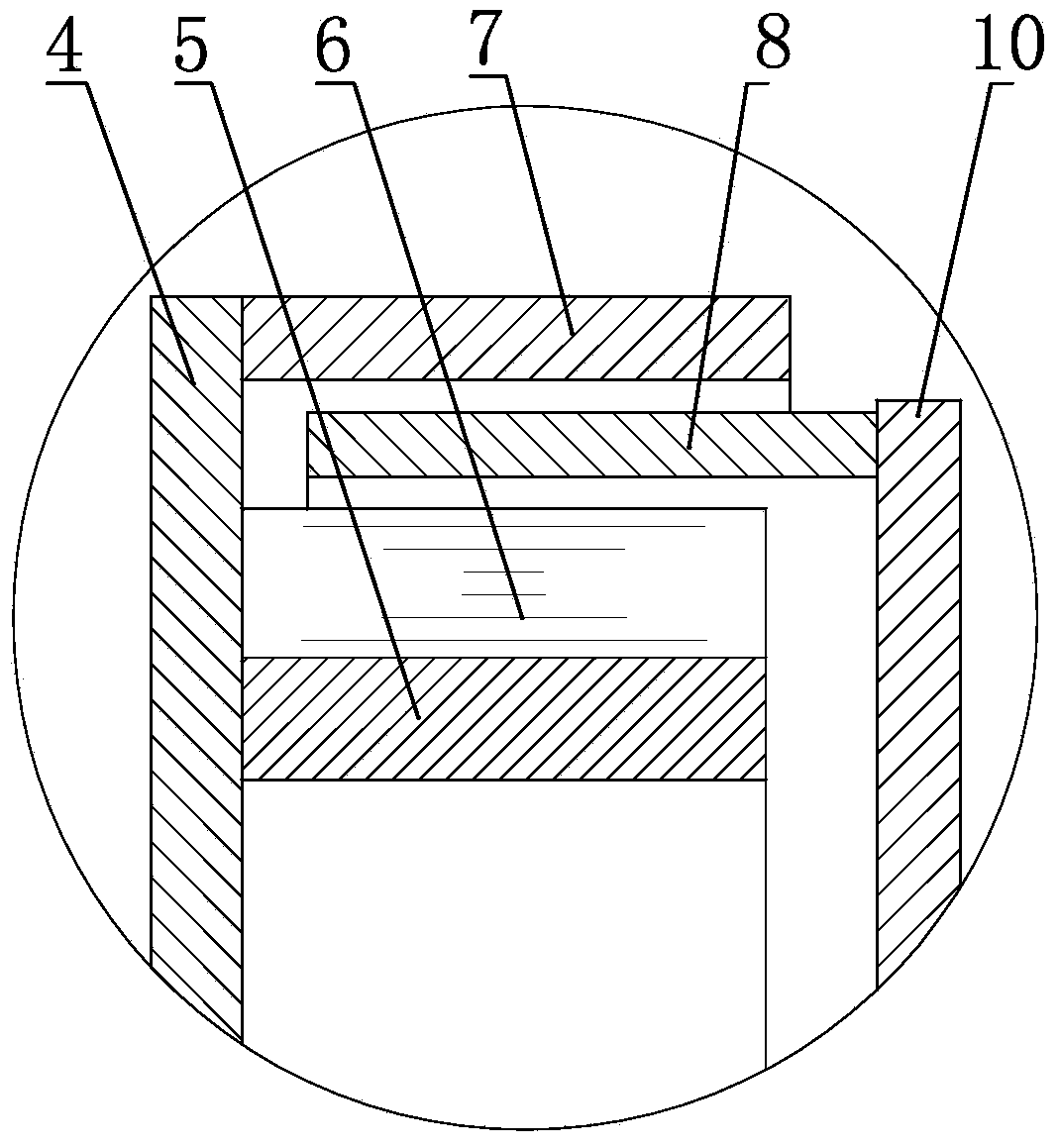

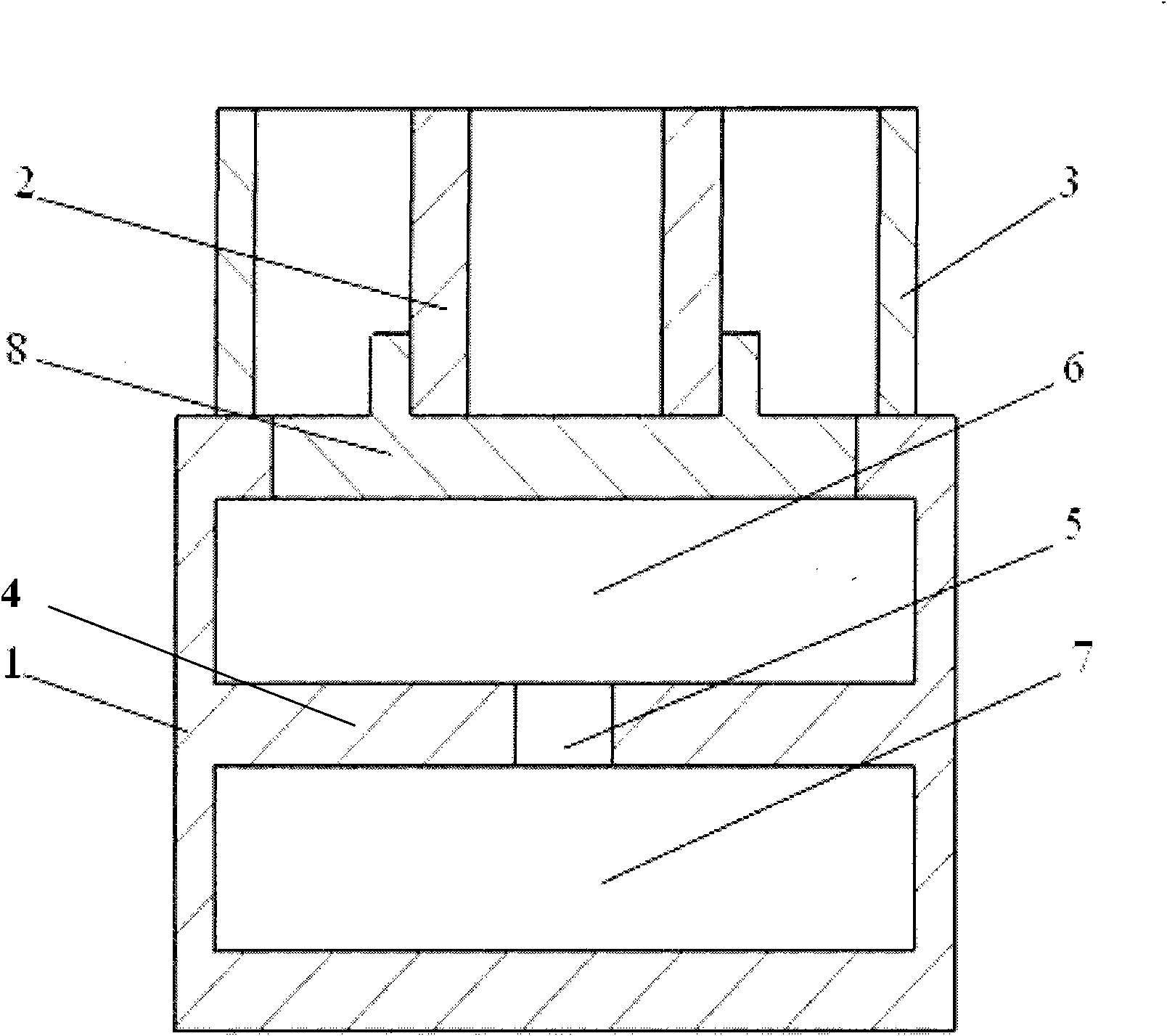

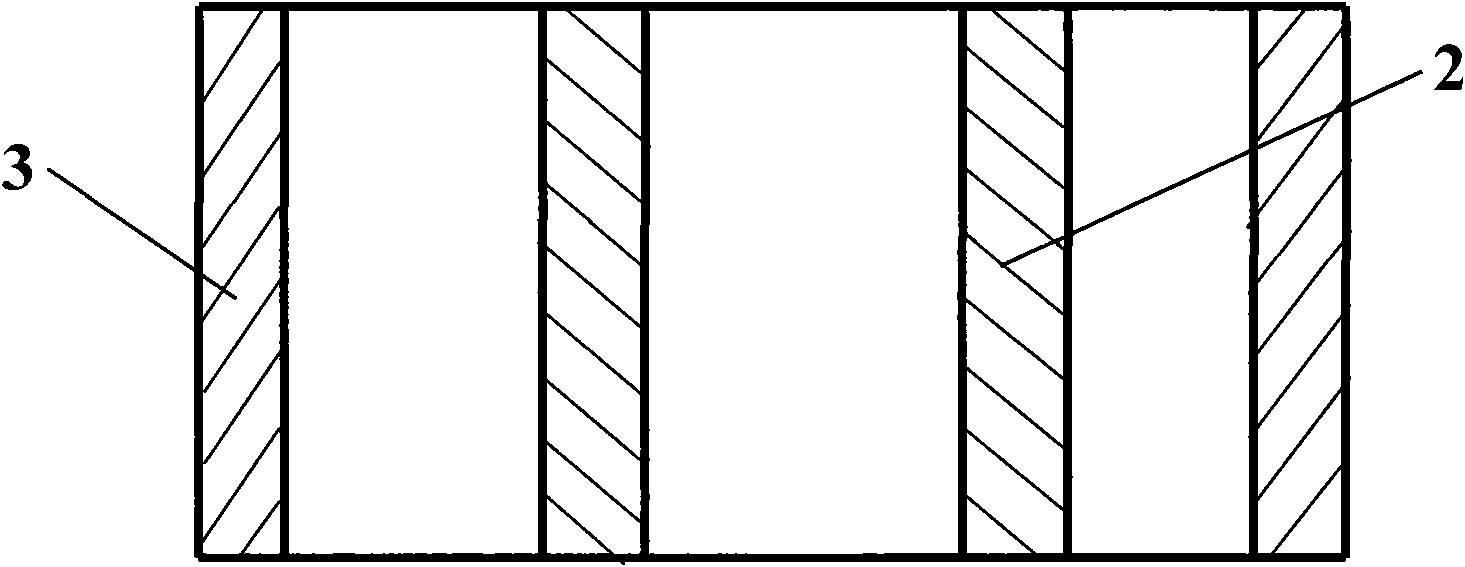

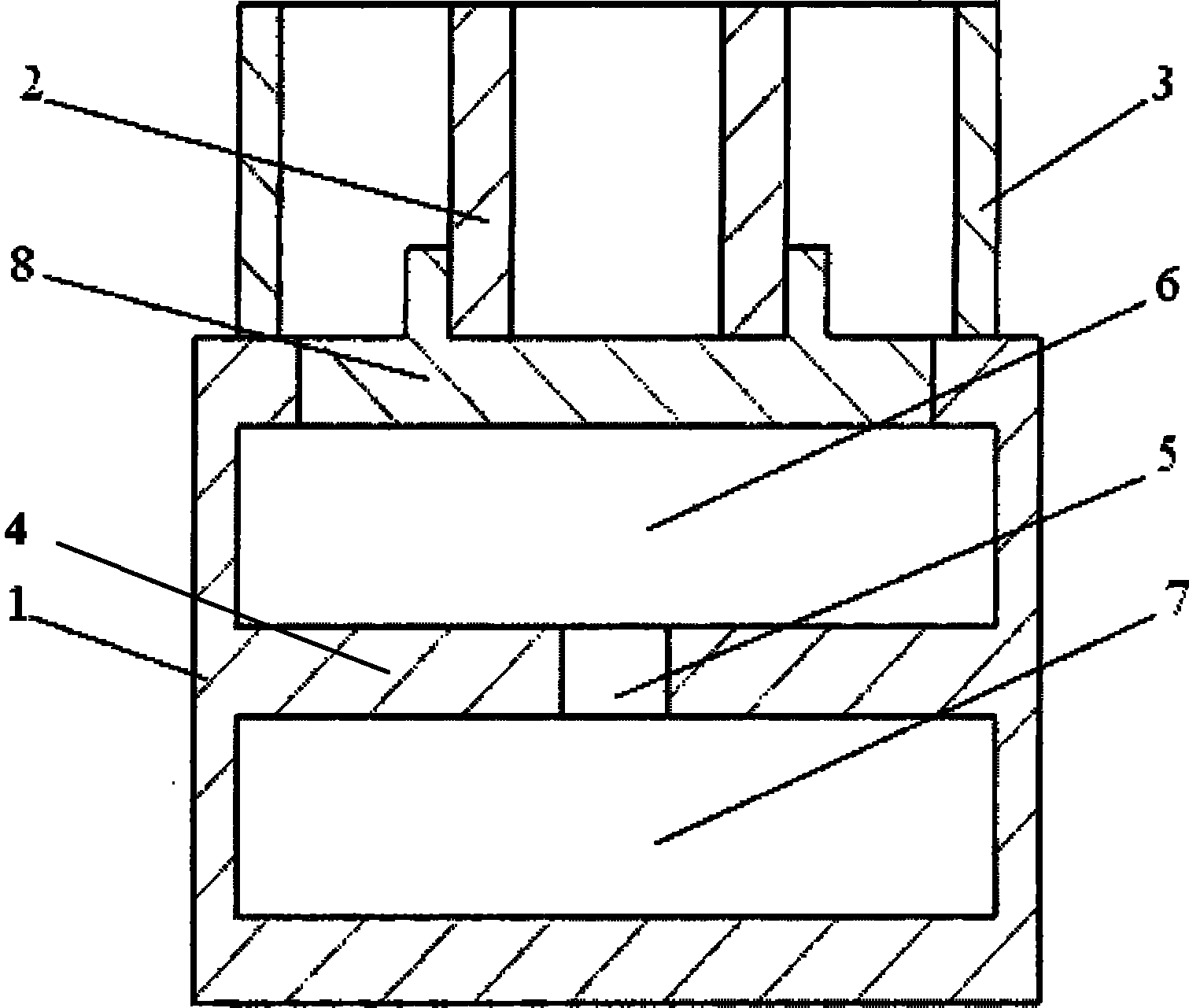

InactiveCN104196955AReliable structureEasy to manufactureNon-rotating vibration suppressionPhysicsHollow cylinder

The invention relates to a particle damping rubber vibration isolator of an engine. According to the technical scheme, the upper end face and the lower end face of vibration isolation rubber (3) are in vulcanizing bonding with a corresponding upper connecting plate (2) and a corresponding lower connecting plate (4), a lower connecting bolt (5) is fixed onto the lower plane of the lower connecting plate (4), an upper connecting bolt (1) is fixed onto the upper plane of the upper connecting plate (2) and a damping rod (7) is fixed onto the lower plane of the upper connecting plate (2). The upper connecting bolt (1), the upper connecting plate (2), the vibration isolation rubber (3), the lower connecting plate (4), the lower connecting bolt (5) and the damping rod (7) are coaxially connected. The vibration isolation rubber (3) is a hollow cylinder, the hollow part of the hollow cylinder forms a closed damping cavity (8) with the upper connecting plate (2) and the lower connecting plate (4), particle damping materials (6) are placed in the damping cavity (8) and the particle damping materials (6) occupy 50-85% of the volume of the damping cavity (8). The particle damping rubber vibration isolator of the engine is simple and reliable in structure, convenient to manufacture and low in cost, has the dynamic characteristics of low-frequency high dynamic stiffness and large damping and also has the dynamic characteristics of high-frequency low dynamic stiffness and small damping.

Owner:WUHAN UNIV OF SCI & TECH

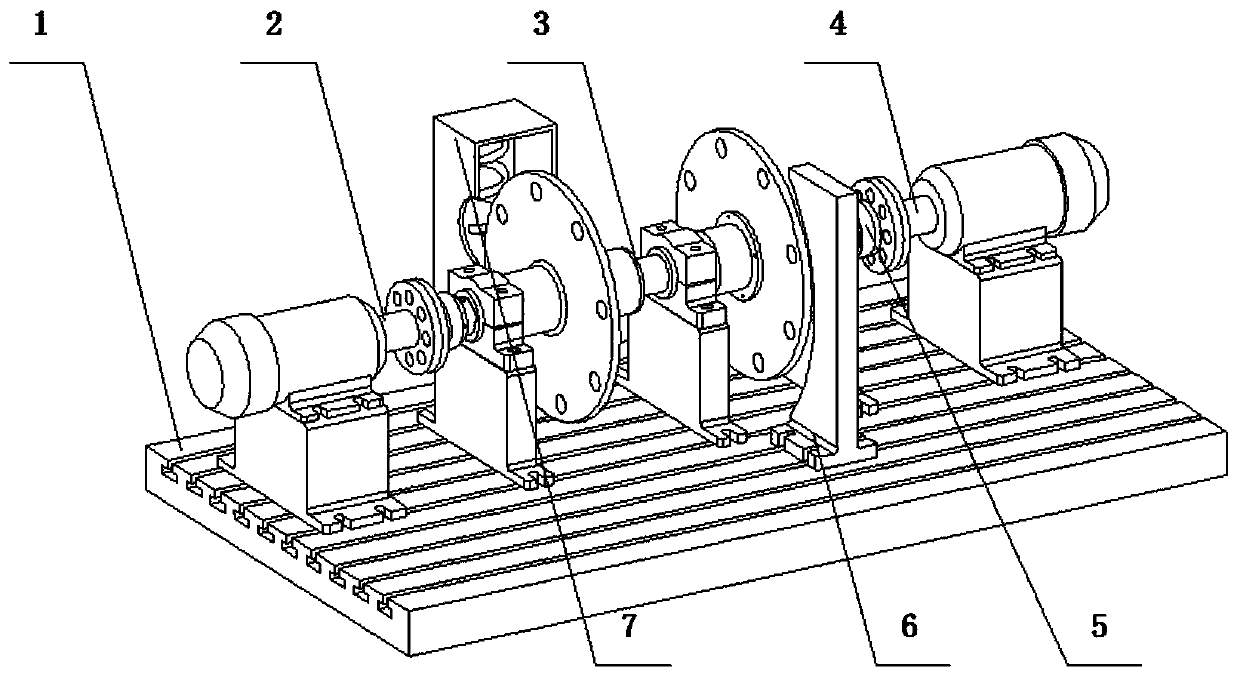

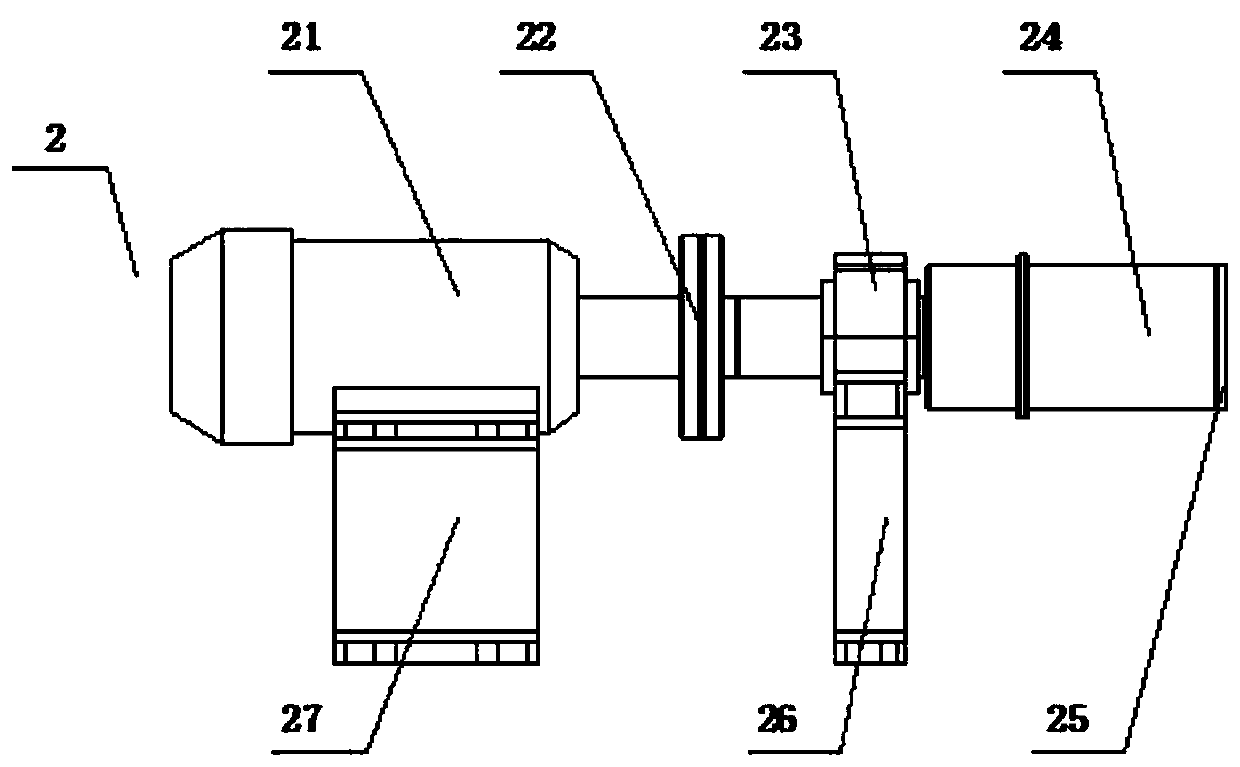

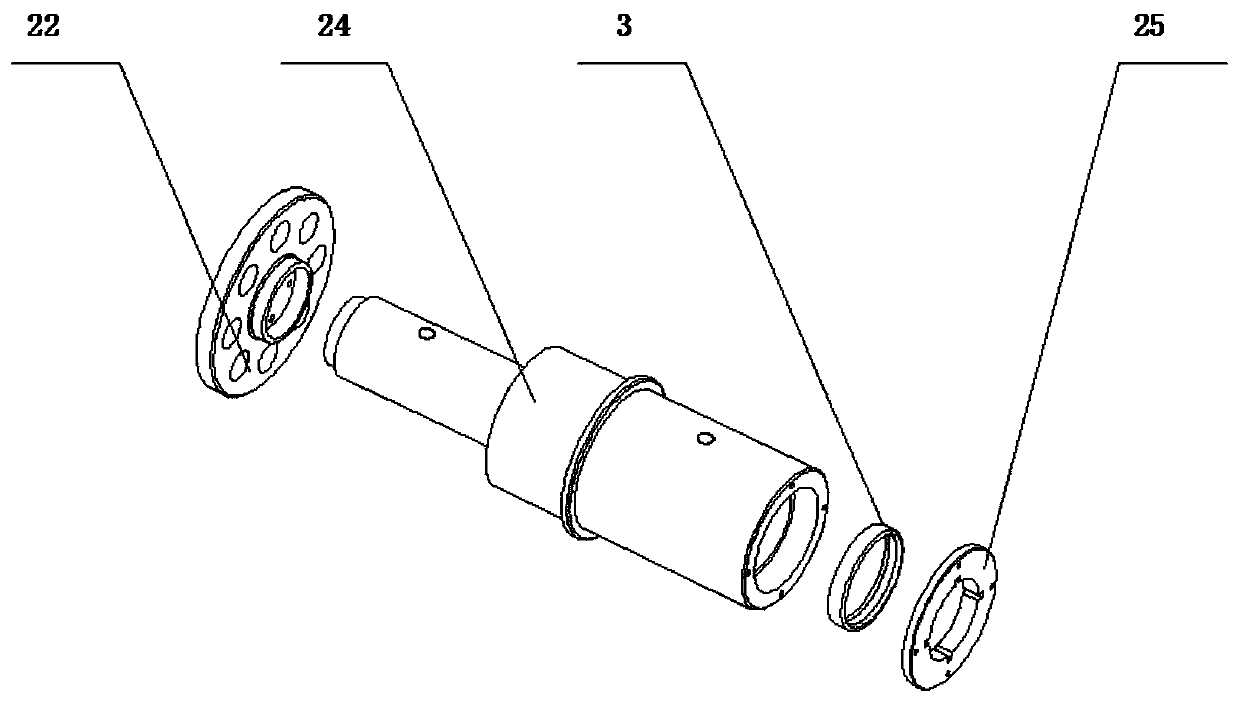

Intershaft bearing vibration experiment device

ActiveCN110243604AAvoid Vibration InterferenceAchieve vibration isolationMachine part testingBearing vibrationEngineering

The invention provides an intershaft bearing vibration experiment device. The intershaft bearing vibration experiment device comprises an experiment table base, a high-pressure rotor system, a low-pressure rotor system, a test system, a load simulation device and a temperature environment simulation device, wherein the high-pressure rotor system and the lower-pressure rotor system are used for allowing an inner sleeve ring and an outer sleeve ring of an intershaft bearing to rotate at different speeds, the test system is used for testing, transmitting and acquiring a vibration signal of the intershaft bearing, the load simulation device is used for simulating a centrifugal load and a radial load which are borne by the intershaft bearing, and the temperature environment simulation device is used for simulating a high-temperature environment of the intershaft bearing. In the intershaft bearing vibration experiment device provided by the invention, the simulation of the temperature environment and the load characteristic of the intershaft bearing is achieved, and meanwhile, the interference of other parts on the vibration signal of the intershaft bearing is prevented; and the proposed intershaft bearing test method is used for directly testing surface vibration of an inner circle and an outer circle of a bearing body, and the vibration characteristic of the intershaft bearing body can be effectively analyzed.

Owner:SHANDONG KAIMEIRUI BEARING TECH CO LTD +1

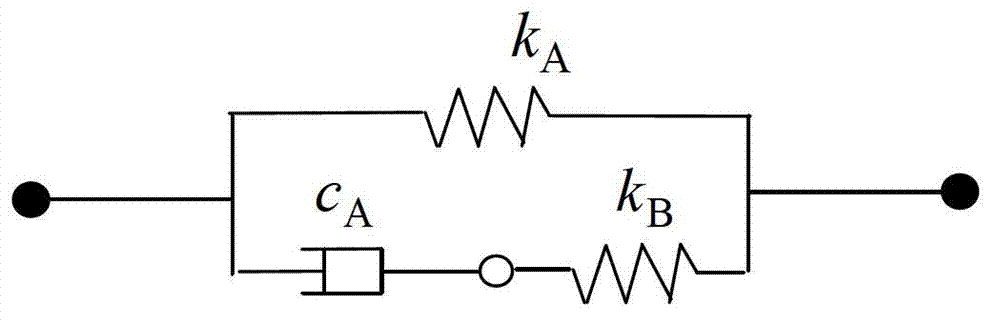

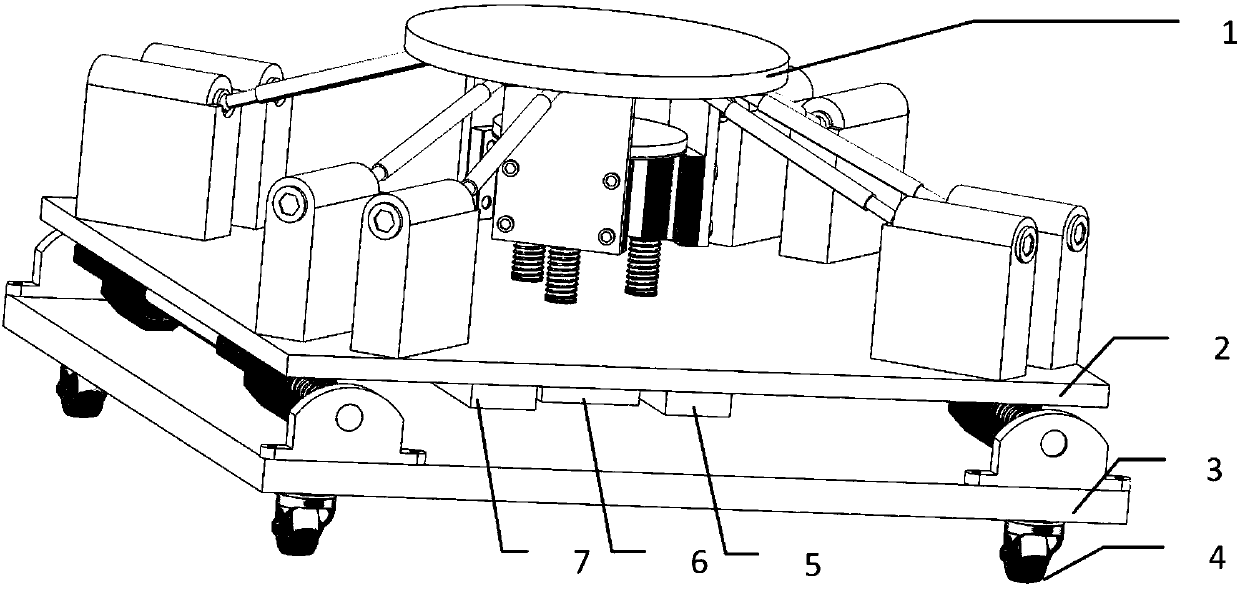

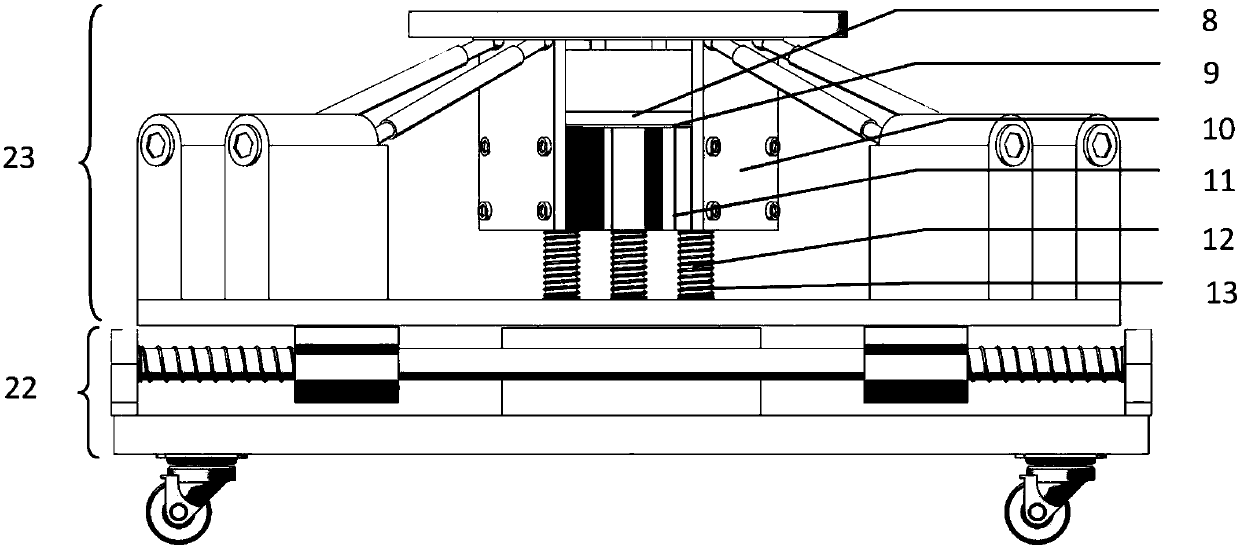

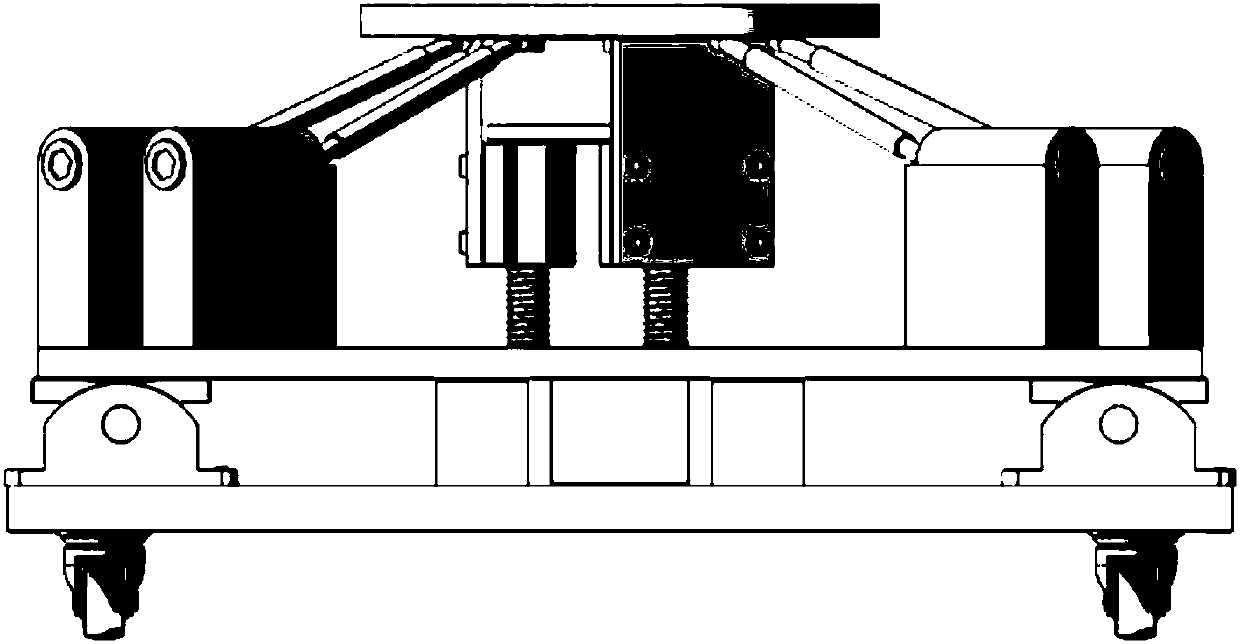

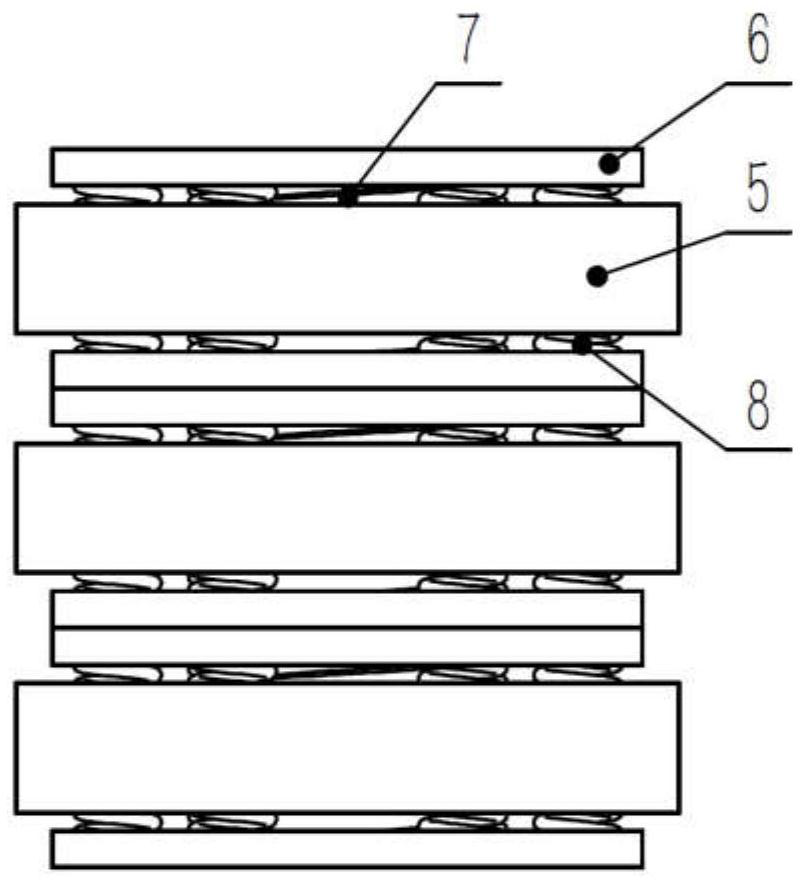

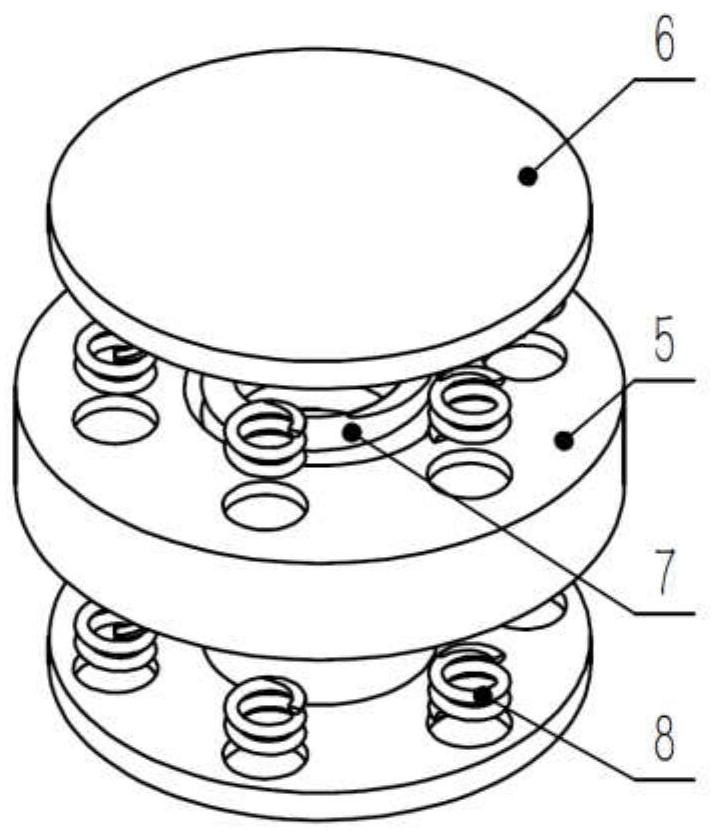

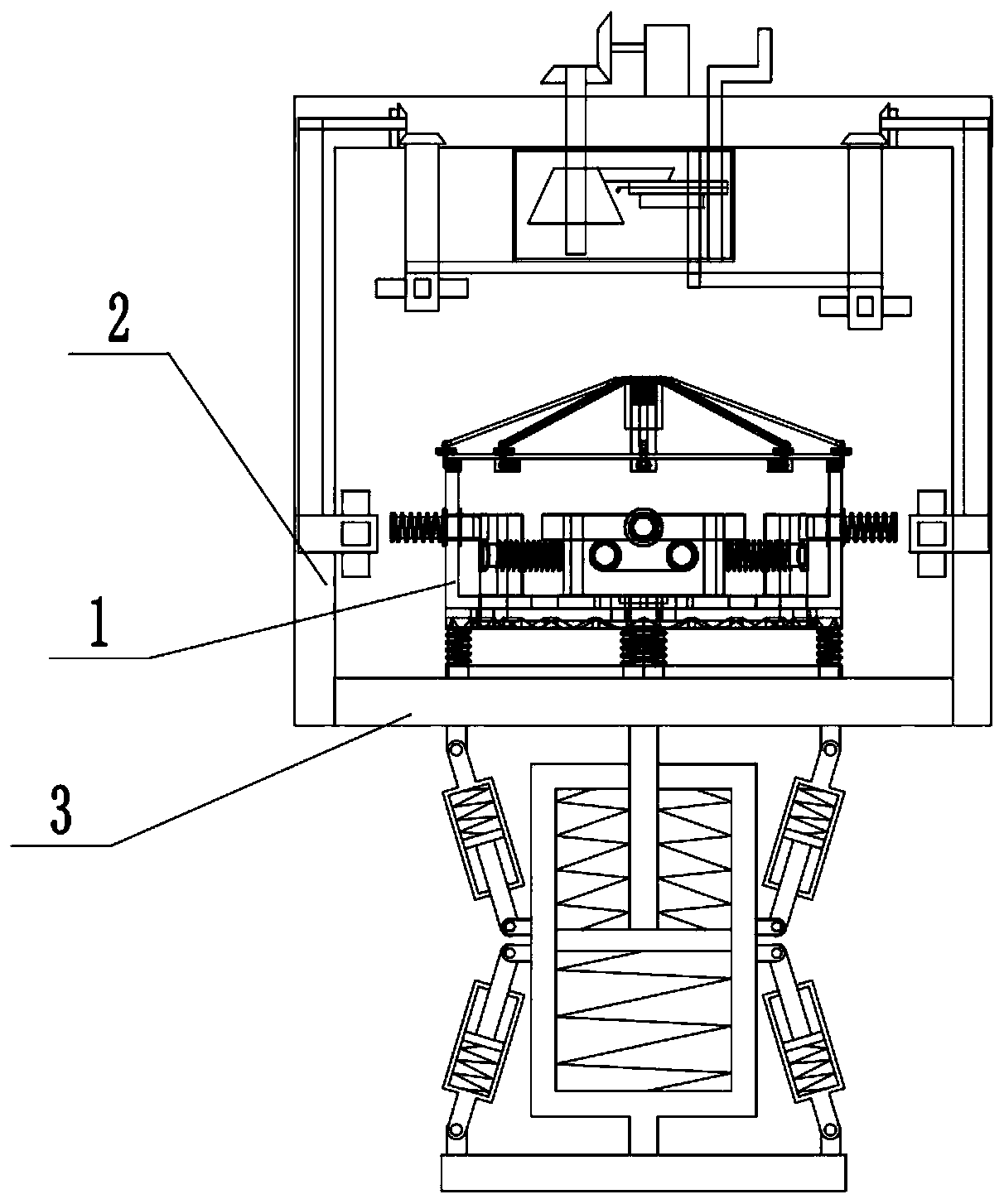

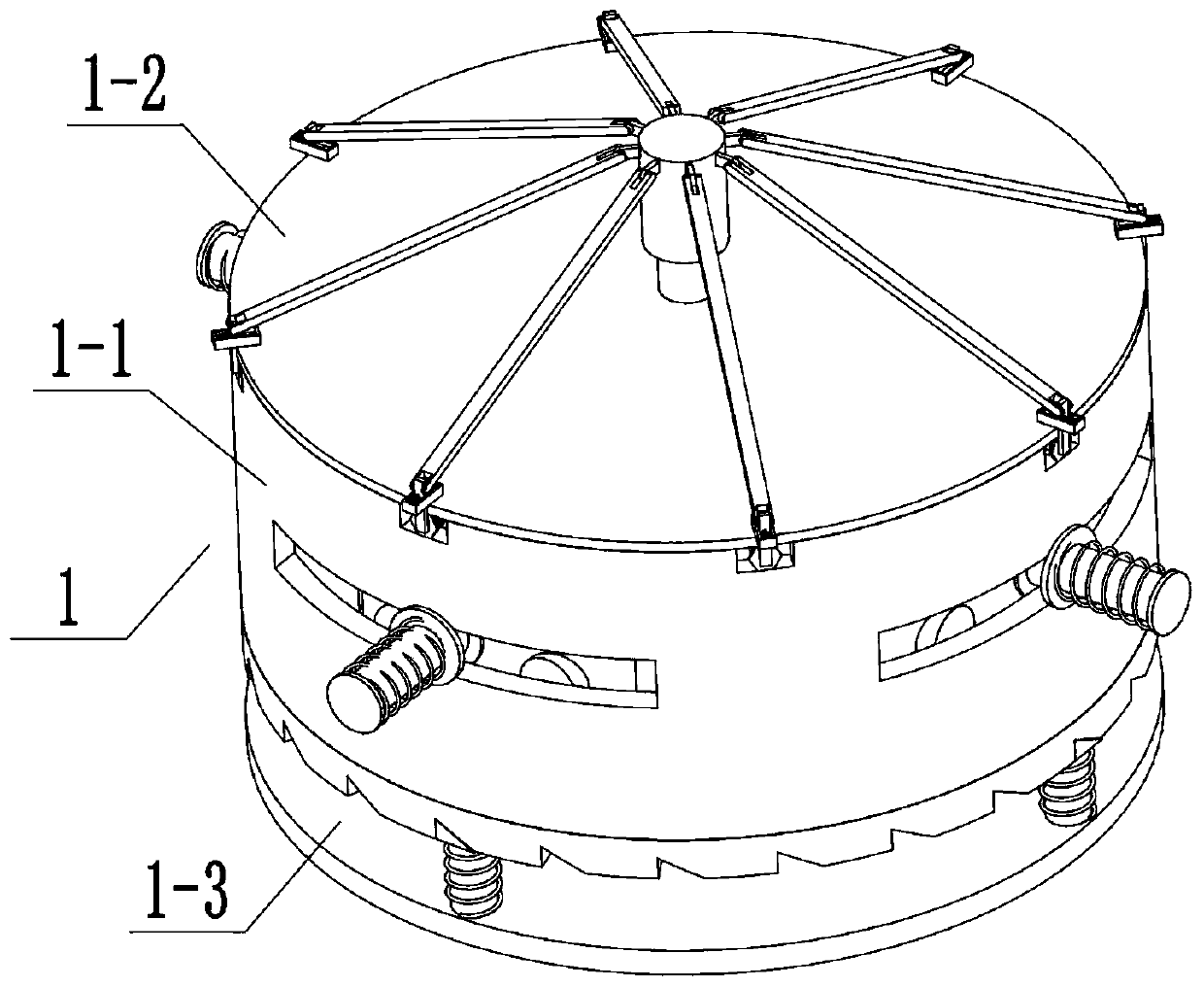

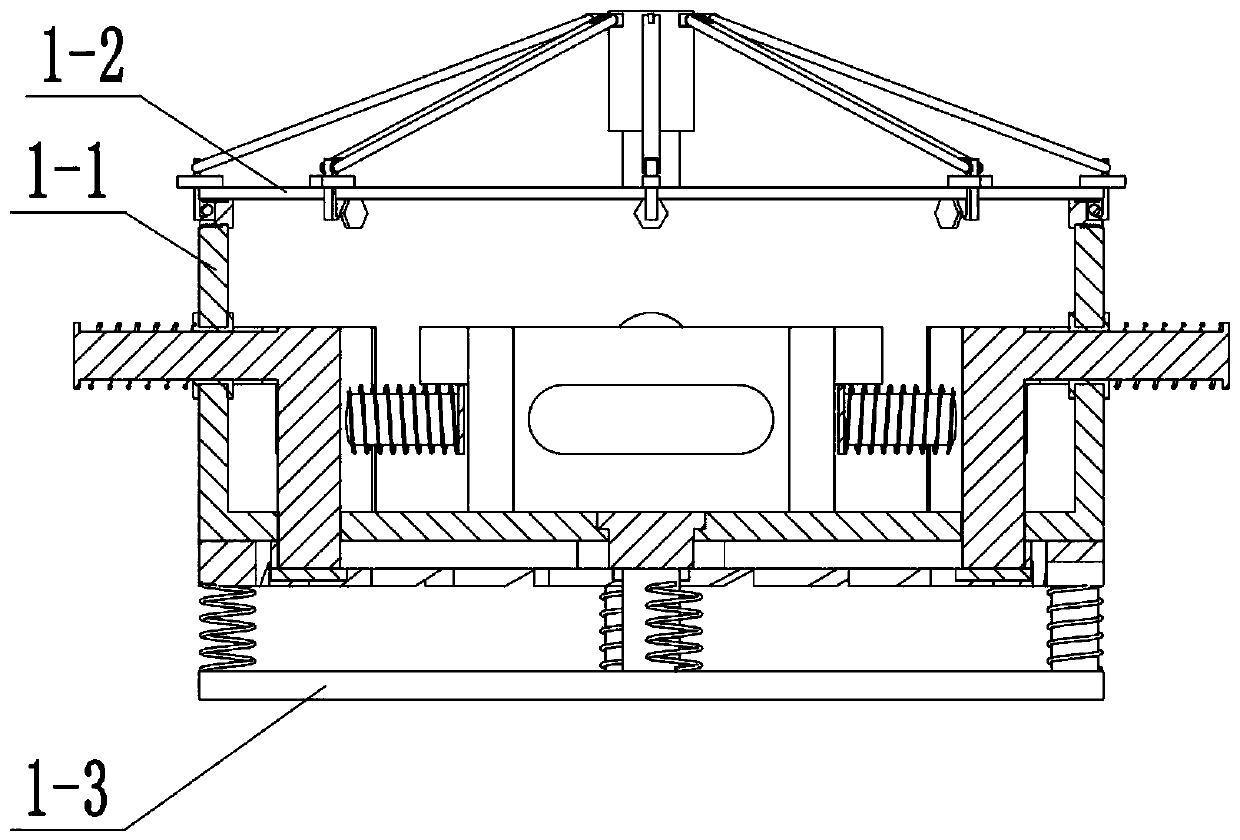

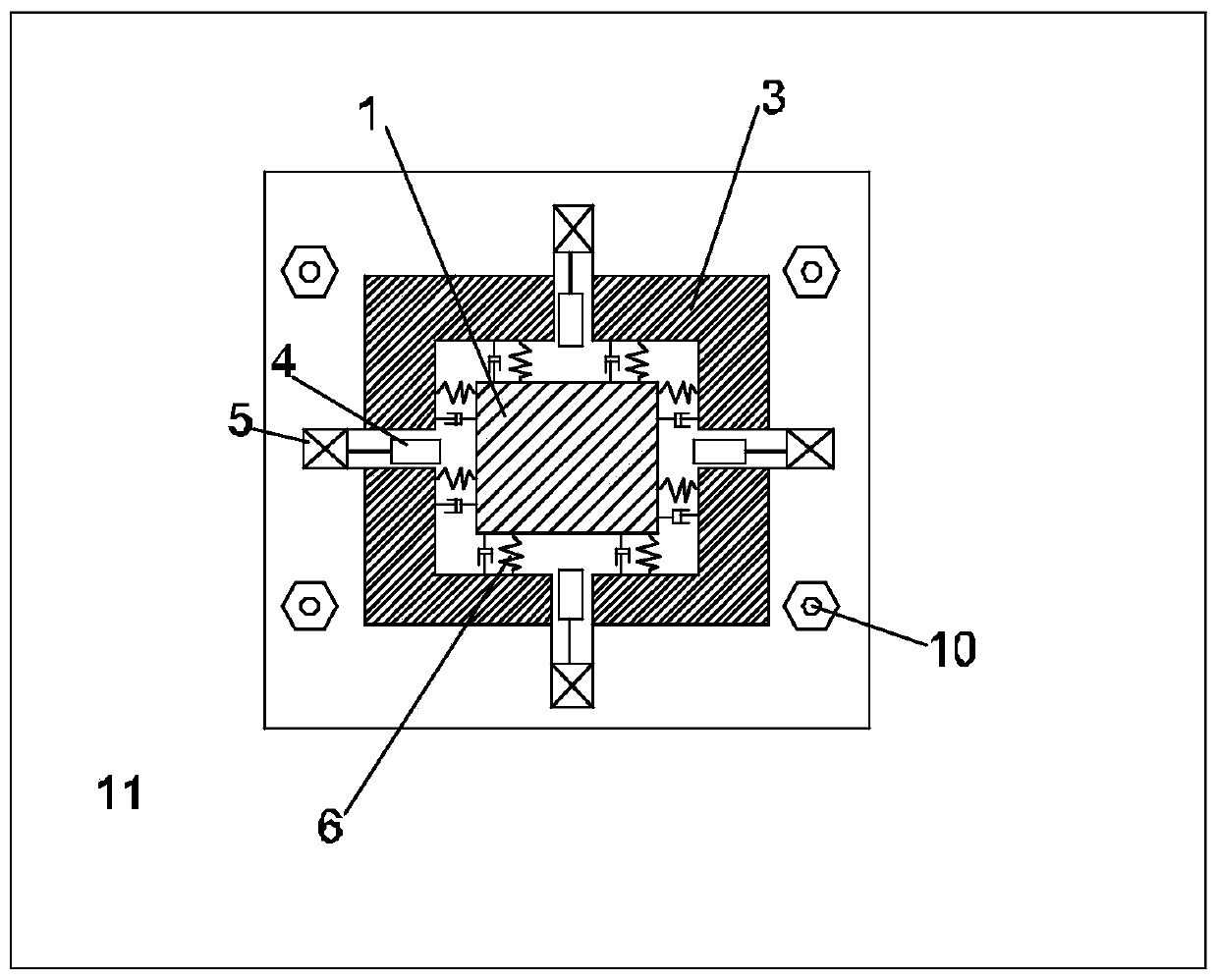

Two-degree-of-freedom positive-negative rigidity parallel low-frequency vibration isolating device

ActiveCN108167363AImprove carrying capacityAchieve vibration isolationSpringsSprings/dampers functional characteristicsPhysicsLow frequency vibration

The invention relates to a two-degree-of-freedom positive-negative rigidity parallel low-frequency vibration isolating device, and belongs to the technical field of vibration isolation. The device comprises an upper-layer vibration isolating device and a lower-layer vibration isolating device; magnets not contacted with each other form negative-rigidity mechanisms of the lower-layer vibration isolating device; slide blocks, springs and the like form positive-rigidity mechanisms of the lower-layer vibration isolating device; a low-frequency vibration isolating device formed by parallel connection of the lower-layer positive-rigidity and negative-rigidity mechanisms can effectively isolate horizontal impact to damped objects; pressure springs, adjusting screws, pressure rods and the like ofthe upper-layer vibration isolating devices form negative-rigidity mechanisms; support springs, connecting plates and the like of the upper-layer vibration isolating devices form positive-rigidity mechanisms; a low-frequency vibration isolating device formed by parallel connection of the upper-layer positive-rigidity and negative-rigidity mechanisms can effectively isolate vertical vibration impact to the damped objects. The upper and lower layers of vibration isolating devices are connected through a middle platform to form a two-degree-of-freedom vibration isolating device; and the device iscompact in structure, and achieves higher engineering application value in the fields of automobiles, precise instruments, unmanned automatic warehousing and the like.

Owner:SHANDONG UNIV

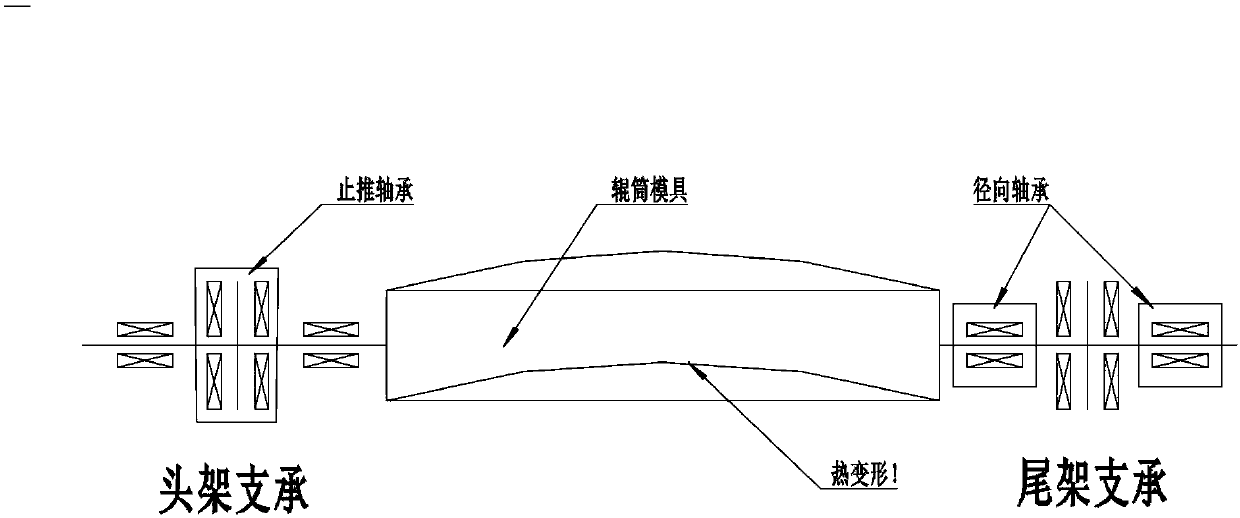

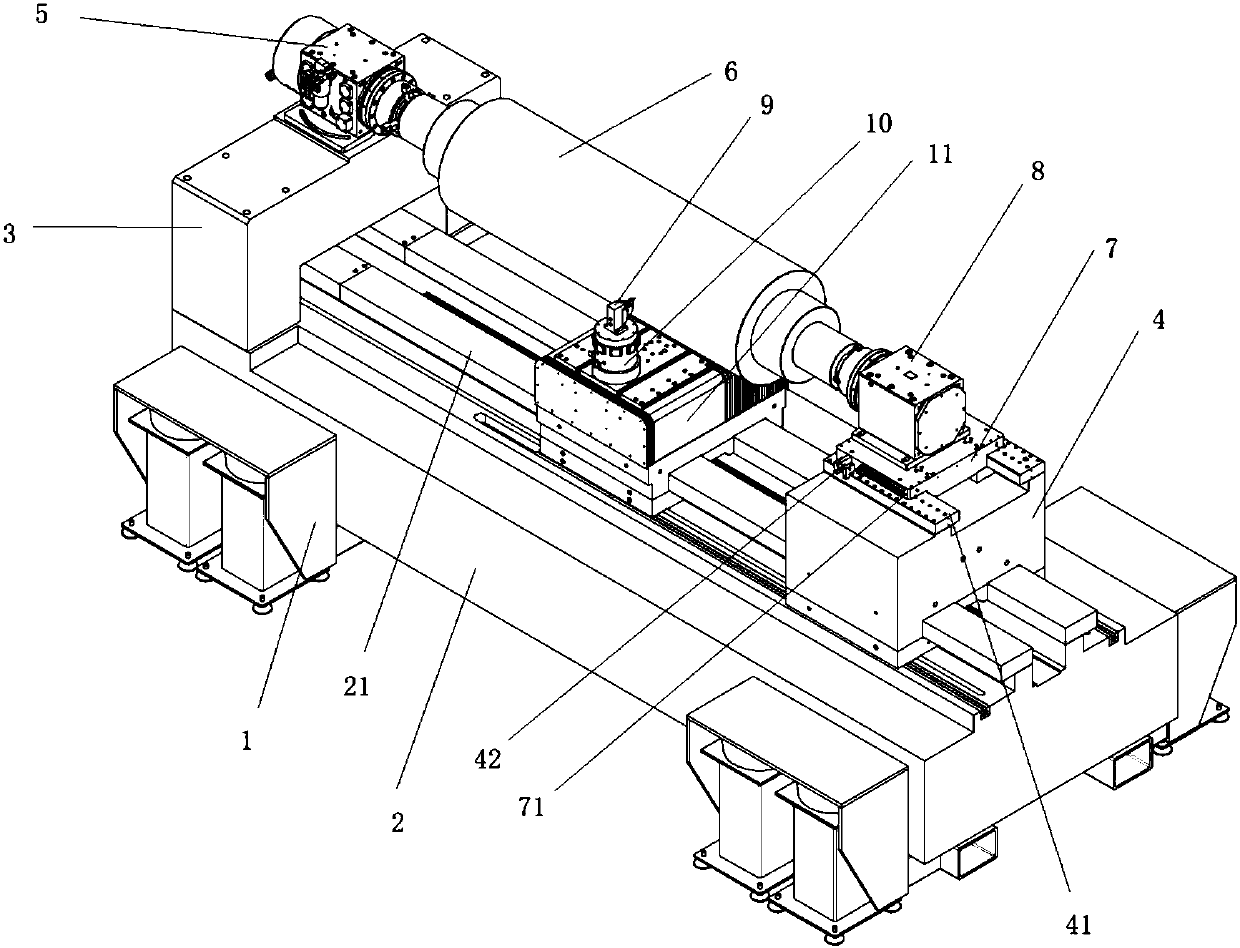

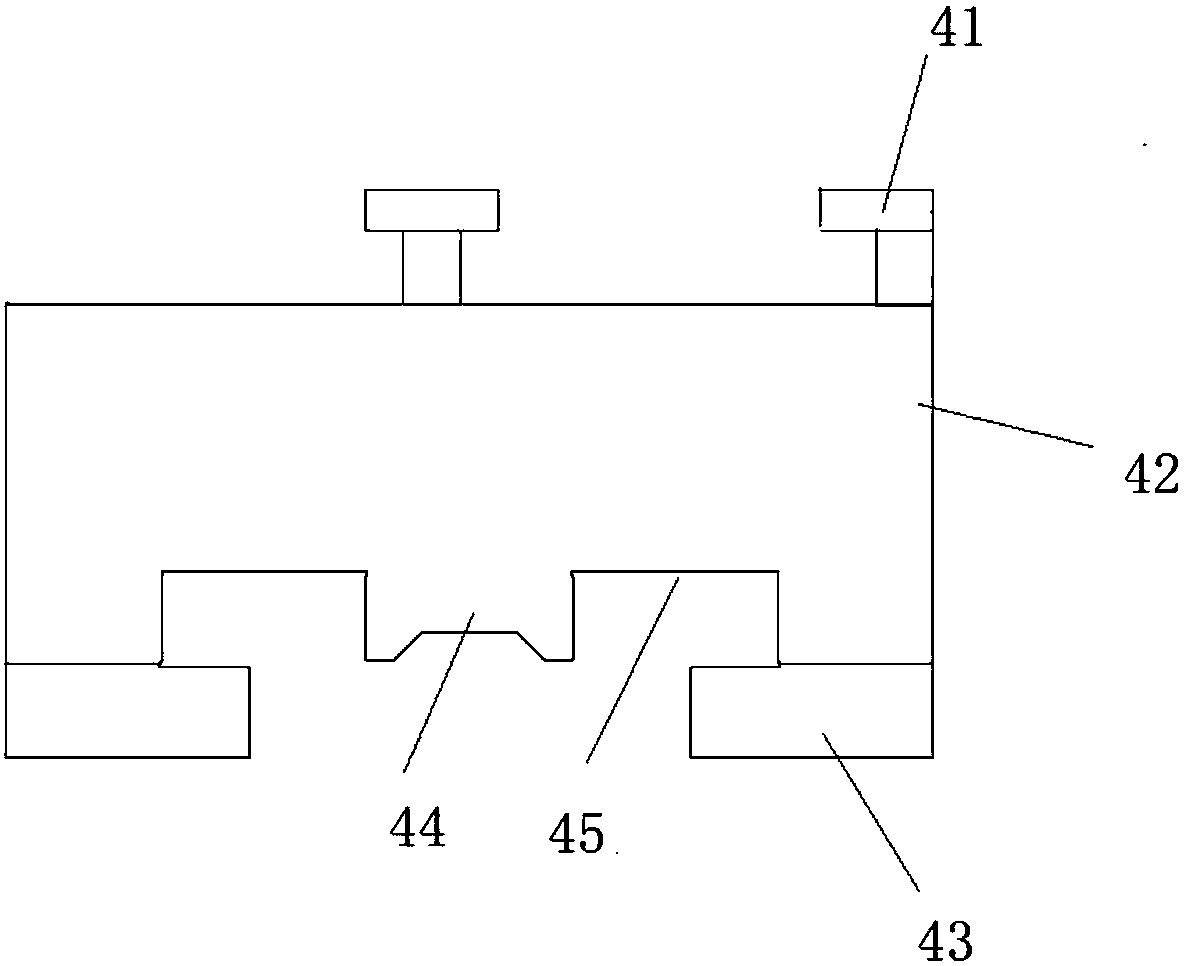

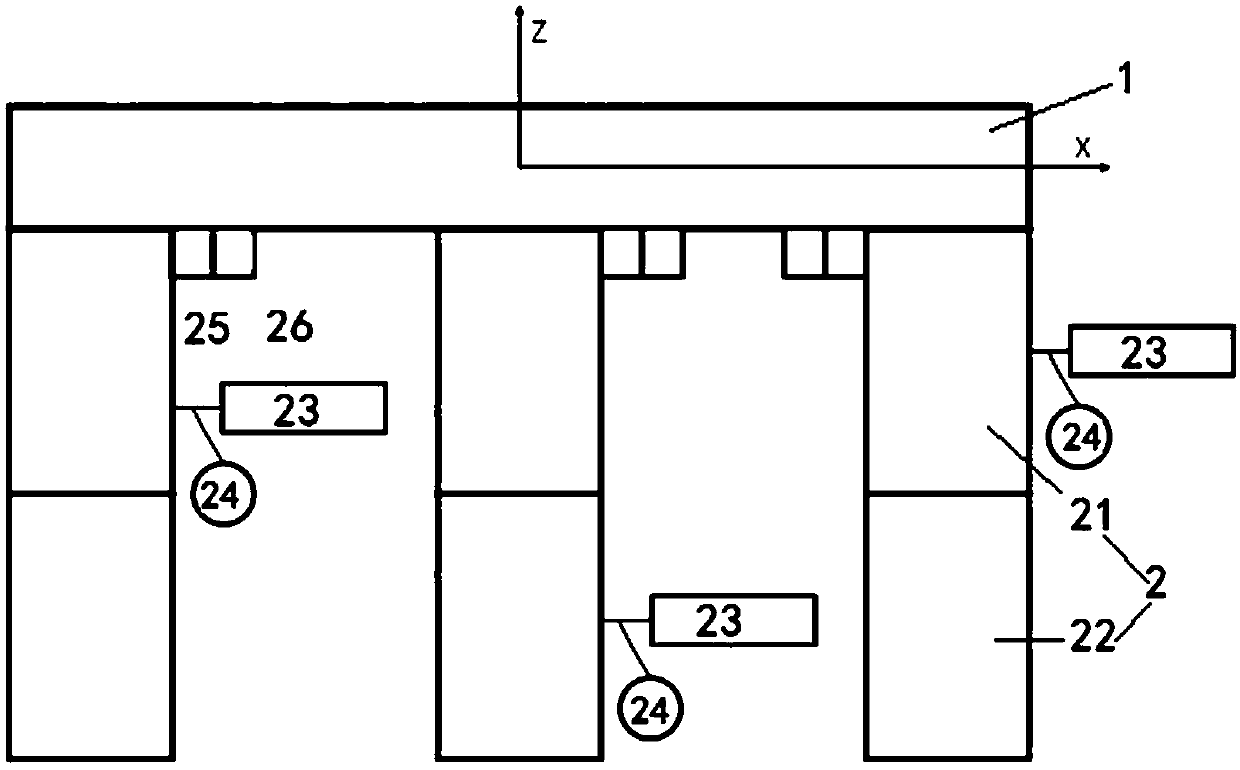

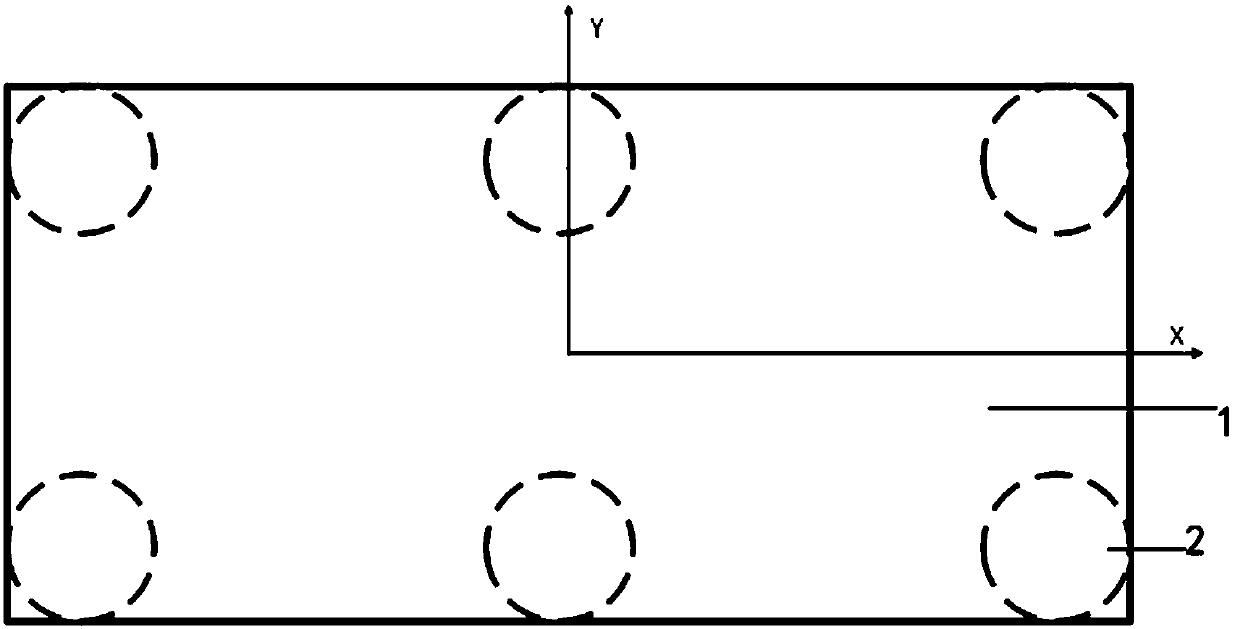

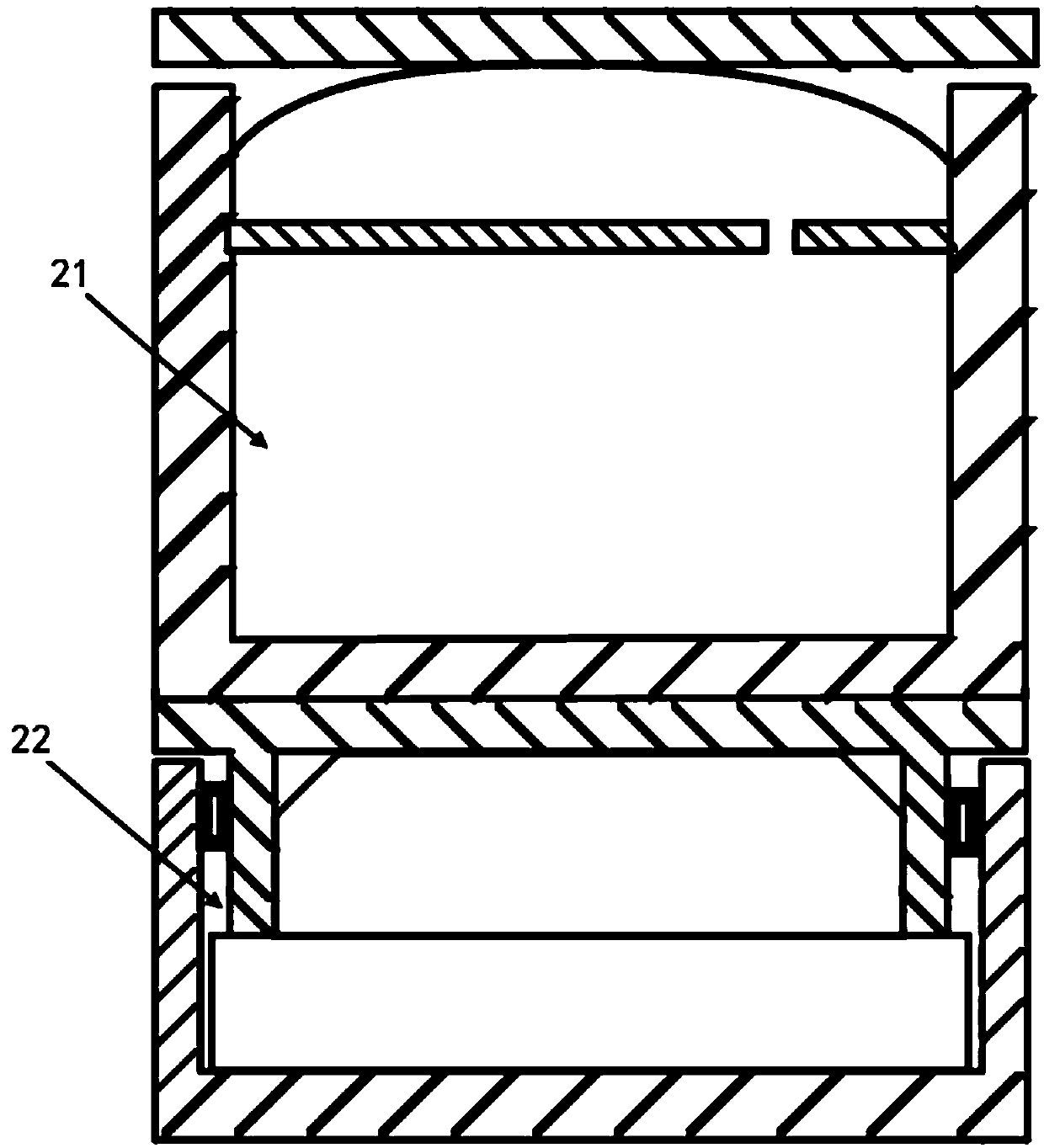

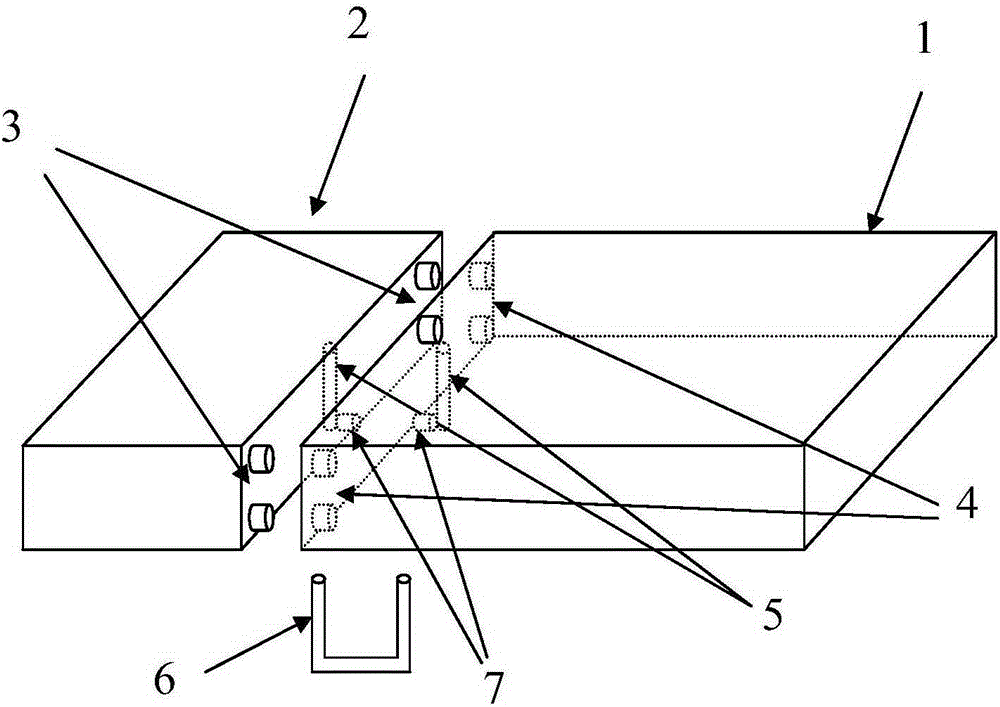

Ultra-precise lathe

InactiveCN107671308AImprove tilt resistanceImprove abilitiesTailstocks/centresMeasurement/indication equipmentsEngineeringHeadstock

The invention relates to an ultra-precise lathe which comprises a supporting device (1) and a lathe body (2) arranged on the supporting device (1). A pair of lathe body guide rails (21) is arranged onthe lathe body (2), and a tailstock support (3) is fixed to the left end of the lathe body (2) and provided with a headstock (5); a first tailstock sliding block (4) arranged on the guide rails (21)is movably fixed to the right end of the lathe body (2), and a second tailstock sliding block (7) is slidably arranged on the first tailstock sliding block (4); a tailstock (8) is arranged at the topof the second tailstock sliding block (7), and a roller mold (6) is arranged between the tailstock (8) and the headstock (5); and a cross-shaped sliding table (11) is further slidably connected abovethe guide rails (21) and between the tailstock support (3) and the first tailstock sliding block (4), and a static pressure rotary table (10) is arranged on the cross-shaped sliding table (11) and provided with a knife rest (9). The ultra-precise lathe is simple in structure and convenient to operate.

Owner:江苏哈博精密机械科技有限公司

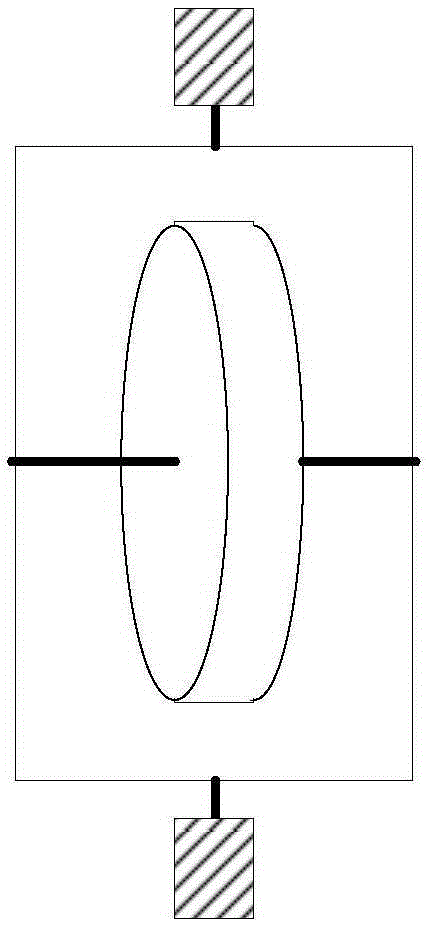

Cylindrical rotating plate permanent magnet coupler

ActiveCN103915975AAvoid relative motionAchieve torque transmissionDynamo-electric gearsElectrical conductorTorque transmission

The invention discloses a cylindrical rotating plate permanent magnet coupler which comprises a first shaft and a second shaft. The first shaft and the second shaft are coaxial. The first shaft is provided with a permanent magnet rotating plate provided with an inner layer cylinder, an outer layer cylinder and a carrying magnet. The inner layer cylinder and the outer layer cylinder are arranged inside and outside the permanent magnet rotating plate in the diameter direction of the rotating plate in a corresponding mode. The carrying magnet is arranged between the inner layer cylinder and the outer layer cylinder and provided with a circle of permanent magnets. The polar direction of the permanent magnets is perpendicular to the axis of the permanent magnet rotating plate. Every two adjacent magnets are installed in a hetero-polar mode. The second shaft is provided with a conductor rotating plate provided with at least one conductor cylinder. The conductor cylinders are arranged in the gap between the inner layer cylinder and the carrying magnet and the gap between the outer layer cylinder and the carrying magnet. Transmission of different kinds of torque is achieved by adjusting the coupling area between rotors, the purposes of isolating vibration, reducing the speed and saving the energy are achieved, installing and debugging are easy, axial moving of a certain degree is allowed, torque transmission between the two parts can be achieved, and the purposes of isolating vibration, reducing the speed and saving the energy are achieved.

Owner:QINGDAO SPRING ENERGY TECH

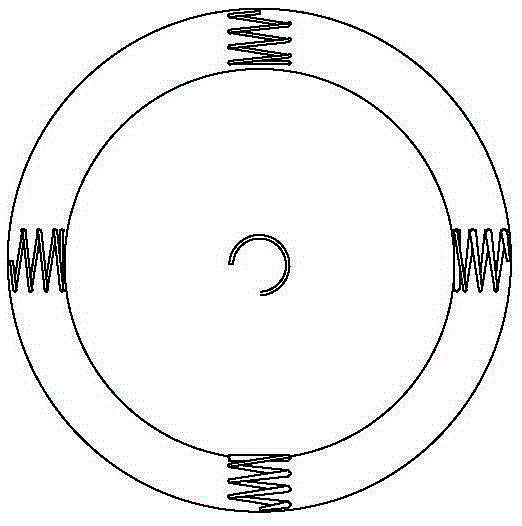

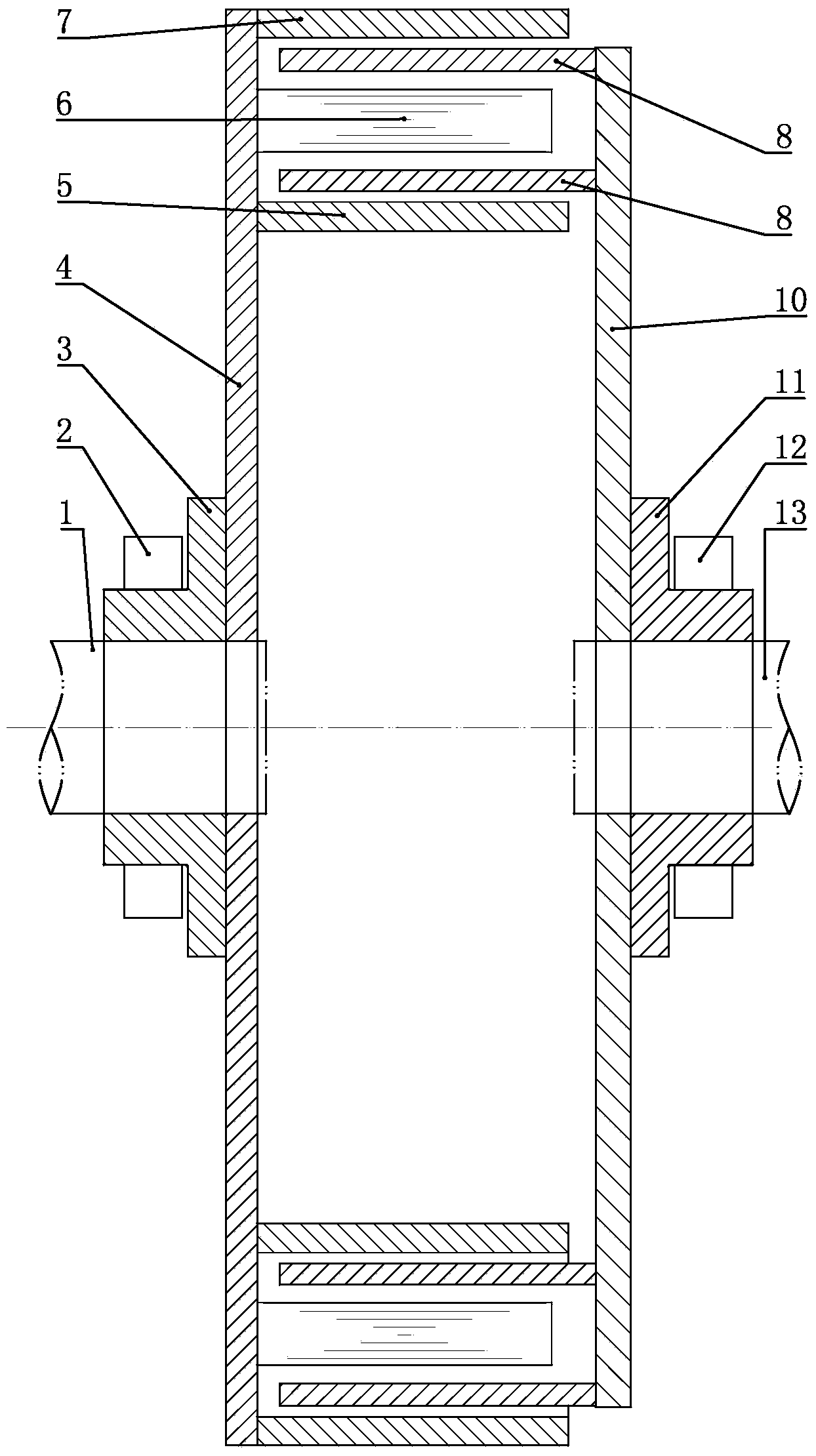

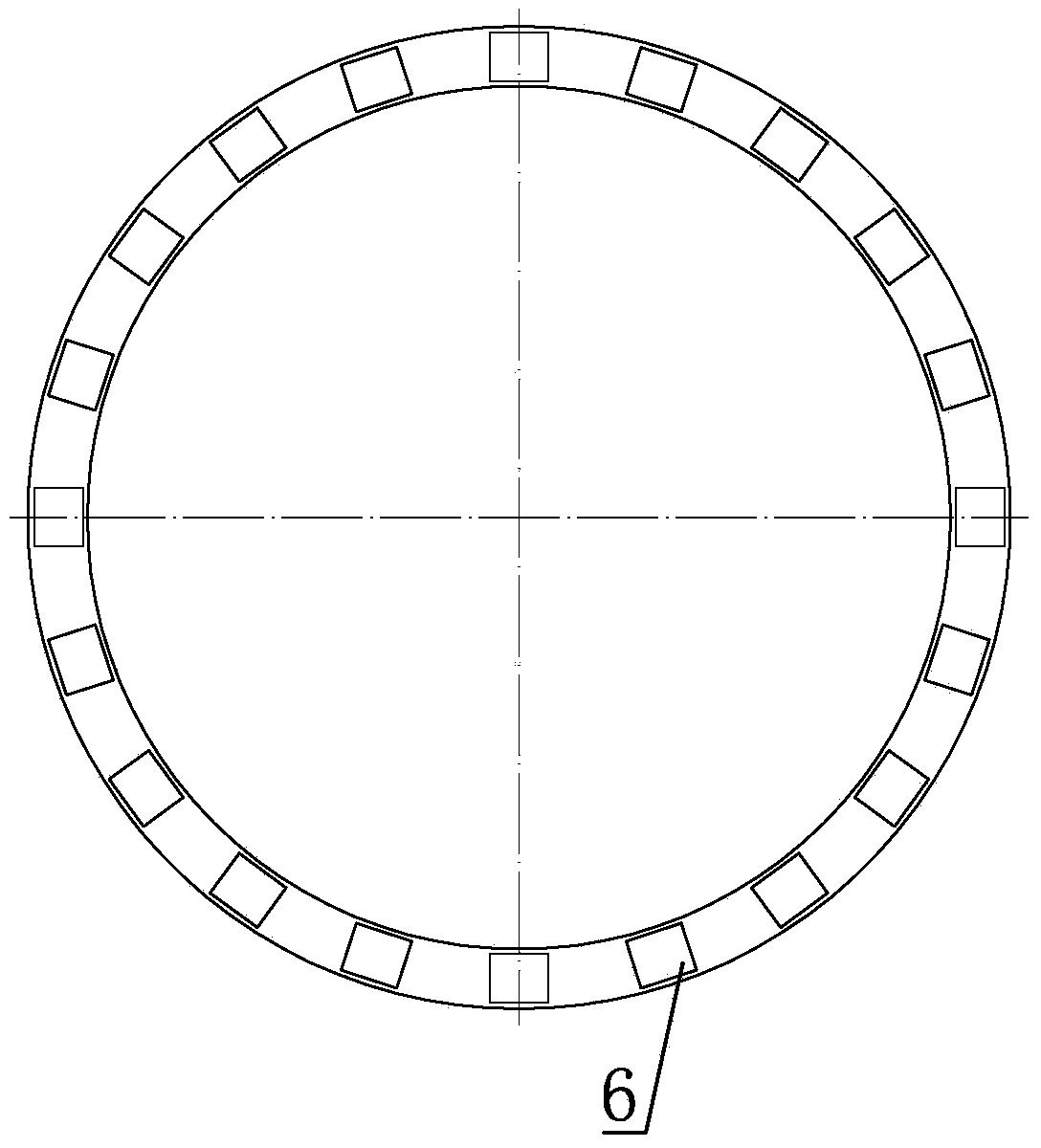

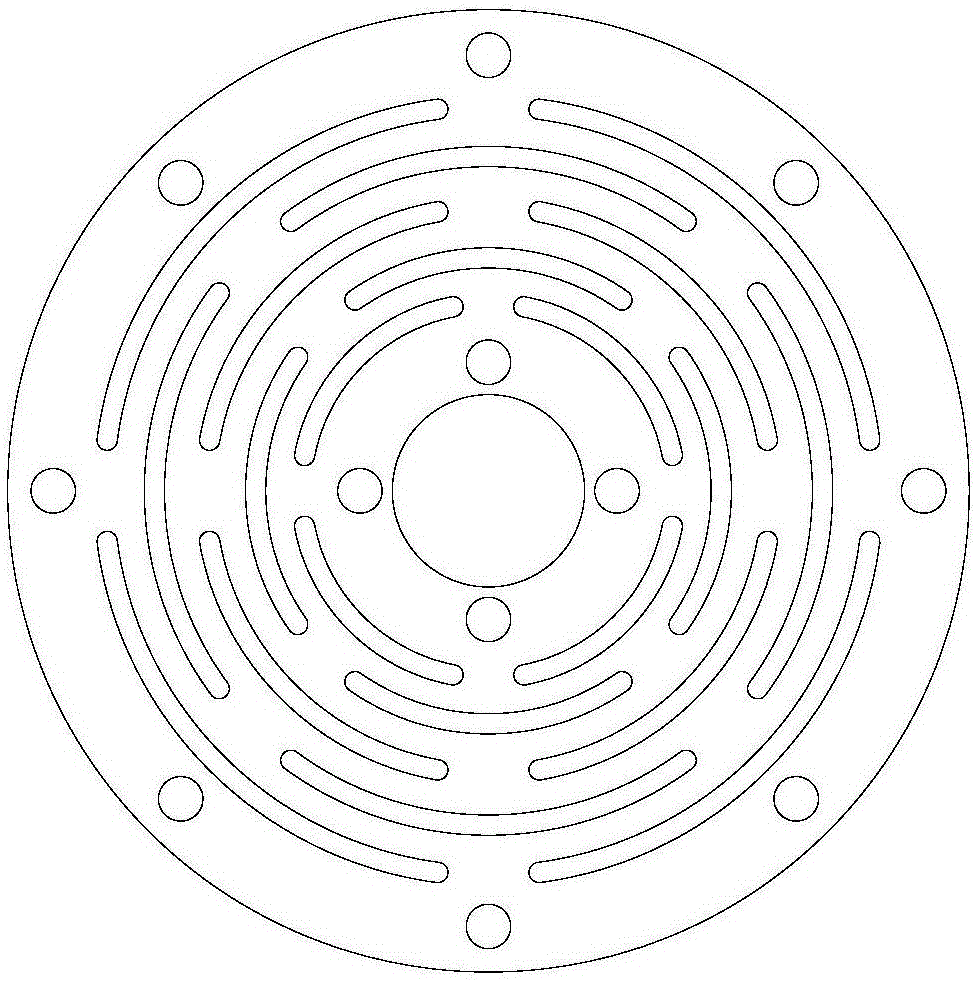

Sandwich type round plate stator and ultrasonic motor using the same

InactiveCN101388621ASolve efficiency problemsAddress mechanical propertiesPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamElastomer

The invention relates to a sandwich disk stator and an ultrasonic motor which uses the stator, which relate to the technical field of piezoelectric ultrasonic motors. The sandwich disk stator and the ultrasonic motor solve the problem in an existing ultrasonic motor that since a mode that a metallic elastomer is pasted with a piezoelectric ceramic slice is adopted to actuate, the mechanical output ability is restricted. Driving elements with even number in the sandwich disk stator are fixed on the upper end surface of a disk, two pairs of piezoelectric ceramic pieces are fixed between each pair of cantilever beams, and a plurality of comb-shaped driving gears are evenly distributed on the lower end surface of the disk. The ultrasonic motor which uses the stator comprises two stators, a rotor component is composed of a rotor and a wear resistance bush ring, wherein the end surface of the wear resistance bush ring is provided with same taper with the upper end surface of the driving gears, two stators are respectively installed on and under the rotor, the pre-tightening between the stator component and the rotor component can be realized through two stator flanges, and the rotor component is connected with bearing blocks of the two stators through output shafts and bearings on two ends of the rotor in a rotary mode. The sandwich disk stator and the ultrasonic motor have simple structure, can realize big force moment output, and have stable performance.

Owner:HARBIN INST OF TECH

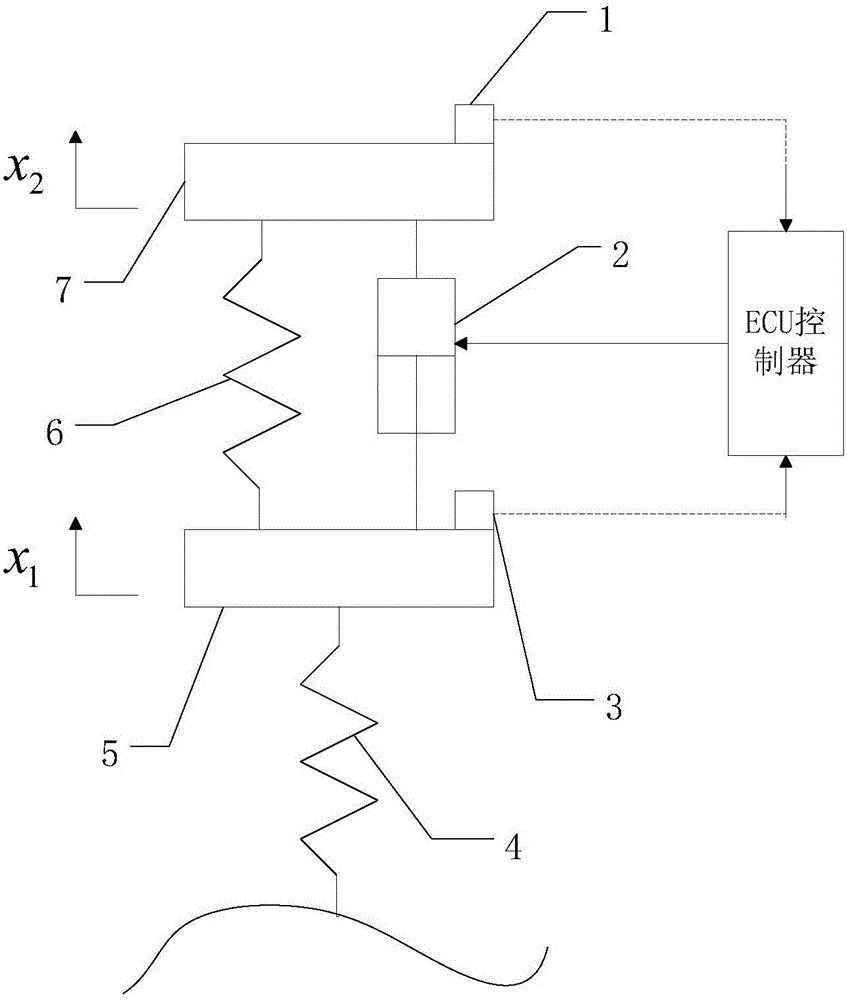

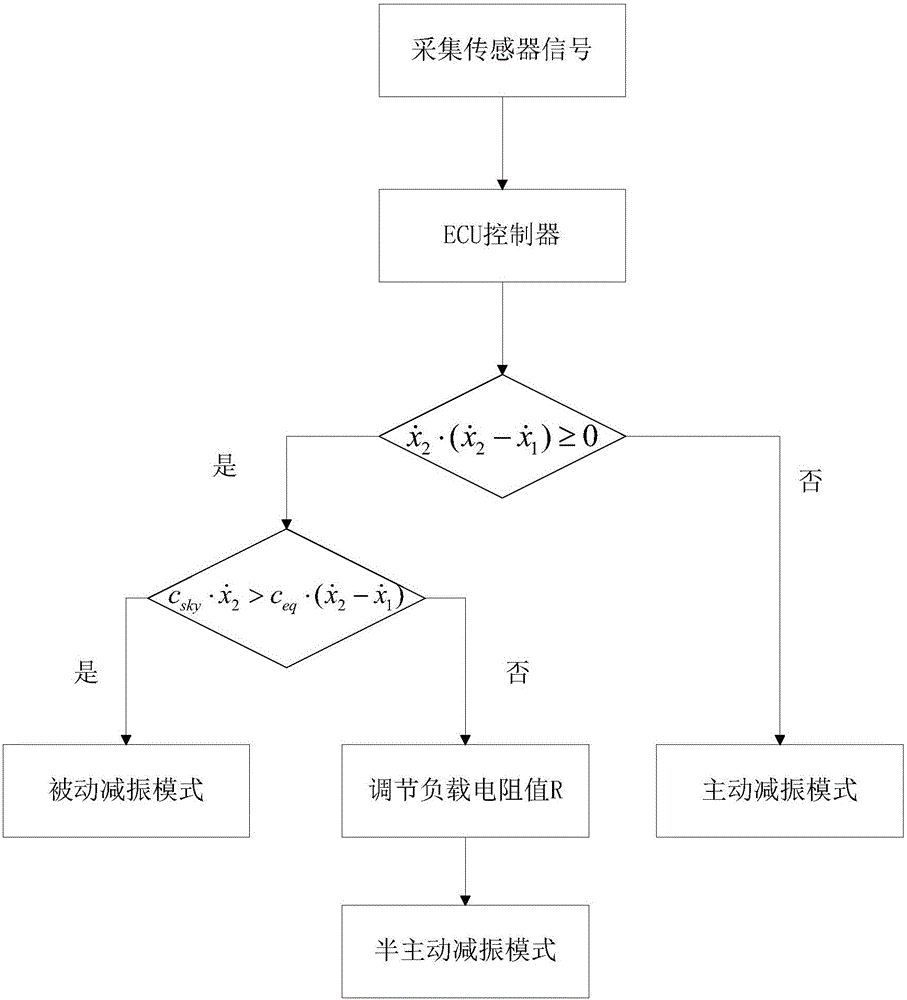

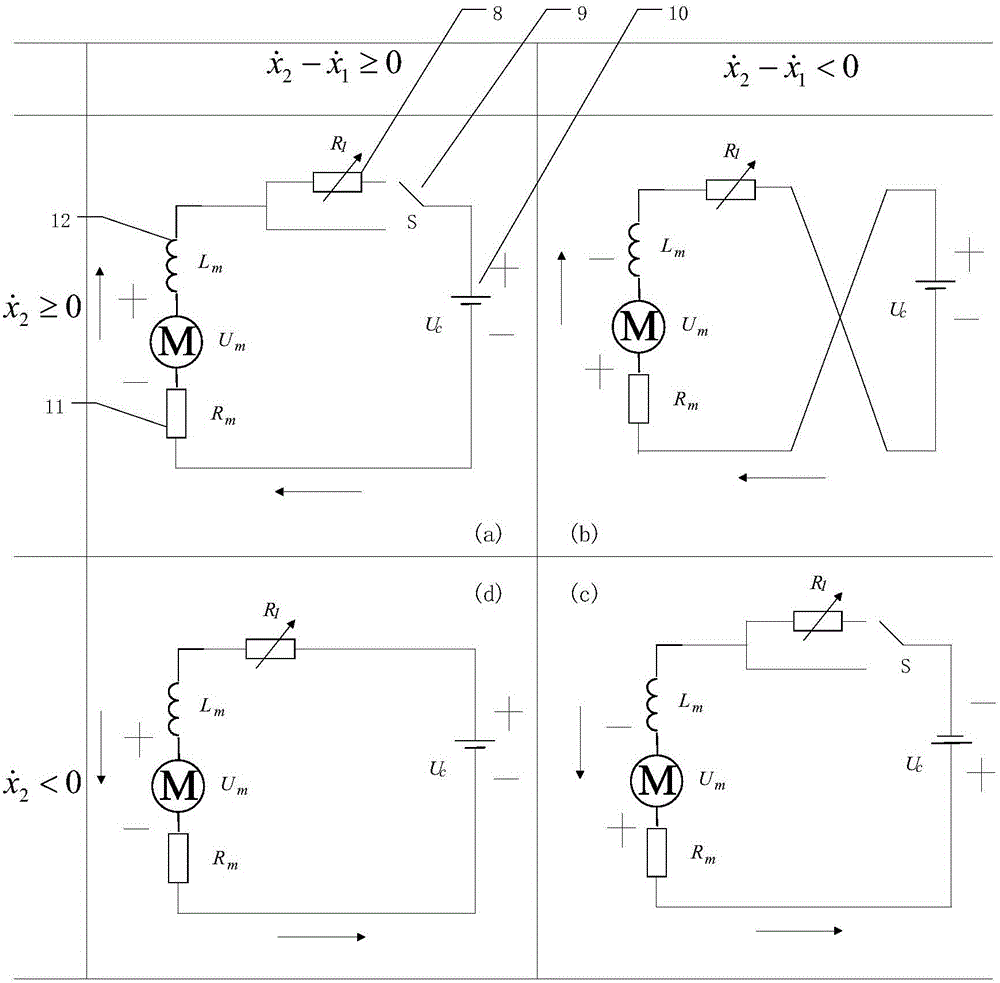

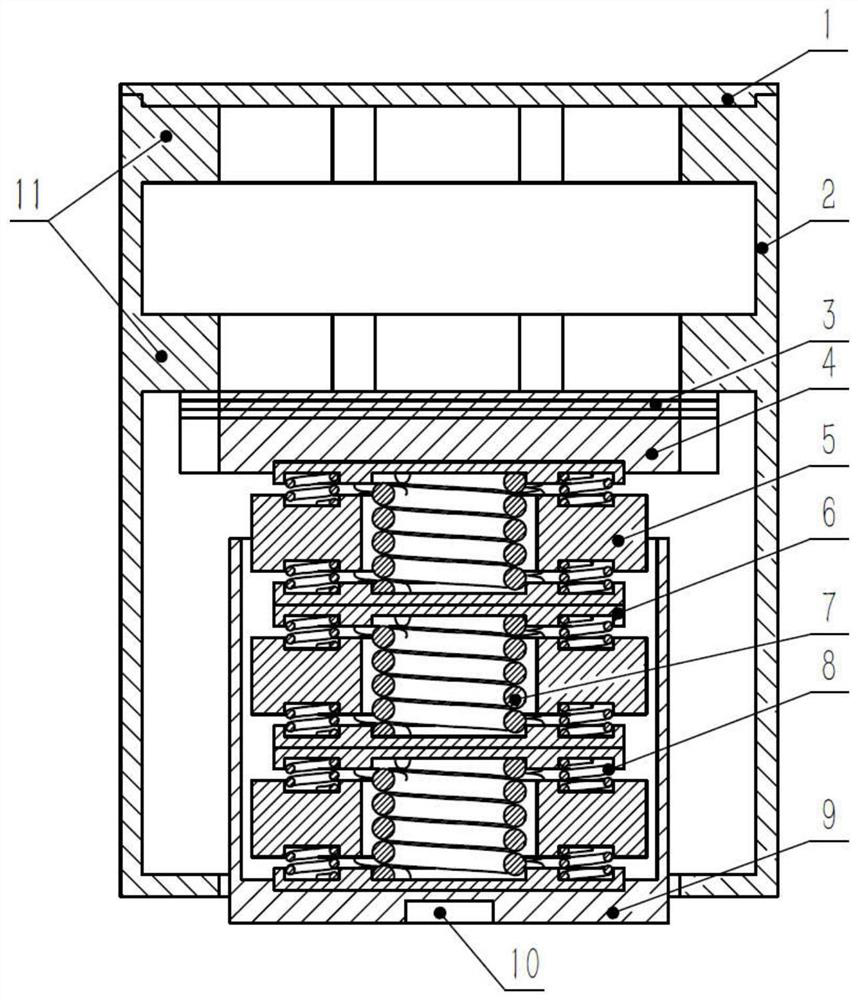

Improved ceiling control method of energy feedback suspension system

ActiveCN105857003AAchieve vibration isolationRealize energy feedingAuxillary drivesResilient suspensionsElectric machineryLinear motor

The invention discloses an improved ceiling control method of an energy feedback suspension system, and belongs to the field of automobile energy conservation and emission reduction. An energy feedback suspension is formed by connecting a spring and a linear motor in parallel, and an improved ceiling control strategy is put forward with the control aim of low suspension energy consumption and excellent riding comfort. The working mode of the linear motor is analyzed and judged by connecting an automobile signal, and the suspension is in three different damping modes; meanwhile, when the suspension is in a driven mode and a semi-driving mode, the energy feedback suspension system can recycle vibration energy through an energy feedback circuit, so the aims of energy conservation and emission reduction are achieved.

Owner:JIANGSU UNIV

Multi-cascade phononic crystal vibration isolator

PendingCN112726297AAchieve vibration isolationOptimal Design StructureNon-rotating vibration suppressionRailway tracksPhotonic crystalIsolator

According to a multi-cascade phononic crystal vibration isolator, phononic crystal cells are arranged in the multi-cascade phononic crystal vibration isolator, a band gap within the frequency band range of 50 Hz to 200 Hz and 1000 Hz to 2000 Hz is generated, vibration of a specific frequency band is eliminated through the band gap, and therefore vibration reduction of a track is achieved, the multi-cascade phononic crystal vibration isolator is of a cylindrical structure and is divided into a vibration isolator outer cylinder structure and a vibration isolator inner cylinder structure; the vibration isolator inner cylinder structure is composed of an inner cylinder and a multi-cascade photonic crystal vibration isolator main body structure, the multi-cascade photonic crystal vibration isolator main body structure is placed in the inner cylinder and is formed by combining a plurality of photonic crystal cells and a bearing top plate, and each cell is composed of a mass element and an elastic element. Characteristics of the circumferential elastic element are brought into full play, and parameter optimization design is facilitated; the isolator has the advantages of being convenient to install, good in compatibility with an outer cylinder and an inner cylinder of an existing floating slab vibration isolator and the like, and has wide applicability in the field of rail transit vibration and noise reduction.

Owner:TONGJI UNIV +1

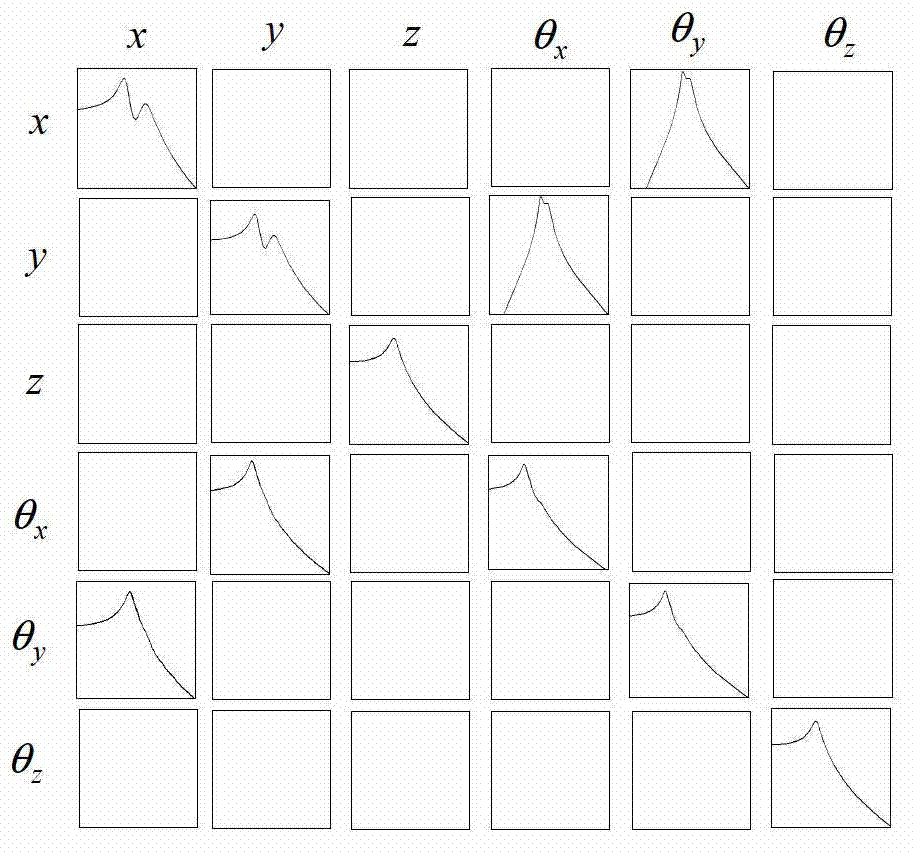

Multi-dimensional parallel platform and system integrating direction pointing and vibration isolation

ActiveCN106842546ASave volumeSave weightTelescopesVibration suppression adjustmentsAxial displacementControl system

The invention provides a multi-dimensional parallel platform and system integrating direction pointing and vibration isolation. The parallel platform includes an upper platform, a lower platform, six drive support legs and an acceleration sensor. The acceleration sensor is arranged above the drive support legs and is used for measuring the motion acceleration of the drive support legs and feeding the motion acceleration back to a control system so as to enable the control system to control movement of the drive support legs. Therefore, vibration isolation is achieved. The drive support legs include displacement sensors used for measuring axial displacement of the drive support legs and feeding the axial displacement to the control system so as to enable the control system to control the posture of the upper platform. Therefore, accurate direction pointing is realized. In this way, the direction pointing function and the vibration isolation function are integrated together, so that the platform provided by the invention replaces a vibration isolation system and a precise direction pointing system working independently in the prior art, so that the size and the weight of space devices are reduced substantially.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

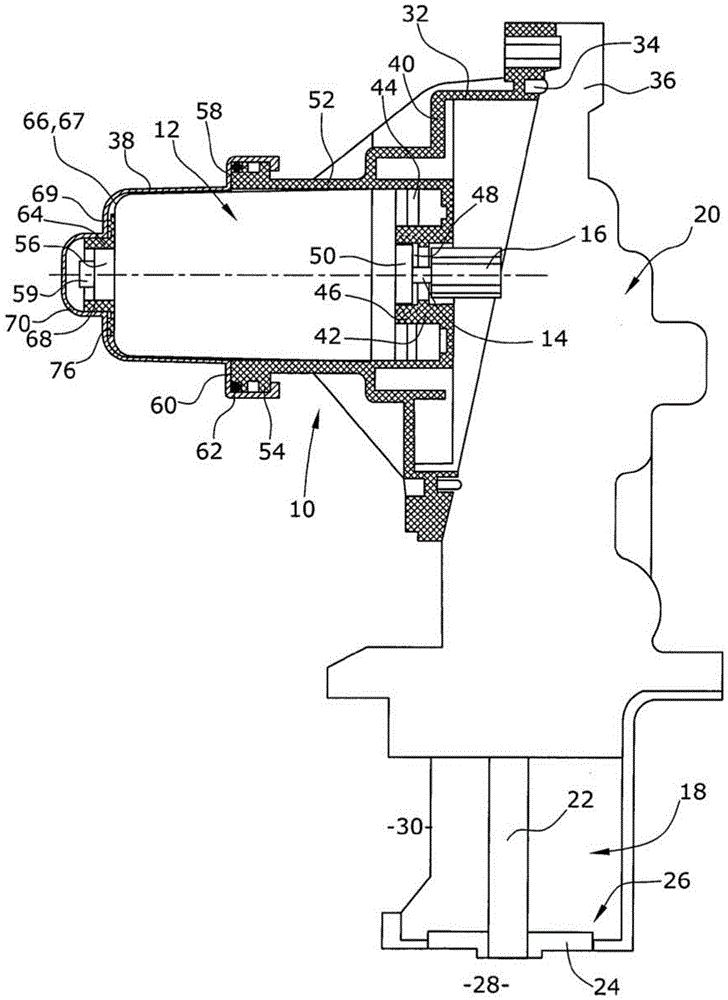

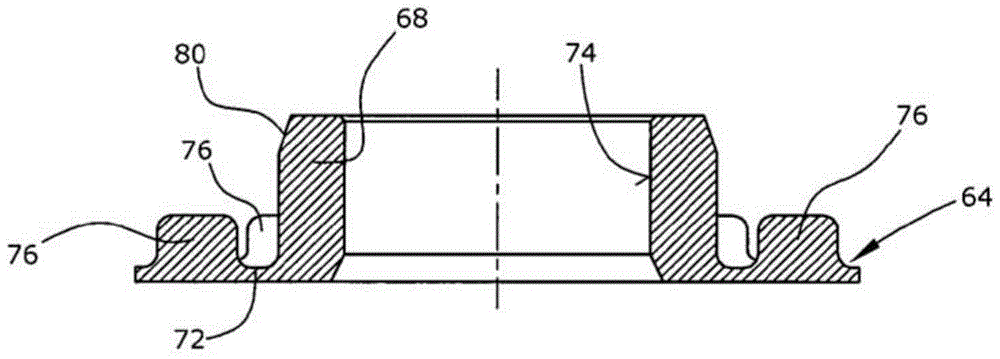

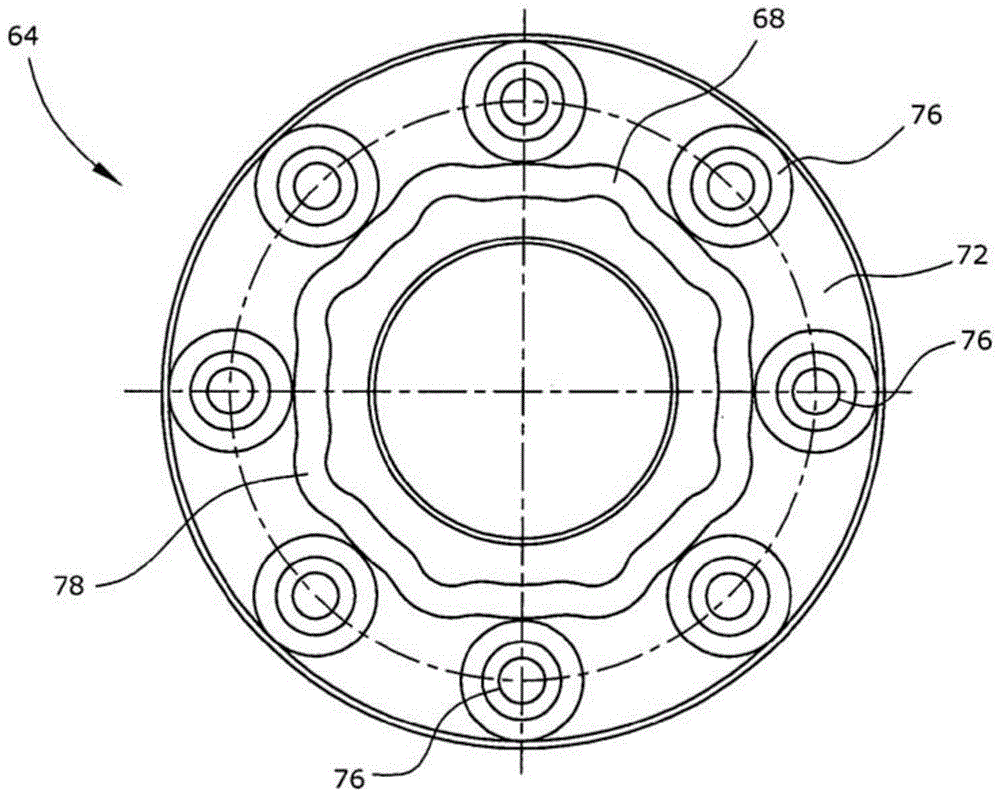

Drive arrangements for an assembly of an internal combustion engine, and exhaust-gas recirculation valve

ActiveCN104995826AExtend your lifeReliable engagementInternal combustion piston enginesSpringsSpring forceEngineering

Drive arrangements for assemblies of an internal combustion engine, in particular for exhaust-gas recirculation valves, having a drive element (12), a housing (10) and an intermediate element (64) that is arranged so as to be preloaded between the drive element (12) and the housing (10), are known. To achieve all-round vibration decoupling of the drive element, it is proposed that the housing (10) have a static receiving part (32) and a cover (38) fastened thereon, which cover bears axially against a stop (60) on the static receiving part (32), wherein the intermediate element (64) is arranged radially between the cover (38) and the drive element (12) and so as to be elastically deformed axially between the drive element (12) and the cover (38), such that, in the case of an exhaust-gas recirculation valve, the electric motor (12) is loaded axially against a drive-side bearing bracket (42), which is formed on the housing (10), by the spring force of an elastically deformed intermediate element (64) and is mounted in the cover (38) radially by means of the intermediate element (64).

Owner:PIERBURG GMBH & CO KG NEUSS

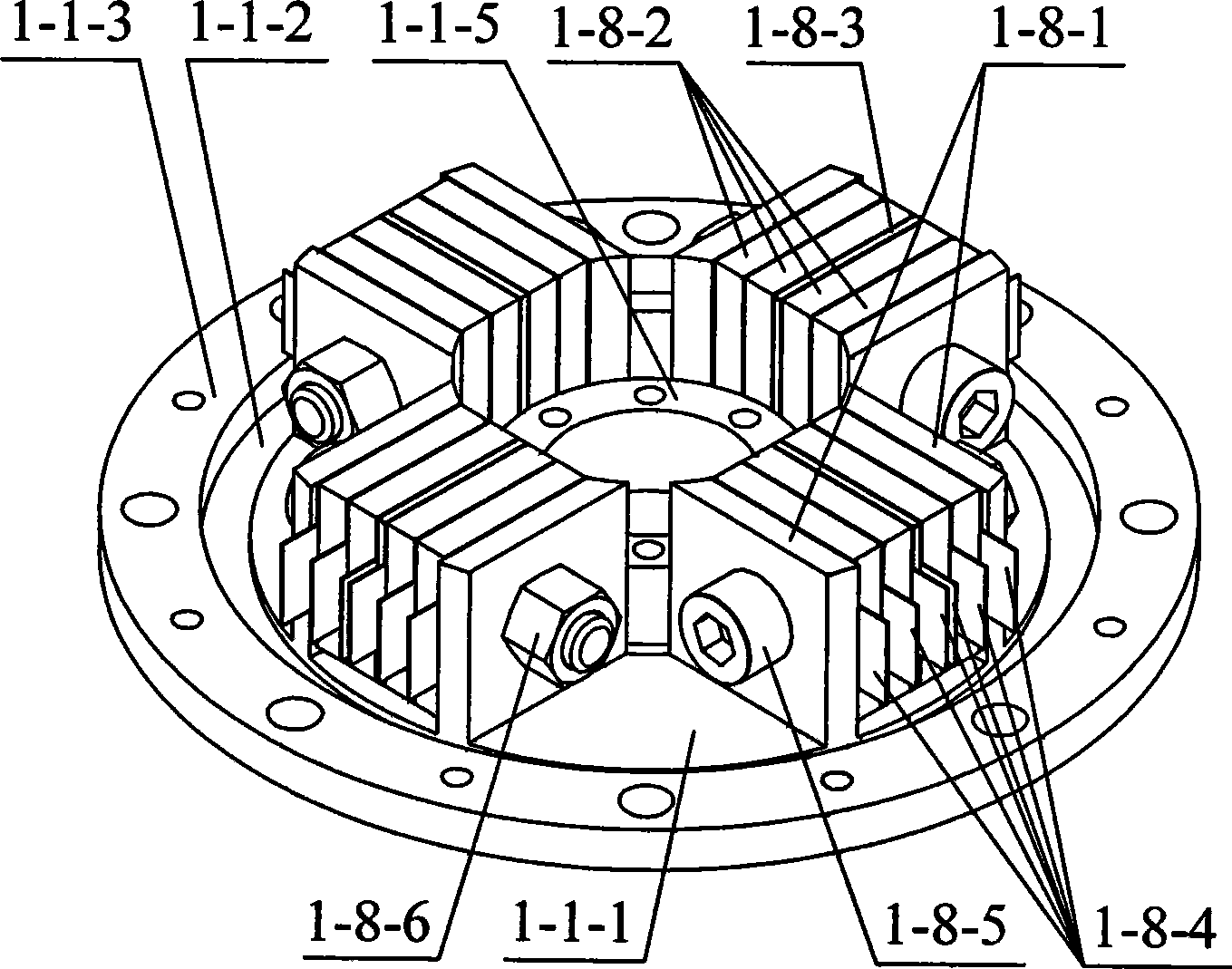

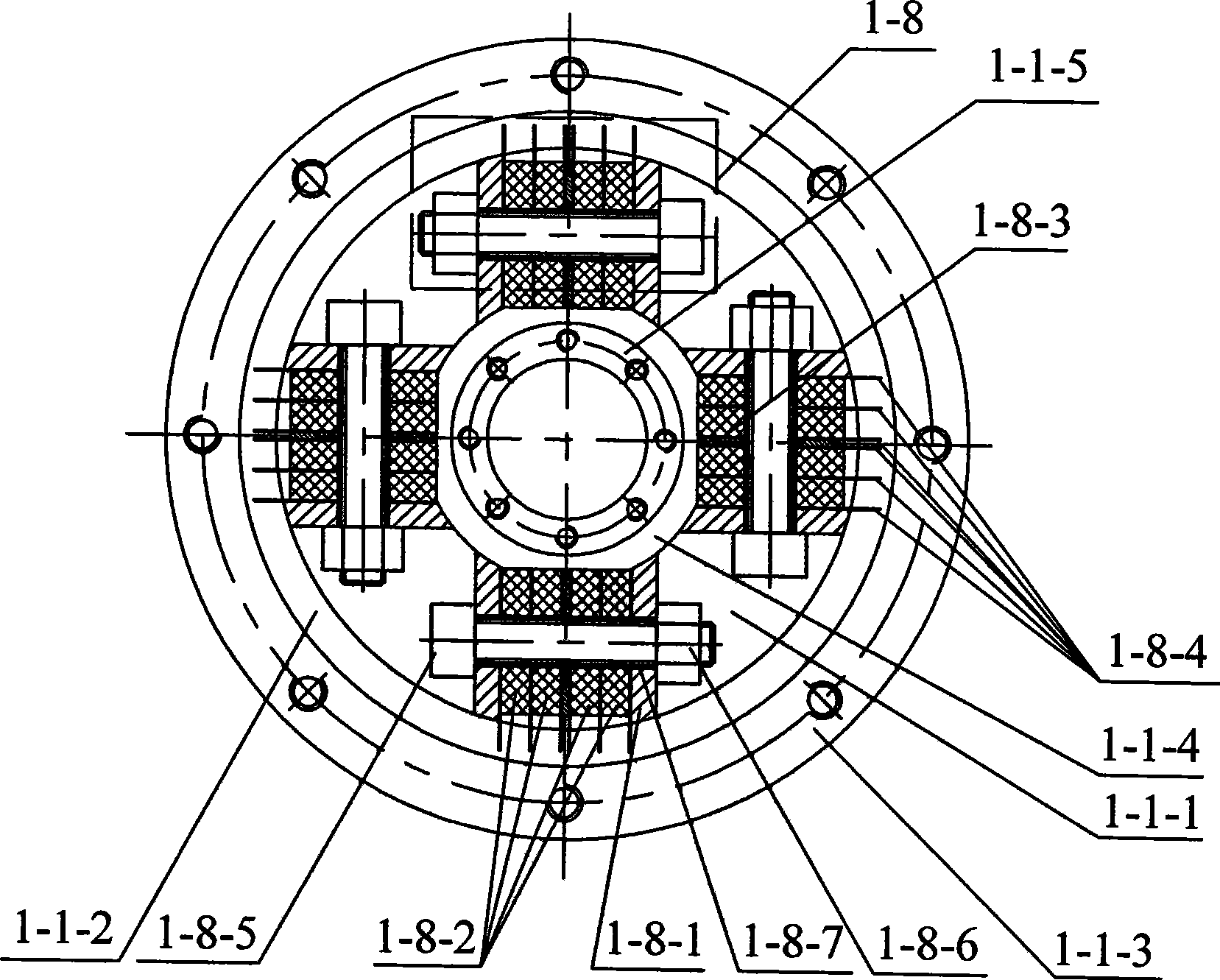

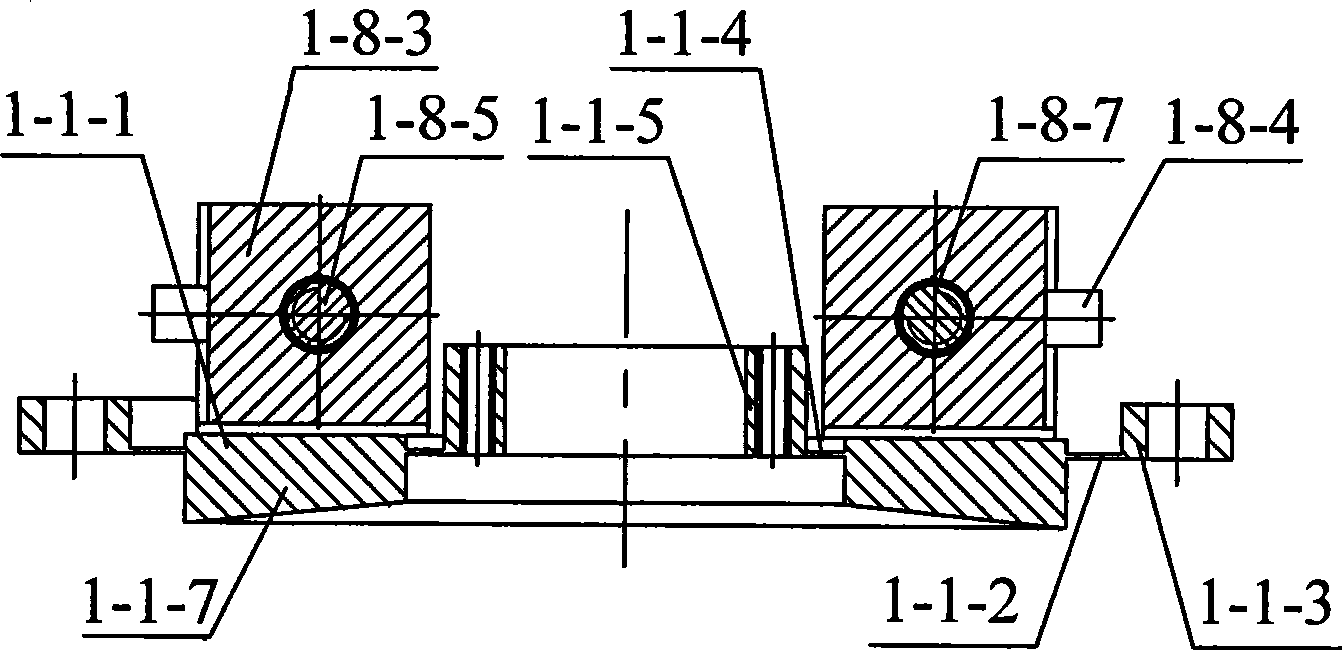

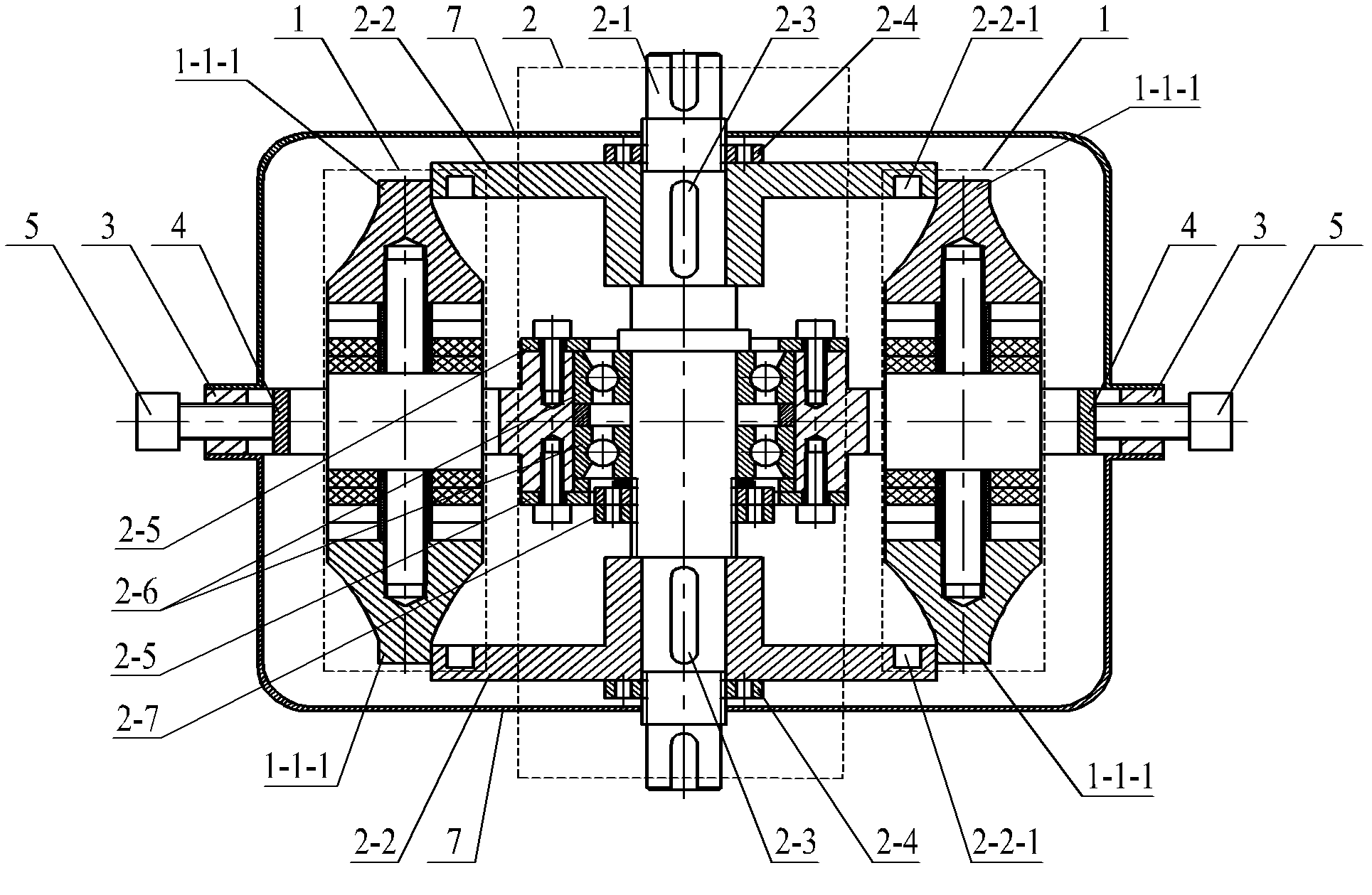

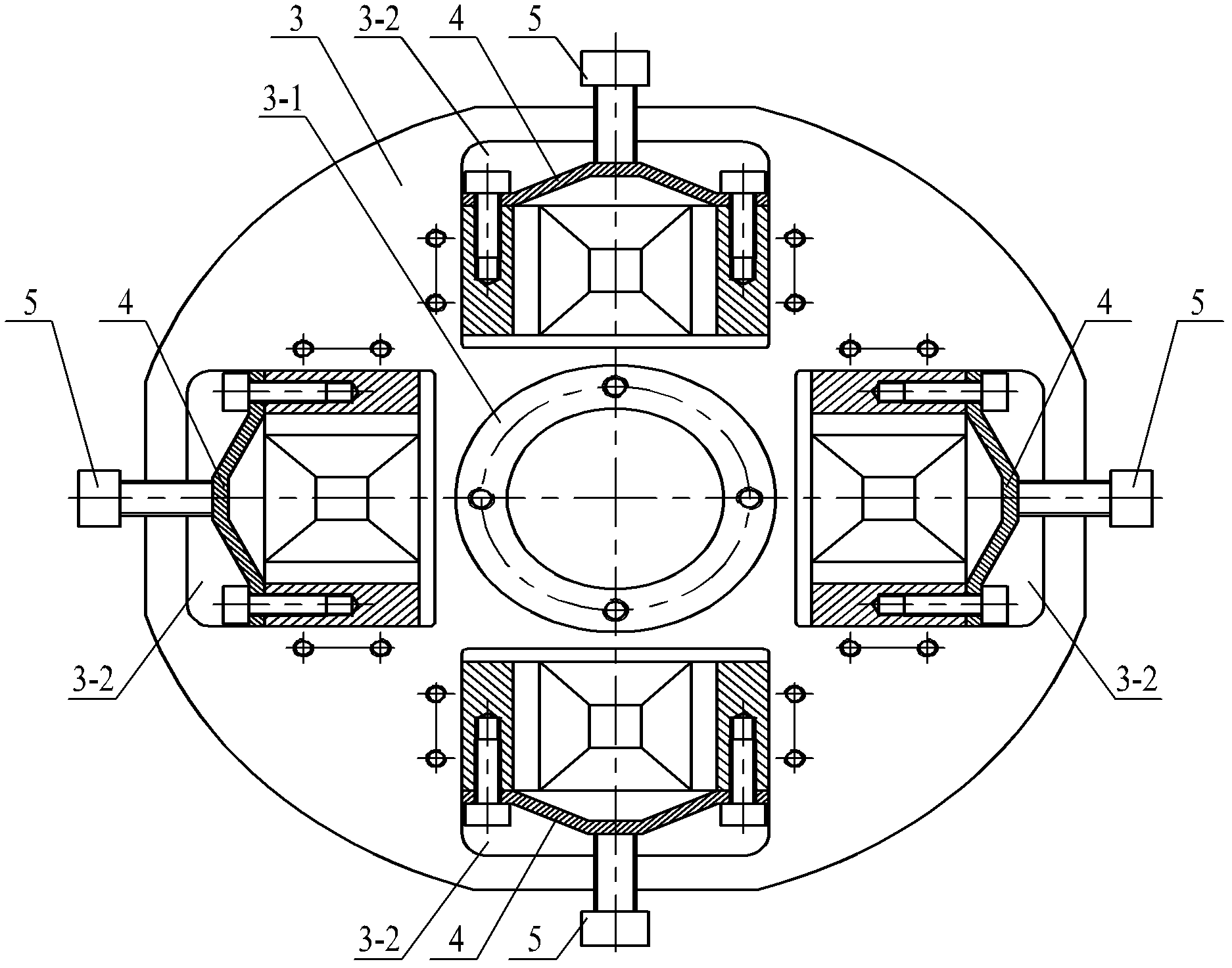

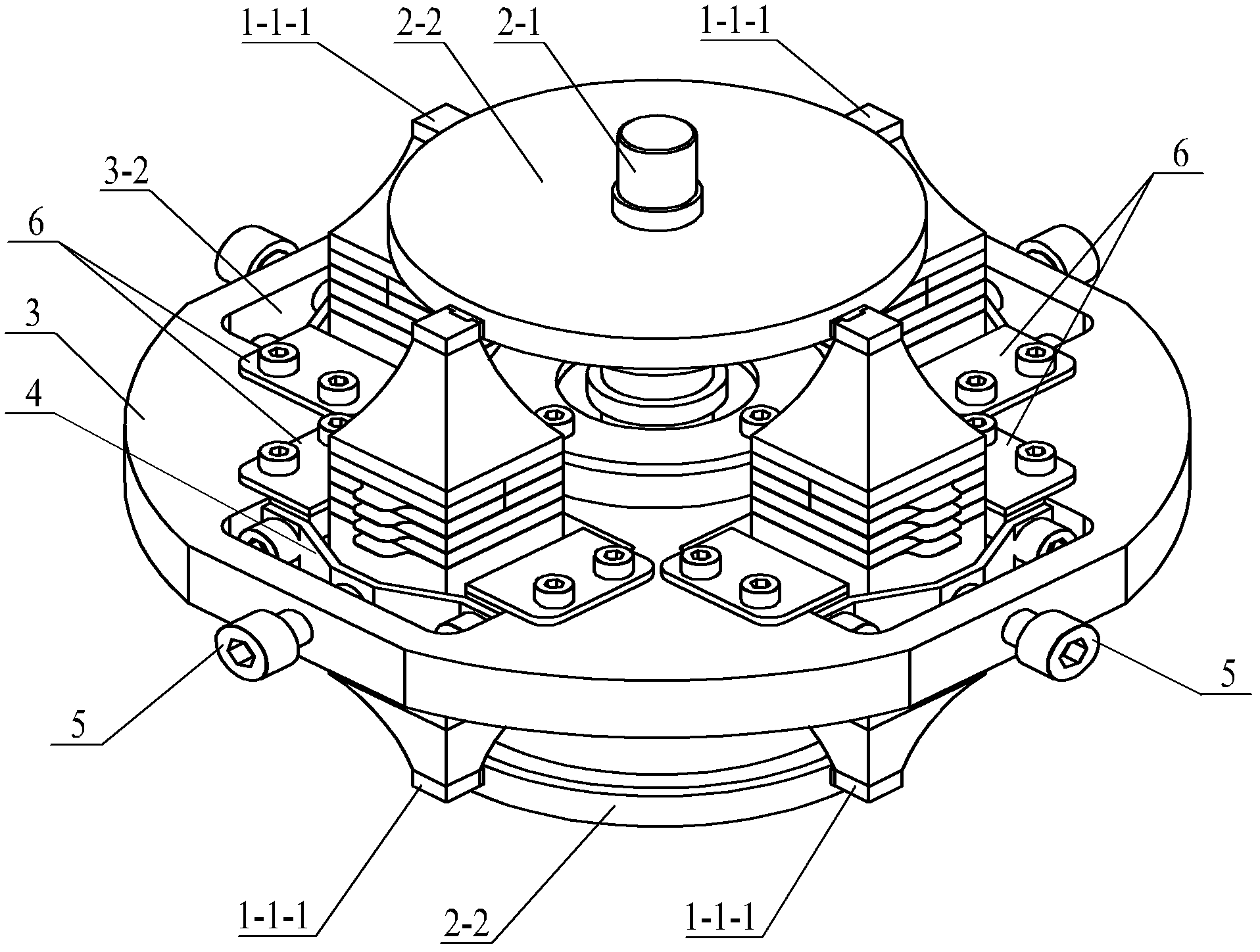

Rotary motor using composite bending vibration biped linear ultrasonic oscillators

ActiveCN102355161AImprove performanceIncrease amplitudePiezoelectric/electrostriction/magnetostriction machinesPatch typeControl theory

The invention provides a rotary motor using composite bending vibration biped linear ultrasonic oscillators, belonging to the technical field of piezoelectric ultrasonic motors. The invention solves the problems that the existing patch type rotary piezoelectric ultrasonic motor has low coupling efficiency, and the mechanical output capability is difficult to improve. The rotary motor provided by the invention comprises n oscillators, a rotor assembly, a base, n plate springs, n pre-pressing screws and 4n baffle plates, wherein n is a positive integer; the center of the base is provided with a central through hole and a bearing seat; the rotor assembly is arranged in the central through hole; n rectangular section slots are uniformly distributed on the base along the outer circumference direction of the bearing seat; one oscillator is arranged in each rectangular section slot; one plate spring is also arranged in each rectangular section slot; and the two ends of each plate spring are respectively connected fixedly with two installing seats of the oscillator positioned in the rectangular section slot. The rotary motor provided by the invention can realize large-torque output.

Owner:HARBIN INST OF TECH

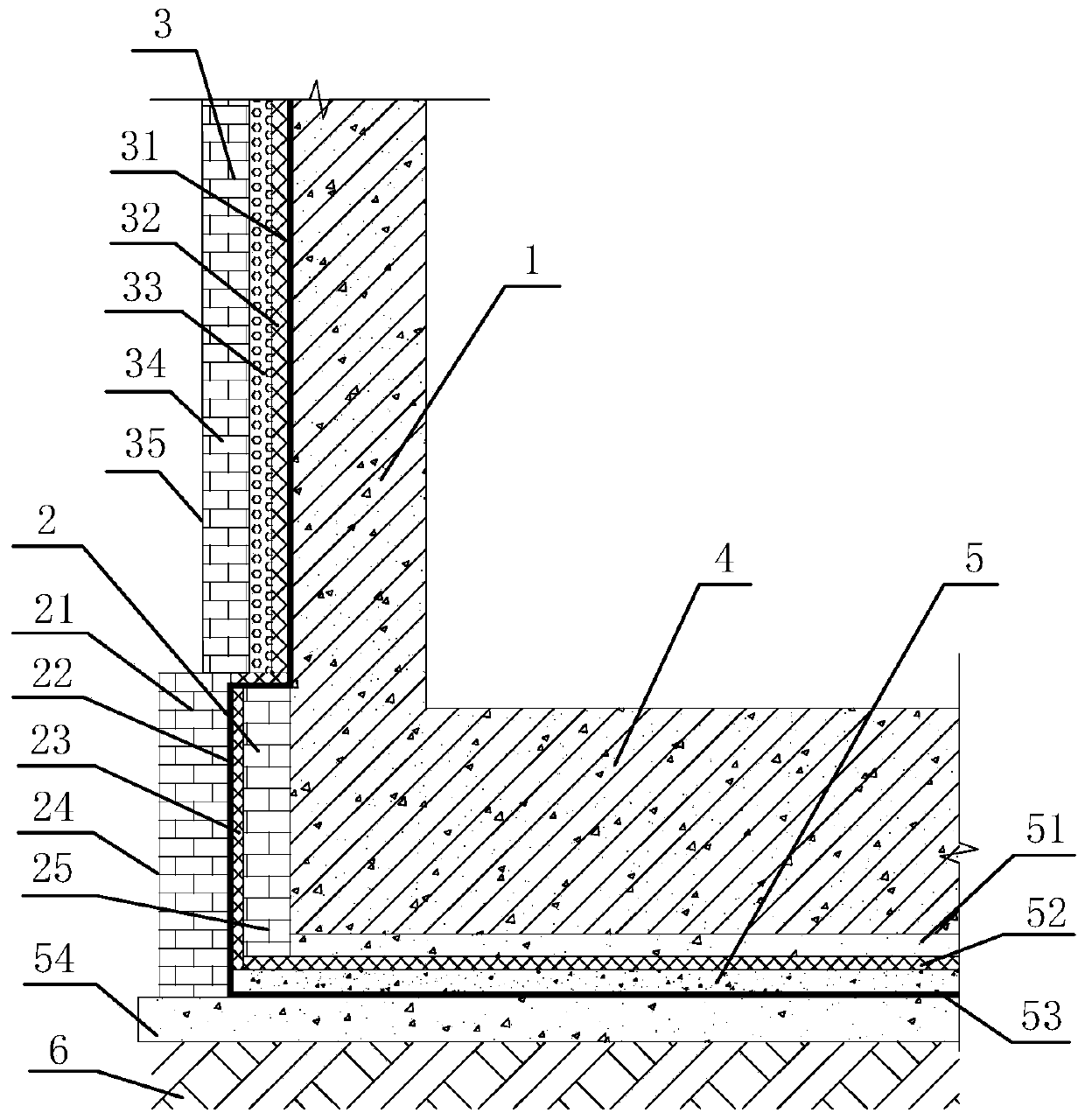

Building foundation vibration isolation structure and construction method thereof

PendingCN109930631AAchieve vibration isolationAchieve waterproof effectProtective foundationVibration attenuationBrick

The invention relates to the technical field of building vibration attenuation, and discloses a building foundation vibration isolation structure and a construction method thereof. The building foundation vibration isolation structure comprises a first side portion vibration isolation assembly and a second side portion vibration isolation assembly which are arranged on the outer side of a buildingfoundation side wall from bottom to top in sequence; the first side portion vibration isolation assembly comprises brick membrane, a first waterproof layer and a first vibration attenuation layer which are overlapped from outside to inside in sequence, and the first vibration attenuation layer is arranged on an outer side surface of the building foundation side wall; the second side portion vibration isolation assembly comprises a second waterproof layer and a second vibration attenuation layer which are overlapped from inside out in sequence, and the second waterproof layer covers the outerside surface of the building foundation side wall; and an upper edge of the first waterproof layer is connected with a lower edge of the second waterproof layer. The building foundation vibration isolation structure divides the vibration isolation assemblies of the building foundation side wall into upper and lower segments, construction is simple, the construction cost is saved, a construction space is optimized, waterproof and vibration attenuation effects are excellent, and conditions are provided for a hot-melt paving mode of a waterproof coiled material.

Owner:BEIJING MUNICIPAL INST OF LABOUR PROTECTION

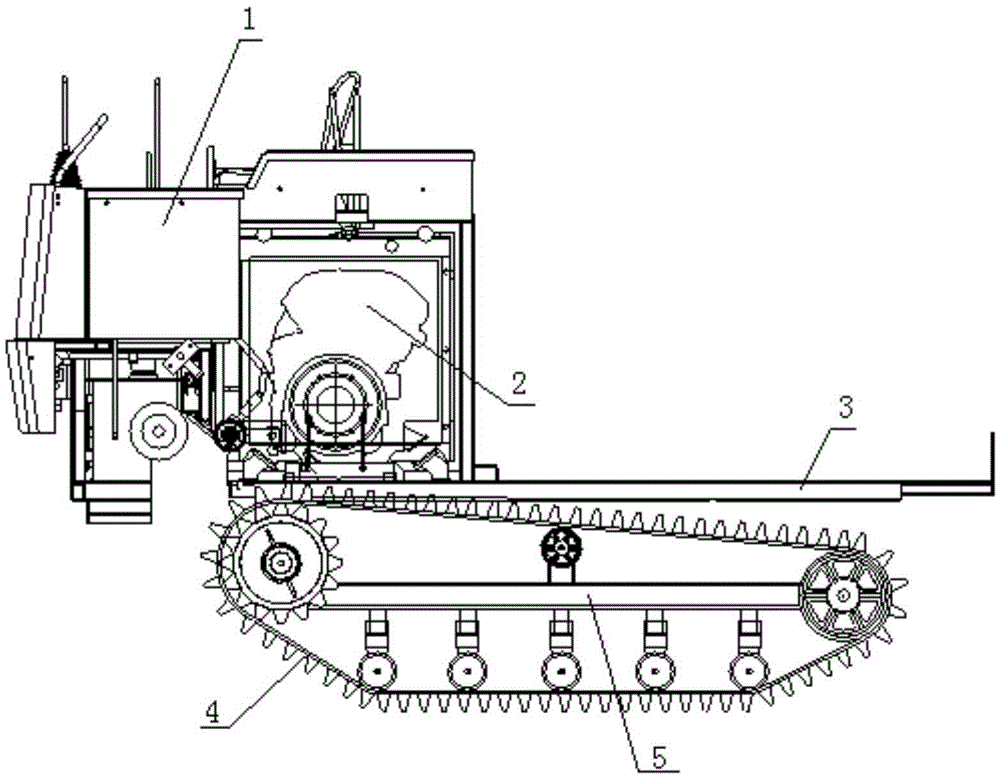

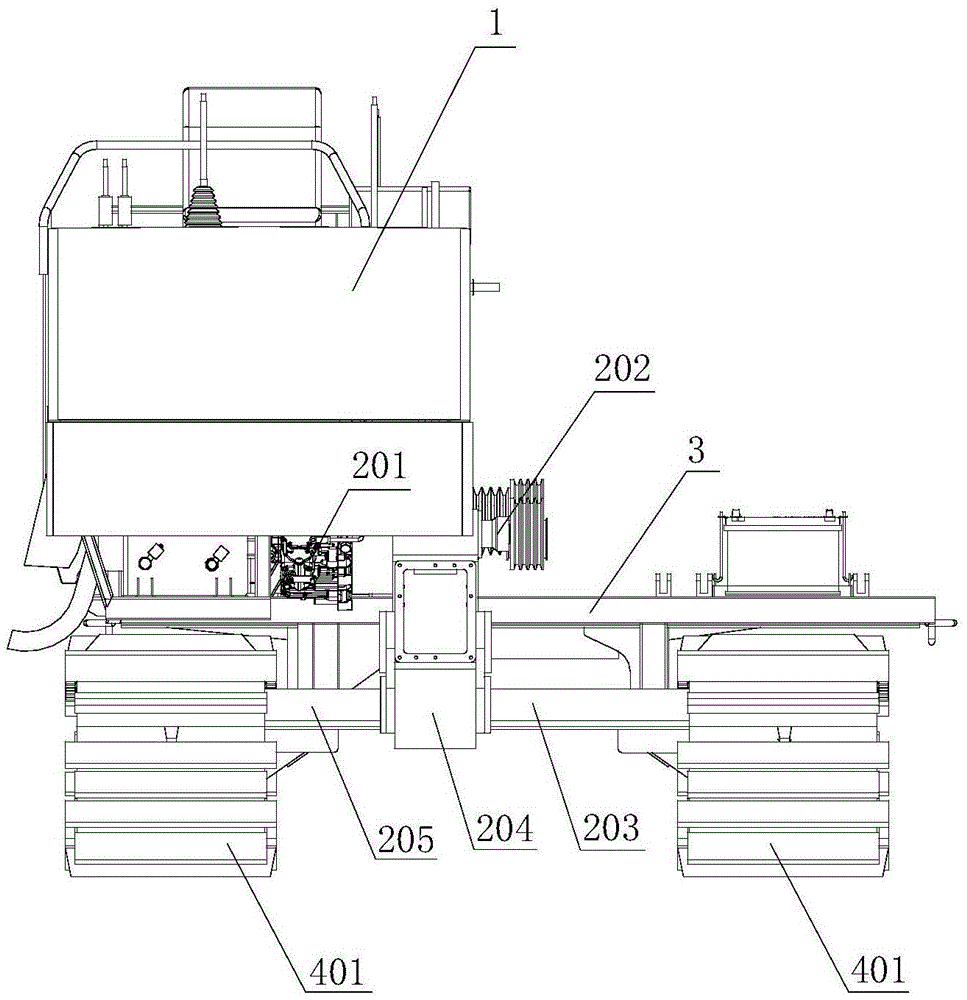

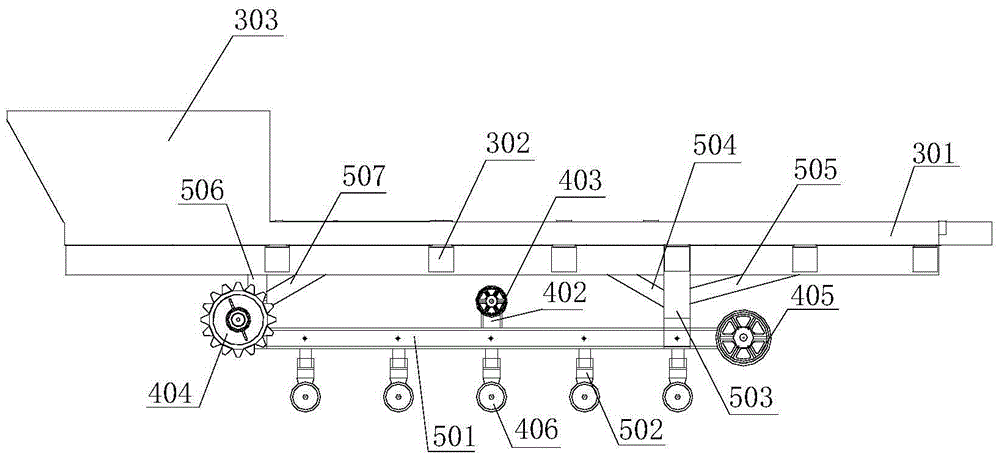

Profiling vibration-damping crawler type traveling chassis of grain combine harvester

ActiveCN105599815AAvoid secondary damping effectsRealize the profiling functionEndless track vehiclesControl systemDrivetrain

The invention provides a profiling vibration-damping crawler type traveling chassis of a grain combine harvester. The profiling vibration-damping crawler type traveling chassis comprises a driving control system, a power transmission system, a chassis rack and crawler belt mechanisms, and the crawler belt mechanisms comprise the crawler belt traveling mechanism and the crawler belt support mechanism; the crawler belt traveling mechanism comprises crawler belts, a riding wheel supporting beam, a crawler belt riding wheel, a crawler belt driving wheel, a crawler belt tensioning wheel and a crawler belt load-bearing wheel; the crawler belt support mechanism comprises a crawler belt support main beam, crawler belt vibration damping subsidiary beams, a crawler belt front support beam and a crawler belt rear support beam; the crawler belt front support beam and the crawler belt rear support beam are fixed to the bottom of the chassis rack in the front-rear direction and located on the same straight line; the lower portion of the crawler belt front support beam and the lower portion of the crawler belt rear support beam are jointly connected with the crawler belt support main beam; the lower portion of the crawler belt support main beam is connected with the multiple sets of crawler belt vibration damping subsidiary beams; the bottoms of the crawler belt vibration damping subsidiary beams are both connected with the crawler belt load-bearing wheel. The traveling chassis has the ground profiling and chassis vibration damping functions, and comfort and stability of the grain combine harvester in the field working process are greatly improved.

Owner:JIANGSU UNIV

Multi-functional network box protection device

ActiveCN110087431AEasy to fixFixed and easy to changeClamping/extracting meansCooling/ventilation/heating modificationsEngineeringFunctional network

The invention relates to a multi-functional network box, and more specifically relates to a multi-functional network box protection device. The multi-functional network box protection device can fix and seal the multi-functional network box through a fixation and protection device, can fix multi-functional network boxes with different specifications through the fixation and protection device, cancarry out cooling on the fixation and protection device through an external cooling device so as to cool the multi-functional network box in the fixation and protection device and prevent the multi-functional network box from overheating, and can isolate vibration for the multi-functional network box through a lower buffer device. The multi-functional network box protection device comprises the fixation and protection device, the external cooling device and the lower buffer device. An inner pusher pushing rod is reversely pushed under the action of an elastic force of an inner pusher pushing spring so as to enable the inner pusher pushing rod to be extruded with the multi-functional network box and complete the fixation of the multi-functional network box; and a lower hinged sliding columnslides along a lower sliding waist groove to adjust the distance between multiple inner-end sliding pusher assemblies, thereby enabling the inner pusher pushing rods on the inner-end sliding pusher assemblies to be changed in spatial position.

Owner:滨州高新区国有资本投资运营有限公司

Concrete pumping operation safety control system, and arrangement method and control method thereof

PendingCN111364771AAchieve vibration isolationReduce vibrationMechanical oscillations controlPipe elementsControl systemSafety control

The invention provides a concrete pumping operation safety control system, and an arrangement method and a control method thereof. The safety control system comprises a vibration reduction fixing module, a vibration sensing module and a vibration safety control module, wherein the vibration reduction fixing module is used for fixing a concrete conveying pipe to reduce vibration of the concrete conveying pipe, the vibration sensing module is arranged on the vibration reduction fixing module to monitor the vibration condition of the vibration reduction fixing module and generate vibration data,and the vibration safety control module comprises an auxiliary damper, an auxiliary damper motor and a central control computer which are installed on the vibration reduction fixing module and used for increasing damping force of the vibration reduction fixing module; and the central control computer is connected with the vibration sensing module, the auxiliary damper motor and a concrete pump forpumping the concrete conveying pipe, and is used for determining whether to start the auxiliary damper motor or not according to the vibration data so as to increase the damping force of the vibration reduction fixing module. According to the safety control system, the vibration of the pumping pipeline in the concrete pumping process is safely controlled, and pipeline damage caused by too large vibration and damage to a lower attachment structure are avoided.

Owner:SHANGHAI CONSTR NO 1 GRP

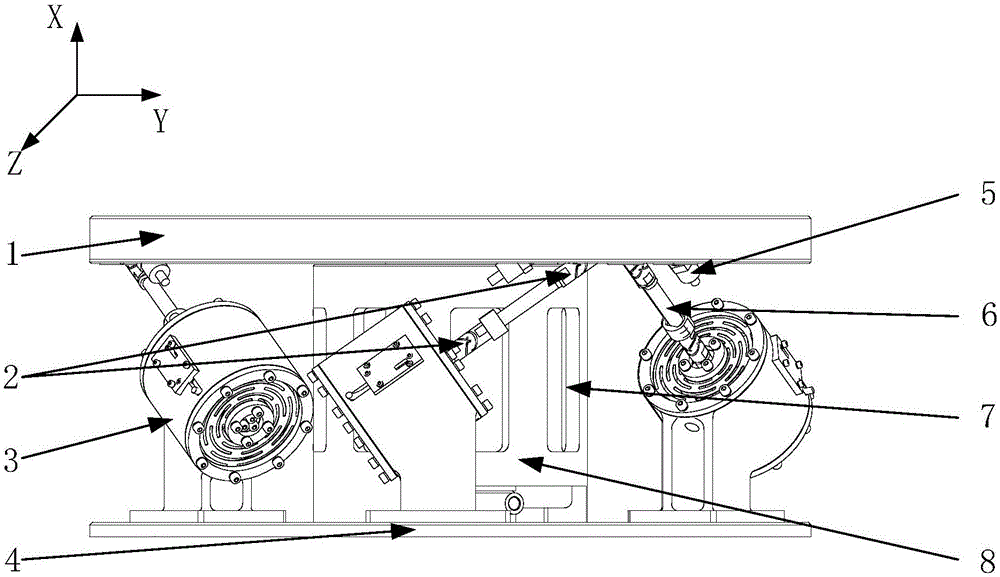

Multi-degree-of-freedom active vibration isolation device and method

ActiveCN108679141AReduce stiffnessLower resonance frequencySpringsSprings/dampers functional characteristicsElectricityResonance

The invention discloses a multi-degree-of-freedom active vibration isolation device and method. The device includes a platform and six support legs arranged on the lower edge of a support platform. The six support legs are evenly arranged in two rows, wherein each support leg includes a double chamber vertical air spring and a horizontal air spring disposed at a lower end of the double chamber vertical air spring. Each support leg is provided with a pneumatic proportional valve, a pressure sensor for detecting gas pressure, a displacement sensor and a speed sensor, which are respectively electrically connected by a controller. Each pneumatic proportional valve is in communication with the double chamber vertical air spring and the horizontal air spring of the corresponding support leg. Theinvention has advantages of suppressing the resonance peak and effectively isolating the vibration exceeding the natural frequency.

Owner:浙江埃特斯力试验设备有限公司

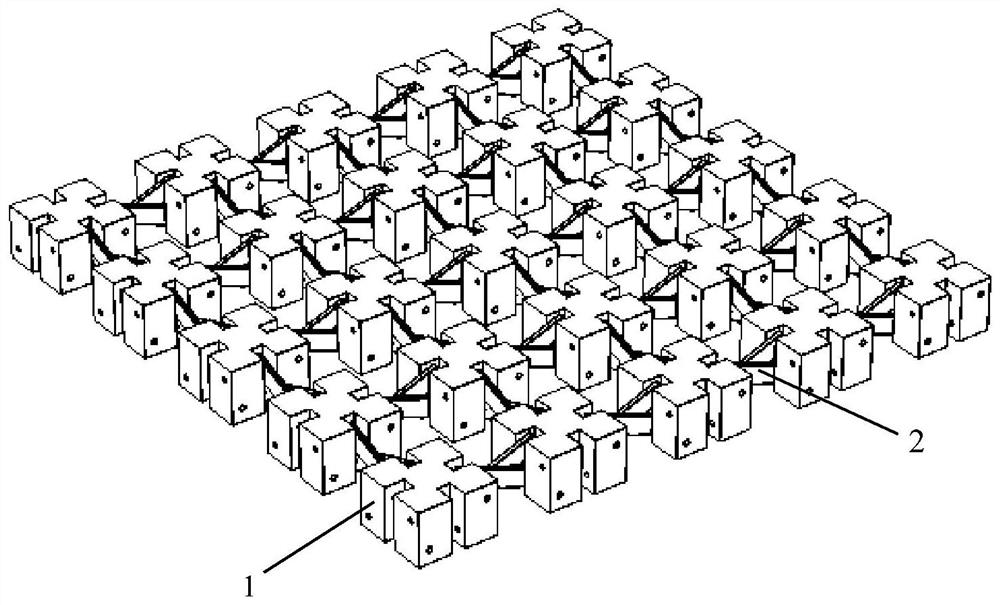

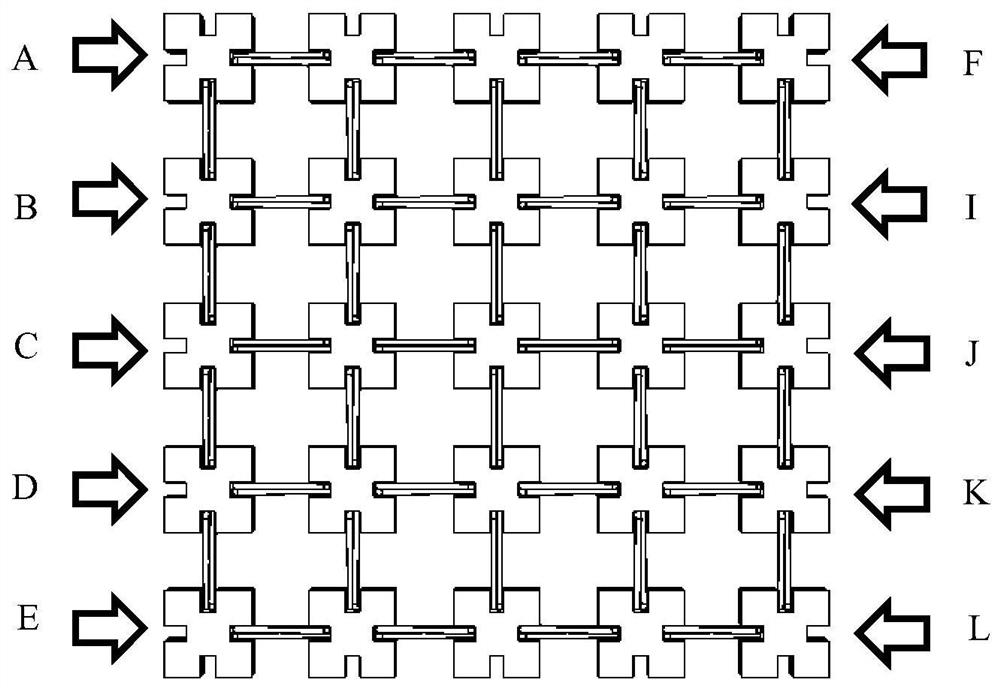

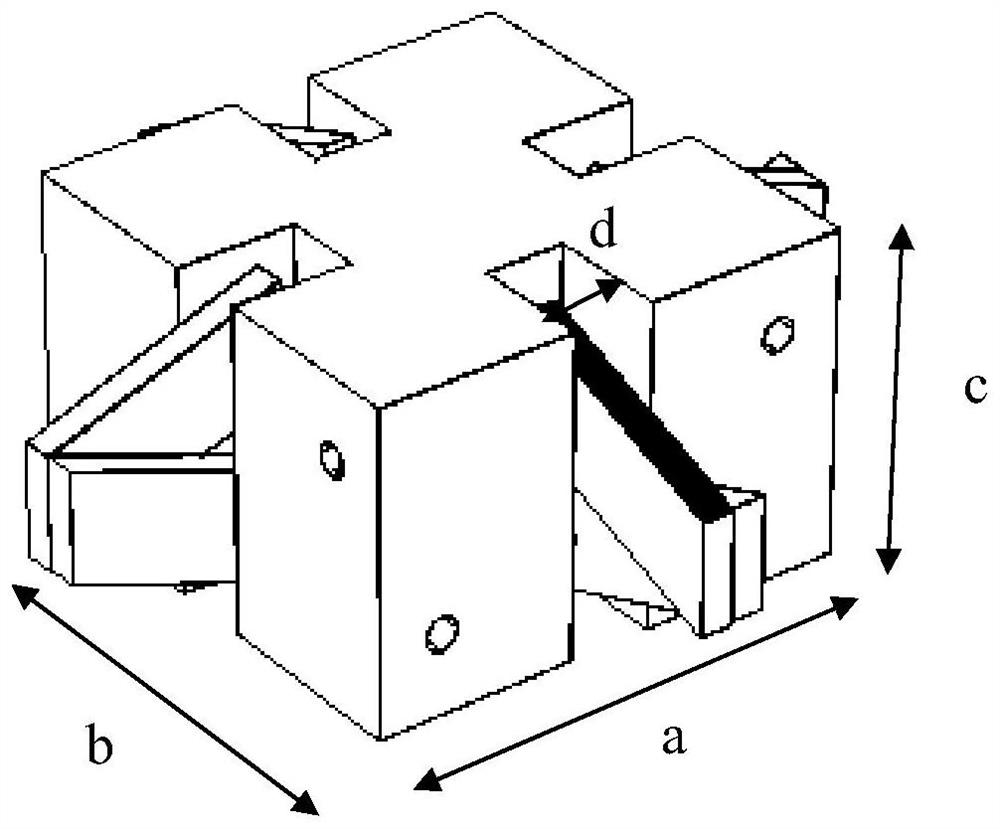

Anti-impact planar quasi-zero stiffness elastic wave metamaterial device

ActiveCN111609069AAchieve protectionAchieve a strong attenuation effectSpringsSprings/dampers functional characteristicsEngineeringMechanical engineering

The invention discloses an anti-impact planar quasi-zero stiffness elastic wave metamaterial device. The device comprises mass blocks and a connecting rod, wherein the mass blocks are of cuboid structures, rectangular grooves of which the upper surfaces and the lower surfaces communicate with each other are formed in the middles of the four side faces of the mass blocks, connecting holes are formed in the upper end of the side wall of one side and the lower end of the side wall of the other side of each rectangular groove, and connecting shafts are mounted in the connecting holes; the mass blocks are hinged to each other through the connecting shafts and the connecting rods to form a planar periodic structure which is arranged in a square shape, each mass block is hinged to the adjacent mass block through a set of connecting rods, and therefore the quasi-zero stiffness characteristic is formed.

Owner:TIANJIN UNIV

Vehicle seat spring damping device

The invention discloses a vehicle seat spring damping device. The vehicle seat spring damping device includes a top plate, a bottom plate, a mounting seat, an air spring and an elastic ball damping device. The air spring is vertically mounted between the top plate and the bottom plate. The elastic ball damping device is vertically arranged in central annular space of the air spring. The elastic ball damping device includes a piston rod fixed to the lower surface of the top plate and a piston barrel fixed to the upper surface of the bottom plate. A piston barrel cover is mounted on the upper end of the piston barrel. A piston head extending into the piston barrel is arranged on the lower end of the piston rod. Space which is in the piston barrel and located under the piston head is a cavity. The cavity is filled with elastic balls. The vehicle seat spring damping device of the invention utilizes the combination design of the rubber air spring and the elastic ball damping device, and sothe damping effect of a vehicle seat is better, vibration generated by bump of a road surface is greatly eliminated, and more comfortable driving environment is provided for a driver.

Owner:文和萍

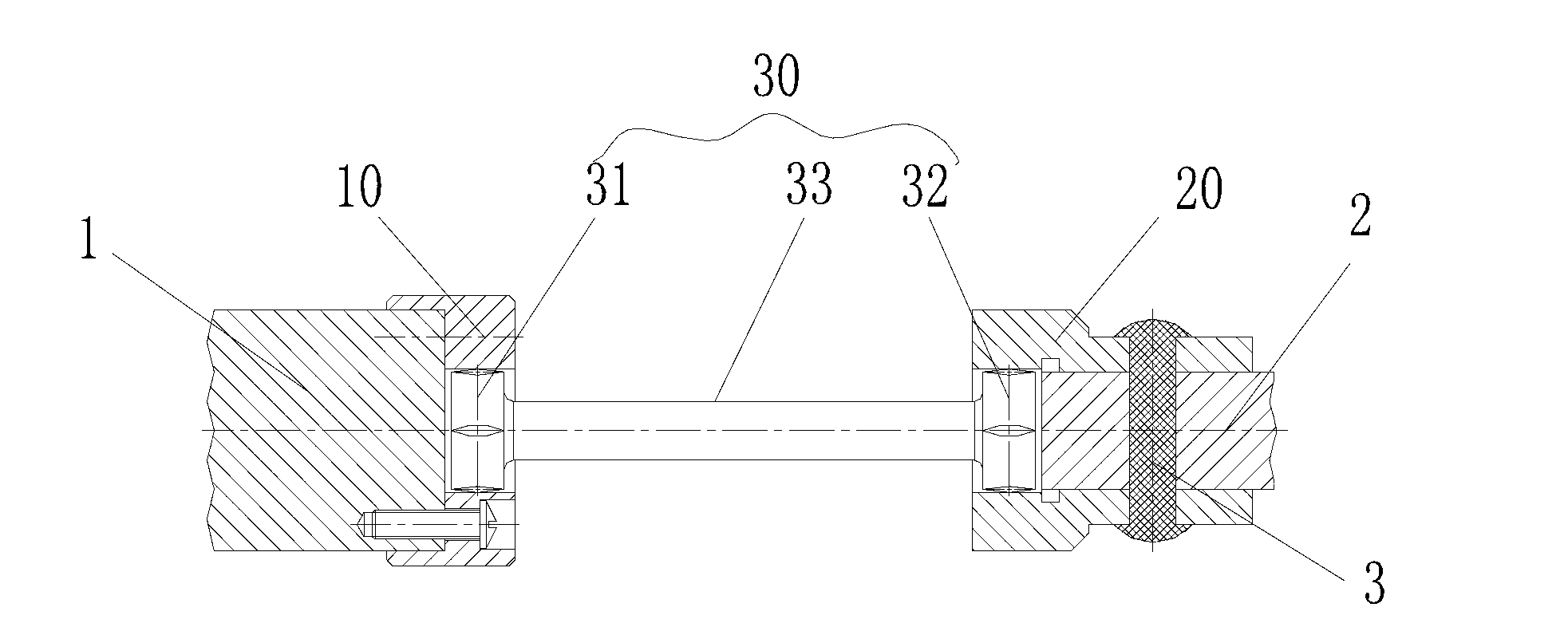

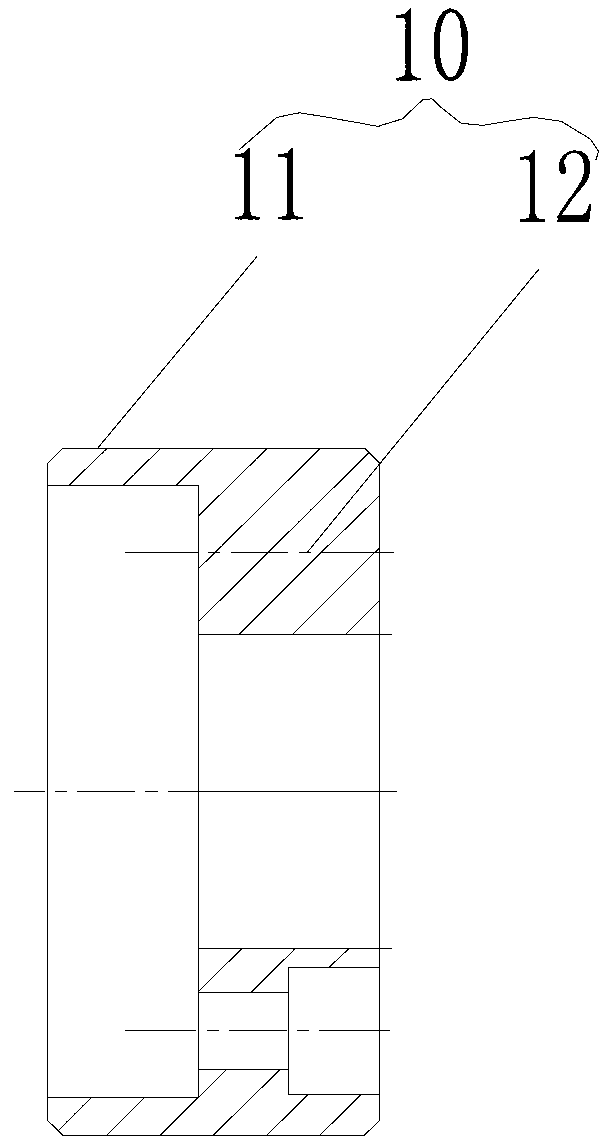

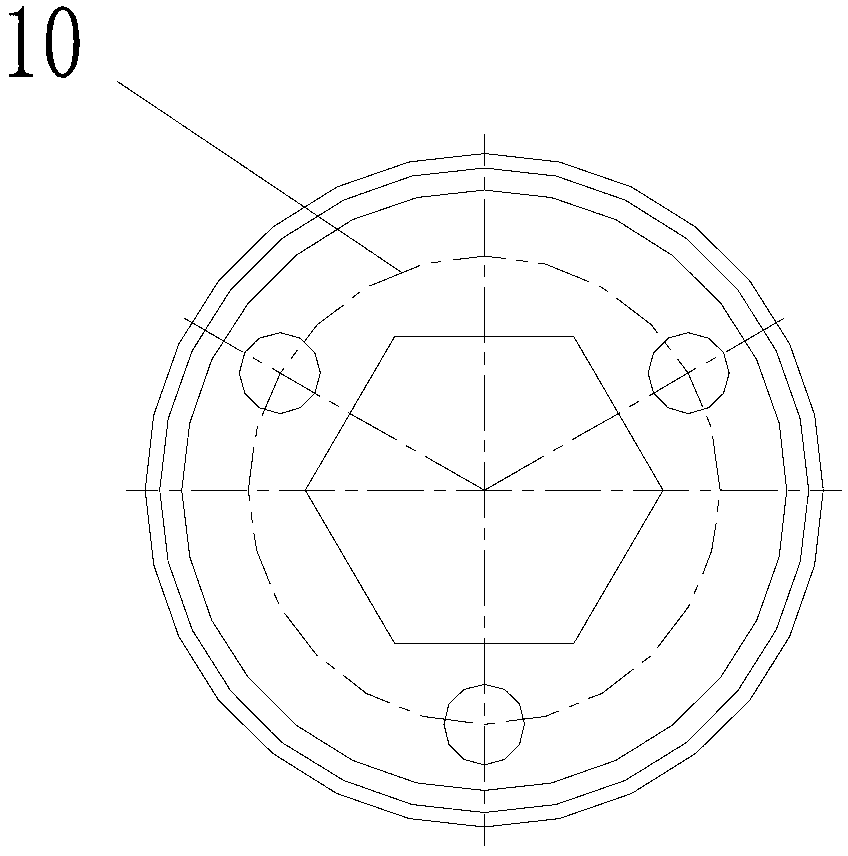

Shaft connecting device

The invention provides a shaft connecting device which comprises a first connecting piece fixedly connected with a transmission shaft, a second connecting piece fixedly connected with a power shaft and a connecting shaft connected with the first connecting piece and the second connecting piece, wherein the connecting shaft comprises a first matching part which is connected with the first connecting piece in such a way that the first matching part and the first connecting piece can swing relatively along the axis of the connecting shaft, and a second matching part which is connected with the second connecting piece in such a way that the second matching part and the second connecting piece can swing relatively along the axis of the connecting shaft. When the coaxiality of the power shaft is different from that of the transmission shaft, and the small torque transmission is adopted, as the first connecting piece can swing relative to the first matching part, and the second connecting piece can swing relative to the second matching part, the connection between the first connecting piece and the first matching part and the connection between the second connecting piece and the second matching part are equivalent to flexible connection, so that vibration cannot be transmitted between the power shaft and the transmission shaft, thus realizing the vibration isolation between the power shaft and the transmission shaft.

Owner:CHINA AVIATION POWER MACHINE INST

Inter-module fast assembly desktop terminal

InactiveCN105307433AAppearance has no effectAppearance effectCasings/cabinets/drawers detailsComputer moduleComputer terminal

The invention discloses an inter-module fast assembly desktop terminal which comprises a host and one or more expansion modules. A number of U-shaped pin jacks are respectively arranged at the bottom or the rear part of the host. A number of corresponding U-shaped pin jacks are respectively arranged at the bottom or the rear part of the expansion module. Grooves are respectively arranged at the bottom and the rear part of the host and the expansion module. One end of each groove extends to the bottom of a U-shaped pin jack, and the other end extends to the combination surface of the host and the expansion module. The desk terminal further comprises a number of U-shaped pins. Two inserters of each U-shaped pin are respectively inserted into a corresponding U-shaped pin jack, and a horizontal connection section is embedded into a groove. According to the desktop terminal, two or more modules are assembled through a number of U-shaped pins; an assembly process does not require any tool, so that the operability is great; and in addition, rubber positioning devices and positioning pits are respectively arranged on the adjacent sides of the host and the expansion module, so that automatic positioning and vibration isolation are realized.

Owner:BEIJING JIAXUN FEIHONG ELECTRIC CO LTD

Low-frequency vibration isolator with three degrees of freedom

ActiveCN101832352ALower natural frequencyGood vibration isolationMagnetic springsGas based dampersIsolation effectThree degrees of freedom

The invention provides a low-frequency vibration isolator with three degrees of freedom, which relates to a vibration isolation device used for the precision field, the IC (integrated circuit) manufacturing field or the optical field. The vibration isolator comprises an air spring and a pair of hollow tubular permanent magnets, wherein the outer hollow tubular permanent magnet is fixed at the top of the main body of the air spring, and the inner hollow tubular permanent magnet is fixed on a rubber piston of the air spring, thereby realizing vibration isolation. The low-frequency vibration isolator can simultaneously realize low-frequency vibration isolation of multiple degrees of freedom, has good low-frequency vibration isolation effect, and has the advantages of few components, less mechanical wear, low cost, long service life, high accuracy and the like.

Owner:TSINGHUA UNIV +1

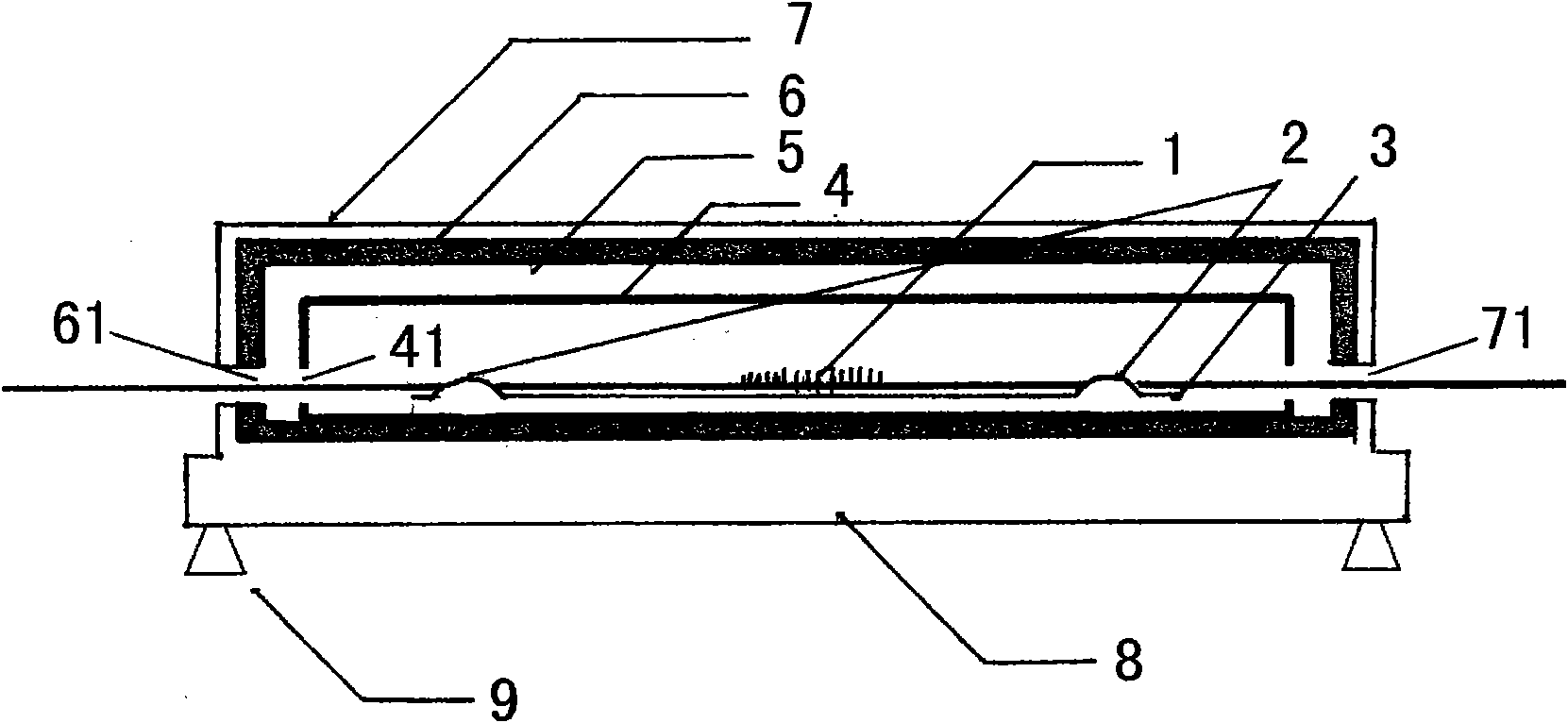

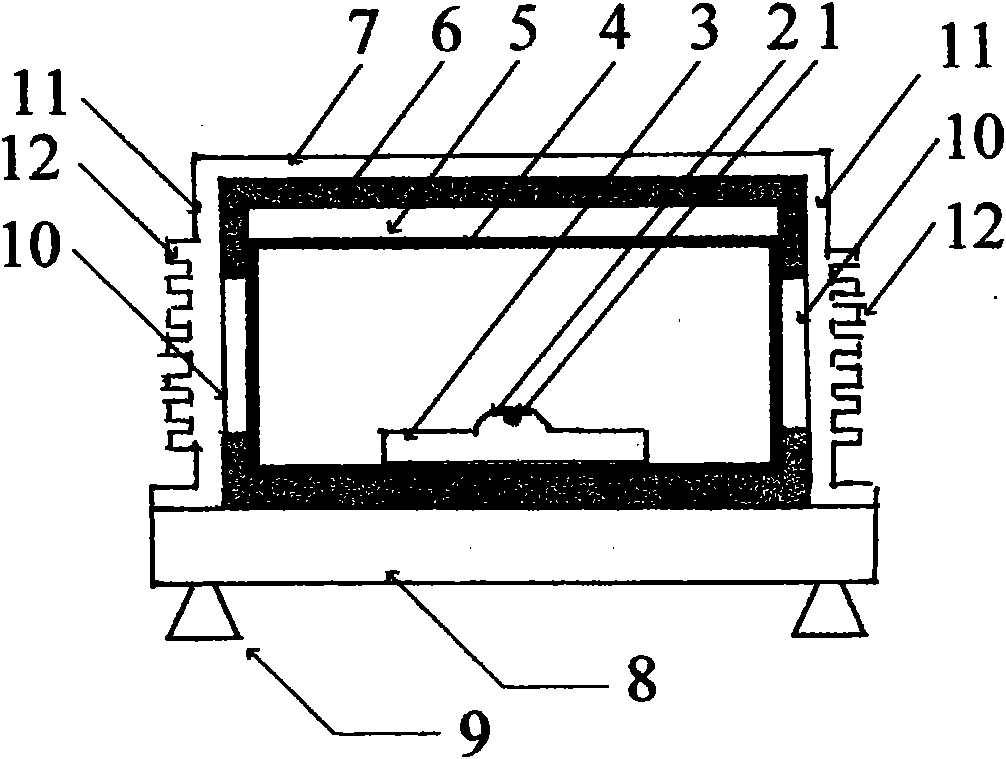

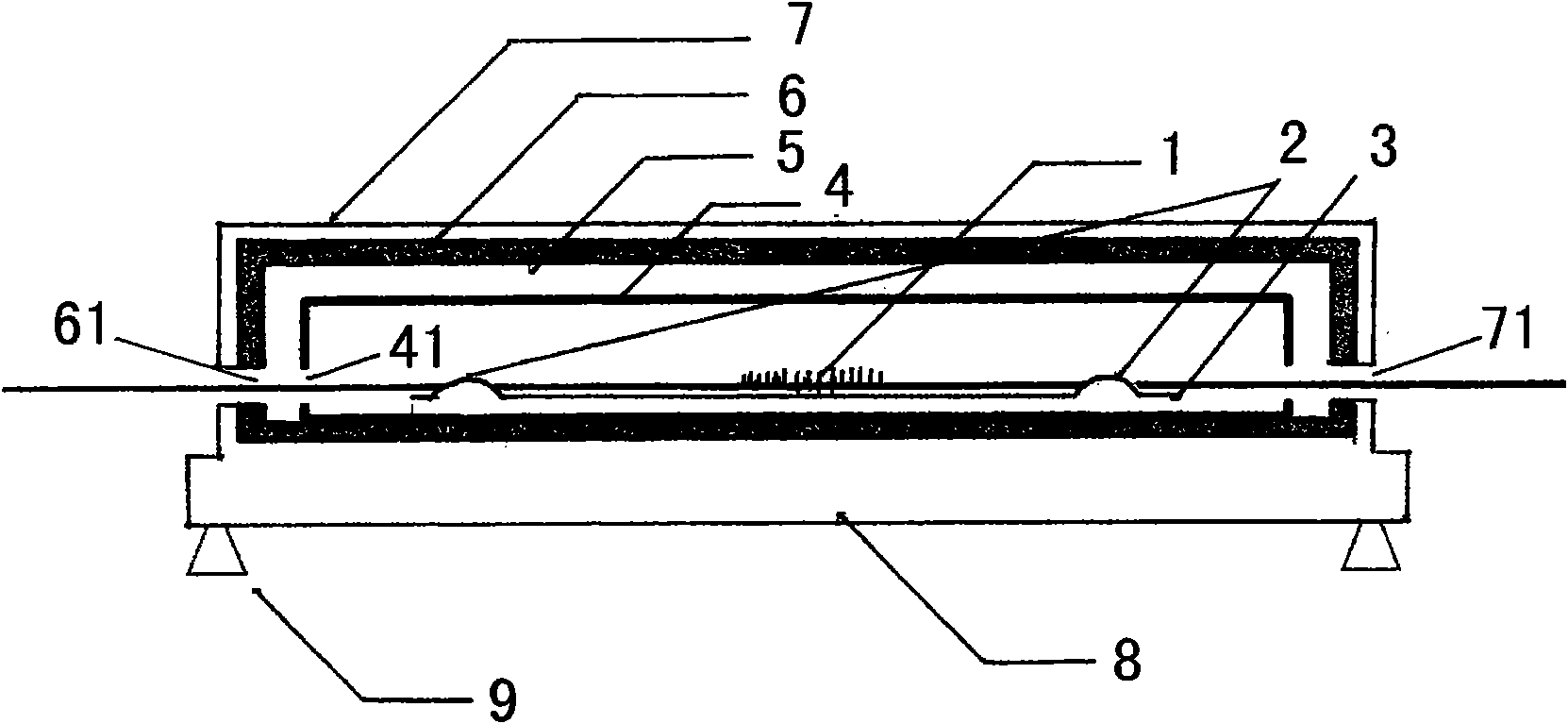

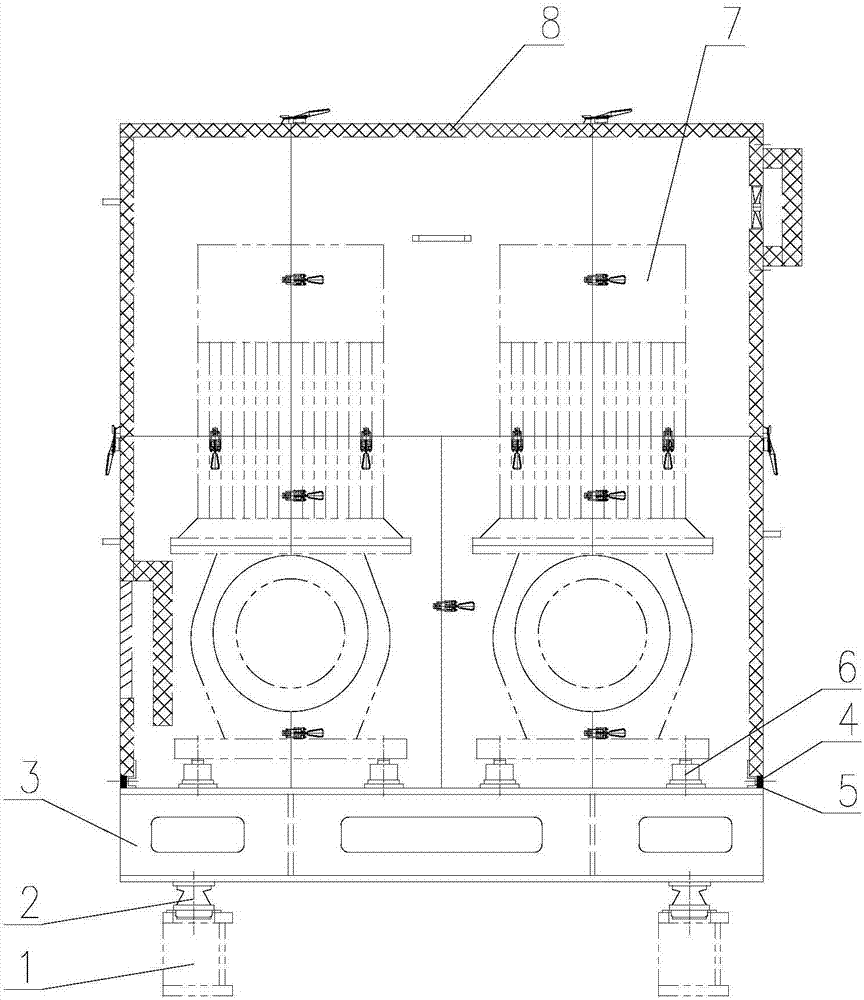

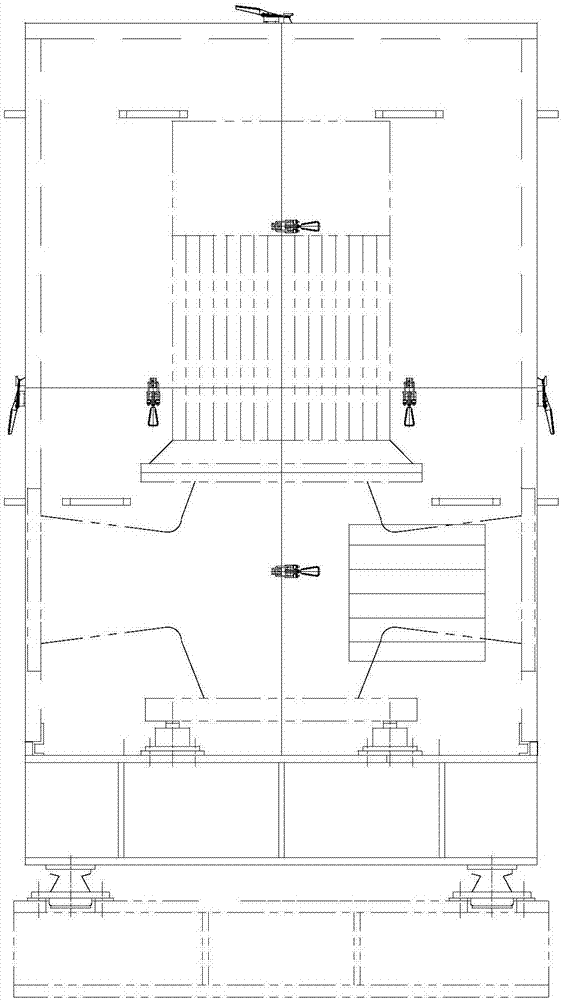

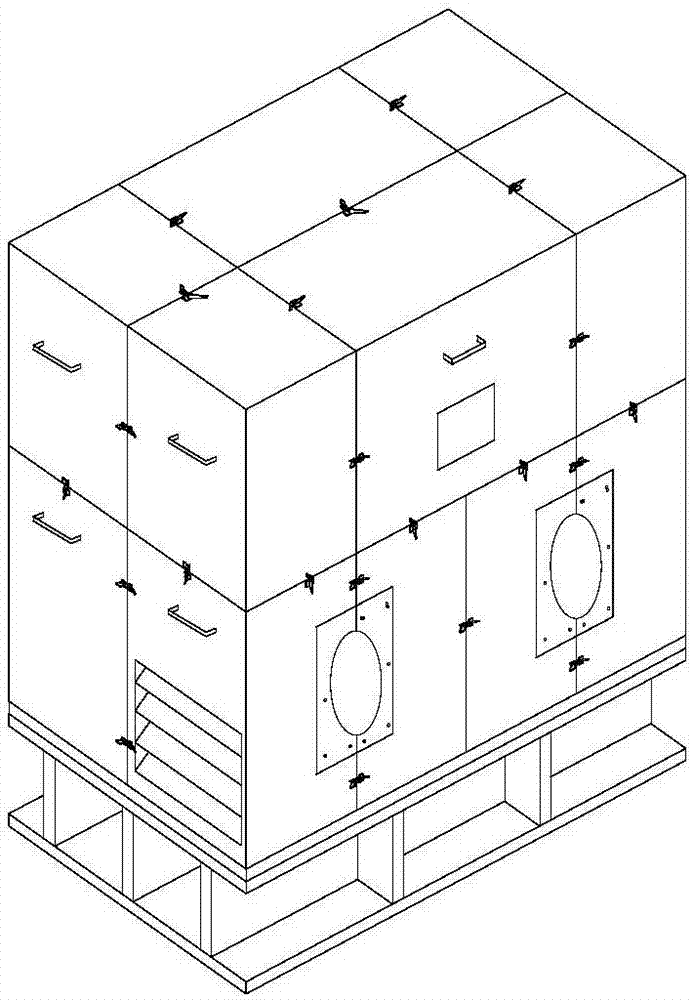

Integrated sound and vibration isolation device for electromechanical equipment

PendingCN107504329AImprove sound insulationImprove working environmentMachine framesNon-rotating vibration suppressionNoise controlNoise

The invention provides an integrated sound and vibration isolation device for electromechanical equipment. The device comprises ship body bases, lower-layer vibration absorbers, a raft frame, a connecting transition boss, a connecting support, upper-layer vibration absorbers and a sound insulation cover, wherein the raft frame and the sound insulation cover are connected and fixed through the connecting transition boss and the connecting support; the raft frame and the ship body bases are connected and fixed through the lower-layer vibration absorbers; and the raft frame and the electromechanical equipment are connected and fixed through the upper-layer vibration absorbers. The integrated sound and vibration isolation device for the electromechanical equipment has the advantages that a vibration isolation function and a sound insulation function are integrated, the structure is compact, disassembly and assembly are convenient, reliability is high, environment adaptability is high, vibration and air noise transmission of ship equipment can be effectively inhibited, and a good solution way is provided for vibration noise control of the ship equipment and popularization and application of the air noise sound insulation cover.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com