Encapsulating structure of distributed feedback (DFB) fiber laser

A fiber laser, packaging structure technology, applied in the laser, the structure/shape of the active medium, laser components and other directions, can solve the problem of no high-frequency modulation function, etc., to achieve the effect of high integration, stable performance, and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

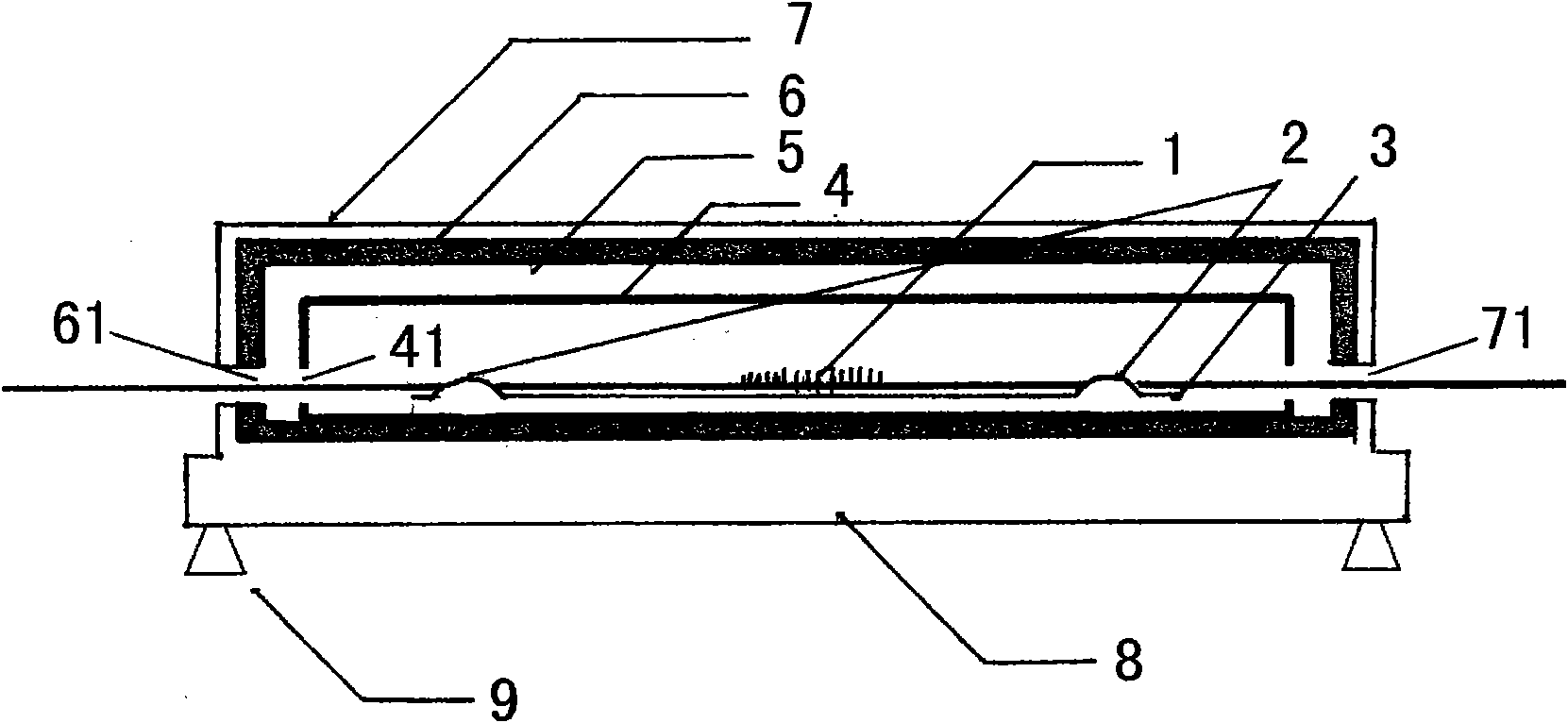

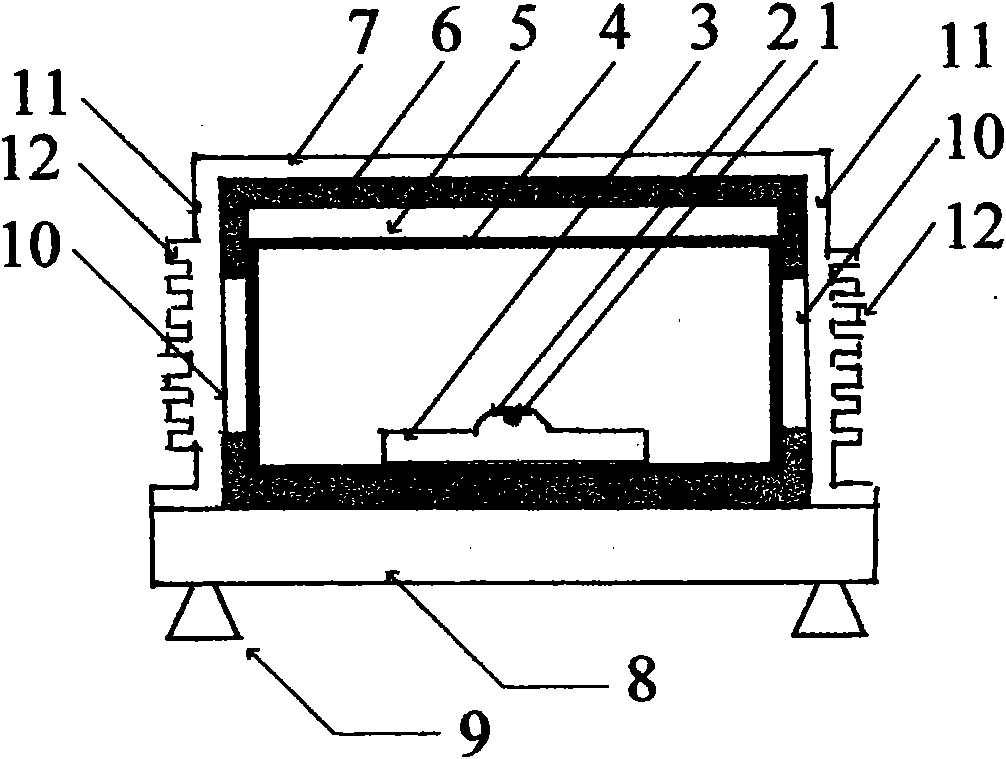

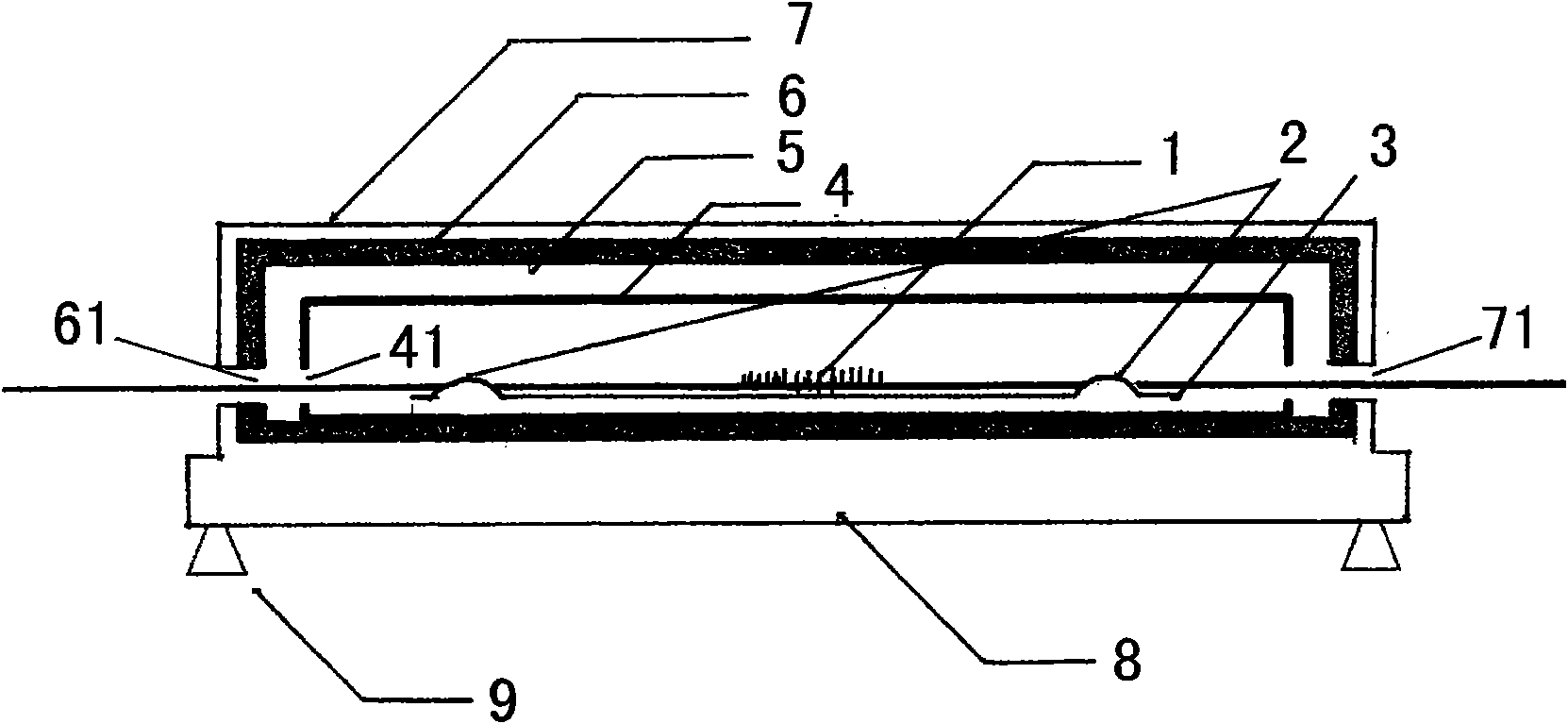

[0025] refer to figure 1 and 2 , the present invention provides a package for a distributed feedback fiber laser, comprising:

[0026] A base 8 is a rectangle. In order to avoid heat exchange with the outside, the base can be made of a material with low thermal conductivity, and what the present invention used is nylon material. Small load wire rope vibration isolators 9 are respectively fixed at the four corners below the base 8 to achieve the purpose of vibration reduction.

[0027] An outer package 7, in order to avoid heat exchange with the outside world, the package 7 needs to be made of a material with a small thermal conductivity, and the present invention is made of nylon material. The outer package 7 is a concave rectangle, buckled on the top of the base 8, so that there is an accommodating space between the base 8 and the outer package 7, the two opposite side walls of the outer package 7 can be concentric Two first circular holes 71 . Outer layer side wall pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com