Patents

Literature

110results about How to "Realize temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

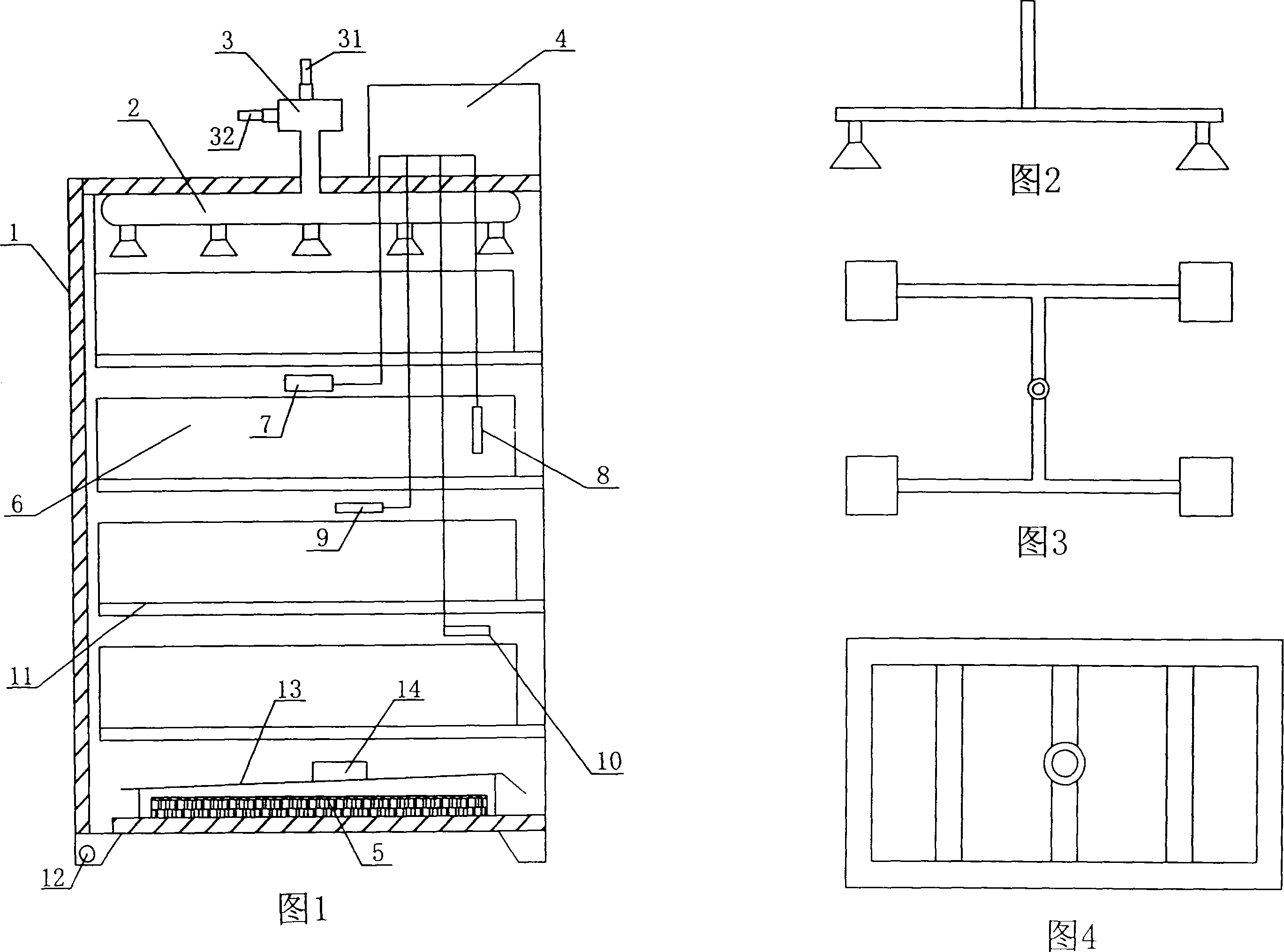

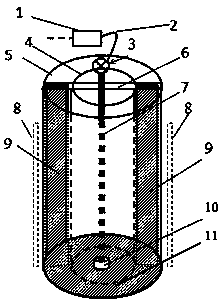

Full-automatic control multifunctional solid-state fermentation tank

ActiveCN106701563ARealize mechanized controlRealize temperature controlBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlControl system

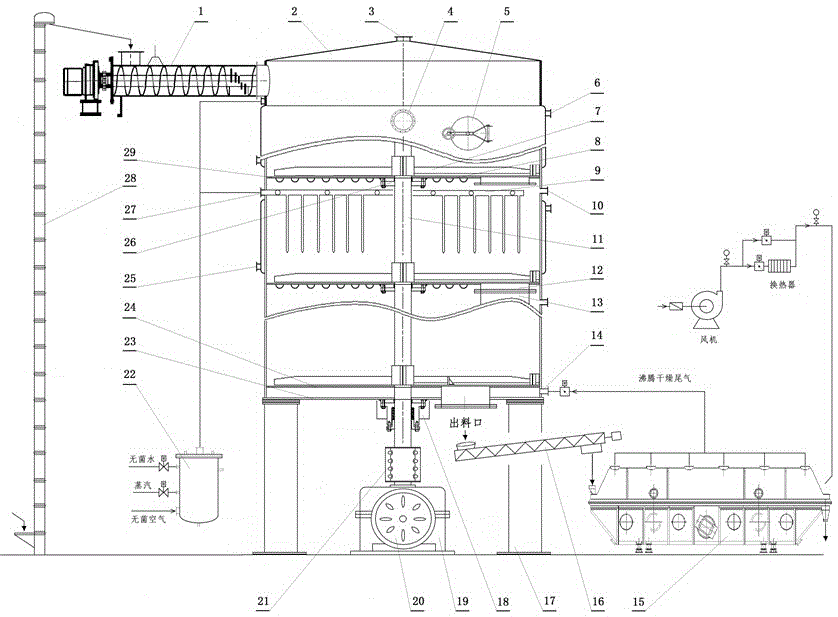

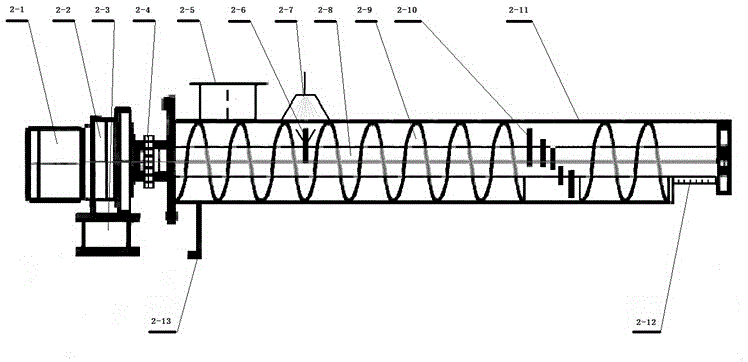

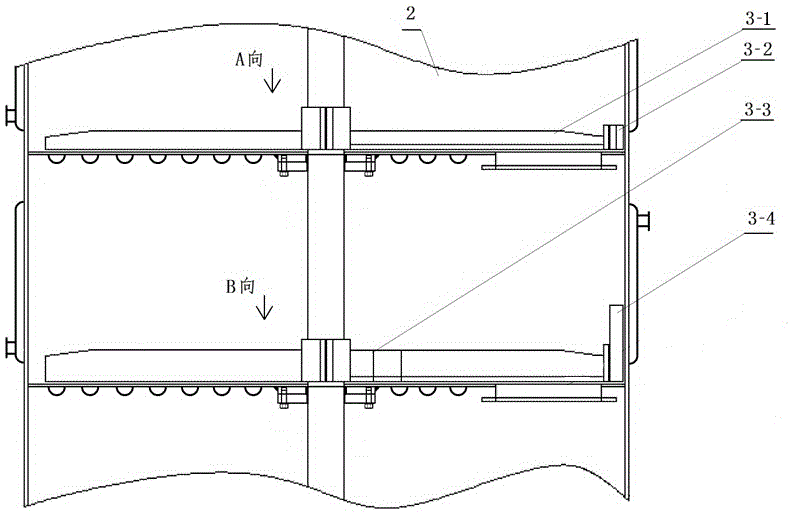

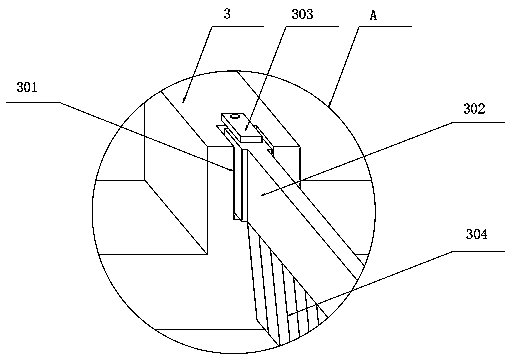

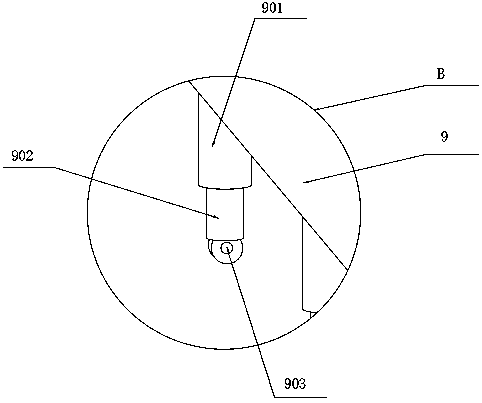

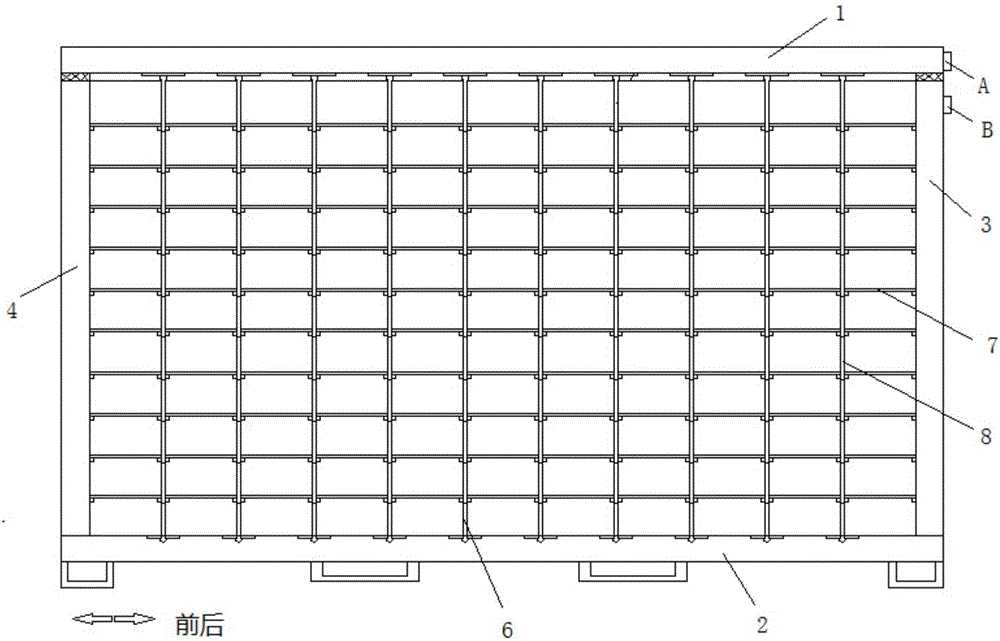

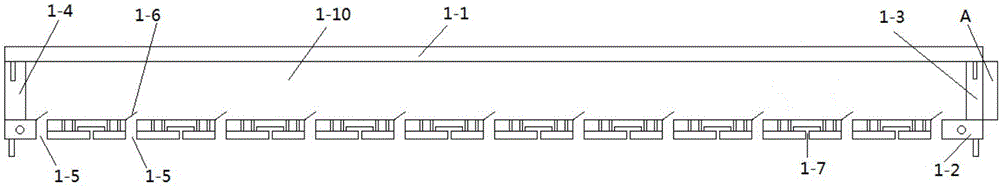

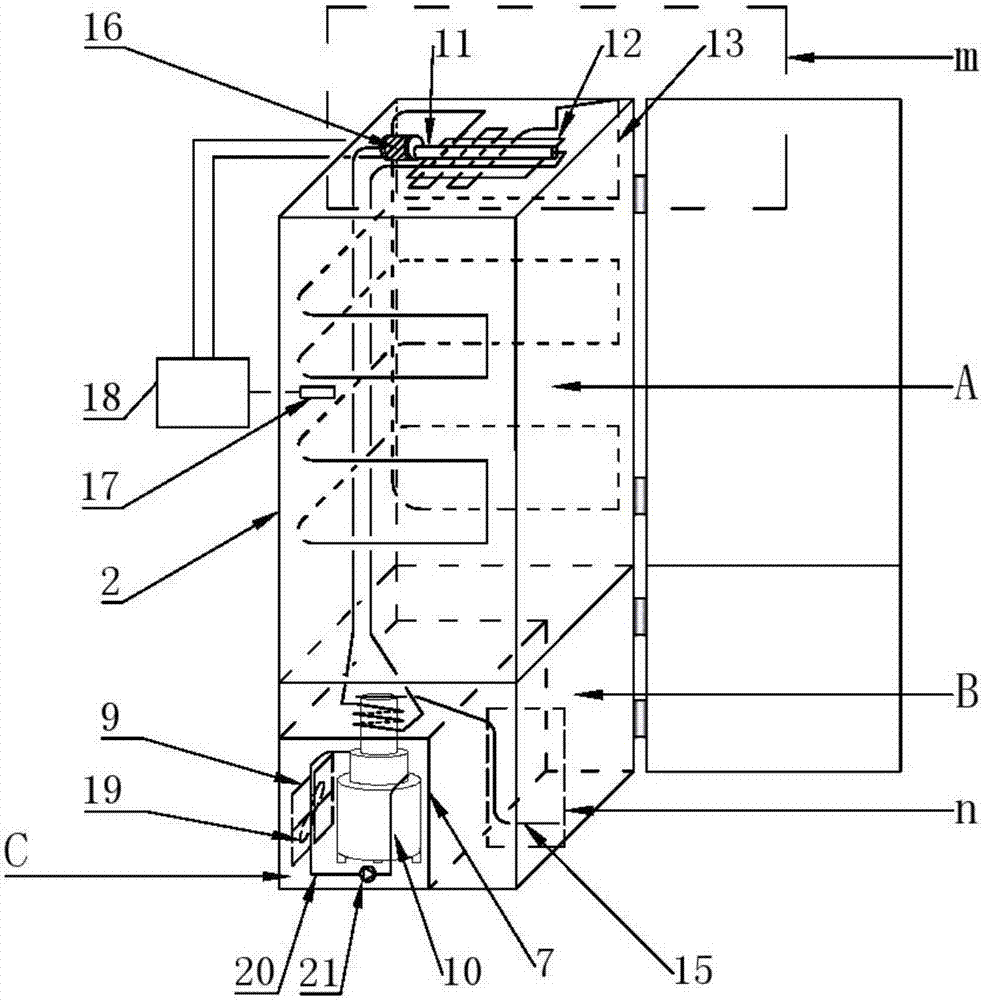

The invention discloses a full-automatic control multifunctional solid-state fermentation tank, comprising a round vertical fermentation tank main body and a fermentation control system, wherein a loading auger is arranged at one side of the upper end of the fermentation tank main body; multiple clapboards are arranged in the fermentation tank main body; a high-material-bed material level automatic control device is arranged in each fermentation layer; a sterile air distribution system is arranged in each fermentation layer and is connected with a sterile air generation tank positioned at the outer side of the fermentation tank main body; a main shaft is rotationally arranged in the fermentation tank main body; and the upper ends of the clapboards are provided with stirring blades. The full-automatic control multifunctional solid-state fermentation tank disclosed by the invention integrates eight functions including dry material mixing, watering material mixing, steam sterilization, inoculation, automatic fermentation control, low-temperature drying, raw material crushing, automatic discharging and finished product smashing, and enables all operations of solid-state fermentation to be completed in a multifunctional biological solid-state fermentation tank; and by virtue of the equipment disclosed by the invention, the fermentation and production preparation processes of solid biological products can be continuously completed.

Owner:郑州良源分析仪器有限公司

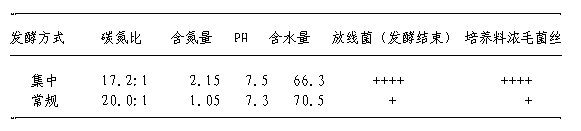

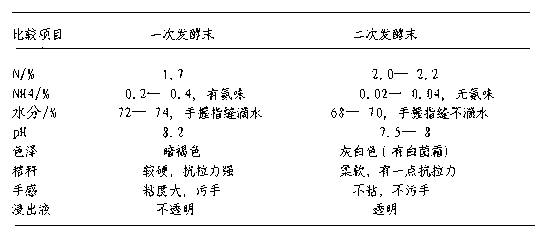

Centralized secondary fermentation method for agaricus bisporus

InactiveCN103319219AQuality productionHigh yield productionBio-organic fraction processingOrganic fertiliser preparationBiotechnologyAnimal Foraging

The invention discloses a centralized secondary fermentation method for agaricus bisporus. The culture medium comprises the following raw materials in parts by weight: 45-60 parts of forage, 35-50 parts of chicken manure, 2-8 parts of gypsum and 3-10 parts of oil cakes. The method comprises the following steps of: uniformly spreading forage in a pre-wetting pool for pre-wetting for 2-5 days; adding chicken manure, gypsum and oil cakes and uniformly and adequately mixing; filling the mixed fermentation material in a ventilating floor in a primary fermentation tunnel, and conveying fresh air to the fermentation material through a fan; fermenting for 4-6 days and transferring the fermentation material to another primary fermentation tunnel. The base material of the primary tunnel fermentation is uniformly stacked on the ventilating floor in a secondary fermentation tunnel, and the temperature of the fermentation material is controlled by operation of the fan. Secondary fermentation comprises the following steps: a balancing stage, a heating stage, pasteurization, cultivation at constant temperature and discharge at low temperature. According to the method, local wheat straw hoods, straws, chicken manure and the like are used as main raw materials to form the culture medium. Centralized scaled production cultivation materials are formed by the technology of pre-treatment of the raw materials, primary fermentation and secondary fermentation.

Owner:SICHUAN MAOSEN BIOLOGICAL SCI & TECH

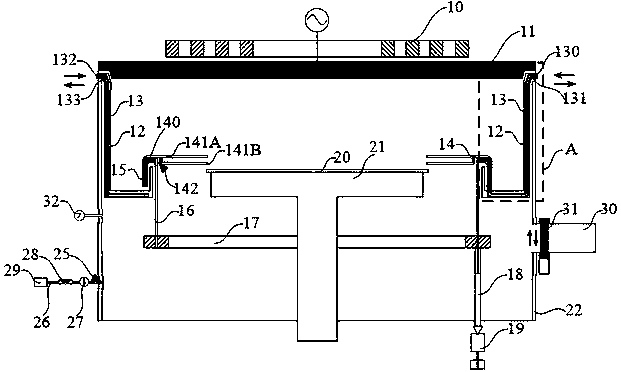

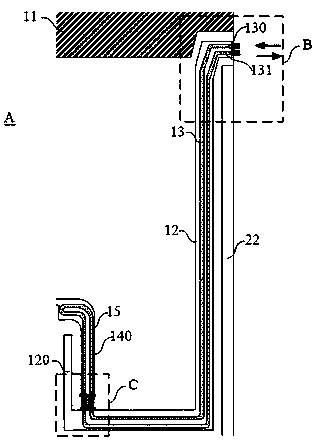

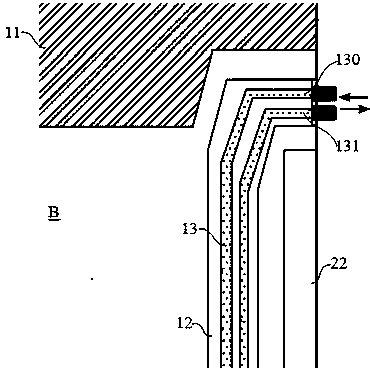

Physical vapor deposition equipment used for thick film deposition

ActiveCN110670042AHeight adjustablePrevent platingVacuum evaporation coatingSputtering coatingTemperature controlWafer

The invention provides physical vapor deposition equipment used for thick film deposition. The physical vapor deposition equipment comprises a permanent magnet device, a target material, a wafer baseand a cavity wall, and further comprises a cavity wall baffle, a wafer shield ring and a shield ring supporting and adjusting device. One end of the cavity wall baffle is fixed between the target material and the cavity wall, the other end of the cavity wall baffle is a free end, and a first cooling pipe cavity used for containing a cooling pipe is arranged in the cavity wall baffle. The wafer shield ring comprises a vertical portion and a horizontal portion, the horizontal portion is annularly arranged on the upper edge of the wafer, the vertical portion is arranged on the periphery of the lower portion of the horizontal portion, a second cooling pipe cavity used for containing a cooling pipe is arranged in the vertical portion, and a groove is formed in the end, close to the vertical portion, of the horizontal portion. The shield ring supporting and adjusting device comprises an ejector pin, an ejector pin ring, a connecting rod and a transmission mechanism. One end of the ejector pin is inserted into the groove, the other end of the ejector pin is fixedly connected with the ejector pin ring, the ejector pin ring is connected with the transmission mechanism arranged on the outerportion through the connecting rod, and the ejector pin ring surrounds the periphery of the wafer base. According to the equipment, cooling and temperature control to the wafer, a deposition cavity and a process set can be effectively achieved in the deposition process.

Owner:BETONE TECH SHANGHAI

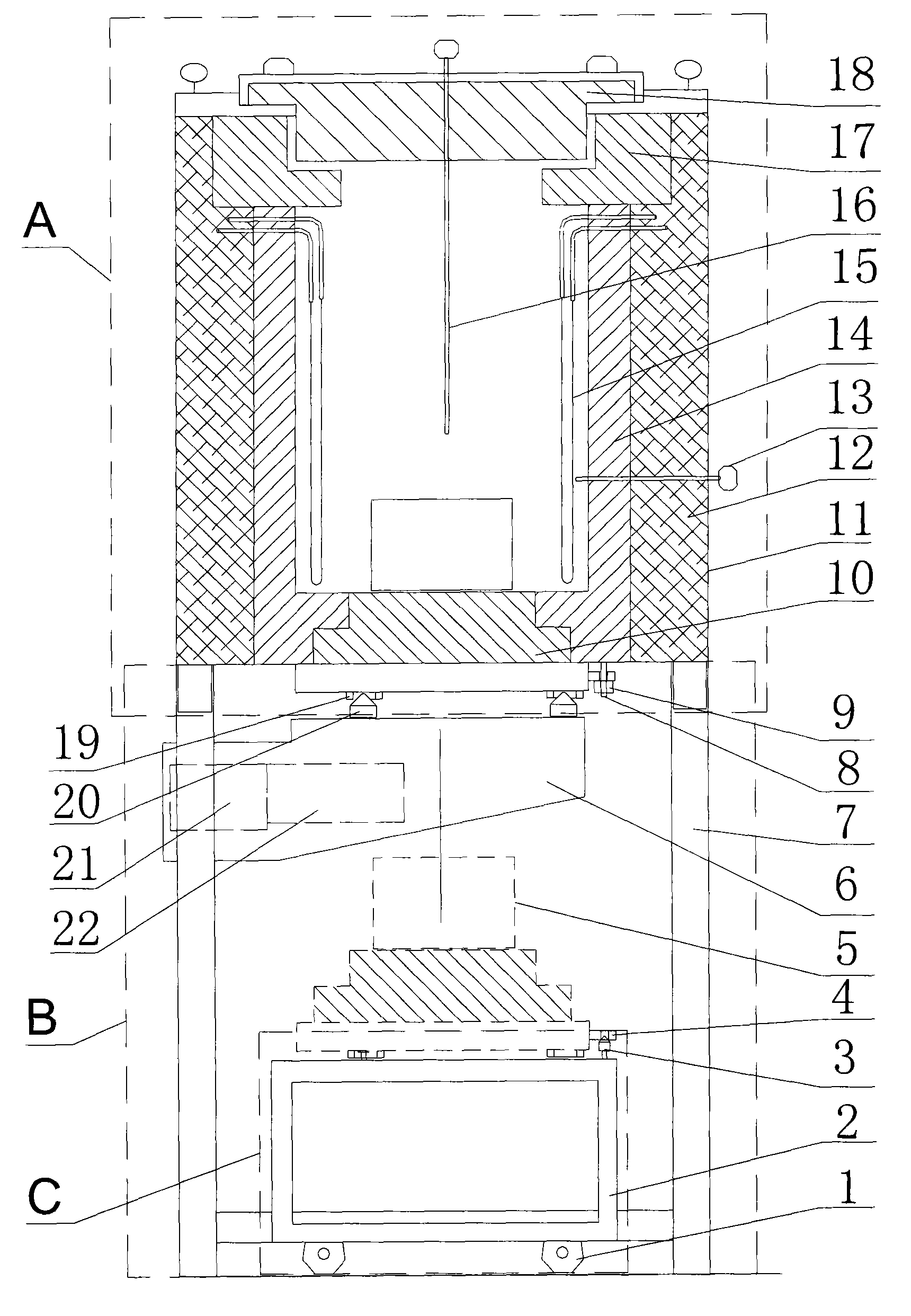

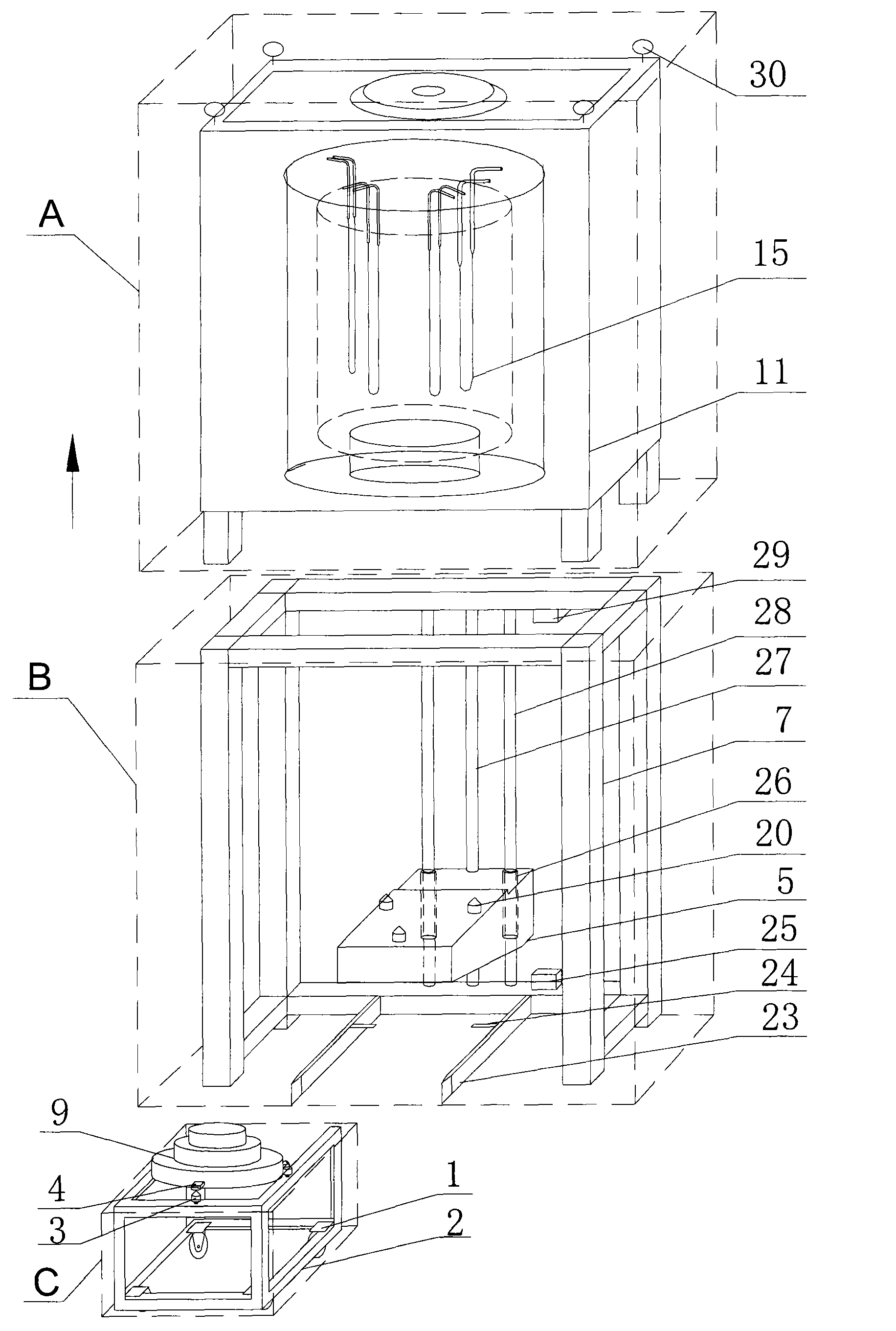

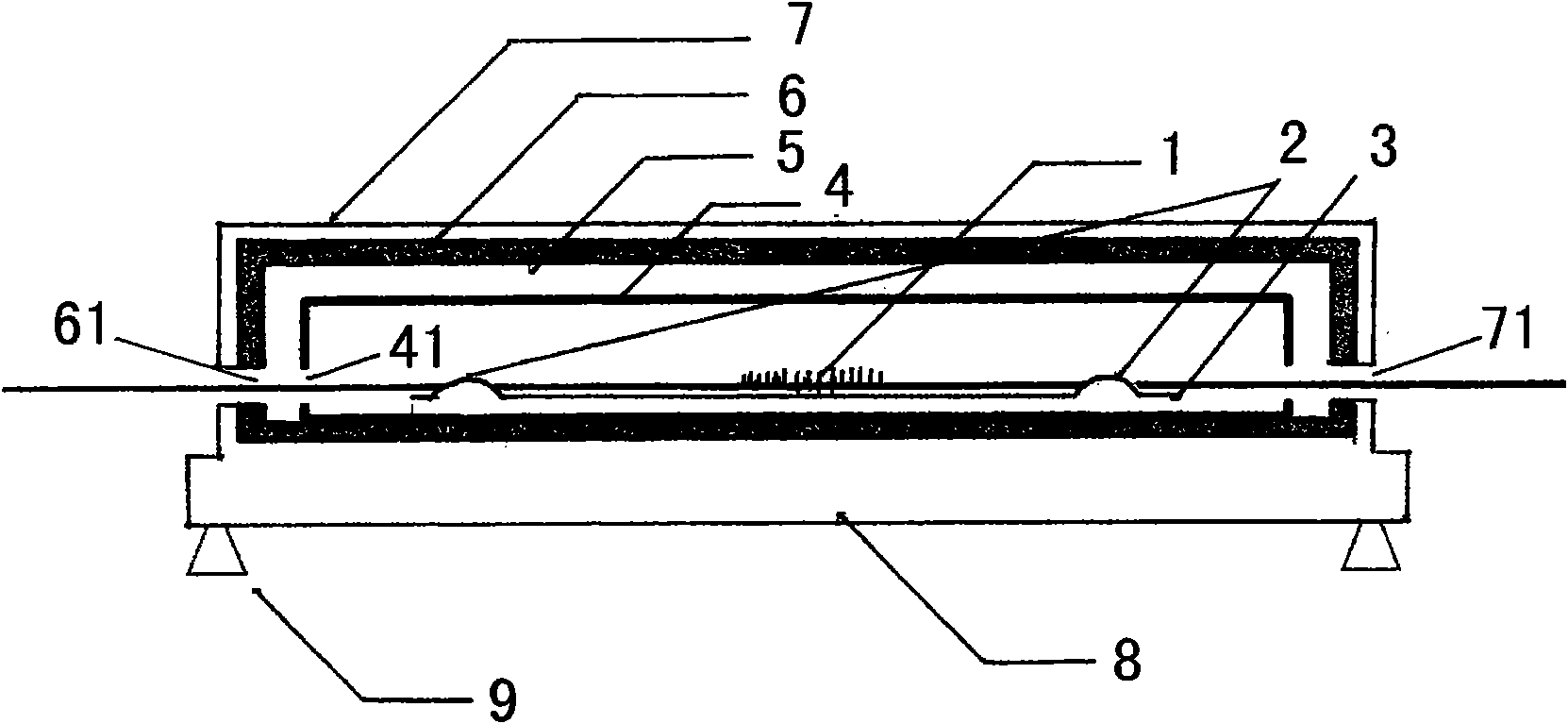

Combined multifunctional resistance furnace

The invention relates to a combined multifunctional resistance furnace comprising a furnace body A, a lifting system B and a cart C, wherein, the furnace body A is provided with an upper furnace mouthand a lower furnace mouth and is respectively provided with an upper furnace cover 18 and a lower furnace seat 10 which are matched with the upper furnace mouth and the lower furnace mouth; the lifting system B is fixedly arranged on a furnace frame 7, the dismountable furnace body A is arranged above the furnace frame 7 in a combined mode, and the cart C is arranged at the lower part in the furnace frame 7. A workpiece 5 can be stably assembled and disassembled by the lifting motion of a lifting platform 6, the plane motion of the cart C and positioning and positioning exchange to the lowerfurnace seat 10 by the above motion. The invention can disassemble the furnace body A to serve as a pit type resistance furnace according to requirements or serve as a lifting resistance furnace by closing the upper furnace cover 18, which realizes one furnace with multiple functions and simultaneously satisfies various complex operation requirements of the resistance furnace. The invention has simple structure, reliable running, safe operation and wide application range and is especially suitable for hot-working treatment and complex operation, such as sintering, smelting, solidifying and thelike of the materials.

Owner:SOUTH CHINA UNIV OF TECH

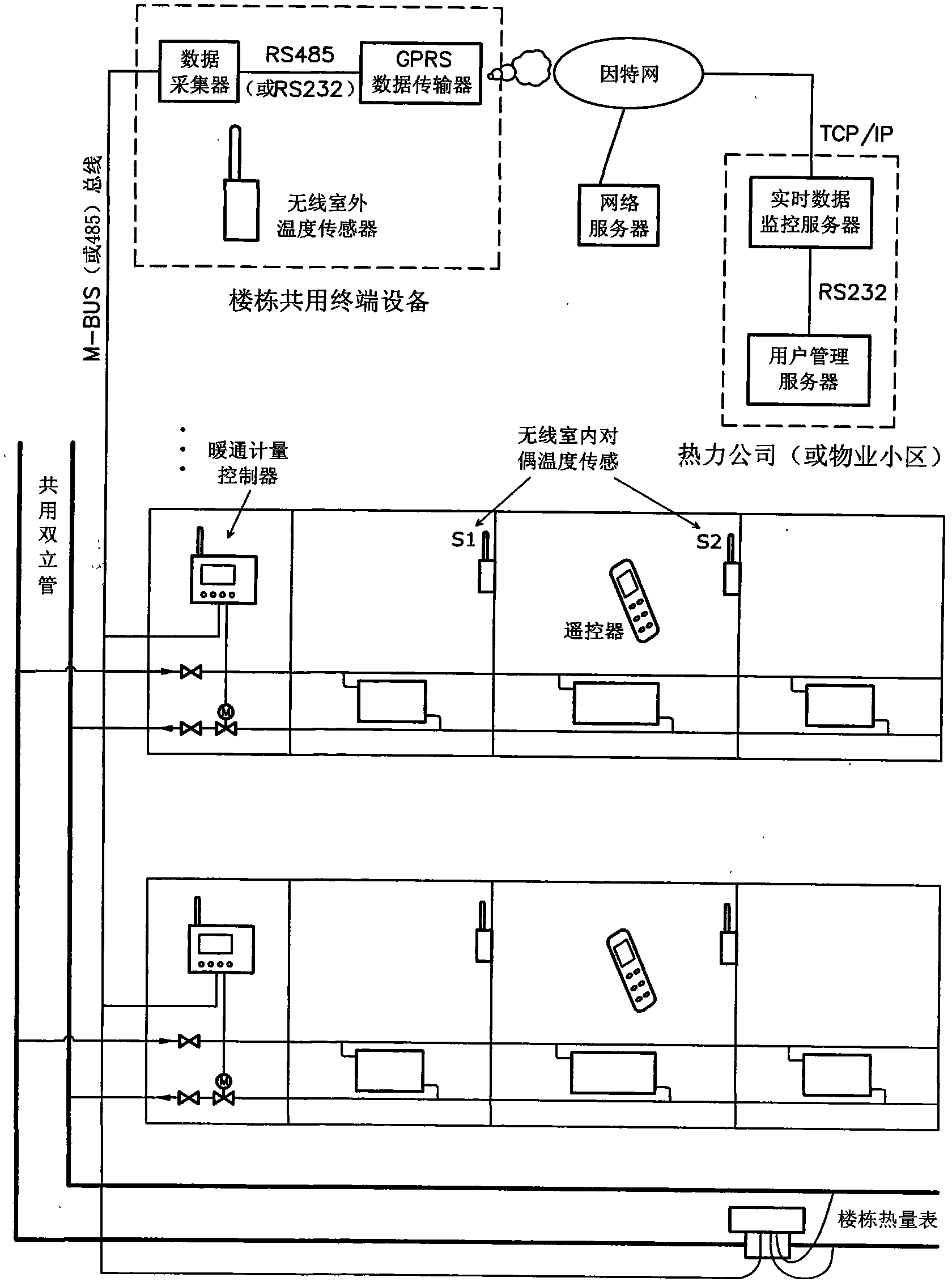

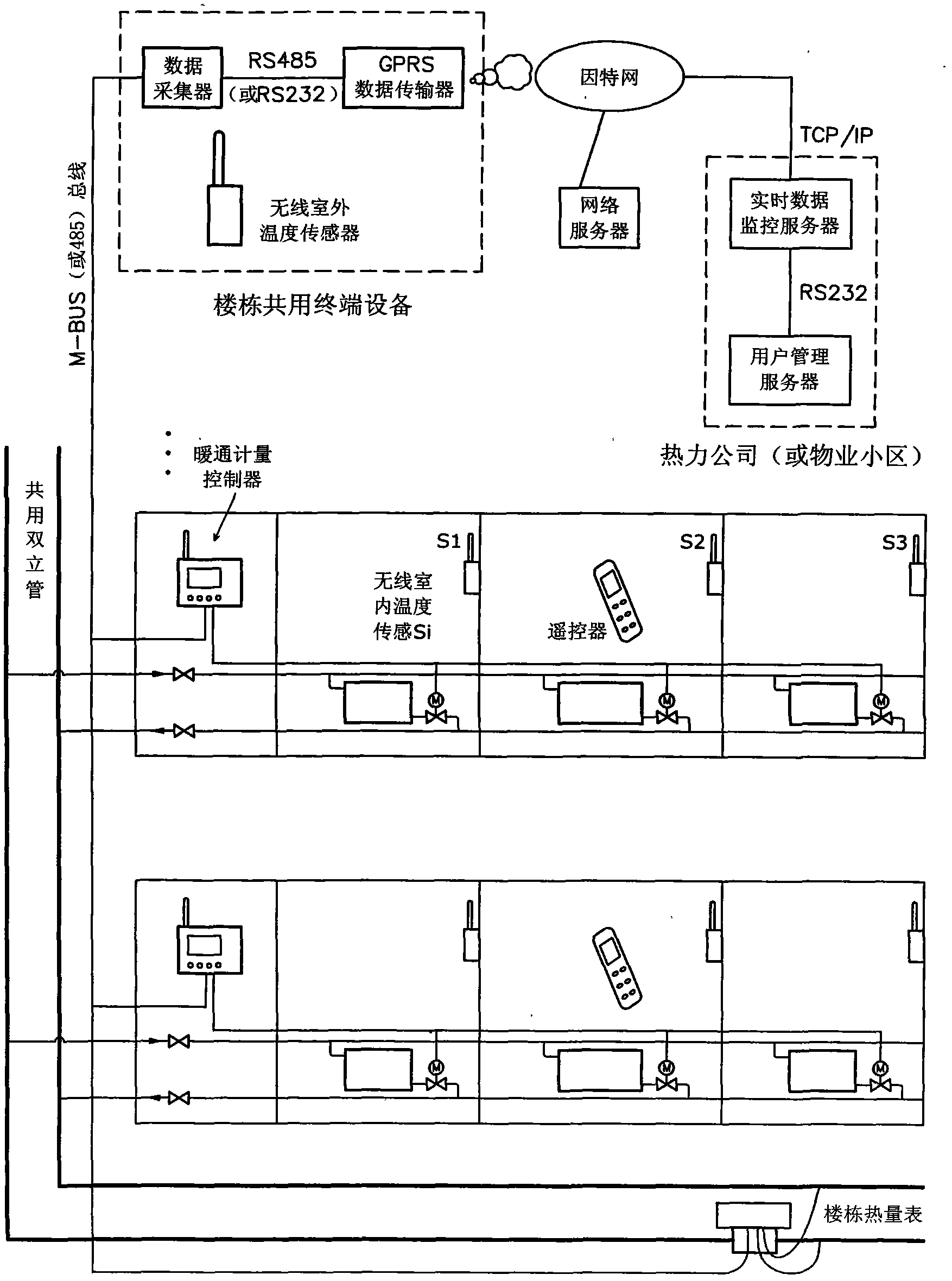

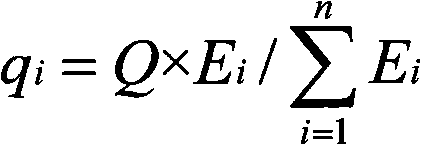

Heat supply measurement sharing method based on heating area, indoor and outdoor temperature difference and heating time

InactiveCN102829804AHigh precisionImprove reliabilityTariff metering apparatusThermal energyEngineering

The invention relates to a heat supply measurement sharing method based on heating area, indoor and outdoor temperature difference and heating time, belonging to the field of centralized heat supply. The technical scheme is as follows: an effective energy consumption concept is introduced from the aspect of actual utility provided for heating users by a heat supply system; effective heat consumption under different outdoor environment temperatures and indoor heating temperatures of the users can be projected by weakening heat loss or gain due to factors such as structures of buildings, heat conduction and heat radiation among different rooms of users, and the like; the product of temperature difference and time corresponding to each of sampling periods of user rooms under real-time outdoor environment temperature and indoor heating temperature is metered; and finally heat measured by building heat meters according to the product of heating area, heating temperature difference and heating time of the users is shared, and the value of the shared heat is taken as the basic evidence for charging the users, therefore, multiple contradictions and problems existed when household metering is carried out by utilizing the traditional metering method are greatly solved.

Owner:武海强

Sprout vegetables intelligent breeding device

InactiveCN101213931ARealize scientific cultivationMeet the requirements of green and high yieldAgriculture gas emission reductionCultivating equipmentsGramEconomic benefits

The present invention relates to a seedling-vegetable intelligentized culture device. According to the latest cultivation research result of the seedling vegetable, a heat-preservation cultivation box is additionally provided with a spray thrower, a heater, a vegetable temperature sensor, a moisture sensor and a carbon-dioxide sensor; through the cooperation amongst an electric-appliance control box, a gas-liquid reversing valve and the heater, the temperature, the moisture and the concentration of the carbon dioxide in the heat-preservation box can be precisely controlled, thereby providing more suitable conditions for the growth of the seedling vegetables. Using the present invention, the seedling vegetables can be free from the hormone and the chemical fertilizer; and only relying on the regulation of the moisture, the temperature and the carbon dioxide gas, the seedling vegetable that is the favorite of the people can be cultivated in high yield; according to the actual cultivation experiment, the cultivation period of the mungbean sprout is six days, and the yield rate for every gram of the mungbean is about 15 grams of the mungbean sprout. The cultivated mungean sprout has good taste and high yield, and is the pollution-free nuisanceless vegetable in deed and has higher economic benefit.

Owner:夏建平

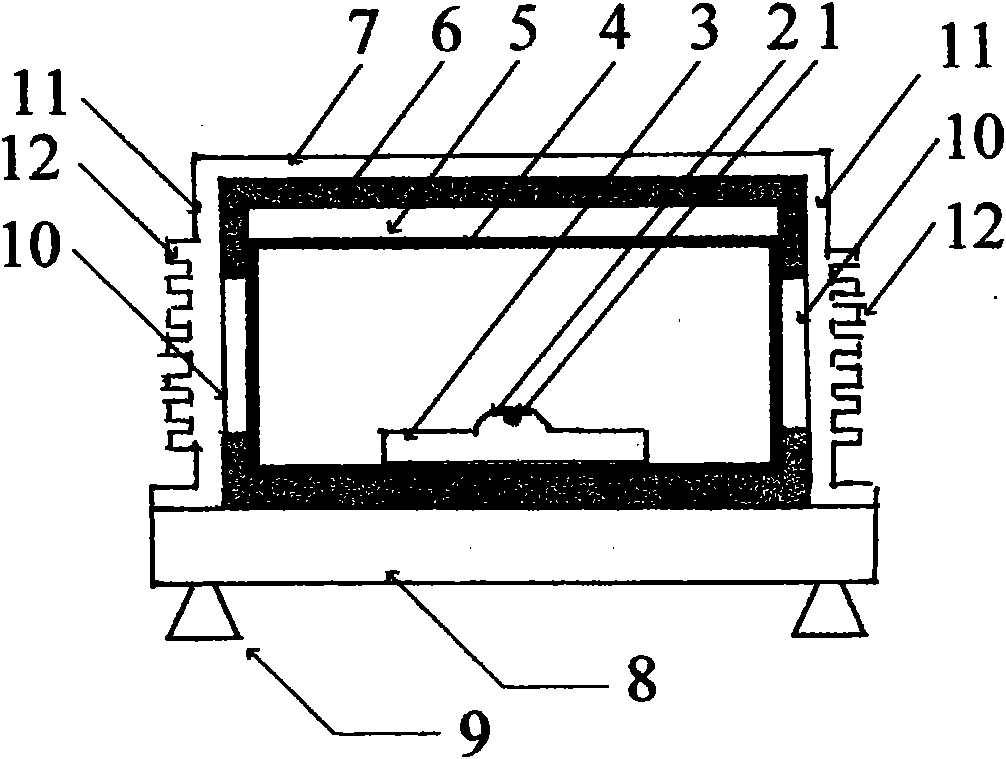

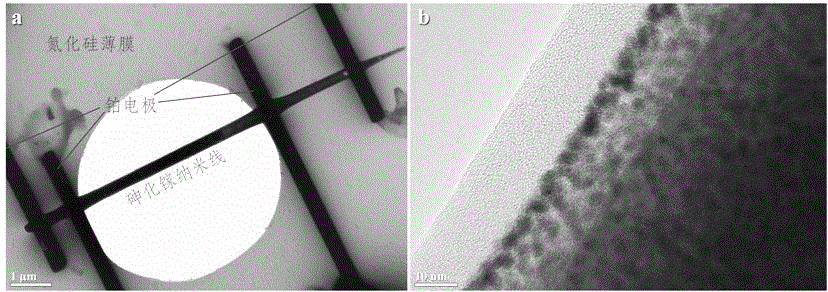

Encapsulating structure of distributed feedback (DFB) fiber laser

InactiveCN102035125AHighly integratedImprove performanceLaser constructional detailsActive medium shape and constructionFiber disk laserEngineering

The invention discloses an encapsulating structure of a distributed feedback (DFB) fiber laser. The encapsulating structure comprises a rectangular base, an outer encapsulating layer, a sound insulating board, an inner encapsulating layer and strip-shaped piezoelectric ceramic, wherein the outer encapsulating layer is an inwardly-concave rectangle and is buckled on the base so as to form an accommodating space between the base and the outer encapsulating layer; two opposite side walls of the outer encapsulating layer are concentrically provided with two first circular holes; the sound insulating board is attached to an inner wall between the base and the outer encapsulating layer and provided with two second circular holes corresponding to the two circular holes on the outer encapsulating layer; the inner encapsulating layer is a hollow rectangular shell fixed on the sound insulating board on the base and provided with two third circular holes corresponding to the two circular holes on the sound insulating board; the strip-shaped piezoelectric ceramic is fixed on the bottom surface of the inner encapsulating layer on the sound insulating board on the base; the DFB fiber laser is fixed on the upper two sides of the strip-shaped piezoelectric ceramic by bonding; and the two ends of the DFB fiber laser pass through the first, second and third circular holes.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

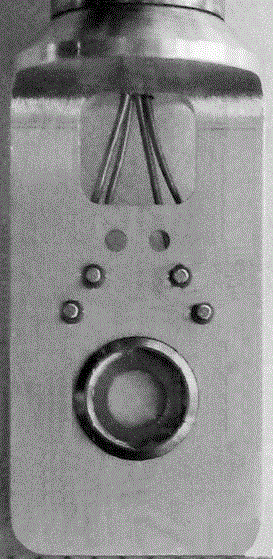

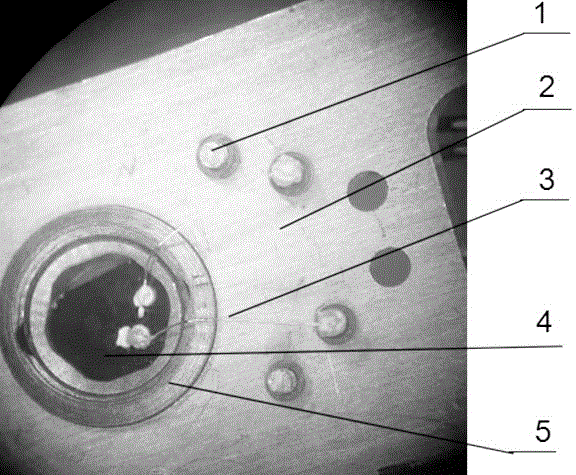

Transmission electron microscope in-situ electrode sample platform

InactiveCN105679631ASimple designReasonable structureElectric discharge tubesMaterial analysis by measuring secondary emissionConventional transmission electron microscopeTemperature control

The invention belongs to the technical field of transmission electron microscope accessories, and specifically to a transmission electron microscope in-situ electrode sample platform. The sample platform comprises five parts: metal electrodes, a sample groove, an enamelled wire, a sample observation widow and a sample pressing ring; a Dewar tank is connected at the back end of the sample platform, and can be used for filling liquid nitrogen to realize temperature control at a temperature interval of 100K-373K; the sample platform is put into a Lorentz transmission electron microscope; an in-situ magnetic field coupling observation environment can be realized at different temperatures; and the observation range of the Lorentz imaging mode can be expanded. According to the sample platform, the sample can be observed under an atomic-scale resolution, and real-time electric and magnetic observation at different temperatures can be realized as well; and the relations and change rules of the electric and magnetic performances and the nanometer microstructures of to-be-tested units can be demonstrated in an in-situ manner.

Owner:FUDAN UNIV

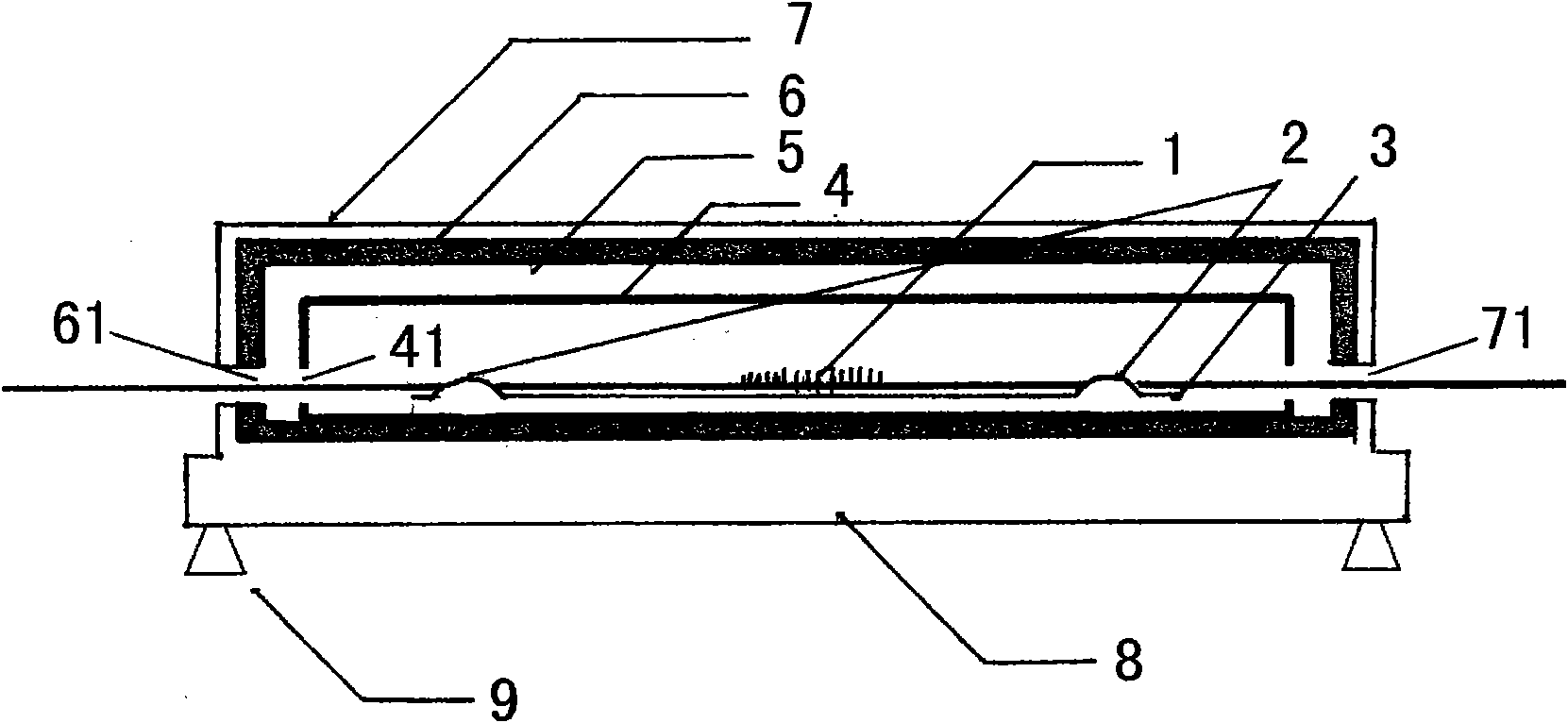

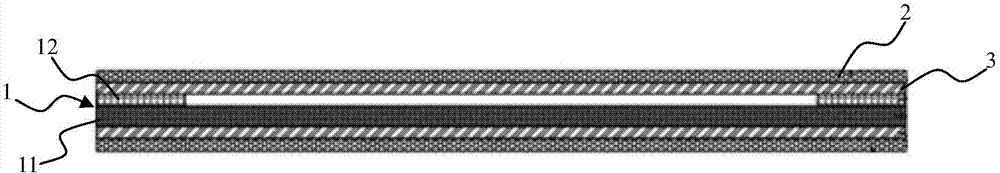

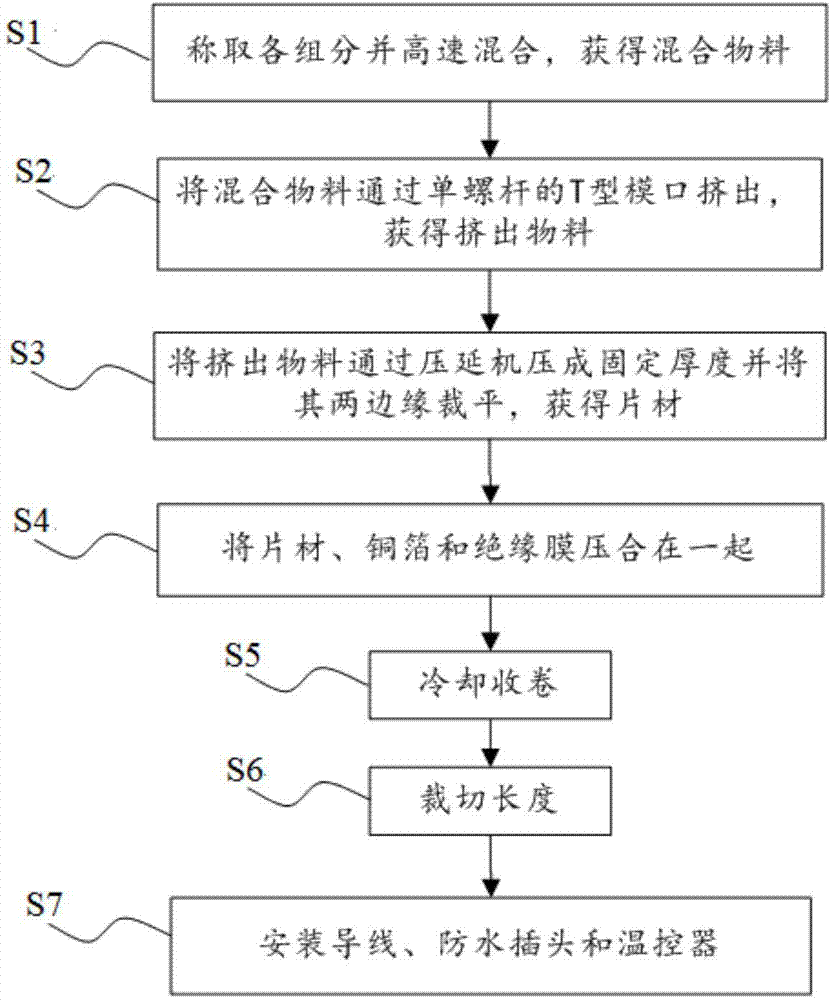

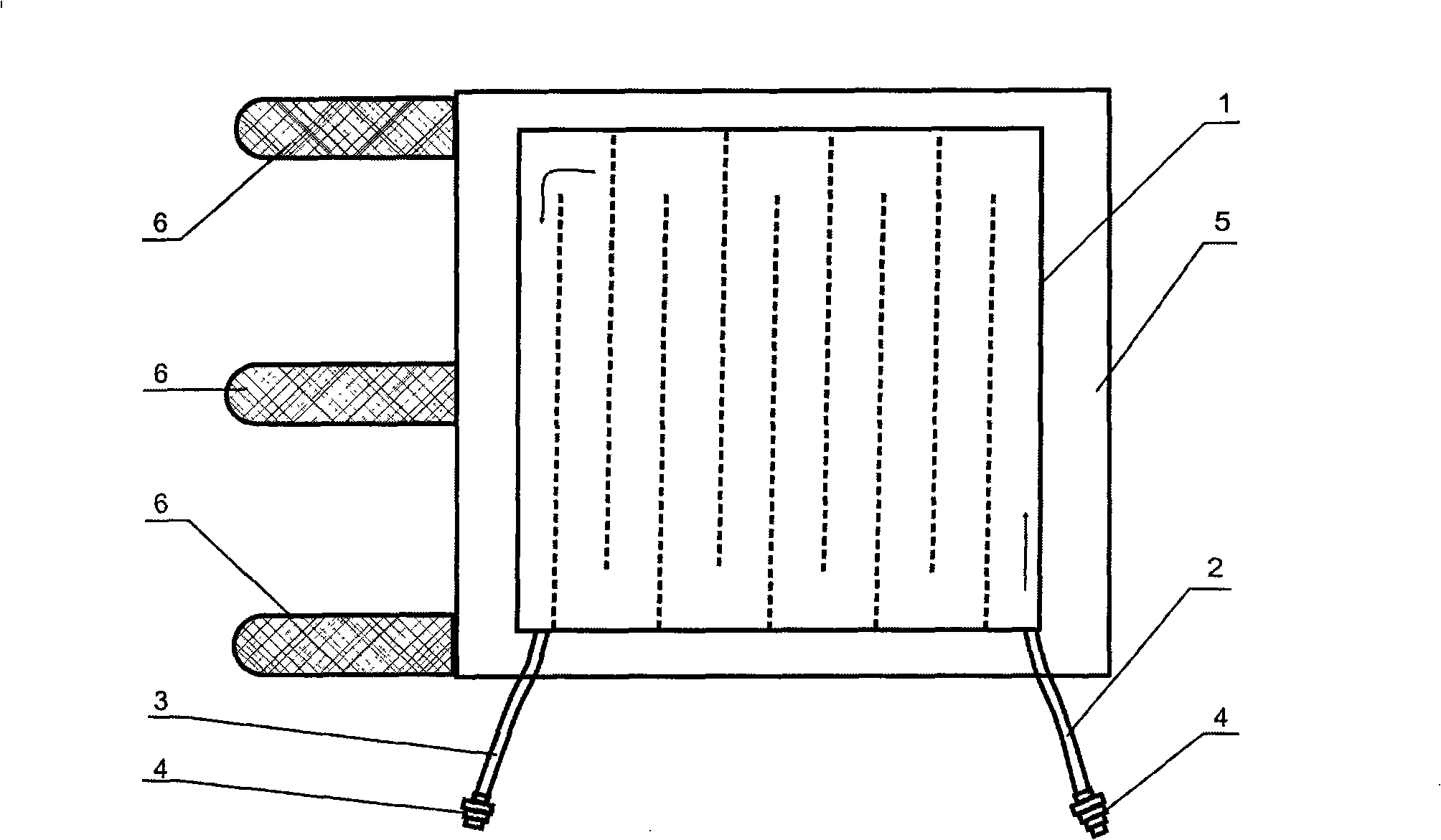

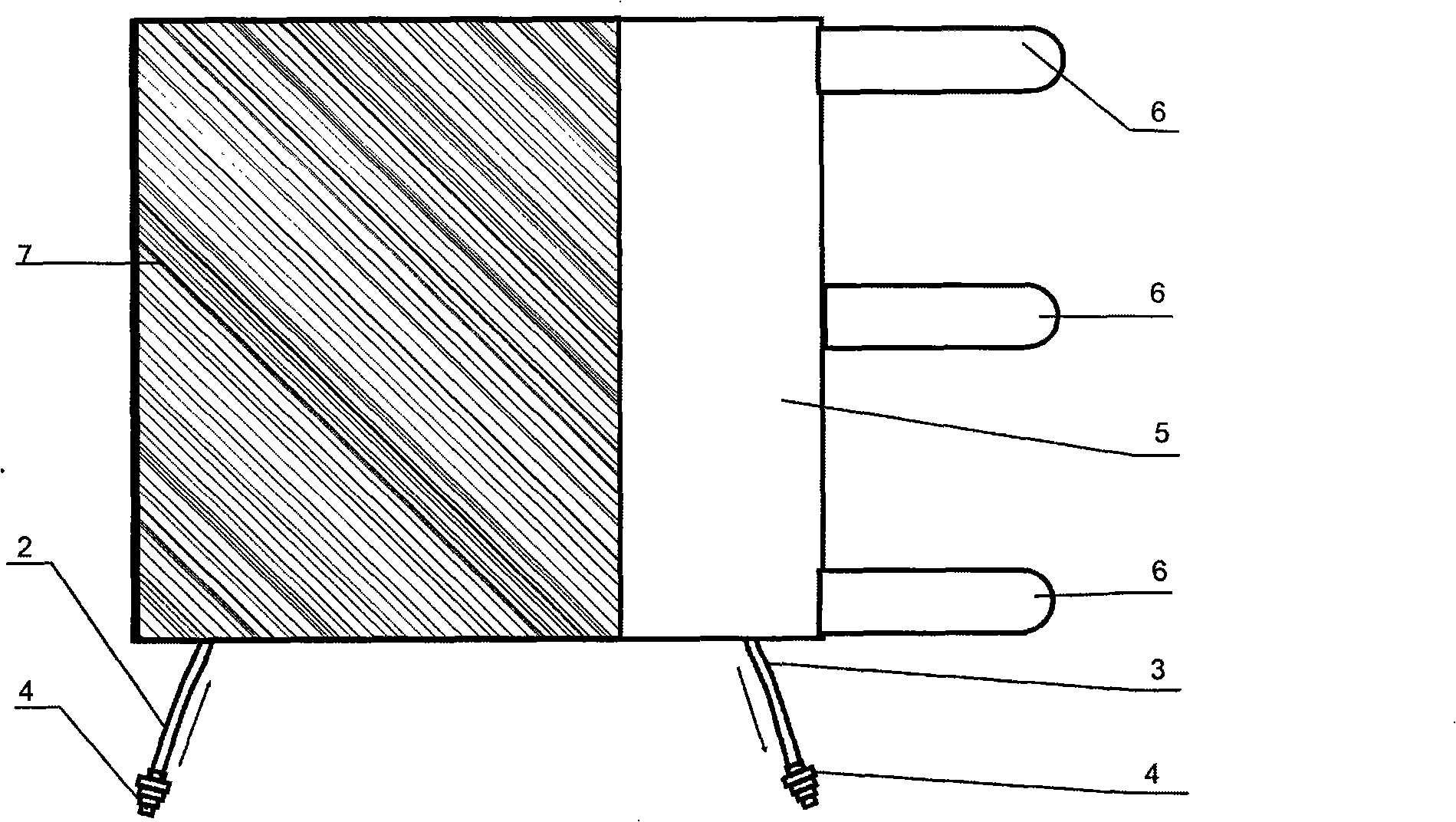

PTC (Positive Temperature Coefficient) heating sheet, low-temperature radiating electrothermal film and preparation method of low-temperature radiating electrothermal film

InactiveCN103687098ALow manufacturing costReduce process complexityOhmic-resistance electrodesHeating element materialsTemperature coefficientHeating film

The invention discloses a PTC (Positive Temperature Coefficient) heating sheet, a low-temperature radiating electrothermal film and a preparation method of the low-temperature radiating electrothermal film. The PTC heating sheet comprises a substrate and conducting electrodes which are compounded on both sides of the substrate; the conducting electrodes are made of copper foils; a plurality of projections are formed on one side of each copper foil, thereby forming a rough surface; each copper foil is fixed on the substrate by thermocompression bonding through the rough surface. The PTC heating sheet, the low-temperature radiating electrothermal film and the preparation method of the low-temperature radiating electrothermal film disclosed by the invention have the advantages of simple process, low cost, high peeling strength, long service life, realization of continuous production, saving in energy, environmental friendliness, comfort, health care and wide application range.

Owner:上海神沃电子有限公司

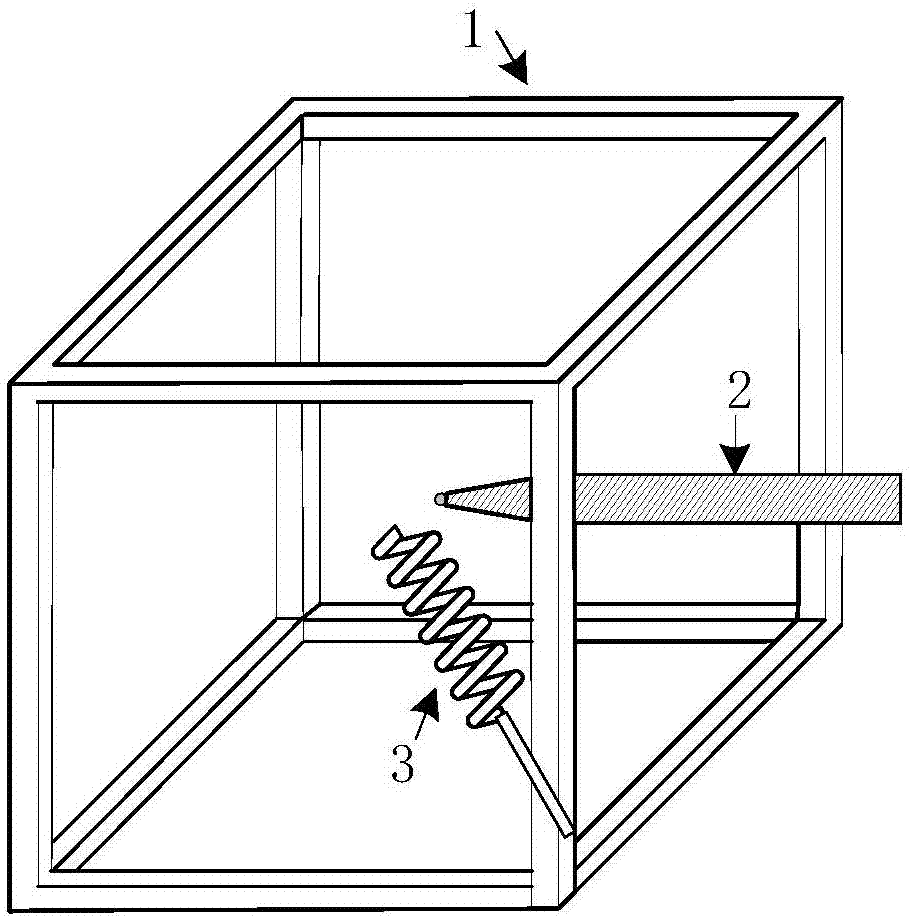

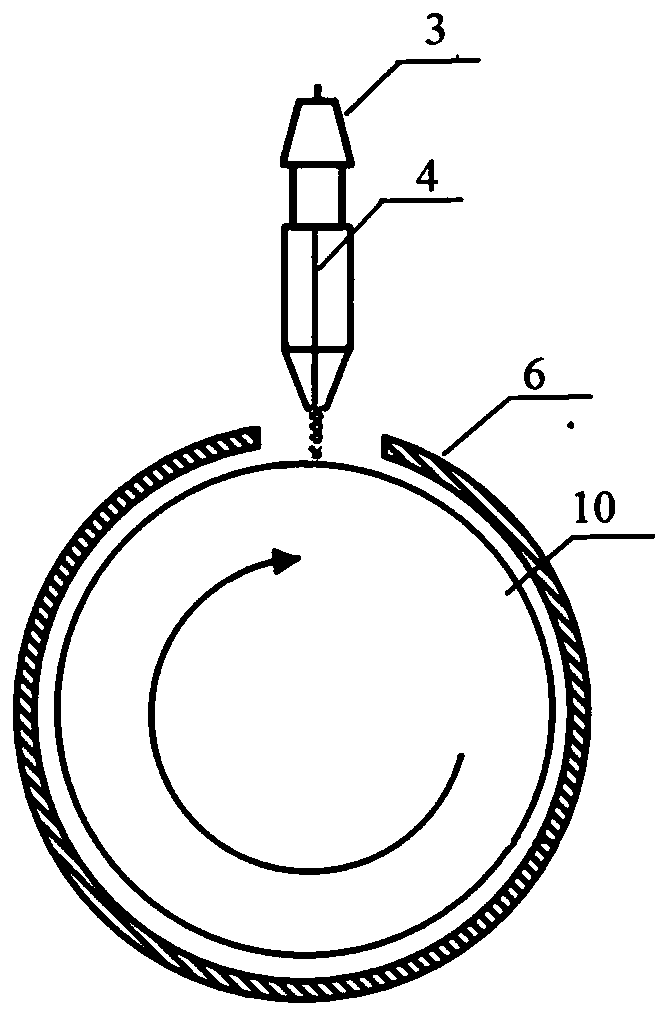

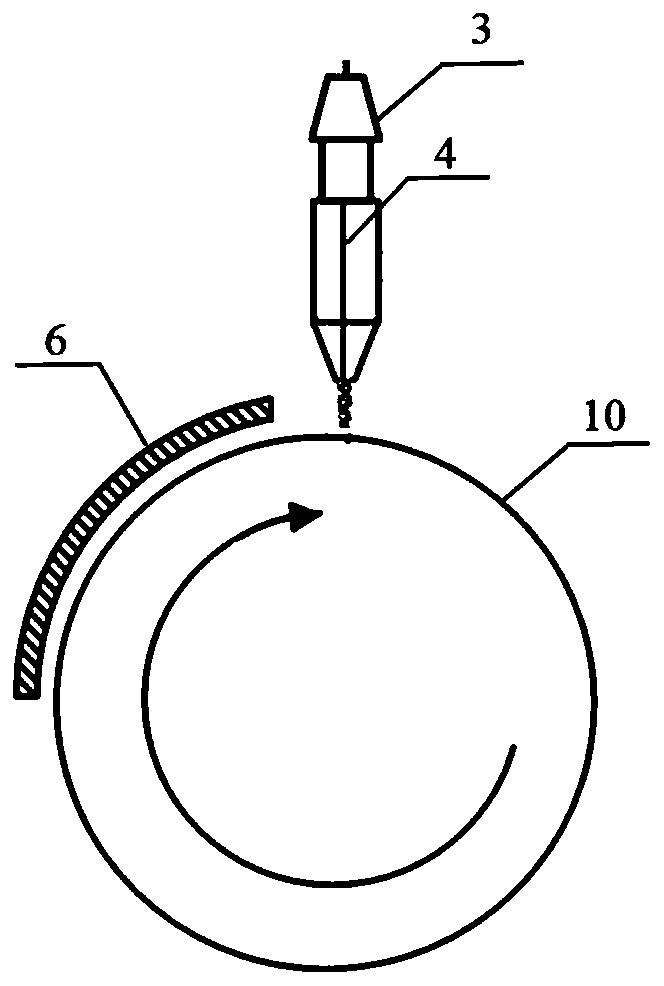

Alga cultivation device with indoor controllable cultivation condition

InactiveCN103756874ARealize temperature controlRealize light controlBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlEngineering

The invention discloses an alga cultivation device with indoor controllable cultivation conditions. A bottom plate is arranged at the bottom of an annular tank; a bearing is vertically connected with a rotating shaft; a rotating transverse arm is horizontally connected to the top of the rotating shaft; the rotating shaft is connected with an adjustable motor; the adjustable motor is connected with a speed regulator through a connection line; thrust blades are respectively vertically connected with two ends of the rotating transverse arm; the thrust blades are arranged inside a tank chamber of the annular tank; light sources are symmetrically arranged on two sides of the annular tank. The alga cultivation device has the advantages that temperature control and light control are achieved, and hydrodynamic condition experiments under different cultivation conditions are provided. In the alga cultivation process, the blades of the device rotate in a uniform speed, so that the problems that the flow speed is not stable, not uniform and the like are effectively solved.

Owner:JIANGXI NORMAL UNIV

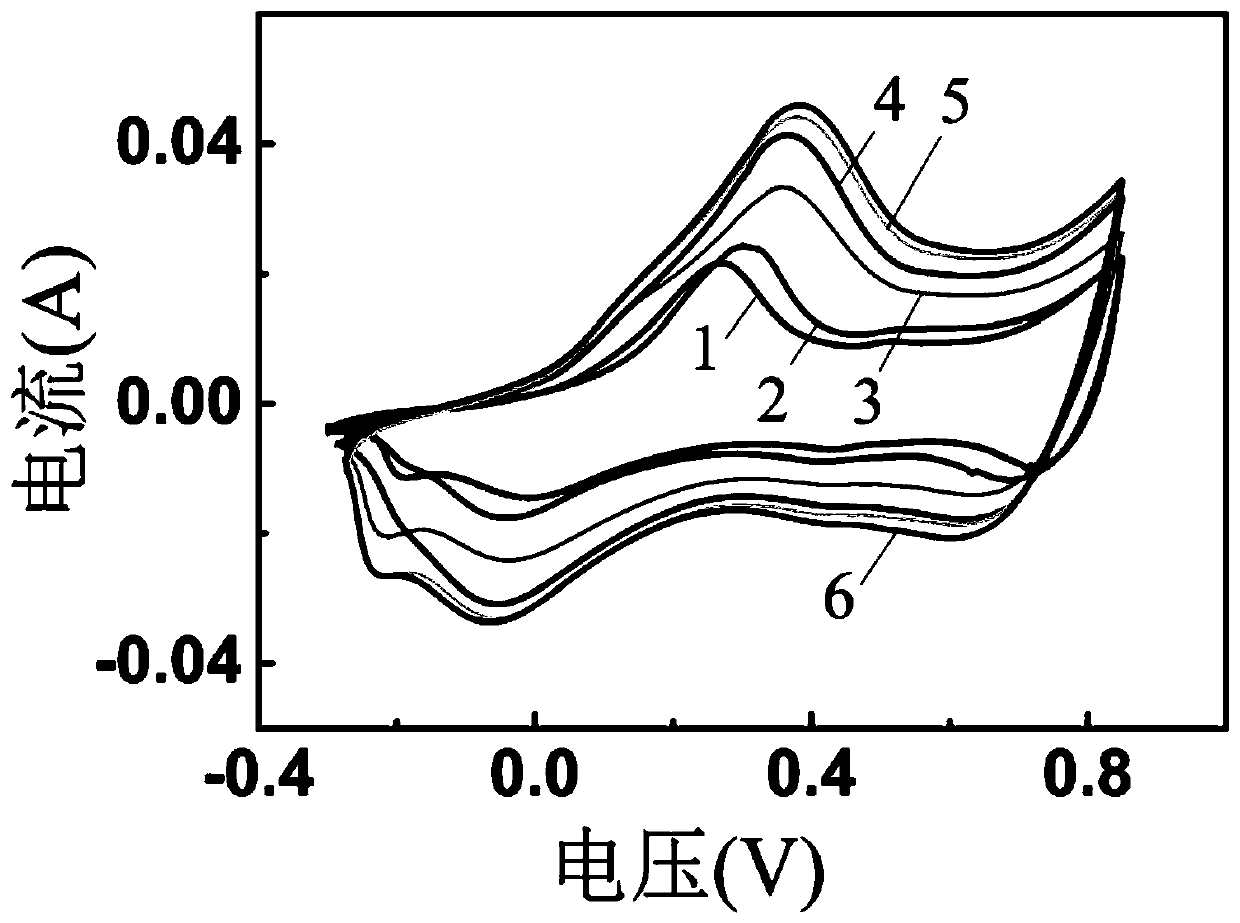

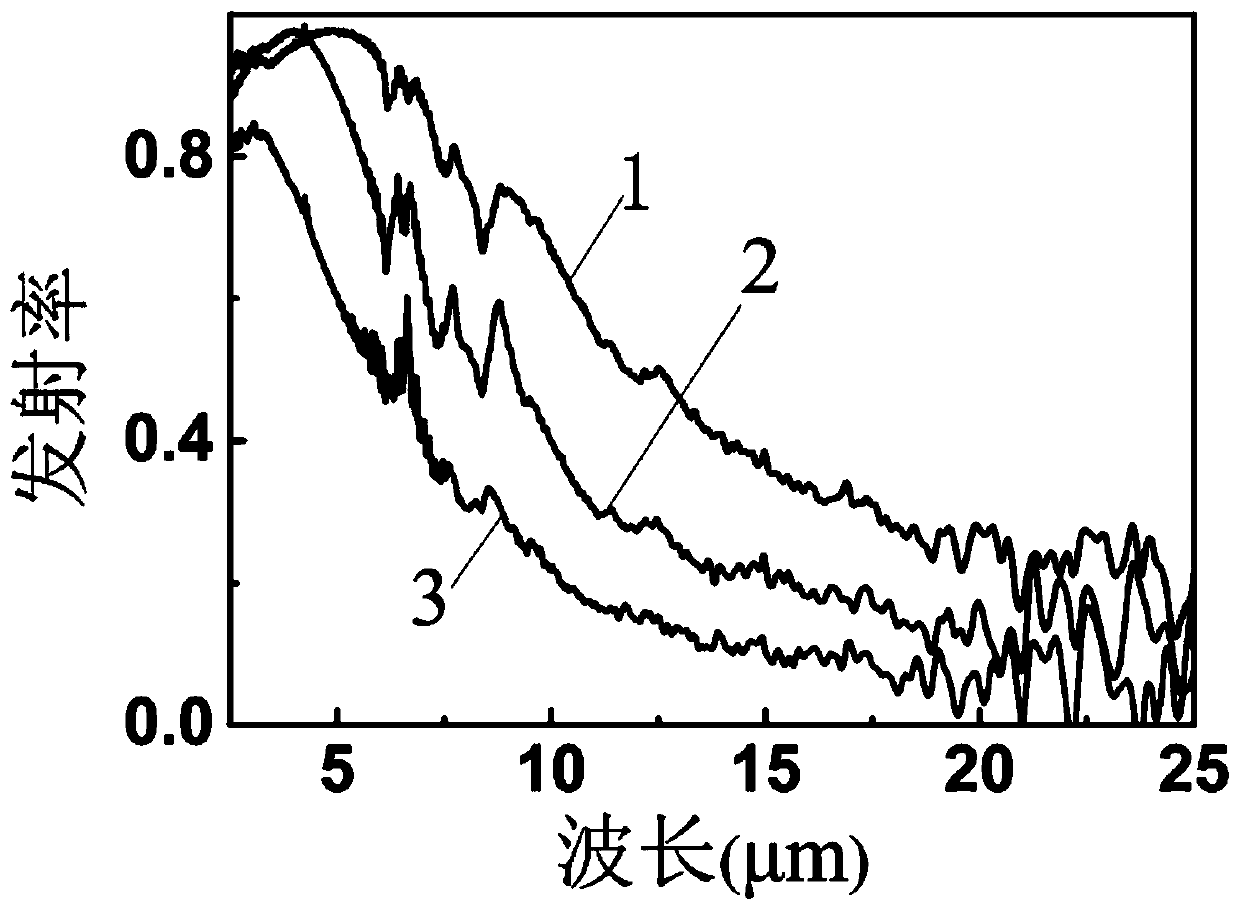

Preparation method of flexible low-working voltage polyaniline electrochromic emissivity film

ActiveCN110846699AEmission reductionSimple processElectrolytic organic material coatingPolymer solutionElectrochemistry

The invention relates to a preparation method of an electrochromic emissivity film, in particular to a preparation method of a flexible low-working voltage polyaniline electrochromic emissivity film,and aims to solve the problems that an existing electrochromic emissivity material is inflexible, complex in preparation process, high in cost and high in driving voltage. The preparation method comprises the steps of 1, preparing a polymer solution; and 2, performing electrochemical deposition to obtain the flexible low-working voltage polyaniline electrochromic emissivity film. According to thepreparation method, the prepared flexible low-working voltage polyaniline electrochromic emissivity film has higher infrared regulation and control capability, is good in cycle stability, and can meetthe requirement for intelligent photothermal regulation and control; and the response time of the flexible low-working voltage polyaniline electrochromic emissivity film is 10-20 seconds. The methodcan be used for preparing the flexible low-working voltage polyaniline electrochromic emissivity film.

Owner:HARBIN INST OF TECH

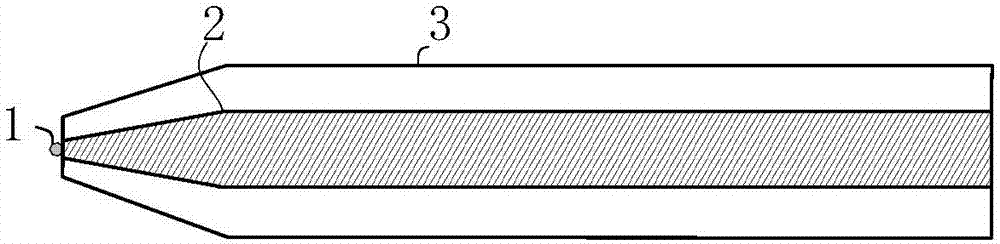

Thermal ablation needle and application method thereof

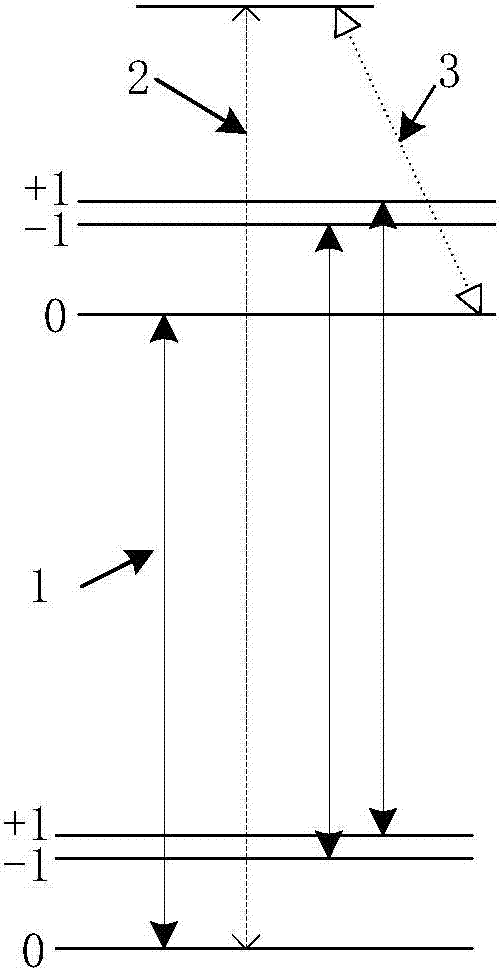

InactiveCN107374719ASmall diameterLight in massSurgical instruments for heatingTemperature controlColour centre

The invention discloses a thermal ablation needle and an application method thereof. The thermal ablation needle comprises an ablation needle head 1, an ablation needle rod and an ablation needle tube. The ablation needle head is made of diamond particles with a high nitrogen vacancy (NV) color center content, and the ablation needle rod is an optical fiber. The ablation needle head adheres to the ablation needle rod in a seamless mode with UV glue or low-melting-point glass powder, and the ablation rod extends into the conical hollow capillary ablation needle tube matched with the ablation rod. Through the optical detection magnetic resonance technology (ODMR), the numerical value of the potential energy D of a crystal field is measured, and the function relation between laser power and the temperature of the ablation needle head is then calculated, so that temperature control is achieved. An NV color center itself can serve as a temperature sensor, and the temperature of the ablation needle head can be measured and controlled in real time. The thermal ablation needle can precisely move between two pieces of tissue by means of an existing CT or ultrasonic image and magnetic resonance imaging system and reach the part needing to be treated more accurately, and the whole thermal ablation needle is small in diameter and low in weight, does not need water cooling, and is simple in system and more flexible.

Owner:子询(深圳)人工智能研究院有限公司

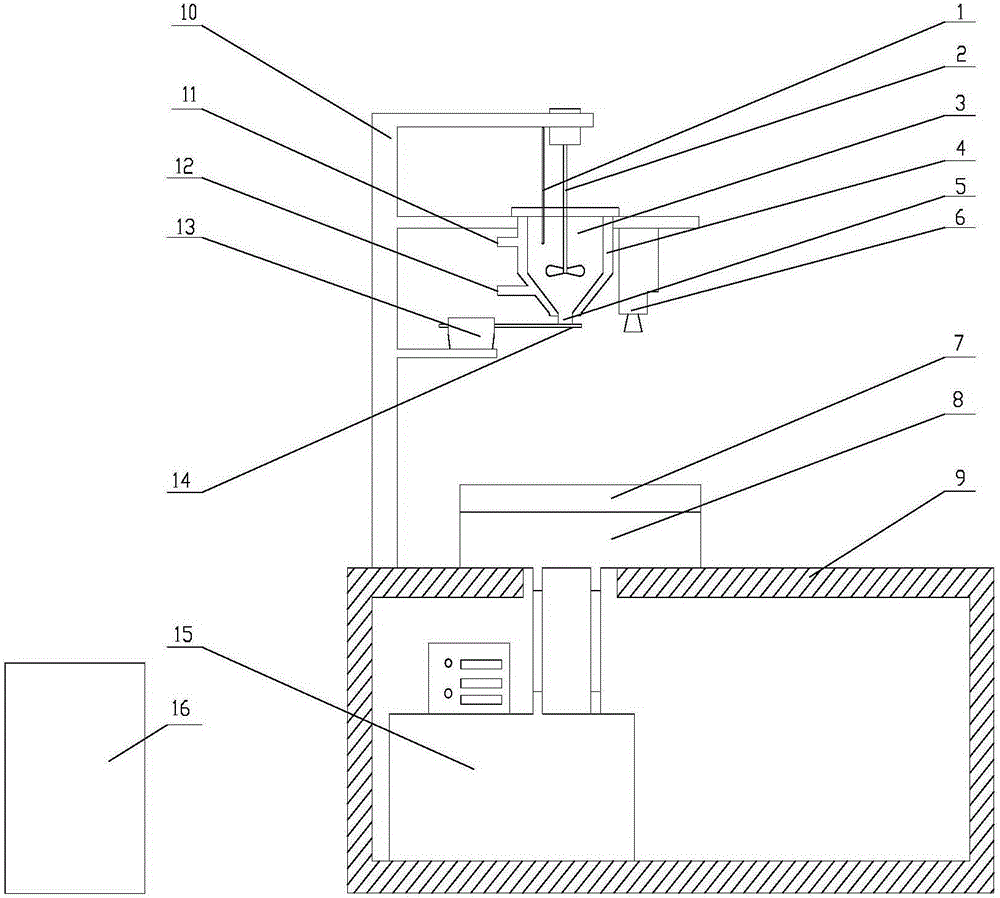

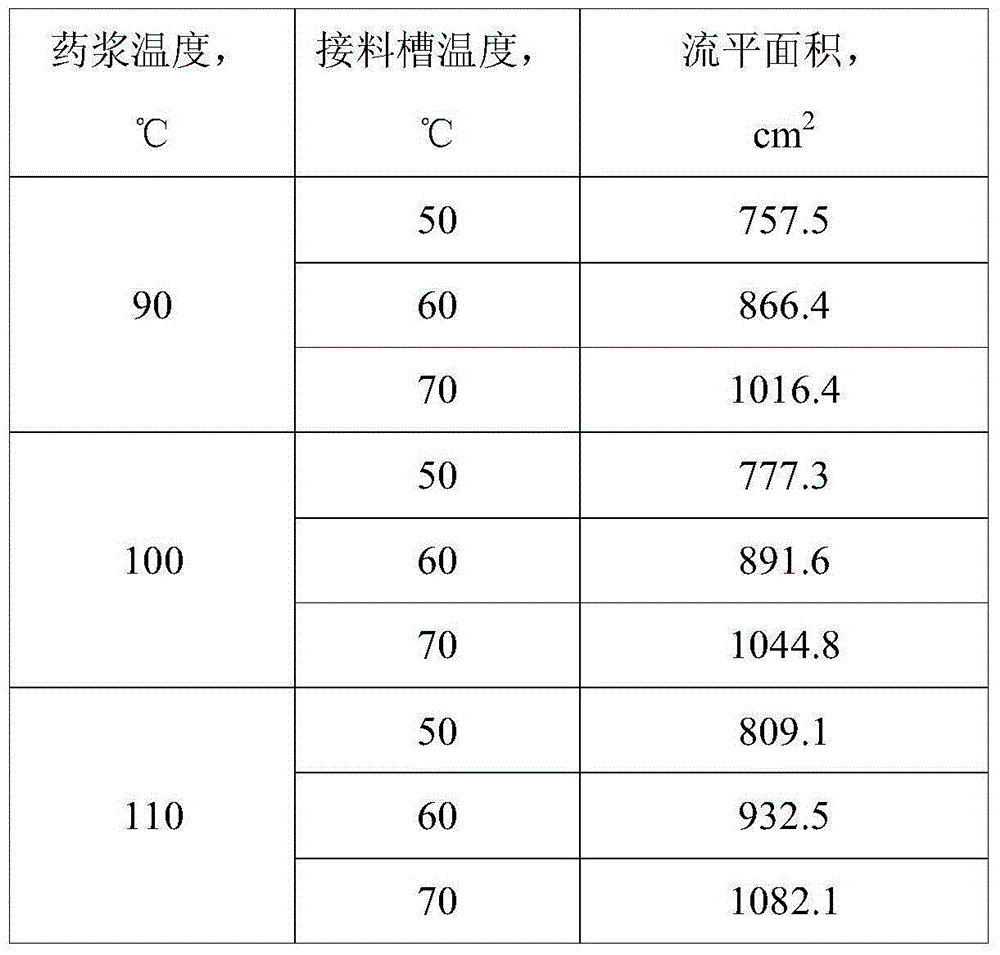

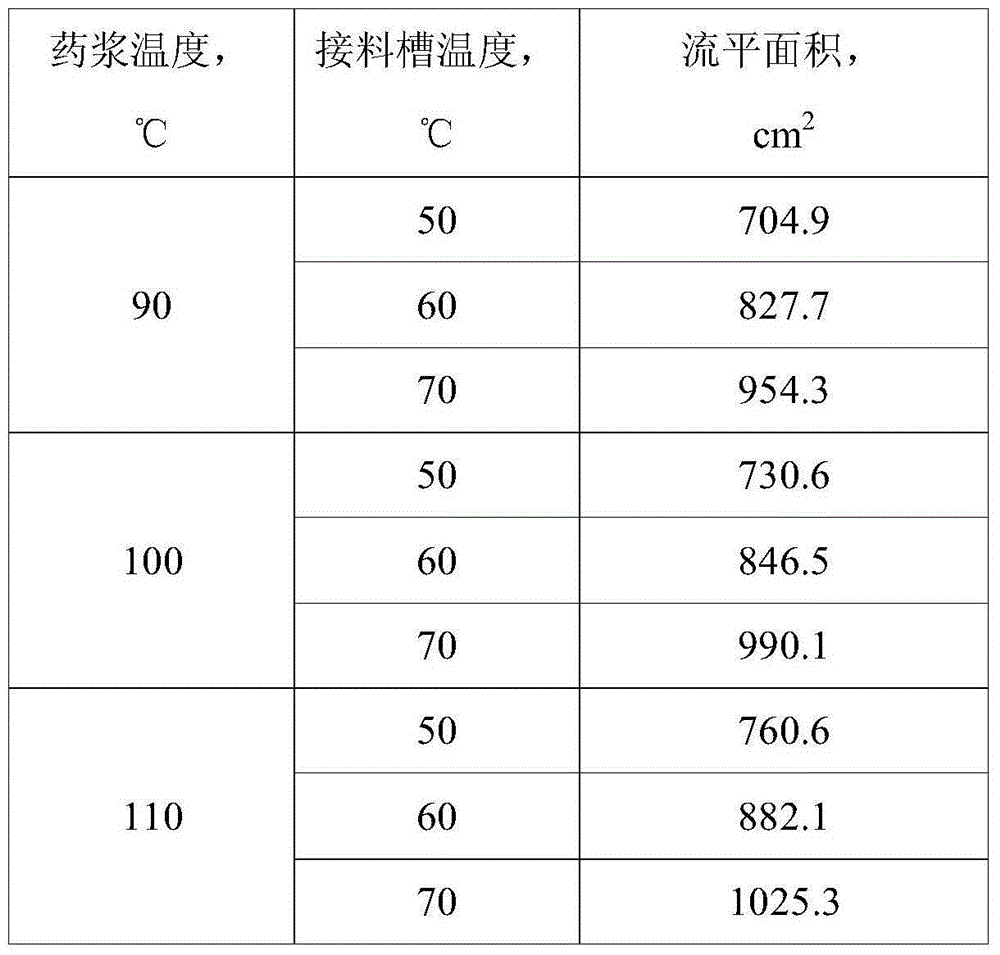

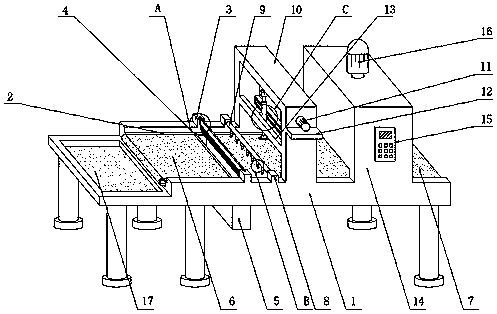

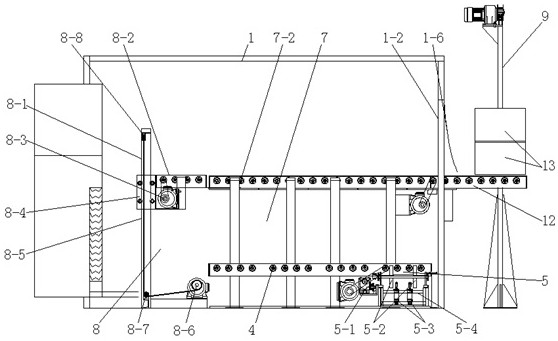

Fusion cast explosive levelability determinator

ActiveCN105203430ARealize temperature controlAvoid the problem of not being able to get the leveling timeFlow propertiesSlurry flowHigh definition

The invention discloses a fusion cast explosive levelability determinator, which solves the problem that the existing conventional levelability determining method is not applicable to fusion cast explosives. The flowing expansion process of explosive slurry in a material collecting tank (7) is recorded through a high-definition camera (6). Through the processing and the calculation on a video image in the explosive slurry flowing expansion process, the final leveling area of the explosive slurry can be obtained, and can be used as an evaluation index of the fusion cast explosive levelability. The device provided by the invention can be used for testing the leveling areas of the fusion cast explosive slurry with different temperatures on the leveling surface with different temperatures. The fusion cast explosive levelability determinator can be used in the technical field of fusion cast explosive technical study, and has important significance on guiding the fusion cast explosive recipe design and optimization and improving the filling quality of the fusion cast explosives in warheads.

Owner:XIAN MODERN CHEM RES INST

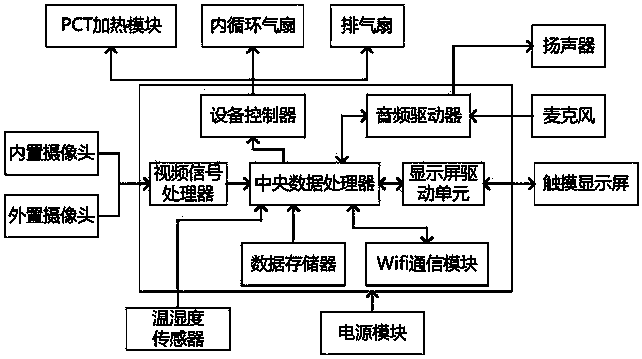

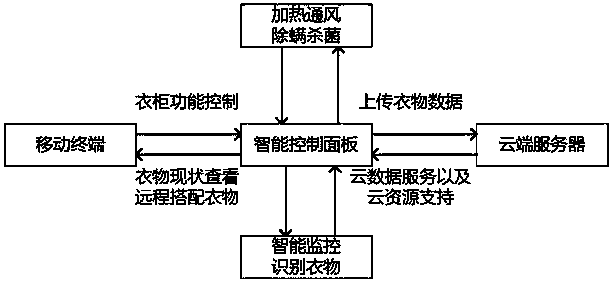

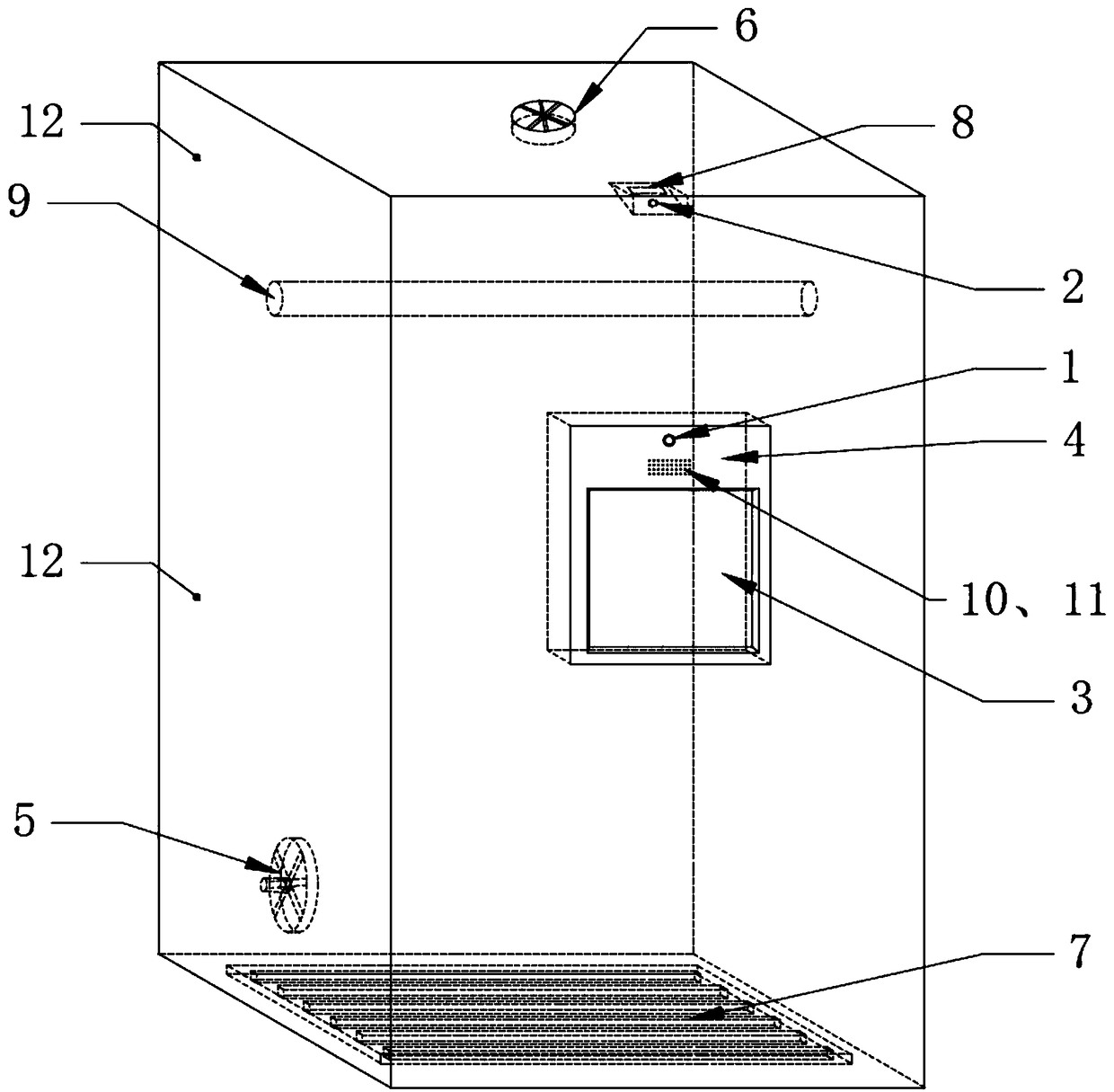

Intelligent clothing identifying and mite killing wardrobe

PendingCN108741731AWith intelligent informationRealize intelligent informatizationWardrobesCharacter and pattern recognitionHorizonThe Internet

The invention relates to the technical fields of smart home, internet of things, cloud platform and voice recognition, and specifically discloses an intelligent clothing identifying and mite killing wardrobe which comprises a wardrobe main body and a control host; an external camera, a microphone, a loudspeaker and a touch display screen are arranged outside the control host; a temperature and humidity sensing probe is arranged inside the wardrobe; a PTC heating plate is arranged at the inner bottom of the wardrobe main body; an inner circulating fan is arranged above the PTC heating plate; anexhaust fan used for communicating air inside the wardrobe with the air outside the wardrobe is arranged on the top of the wardrobe; single or multiple built-in cameras used for ensuring that a monitoring horizon covers a space contained in the wardrobe are arranged in the wardrobe; and the digital intelligent management and application of the clothing are realized through a program and an Internet. The wardrobe provided by the invention has the functions of intelligently identifying clothing and intelligently killing mites; on this basis, an intelligent virtual fitting function and an intelligent costume matching pushing function are realized through the internet and a cloud server, and various functions that the intelligent wardrobe can be connected, viewed and controlled through a mobile terminal are further realized.

Owner:王长贵

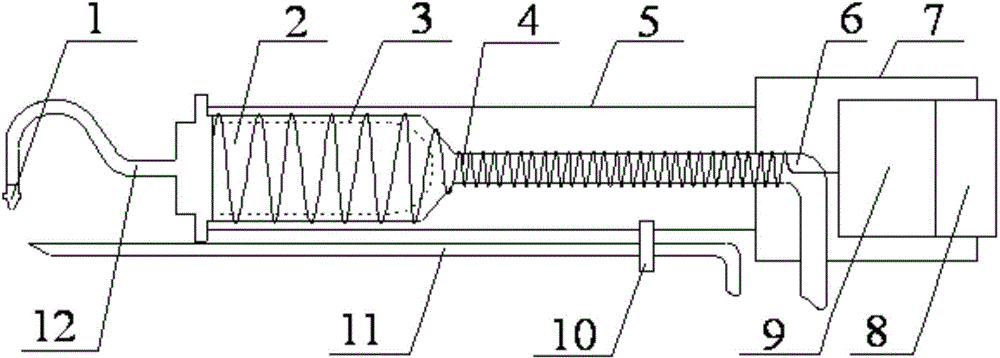

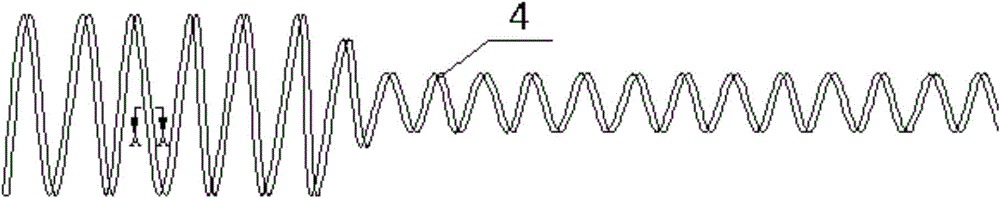

Smoke heating and sampling gun

ActiveCN104359725AAvoid wastingEasy to assemble and disassembleWithdrawing sample devicesPreparing sample for investigationTemperature controlDouble tube

The invention provides a smoke heating and sampling gun which at least comprises a smoke sampling cylinder and a heater, wherein a smoke sampling nozzle communicated with the smoke sampling cylinder is arranged at the front end of the smoke sampling cylinder; a smoke sampling pipe communicated with the smoke sampling cylinder is arranged at the rear end of the smoke sampling cylinder; a filter cartridge is arranged inside the smoke sampling cylinder; the heater is a spring heating ring in which a thermocouple is arranged; spring heating rings are tightly arranged outside the smoke sampling cylinder and the smoke sampling pipe in a sleeving manner; the spring heating rings are double-tube spring rings; one ends of the two spring rings are connected with each other to form a spring heating ring, and the other ends of the two spring rings are respectively connected with a power line to form positive and negative poles of the spring heating rings; an outer pipe is arranged outside the spring heating rings; a temperature controller and a power plug are arranged on the outer pipe; and the temperature controller is connected in series between the spring heating rings and the power plug. According to the sampling gun, the filter cartridge and the sampling pipe can be simultaneously heated, automatic heating and temperature control are realized, smooth sampling is guaranteed, the sampling result is accurate, and the sampling effect is good.

Owner:WUHAN HONGXING WEIYE ENVIRONMENTAL SCI & TECH

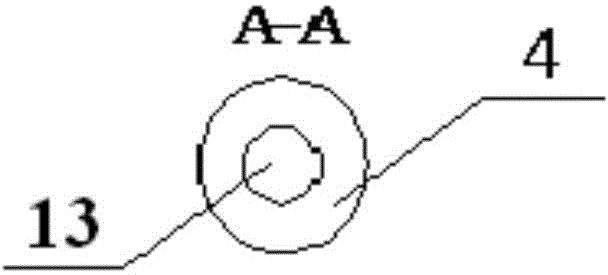

Explosion-proof strategy for battery prefabricated cabin of lithium iron phosphate energy storage power station

InactiveCN110649332AReduce concentrationExplosion-proof realizationFire rescueSecondary cells testingLithium iron phosphatePower station

The invention belongs to the field of a lithium iron phosphate energy storage power station and particularly relates to an explosion-proof strategy for a battery prefabricated cabin of the lithium iron phosphate energy storage power station. The explosion-proof strategy comprises steps that a first threshold value and a second threshold value of a combustible gas detection alarm system are set; when a detection value of the combustible gas detection alarm system reaches a first threshold value, a BMS battery management system is linked to start an explosion-proof electric fan; when the combustible gas detection alarm system reaches a second threshold value, after the BMS detects tripping of a PCS circuit breaker, the BMS closes the explosion-proof electric fan and starts a fire extinguishing system at the same time. The explosion-proof strategy is advantaged in that dual purposes of fire extinguishing and temperature control can be achieved, and explosion prevention of a lithium iron phosphate power station battery is achieved.

Owner:STATE GRID JIANGSU ECONOMIC RES INST +1

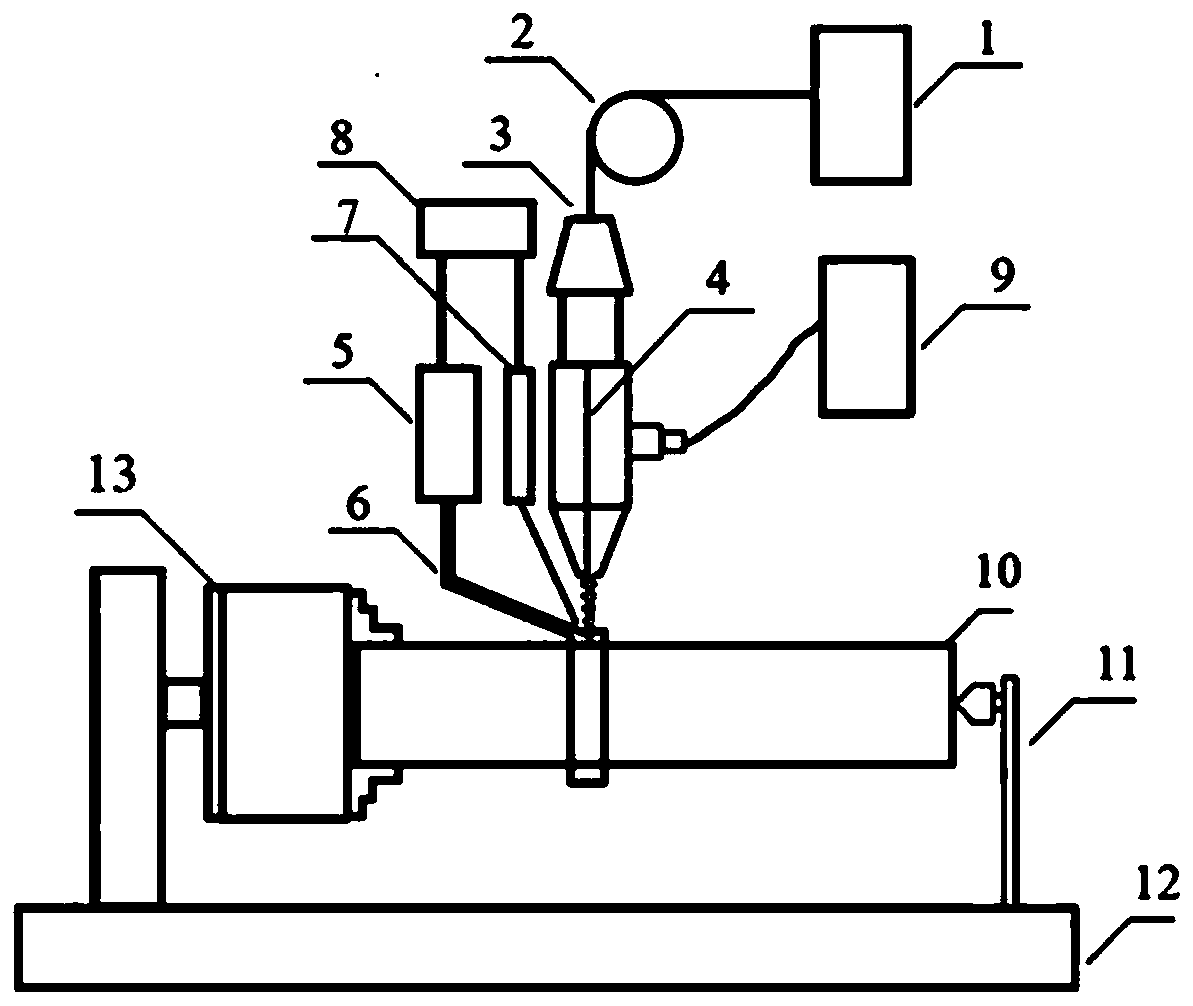

Steel surface coating, preparation method and device

PendingCN110923700AImprove wear resistanceImprove metallurgical qualityMetallic material coating processesNumerical controlCobalt

The invention relates to a steel surface coating, a preparation method and a device. The coating is prepared and obtained by iron-base alloy powder, nickel-base alloy powder, cobalt-base alloy powderor cermet composite alloy powder, and the preparation method is characterized in that an induction coil is adopted for simultaneously heating a workpiece while high-speed laser cladding is carried outso as to achieve composite processing; and the device comprises a laser, a transmission fiber, a high-speed laser cladding head, a powder feeder, a numerical control machine tool, an induction powersupply, the induction coil, an infrared thermometer, a temperature controller and the like. According to the preparation method, iron base, nickel base, cobalt base and a cermet composite cladding layer with the hardness of 68 HRC or above can be prepared, the residual stress and the cracking tendency of the cladding layer can be reduced, the problem of easy cracking when the large-area, large-thickness and high-hardness cladding layer is prepared by high-speed laser cladding is solved, the thickness of the cladding layer can reach 15 mm or above, and the cladding linear speed of the claddinglayer can reach 25 m / min to 300 m / min, and the cladding efficiency of the cladding layer can reach 300 g / min.

Owner:中山市名鼎科技节能有限公司

Temperature controllable printing device for packaging box production

ActiveCN109109477AReasonable structural designReduce labor intensityStampingElectrical and Electronics engineeringEngineering

The invention discloses a temperature controllable printing device for packaging box production. The temperature controllable printing device for packaging box production comprises two transverse rodswhich are symmetrically arranged, wherein a base is arranged between the transverse rods; first fixed blocks are arranged on the upper surfaces of the transverse rods; notches are formed in the positions, close to the lower parts of the first fixed blocks, of the upper surface of the base; a collection box is fixedly arranged below the notches; a first conveyor belt is rotatably arranged at theposition, close to one sides of the notches, of the upper surface of the base; and a second conveyor belt is rotatably connected to the position, close to the other sides of the notches, of the upper surface of the base. The temperature controllable printing device for packaging box production is reasonable in structural design, can facilitate movement of packaging boxes on the base through the first conveyer belt and the second conveyer belt, do not need manual movement, and reduces the labor intensity of workers; dust on the surfaces of the packaging boxes can be cleared away by a hairbrush ina moving process; and the cleared dust can enter the collection box.

Owner:广州市程光彩印包装有限公司

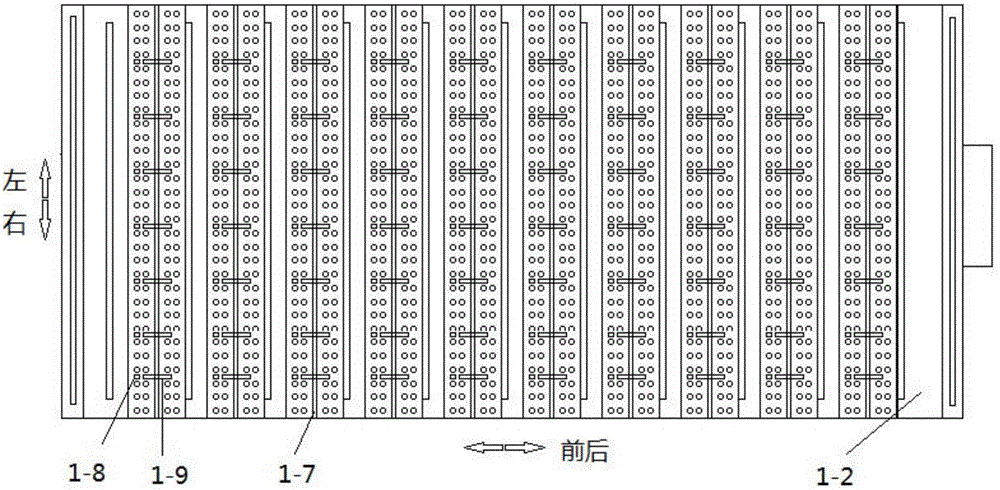

Mobile warehouse with multiple temperature zones

InactiveCN105691963AShorten delivery timeReduce loss rateRefrigerated goods vehicleLarge containersTemperature controlEngineering

The invention discloses a mobile warehouse with multiple temperature zones. The mobile warehouse comprises a carriage body framework, wherein the carriage body framework at least consists of a carriage top plate, a carriage base plate, a front side plate and a rear side plate; a plurality of transverse diaphragm plates, longitudinal diaphragm plates and bottom diaphragm plates are arranged in the carriage body framework; the carriage body framework is separated into a plurality of temperature control zones which are independent of one another by the diaphragm plates; all the temperature control areas communicate in the left-right direction; a ventilation port is formed in each temperature control area; and a ventilation valve is arranged at each ventilation port and is used for controlling the opening and the closing of the corresponding ventilation port, so that whether each temperature control zone and the adjacent temperature control zone communicate or not is controlled. According to the mobile warehouse disclosed by the invention, all the temperature control zones are used as small-sized warehouse positions and are used for respectively storing products of different types and storing goods in a classifying way according to the properties of the goods; and an internal detachable structure can be used for storing products with different sizes, so that the quality guarantee and the distribution efficiency of electric-business industry are improved.

Owner:董康辉

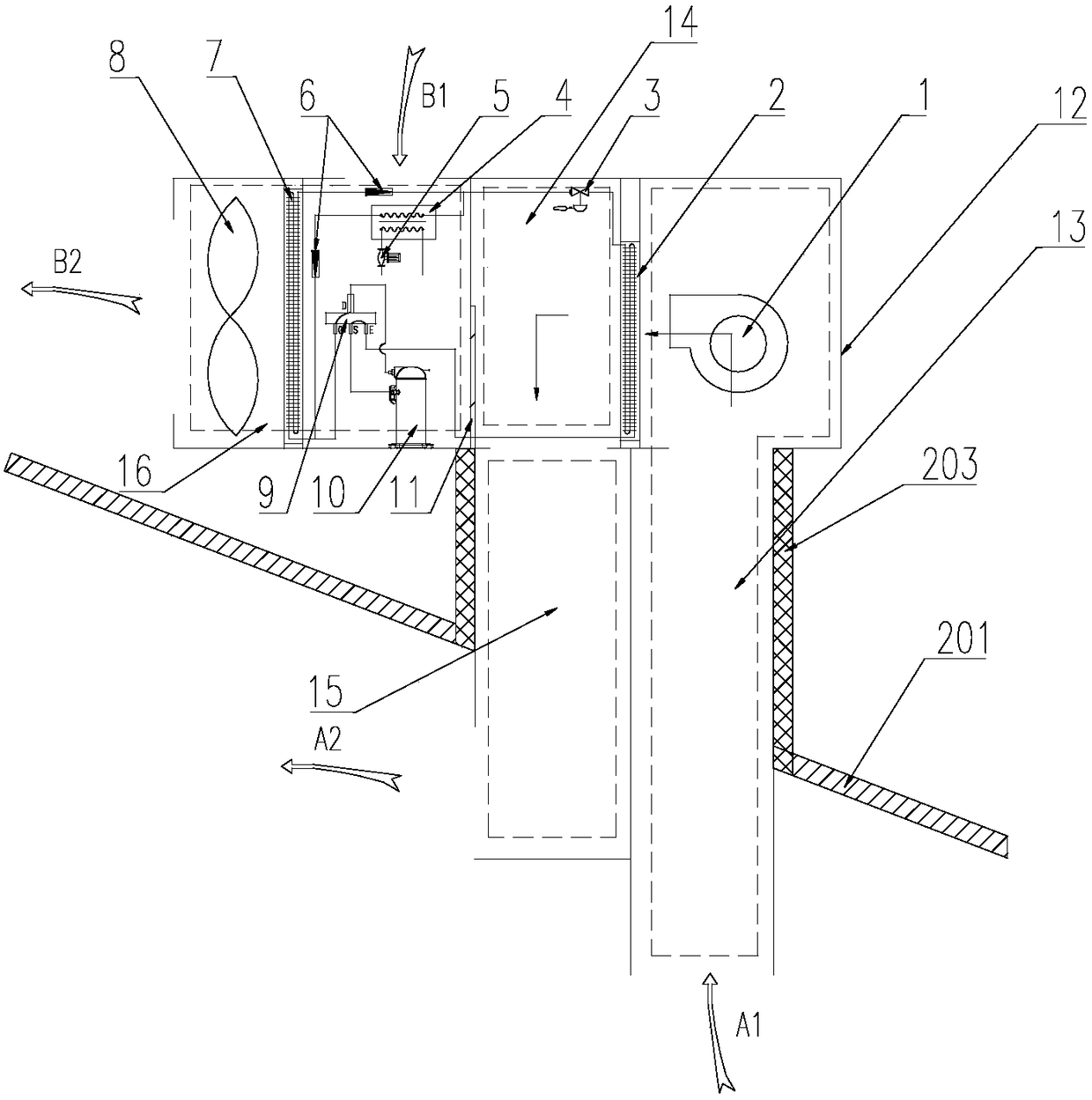

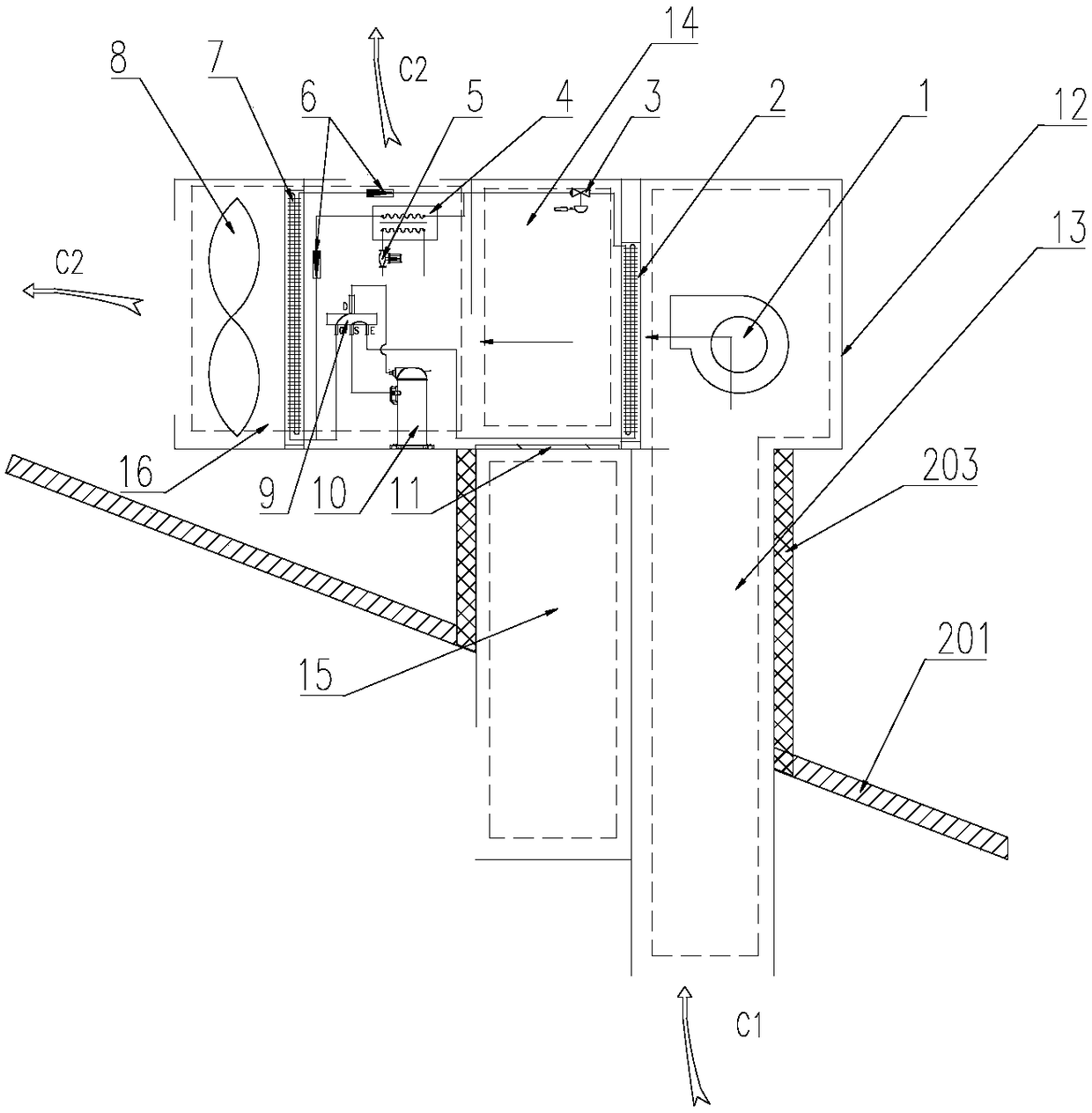

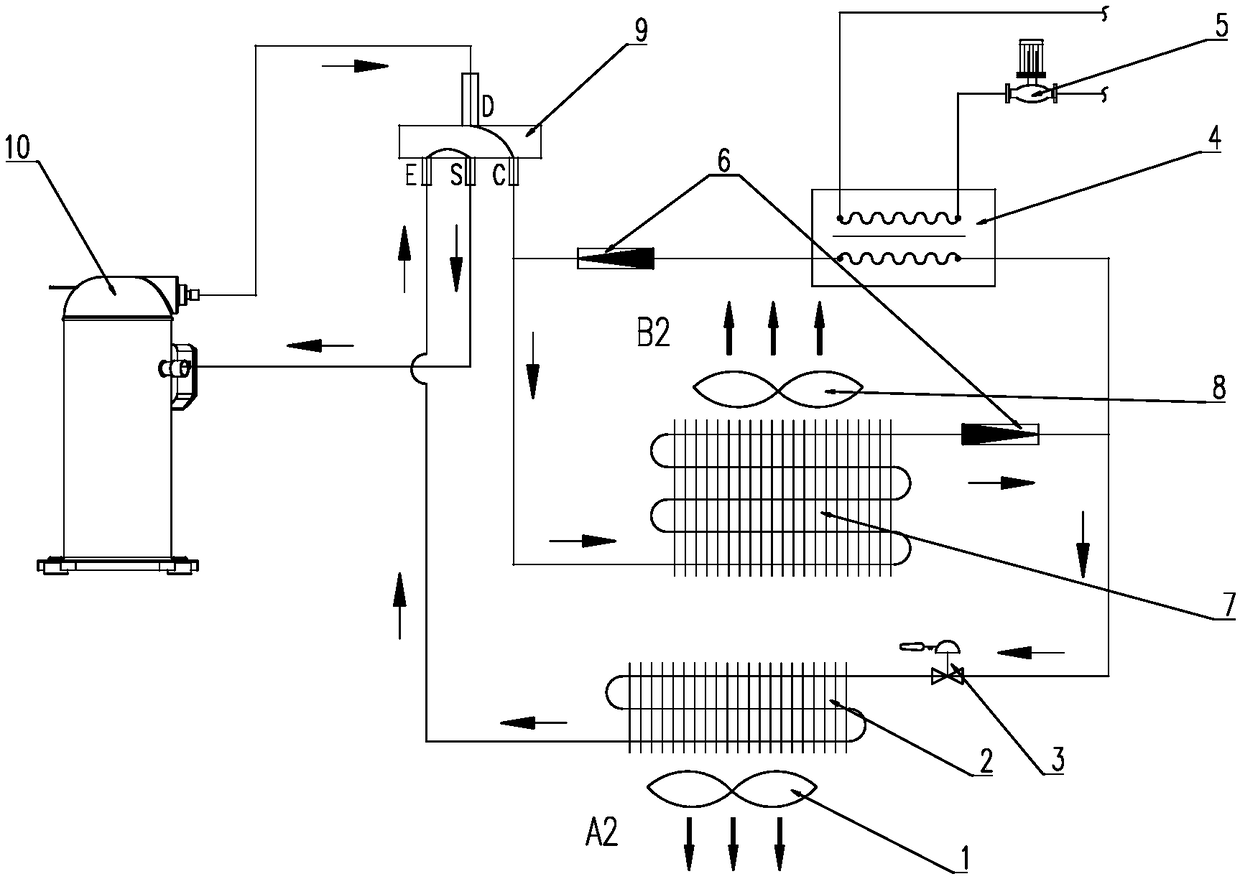

Cold recycling equipment for ultrahigh grain depot and grain storage system provided with equipment

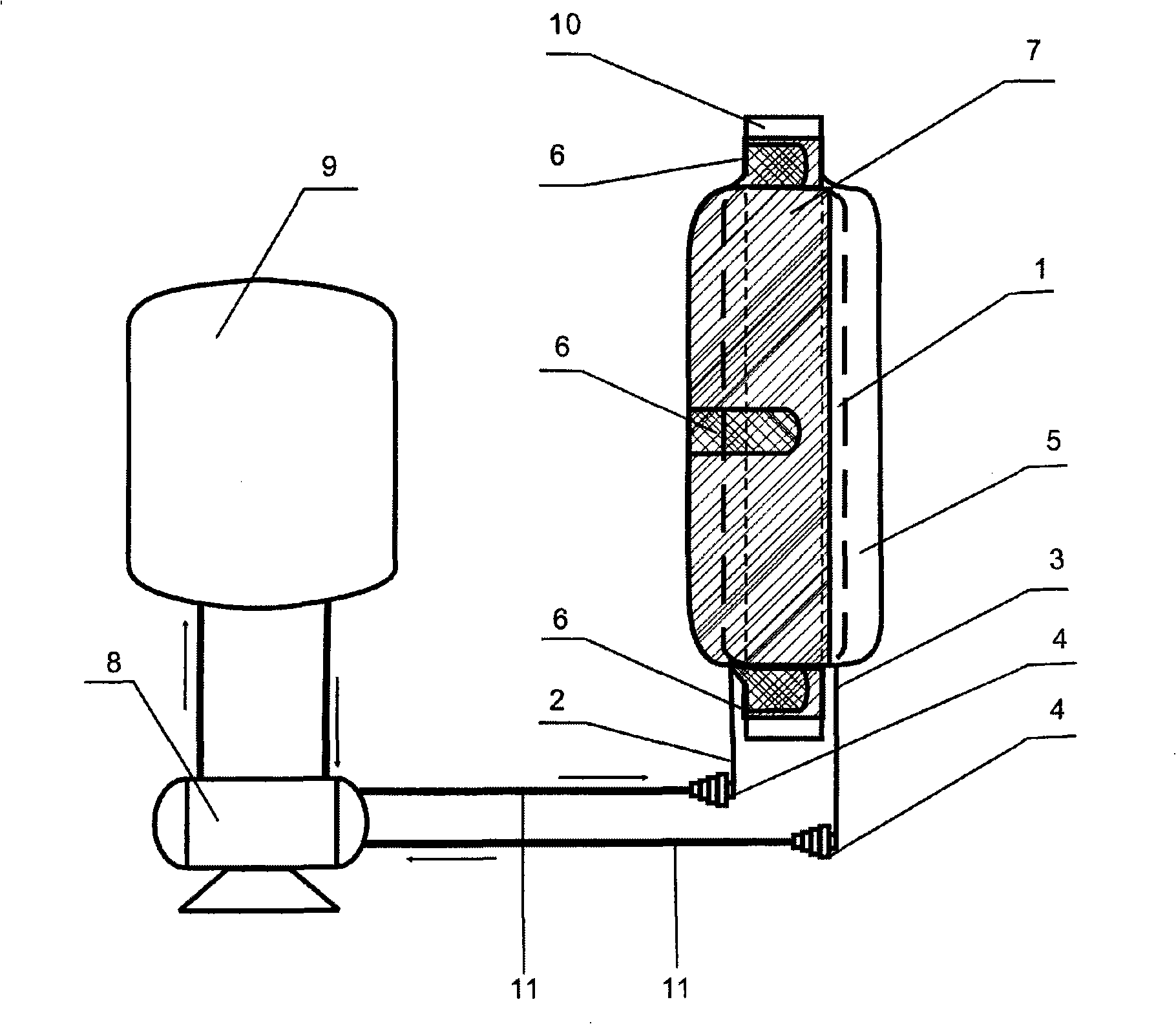

ActiveCN108507216ARealize temperature controlReduce energy consumptionMechanical apparatusFluid circulation arrangementTemperature controlSurface layer

The invention discloses cold recycling equipment for a ultrahigh grain depot and a grain storage system provided with the equipment. The cold recycling equipment comprises a shell, wherein an air return cavity, an air outlet cavity, an air feeding cavity and a condensation air cavity are formed in the shell; an evaporation blower is arranged in the air return cavity; a heat exchanger is arranged between the air return cavity and the air outlet cavity; a refrigeration system and a condensation blower are arranged in the condensation air cavity; a condenser is arranged between the refrigerationsystem and the condensation blower; an air cavity connection / disconnection mechanism is arranged between the air outlet cavity and the air feeding cavity; the air return cavity communicates with the air feeding cavity and a surface layer space of a grain stack; and the condensation air cavity communicates with an external environment. According to the cold recycling equipment for the ultrahigh grain depot disclosed by the invention, temperature control can be realized, and cooling capacity recovery also can be carried out, so that energy consumption of an all fresh air whole warehouse during cooling is effectively reduced.

Owner:CHENGDU LANGBOWANG SCI & TECH DEV

Preparation process of As2O3/Fe3O4 composite nano-particles

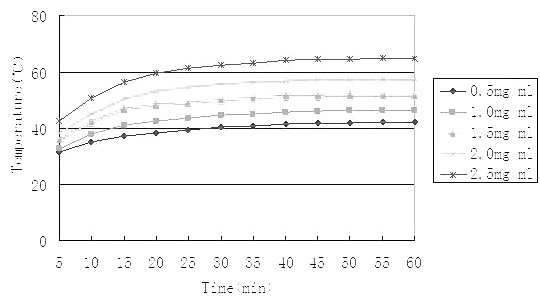

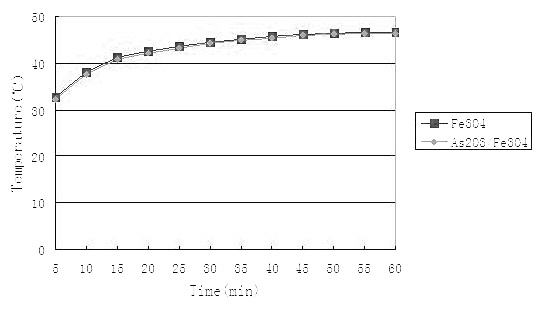

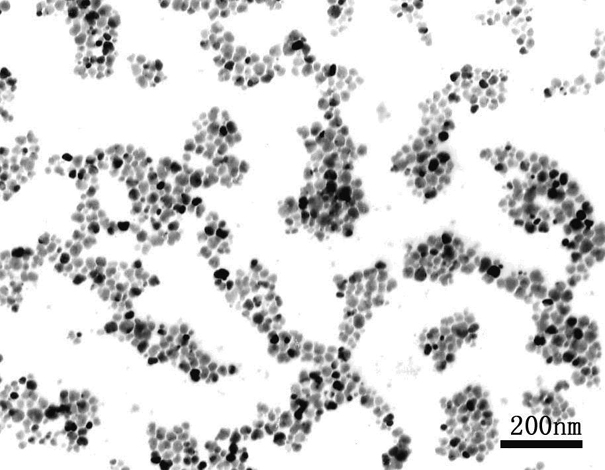

InactiveCN101966153AStrong magnetic responseSmall particle sizePowder deliveryInorganic active ingredientsWater bathsNanoparticle

The invention provides a preparation process of As2O3 / Fe3O4 composite nano-particles, which relates to a novel antitumor medicament preparation process through thermotherapy combined with chemotherapy. The preparation process comprises the following steps of: by applying a chemical coprecipitation method, mixing a FeCl3 solution and a FeCl2 solution according to the mol ratio of 5:3, dropwise adding NH4OH under N2 protection and stirring until the pH of reaction liquid is equal to 9 to generate black precipitates, curing at high temperature, washing and carrying out vacuum drying to prepare Fe3O4 magnetic nano-particles; and by adopting a dipping method, fully mixing As2O3 solutions with different concentrations and pH equal to 5 and a certain mass of Fe3O4 magnetic nano-particles under the condition of ultrasonic dispersion to prepare an As2O3 / Fe3O4 nano-composite material through the steps of settling, water bath at high temperature of 80 DEG C, centrifuging, washing, drying, and the like. The prepared As2O3 / Fe3O4 composite nano-particles have good magnetic responsiveness and temperature-rising and temperature-controlling capabilities, simultaneously have good biocompatibility and can be further used for tumor thermochemotherapy.

Owner:SOUTHEAST UNIV

Intelligent chilled livestock and poultry meat storing and freshness-retaining device

InactiveCN108387043ADelayed phase transitionReduce churnLighting and heating apparatusDomestic refrigeratorsEngineeringElectromagnetic field

The invention relates to an intelligent chilled livestock and poultry meat storing and freshness-retaining device comprising a box, a cover and a base. A circuit board, a sensing system, an electromagnetic field, a probe, a refrigerating system, a damping system, a heat insulation system and a defrosting system are arranged inside the intelligent chilled livestock and poultry meat storing and freshness-retaining device.

Owner:SHANDONG INST OF COMMERCE & TECH

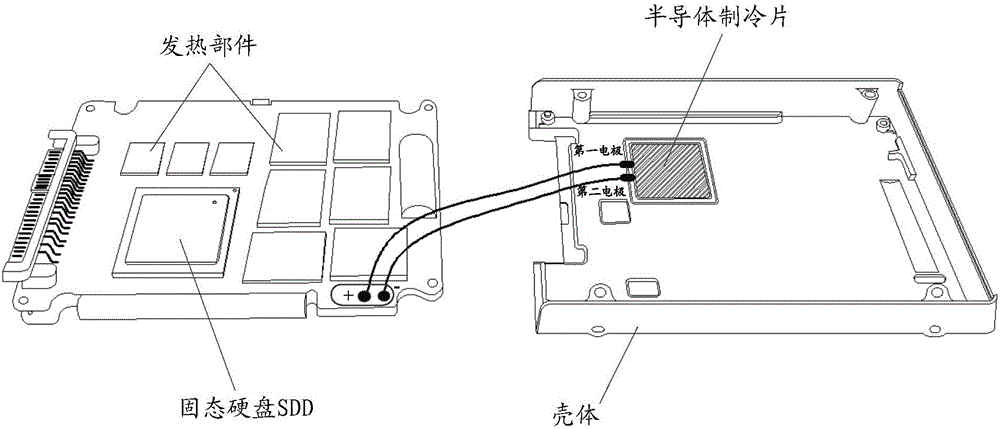

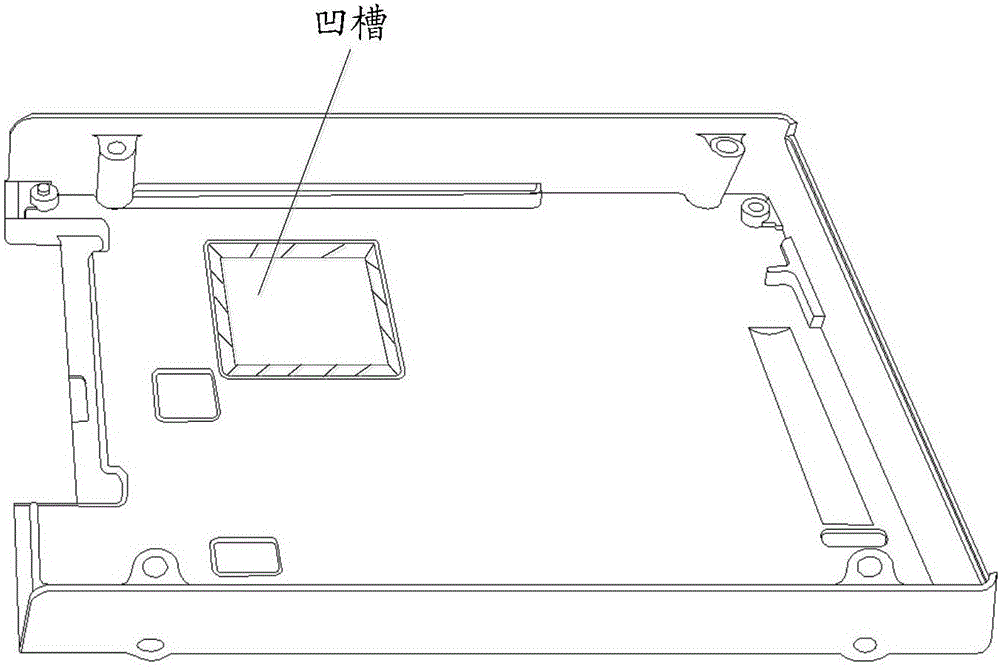

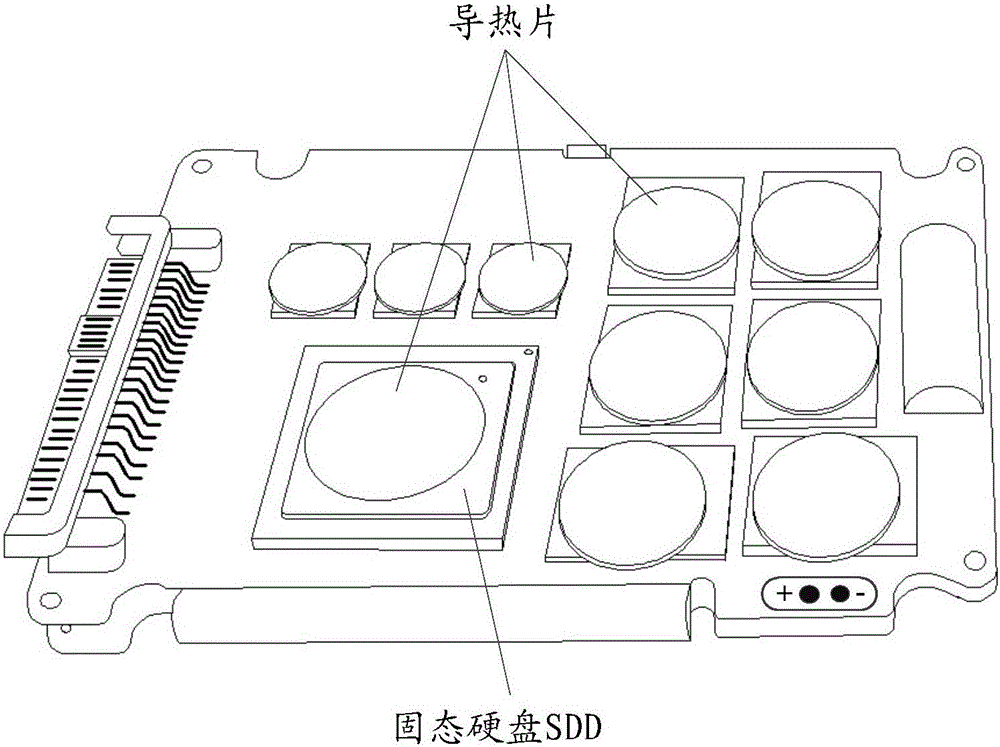

Adjustment device and electronic equipment

ActiveCN105913867AEasy temperature adjustmentRealize temperature controlReducing temperature influence on carrierRecord information storageEngineeringRefrigeration

The invention provides an adjustment device and the electronic equipment and aims to solve a technical problem of relatively poor temperature adjustment effects of the electronic equipment on a SDD. The adjustment device comprises the solid state disk (SDD), a casing used for accommodating the SDD, and a semiconductor refrigeration slice which is connected with the SDD, is arranged between the SDD and the casing and is used for adjusting the temperature of the SDD.

Owner:LENOVO (BEIJING) LTD

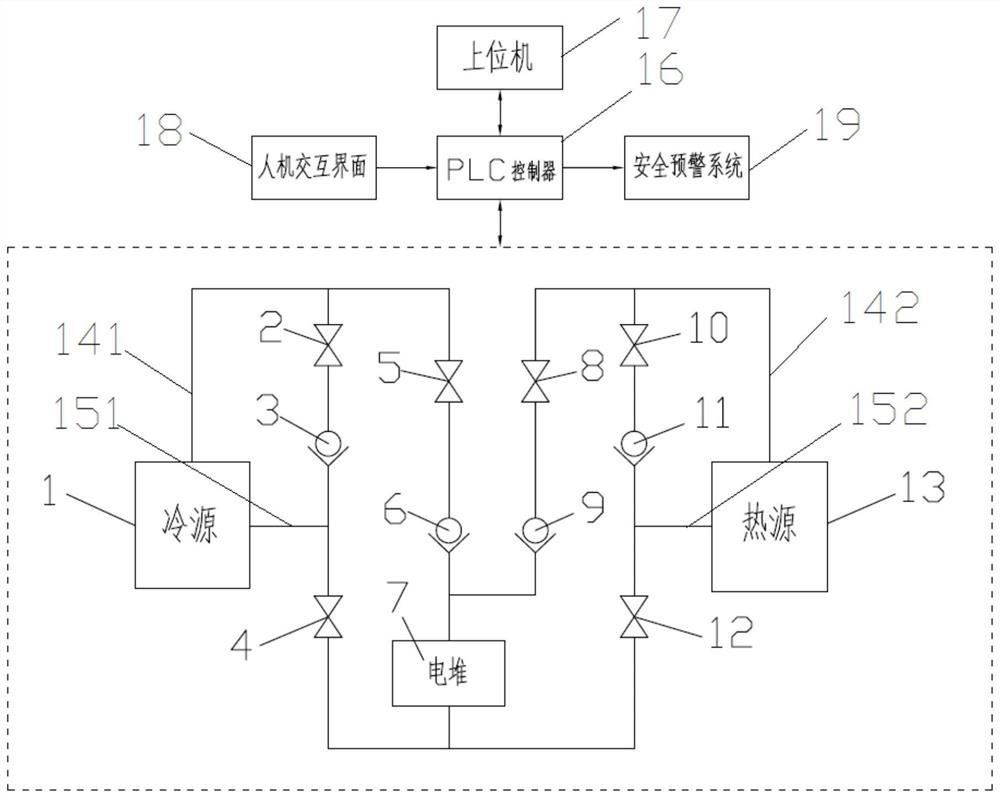

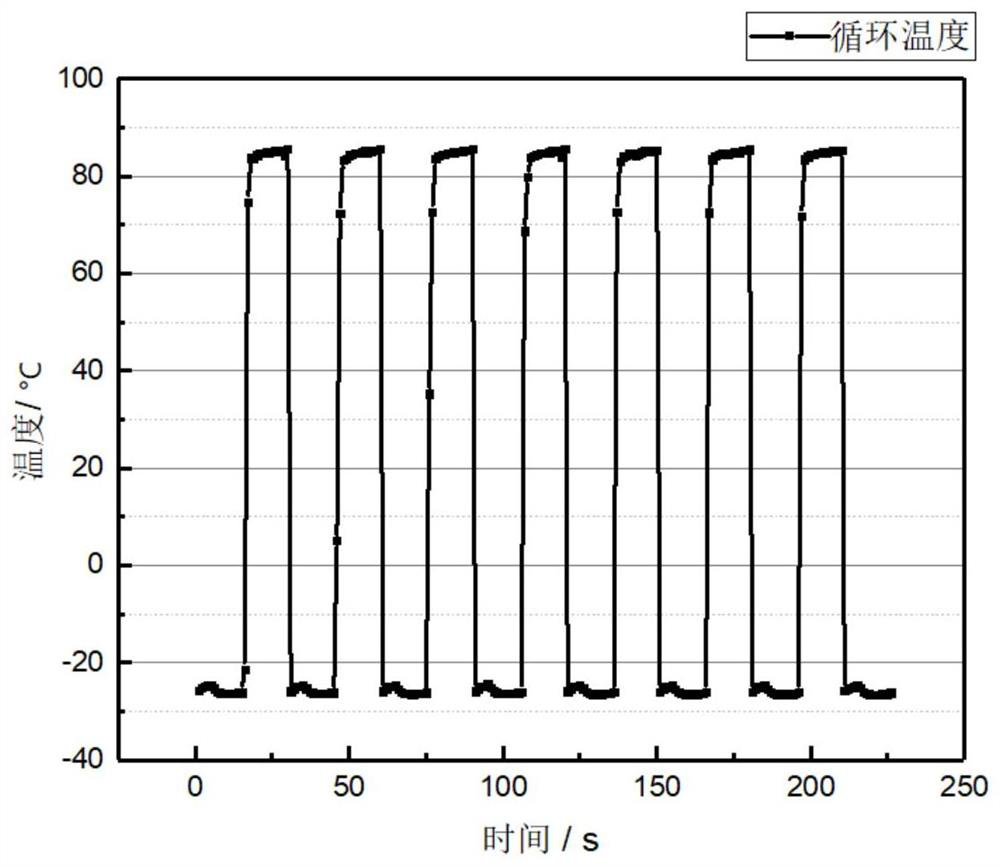

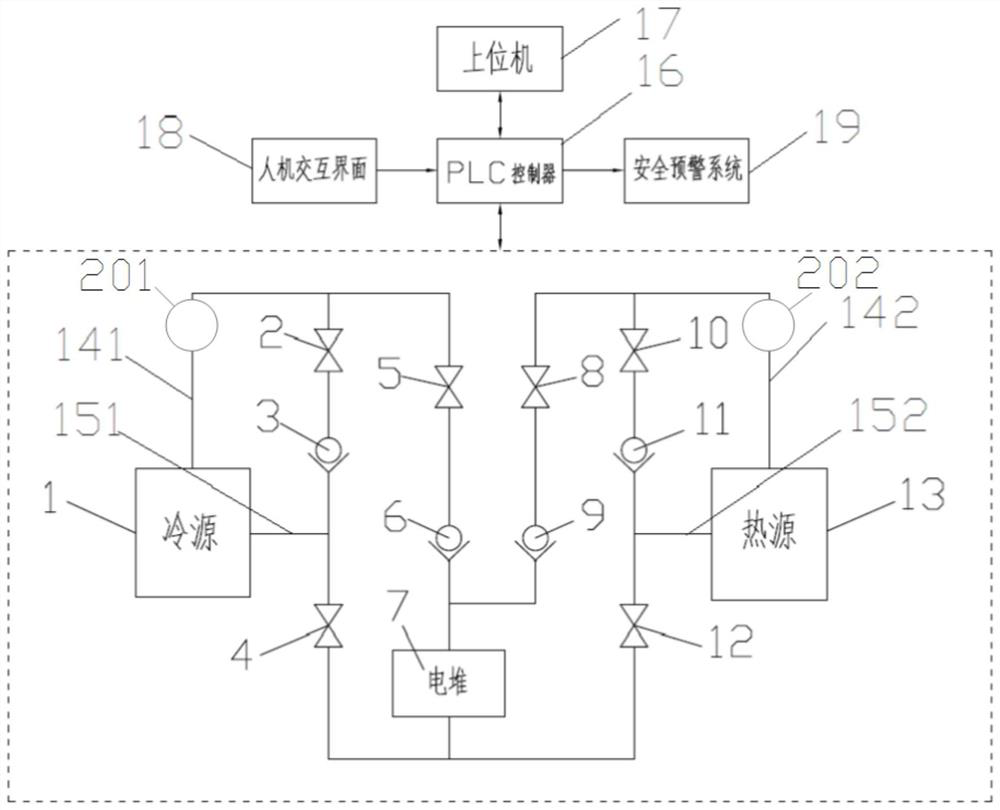

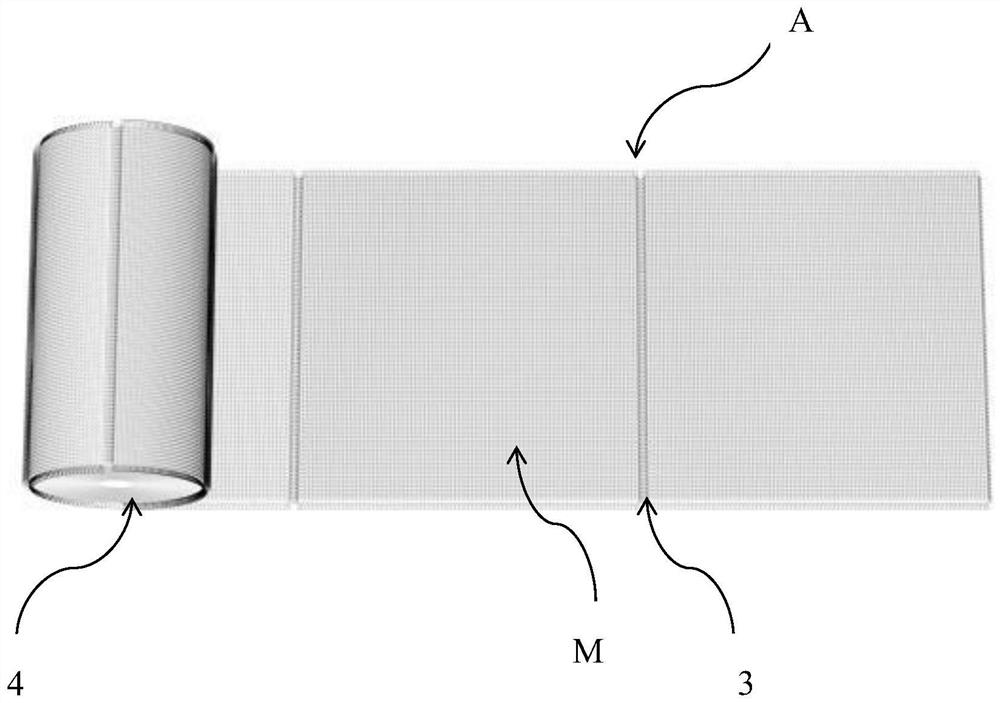

High and low temperature cycle test system for proton exchange membrane fuel cell

PendingCN113237823AQuick reviewRapid heating and cooling switchingWeather/light/corrosion resistanceElectrical testingEngineeringHeat conservation

The invention relates to a high and low temperature cycle test system for a proton exchange membrane fuel cell. The system comprises a low temperature cycle impact structure and a high temperature cycle impact structure which are mutually independent, the low-temperature circulation impact structure comprises a cold source, a cold source working channel and a cold source self-circulation channel, the cold source is communicated with the to-be-tested piece through the cold source working channel to form a low-temperature circulation impact loop, and the cold source is further communicated with the cold source self-circulation channel to form a low-temperature heat preservation adjusting loop; the high-temperature circulation impact structure comprises a heat source, a heat source working channel and a heat source self-circulation channel, the heat source is communicated with the to-be-tested piece through the heat source working channel to form a high-temperature circulation impact loop, and the heat source is further communicated with the heat source self-circulation channel to form a high-temperature heat preservation adjusting loop; and the cold source, the cold source working channel, the cold source self-circulation channel, the heat source, the heat source working channel and the heat source self-circulation channel are all connected to the controller. Compared with the prior art, heating and refrigeration switching can be rapidly carried out, and rapid evaluation of the durability of an electric pile material and key components is achieved.

Owner:TONGJI UNIV

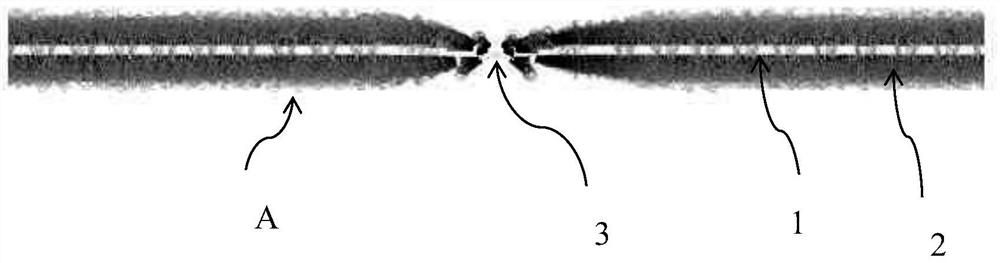

Continuous polyester fiber textile fabric capable of being torn into sheets, processing equipment and method

ActiveCN114714730ARealize temperature controlConsistent temperatureLamination ancillary operationsWeft knittingPolyesterFiber

The invention discloses continuous polyester fiber textile cloth capable of being torn into sheets, processing equipment and a processing method, an ultrasonic hot melting technology is adopted, polyester fiber textile is subjected to the action of a metal cutting die and an ultrasonic welding head, instant high frequency is generated, high temperature is generated, silk threads of a looped pile layer and a base layer are melted into one line, and a thin strip melting body capable of being torn is formed; the toughness of the base layer is ensured, and meanwhile, the effects that melting is not broken and breaking is achieved once tearing is conducted are achieved; during preparation, an ultrasonic welding head or a metal cutting die does not need to be preheated, and formation and temperature control of a linear high-temperature band are realized by utilizing the fact that the cutting die and the ultrasonic welding head get close to resonance to generate heat and get away from resonance to disappear and reduce heat, so that continuous operation can be realized, and the temperature of the cutting head is basically consistent each time; and the consistency of the thin line melts is ensured.

Owner:NINGBO XIN RUN TEXTILES LTD

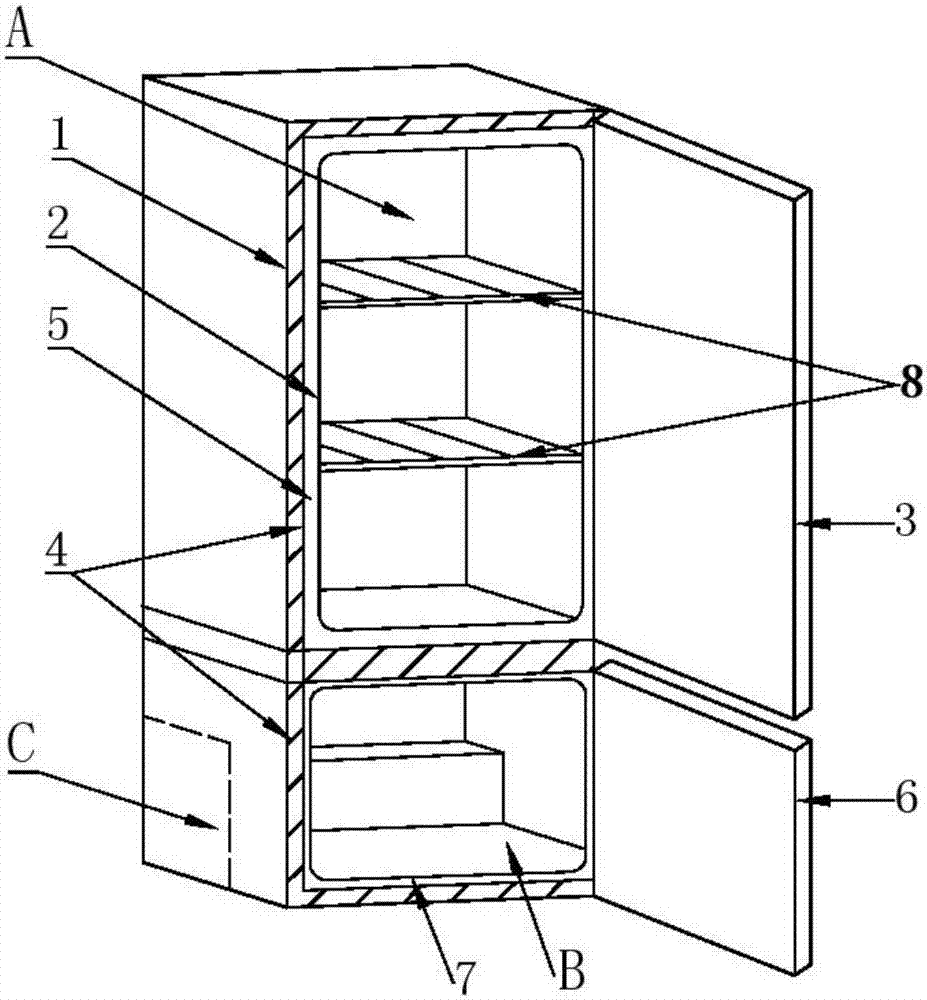

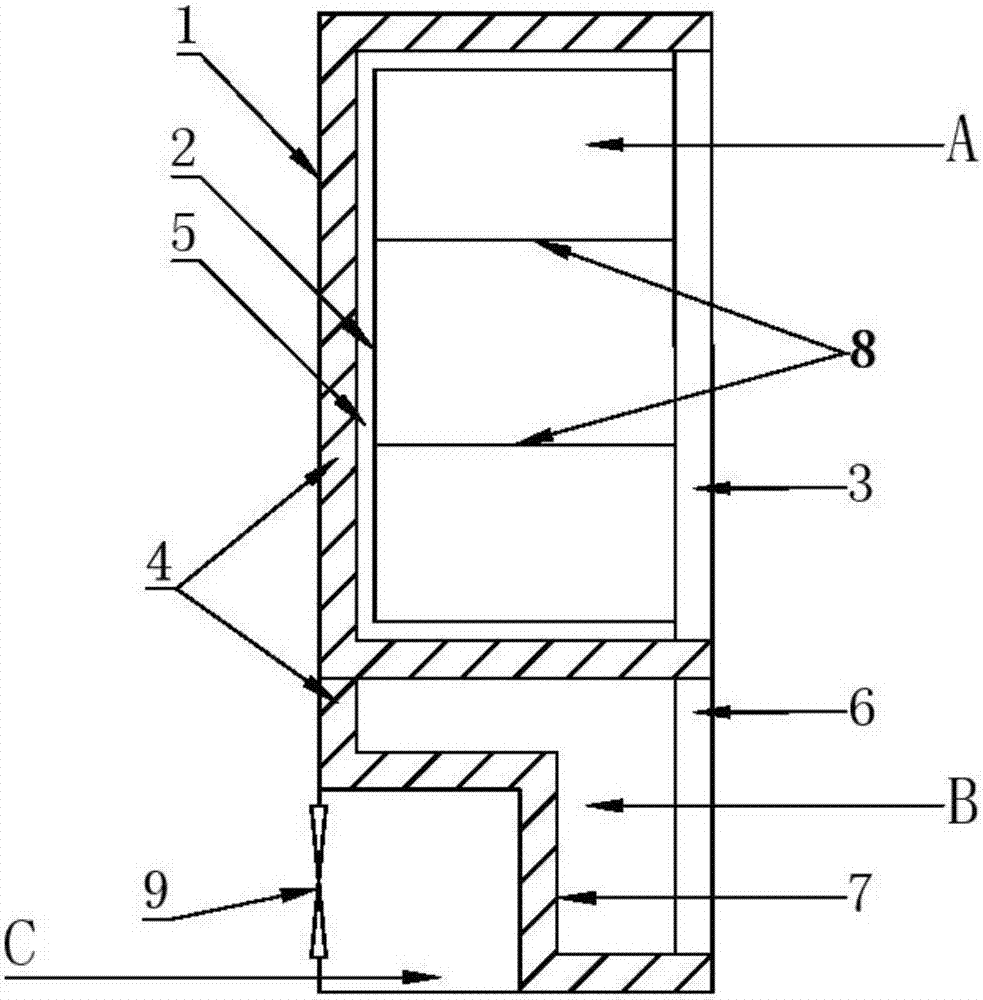

Low-temperature refrigerator

PendingCN107289705ALow failure rateEliminate vibrationLighting and heating apparatusDomestic refrigeratorsEngineeringLoop heat pipe

The invention relates to a low-temperature refrigerator comprising a refrigerator body and a refrigerating system. The refrigerator box is divided into a freezing chamber, a quick-freezing chamber and a mechanical chamber. The refrigerating system comprises a low-temperature refrigerating machine, a first heat pipe heat transfer system and a second heat pipe heat transfer system, wherein the cooling capacity prepared by the refrigerating machine is transferred to the freezing chamber and the quick-freezing chamber through the first heat pipe heat transfer system and the second heat pipe heat transfer system correspondingly. The first heat pipe heat transfer system comprises at least one loop heat pipe, a coldness guiding plate and a heat transfer module. An electric heating piece is attached to the surface of a compensation device of each loop heat pipe to control the work temperature of the compensation device. The heat transfer module has three implementation modes, specifically, according to the heat transfer module (I), at least one gravity siphon heat pipe is included, according to the heat transfer module (II), at least one channel heat pipe is included, and according to the heat transfer module (III), at least one gravity siphon heat pipe and at least one channel heat pipe are included. The second heat pipe heat transfer system comprises at least one channel heat pipe. According to the low-temperature refrigerator, oil blocking is avoided, the structure is flexible, vibration caused due to the fact that a low-temperature refrigerating machine is placed above a freezing chamber is eliminated, the control accuracy is high, and the quick-freezing chamber is arranged, so that the functions are more complete.

Owner:SHANGHAI XUNKE ENERGY SAVING TECH CO LTD

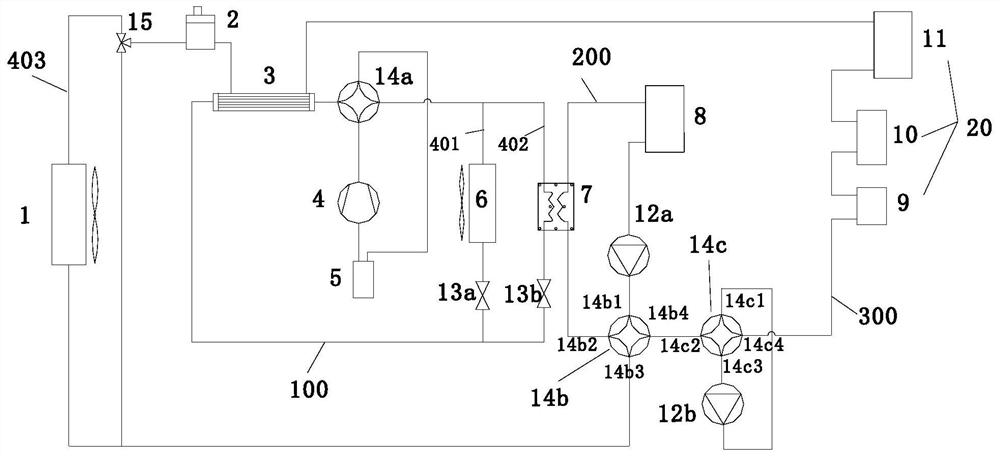

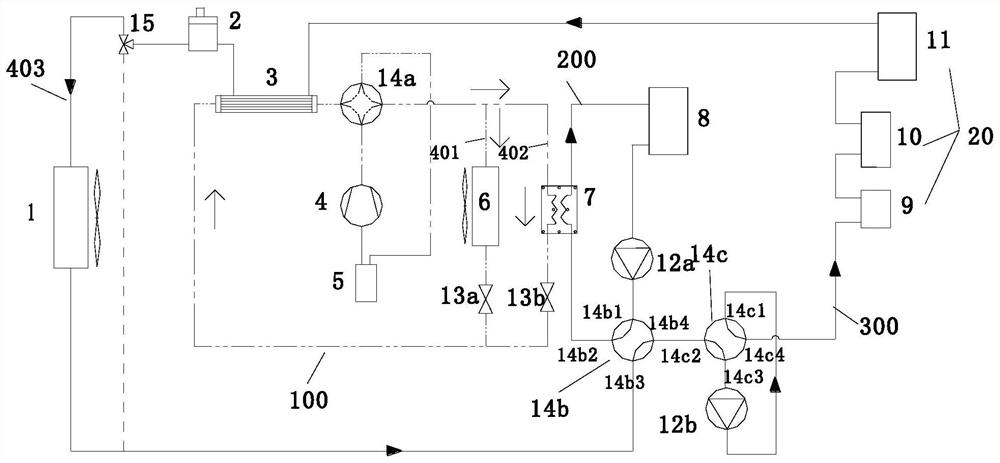

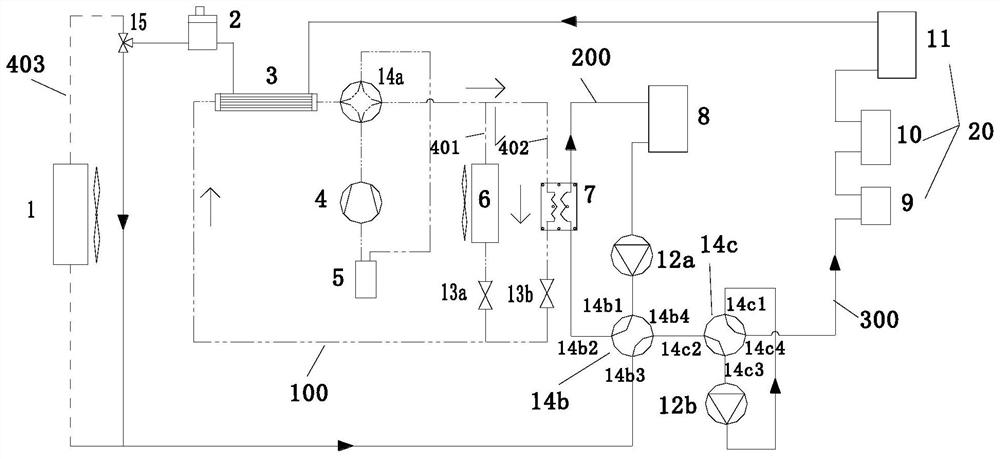

Heat management system, control method and electric vehicle

PendingCN112046237AHigh temperature control accuracyHigh speedAir-treating devicesCell temperature controlHeat managementElectrical battery

The invention provides a heat management system, a control method and an electric vehicle. The heat management system comprises a heat pump circulation pipeline, a battery circulation pipeline and a motor circulation pipeline; a compressor, a first heat exchanger, a second heat exchanger and a battery heat exchanger are arranged on the heat pump circulation pipeline, and the interior of the vehicle or the interior of the room can be heated or refrigerated through the second heat exchanger; part of the battery heat exchanger is further arranged on the battery circulation pipeline so that the heat pump circulation pipeline and the battery circulation pipeline can conduct heat exchange at the battery heat exchanger; and part of the first heat exchanger is further arranged on the motor circulation pipeline so that the heat pump circulation pipeline and the motor circulation pipeline can conduct heat exchange at the battery heat exchanger. According to the heat management system, the control method and the electric vehicle, the heat pump circulation pipeline, the battery circulation pipeline and the motor circulation pipeline are effectively combined, so that the working temperatures ofthe battery system and the motor system are kept within a reasonable range, the heat management of the whole vehicle is realized, and the energy utilization rate of the electric vehicle is improved.

Owner:GREE ELECTRIC APPLIANCES INC

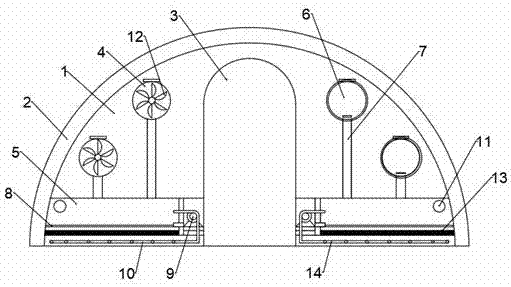

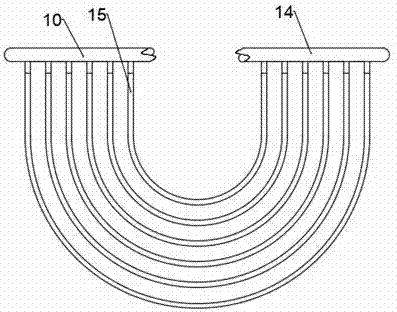

Ventilation heating device of vegetable cultivation greenhouse

InactiveCN107466734AEasy to passKeep the growing environment under controlClimate change adaptationGreenhouse cultivationTemperature controlGreenhouse

The invention discloses a ventilation heating device of a vegetable cultivation greenhouse. The device includes a semi-circular outer framework provided with an airbag edge, the bottom of the outer framework is provided with a heating cavity, the middle of the outer framework is provided with an openable door, two venting holes are formed in the two sides of the openable door and internally provided with fans, and the bottoms of the venting holes are connected with inner connecting pipes; one end of each inner connecting pipe is connected with the heating cavity formed on the bottom of the outer framework, a heat preservation bottom plate is arranged on the bottom of the interior of each heating cavity, and the top of each heat preservation bottom plate is provided with an electric heating plate; one side of each heating cavity is connected with one micro water pump through a pipeline, the two micro water pumps are connected with a branched pipe A and a branched pipe B through the pipeline to achieve separated-type temperature control ventilation in the greenhouse respectively, and through a terrestrial heating mode, much quicker and stabler control over temperature is effectively achieved.

Owner:安顺市平坝区银河特色种植专业合作社

Dismountable type constant temperature sleeve

InactiveCN101301536AAvoid duplication of wasteUniform temperature fieldHeating or cooling apparatusBiological testingTemperature controlEngineering

The invention discloses a detachable constant temperature sleeve, characterized by comprising a circular temperature-controlling jacket and a temperature-preserving coat, the circular temperature-controlling jacket is made of two layers of PVC plastic films, the interior forms, by means of thermal sealing, an access for circulation of a medium, and surrounding is thermally sealed, meanwhile, an input end is thermally sealed with an input pipe of a connector assembly and an output end is thermally sealed with an output pipe of the connector assembly; the temperature-preserving coat is made of temperature-preserving materials and has longer length and width than those of a circular water jacket which is covered within the temperature-preserving coat, the surface of the outer layer of the temperature-preserving coat is fixedly connected with a fastening tape. On account of usage of PVC plastic and general temperature-preserving materials, the cost is reduced; the fastening tape is designed to be convenient in detachment, and the invention meets the requirements of chromatographic posts with diverse forms of heights and lengths, in contrast to the current low temperature cold chamber or low temperature chromatographic cabinet, the invention is in no need of designated maintenance and is able to lessen consumption of the energy in the meantime.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

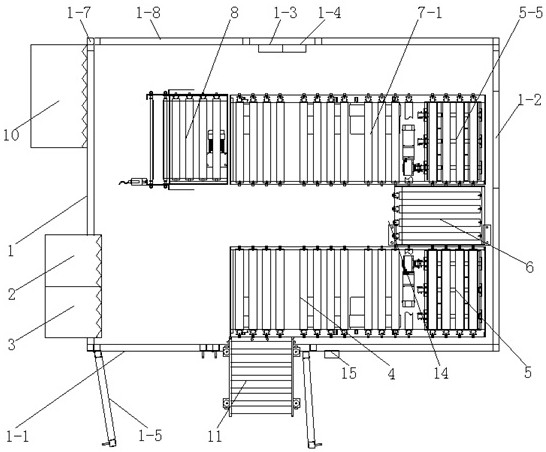

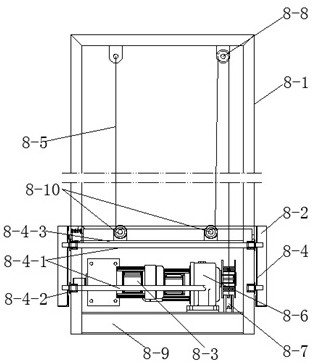

Automatic food fermentation chamber

PendingCN111602694ARealize temperature controlRealize humidity controlMeasurement devicesLifting framesTemperature controlEngineering

The invention discloses an automatic food fermentation chamber. The fermentation chamber is provided with an input port and an output port; a constant temperature machine, a moisturizing machine, a temperature sensor and a humidity sensor are arranged in the fermentation chamber; a conveyor is installed in the fermentation chamber, the upstream of the conveyor is located at the input port, and thedownstream of the conveyor is provided with a steering conveyor I, a transition conveyor, a steering conveyor II, a double-layer conveyor and a lifting conveyor sequentially; and the downstream of anupper-layer conveyor of the double-layer conveyor is located at the output port. According to the technical scheme, the functions of temperature control, humidity control and time telling of the fermentation chamber can be achieved, the functions of automatic conveying, stacking and outputting of the food fermentation boxes can be achieved, and therefore, the whole fermentation process is high inautomation degree, clean and sanitary.

Owner:XINXIANG ZHEN YING MACHINERY EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com