Preparation method of flexible low-working voltage polyaniline electrochromic emissivity film

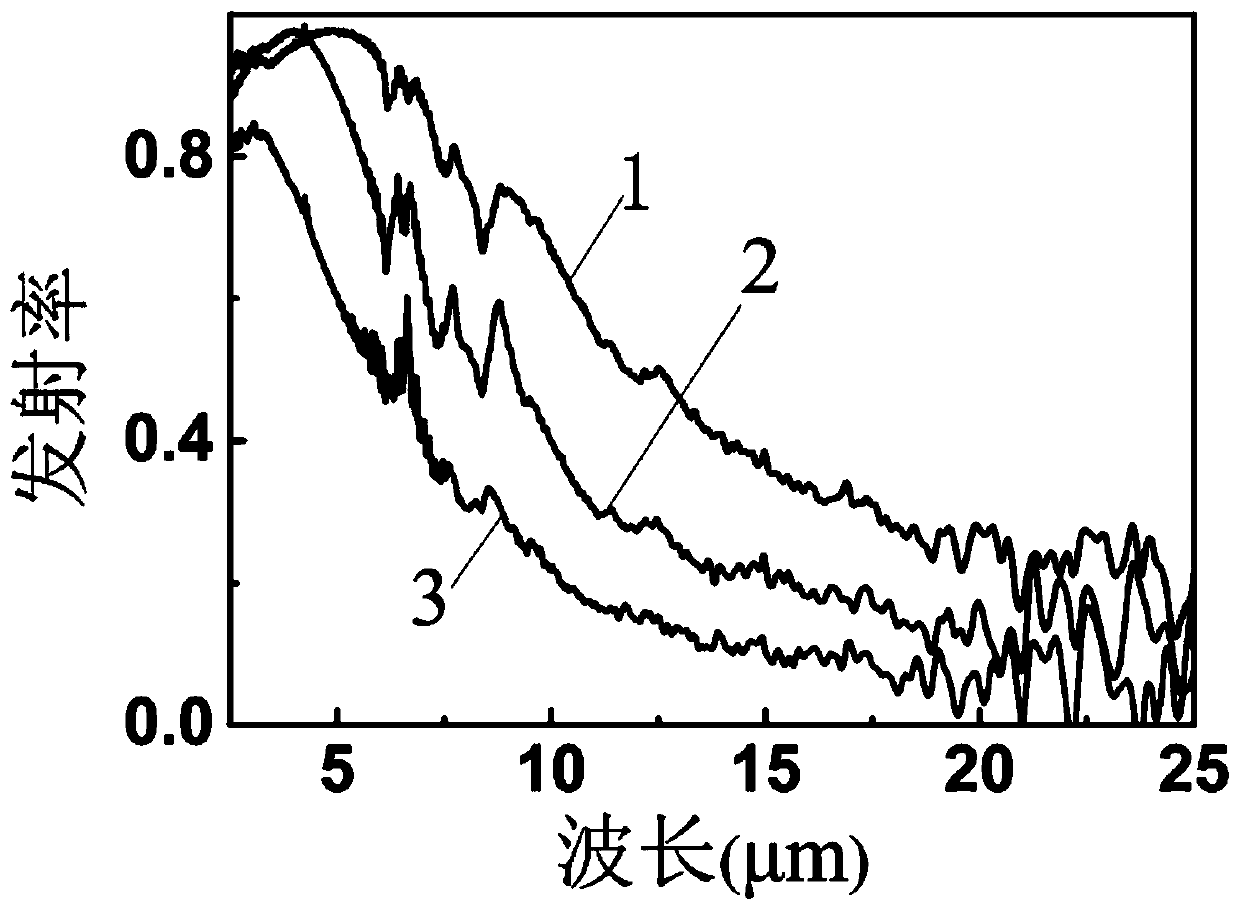

A technology of polyaniline film and working voltage, applied in the direction of electrolytic organic material coating, etc., can solve the problems of high driving voltage, high cost, complicated preparation process, etc., and achieve the effect of high infrared radiation, high reflection, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

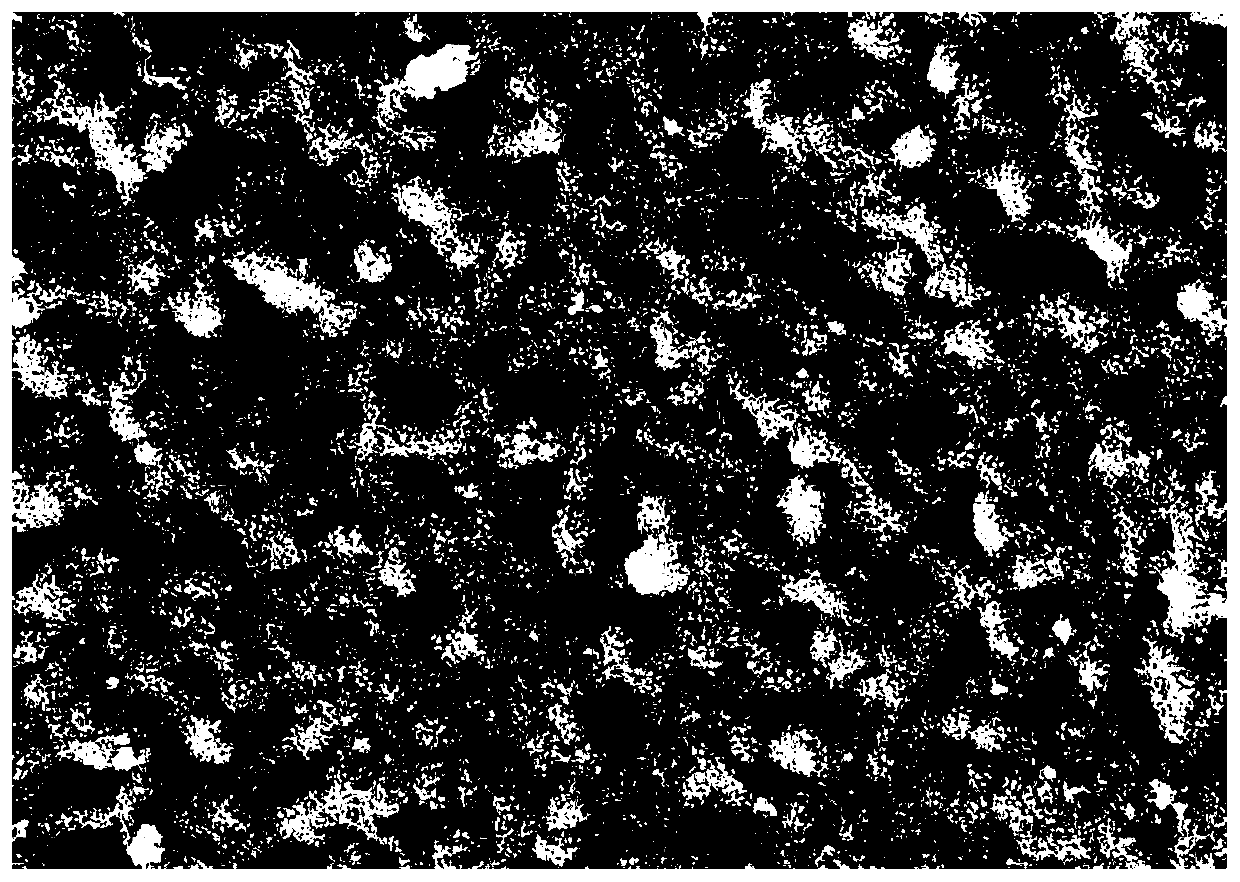

[0021] Embodiment 1: This embodiment is a method for preparing a flexible low-voltage polyaniline electrovariable emissivity film, which is completed according to the following steps:

[0022] 1. Preparation of polymer solution:

[0023] At room temperature, dissolving sulfuric acid into deionized water, then adding aniline, and then stirring to obtain a polymer solution;

[0024] The mol ratio of sulfuric acid and aniline in the polymer solution described in step 1 is (1~5):1;

[0025] The volume ratio of the amount of aniline in the polymer solution described in step 1 to deionized water is (0.1mol~0.3mol):(100mL~200mL);

[0026] 2. Electrochemical deposition:

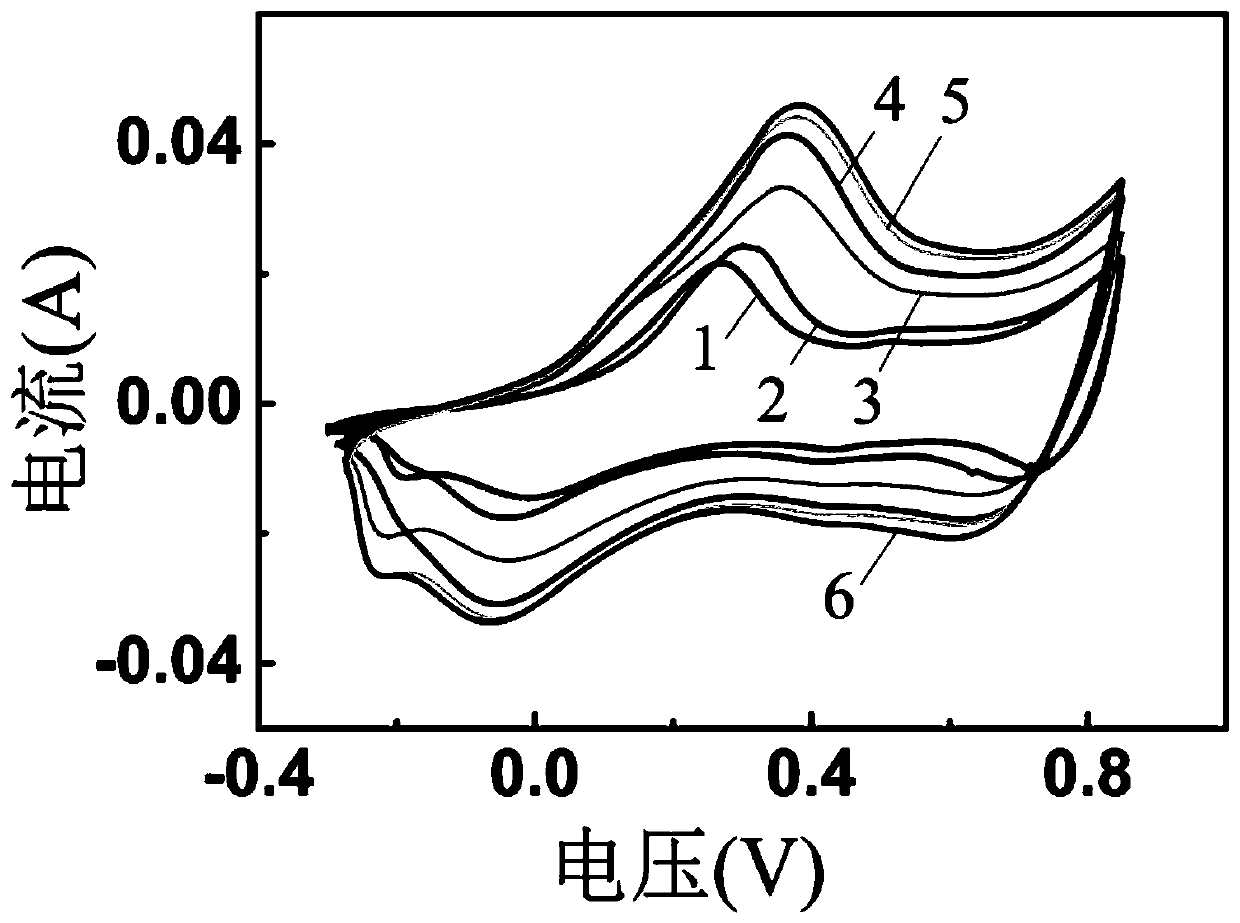

[0027] With the silver / silver chloride electrode as the reference electrode, the platinum electrode as the counter electrode, the gold-plated porous membrane or ITO as the working electrode, and the polymer solution obtained in step 1 as the electrolyte, the CHI660E electrochemical workstation was used to measure t...

specific Embodiment approach 2

[0034] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass fraction of sulfuric acid described in step 1 is 80%-98%. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the stirring speed in step 1 is 500r / min-1000r / min, and the stirring time is 30min-35min. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com