High and low temperature cycle test system for proton exchange membrane fuel cell

A high-low temperature cycle, proton exchange membrane technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring electricity, analyzing materials, etc., can solve the problems of inability to achieve high and low temperature fast switching, low impact frequency, etc., to achieve configuration Variety of schemes, durability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

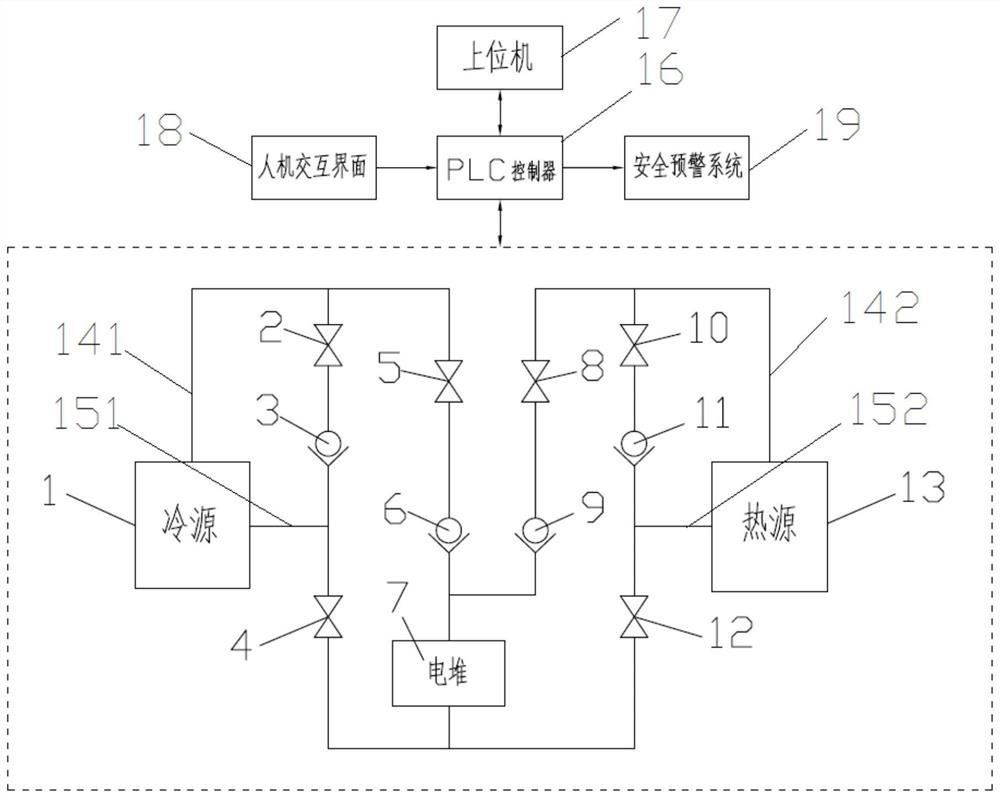

[0033] Such as figure 1 As shown, this embodiment provides a proton exchange membrane fuel cell high and low temperature cycle test system, which includes a low temperature cycle impact structure and a high temperature cycle impact structure that are independent of each other;

[0034] The low-temperature cycle impact structure includes a cold source 1, a cold source working channel, and a cold source circulation channel. The cold source 1 communicates with the object to be tested through the cold source working channel to form a low-temperature cycle impact circuit. The cold source 1 is also connected with the cold source circulation channel. Form a low temperature insulation regulation loop;

[0035] The high-temperature cycle impact structure includes a heat source 13, a heat source working channel and a heat source circulation channel. The heat source 13 communicates with the test piece through the heat source working channel to form a high-temperature cycle impact circuit...

Embodiment 2

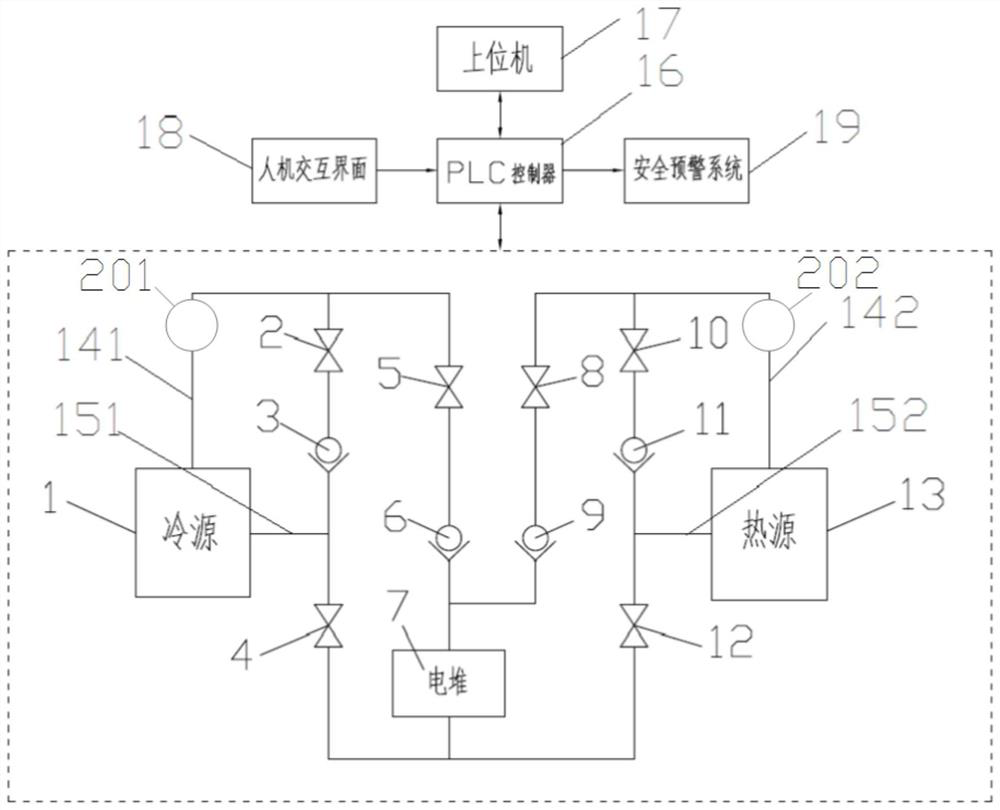

[0049] Such as image 3 As shown, this embodiment provides a proton exchange membrane fuel cell high and low temperature cycle test system, which is roughly the same as that of embodiment 1.

[0050] The difference is that in Embodiment 1, the cold source 1 contains a drive pump capable of driving the flow of circulating fluid. The heat source 13 contains a drive pump capable of driving the flow of circulating fluid. In Embodiment 2, the low-temperature cycle impact structure includes a drive pump 201, and the drive pump 201 is installed on the inlet connection channel 141 of the low-temperature cycle impact structure; the high-temperature cycle impact structure includes a drive pump 202, and the drive pump 202 is installed in the low-temperature cycle impact structure The inlet of the impact structure is connected to the channel 142 .

[0051] When the cold source 1 is working, the first solenoid valve 2 is closed, the second solenoid valve 4 and the third solenoid valve 5 ...

Embodiment 3

[0054] Such as Figure 4 As shown, this embodiment provides a proton exchange membrane fuel cell high and low temperature cycle test system, which is roughly the same as that of embodiment 1.

[0055] The difference is that the cold medium inlet and the cold medium outlet of the cold source working channel and the cold source circulation channel are respectively connected to the cold source 1 through independent inlet communication pipes and outlet communication pipes, and the heat source working channel and the heat source circulation channel are connected to the cold source 1 through independent inlet and outlet communication pipes. The heat medium inlet and the heat medium outlet are respectively connected to the heat source 13 through independent inlet communication pipes and outlet communication pipes. Specifically, such as image 3 As shown, the cold medium inlet of the cold source working channel is connected to the cold source 1 through the inlet connecting pipe 143, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com