Cold recycling equipment for ultrahigh grain depot and grain storage system provided with equipment

A technology for cold recycling and grain storage, which is applied in the direction of compressors with reversible circulation, household appliances, mechanical equipment, etc., can solve the problems of waste of cooling capacity, high energy consumption, and the temperature uniformity of ultra-high grain piles has not been effectively solved. , to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

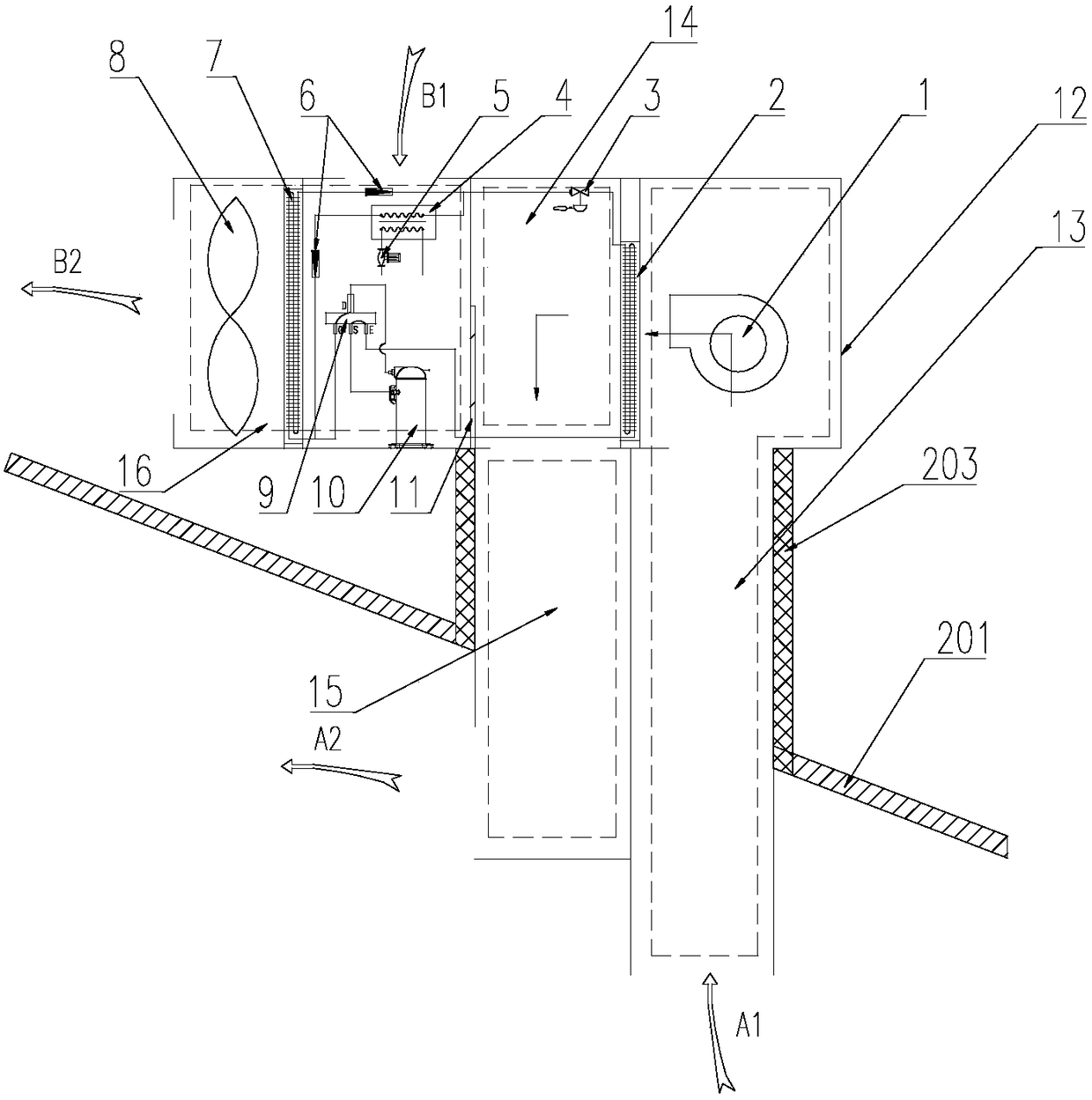

[0031] Such as figure 1 As shown, a kind of cold recovery equipment for ultra-high grain depots includes a housing 12, and the housing 12 is provided with a return air chamber 13, an air outlet chamber 14, an air supply chamber 15 and a condensation air chamber 16, and the return air chamber 13 is An evaporating fan 1 is provided, a heat exchanger 2 is provided between the return air chamber 13 and the air outlet chamber 14, a refrigeration system and a condensing fan 8 are provided in the condensing air chamber 16, and a condenser is provided between the refrigerating system and the condensing fan 8 7. An air chamber on-off mechanism 11 is set between the air outlet chamber 14 and the air supply chamber 15. The return air chamber 13 communicates with the air supply chamber 15 and the surface space of the grain pile, while the condensation air chamber 16 communicates with the external environment.

[0032] The air chamber on-off mechanism 11 has two working states. In the firs...

Embodiment 2

[0035] This embodiment is based on Embodiment 1 to further illustrate the present invention.

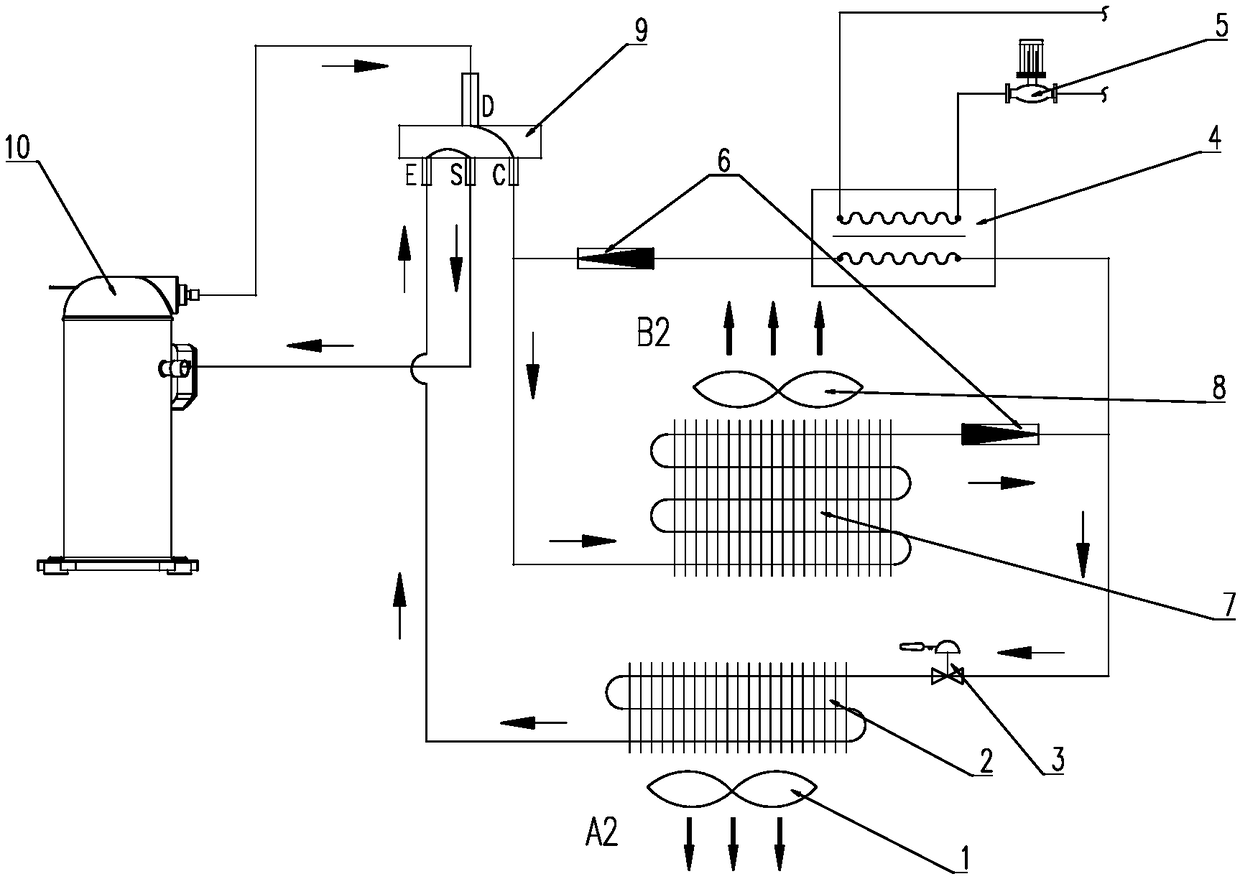

[0036] Such as figure 1 , image 3 As shown, in the temperature control mode, the air chamber on-off mechanism 11 disconnects the air outlet chamber 14 from the condensation air chamber 16, and the air outlet chamber 14 communicates with the air supply chamber 15; the high-temperature and high-pressure gaseous refrigerant is discharged by the compressor 10 Finally, it enters port D of the four-way reversing valve 9 and is connected to port C. Due to the action of the one-way valve 6, the refrigerant flows to the condenser 7. In the condenser 7, it exchanges heat with the condensed air and continues to flow to The throttling element 3 flows to the heat exchanger 2. In the heat exchanger 2, it exchanges heat with the evaporative return air A1, the temperature of the evaporative return air decreases, and becomes the low-temperature evaporative outlet air A2, which is sent in by the eva...

Embodiment 3

[0039] This embodiment is based on Embodiment 1 to further illustrate the present invention.

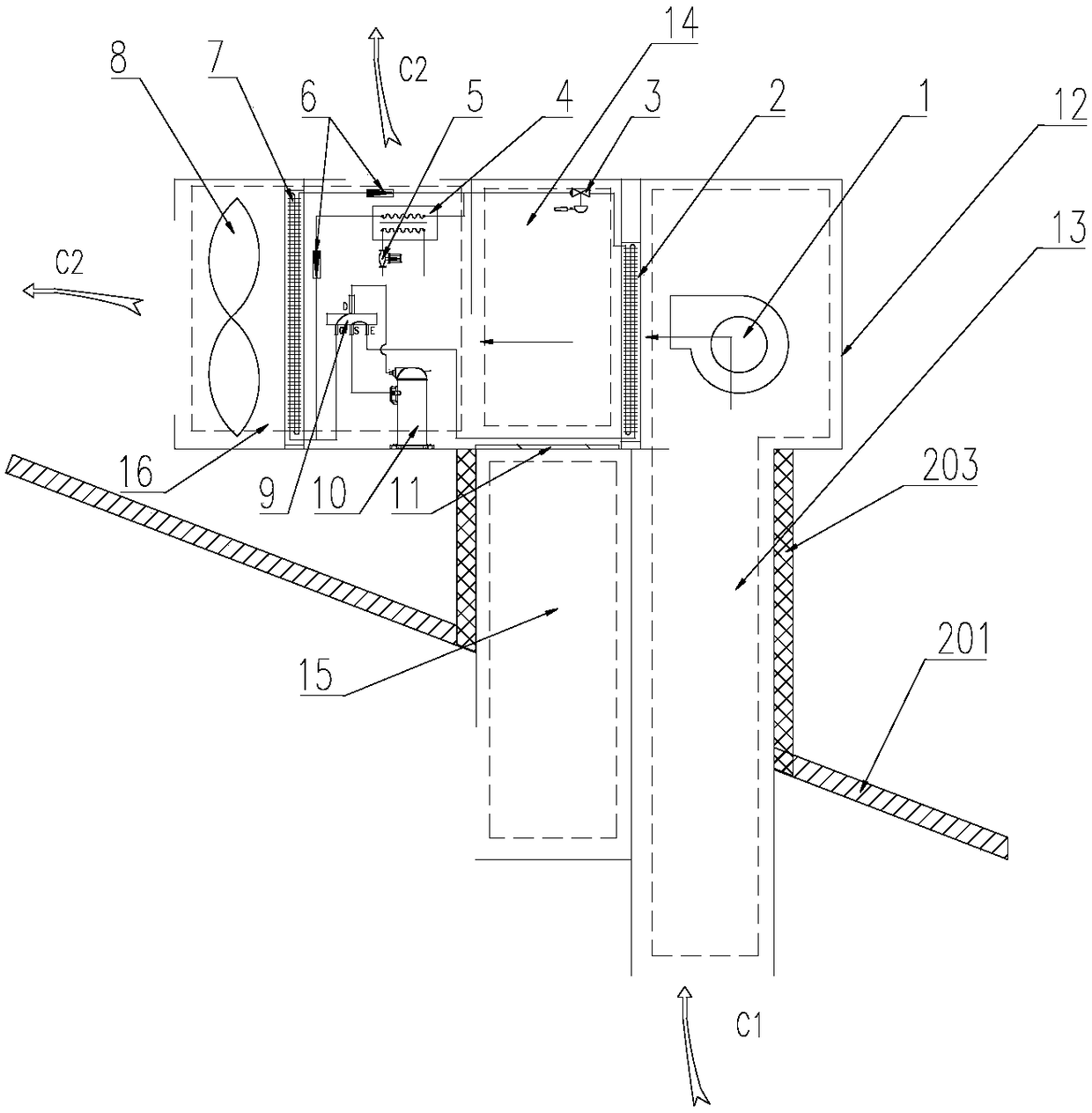

[0040] Such as figure 2 , Figure 4 As shown, in the cold recovery mode, the air chamber on-off mechanism 11 connects the air outlet chamber 14 with the condensation air chamber 16, the outlet air chamber 14 is disconnected from the air supply chamber 15, and the cold recovery air of the return air chamber 13 passes through The heat exchanger 2, after being heated by the heat exchanger 2, passes through the air outlet chamber 14, reaches the condensation air chamber 16, and is discharged into the external environment;

[0041] After the high-temperature and high-pressure gaseous refrigerant is discharged by the compressor 10, it enters the D port of the four-way reversing valve 9 and is connected to the E port. The recovered inlet air C1 is heated into cold recovered outlet air C2, and discharged into the external environment, while the refrigerant is cooled into a high-pressure l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com