Fusion cast explosive levelability determinator

A technology of melting and casting explosives and leveling, which is applied in the direction of flow characteristics, instruments, measuring devices, etc., and can solve problems such as solidification, inability to use flow time, and inability to measure the leveling of melting and casting explosives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

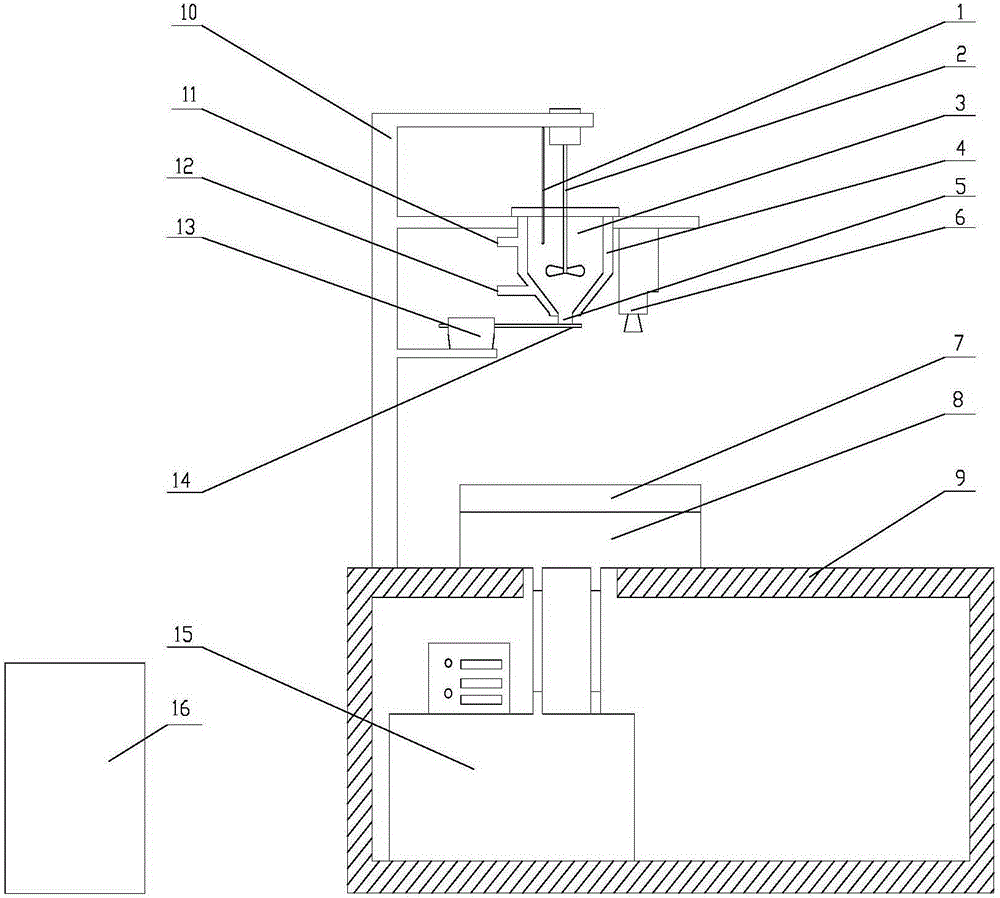

Method used

Image

Examples

Embodiment 1

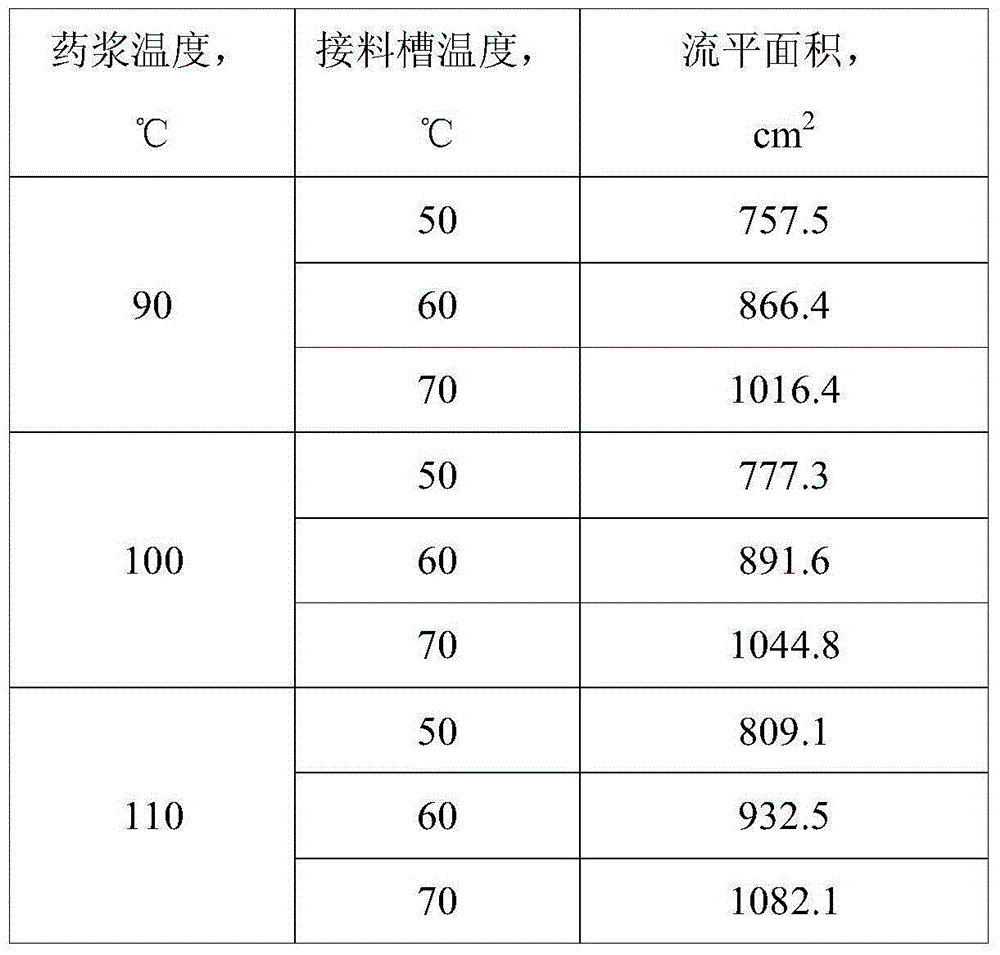

[0027] Select explosive B as the sample, pour the slurry into the slurry storage bin and adjust the temperature of the slurry to 90°C, 100°C, and 110°C respectively; Outlet, test the leveling area of the slurry, and the test results are shown in Table 1.

[0028] Table 1B Leveling test of explosives

[0029]

[0030] It can be seen from the test results that the temperature of the contact surface has a significant impact on the leveling of B explosive, and the increase of the temperature of the slurry itself has a certain effect on the improvement of the leveling.

Embodiment 2

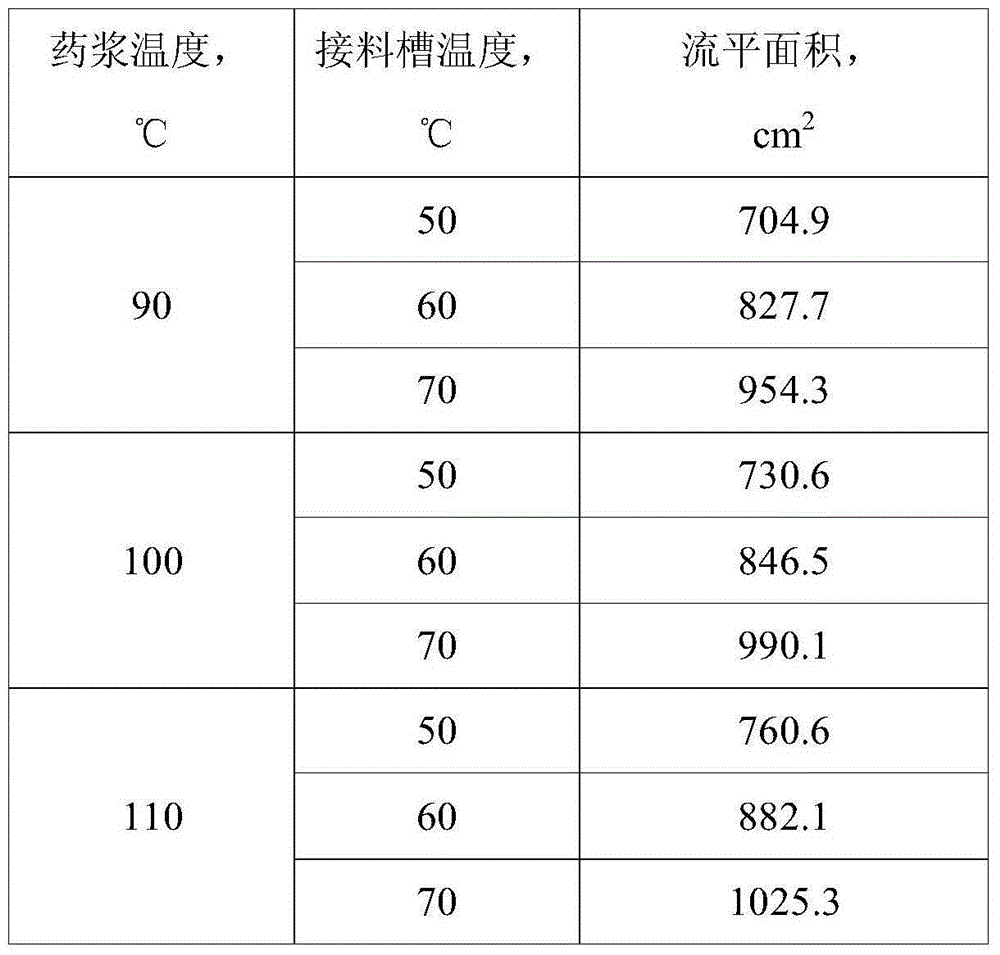

[0032] Select Octol explosive as the sample, pour the slurry into the slurry storage bin and adjust the temperature of the slurry to 90°C, 100°C, and 110°C respectively; Outlet, test the leveling area of the slurry, and the test results are shown in Table 2.

[0033] Table 2 Leveling test of Octol explosive

[0034]

[0035] It can be seen from the test results that it is more consistent with the test results of B explosive, the temperature of the contact surface has a significant impact on the leveling of Octol explosive, and the increase of the temperature of the slurry itself also has a certain effect on the improvement of leveling .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com