Temperature controllable printing device for packaging box production

A packaging and printing technology, applied in printing, stamping and other directions, can solve the problems of affecting service life, inability to dry, unreasonable design, etc., to achieve the effect of easy installation and disassembly, realization of temperature control function, and improvement of printing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

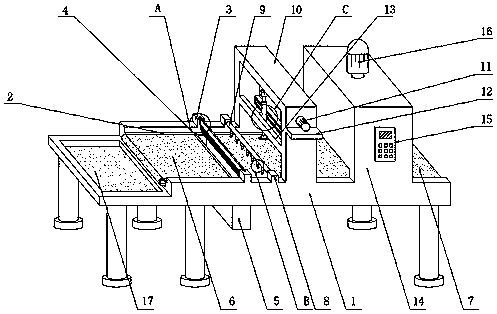

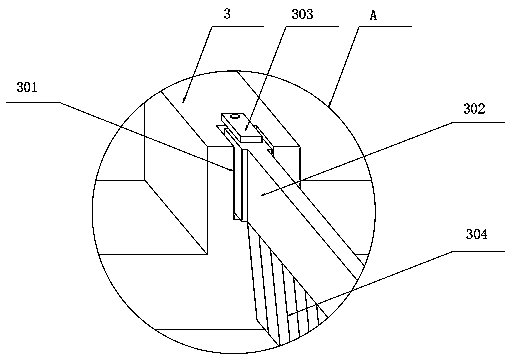

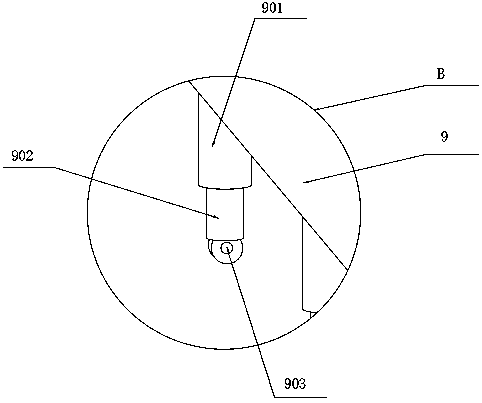

[0024] see Figure 1-7 , in an embodiment of the present invention, a temperature-controllable printing device for packaging box production, including two crossbars 1, the crossbars 1 are symmetrically arranged, and a base 2 is arranged between the crossbars 1, and the crossbars The upper surface of 1 is provided with a first fixed block 3, and the upper surface of the base 2 is provided with a notch 4 near the position below the first fixed block 3, and a collection box 5 is fixedly installed below the notch 4, and the base 2 A first conveyor belt 6 is rotated on one side of the upper surface close to the notch 4, and a second conveyor belt 7 is rotatably connected to the other side of the upper surface of the base 2 close to the notch 4. The upper surface of the cross bar 1 A second fixed block 8 is provided near the first fixed block 3, and a frame 10 is provided on the upper surface of the cross bar 1 close to the second fixed block 8, and the upper surface of the cross ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com