Full-automatic control multifunctional solid-state fermentation tank

A solid-state fermenter, multi-functional technology, applied in solid-phase fermentation bioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problem of uneven fermentation process and unreasonable structure , has not yet seen and other problems, to achieve the effect of reducing production costs and equipment investment, easy operation, and realizing mechanized control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

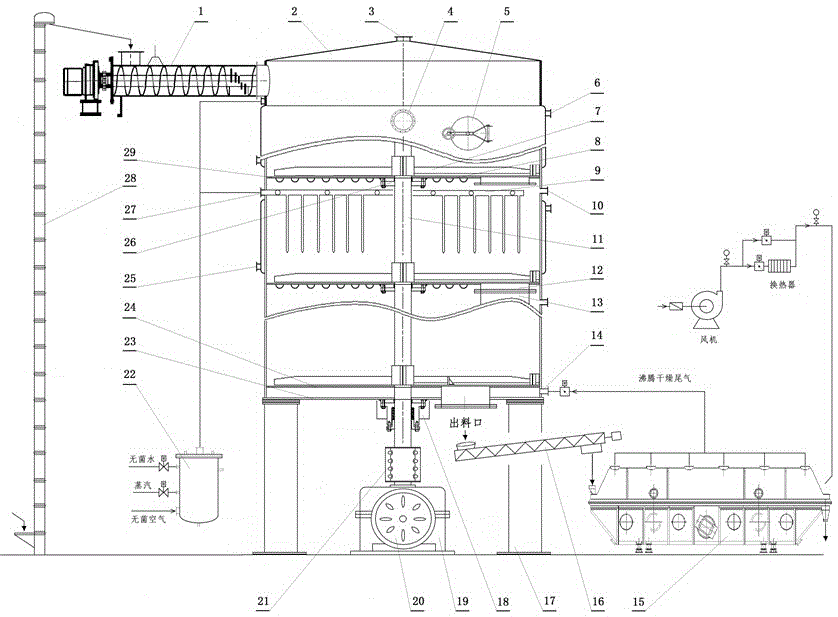

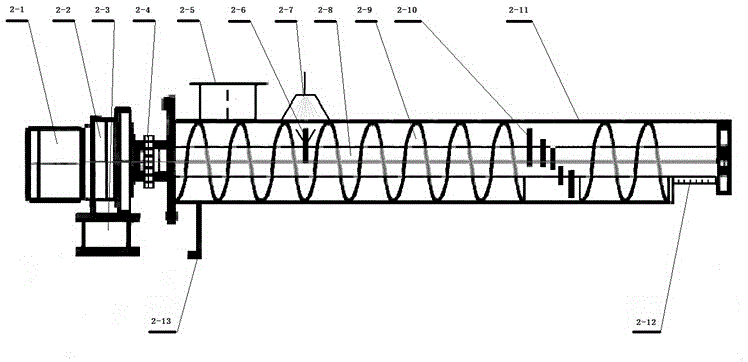

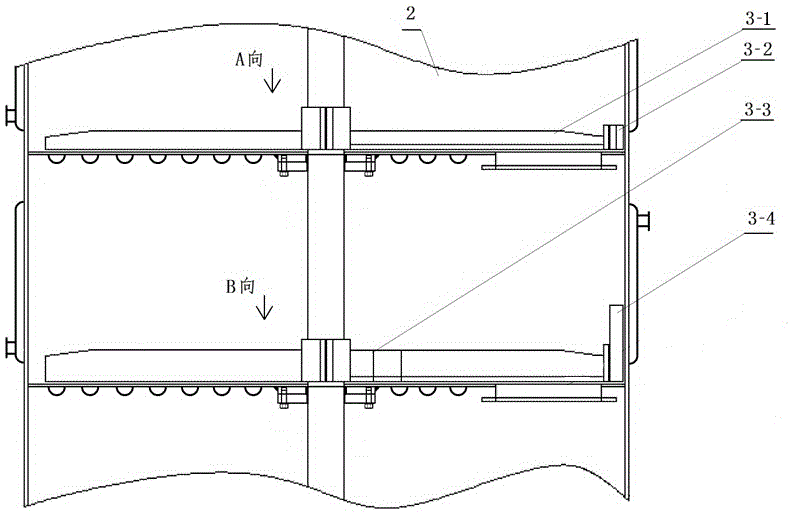

[0041] Such as Figure 1 to Figure 14 The fully automatic control multifunctional solid-state fermentation tank shown includes a circular vertical fermentation tank main body 2 and a fermentation control system. Dragon 1, feeding auger 1 is connected to bucket elevator 28; inside the fermentation tank main body 2 is provided with a plurality of partitions 29, and each partition 29 is provided with a feeding port 12, and the feeding port 12 is along the fermenting tank The axis of the main body 2 is set in a spiral shape, and the partition 29 divides the main body 2 of the fermenter into multiple fermentation layers and a pre-drying layer, and each fermentation layer is equipped with an automatic control device 13 for the high material level; Each layer is equipped with a sterile air distribution system 9, and each aseptic air distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com