Descending type suspended casting hanging basket and construction method thereof

A hanging and cantilever truss technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of increased workload, high safety risk, repeated adjustment, etc., to reduce personnel requirements, high surface flatness, safety and reliability. The effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings and examples.

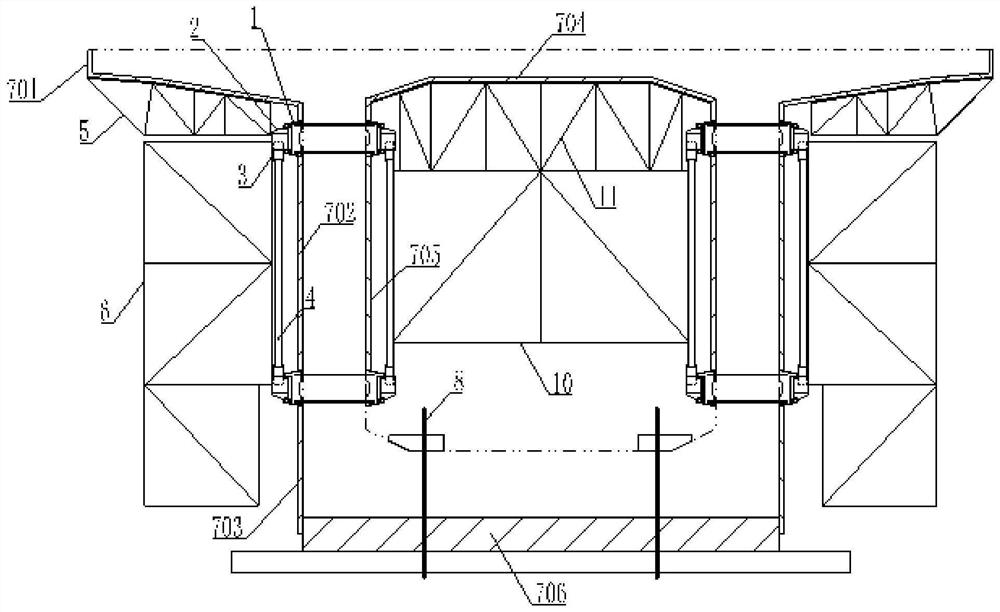

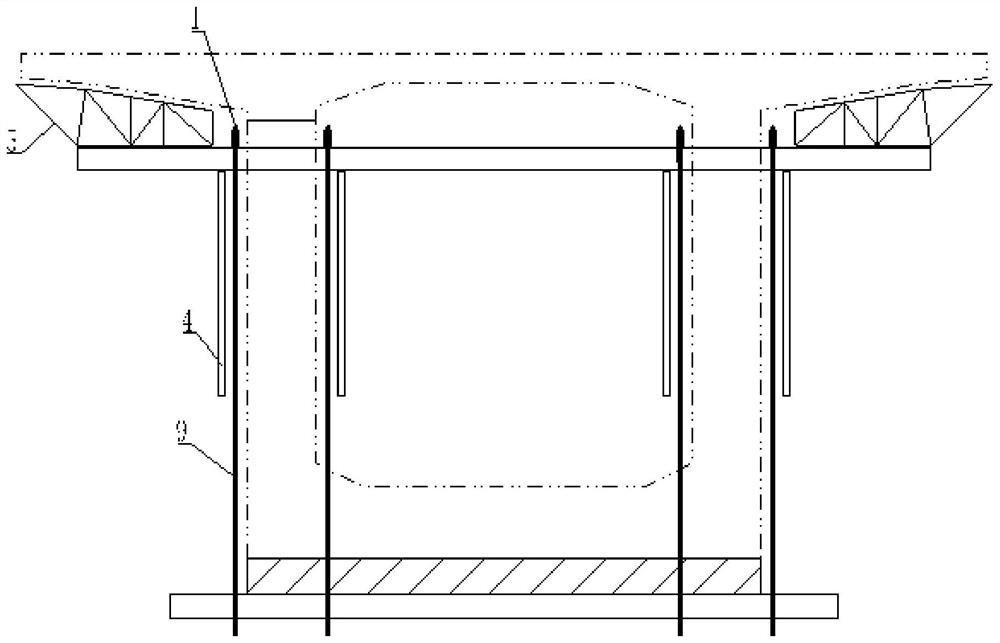

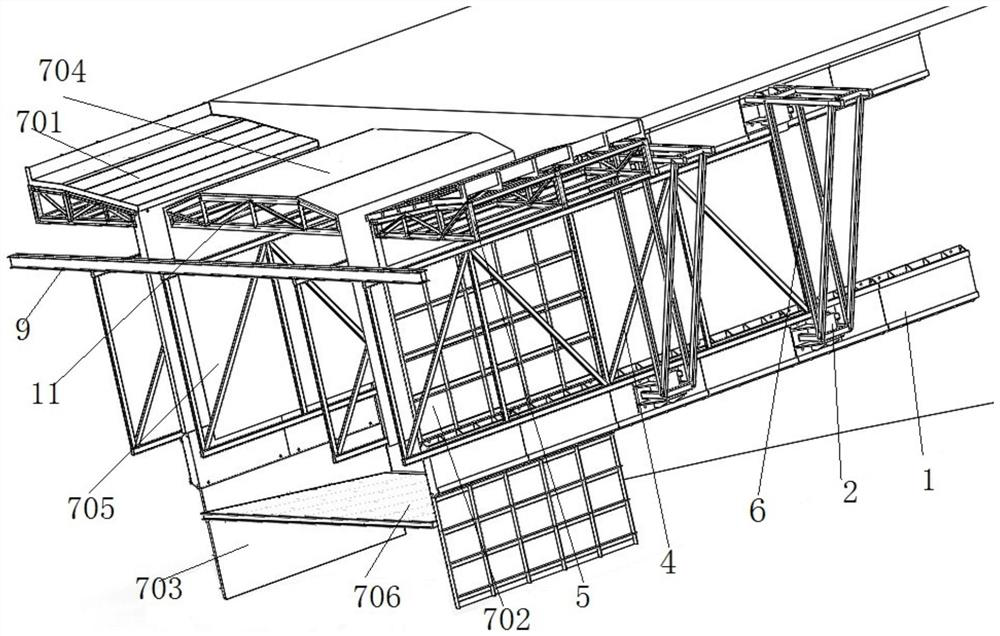

[0036] like Figure 1 to 4As shown in a downlink of Formula Suspended Casting Basket, comprising a template bearing parts 1, 2 corbels support the running, adjusting cylinder 3, cantilevered truss 4, mold flange 5, the bracket 6 attached to the side, the template system 7, after hanging hanging system 8, 9 before the hanging system, the tank holder 10 and the top mold 11; box 1 adhered webs template has been poured fixed bearing parts of the upper and lower inner and outer sides, the inner side surface of the template bearing parts 1 as a template, with the outer side surface of the running rail, with the support 2 fitted corbel traveling traveling within the track, the inner and outer sides positioned Box cantilever truss web support 4 and connected to upper and lower sides of the supporting cylinder by adjusting the vertical side 3 traveling corbel 2, each side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com