Patents

Literature

60 results about "Cantilever bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In designing engineering structures, such as buildings and bridges, cantilever beams are a main structural element receiving bending forces. This chapter considers the bending of a static cantilever beam of a constant cross section by a force at the end of the beam.

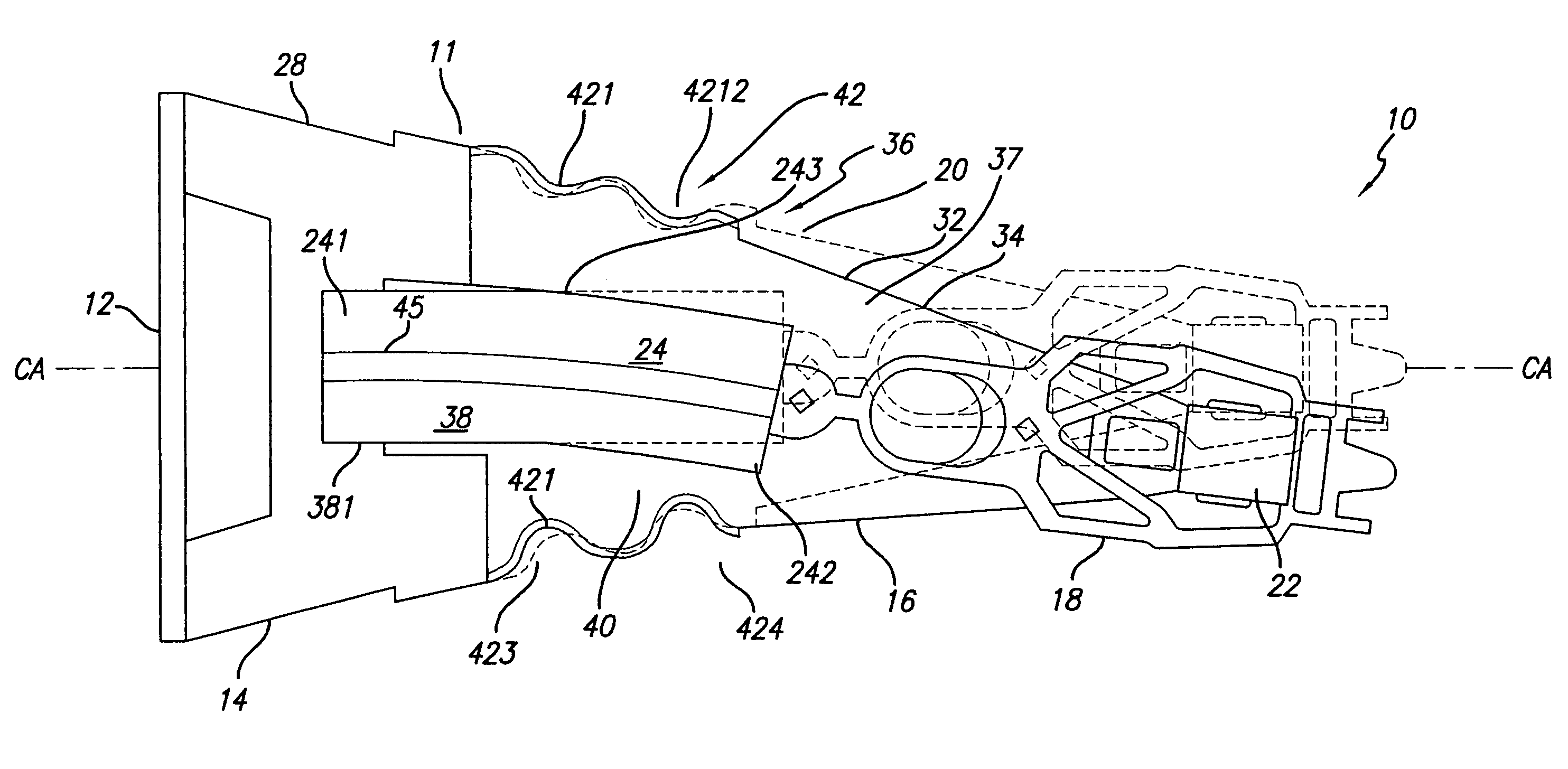

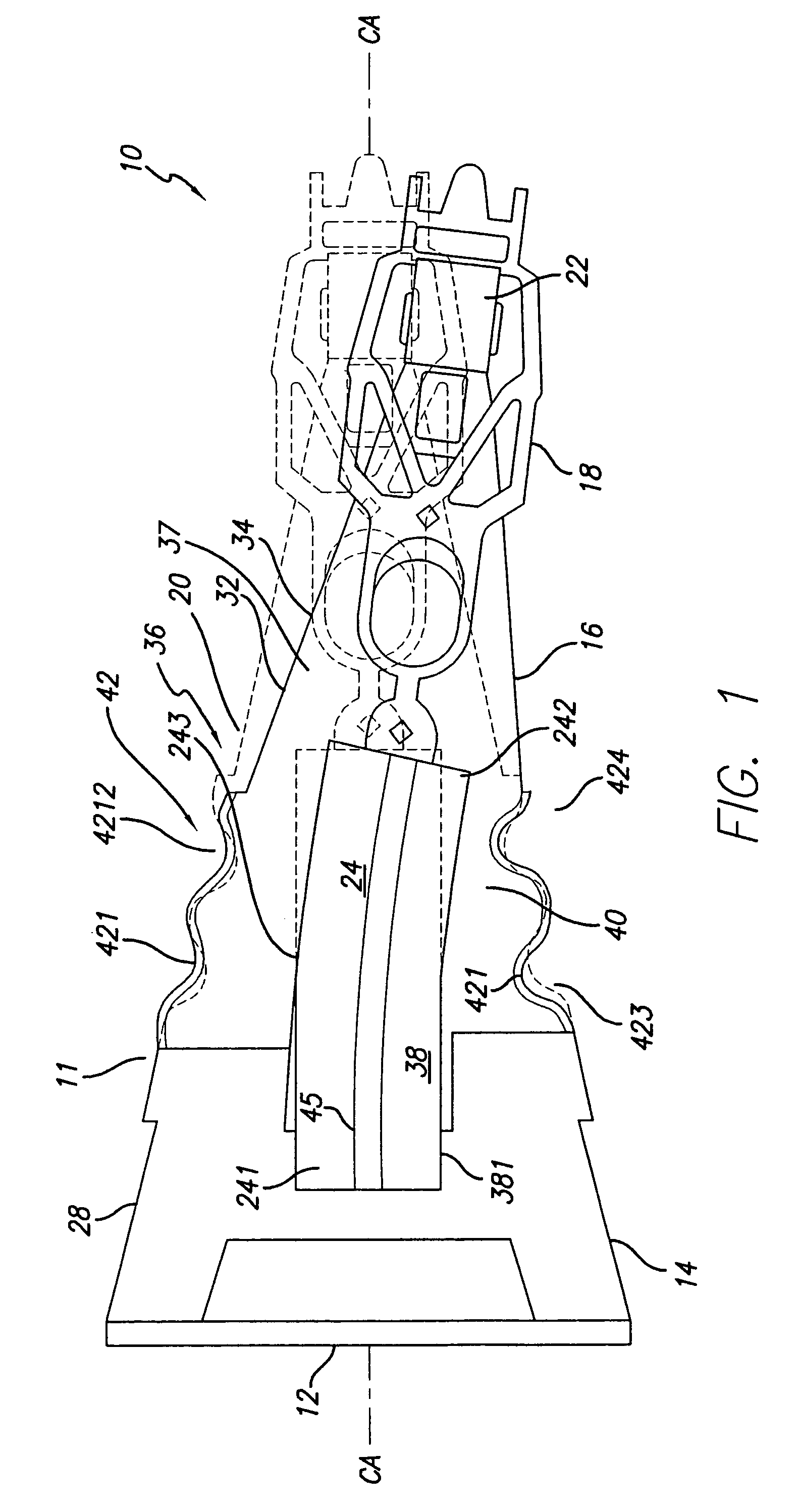

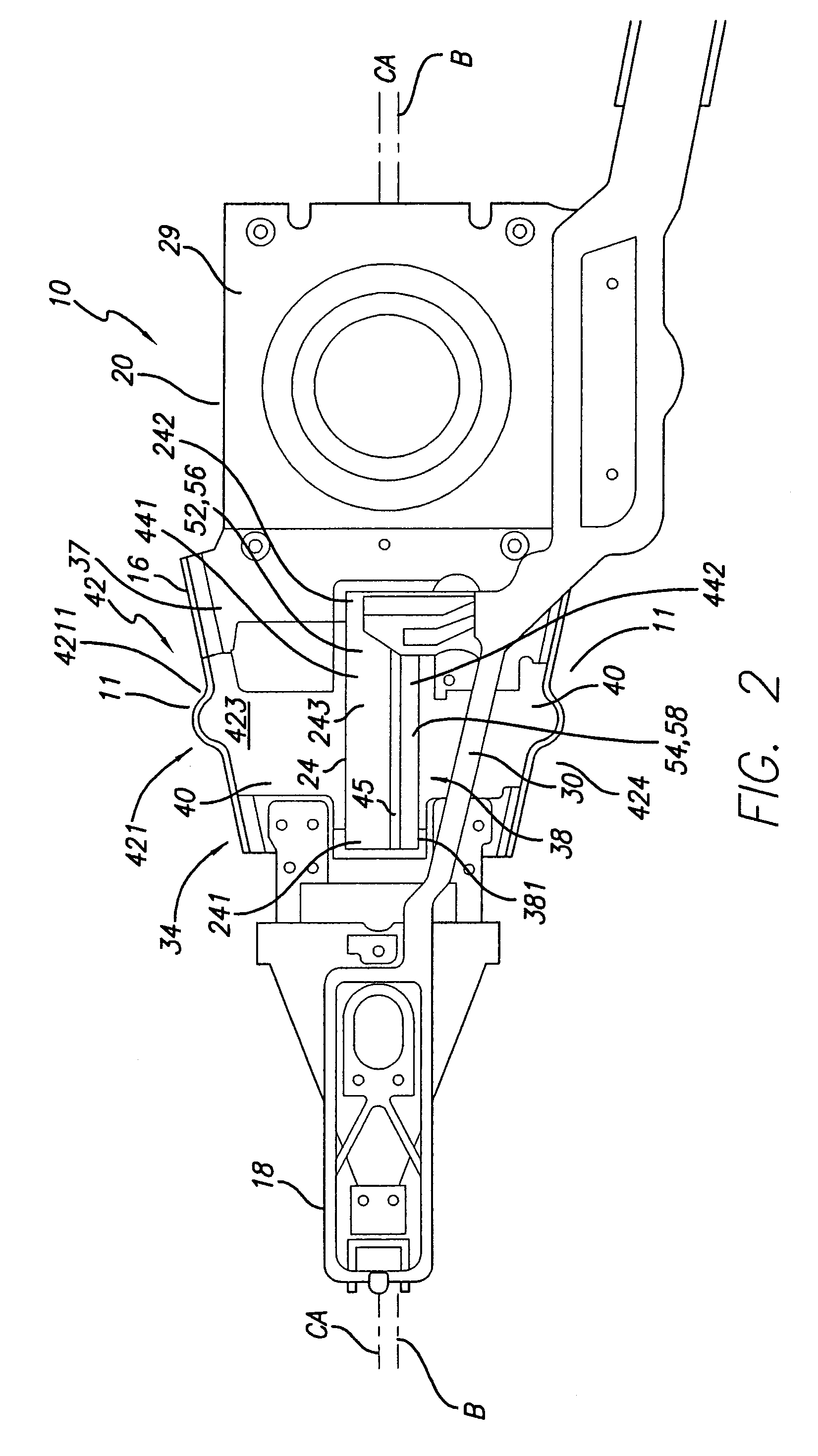

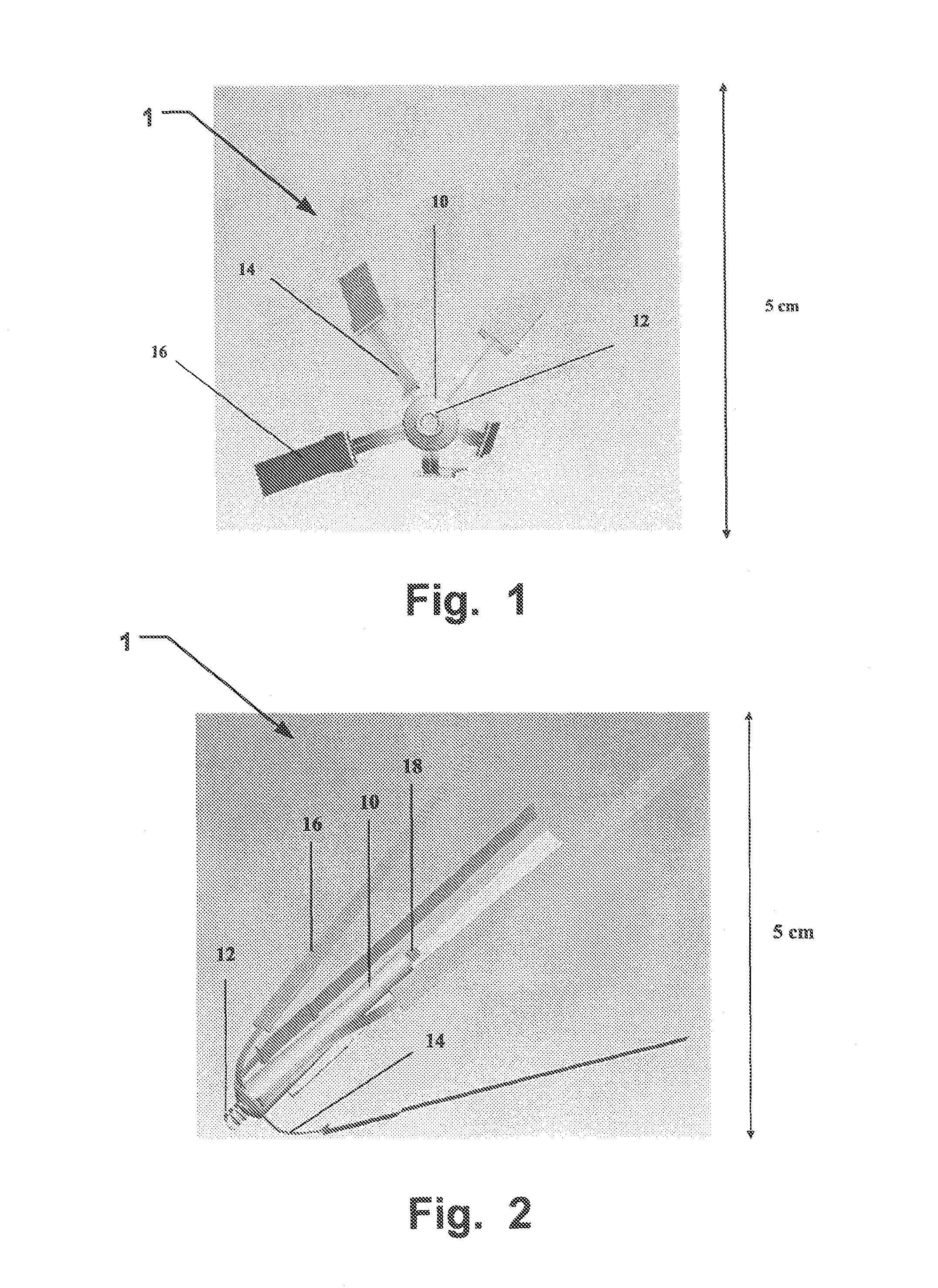

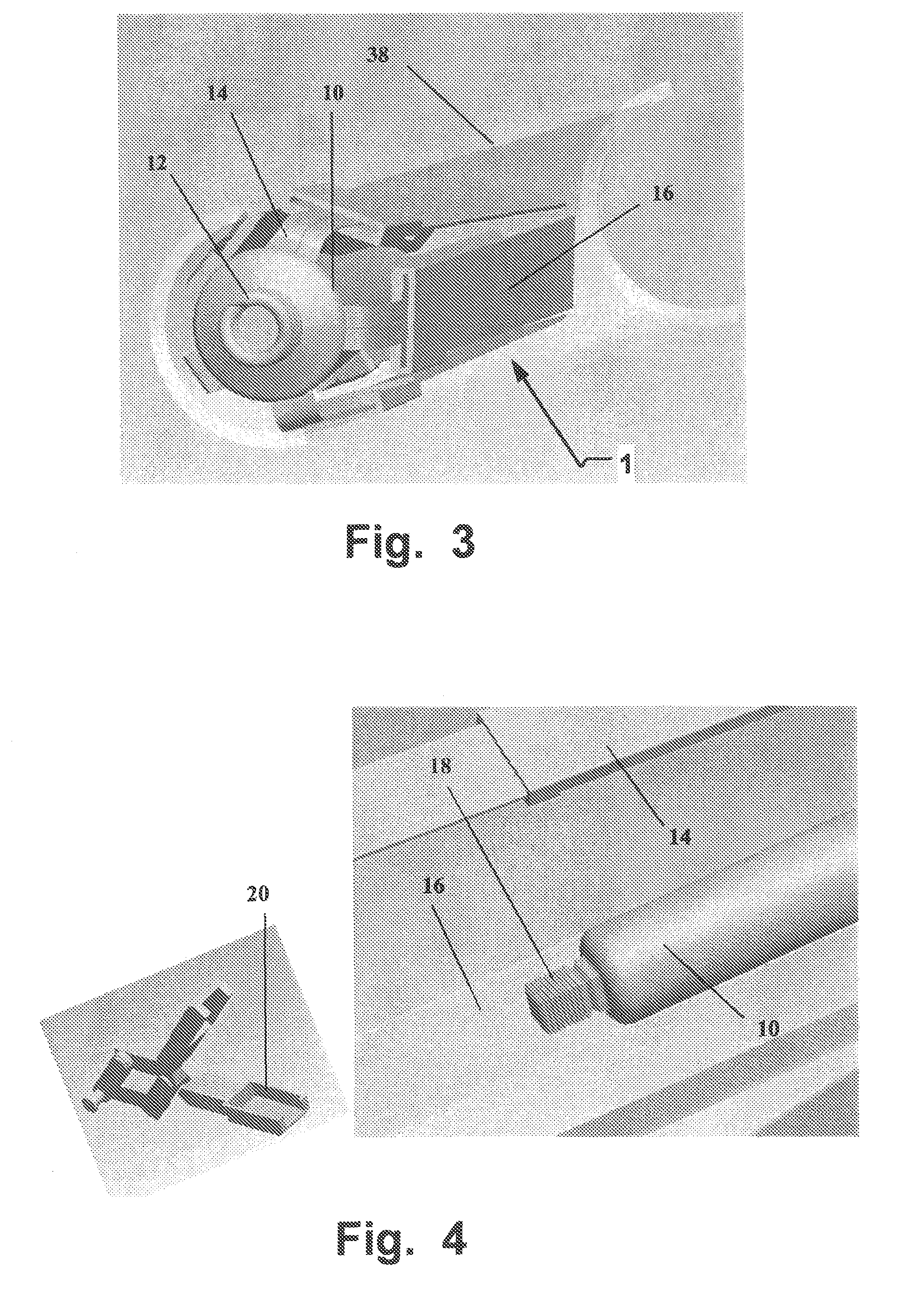

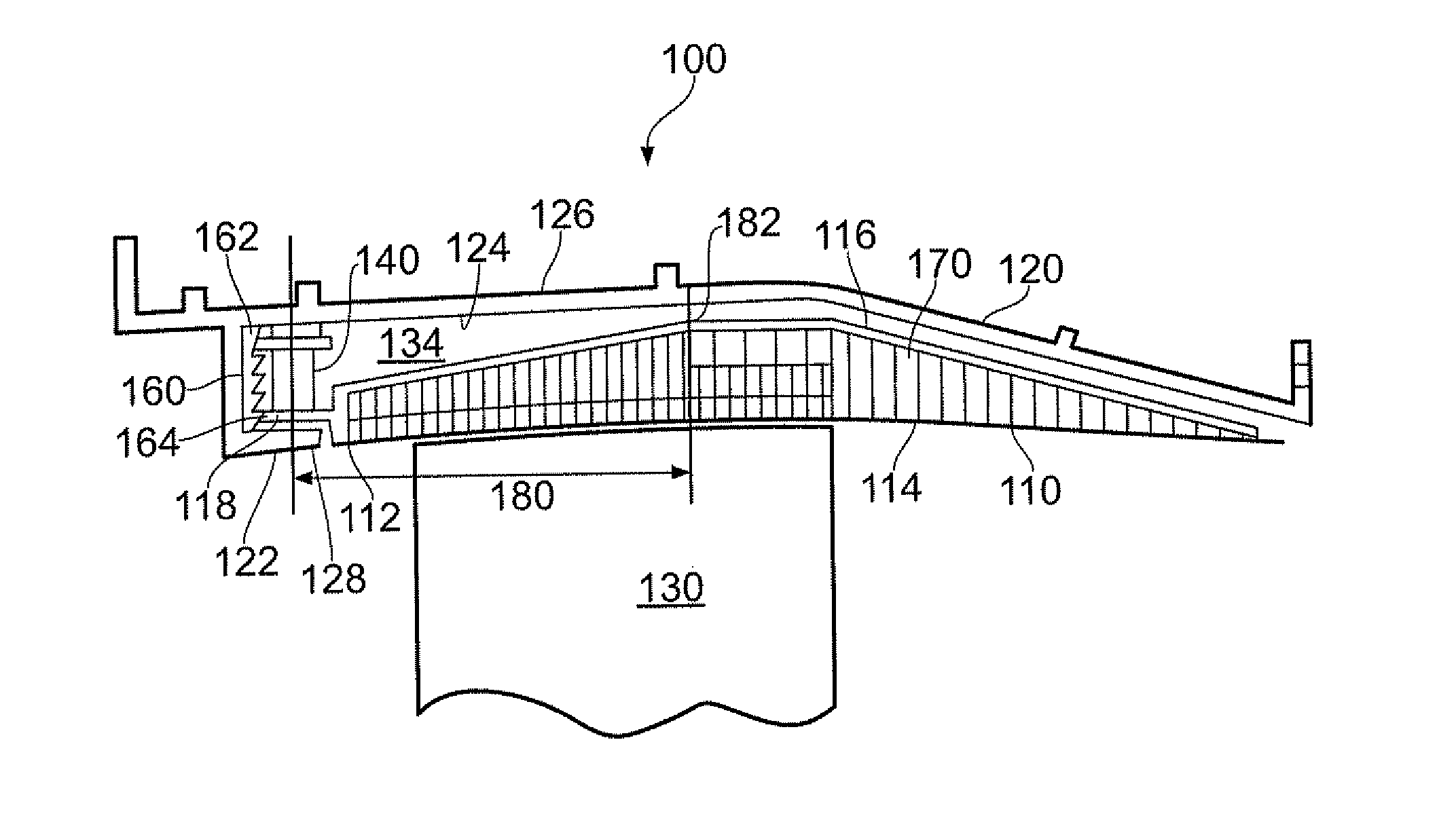

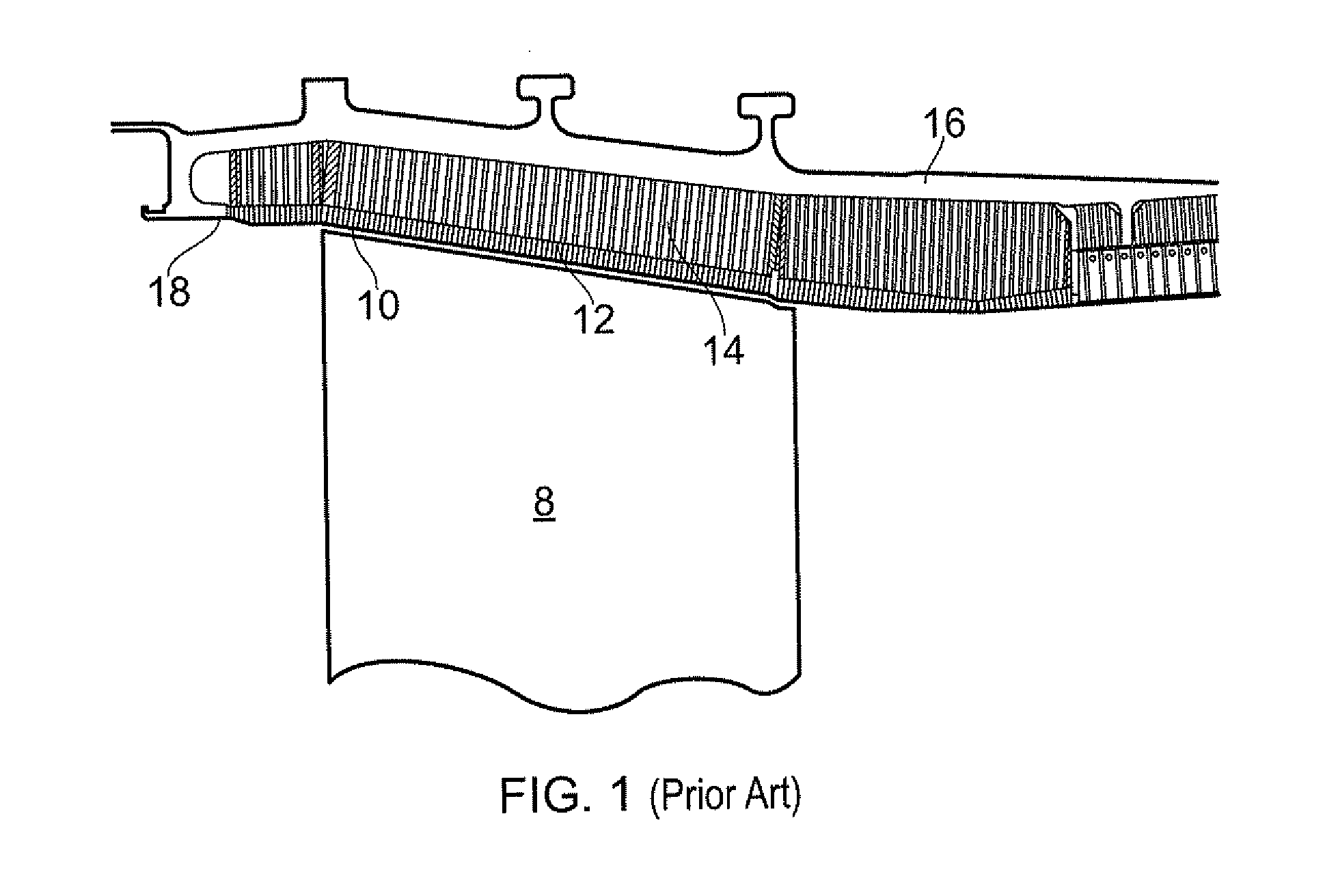

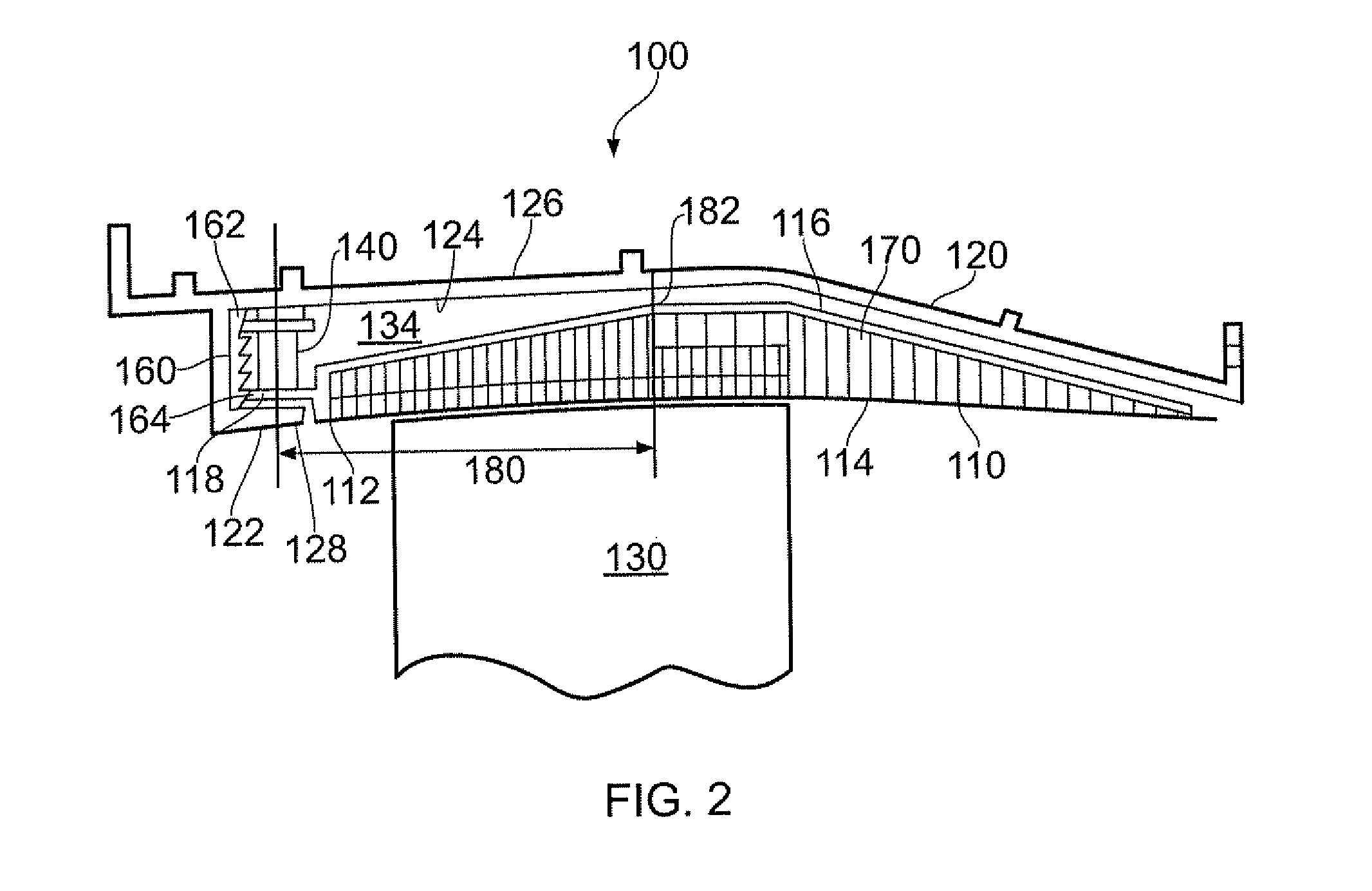

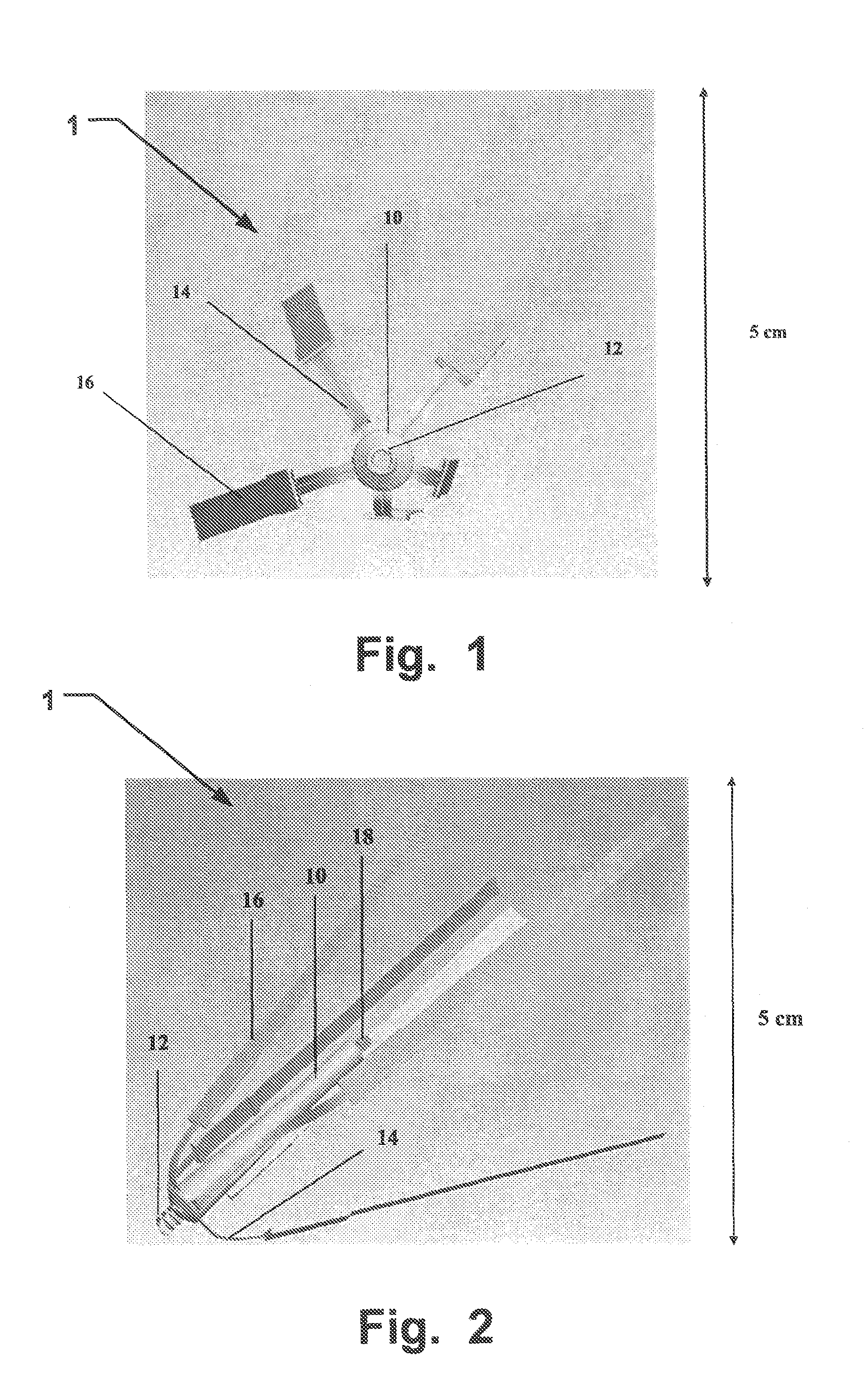

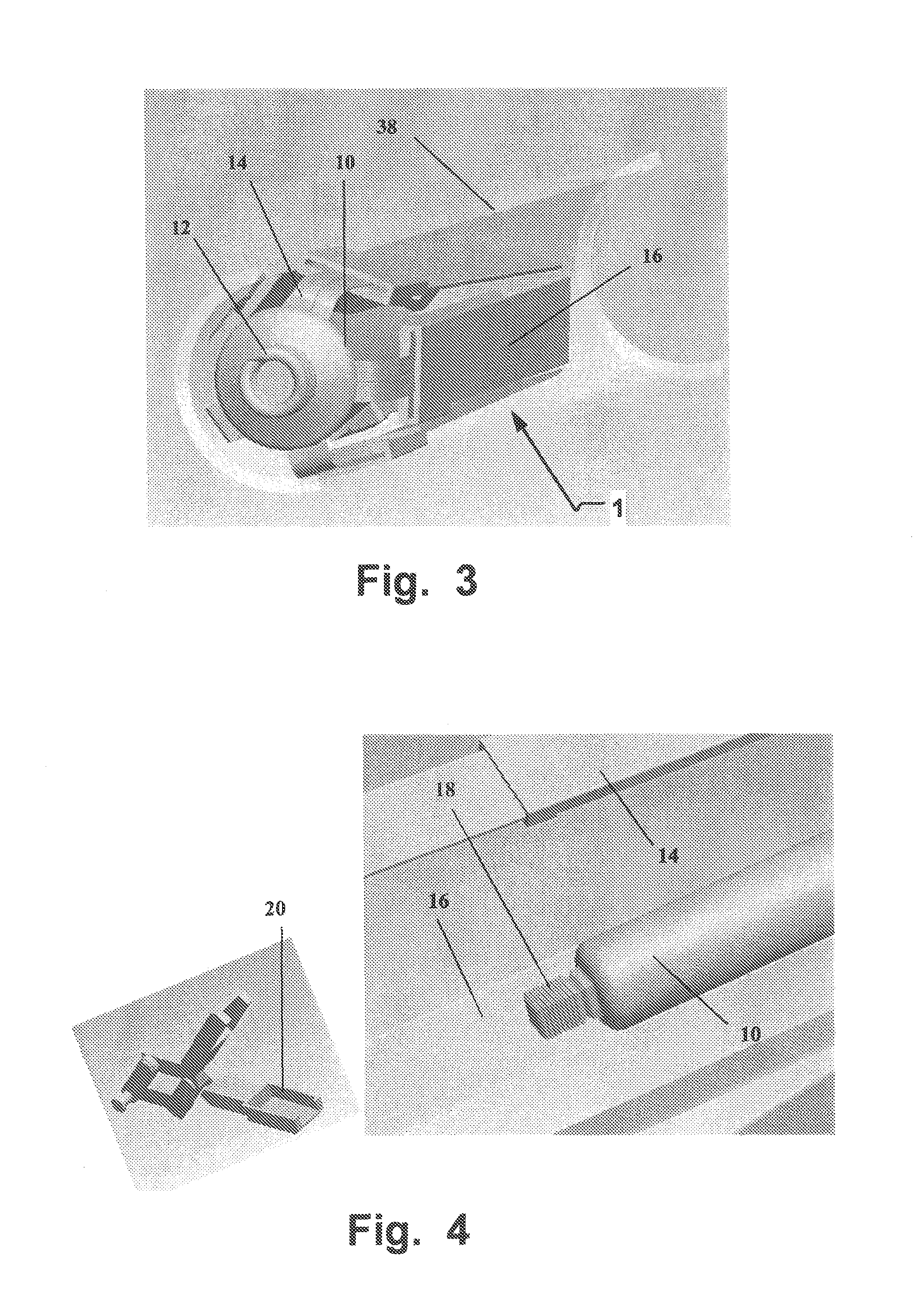

Loading-protected bending microactuator in additive suspensions

ActiveUS7459835B1Improved disk drive suspensionLow costPiezoelectric/electrostriction/magnetostriction machinesArm with actuatorsDistal portionEngineering

A microactuated disk drive suspension for supporting a slider at a disk includes a load beam extending in a plane and having on a common axis a base section adapted for mounting to an actuator, a spring section and a beam section carrying a flexure and the slider thereon. The suspension has relatively movable proximate and distal portions on the common axis that are joined by a bending system cantilevered from the proximate portion and including a cantilevered bending motor opposed to the common axis and having a laterally bendable unsupported region. A cantilevered laterally bendable load assist structure defined by the suspension edges is provided arranged to block undue loading of the bending motor unsupported region.

Owner:MAGNECOMP

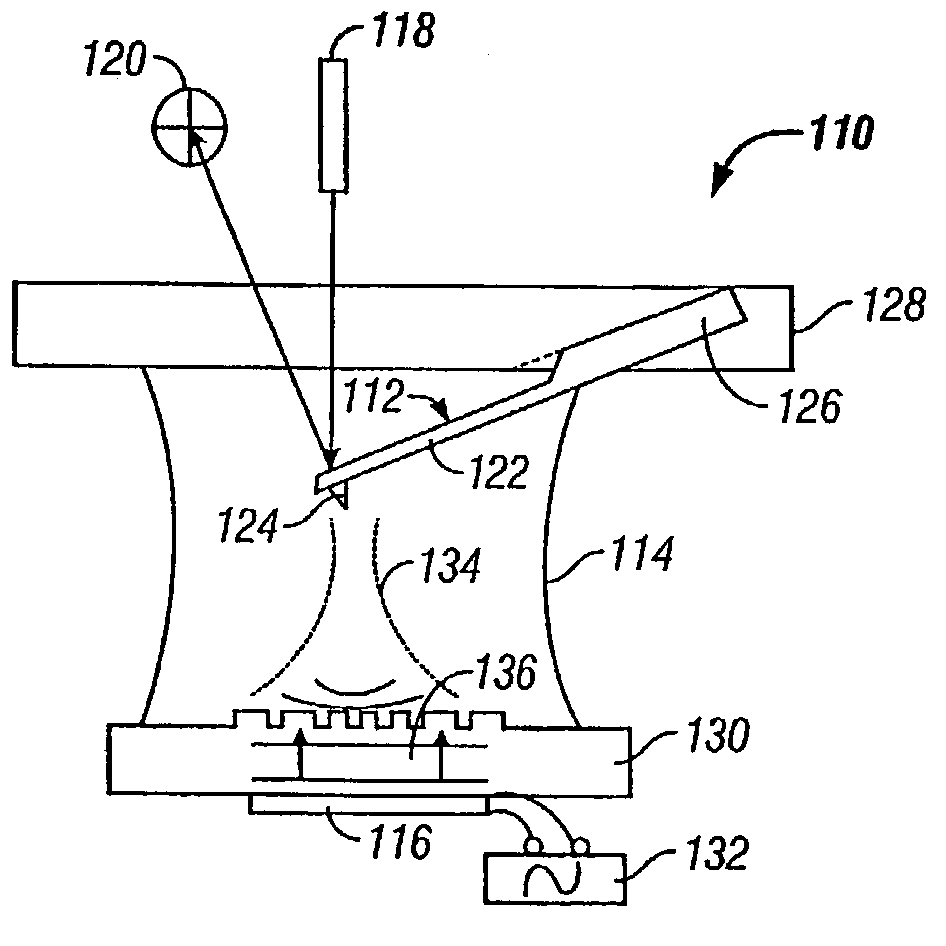

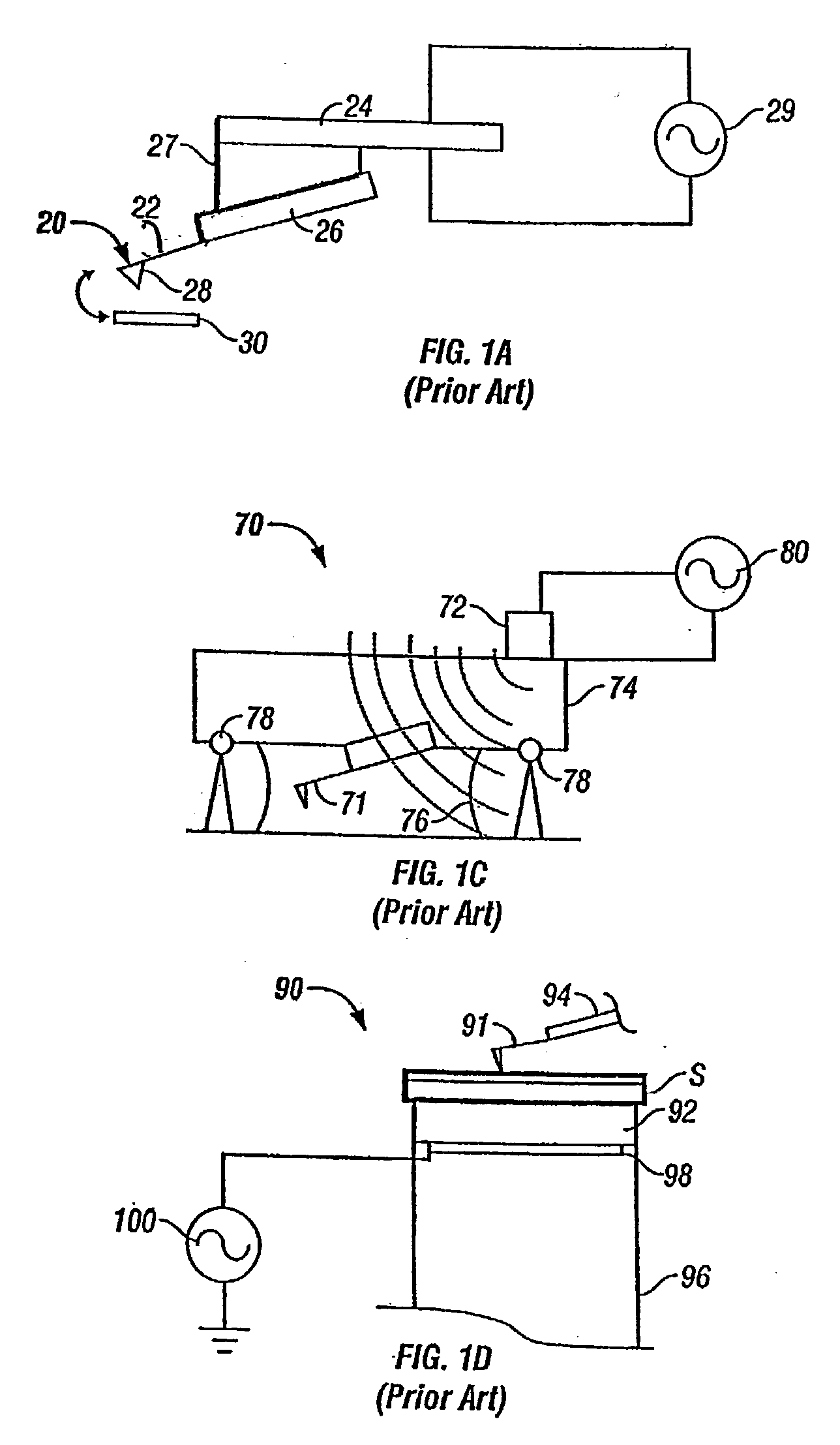

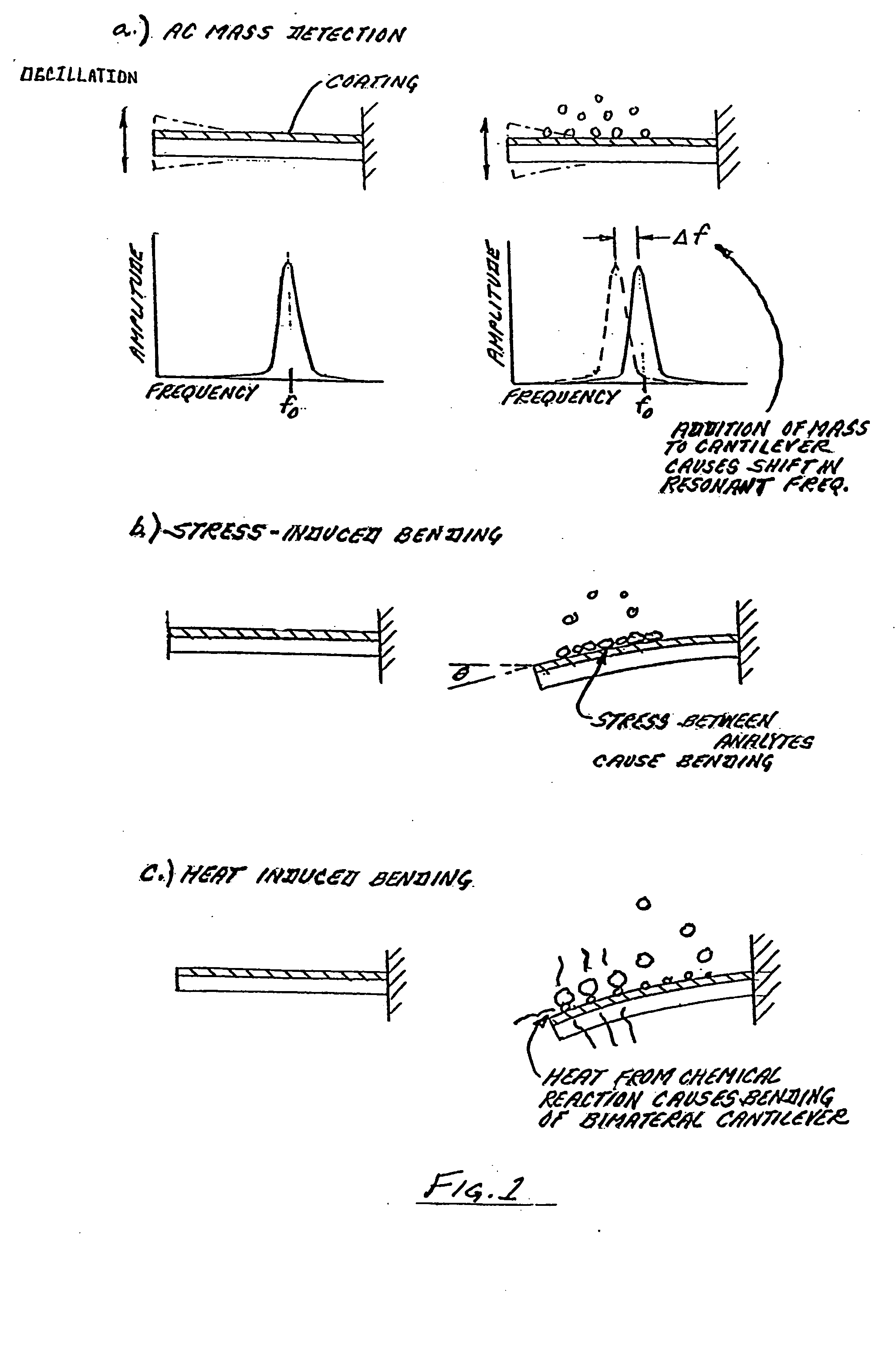

Method and apparatus for the actuation of the cantilever of a probe-based instrument

InactiveUS20040020279A1NanotechAnalysing solids using sonic/ultrasonic/infrasonic wavesResonanceCarrier signal

An electromagnetic drive causes a cantilever of a probe-based instrument to deform flexurally by transmitting a high frequency AC signal through an electromagnetic actuator located in the vicinity of the cantilever. The AC signal preferably is an RF carrier signal having a frequency that is substantially higher than the resonant frequency of the cantilever. The carrier signal may, if desired, be modulated with a lower frequency modulation signal to induce the cantilever to oscillate, preferably at resonance. Alternatively, the carrier signal may be transmitted to the electromagnetic actuator without being modulated in order to deflect the cantilever quasi-statically. Cantilever response can then be monitored either directly in response to the imposition of the electromagnetically induced deformation of the cantilever in response to probe / sample interaction to obtain measurements regarding characteristics of the sample, the environment, and / or the cantilever.

Owner:GEORGIA TECH RES CORP

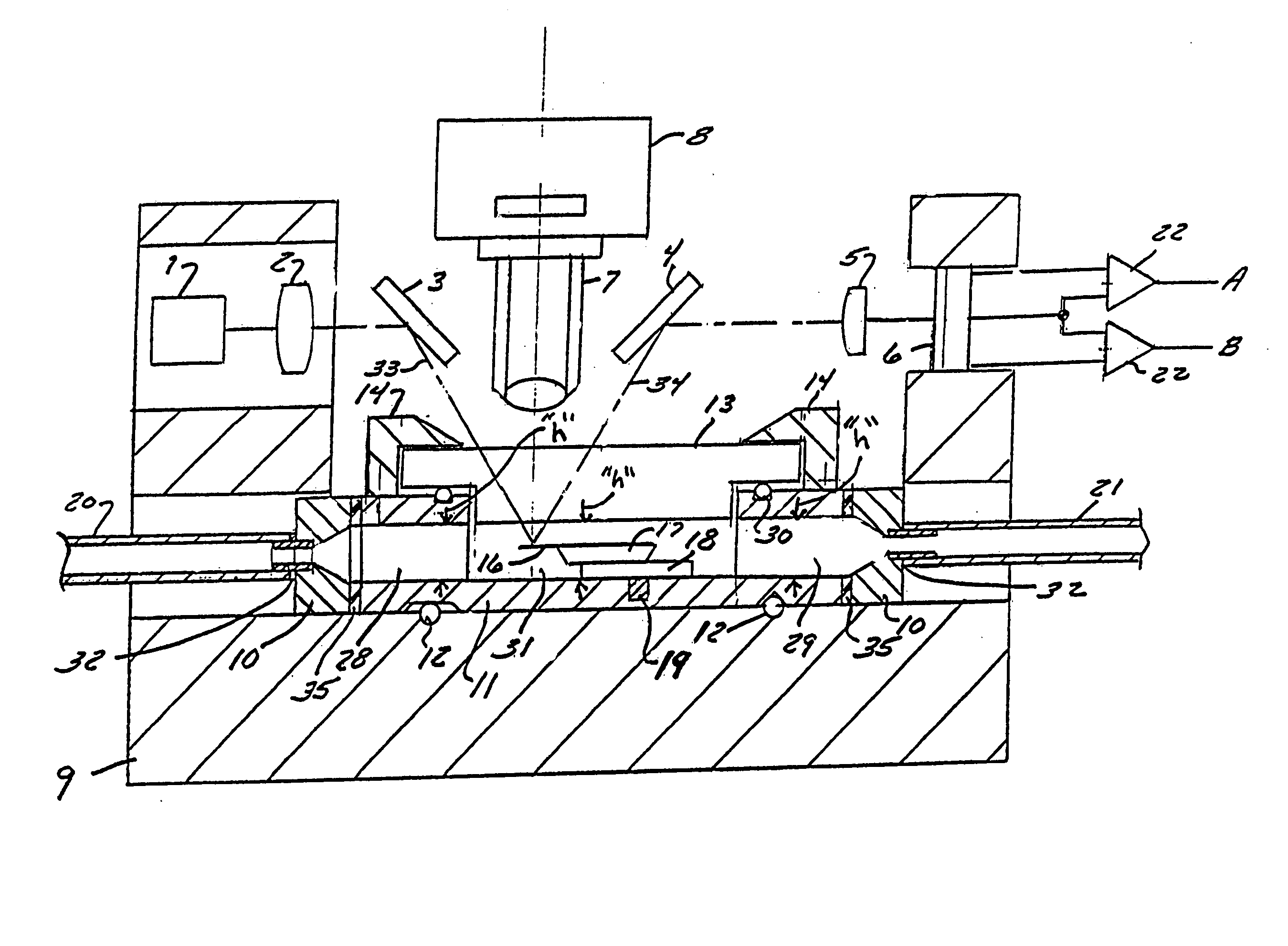

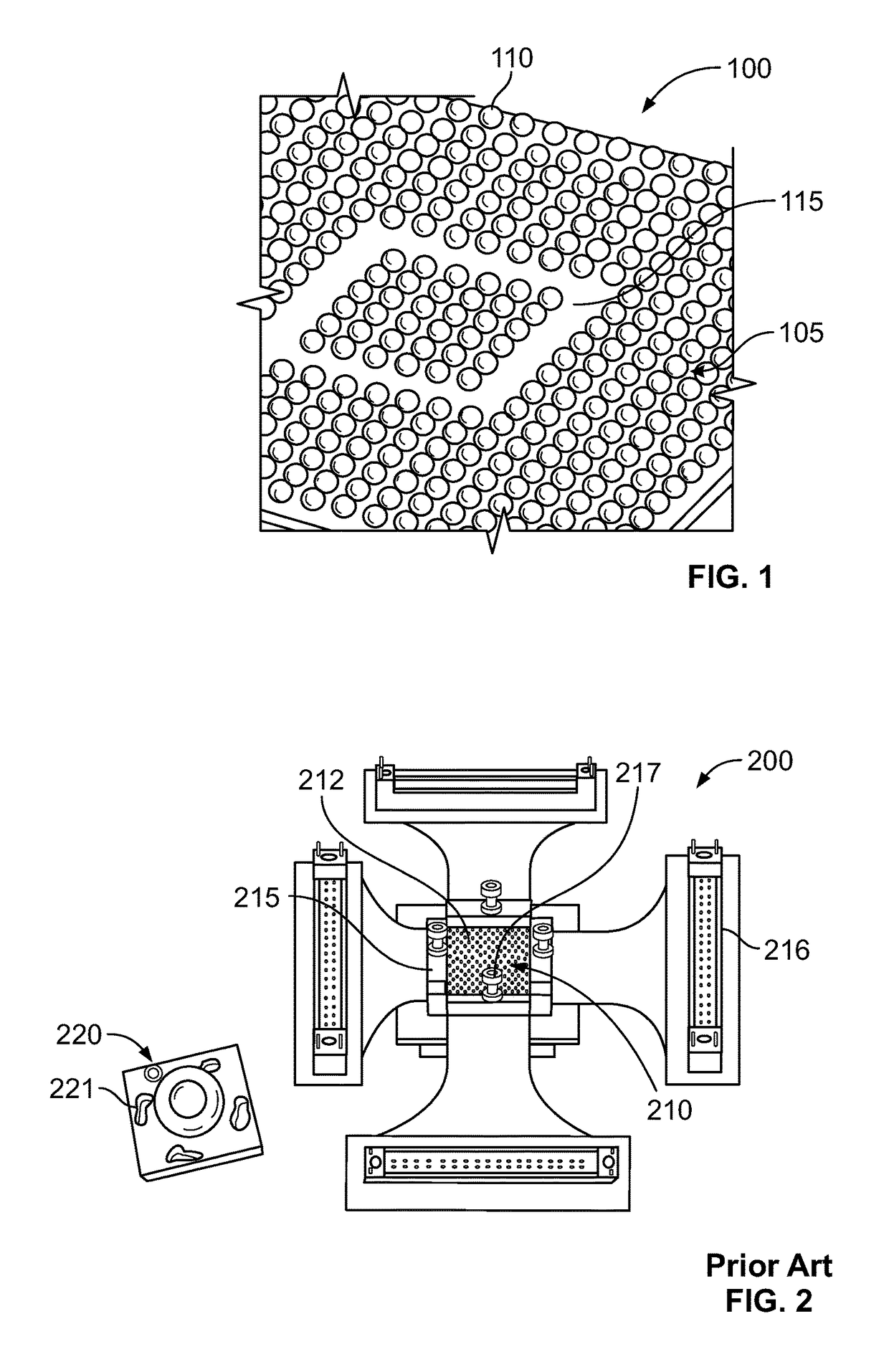

Cantilever array sensor system

InactiveUS20050121615A1Accurately detectsAccurate measurementRadiation pyrometryNanotechnologySensor arrayFlow cell

An integrated cantilever sensor array system that accurately detects and measures the presence of target substances in various environmental conditions. The integrated cantilever sensor array system comprises a cantilever sensor measurement head, a cantilever sensor system for measuring the oscillatory properties of the cantilevers and a measurement chamber. The measurement head includes a cantilever array having at least one cantilever, a light source and a detector positioned to detect incoming light reflected by the cantilevers within the cantilever array. The cantilever sensor system measures the oscillatory properties generated by the cantilevers within the cantilever array. The system includes the cantilever array and a detection system that measures a signal related to the bending of the cantilever. In addition, optional components such as a high frequency clock, Q-Control, may be added to more accurately measure the oscillation of the cantilevers within the cantilever array. The measurement chamber includes a flow cell, a cantilever sensor array mounted within the flow cell. The flow cell is designed to minimize dead volume and unwanted air bubbles within the cell, which may reduce accuracy of measurement.

Owner:PRATER CRAIG +5

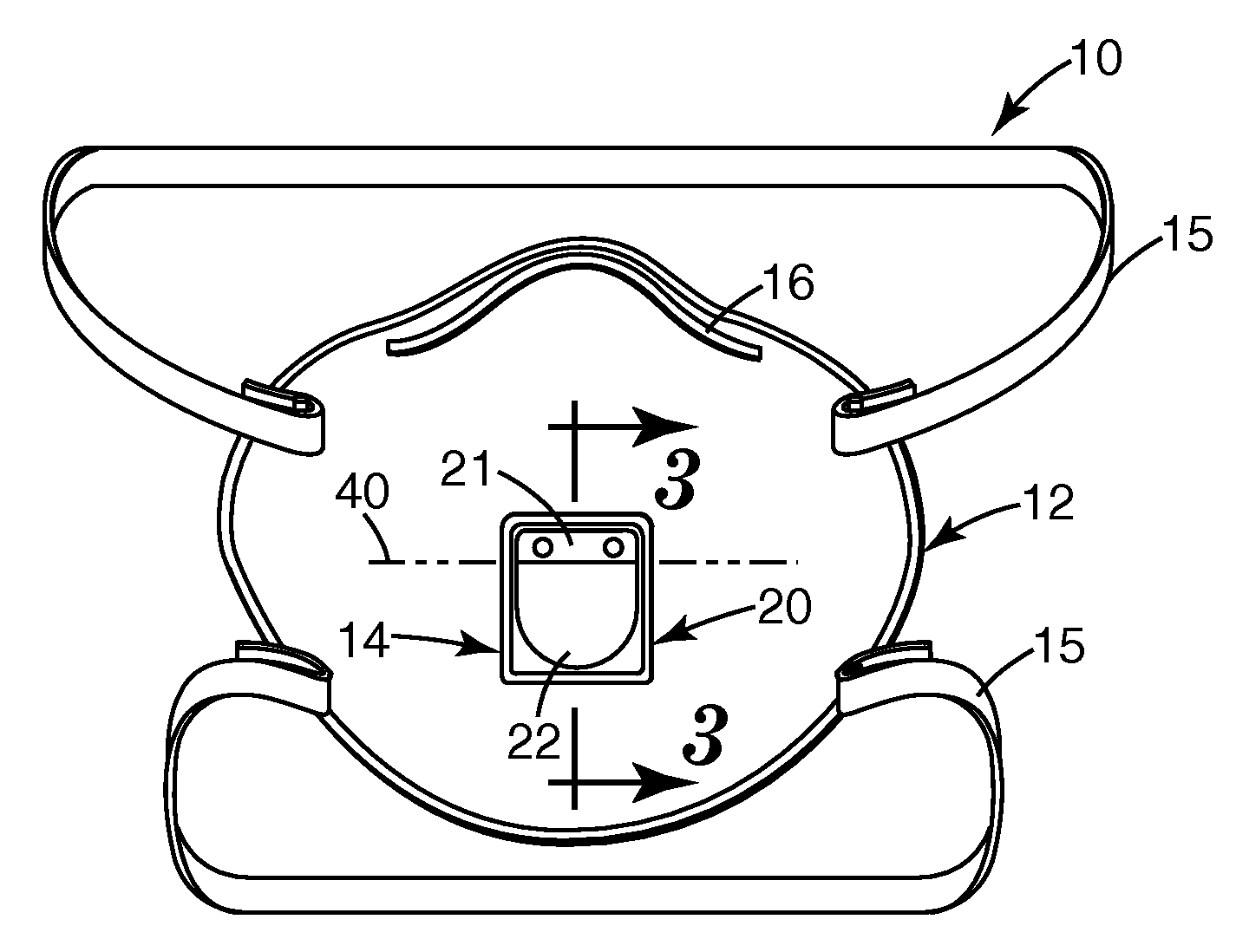

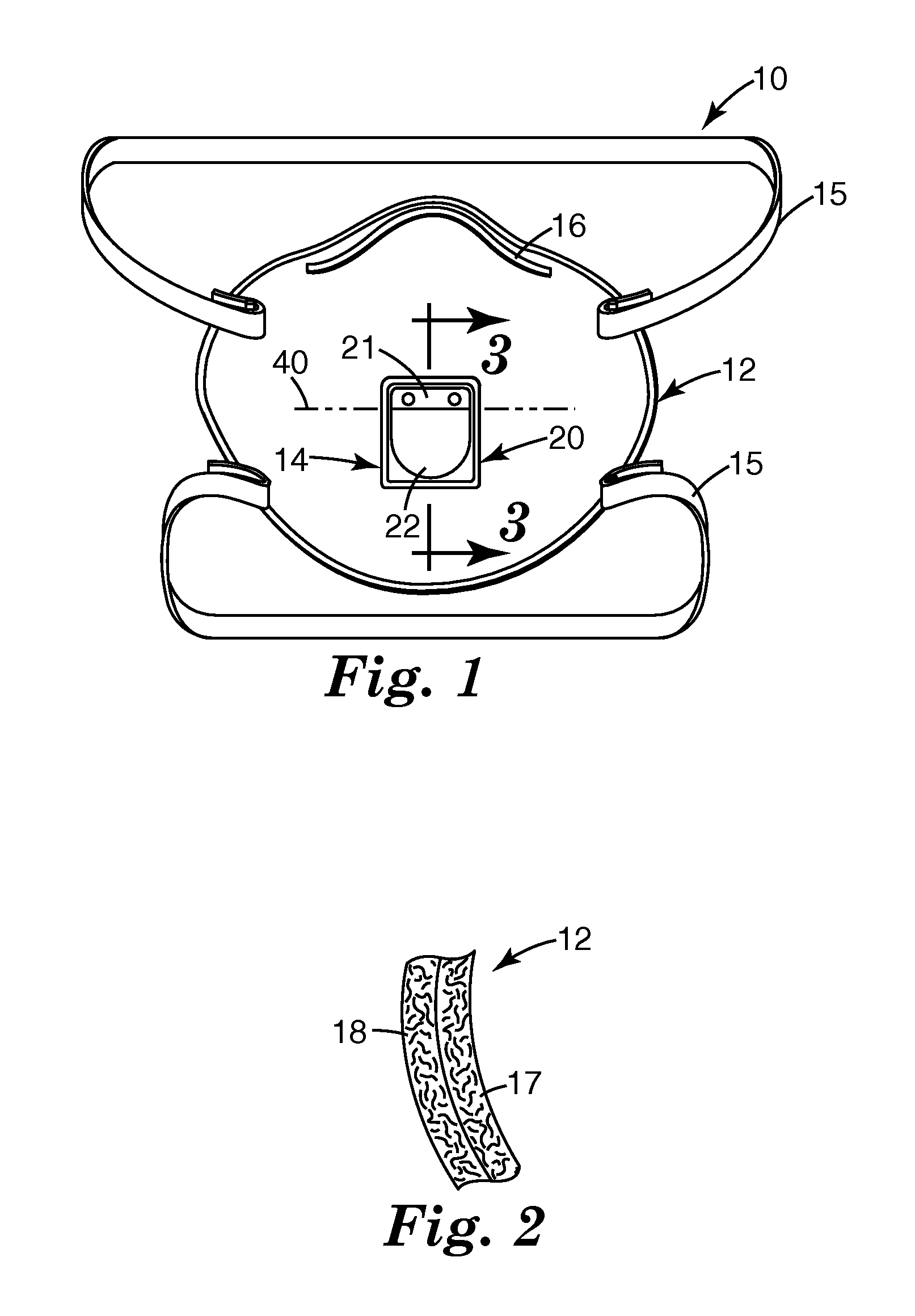

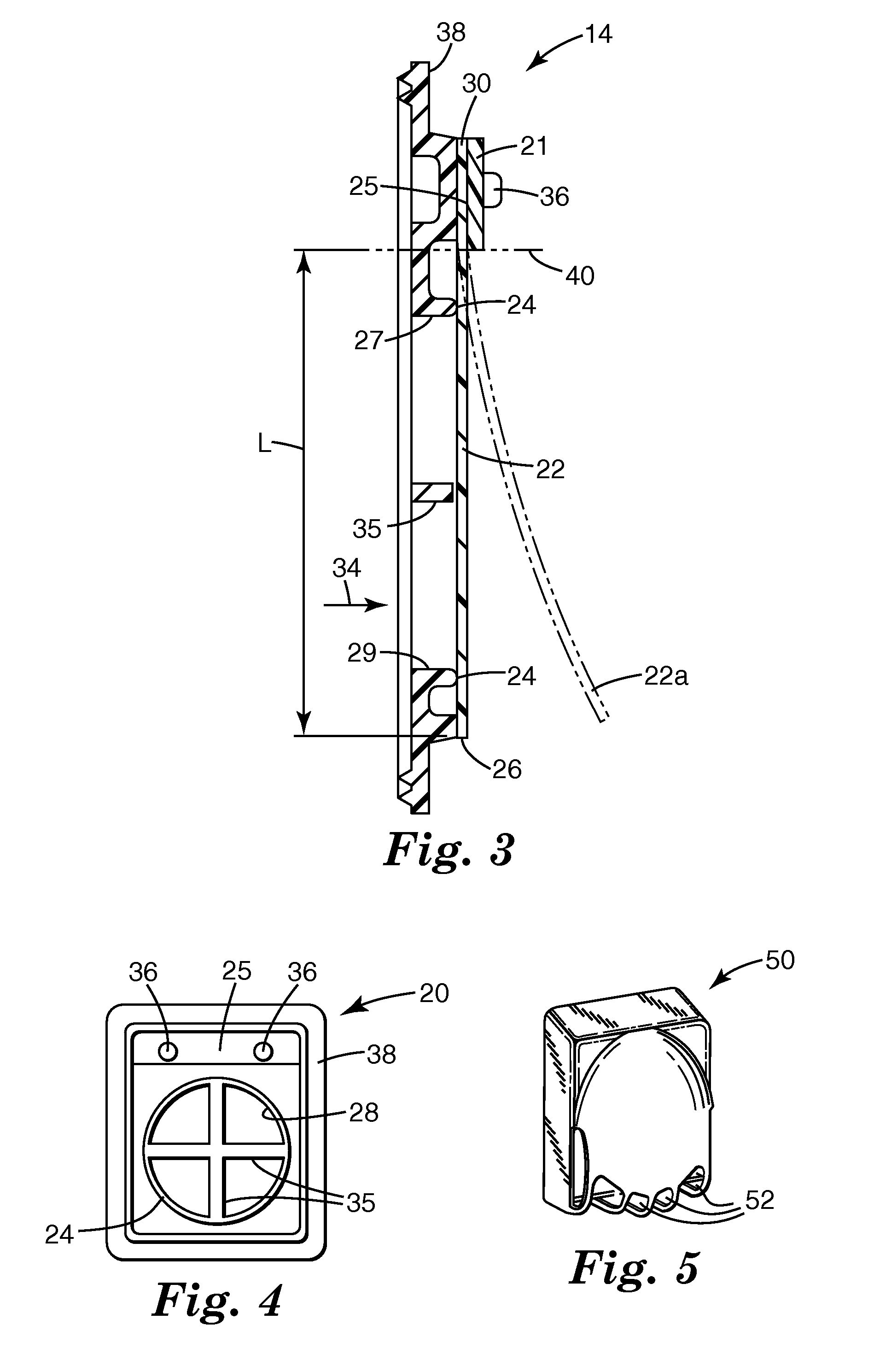

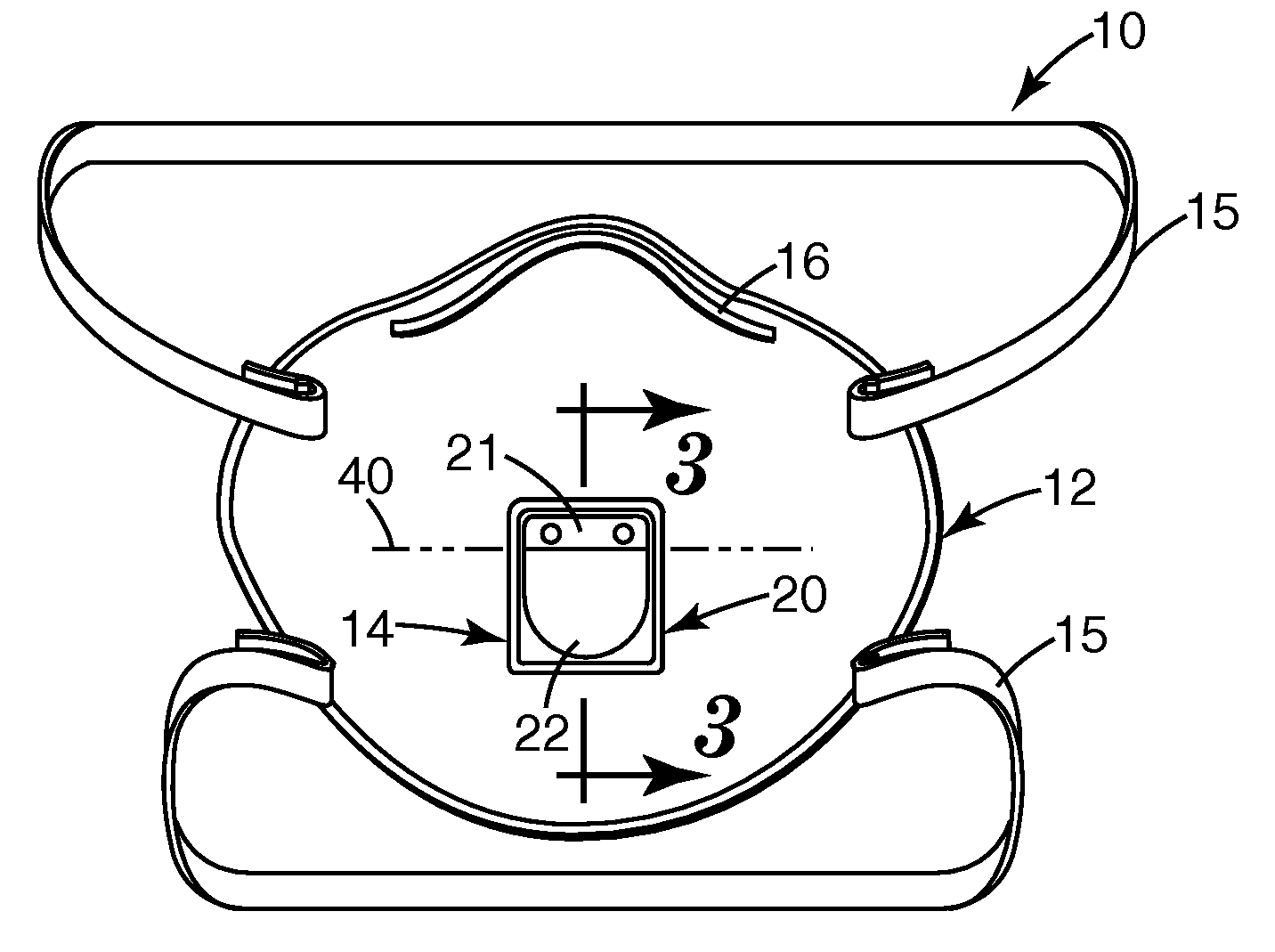

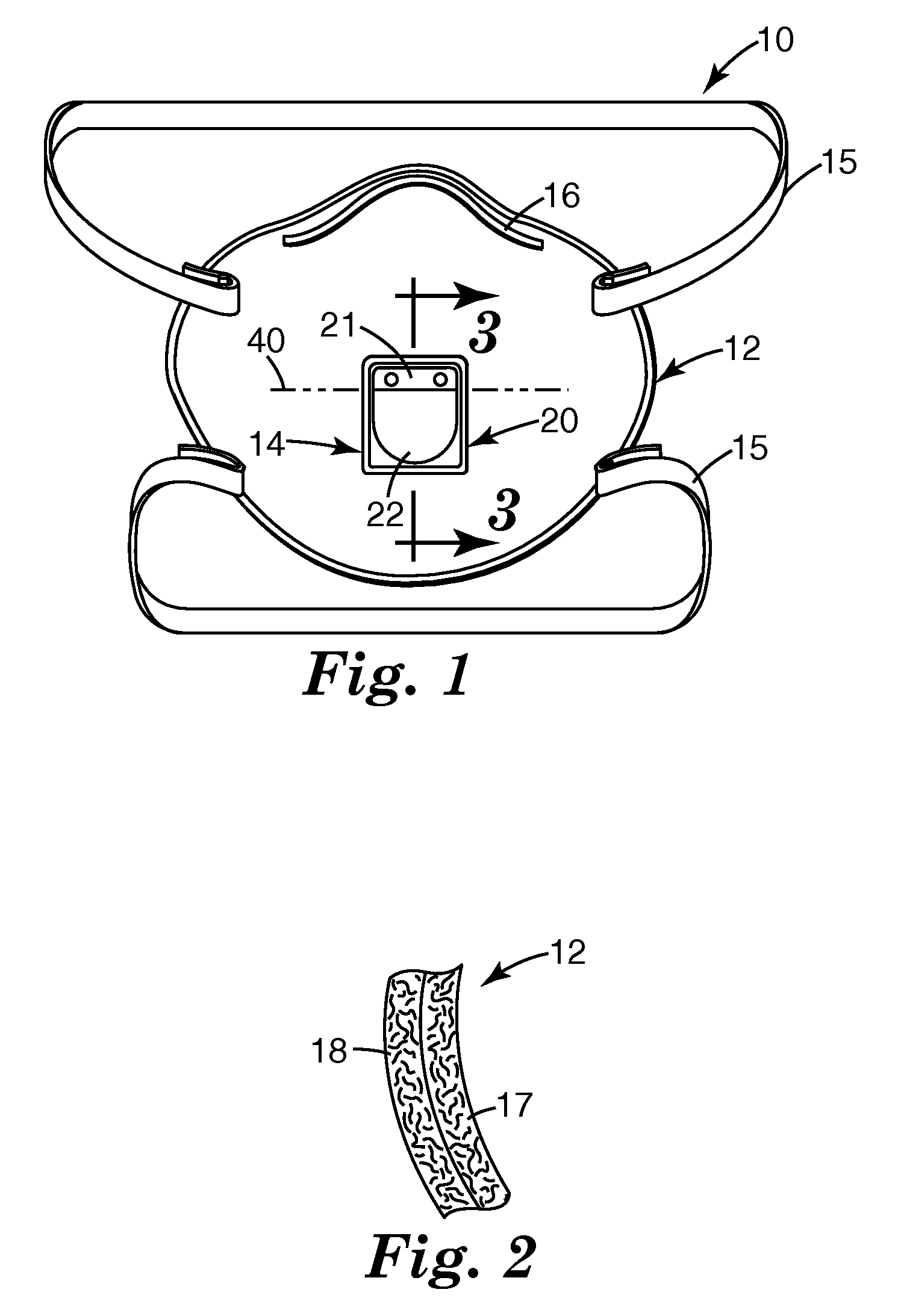

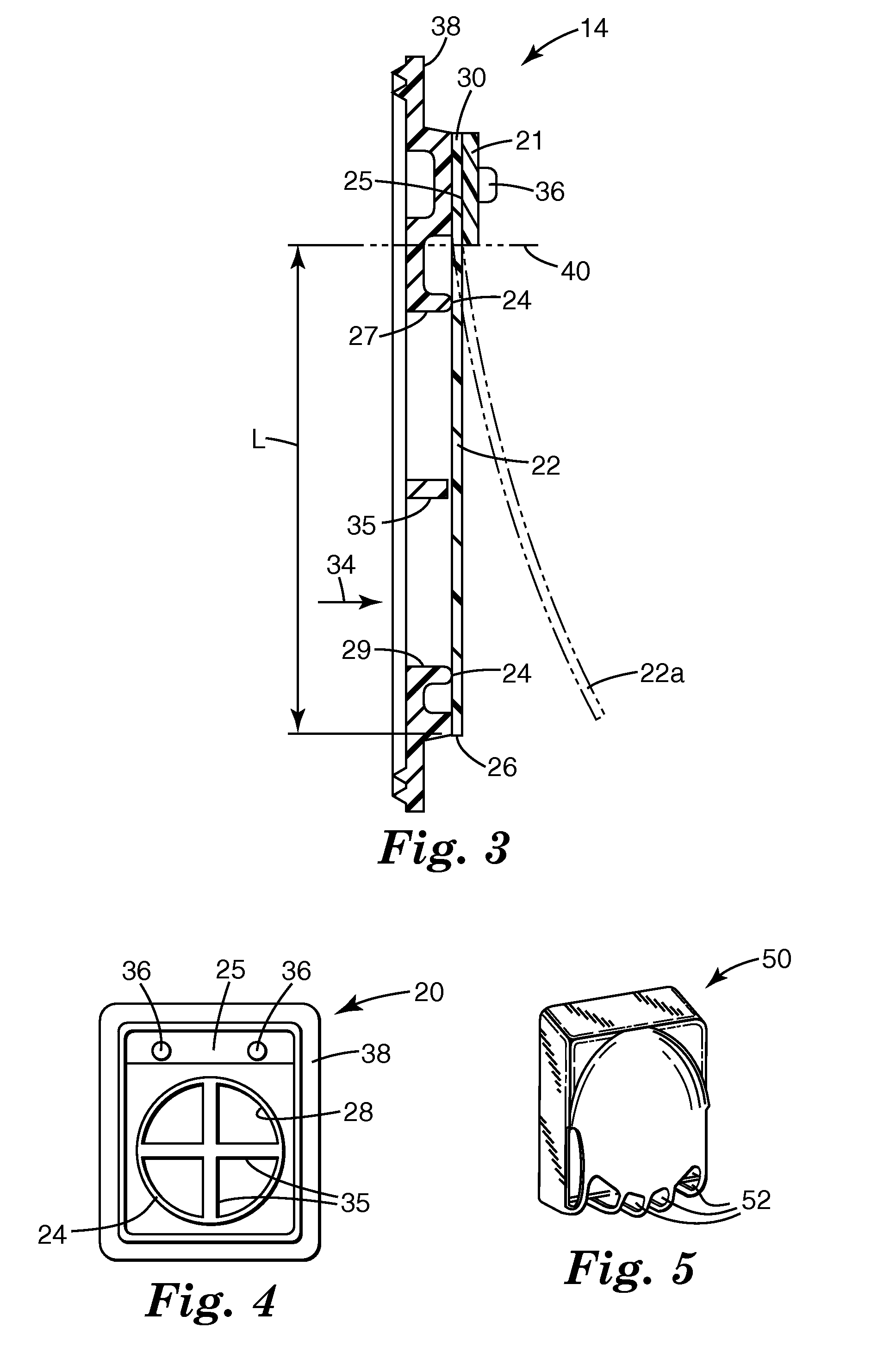

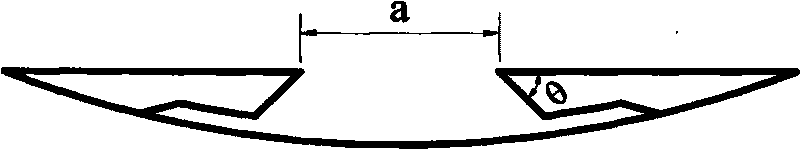

Filtering Face Mask with a Unidirectional Valve Having a Stiff Unbiased Flexible Flap

InactiveUS20070144524A1Reduce the required powerReduce actuation powerBreathing filtersBreathing masksNoseExhaled air

A filtering face mask that includes a mask body that is adapted to fit at least over the nose and mouth of a wearer to create an interior gas space when worn; and an exhalation valve that is in fluid communication with the interior gas space. The exhalation valve includes a valve seat with a seal surface and an orifice through which exhaled air may pass to leave the interior gas space; and a flexible flap that is mounted to the valve seat such that the flap makes contact with the seal surface when the valve is in its closed position and such that the flap can flex away from the seal surface during an exhalation to allow exhaled air to pass through the orifice. The flap is unbiased when in its closed position and exhibits a cantilever bend ratio of 0.0050 or less.

Owner:3M INNOVATIVE PROPERTIES CO

Beamed elastic laminate properties

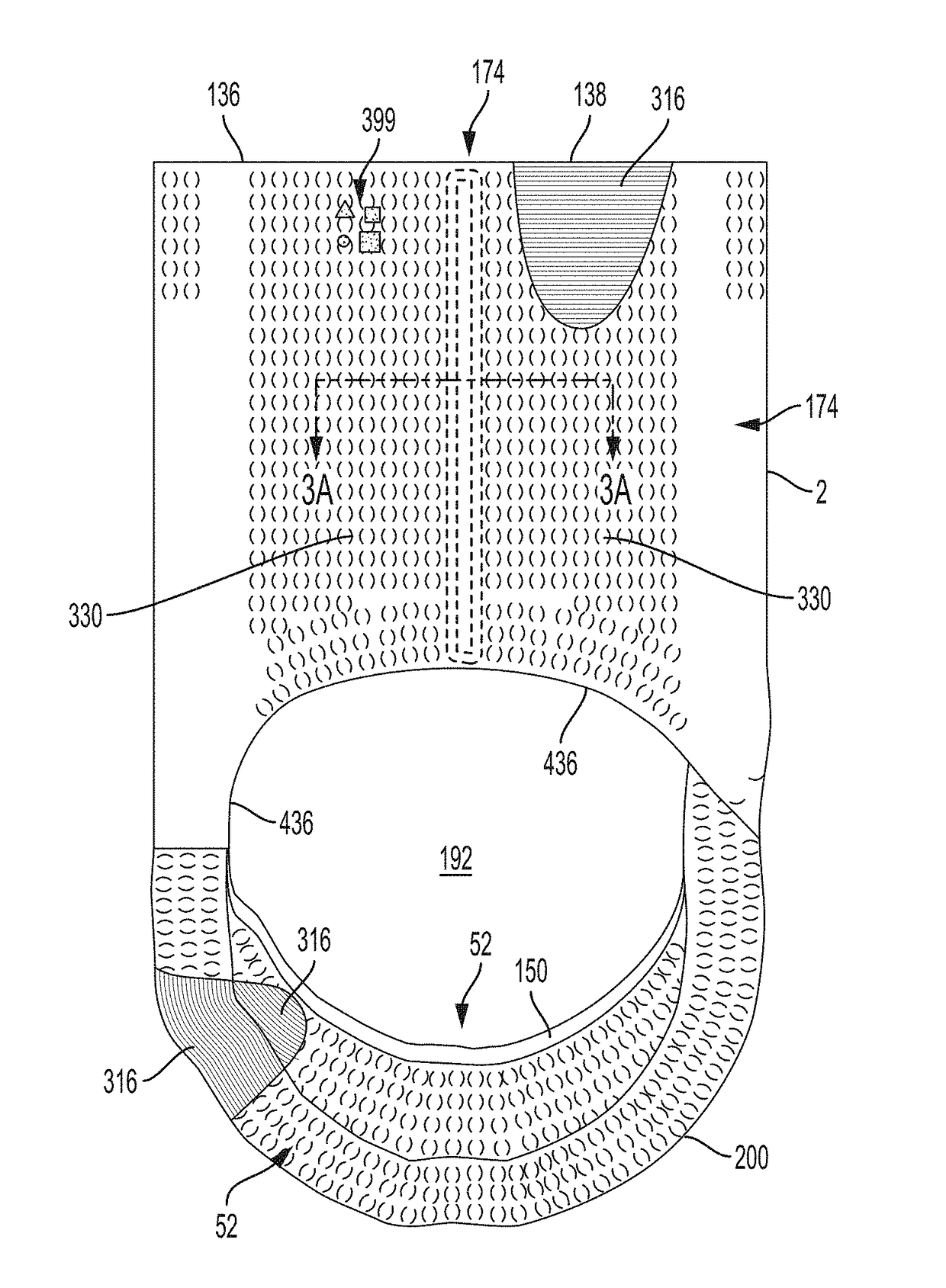

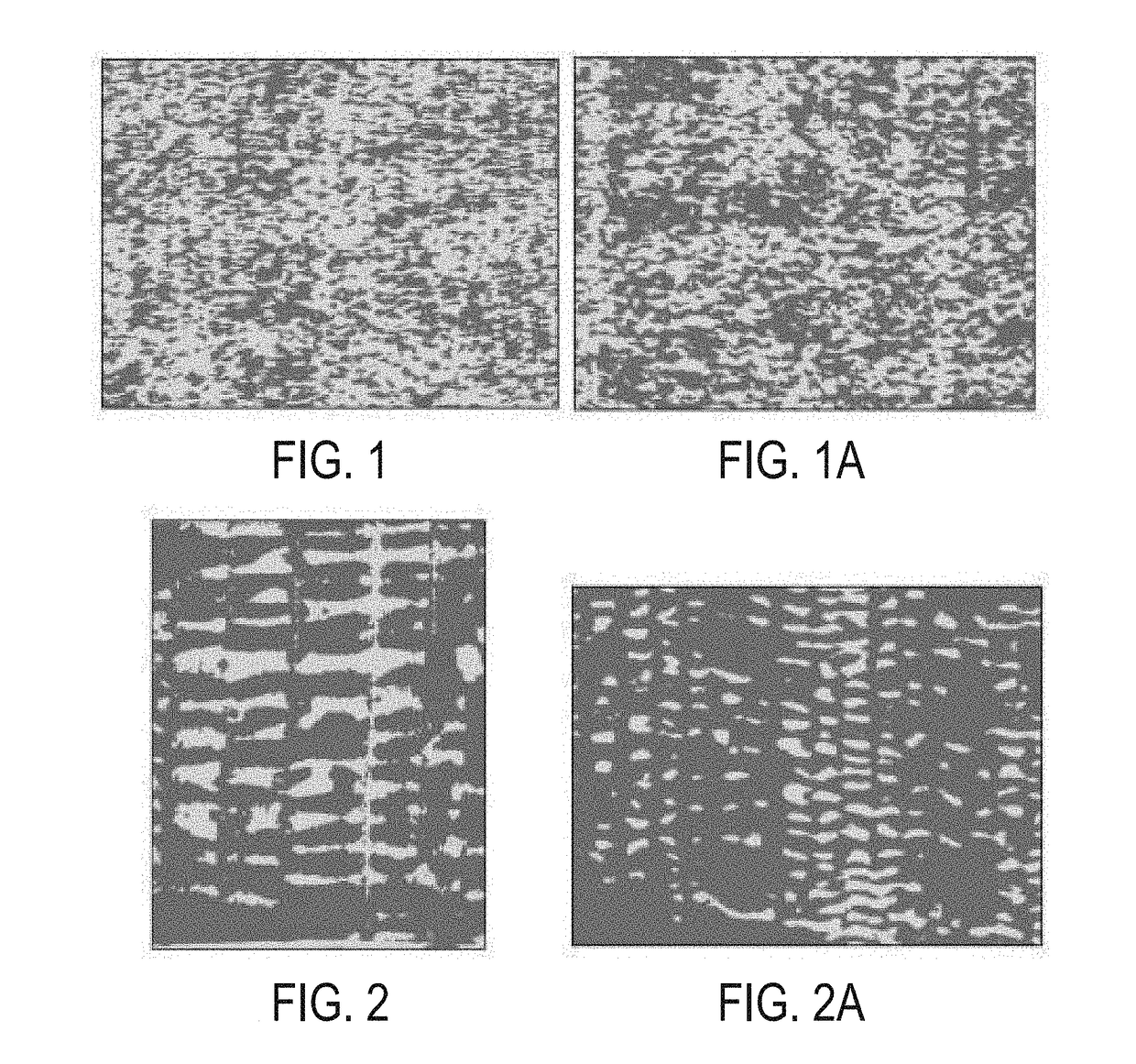

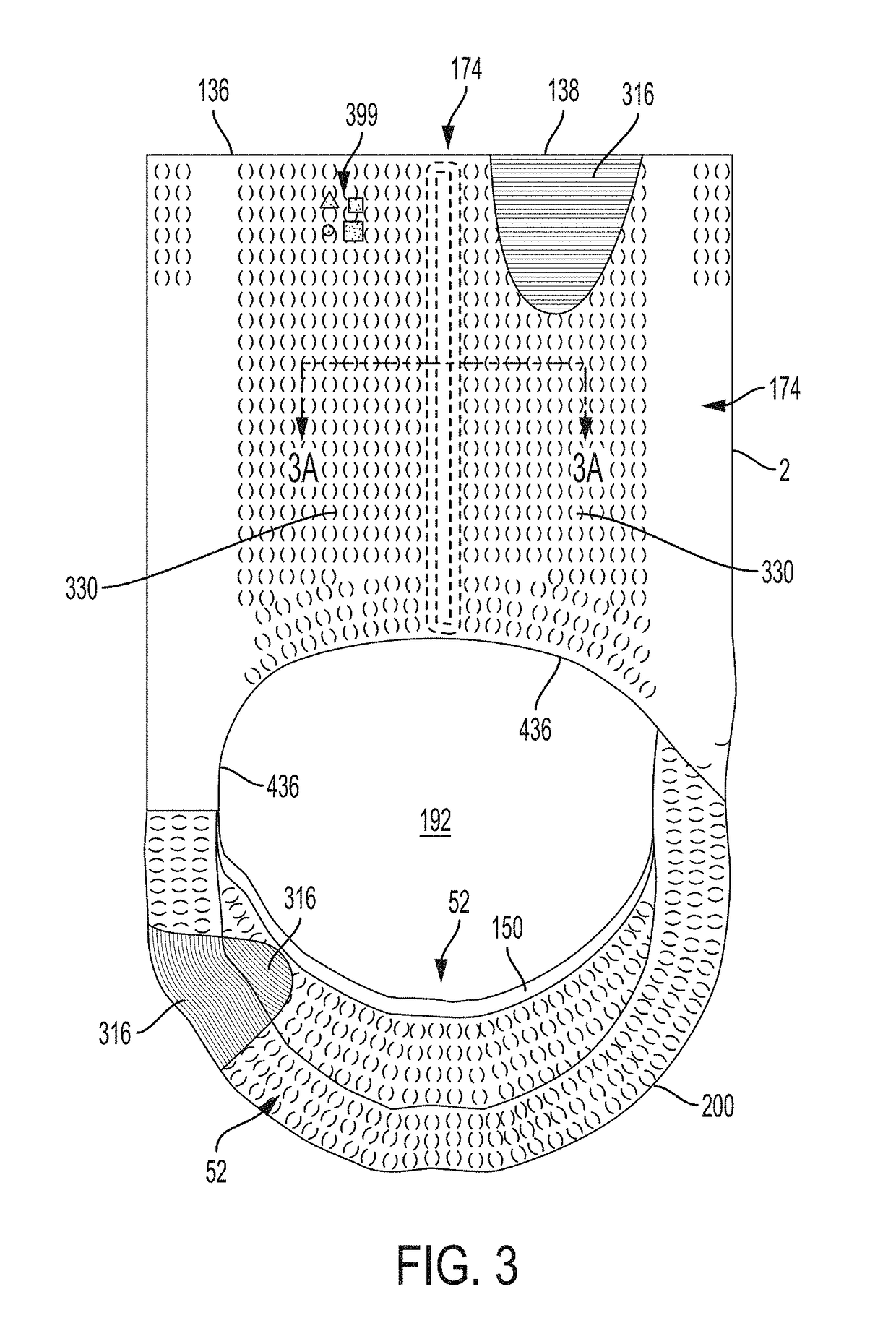

The present disclosure relates to one or a combination of an absorbent article's chassis, inner leg cuffs, outer leg cuffs, ear panels, side panels, waistbands, and belts that may comprise one or more pluralities of tightly spaced (less than 4 mm, less than 3 mm, less than 2 mm, and less than 1 mm) and / or low Average-Dtex (less than 300, less than 200, less than 100 dtex) and / or low Average-Pre-Strain (less than 300%, less than 200%, less than 100%) elastics to deliver low Pressure Under Strand (less than 1 psi according to the conditions defined by the Pressure-Under-Strand Test), while providing adequate Section-Modulus (between about 2 gf / mm and 15 gf / mm) to make the article easy to apply and to comfortably maintain the article in place on the wearer, even with a loaded core (holding at least 100 mls of liquid), to provide for the advantages described above. Further, the elastomeric laminates of the present disclosure outperform existing laminates currently used for disposable absorbent articles as it relates to one or more key parameters (including Percent Contact Area, 2-98% Height Value, Pressure-Under-Strand, Air Permeability, Water Vapor Transmission Rate, Caliper, Caliper Retention Value, Cantilever Bending, Open Area, Section-Modulus, Rugosity Wavelength, Rugosity Frequency, Graphic Distortion Ratio).

Owner:THE PROCTER & GAMBLE COMPANY

Filtering face mask with a unidirectional valve having a stiff unbiased flexible flap

InactiveUS7503326B2Greater this facial discomfortRemissionBreathing masksRespiratory apparatusNoseExhaled air

A filtering face mask that includes a mask body that is adapted to fit at least over the nose and mouth of a wearer to create an interior gas space when worn; and an exhalation valve that is in fluid communication with the interior gas space. The exhalation valve includes a valve seat with a seal surface and an orifice through which exhaled air may pass to leave the interior gas space; and a flexible flap that is mounted to the valve seat such that the flap makes contact with the seal surface when the valve is in its closed position and such that the flap can flex away from the seal surface during an exhalation to allow exhaled air to pass through the orifice. The flap is unbiased when in its closed position and exhibits a cantilever bend ratio of 0.0050 or less.

Owner:3M INNOVATIVE PROPERTIES CO

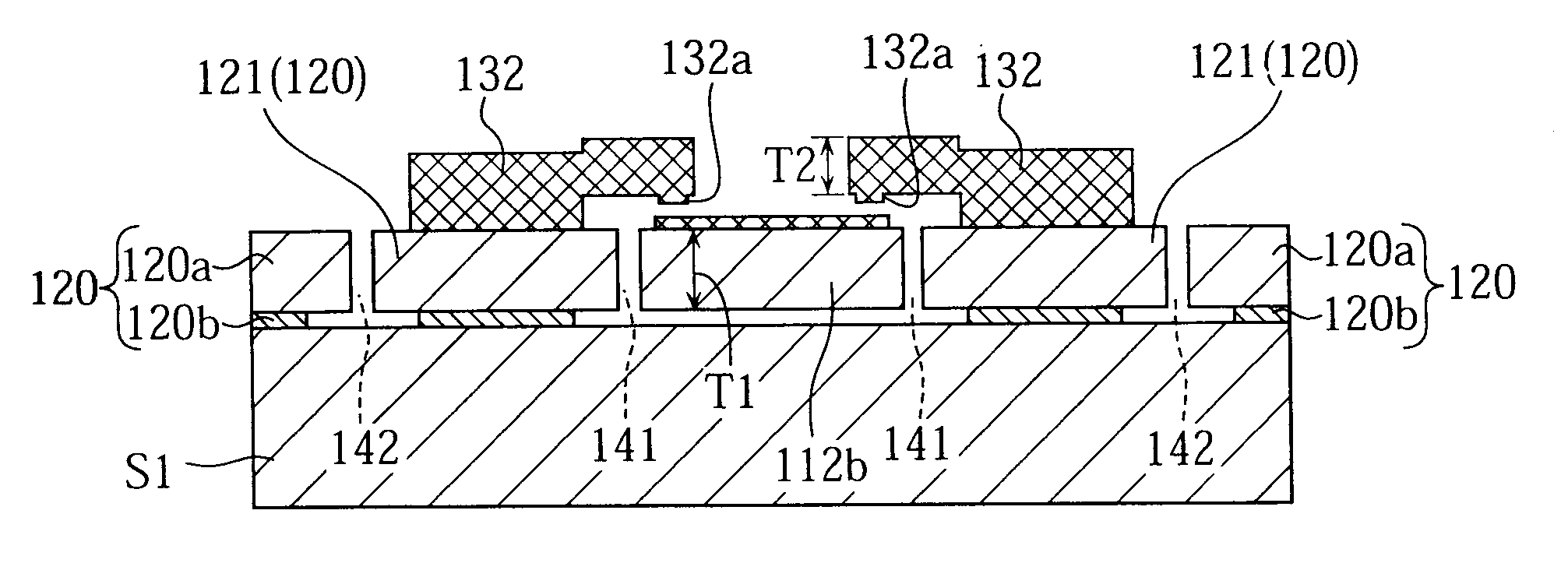

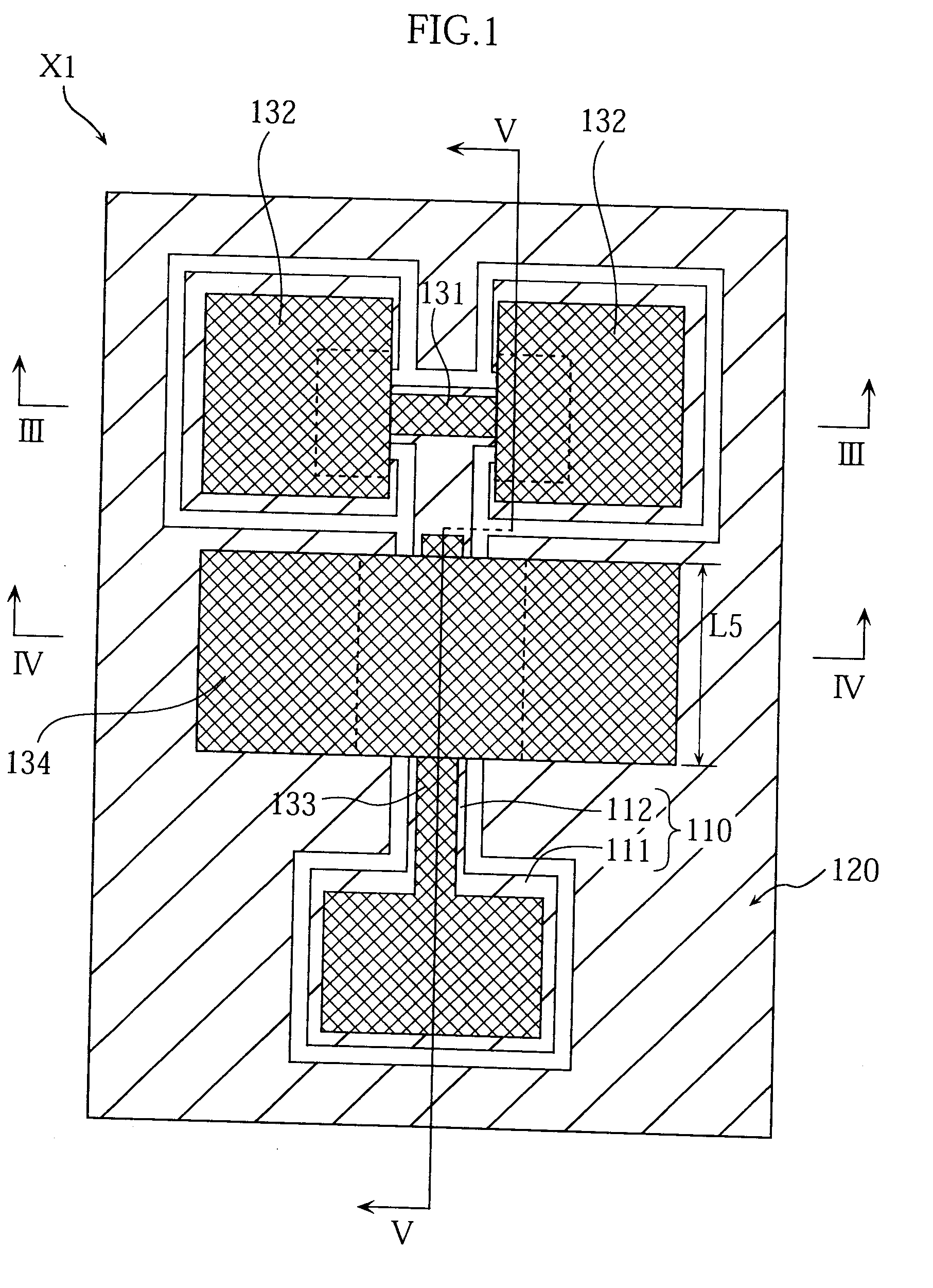

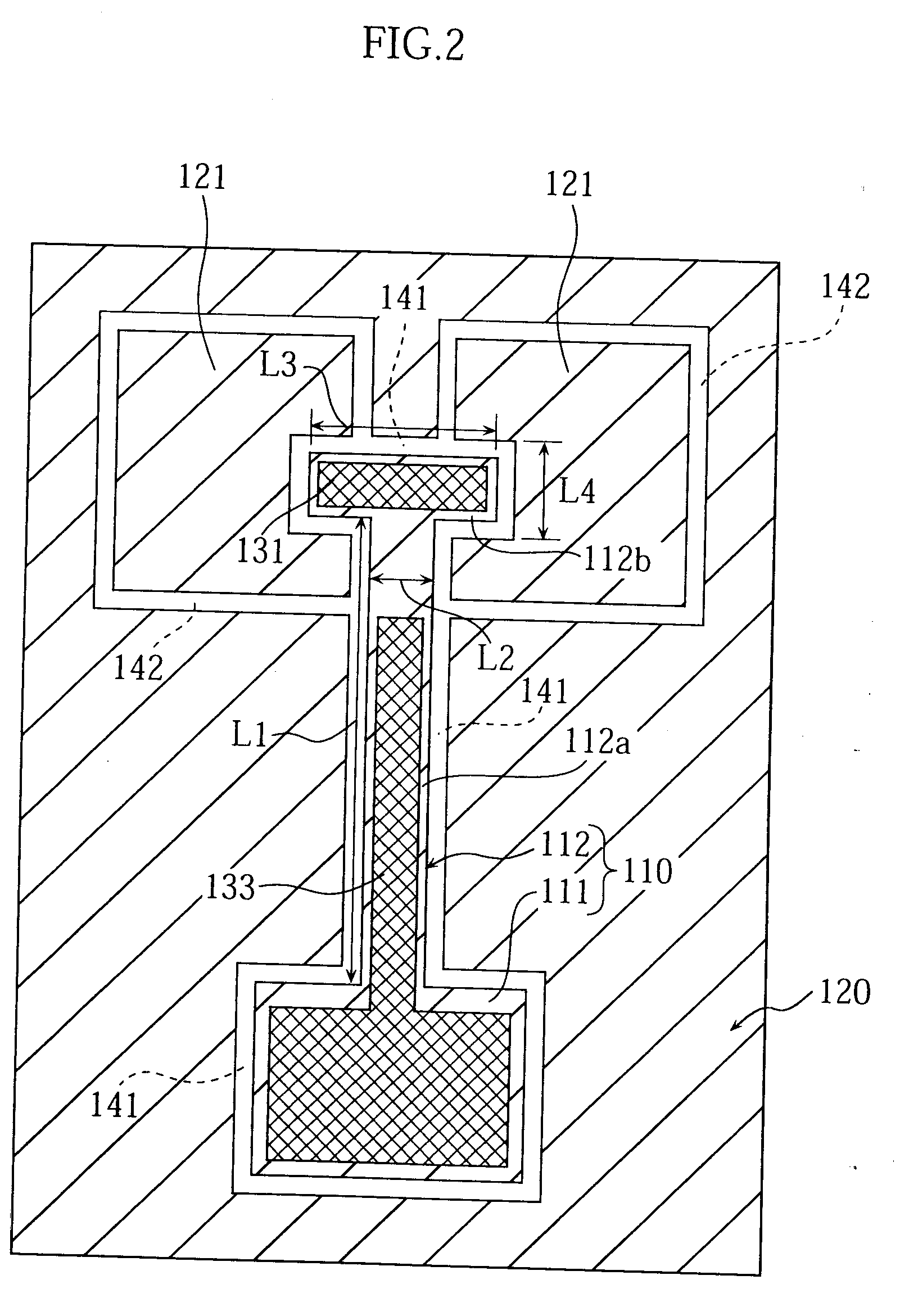

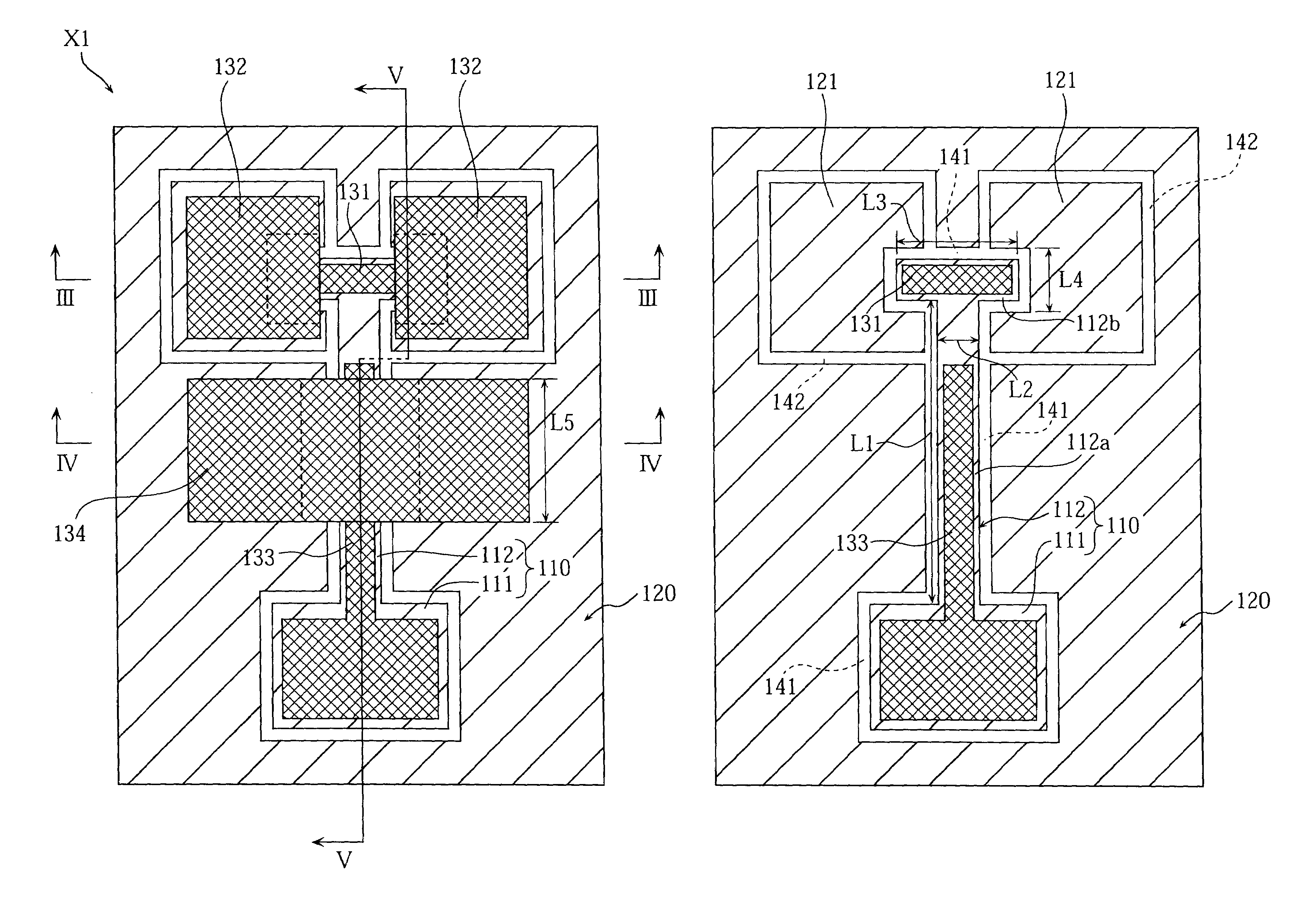

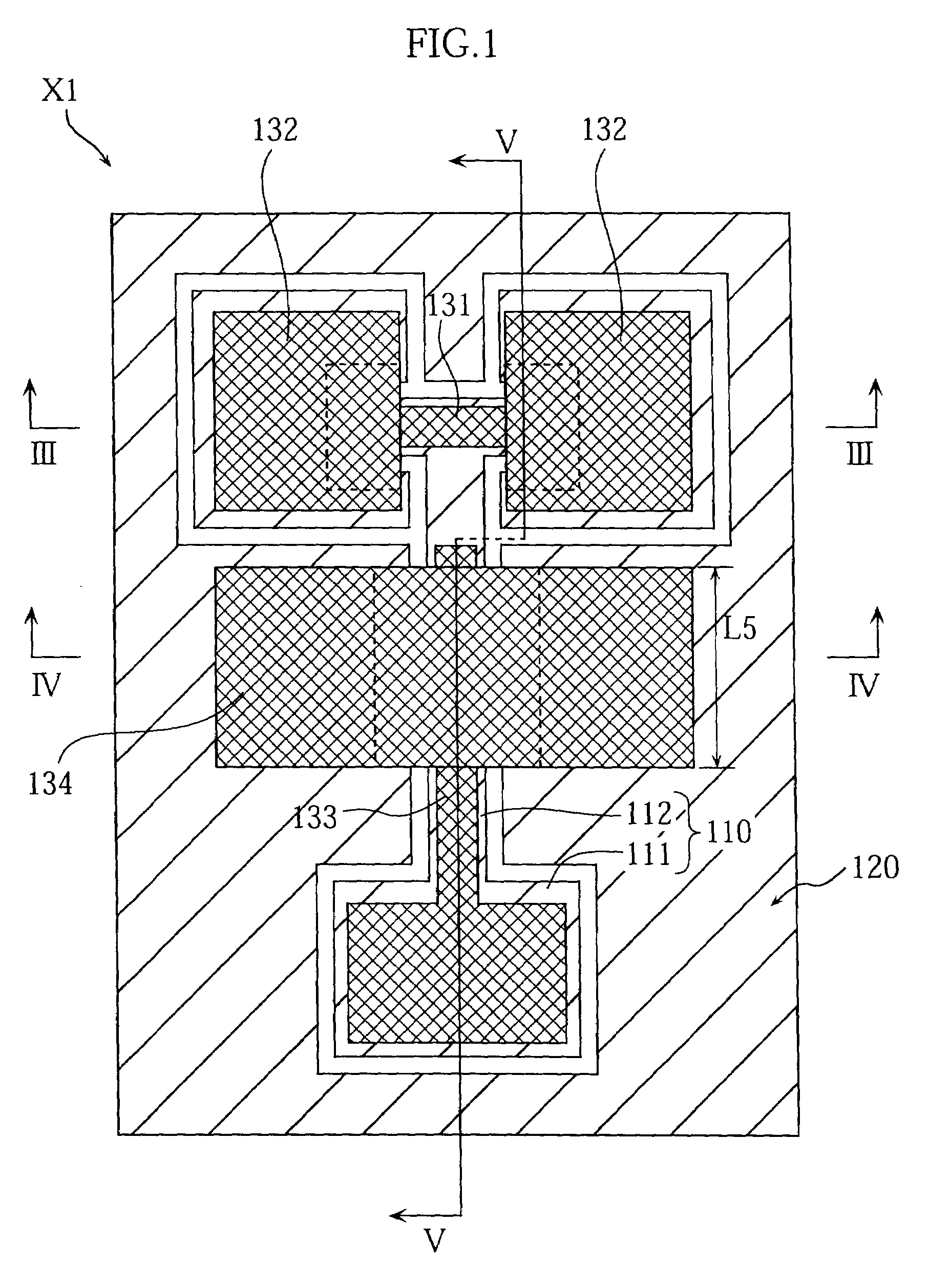

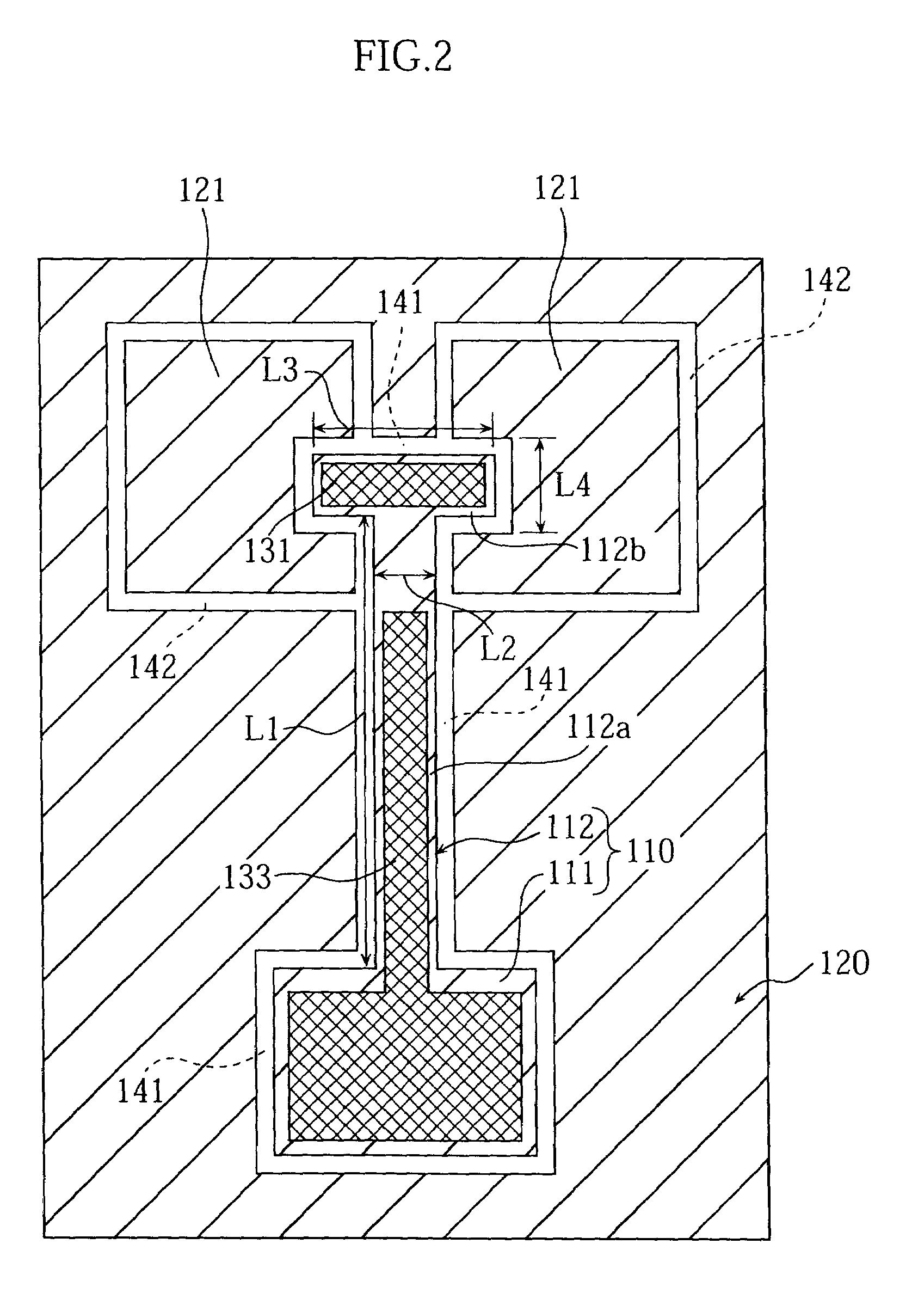

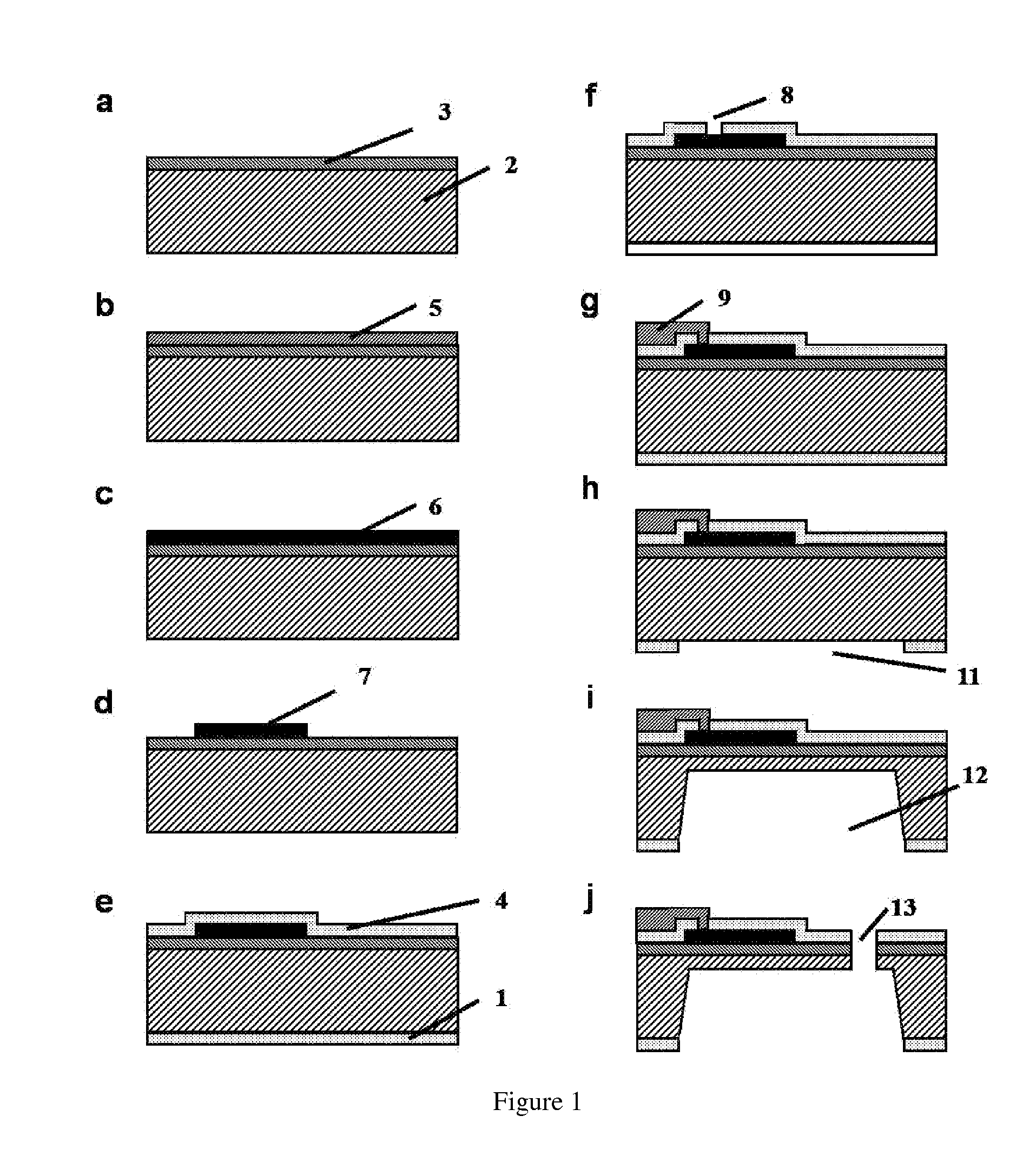

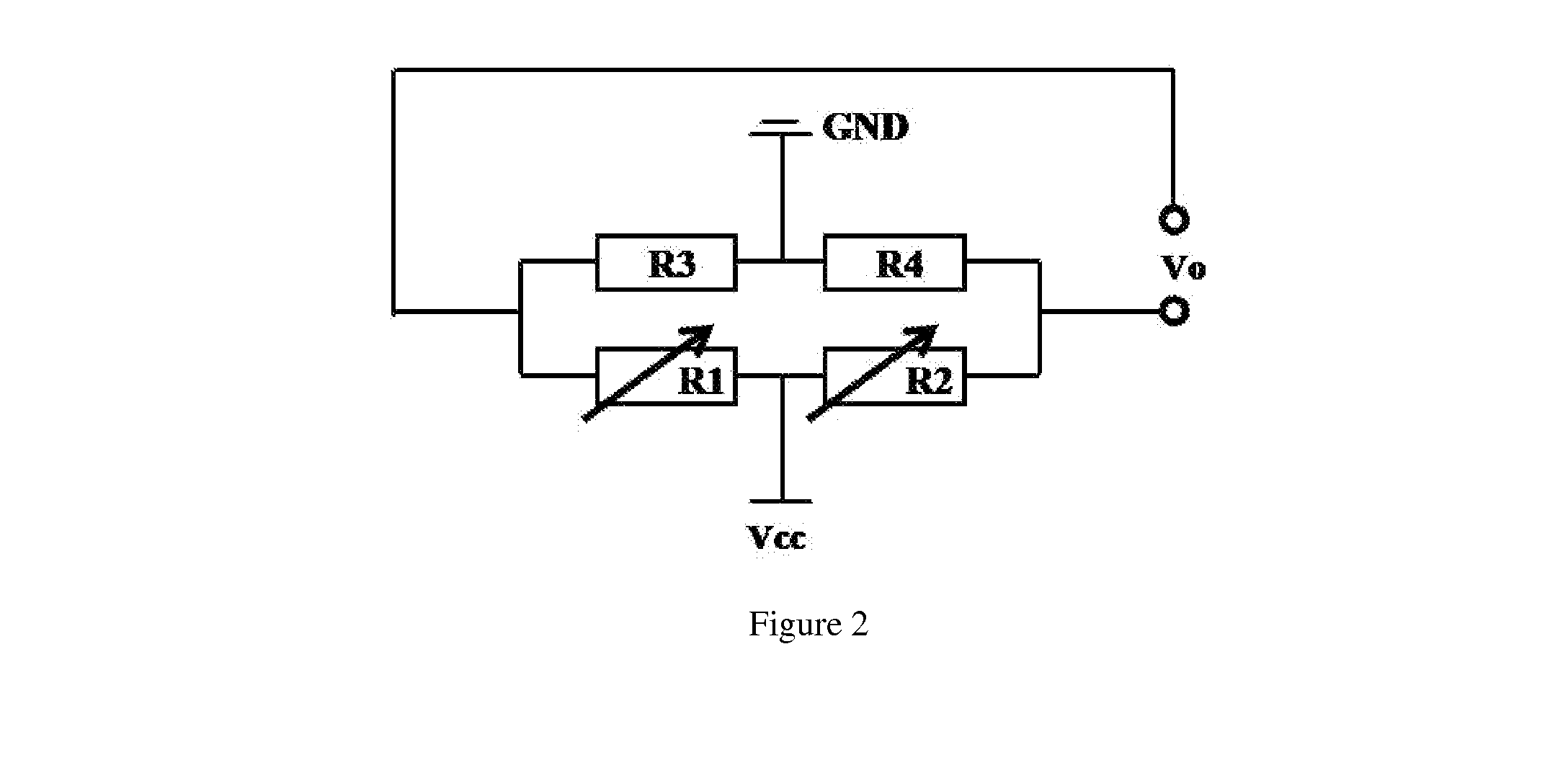

Micro-switching device and method of manufacturing micro-switching device

InactiveUS20050225921A1Reduced insertion lossSuppress internal stressElectrostatic/electro-adhesion relaysDecorative surface effectsEngineeringElectrical and Electronics engineering

A micro-switching device includes a base substrate and a cantilever fixed to the base substrate via a spacer or anchor portion. The cantilever has an inner surface facing the substrate and an outer surface opposite to the inner surface. A conductive strip is formed on the outer surface of the cantilever. The switching device also includes a pair of stationary electrodes fixed to the base substrate. Each of the electrodes includes a downward contacting part spaced from the conductive strip on the cantilever. As the cantilever bends upward, the conductive strip is brought into contact with the contacting parts of the respective stationary electrodes.

Owner:FUJITSU LTD

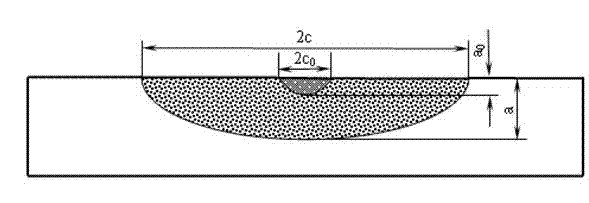

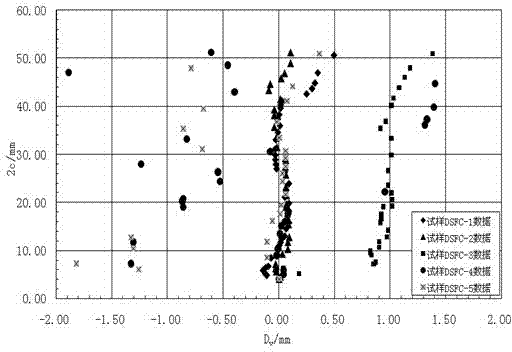

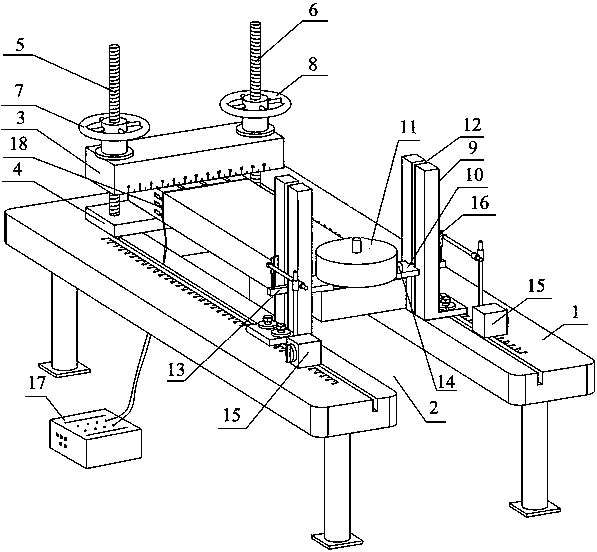

Strain control method of cantilever bending and loading low-circle fatigue test

InactiveCN101694436AImprove reliabilityImprove test test accuracyMaterial strength using steady bending forcesMechanical solid deformation measurementsElectrical resistance and conductanceTest sample

The invention introduces a strain control method of a cantilever bending and loading low-circle fatigue test. The strain control method is characterized in that a COD gauge integral holding knife edge is designed on an original test sample, the one-to-one correspondence between strain at the position of the COD gauge holding knife edge and strain measured by a resistance strain gauge at a surface crack front is established through pre-calibration. According to the correspondence, the strain at the position of the COD gauge holding knife edge is used to replace strain at a test sample surface crack front measured by the resistance strain gauge, and corresponding strain at the position of the COD gauge holding knife edge is inputted into a computer, thereby realizing strain control of the cantilever bending and loading low-circle fatigue test. The method is capable of improving test measuring accuracy, increasing data reliability, saving cost, lowering labor intensity, and solving the technical problem that test samples are scrapped as a testing machine is led to lose stability suddenly when the resistance strain gauge is easily fatigue and damaged in strain sticking method of the resistance strain gauge.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

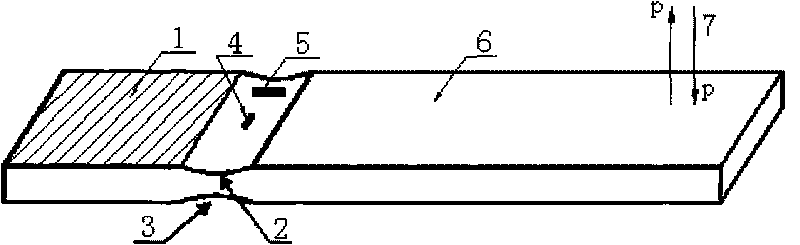

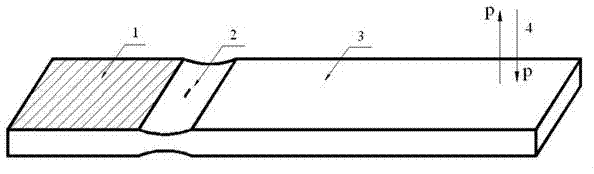

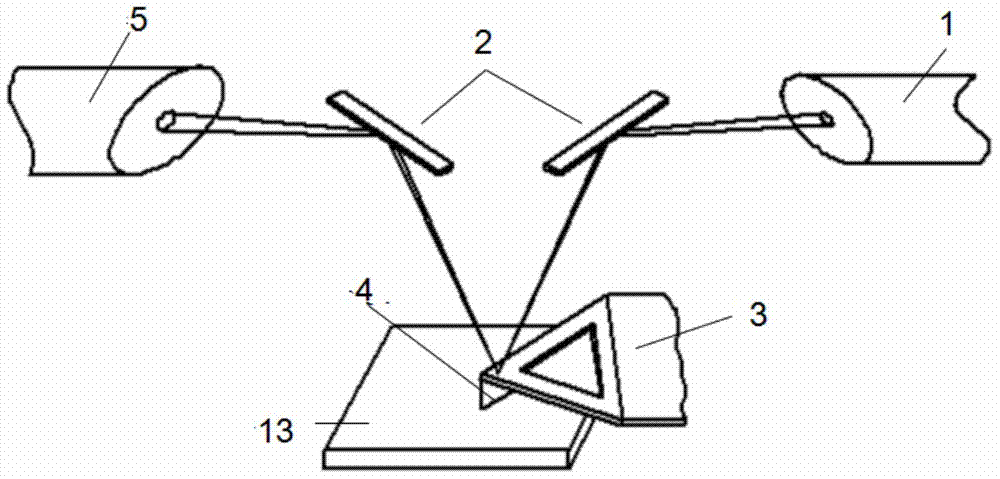

Cantilever bending load metal material fatigue damage test measurement method

InactiveCN103323351AConstant monitoring of fatigue damageMaterial strength using repeated/pulsating forcesMathematical definitionFatigue damage

The invention relates to a cantilever bending load metal material fatigue damage test measurement method. According to a damage equivalence principle, based on a factor that metal material force application point displacement characteristic value is bound to change when fatigue damage occurs, with a material fatigue damage variable mathematical definition D=1-A' / A=(Delta A) / A, and through establishing a functional relationship between a smooth plate sample fatigue damage amount and the force application point displacement characteristic value, a restriction face (1), a notch (2), a cantilever zone (3), and a circulation load P force application point (4) are arranged on the smooth plate sample, such that the fatigue damage amount of the smooth plate sample can be monitored in real time. The fatigue damage amount is compared with a fatigue damage amount critical value, such that the safety and reliability of the service of the metal material or a metal component can be evaluated. The invention discloses the metal material fatigue damage quantitative test from one aspect, and provides a possibility for macroscopic measurement of metal material fatigue damage. The method has certain popularization value.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

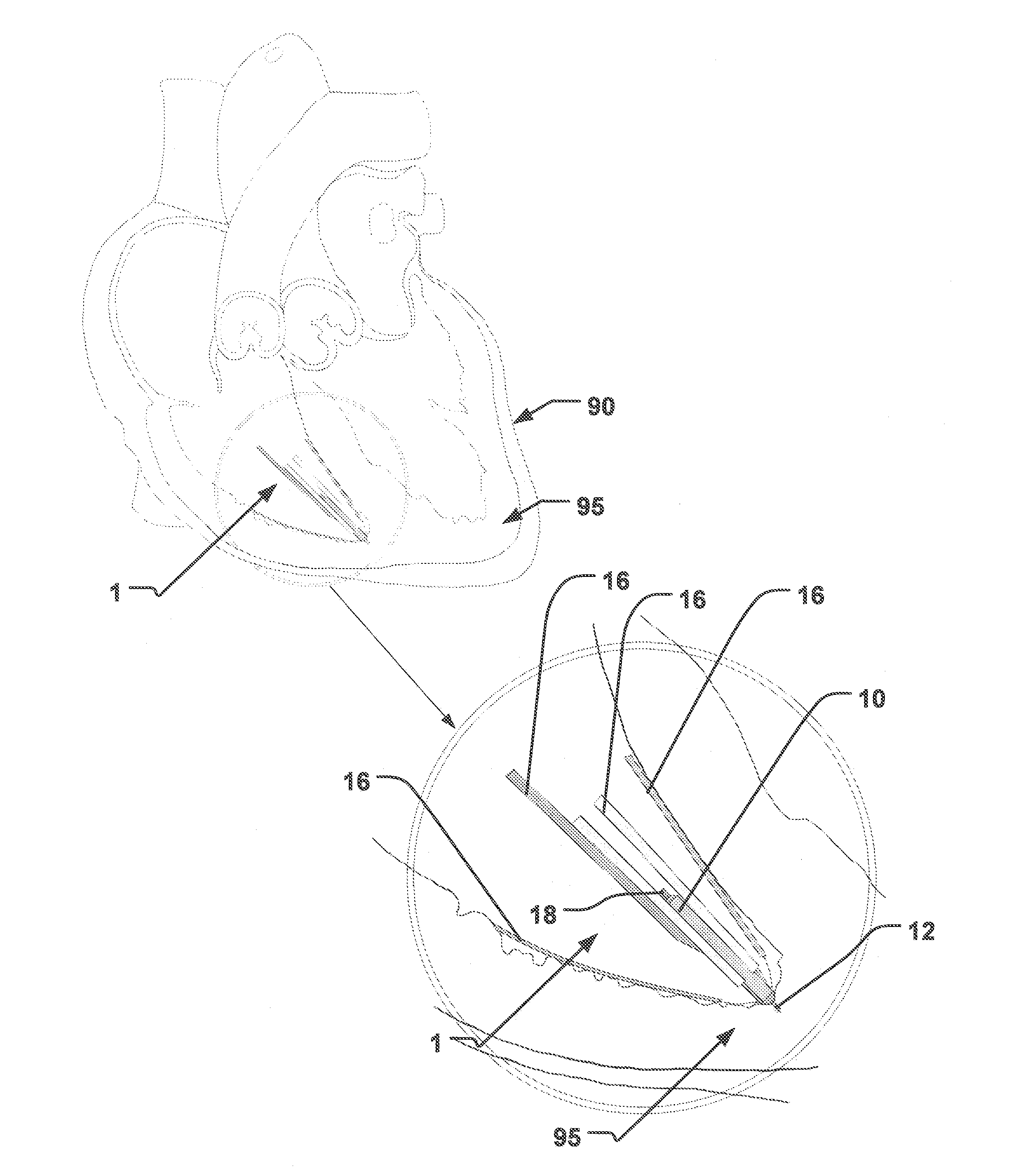

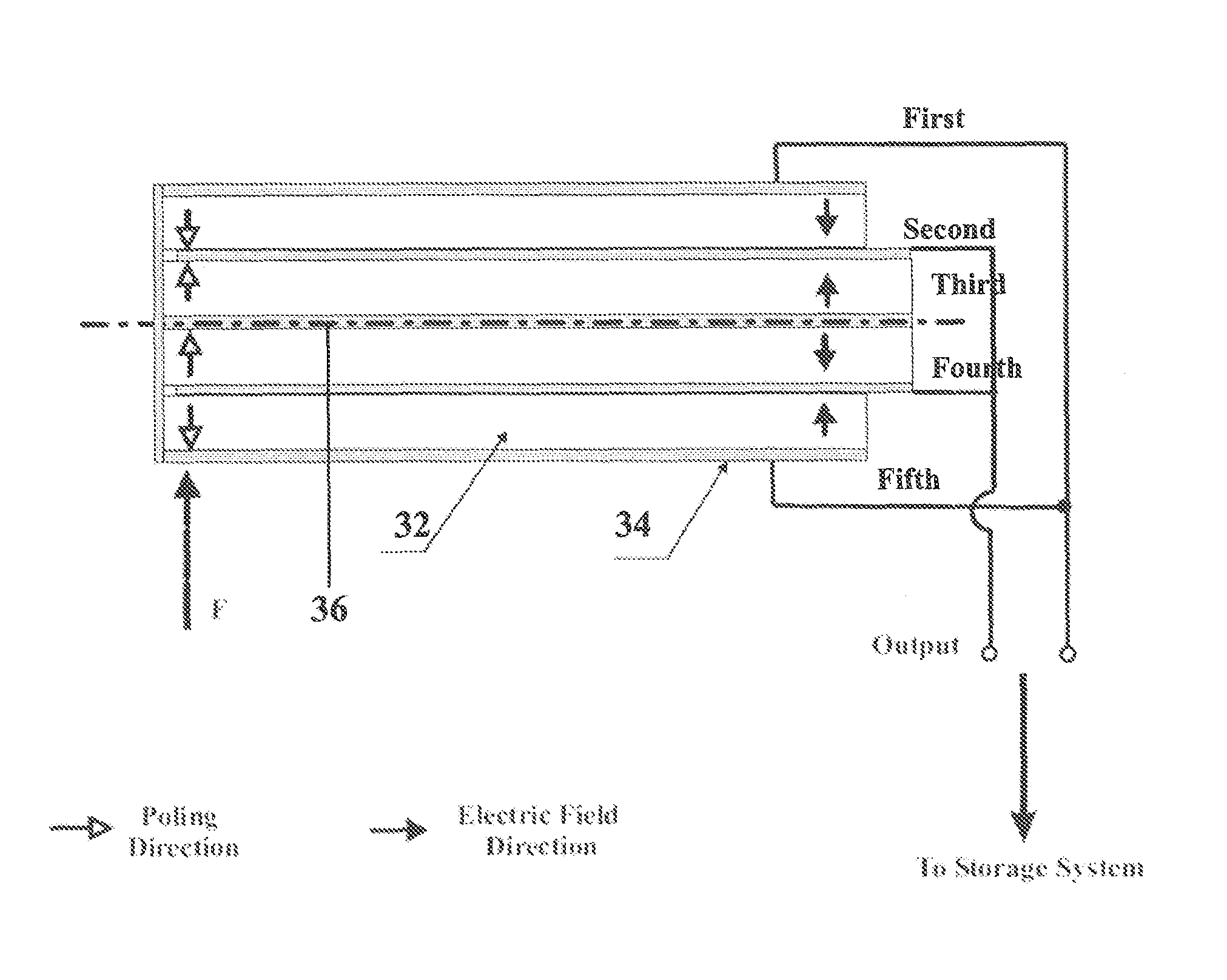

Medical System, Piezoelectric Kit, Related Methods And Medical Procedures

ActiveUS20130226260A1More productivePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesHigh energyPiezo electric

A system for harvesting of natural power of the heart movement to be deployed entirely inside or outside human heart. The means and the method for the system deployment / extraction are provided. The system is implemented as storage “satellite” container / housing / carrier unit for piezoelectric power generator, power storage and spare volume for transported cardio stimulator devices. The piezoelectric power generator comprises embedding circuits containing the diode bridge, controller, capacitor and a number of piezo-electric elastic ceramic rods—“leaflets”, originally strained asymmetrically with accordance to the heart 3D geometry in order to obtain high energy conversion efficiency and high sensitivity to the heart movement. The innovative construction of the piezoelectric generator is applied to piezoelectric transformer based on cantilever bending vibrations.

Owner:PI HARVEST HLDG

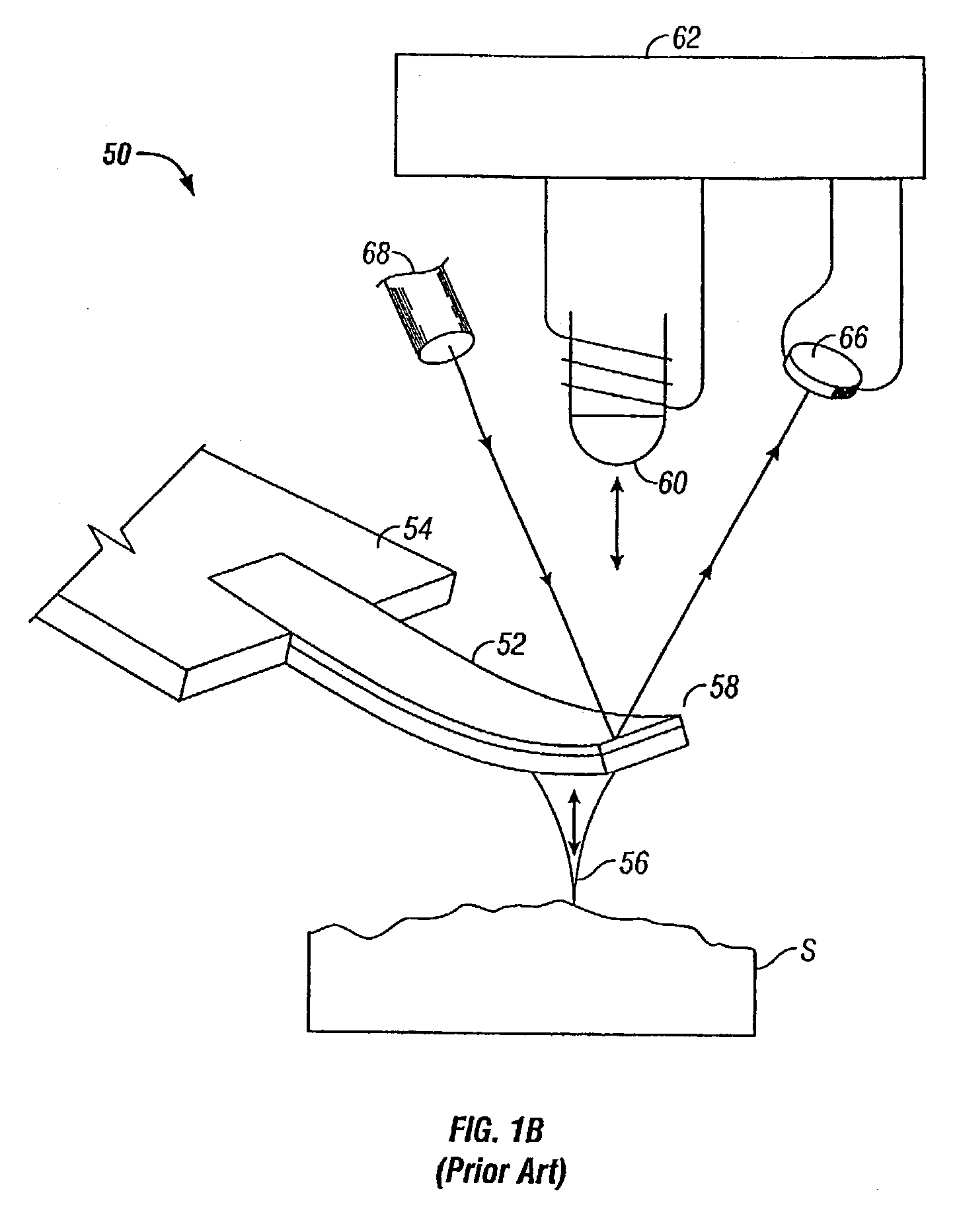

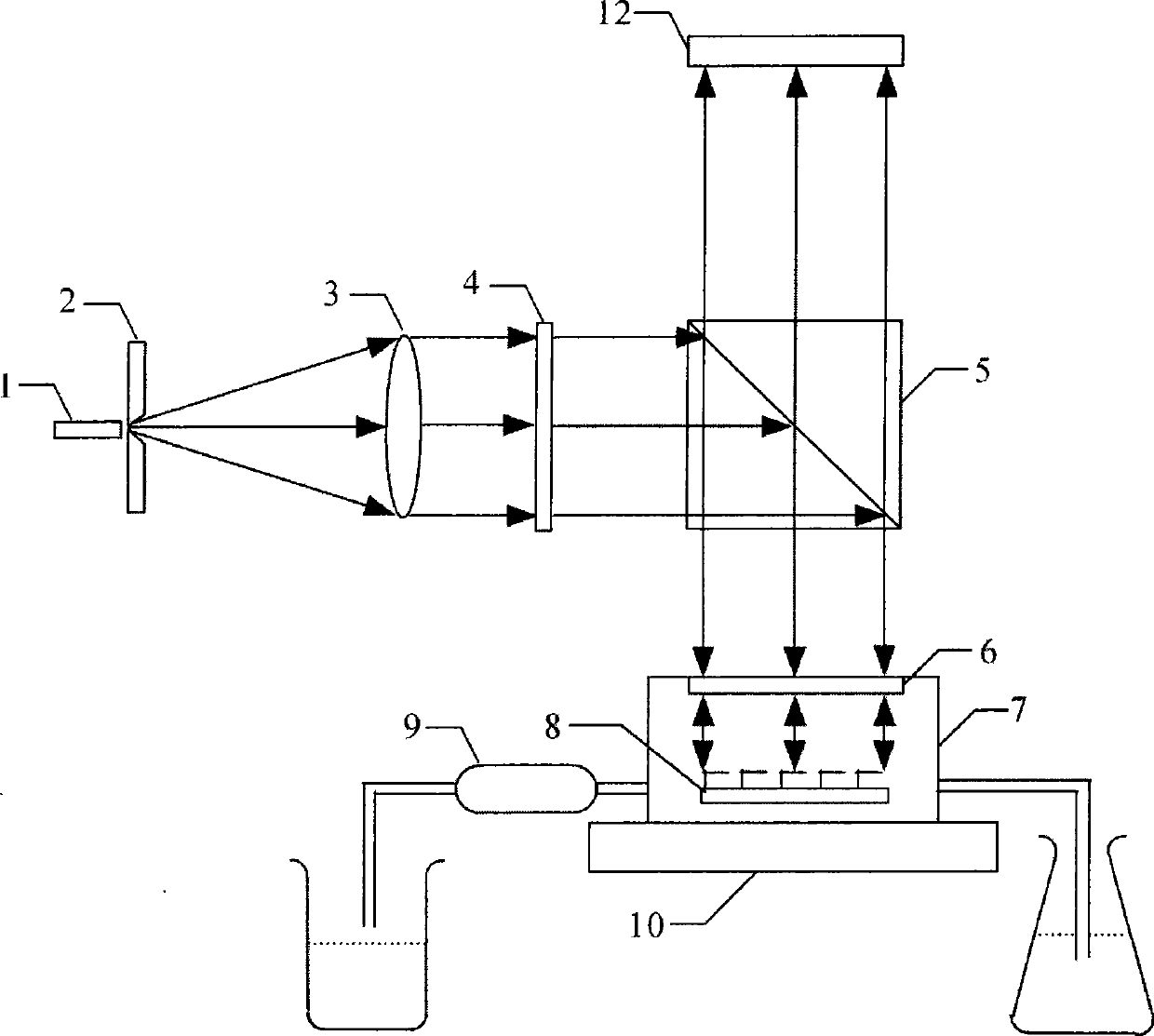

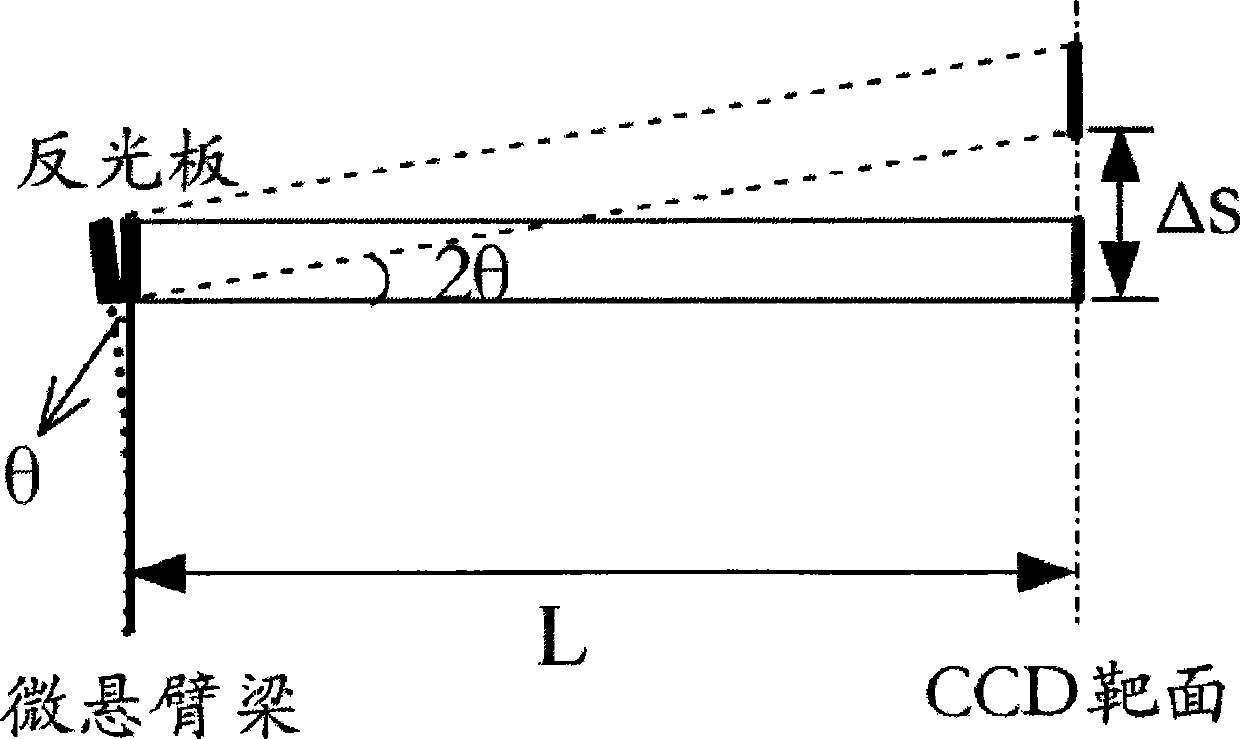

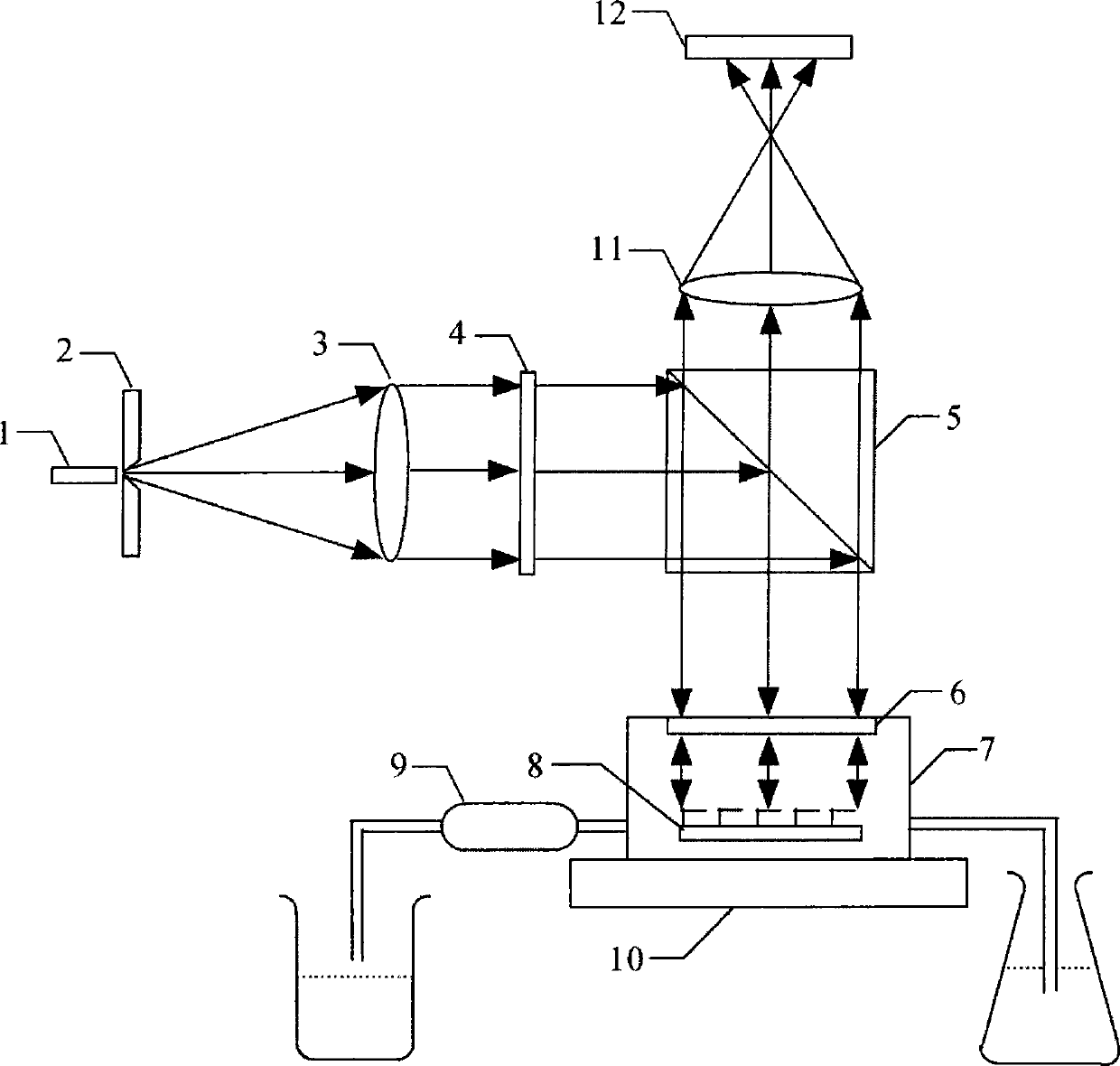

Method and apparatus for monitoring macromolecule conformation transformation and biochemical reaction of target and probe

InactiveCN101373175ARealize monitoringRemove noise signalSurface/boundary effectMaterial analysis by optical meansRefractive indexLight beam

The invention discloses a method and a device for observing the conformation transition of macromolecules and the biochemical reaction between target molecules and probe molecules. The method comprises the steps as follows: the macromolecules and one or more of the probe molecules which are different or identical are arranged on single side surfaces of various micro-cantilevers in a micro-cantilever array; the incident parallel rays emitted from a light source reach the micro-cantilevers, and the reflection rays are received by an optical receiver assembly to form an array of reflection ray spots corresponding to the micro-cantilevers one by one; when the conformation transition of macromolecules occurs or the combination of the probe molecules and the target molecules present in a solution to be tested occurs, the micro-cantilevers bend and deform with the deflection of the reflection rays, and accordingly, the positions of the corresponding reflection ray spots change; and according to the position change and the displacement of the reflection ray spots corresponding to each micro-cantilever, the conformation transition of the macromolecules can be learned, whether the target molecules corresponding to the probe molecules are present or absent in the solution to be tested can be determined, and the concentration of the target molecules present in the solution can be obtained. The invention can realize the simultaneous observation of the displacement signals of a plurality of micro-cantilevers, and at the same time eliminate the noise signals due to the variation of the refraction index and the change of the intensity of a light source. The invention has the advantages that the effects of vagabond rays can be greatly reduced by controlling the measurement of the light beam polarization state, and the measurement precision is improved.

Owner:张青川

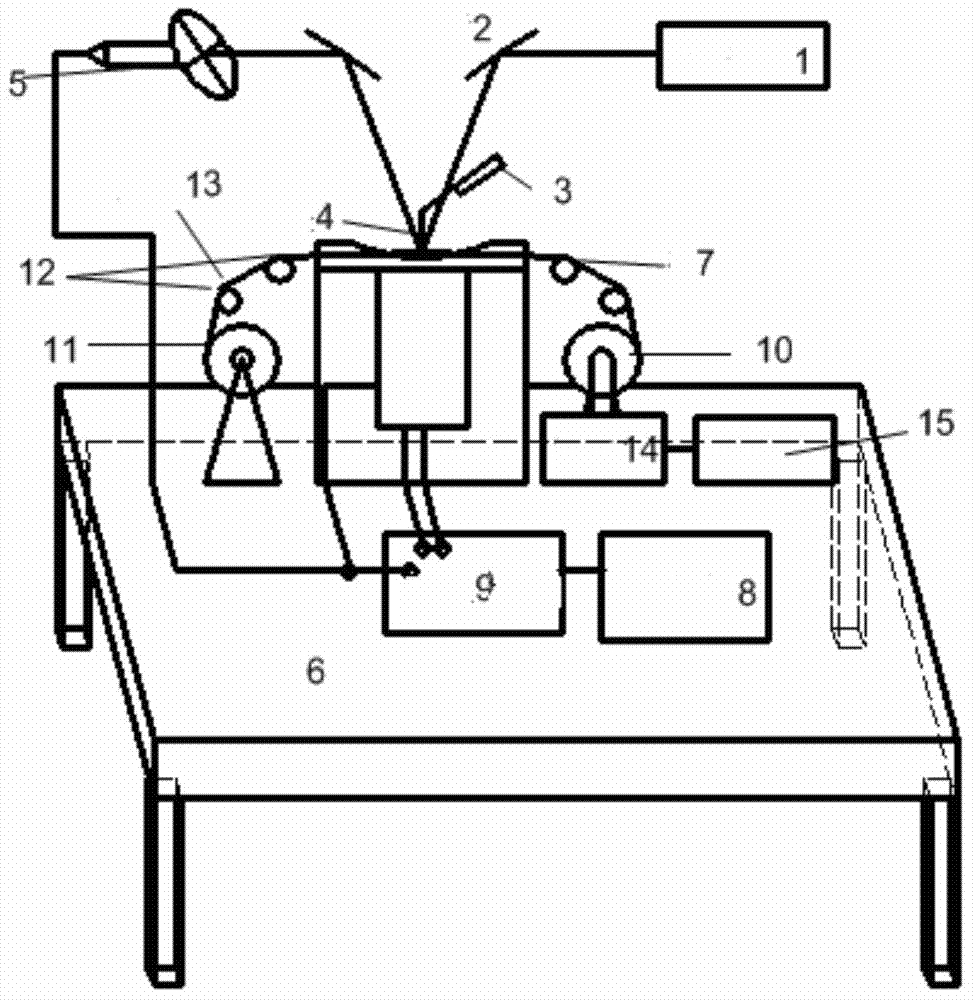

Surface roughness online detection device and method for high-temperature coating superconductive baseband

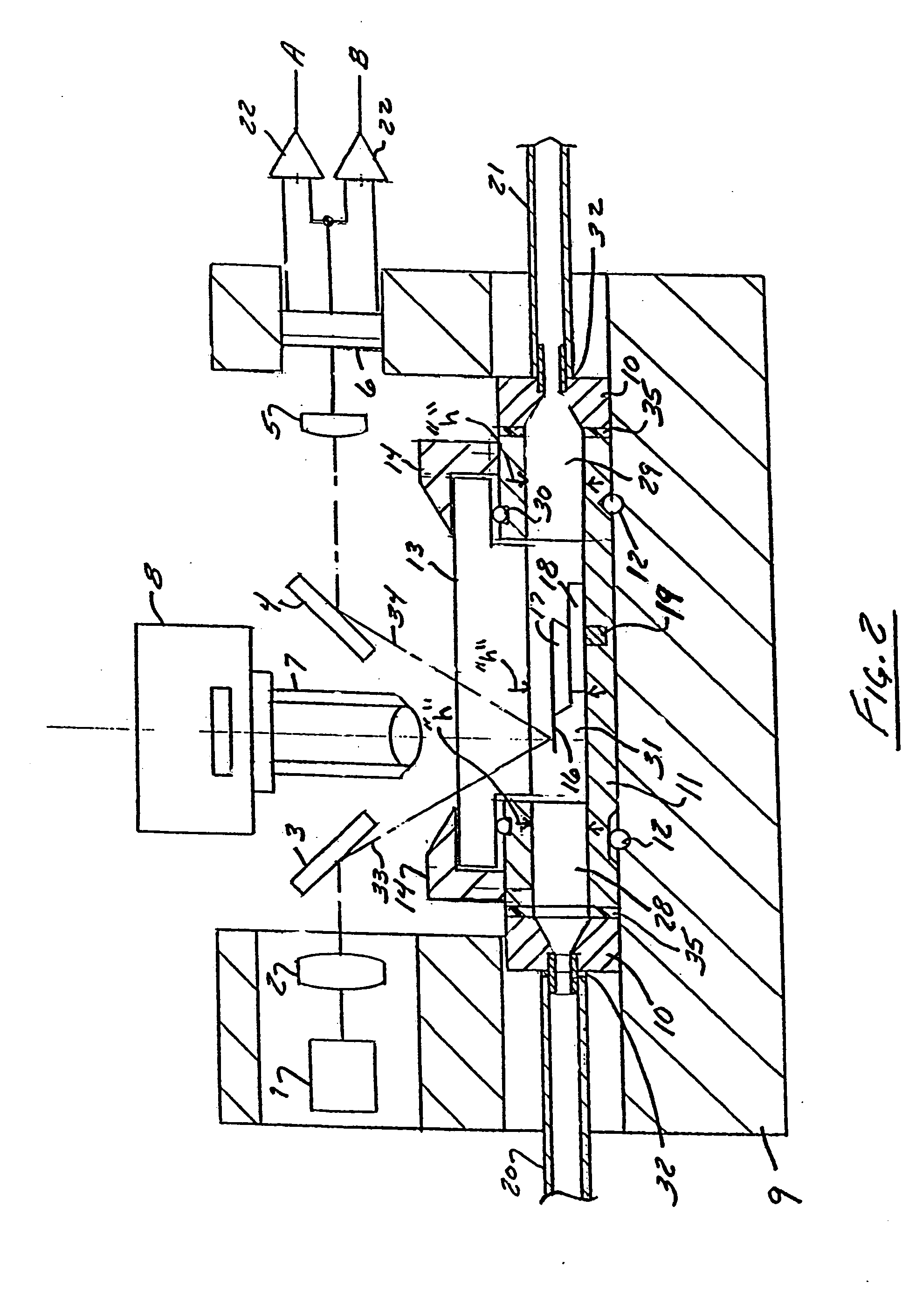

The invention discloses a surface roughness online detection device and method for a high-temperature coating superconductive baseband and belongs to the technical field of detection of high-temperature coating superconductive basebands. The surface roughness online detection device for the high-temperature coating superconductive baseband comprises a band winding and unwinding system, an atomic force microscope, a power system and an IPC (Industrial Personal Computer) system. A surface roughness online detection method comprises that a baseband is placed on a sample stage of the atomic force microscope through the band winding and unwinding system, a probe tip acts on the surface of the baseband to be detected, laser beams emitted by a laser is focused on a back surface of a micro-cantilever through a reflector and is reflected on a light spot position detector, during sample detection, due to interaction forces between atoms on a baseband surface and atoms at the tip of the probe of the micro-cantilever, the micro-cantilever bends and fluctuates along with the surface topography of the baseband, reflected beams also offsets along with the surface topography of the baseband, then a control system indicates a position of a light spot through a light-difference-converted voltage signal, and a baseband RMS (root-mean-square) roughness Rq and an arithmetic mean roughness Ra are computed through a computer. The simple-structure atomic force online checking device and detection method can meet requirements of surface inspection of samples.

Owner:深创超导(深圳)科技有限公司

Stepping piezoelectric drive motor

ActiveCN105846714AStrong tolerancePiezoelectric/electrostriction/magnetostriction machinesElectricityElastic substrate

The invention relates to a stepping piezoelectric drive motor, which comprises piezoelectric vibrators, a rotating shaft, mass blocks, a base and composite cantilevers, wherein two ends of each piezoelectric vibrator are fixedly connected to the rotating shaft and the corresponding mass block respectively; each composite cantilever is in a sheet structure and is formed by laminating a high-friction elastic material and a low-friction elastic material; the friction coefficients of the high-friction elastic materials and the low-friction elastic materials are different; the composite cantilevers are vertically arranged on the lower surfaces of the mass blocks; the laminated surfaces of each high-friction elastic material and the corresponding low-friction elastic material is parallel to the bonded surface of piezoelectric ceramic and one corresponding elastic substrate; the rotating shaft and the base form a rotation pair; the piezoelectric vibrators vibrate to drive the mass blocks to vibrate; the composite cantilevers are bent; and the motor directionally rotates by combining the action of the materials with two friction coefficients adopted by the composite cantilevers. The stepping piezoelectric drive motor has the advantages of being long in service lifetime and simple in structure.

Owner:谐振机电精密技术(苏州)有限公司

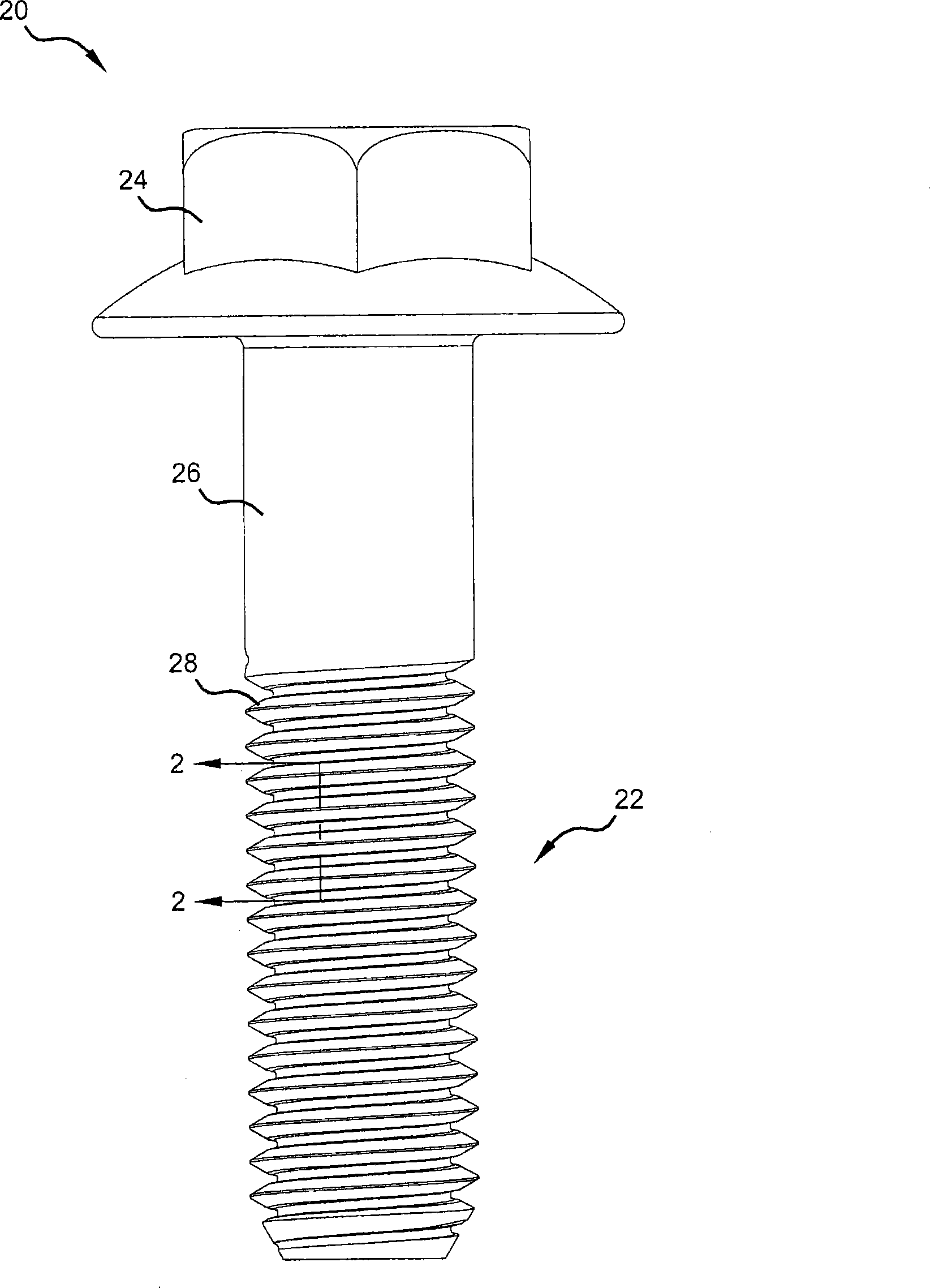

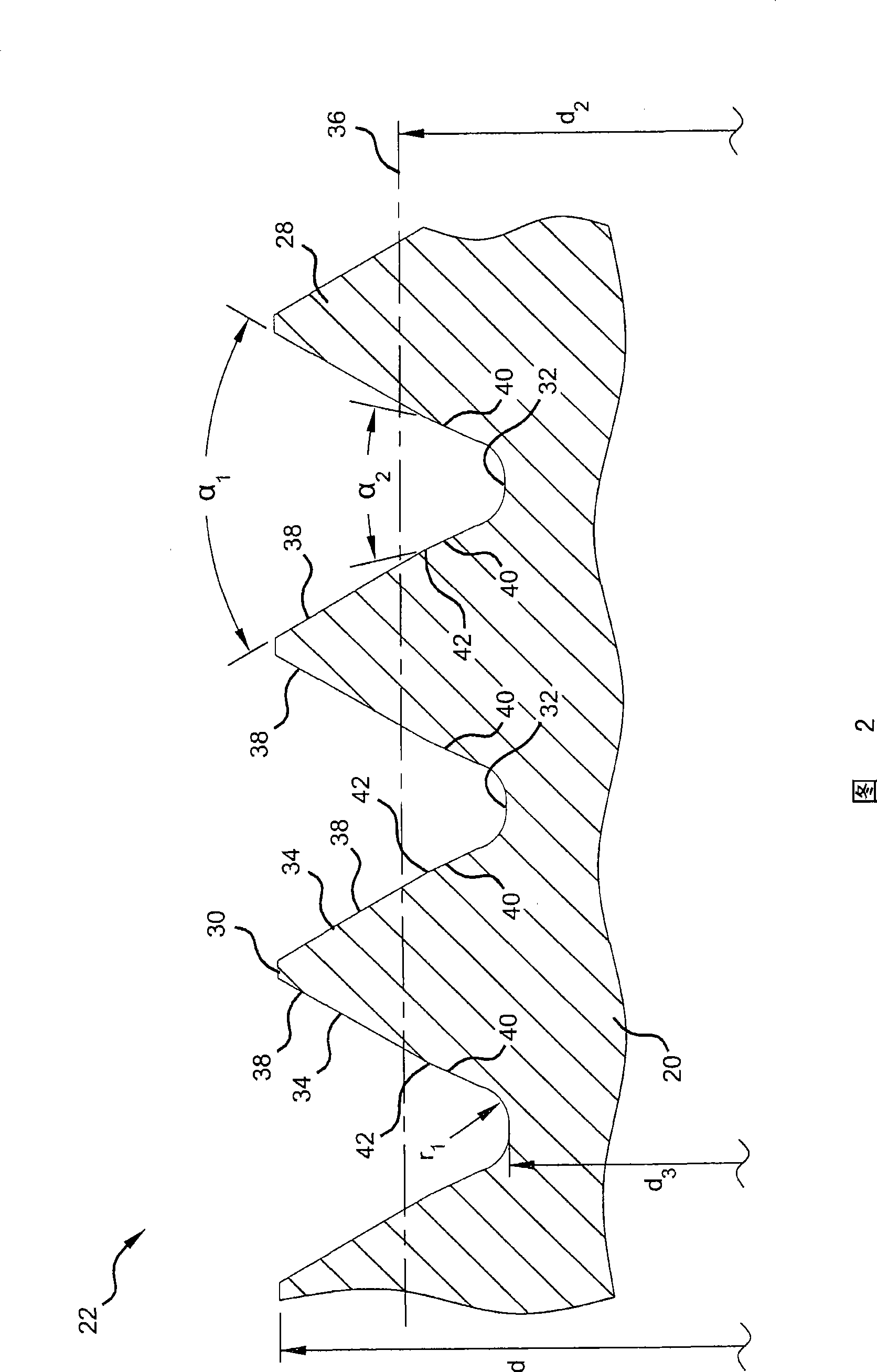

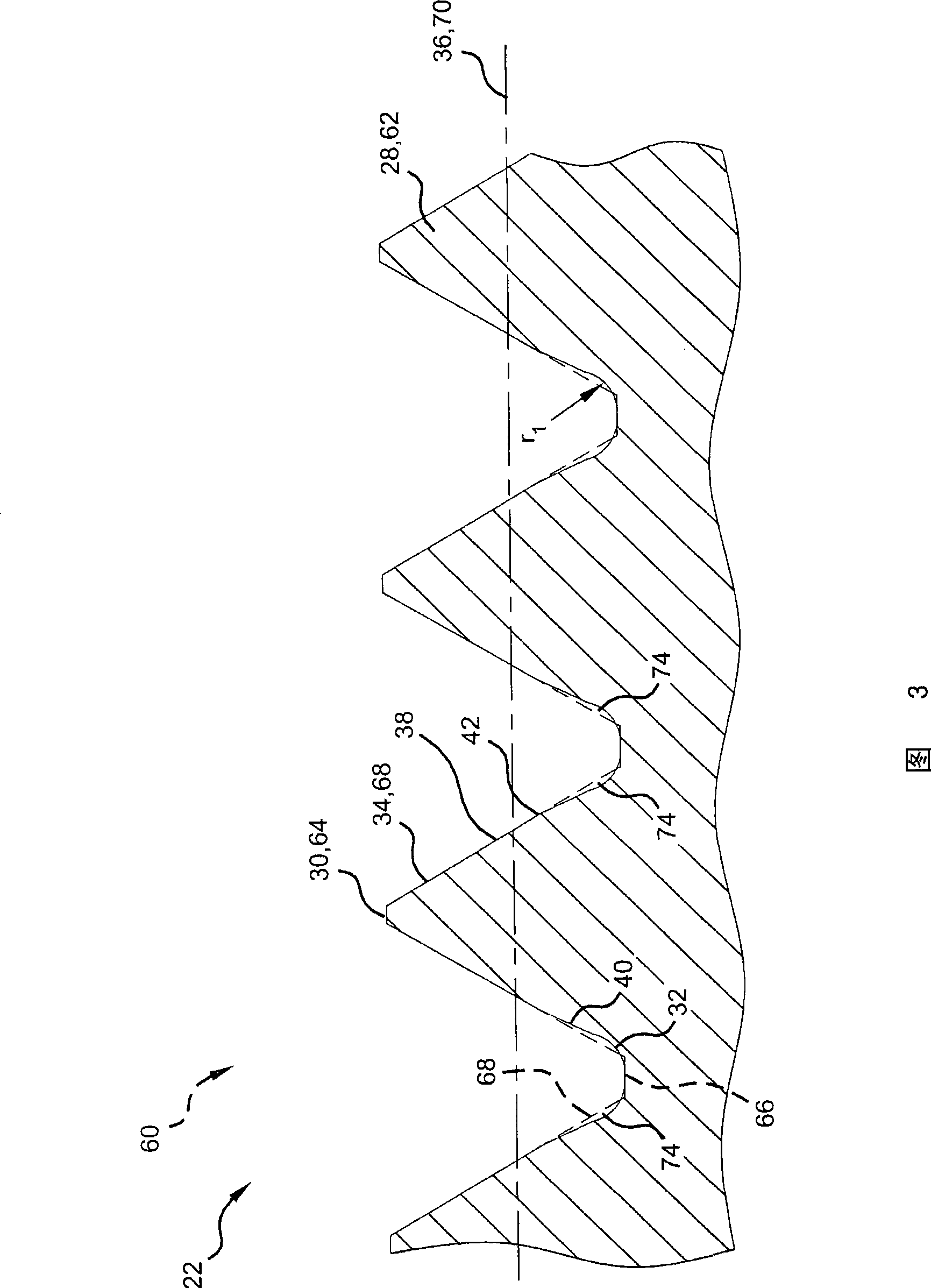

Thread profile modification for controlled stiffness

InactiveCN101424295ALow bending stiffnessReduce stiffnessNutsBoltsScrew threadBiomedical engineering

The thread form can provide a controlled thread stiffness which can more evenly distribute loads and can be less sensitive to changes in relative pitch. The controlled stiffness of the thread can provide a desired cantilever bending of the thread under assembled load. The thread form can utilize a traditional thread form at and / or above the pitch diameter, thereby maintaining the area of contact close to that of a standard thread form. Standard gaging implements can be used to ascertain the thread pitch and for quality control. The thread form includes a side extending between the crest and the root. The side has a first portion extending from the crest toward the root and the second portion extending from the first portion toward the root. The first and second portions extend toward the root in different orientations relative to the thread.

Owner:GM GLOBAL TECH OPERATIONS LLC

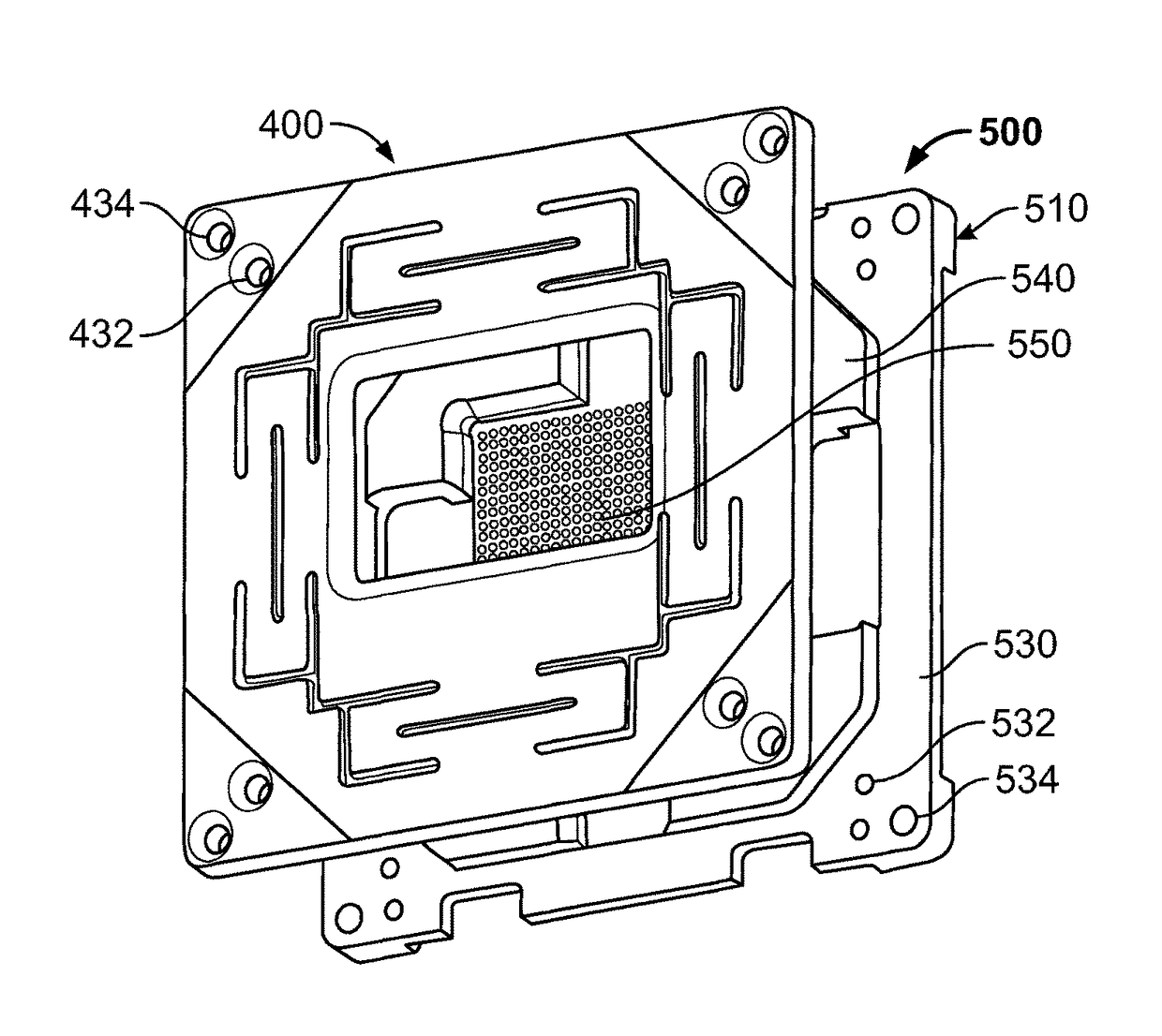

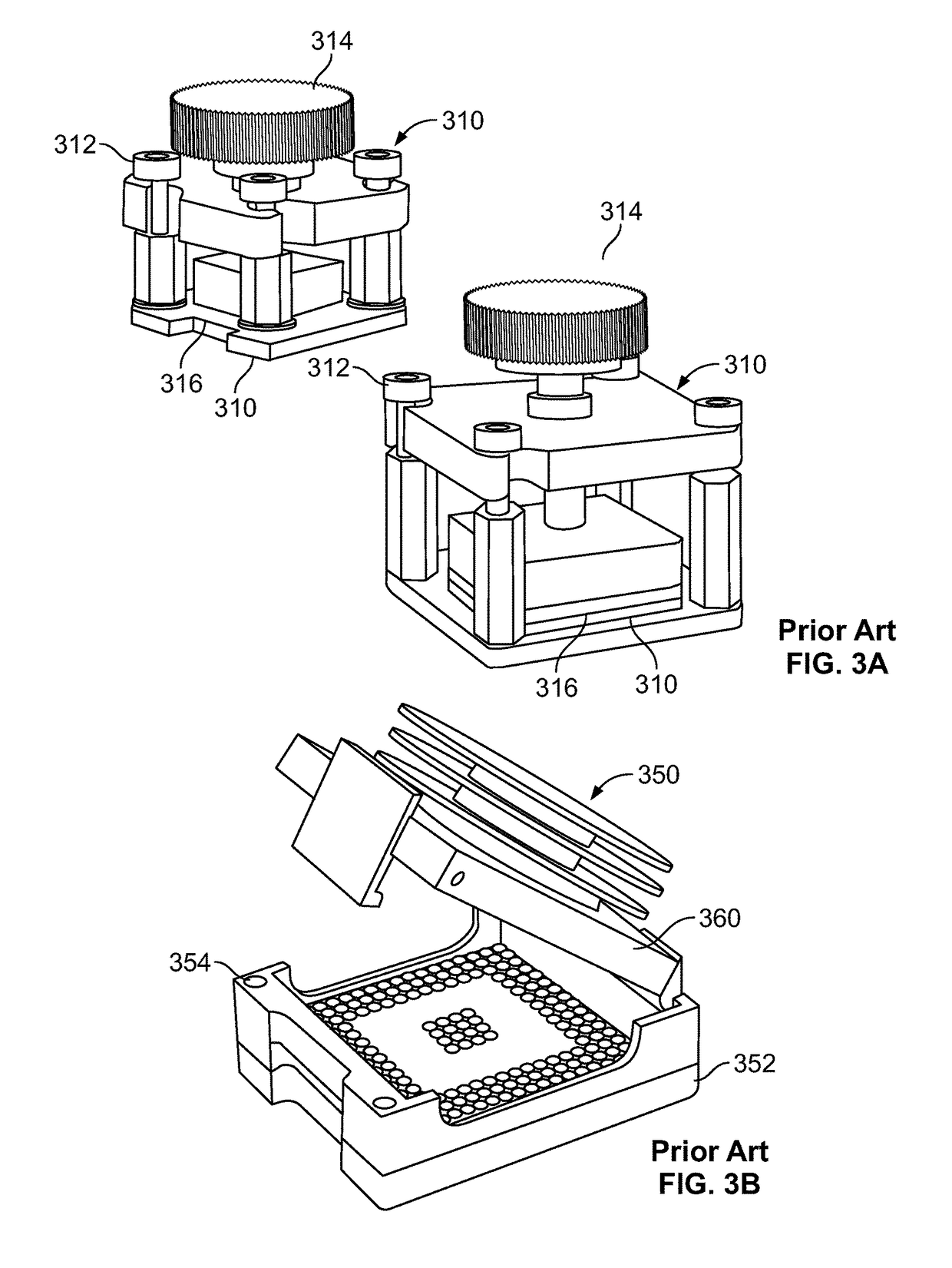

Push plate, mounting assembly, circuit board, and method of assembling thereof for ball grid array packages

ActiveUS9653230B1Minimize torqueInterference minimizationEngagement/disengagement of coupling partsPrinted circuit assemblingBall grid arrayMechanical engineering

A push plate that includes springs in the form of cantilever flexures and an inspection window is disclosed. The push plate provides a known, uniform, down force and minimal torque to a package to be tested. The cantilevers have a known, calculable down force producing stiffness. The window provides for viewing of the package during testing.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Turbomachine casing assembly

ActiveUS20130189095A1Reduce weightEasy to manufactureEngine manufacturePump componentsEngineeringMechanical engineering

A turbomachine casing assembly includes a first casing element, located radially outward of one or more rotating aerofoil elements of a turbomachine, and a second casing element, located radially distal to the first element. A void is provided at a first end of the first element, between radially proximal faces of the first and second elements. The first end of the first element is located against a corresponding first end of the second element by an energy absorbing element. The first element includes a cantilever, arranged in a region extending along the first element from the first end with a pivot axis at its mid-portion. Release of one of the rotating aerofoil elements, resulting in impact with the first element, further results in the cantilever bending into the void between the first and second elements, enabling the rotating aerofoil element to be trapped within the casing assembly.

Owner:ROLLS ROYCE PLC

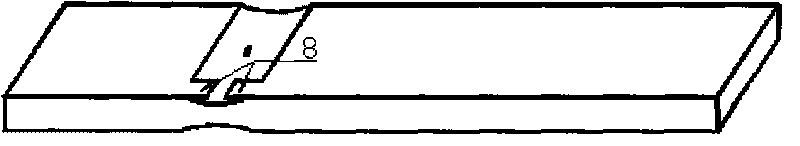

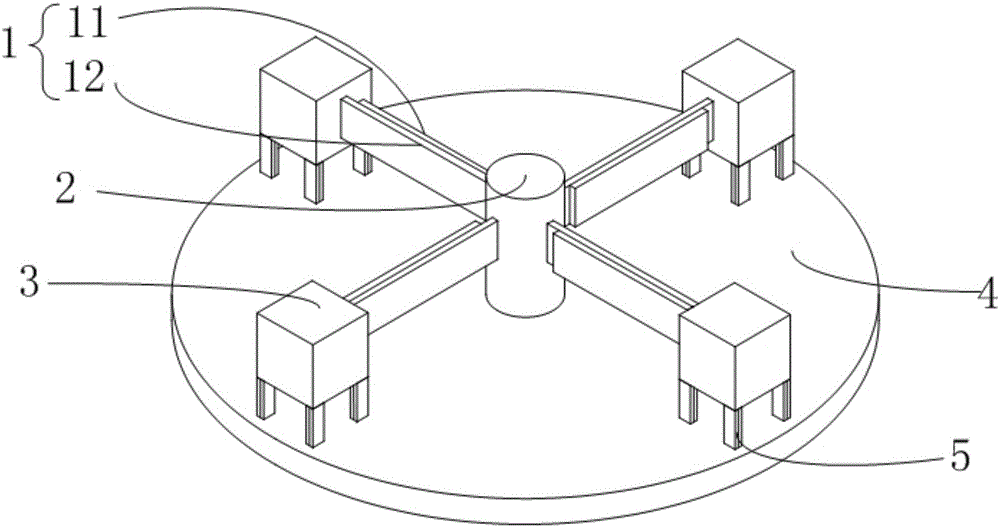

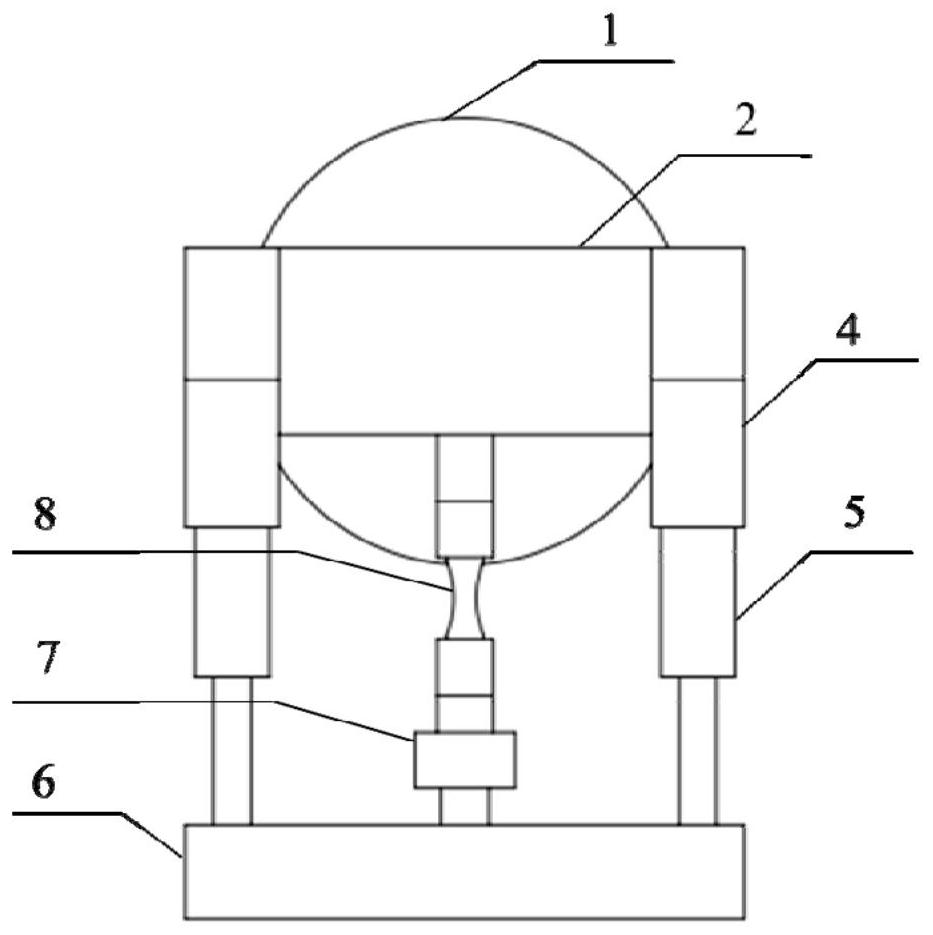

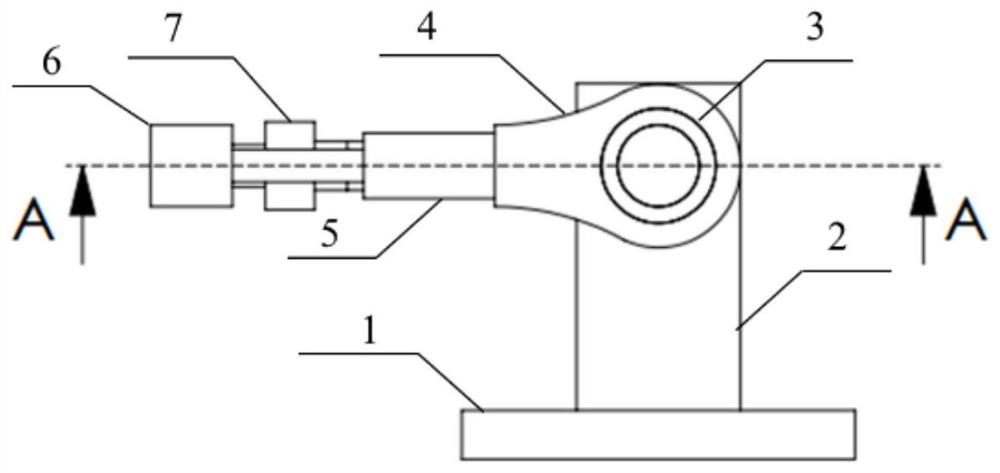

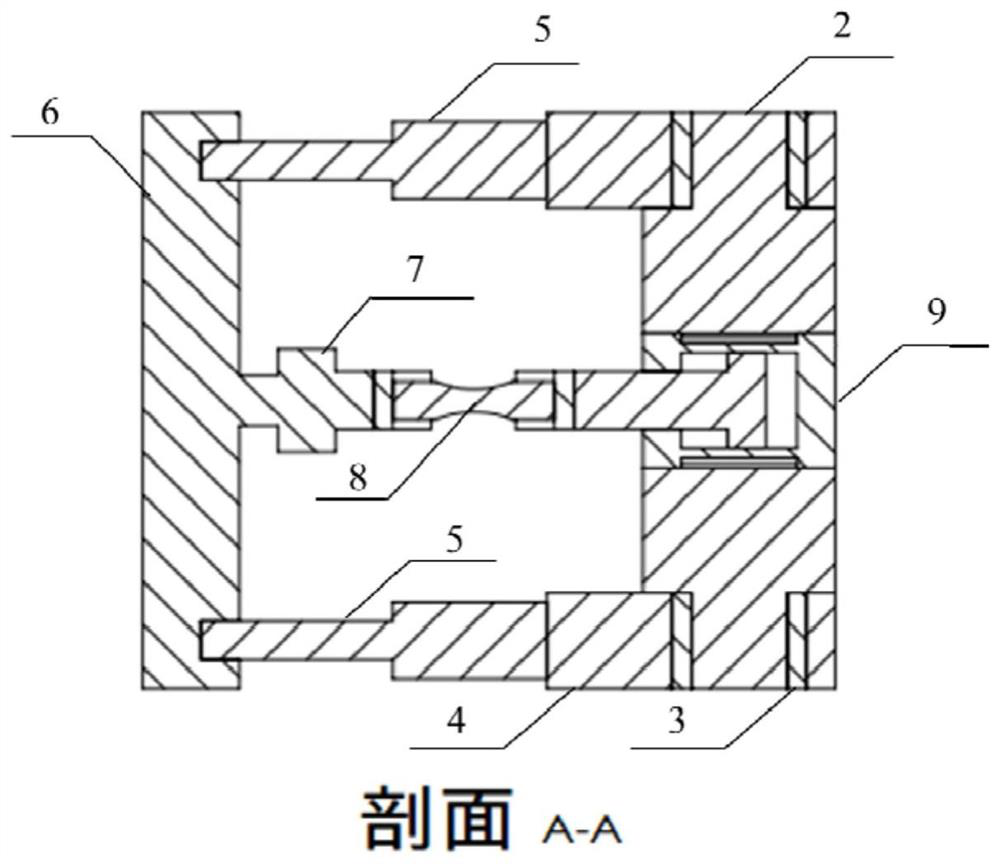

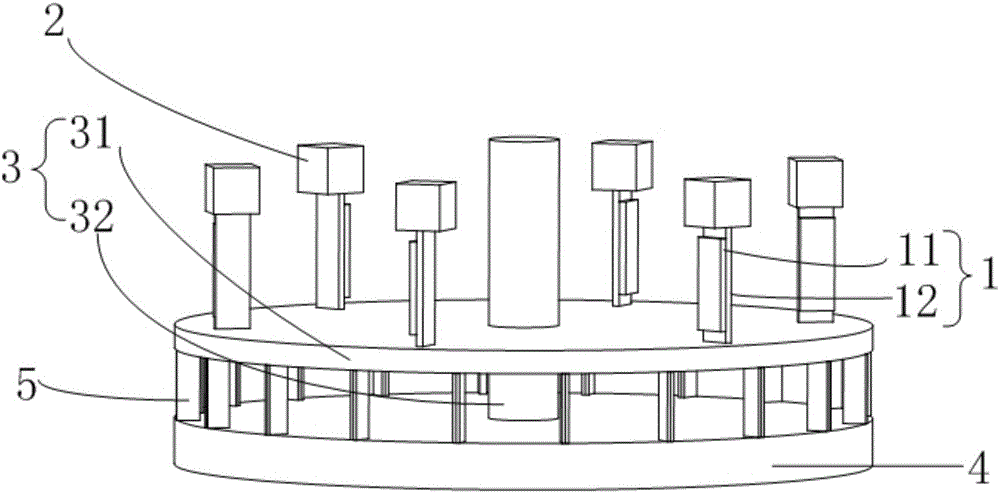

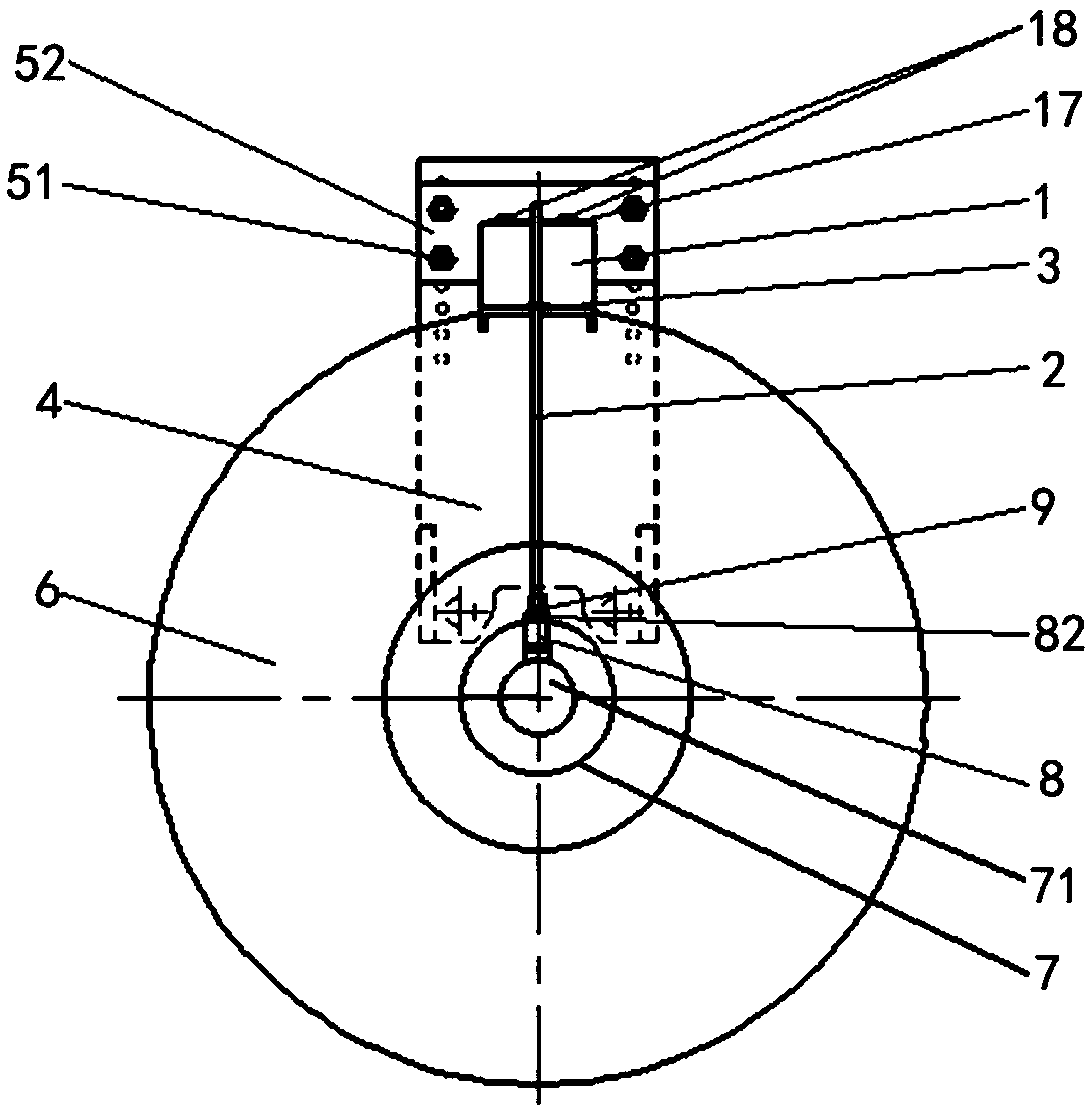

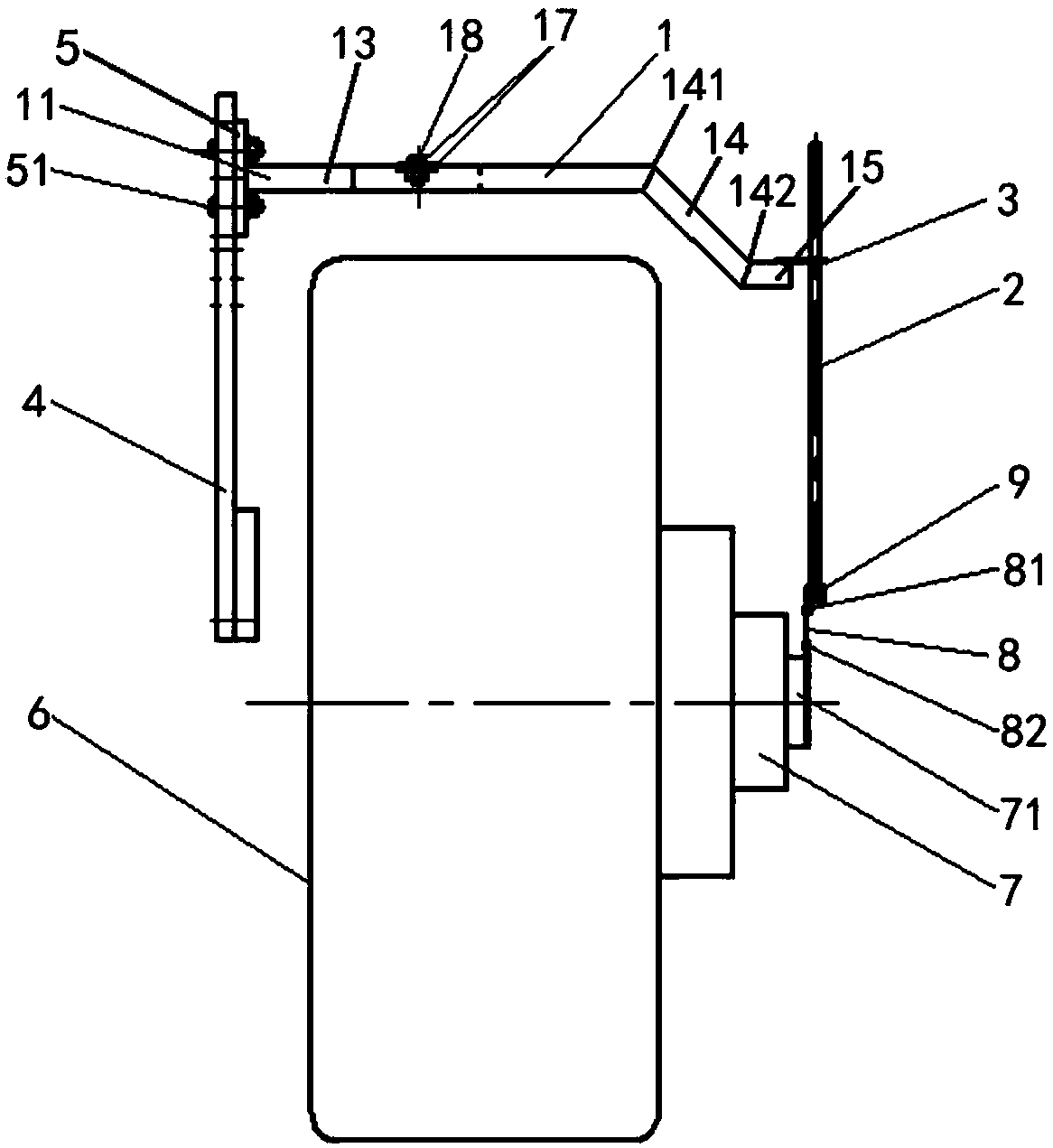

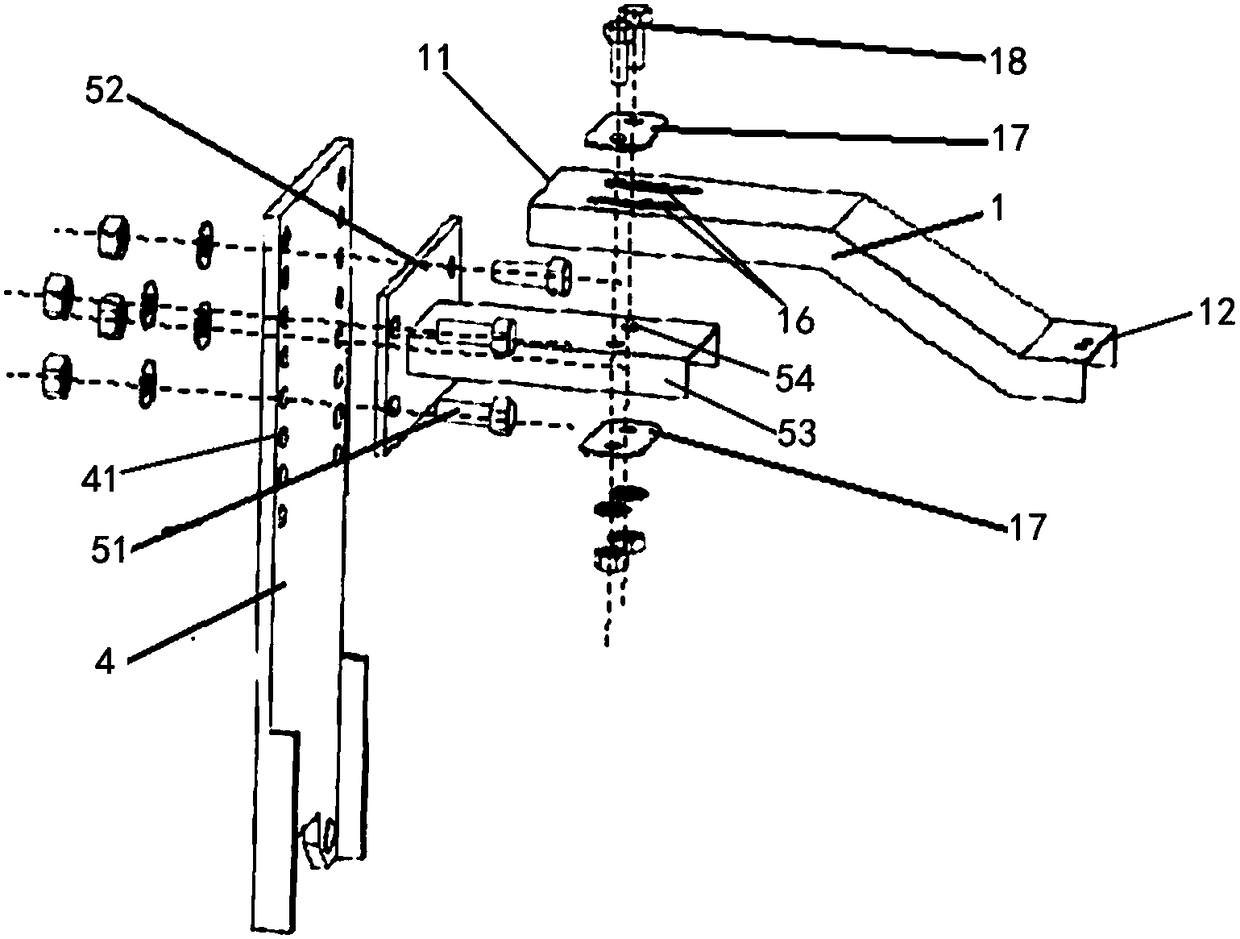

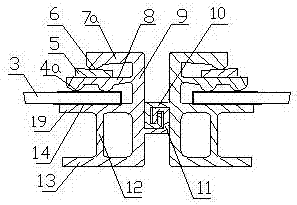

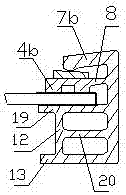

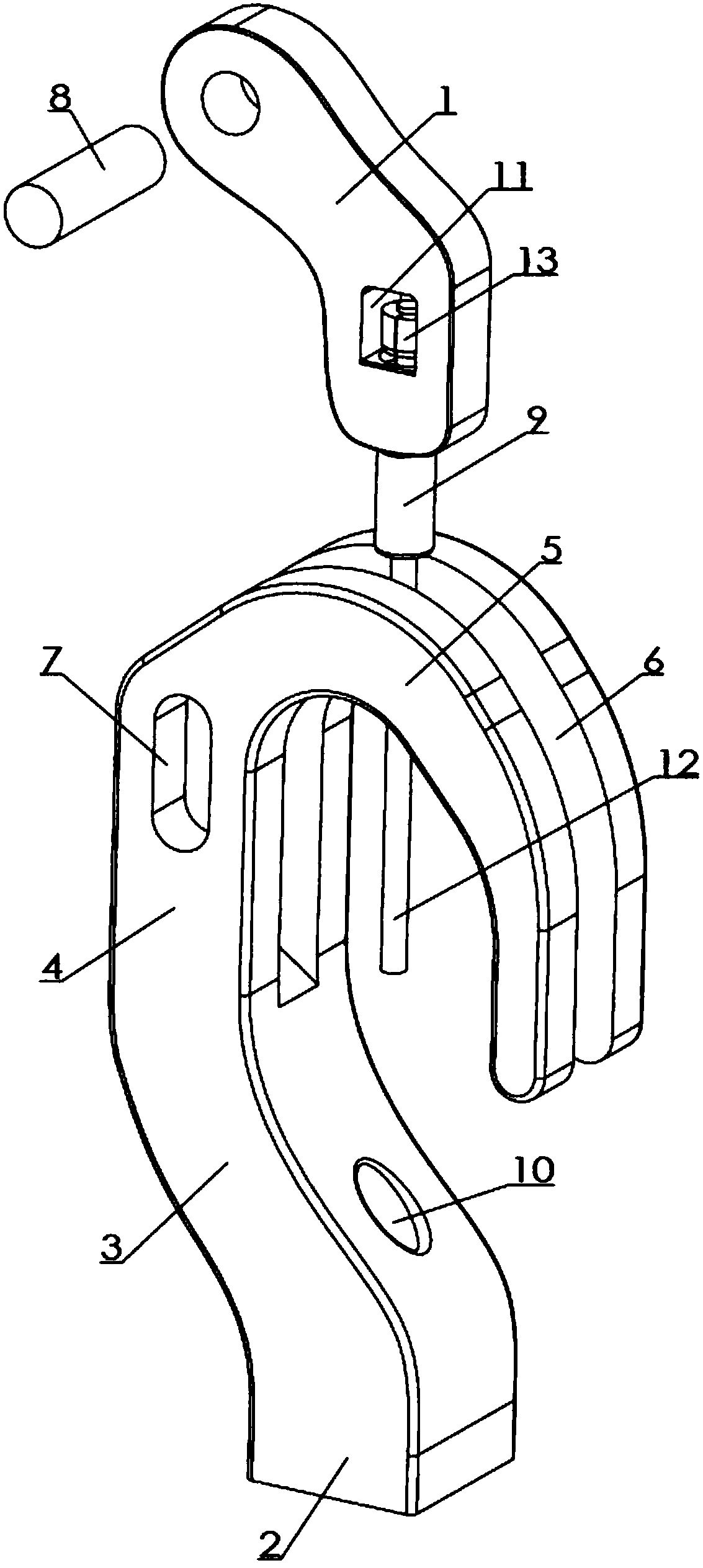

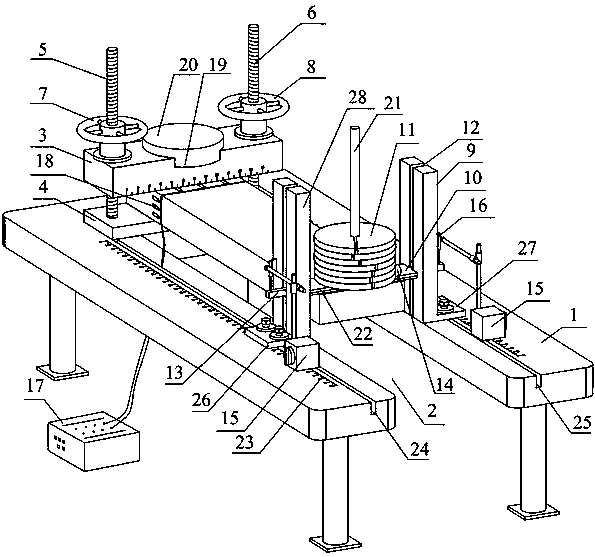

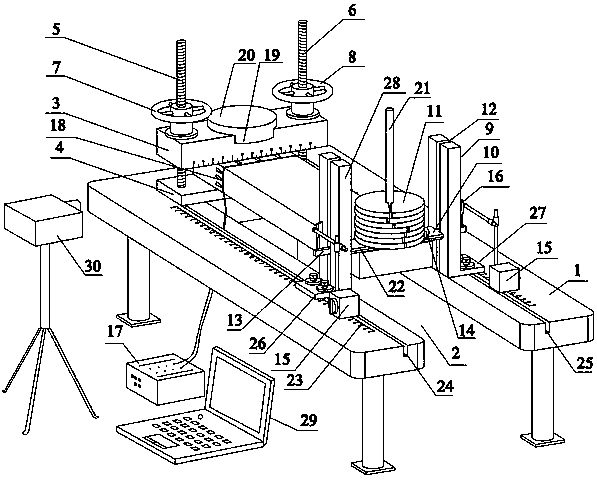

Axial and vibration high-low cycle composite fatigue test device

ActiveCN111649926ARealize cooperative loading testMachine part testingMaterial strength using repeated/pulsating forcesFatigue loadingAxis of symmetry

The invention relates to an axial and vibration high-low cycle composite fatigue test device. The device comprises a base (2) which is rigidly connected with excitation equipment through a transitionplate (1), cantilevers arranged on two sides of the base (2) are connected with connecting arms (4); one end of each of two connecting rods (5) is mounted on one connecting arm (4); a beam (6) is installed at the other end of each connecting rod; the beam (6), bearings (3) arranged on the two sides of the base (2), the connecting arms (4) and the connecting rods (5) form a load frame capable of smoothly rotating around cantilevers on the two sides of the base (2), a sample (8) and an axial force applying device (9) are connected to the symmetry axis of the load frame in series, and an axial force applying device (9) is fixed to the base (2). The axial force applying device of the test device can axially load the sample; when the excitation equipment excites at a resonance frequency, the load frame drives the sample to resonate, and the cantilever bending load generated by resonance is completely borne by the sample, so that the high-cycle vibration fatigue load is superposed on the low-cycle axial fatigue load.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

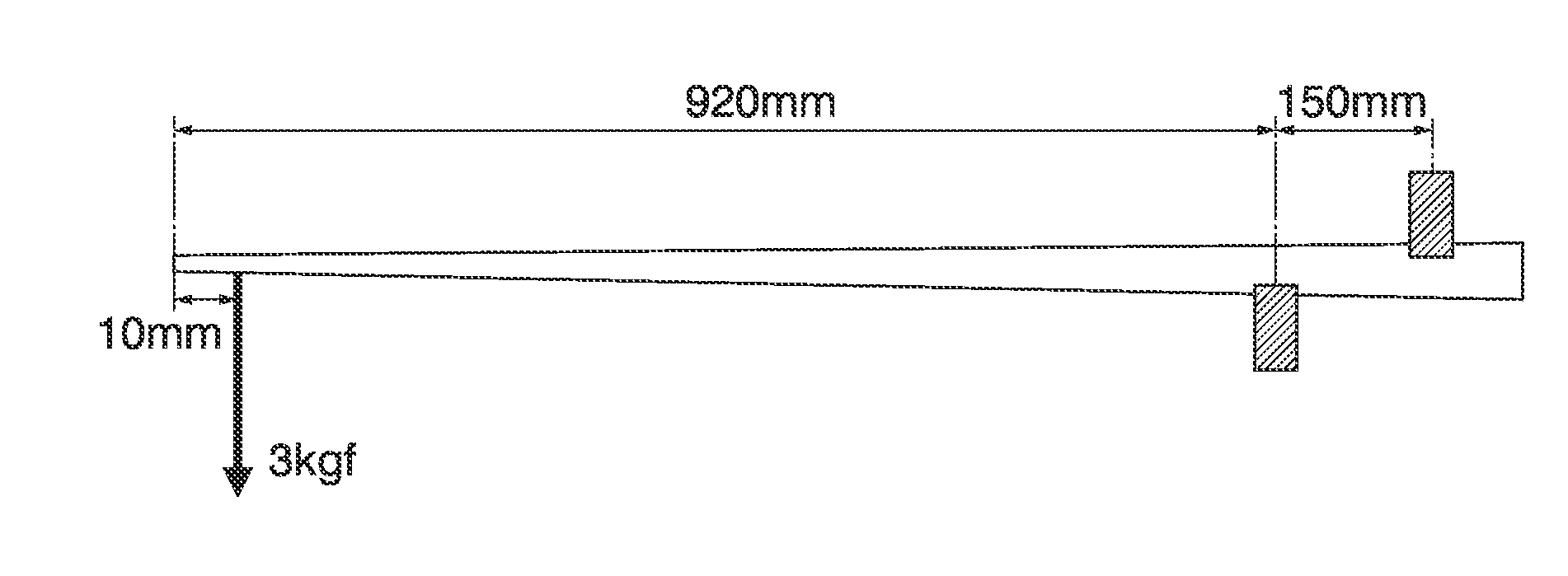

Golf club shaft for wood club

ActiveUS20150157906A1Reduce weightUniform intensity distributionGolf clubsRacket sportsFiberGolf Ball

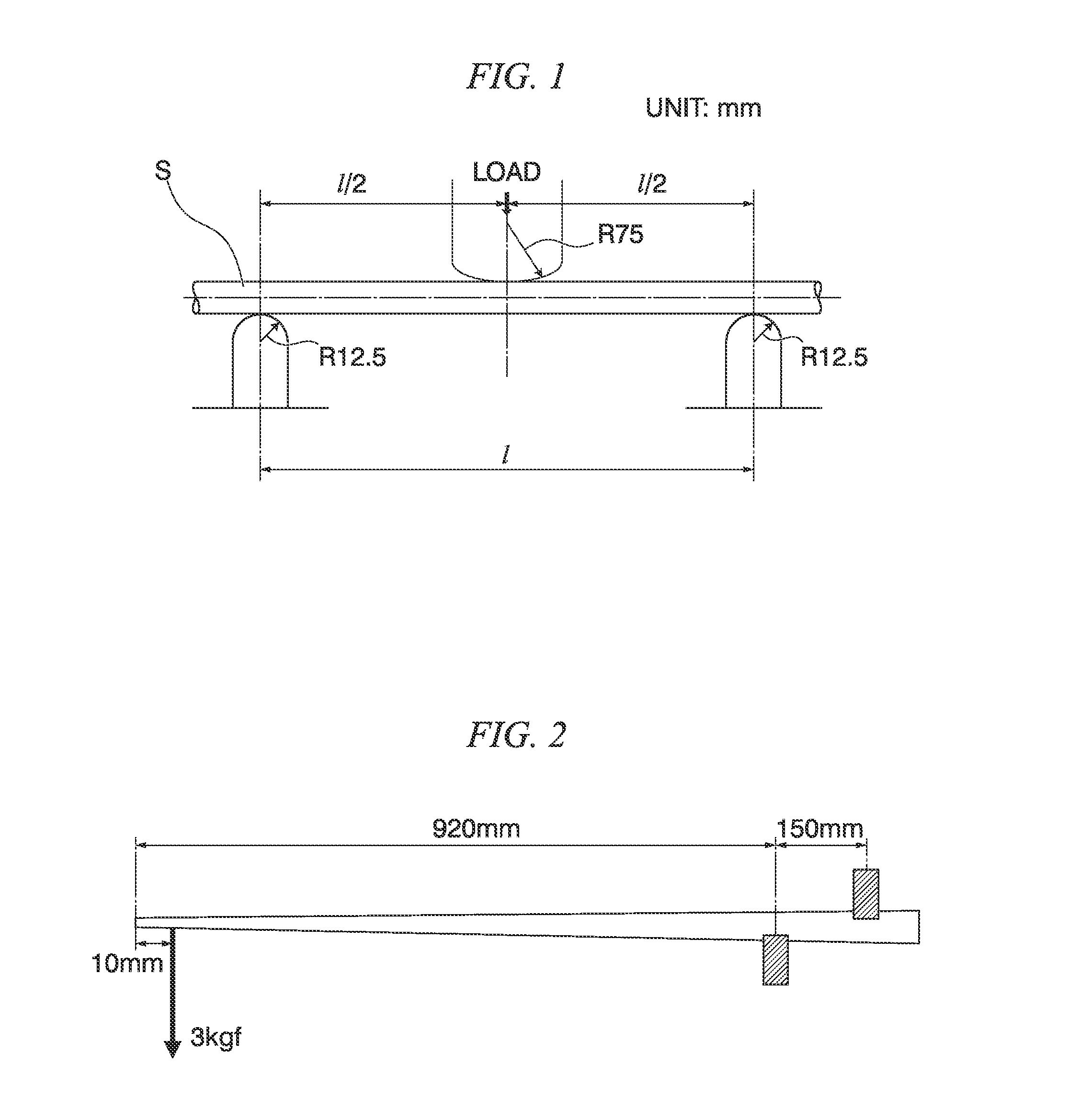

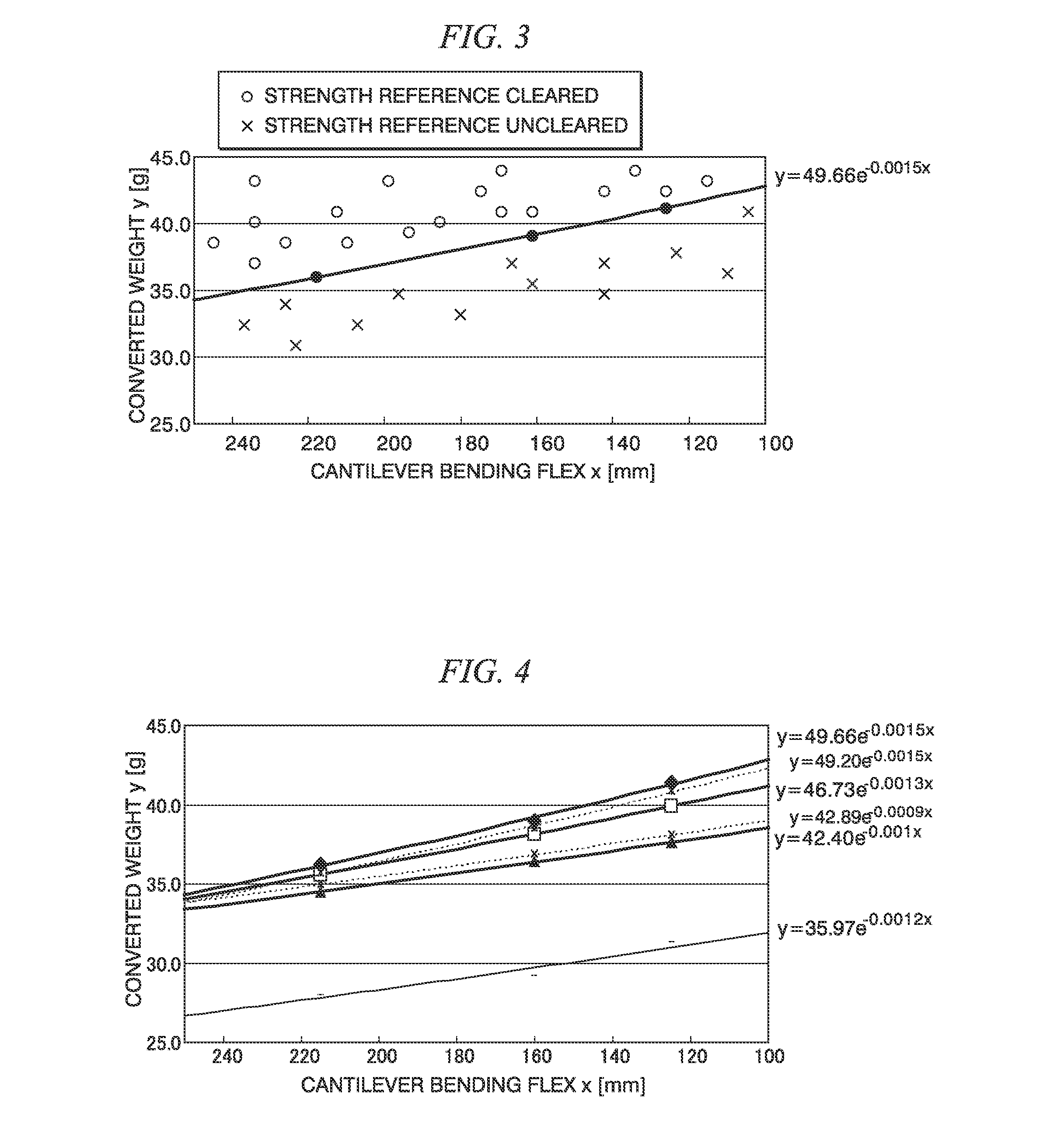

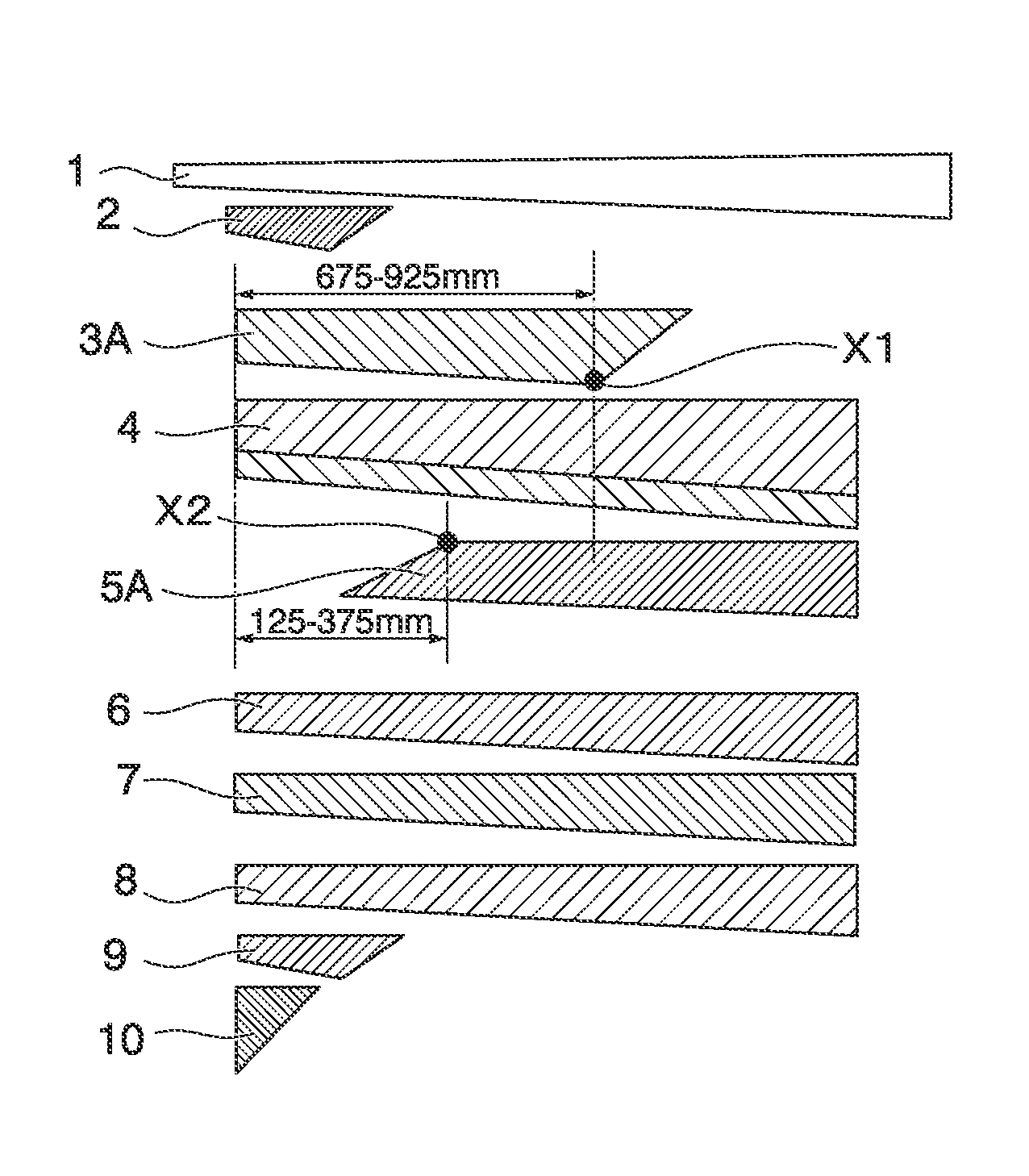

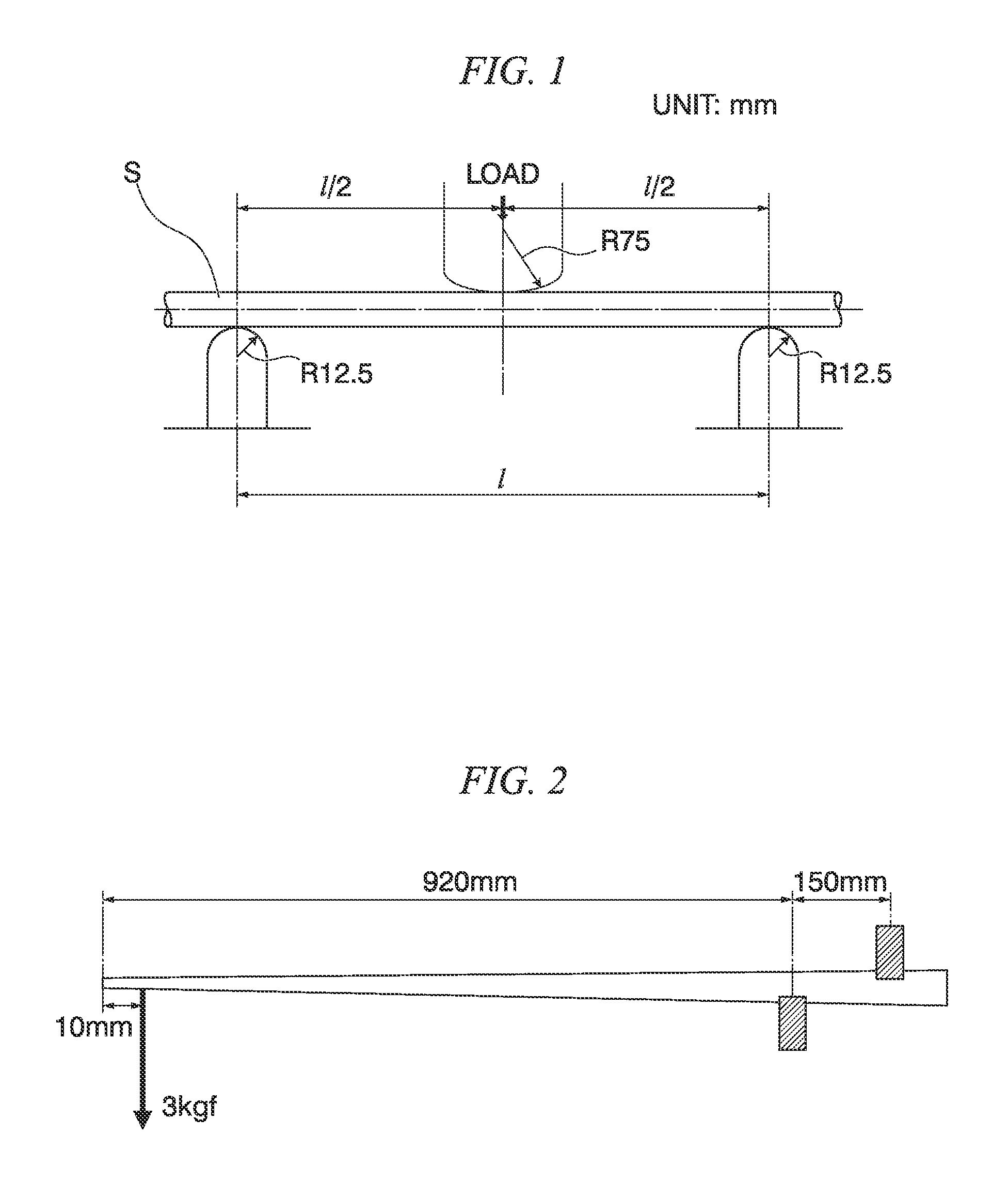

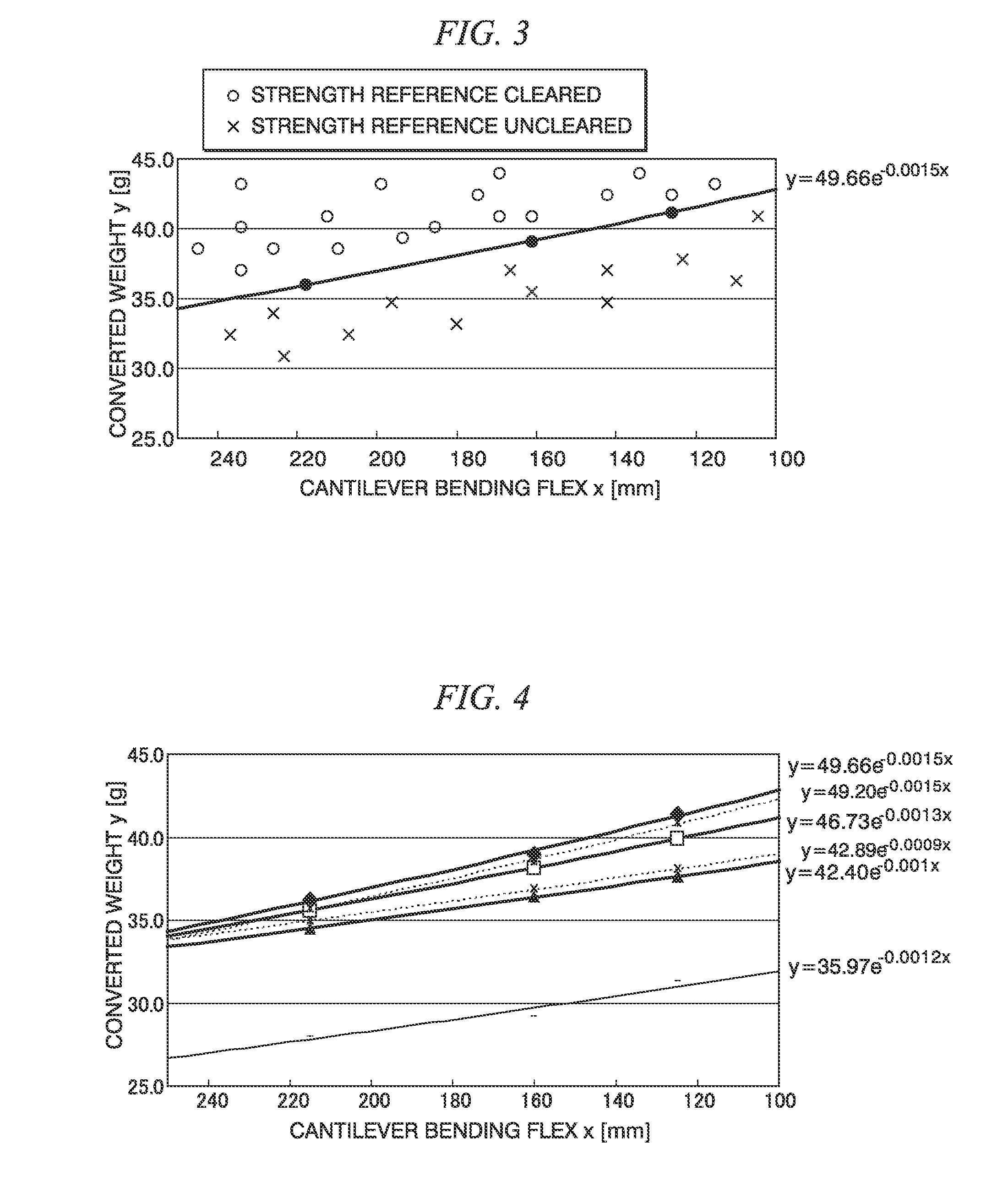

A golf club shaft which satisfies strength and is lightweight is provided by the present invention. This golf club shaft comprises one or more fiber-reinforced resin layers, and is characterized by satisfying the following relationship (1), wherein x [mm] is the displacement in a cantilever bending test, M [g] is the mass of the golf club shaft, and L [mm] is the length thereof, and by satisfying the following strength standard values [1]-[4]: M×(L / 1168)<49.66 e−0.0015x (relationship 1); [1] the three-point bending strength at T-90 (the position 90 mm apart from the smaller-diameter end) is 800 N or higher; [2] the three-point bending strength at T-175 (the position 175 mm apart from the smaller-diameter end) is 400 N or higher; [3] the three-point bending strength at T-525 (the position 525 mm apart from the smaller-diameter end) is 400 N or higher; and [4] the three-point bending strength at B-175 (the position 175 mm apart from the larger-diameter end) is 400 N or higher.

Owner:MITSUBISHI CHEM CORP

Golf club shaft for wood club

ActiveUS9387378B2Reduce weightUniform intensity distributionGolf clubsRacket sportsFlexural strengthEngineering

A golf club shaft which satisfies strength and is lightweight is provided by the present invention. This golf club shaft comprises one or more fiber-reinforced resin layers, and is characterized by satisfying the following relationship (1), wherein x [mm] is the displacement in a cantilever bending test, M [g] is the mass of the golf club shaft, and L [mm] is the length thereof, and by satisfying the following strength standard values [1]-[4]: M×(L / 1168)<49.66 e−0.0015x (relationship 1); [1] the three-point bending strength at T-90 (the position 90 mm apart from the smaller-diameter end) is 800 N or higher; [2] the three-point bending strength at T-175 (the position 175 mm apart from the smaller-diameter end) is 400 N or higher; [3] the three-point bending strength at T-525 (the position 525 mm apart from the smaller-diameter end) is 400 N or higher; and [4] the three-point bending strength at B-175 (the position 175 mm apart from the larger-diameter end) is 400 N or higher.

Owner:MITSUBISHI CHEM CORP

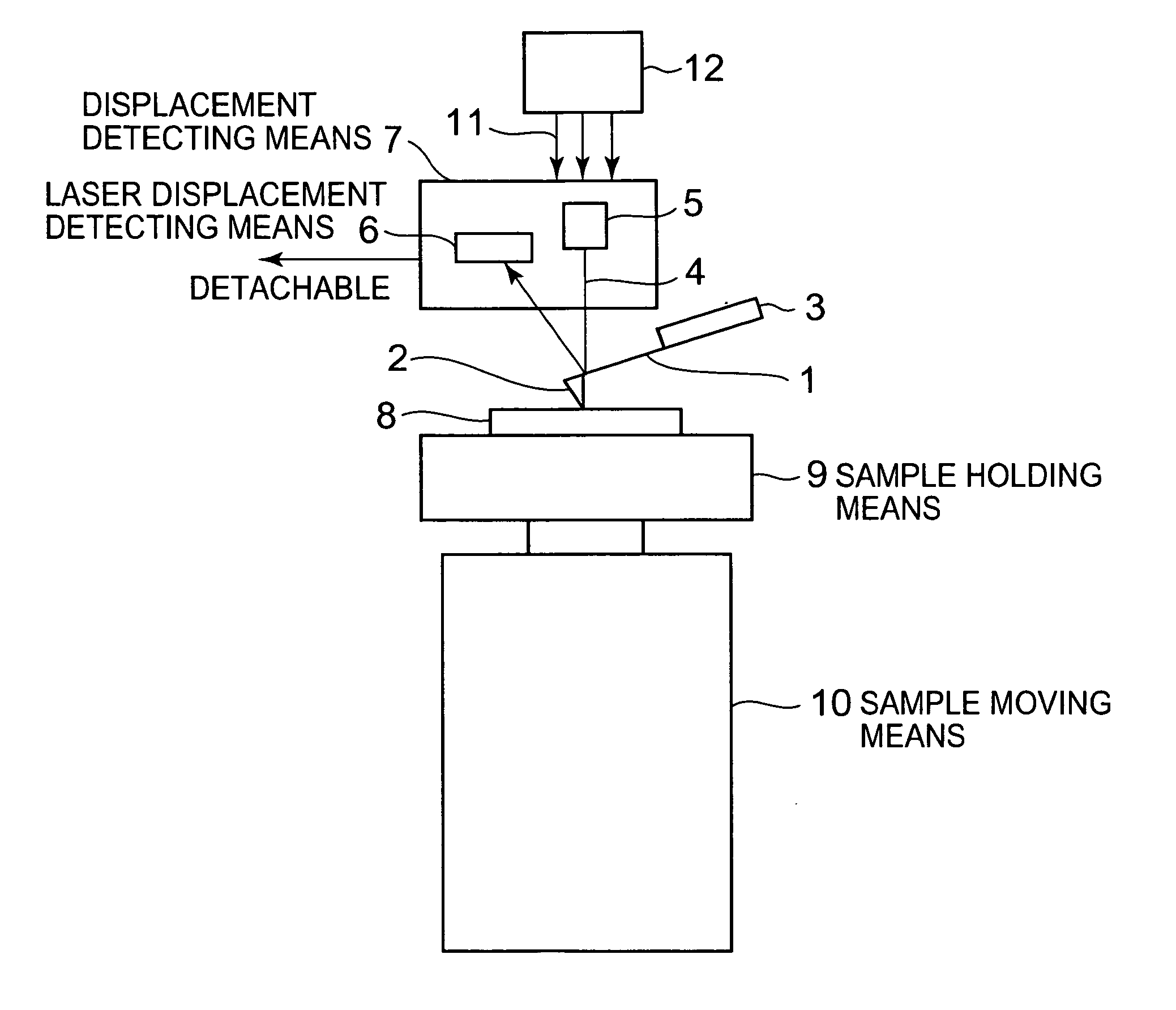

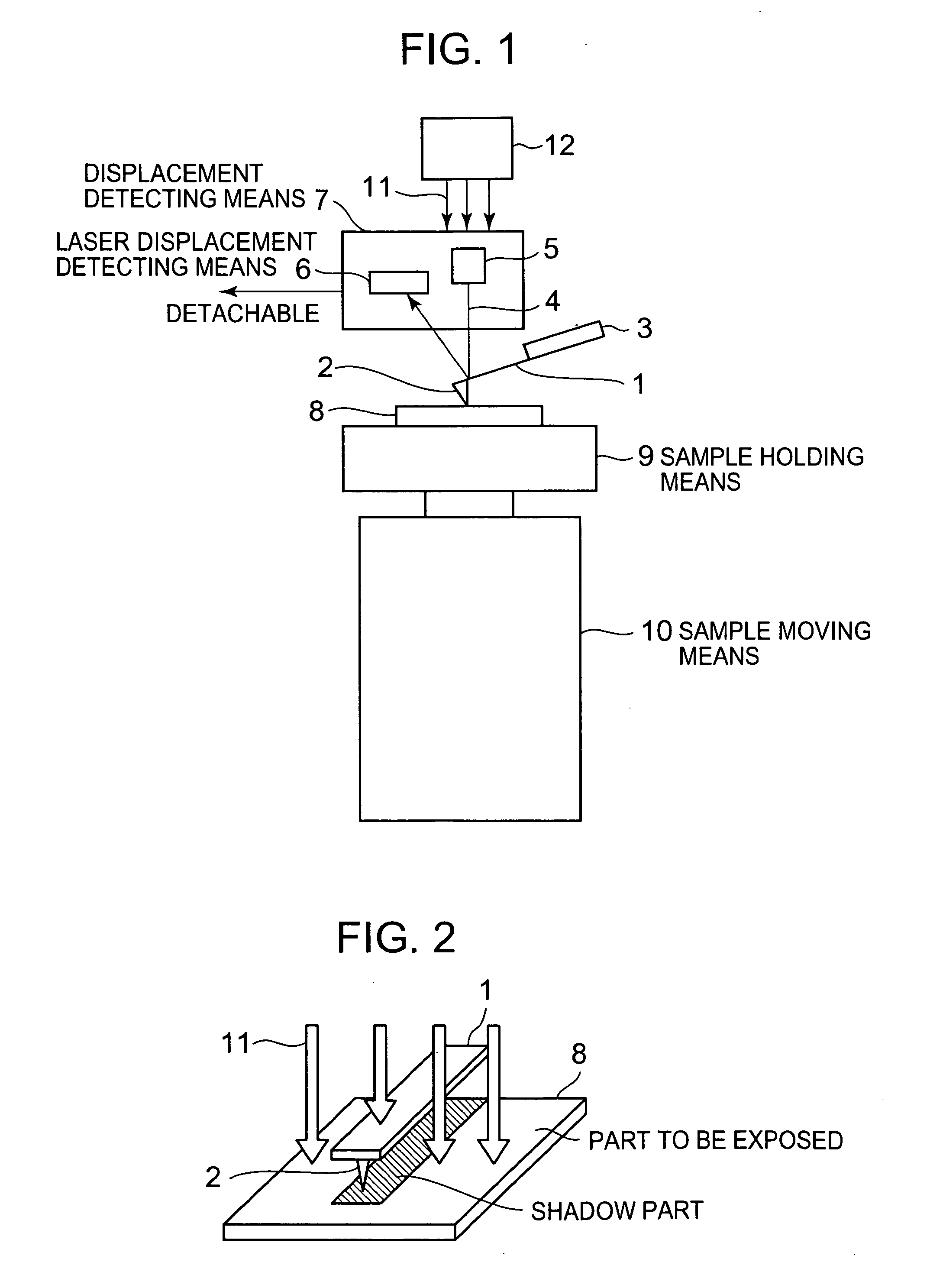

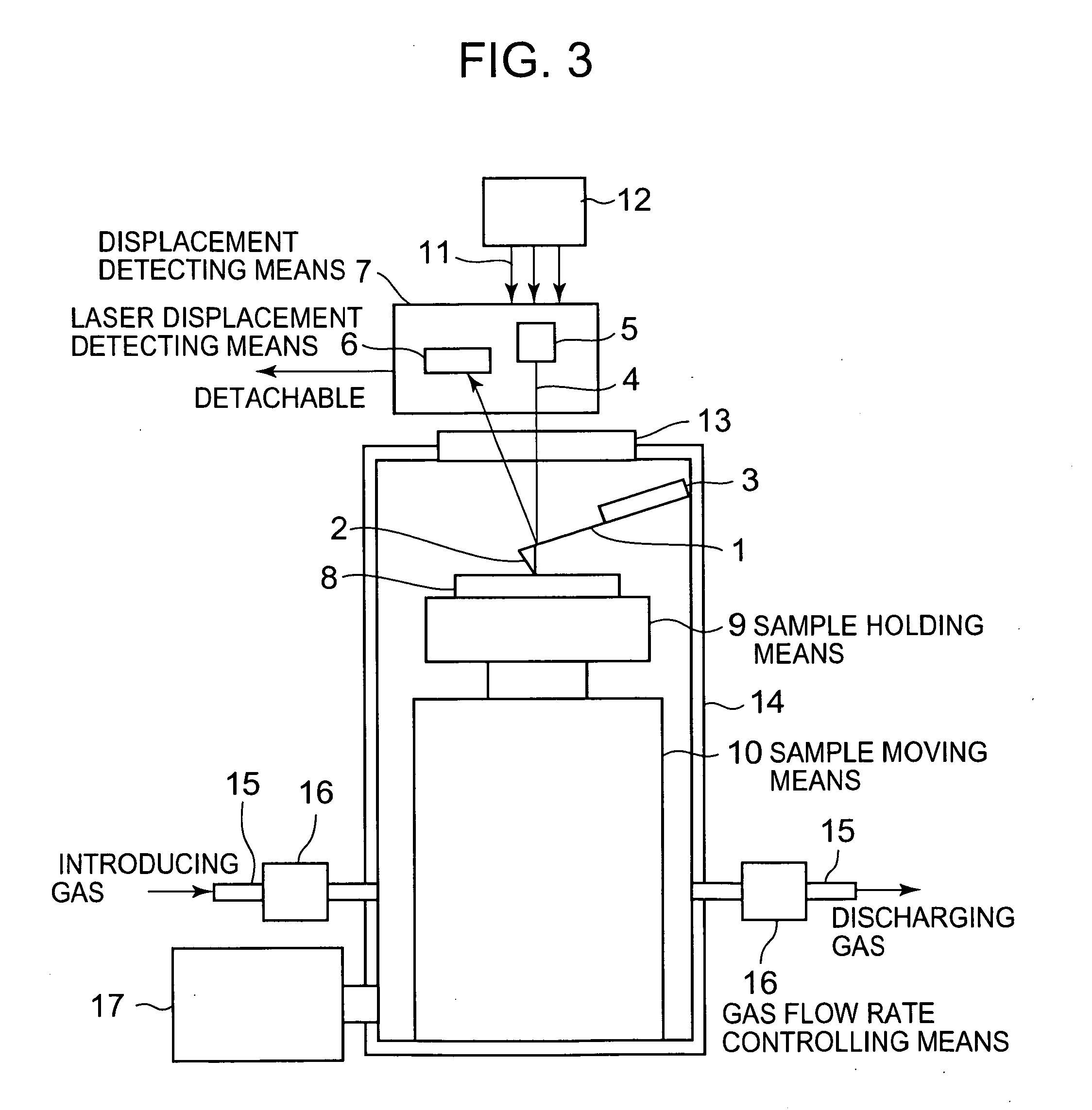

Scanning probe microscope and measuring method by means of the same

InactiveUS20050210966A1Limiting conditionEfficient analysisNanotechnologyScanning probe techniquesScanning probe microscopyLaser beams

A scanning probe microscope capable of radiating light on a sample without moving the sample from the scanning probe microscope and measuring the sample with controlling the condition under which the sample is placed and without changing the location of the sample is provided. The scanning probe microscope includes a cantilever having a probe on a top end thereof, sample moving means for moving the sample, detachable cantilever bending amount detecting means for detecting bending amount of the cantilever by means of a laser beam and exposure means for exposing the sample to light from upper side of the cantilever, wherein the cantilever bending amount detecting means is independently detachable when exposure of the sample is carried out.

Owner:HITACHI HIGH TECH SCI CORP

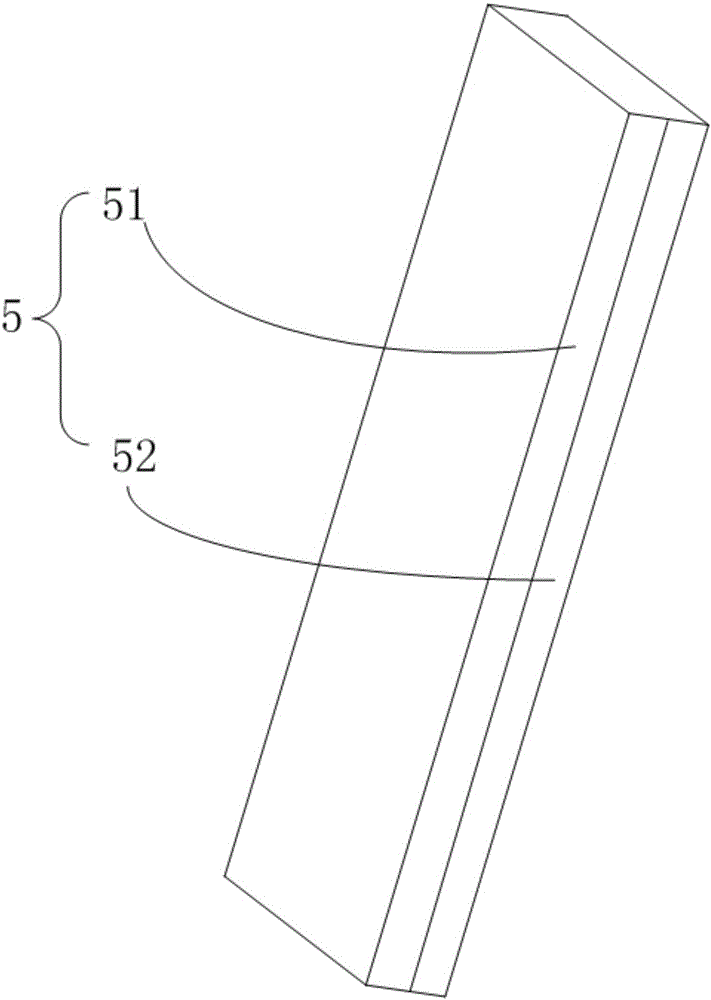

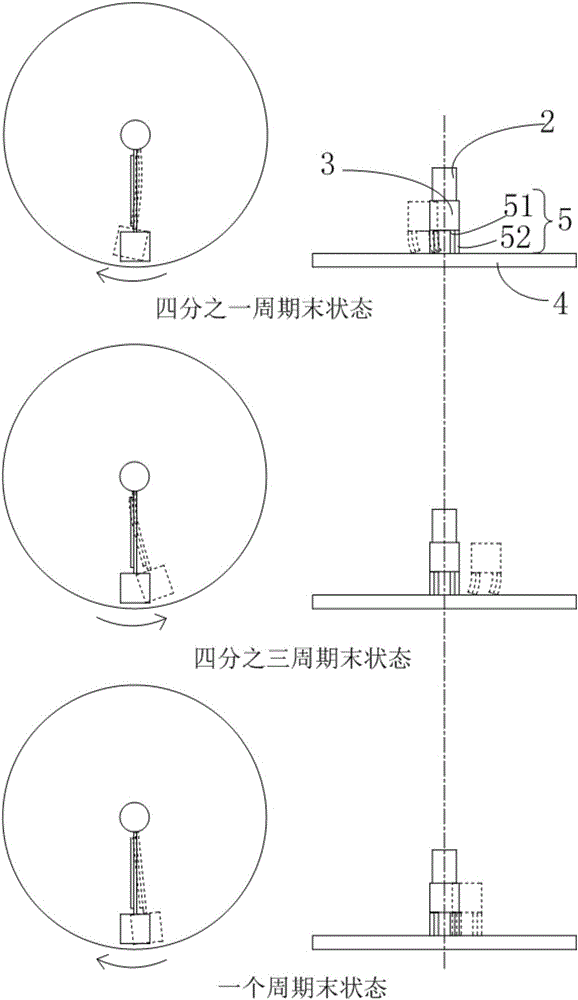

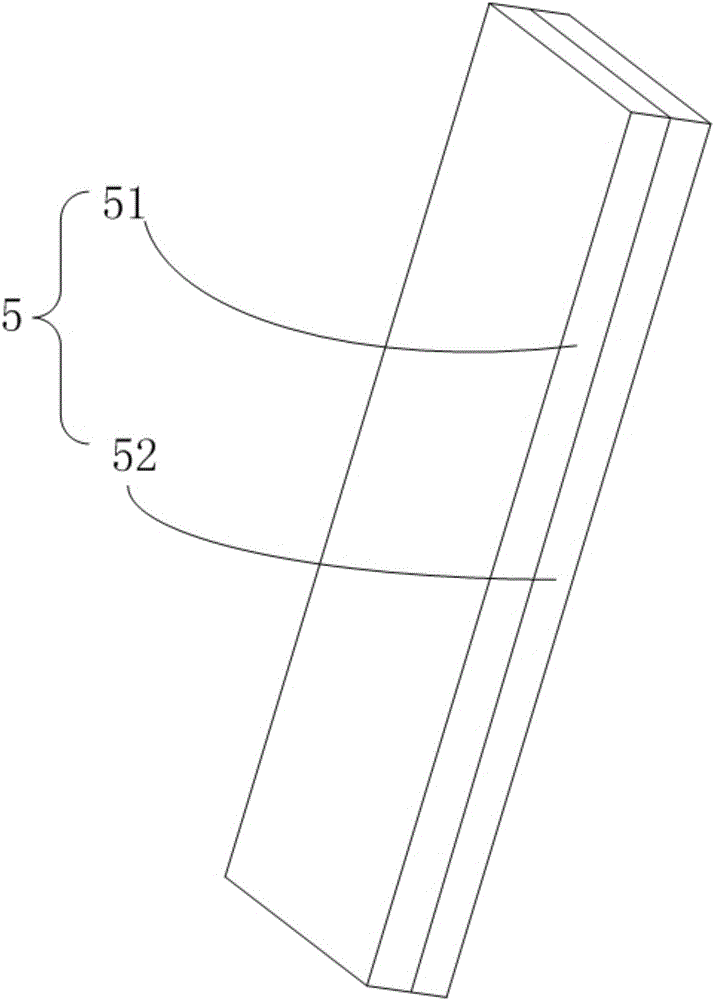

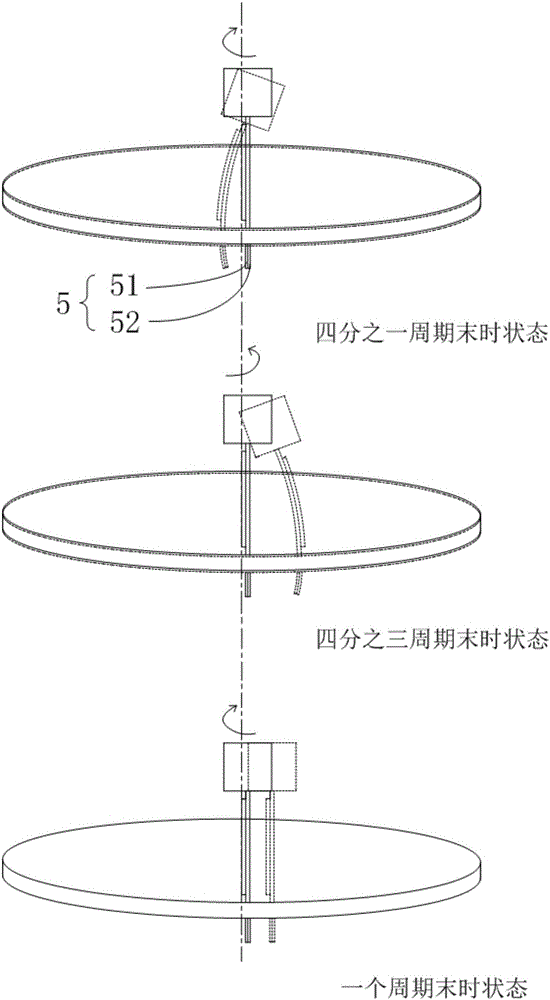

Inertia piezoelectric driving motor

ActiveCN105827147AStrong toleranceLongevityPiezoelectric/electrostriction/magnetostriction machinesCircular discRotary stage

The invention relates to an inertia piezoelectric driving motor. The inertia piezoelectric driving motor comprises piezoelectric vibrators, mass blocks, a rotating table, a base and a composite cantilever, wherein the two ends of each piezoelectric vibrator are fixedly connected to the corresponding mass block and a rotating disc; the rotating table comprises the rotating disc and a rotating shaft; the composite cantilever is of a sheet structure and formed by laminating a high-friction elastic material and a low-friction elastic material, the high-friction elastic material and the low-friction elastic material are the same in size and different in friction coefficient, the composite cantilever is fixedly connected to the lower surface of the rotating disc, and the laminating surface of the high-friction elastic material and the low-friction elastic material passes through the diameter of the rotating disc; the base and the rotating shaft form a rotation pair, the piezoelectric vibrators drive the mass blocks to vibrate, and the composite cantilever bends due to inertia and does rotating motion as the two materials are different in friction coefficient. The inertia piezoelectric driving motor has the advantages of being long in service life, high in fault tolerance, low in precision requirement and the like.

Owner:谐振机电精密技术(苏州)有限公司

Micro-switching device and method of manufacturing micro-switching device

InactiveUS7515023B2Reduced insertion lossSuppress internal stressElectrostatic/electro-adhesion relaysDecorative surface effectsElectrical and Electronics engineeringCantilever bending

A micro-switching device includes a base substrate and a cantilever fixed to the base substrate via a spacer or anchor portion. The cantilever has an inner surface facing the substrate and an outer surface opposite to the inner surface. A conductive strip is formed on the outer surface of the cantilever. The switching device also includes a pair of stationary electrodes fixed to the base substrate. Each of the electrodes includes a downward contacting part spaced from the conductive strip on the cantilever. As the cantilever bends upward, the conductive strip is brought into contact with the contacting parts of the respective stationary electrodes.

Owner:FUJITSU LTD

Fixing and limiting device for front wheel six-component slip ring and method and medium and heavy trucks

ActiveCN108572084AAvoid impact damageAvoid noise disturbanceVehicle wheel testingLateral extensionEngineering

The invention discloses a fixing and limiting device for a front wheel six-component slip ring and method and medium and heavy trucks. The device comprises a fixing assembly and an elastic limiting assembly, wherein the fixing assembly comprises a cantilever bending plate and a vertical supporting plate, the vertical supporting plate extends along a vertical direction, the cantilever bending plateextends along a transverse direction, the cantilever bending plate is connected with the vertical supporting plate, and the cantilever bending plate crosses to the outer side of a tire from the innerside of the tire; the elastic limiting assembly comprises a guiding rod and a limiting support, the guiding rod extends along a vertical direction, and the lower end of the guiding rod is fixedly connected with the slip ring of a six-component sensor; and the limiting support is connected with a suspending end, the limiting support is provided with a limiting hole for enabling the upper end of the guiding rod to pass through and enabling the guiding rod to move freely along a vertical direction, the upper end of the guiding rod is a preset height higher above the limiting support, and transverse and vertical movement of the guiding rod is limited. The problems of inadequate structural strength reliability, high manufacturing cost, poor generality, large measurement data errors and low slip ring service life existing in the medium and heavy truck six-component slip ring fixing device in the prior art can be solved.

Owner:BEIJING FOTONDAIMLER AUTOMOTIVE

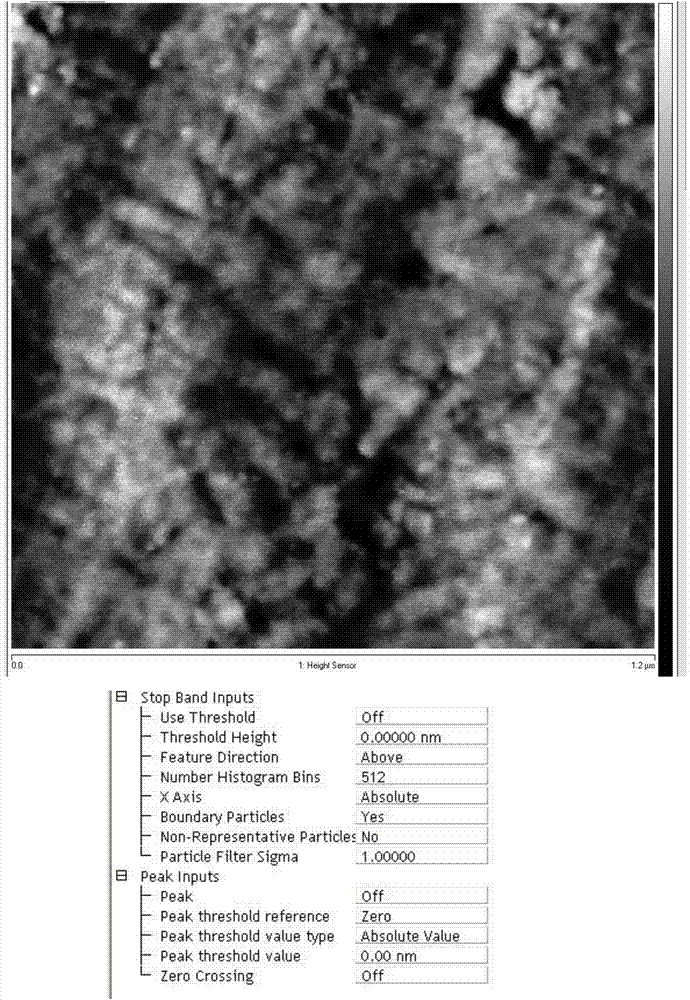

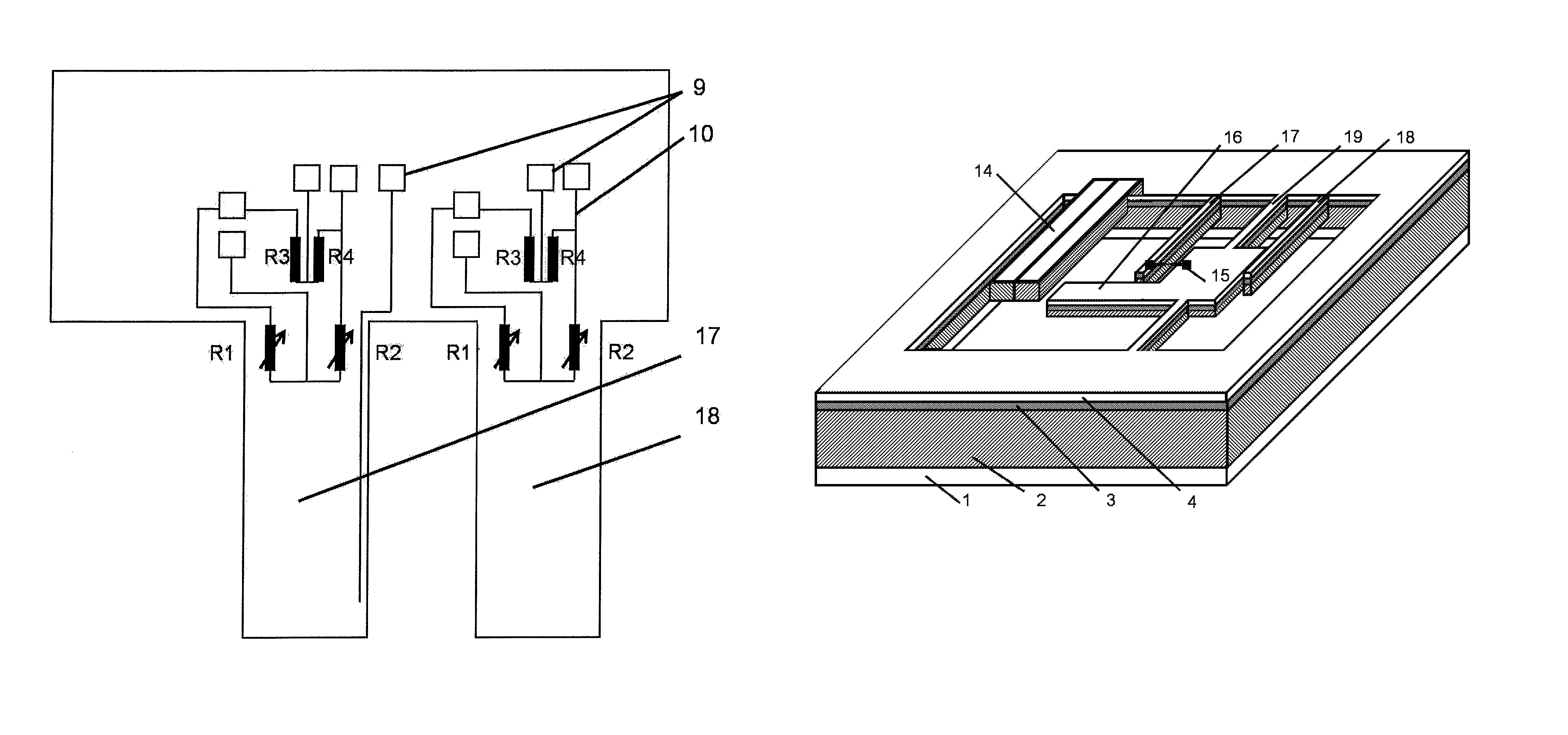

Sensor for quantitative measurement of electromechanical properties and microstructure of nano-materials and method for making the same

ActiveUS8302494B2Material analysis using wave/particle radiationElectric discharge tubesHigh resolution imagingStress–strain curve

A sensor for quantitative testing electromechanical properties and microstructure of nano-materials and a manufacturing method for the sensor are provided. The sensor comprises a suspended structure, pressure-sensitive resistor cantilevers, support beams, bimetallic strip and other components. When the bimetallic strip produces bending deformation, one of the pressure-sensitive resistor cantilevers is actuated and then stretches the low-dimensional nano-materials which drive the other pressure-sensitive resistor cantilever to bend. Through signal changes are outputted by the Wheatstone bridge, the variable stresses of low-dimensional nano-materials are obtained. Meanwhile, the variable strains of low-dimensional nano-materials are obtained by the horizontal displacements between two cantilevers, so the stress-strain curves of low-dimensional nano-materials are worked out. When the low-dimensional nano-materials are measured in the power state, the voltage-current curves are also obtained. In addition, by the help of high resolution imaging system in the transmission electron microscopy, the mechanical-electrical-microstructure relationship of the nano-materials can be recorded in situ and in atomic lattice resolution.

Owner:BEIJING UNIV OF TECH

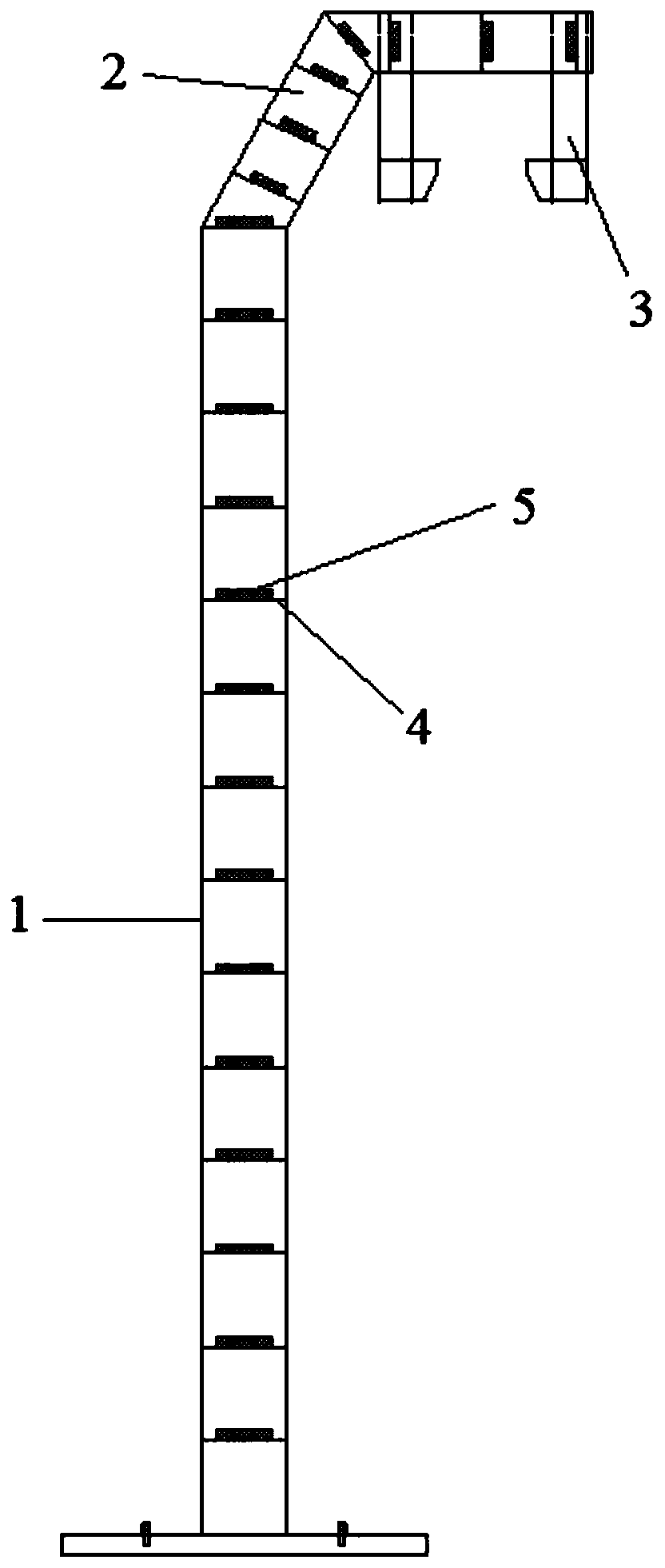

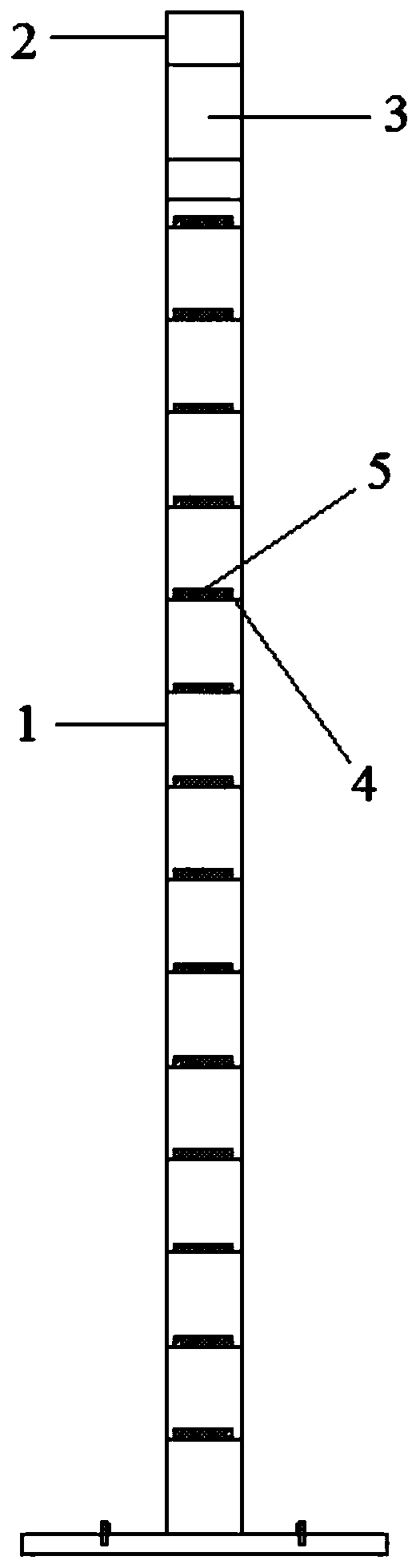

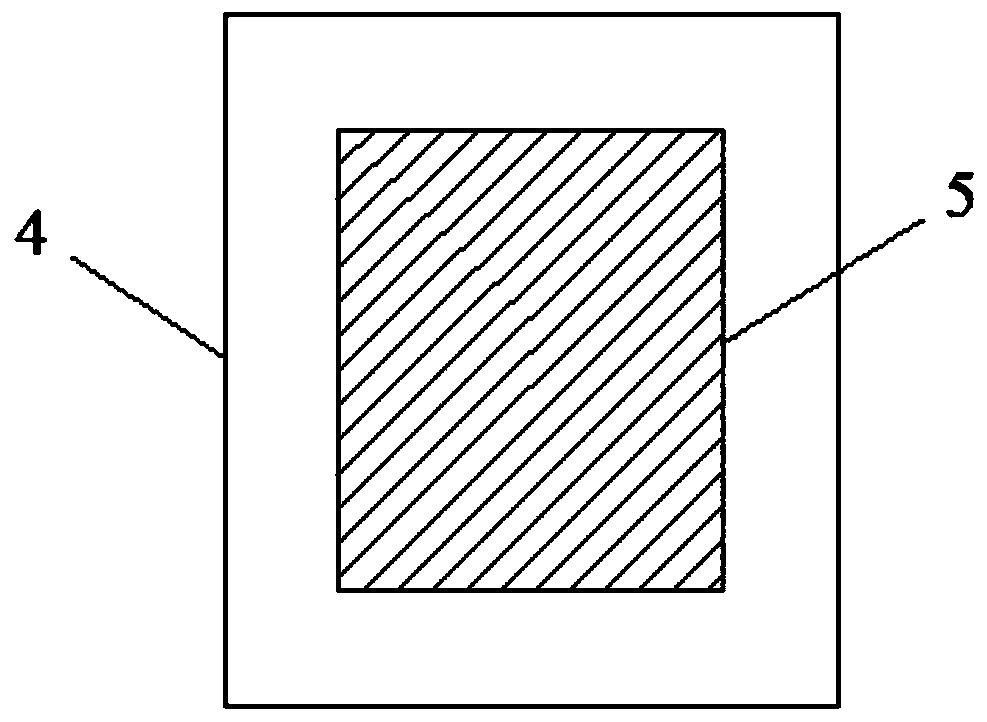

Aeroelastic model of suspended monorail wind tunnel test pier stud

The invention discloses an aeroelastic model of a suspended monorail wind tunnel test pier stud. The aeroelastic model comprises a pier body and a cantilever end. The cantilever end connected to the top of the pier body is provided with a lower bending bracket. The pier body and the cantilever end have steel box structures and each of the pier body and the cantilever end is provided with a plurality of steel partition plates at intervals in a respective length direction; each steel partition plate is connected with a counterweight block; and each counterweight block is not in contact with theinner wall of the pier body or the inner wall of the cantilever end. According to the aeroelastic model, the additional mass is provided by using all counterweight blocks to meet the model need; sincethe counterweight blocks are not in contact with the inner wall of the pier body or the inner wall of the cantilever end, the structural damping influence is avoided; the counterweight blocks are arranged discontinuously in the respective length direction of the pier body or the cantilever end to prevent the influence on the rigidity of the structure, so that conformity to the actual condition ofthe structure is improved and the wind tunnel test becomes real, accurate and reliable. The aeroelastic model has advantages of simple structure, great convenience in setting, and good effect.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Adhesive-free packaged photovoltaic module

ActiveCN107316910AExtended service lifeAvoid problems such as seal failurePhotovoltaicsPhotovoltaic energy generationFiberSilanes

The invention discloses an adhesive-free packaged photovoltaic module. The photovoltaic module comprises a lamination part and a frame body; a hydrophobic film layer is arranged on the edge and side surfaces of the lamination part; the hydrophobic film layer is formed by coating the surface of fiber net cloth with a mixed liquid of ethyl orthosilicate and methyltriethoxysilane; the frame body comprise side plates, backup plates, calendering sheets, supporting plates and seat plates, wherein one ends of the backup plates are connected with the side plates in sequence at intervals in a cantilever manner while bumps are arranged at the other ends of the backup plates; pressing heads are arranged at the other ends of the calendering sheets at intervals; groove openings are formed between the calendering sheets and the supporting plates; support plates are arranged between the supporting plates and the seat plates; and wedge-shaped blocks which enable the cantilever ends of the calendering sheets to be bent downwardly are arranged between the calendering sheets and the backup plates at intervals. Sealing connection between a guiding-pressing part and the frame body can be realized without needing adhesive or sealing strips in packaging, so that the problem of sealing failure in manual adhesive coating or sealing strip pressing and mounting can be avoided, so that seal packaging can be ensured effectively, the packaging process is simplified, material and man-hour cost can be saved, and power generation efficiency is improved.

Owner:江西仁江科技有限公司

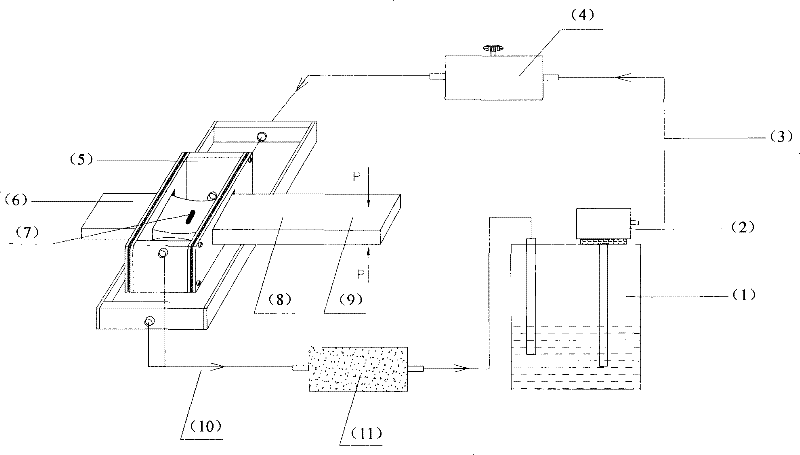

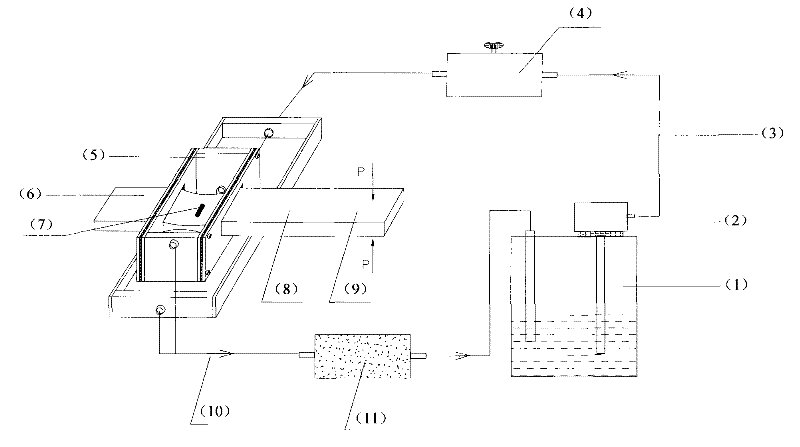

A Seawater Circulation System for Corrosion Fatigue Tests on Metal Materials

InactiveCN101566554BSolve the problem of fragile corrosion equipmentEasy to cleanWeather/light/corrosion resistanceStrength propertiesFiltrationMetallic materials

A seawater circulation system for performing corrosion fatigue tests on metal materials consists of a seawater container 1, a micro-pump 2, a rubber conduit 3, a water flow control valve 4, a double-layer anti-leakage corrosion device 5, a sample fixing end 6, and a sample surface crack end 7. Low cycle fatigue test sample end 8, sample loading end 9, conduit 10, and filter box 11. The seawater container is inserted into the micro-pump, and the rubber conduit connects the micro-pump and the water flow control valve and communicates with the double-layer anti-leakage corrosion device. The fixed end of the sample, the crack end of the sample surface, and the low-cycle fatigue test can be fixed on the double-layer anti-leakage corrosion device. The sample end, the sample loading end, and the other end of the double-layer anti-leakage corrosion device communicate with the filter box through a conduit, and return to the seawater container after filtration. The low-cycle corrosion fatigue test under the cantilever bending loading mode can be carried out, which changes the previous status of using air fatigue performance data instead of seawater fatigue performance data for metal verification, and increases the safety, reliability and service life of the ship.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Tying-hanging type vehicle-mounted winch system

The invention discloses a set-mounted vehicle-mounted winch system, which is characterized in that it includes a main hook and an inner swing arm, the main hook is provided with a longitudinal column, the front end of the longitudinal column is connected with an oblique arm inclined to the left, and the front end of the oblique arm is connected with a A straight arm stretching forward in the same direction as the longitudinal column. The straight arm is connected with a cantilever that bends to the right and then bends backward to form a hook. A gap is set in the center of the straight arm and the cantilever. The gap runs through the cantilever front and back, and the gap runs through the straight From the arm to the joint between the straight arm and the oblique arm, the straight arm is provided with a chute in the front and rear directions that communicates with the gap, and the center of the longitudinal column is provided with a through hole that runs through the front and back. The inner swing arm is elbow-shaped and the thickness is equal to the width of the gap. The front end of the swing arm is located in the gap and is connected to the chute through the hinge shaft. The rear end of the inner swing arm is provided with a cylindrical boss, and the front end of the through hole is provided with a positioning hole that can match the boss; it will not be unhooked even if it is loose, and the traction rope is bent and deformed. The friction and friction are small, the service life of the traction rope is longer, and it is not easy to produce dead bends.

Owner:CHONGQING TUOZHUO METAL MATERIALS CO LTD

Medical system, piezoelectric kit, related methods and medical procedures

ActiveUS9259580B2More productivePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesHigh energyPiezo electric

Owner:PI HARVEST HLDG

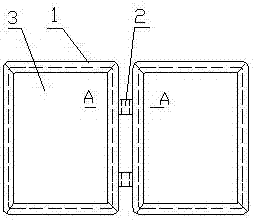

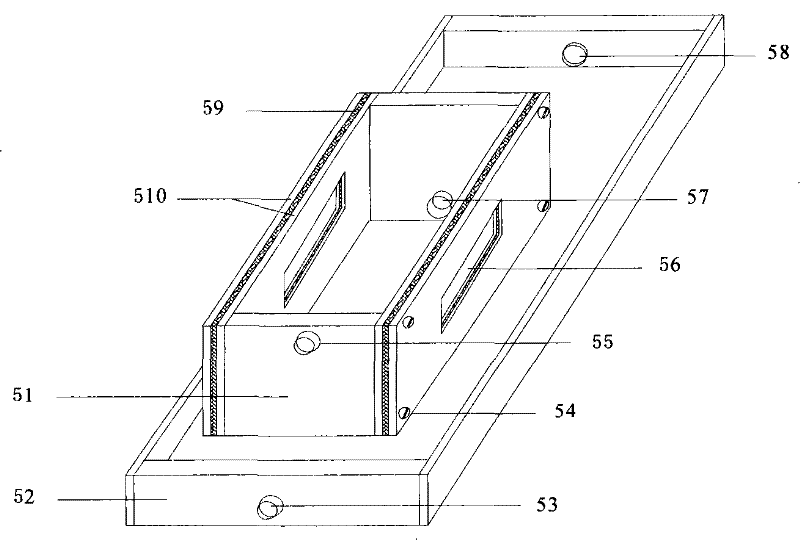

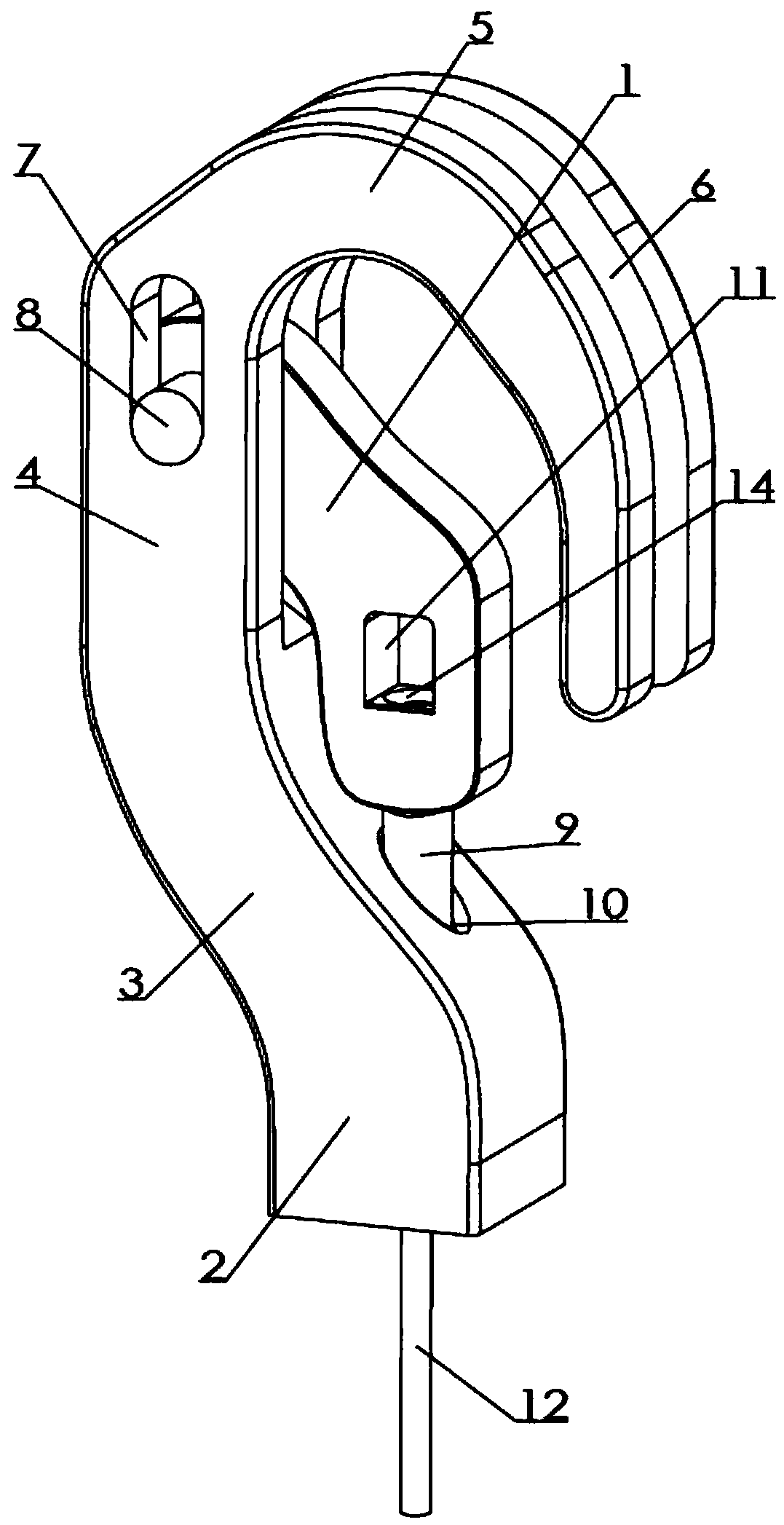

A cantilever bending test device for rock slab samples

ActiveCN106442112BImprove clamping stabilityImprove accuracyMaterial strength using steady bending forcesElectricityData acquisition

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com