Tying-hanging type vehicle-mounted winch system

A winch, vehicle-mounted technology, used in vehicle parts, traction connectors, transportation and packaging, etc., can solve problems such as dead bends and easy injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

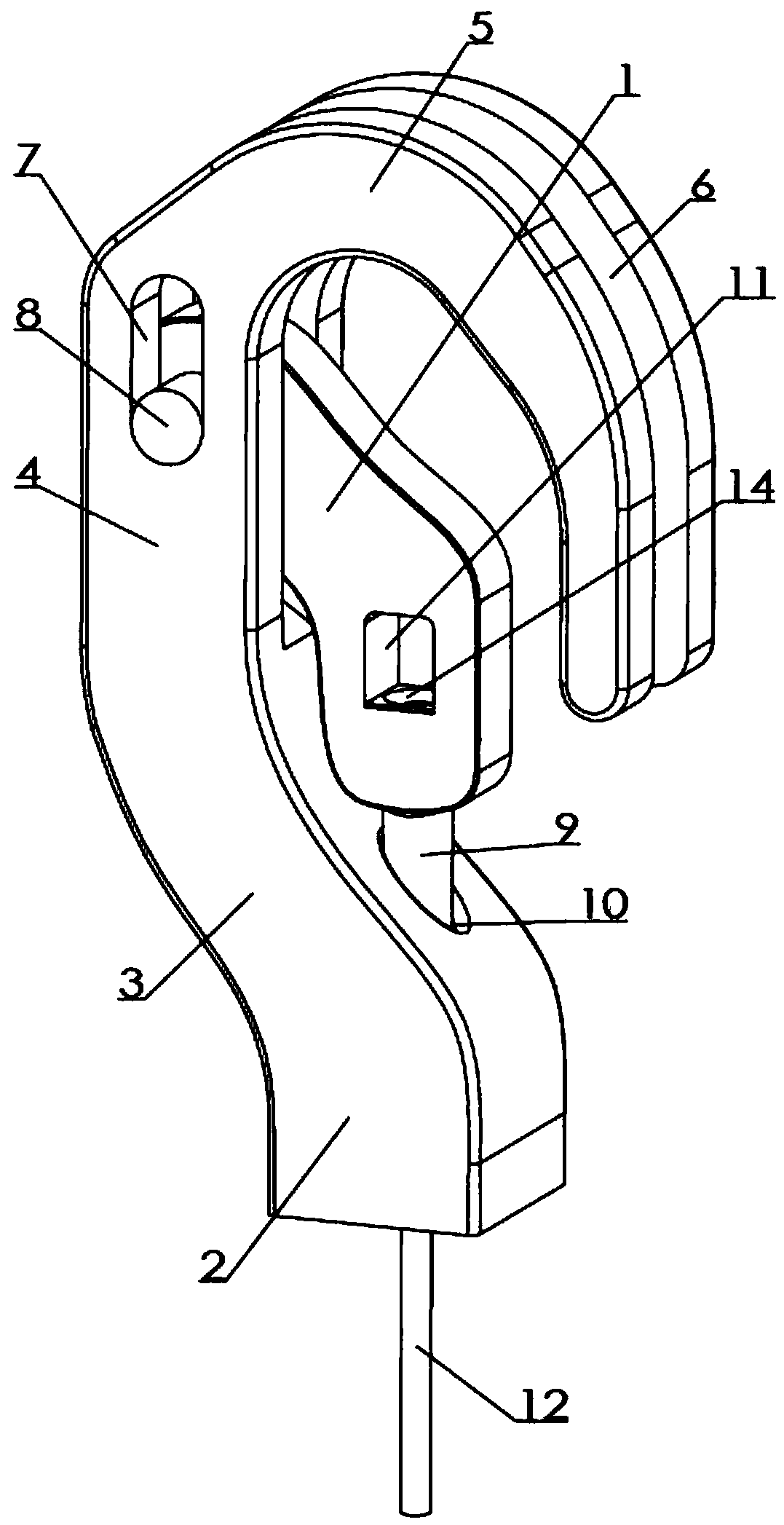

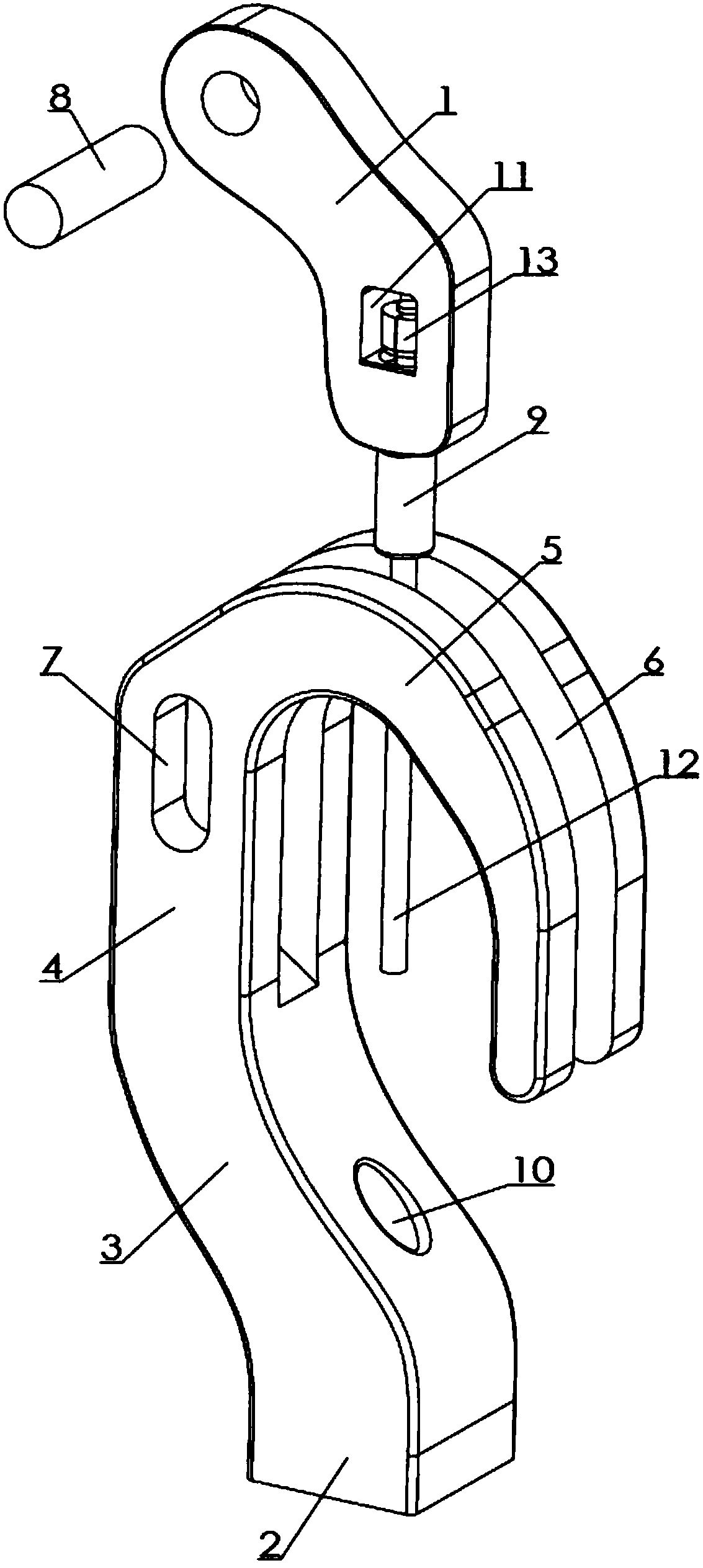

[0011] Examples of the present invention figure 1 , 2 As shown, the set-mounted vehicle-mounted winch system is provided with a main hook and an inner swing arm 1, the main hook is provided with a longitudinal column 2, the front end of the longitudinal column is connected with an oblique arm 3 inclined to the left, and the front end of the oblique arm is connected with a forward The stretched straight arm 4 is in the same direction as the longitudinal column. The straight arm is connected with a cantilever 5 that bends to the right and then bends backward to form a hook. A gap 6 is set in the center of the straight arm and the cantilever. The front and rear directions of the gap run through the cantilever, and the gap runs from front to back. Run through the straight arm to the connection between the straight arm and the oblique arm. The straight arm is provided with a chute 7 communicating with the gap in the front and rear directions. The inner swing arm is elbow-shaped an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com