Cantilever bending load metal material fatigue damage test measurement method

A technology of fatigue damage and cantilever bending, applied in the direction of applying repetitive force/pulse force to test the strength of materials, etc., can solve the problems of indirect measurement that has not been reported, direct measurement difficulties, and safe use threats.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

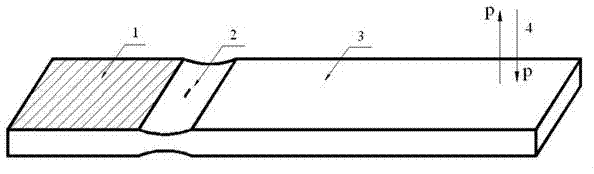

[0033] combine figure 2 , the smooth plate sample is made of quenched and tempered 10CrNiMo structural steel with a thickness of 26 mm, and five identical smooth plate samples are processed. The numbers of the five smooth plate samples are DFSC-01~05 in sequence, and each piece The notch width of the smooth plate sample is 63mm and the thickness is 12.5mm. The radius of the upper and lower arcs at the notch of each smooth plate sample is 55mm, and the total length of the smooth plate sample is 420mm.

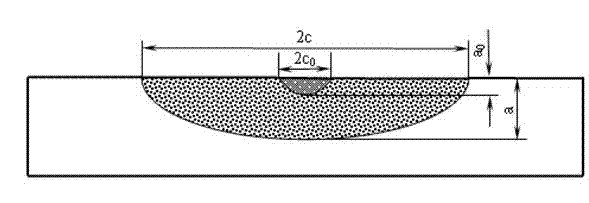

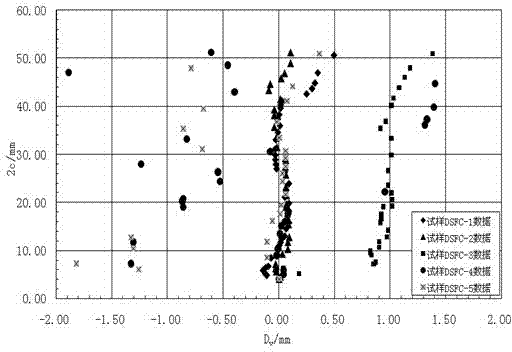

[0034] The cyclic load at the force point is P=4.0kN, the frequency f=1.0hz, and the test waveform is a sine wave. After installing the smooth plate samples, start the testing machine to start the test on five smooth plate samples in turn, when the initial surface crack notch length of the five smooth plate samples is 2c 0 When reaching about 10mm, 20mm, 30mm, 40mm and 50mm respectively, remove each smooth plate sample and measure the initial surface crack depth a 0 , note: i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com