Patents

Literature

32 results about "Notch width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The notch width increased gradually from a mean of 1.8 cm at the distal aspect to a mean of 2.3 cm at the most proximal portion. The notch height increased from a mean value of 1.8 cm at the distal-most portion to a maximum of 2.4 cm at 1.8 cm from the distal-most portion of the notch.

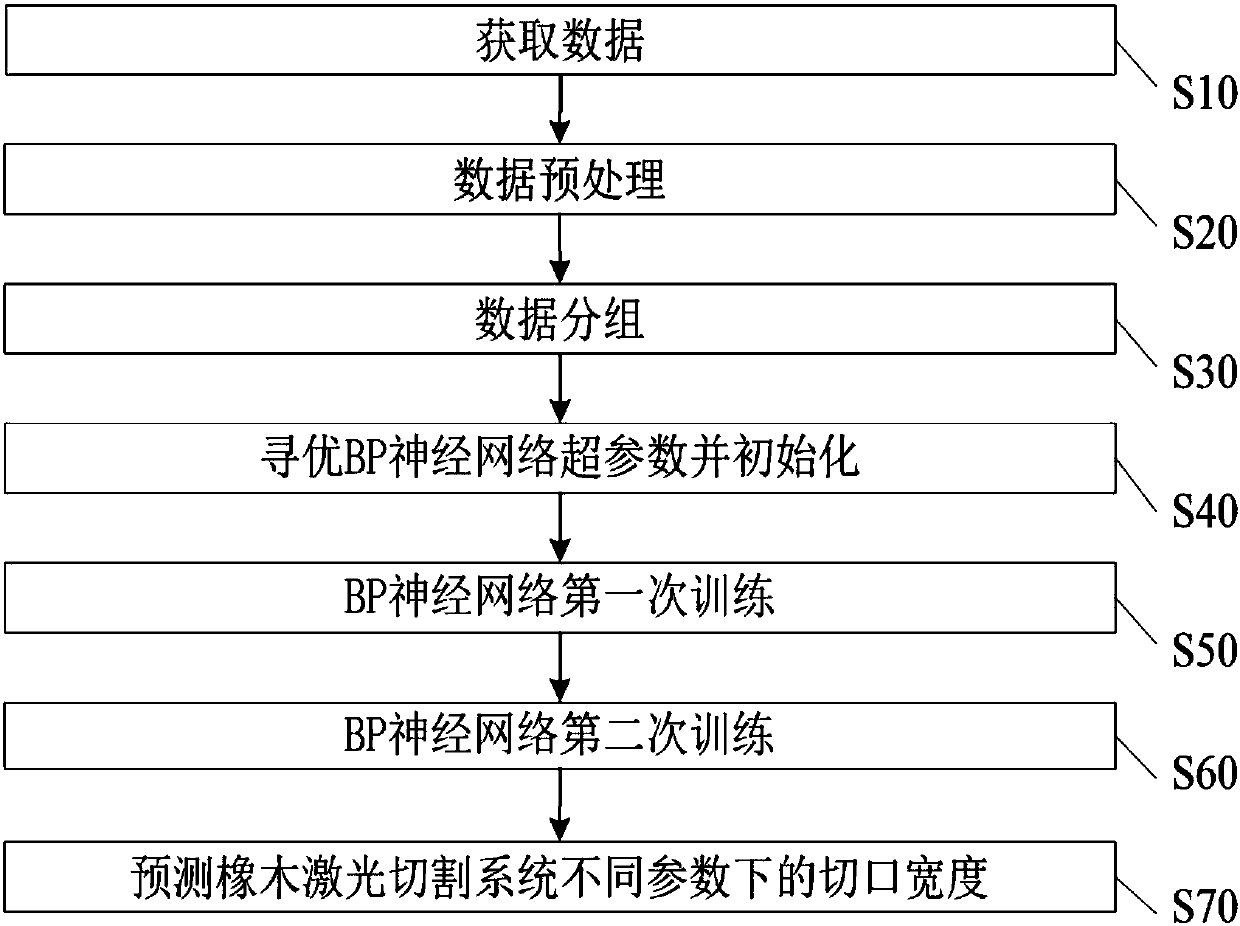

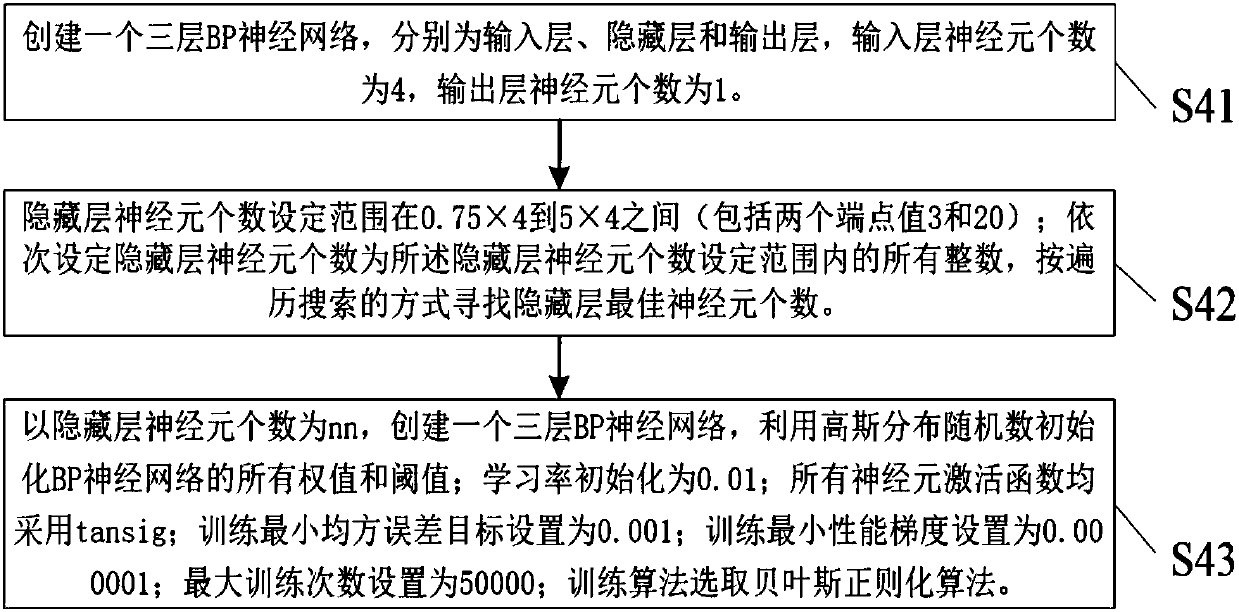

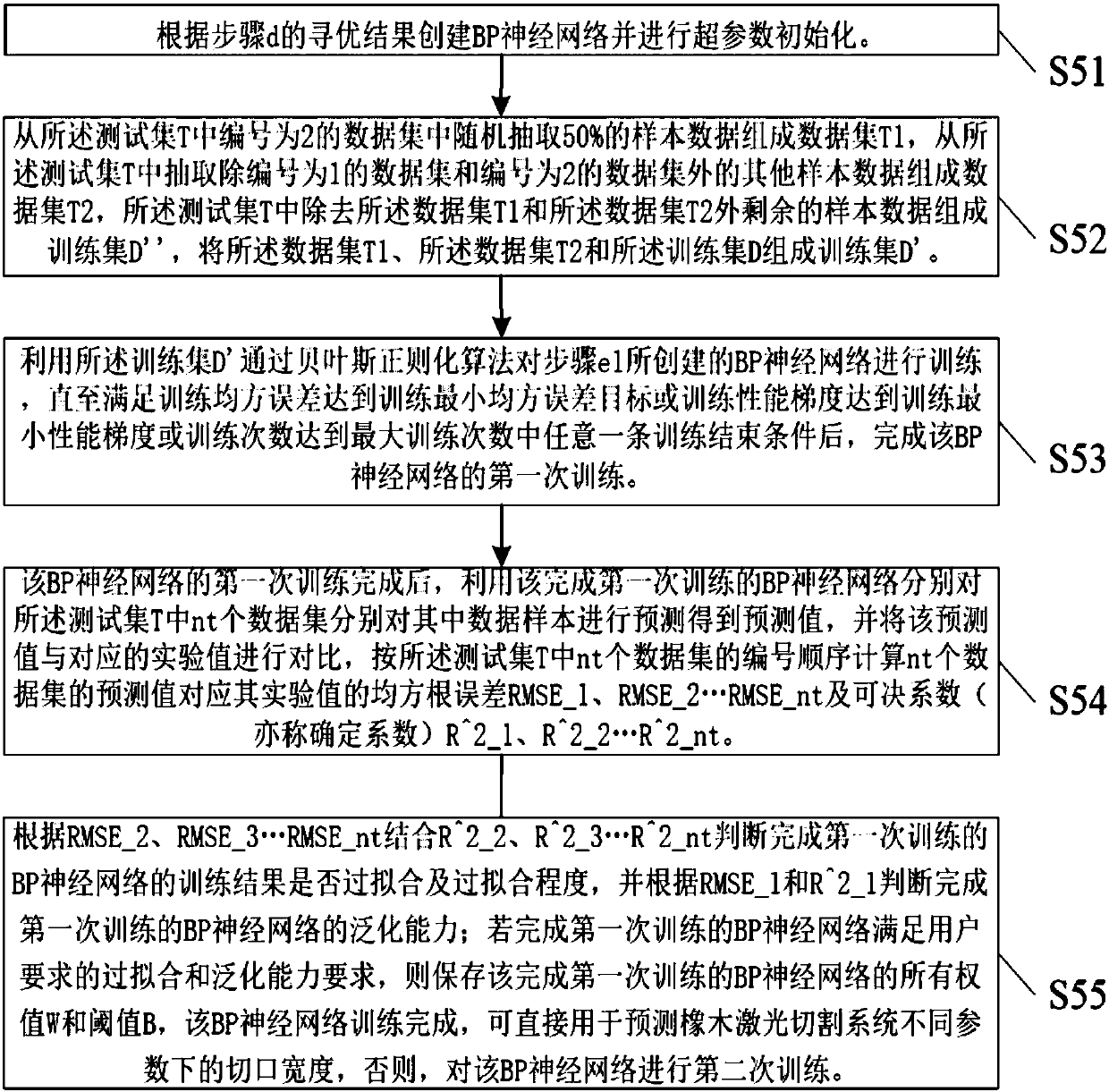

Training test method of BP neural network regression model and application system thereof

InactiveCN107633301AReduce data redundancyImprove training effectCharacter and pattern recognitionNeural learning methodsData setData acquisition

The invention relates to a training test method of a BP neural network regression model and is applied to an oak laser cutting system to predict notch widths. The method mainly comprises steps that a,data acquisition, data sets of N experiment samples are acquired, and M sets of experiment data are totally included; b, data pre-processing; c, data grouping; d, optimization searching of super parameters of a BP neural network and initialization; e, first-time training of the BP neural network; f, second-time training of the BP neural network; and g, training accomplishment of the BP neural network, the notch widths of the oak laser cutting system under different parameters are predicted. The method is advantaged in that over-concentrated and over-sparse data conditions are trained, and thetraining effect of the BP neural network is improved.

Owner:GUANGDONG UNIV OF TECH

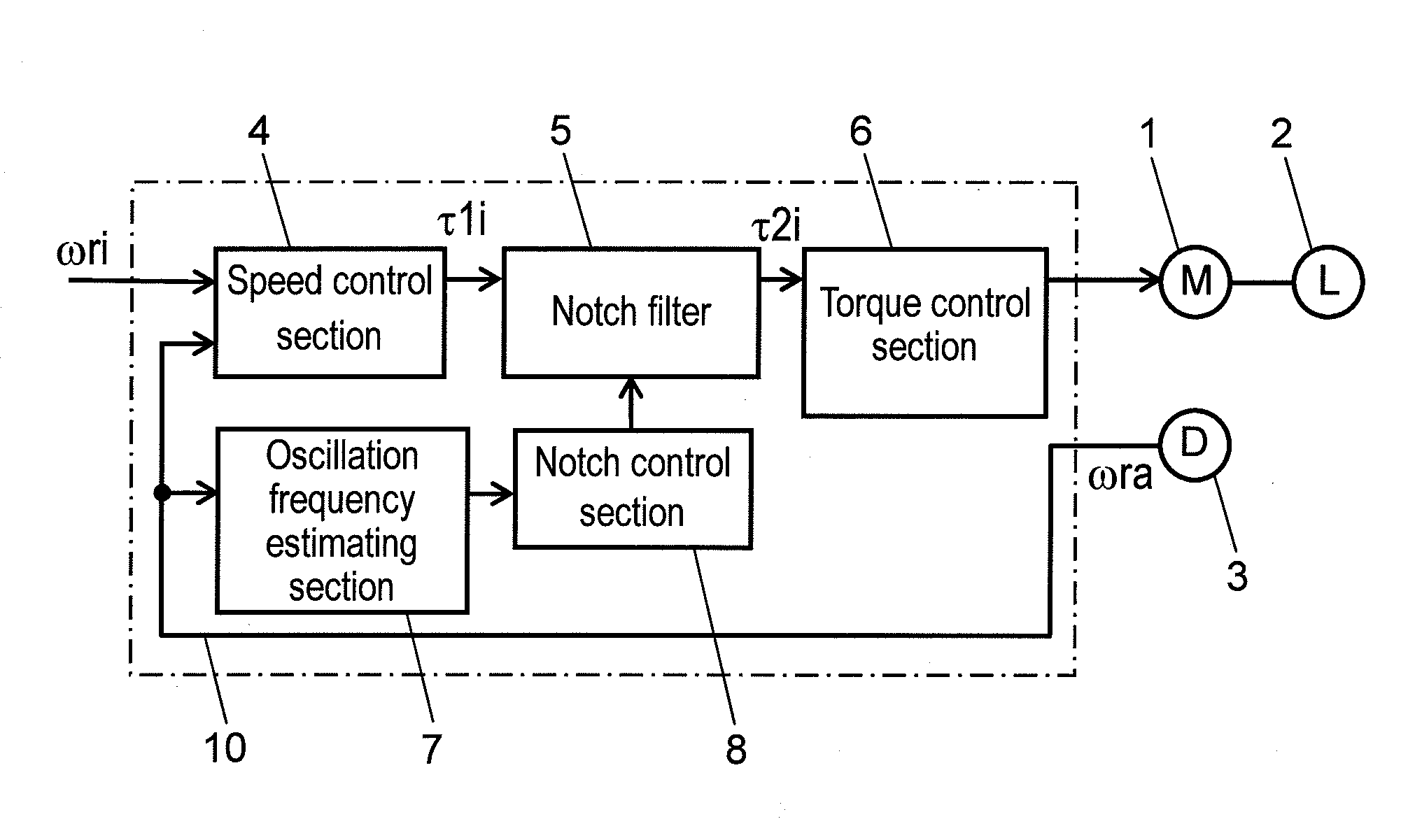

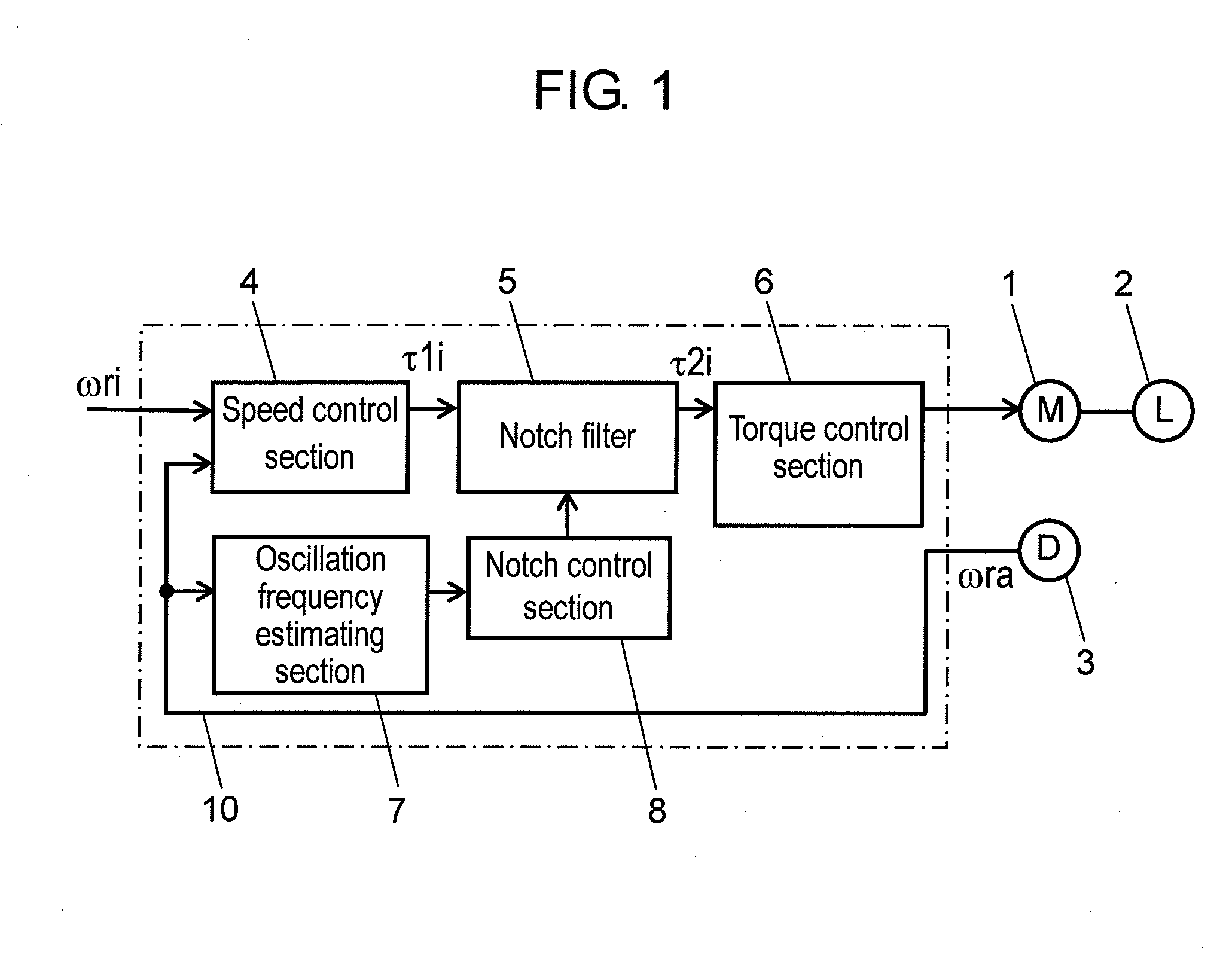

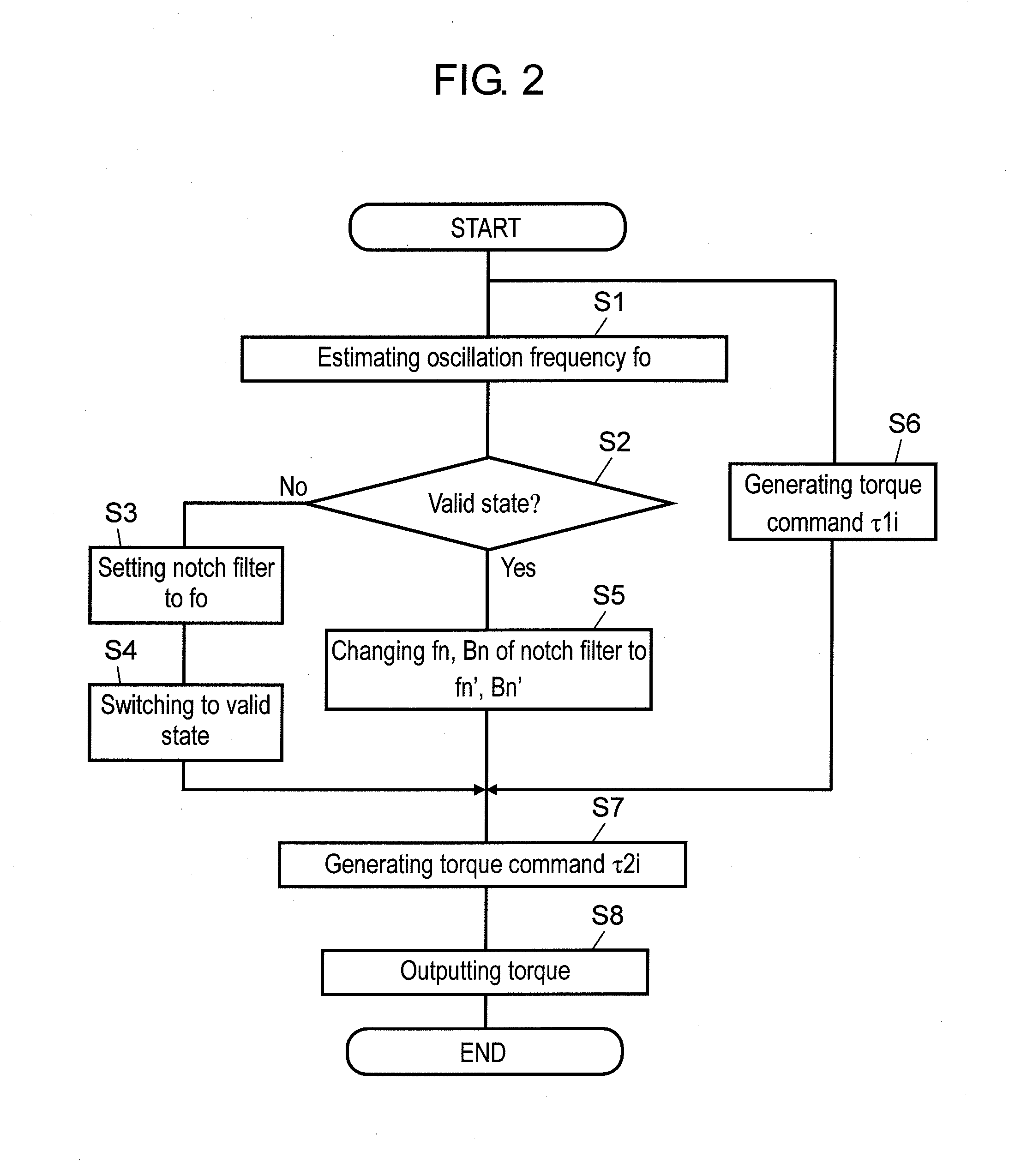

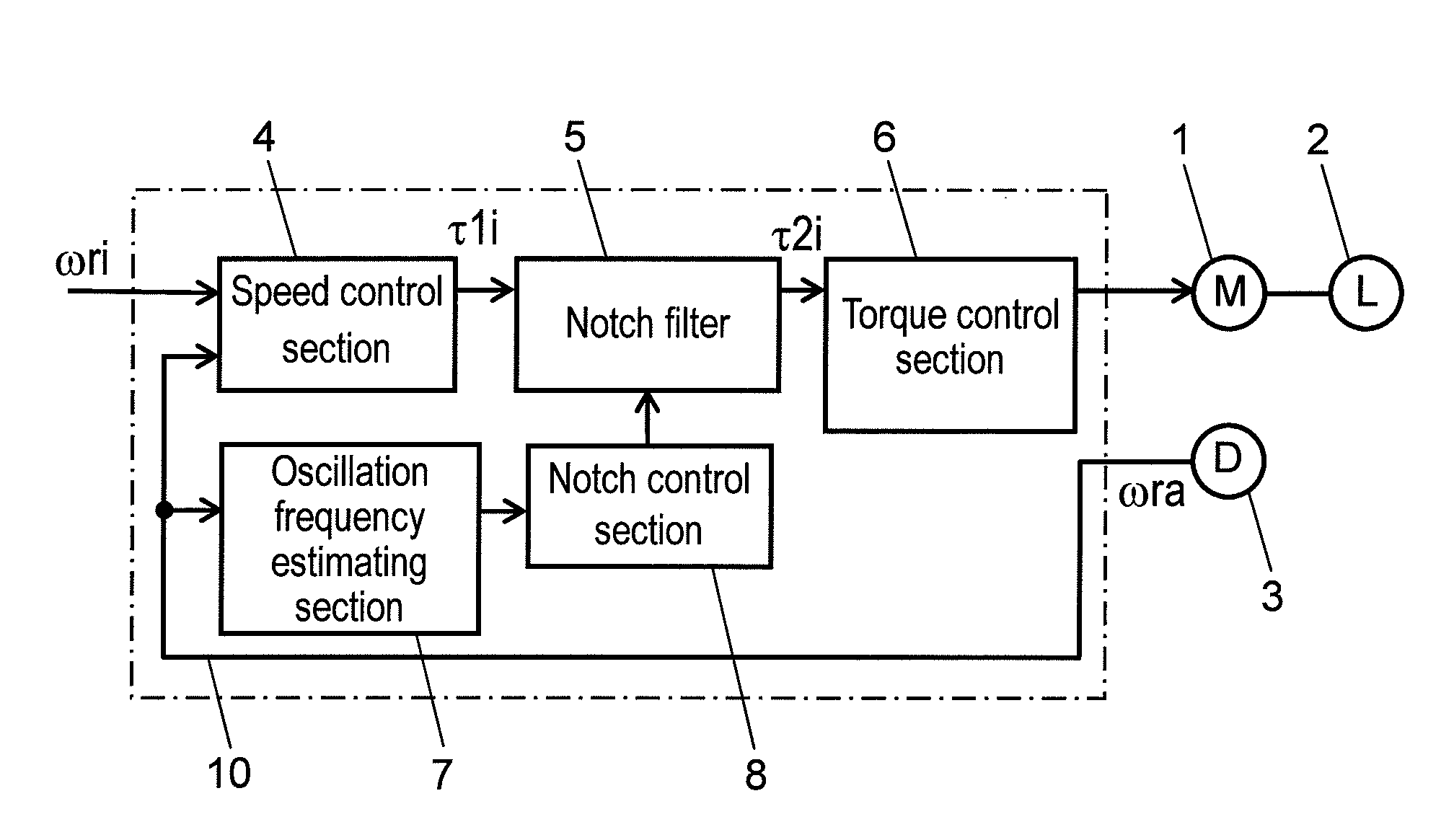

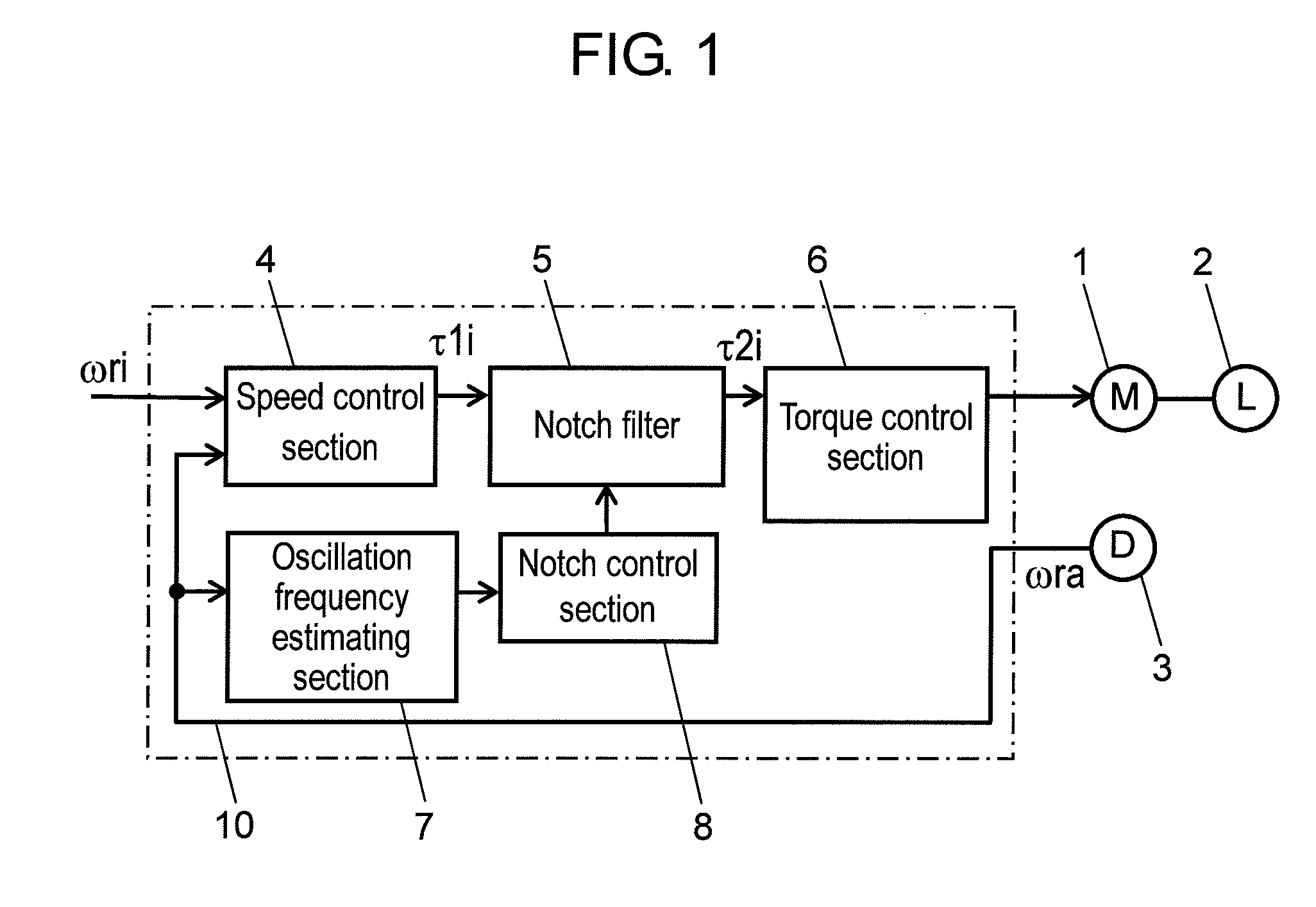

Motor controller

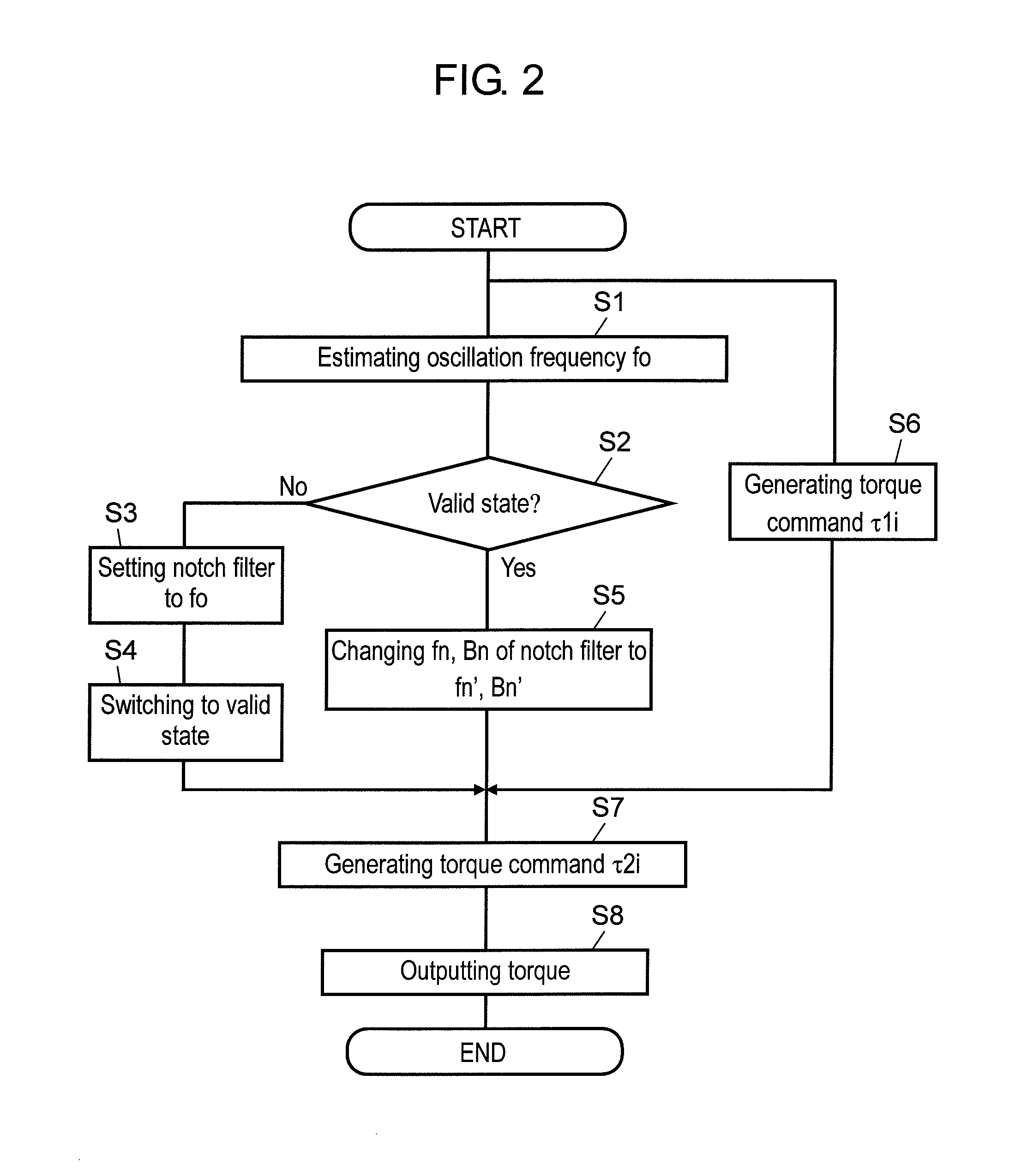

InactiveUS20080309279A1Suppressing short-time oscillationConstantly and stablyElectric motor controlElement comparisonControl systemMotor controller

A motor controller includes: a notch filter arranged inside a control system; an oscillation frequency estimating section which estimates an oscillation frequency component in a motor; and a notch control section which controls a notch filter so as to change a notch frequency and a notch width. The notch control section changes a frequency between an oscillation frequency and a notch frequency set in a notch filter as a new notch frequency, while changing a notch width to a new notch width such that the notch width is larger after the change than before the change.

Owner:PANASONIC CORP

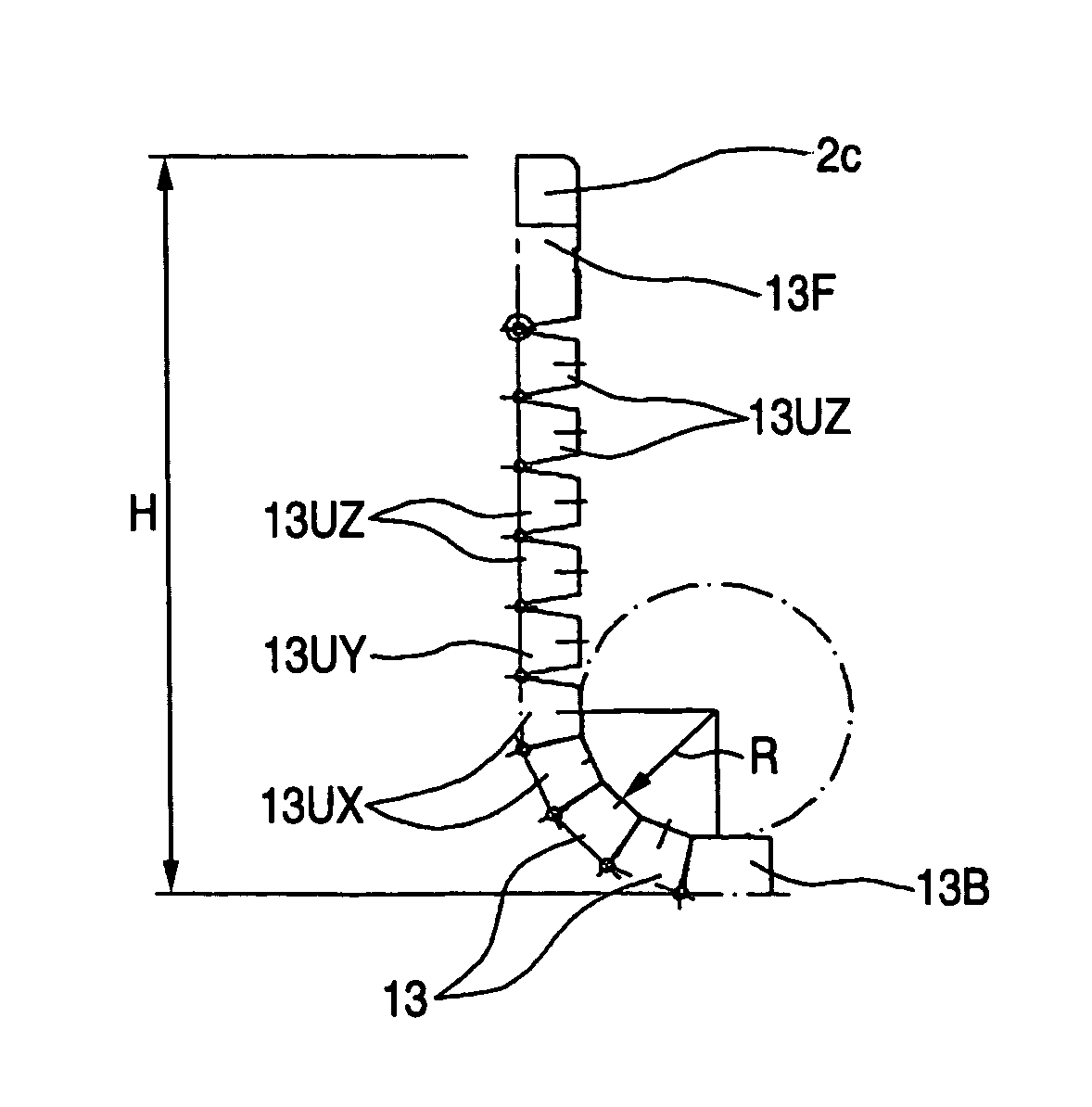

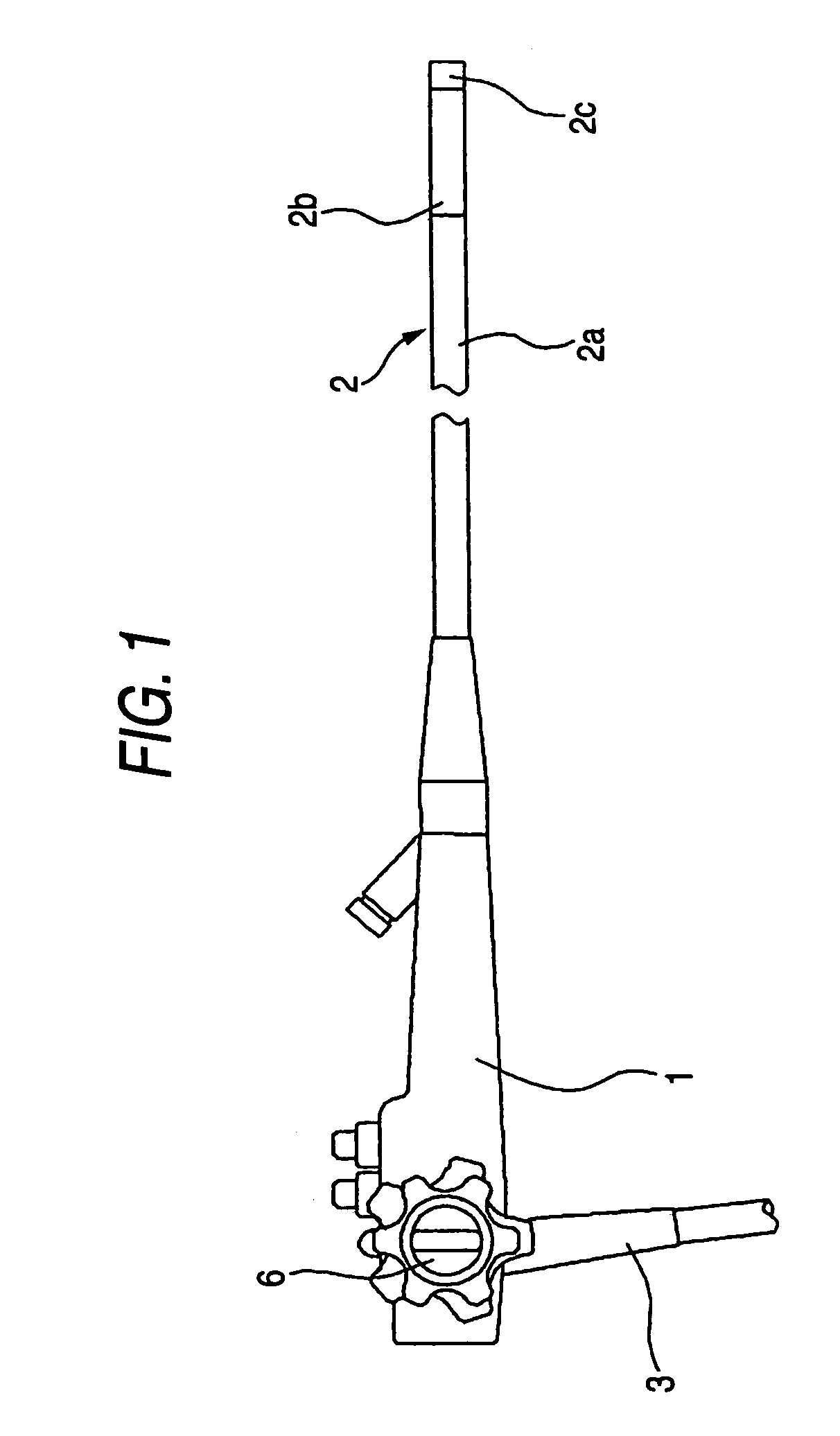

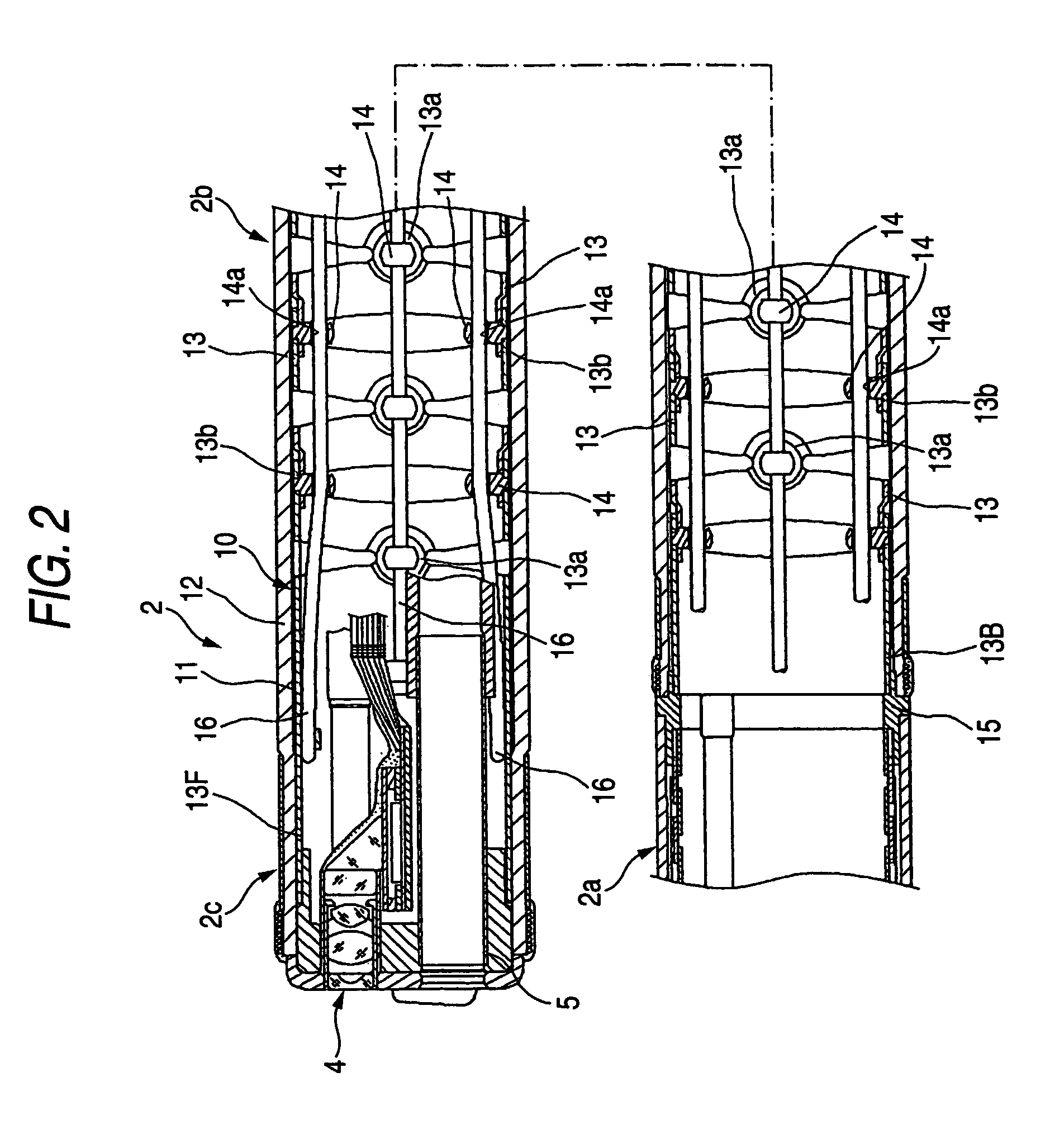

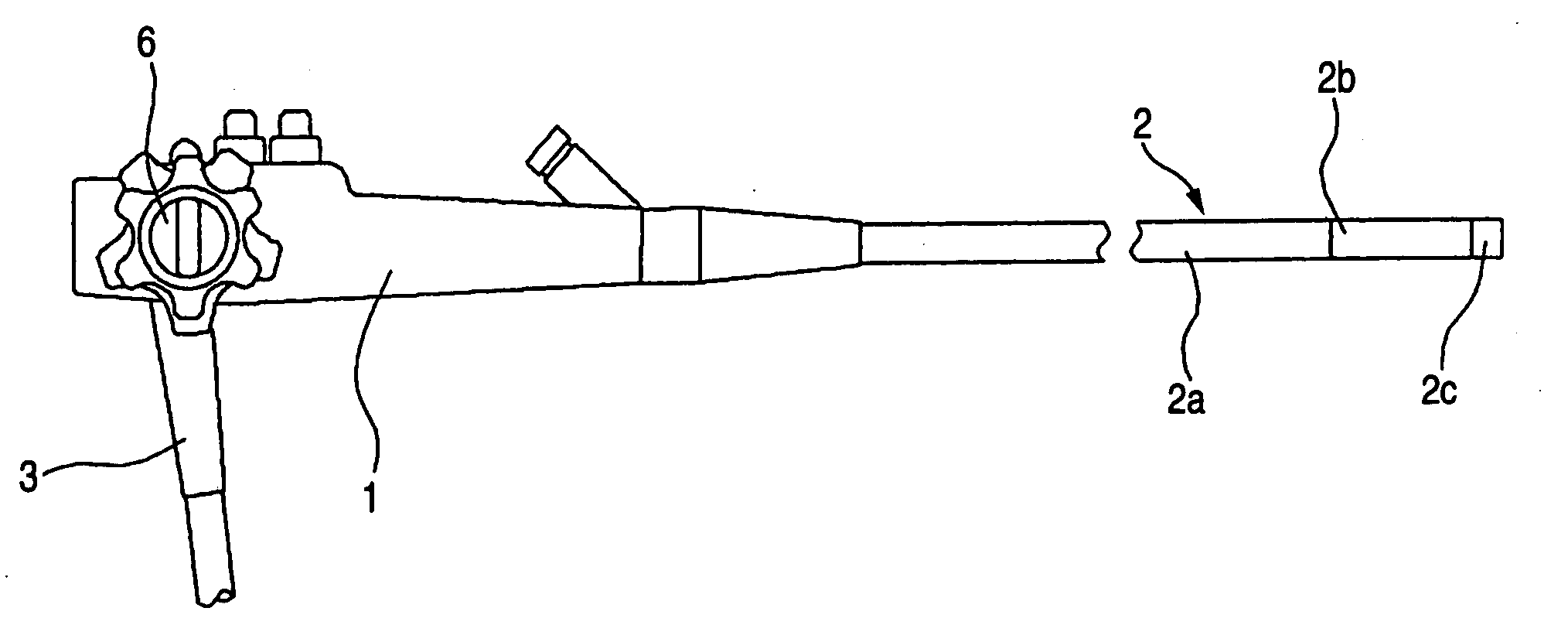

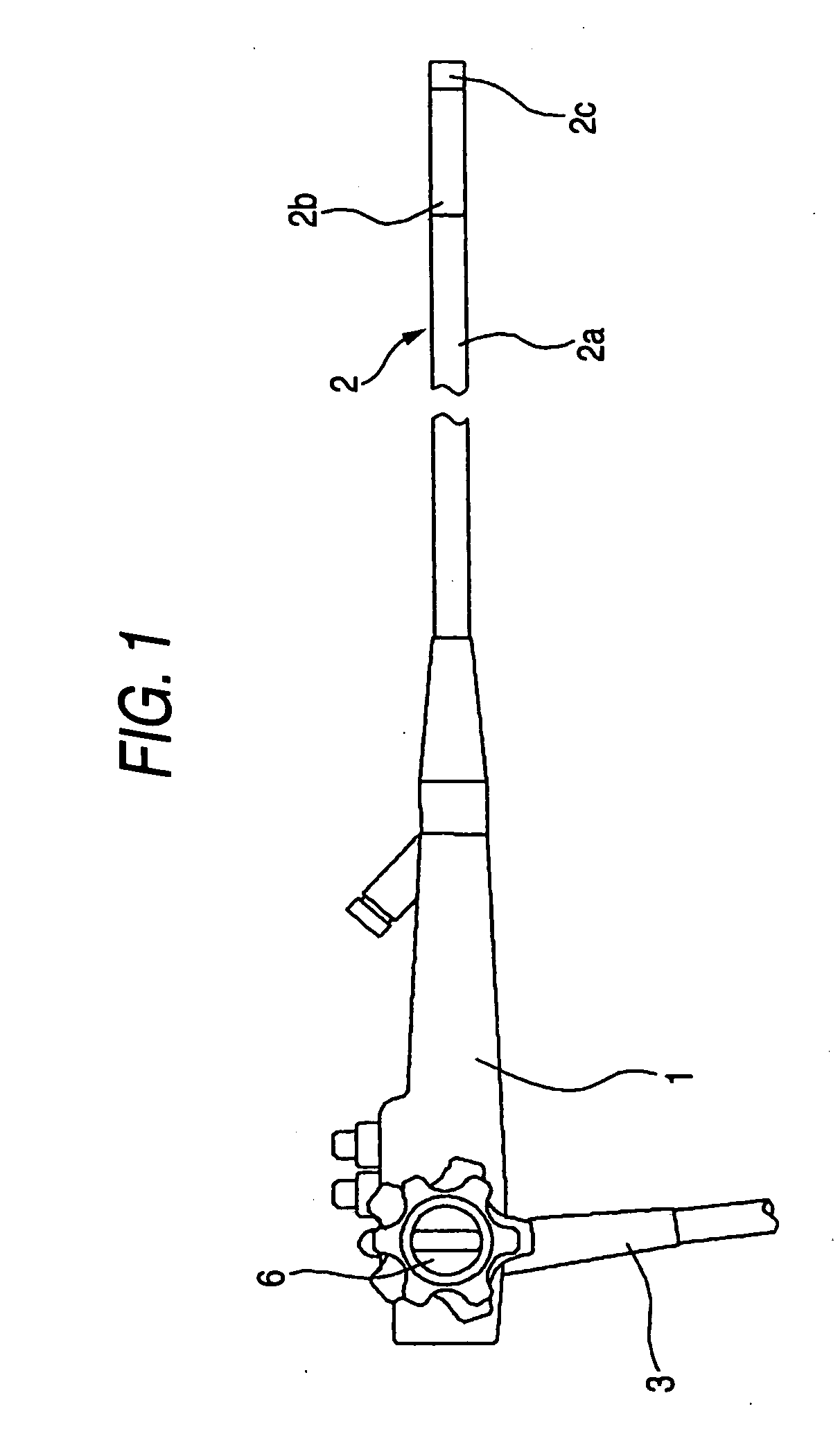

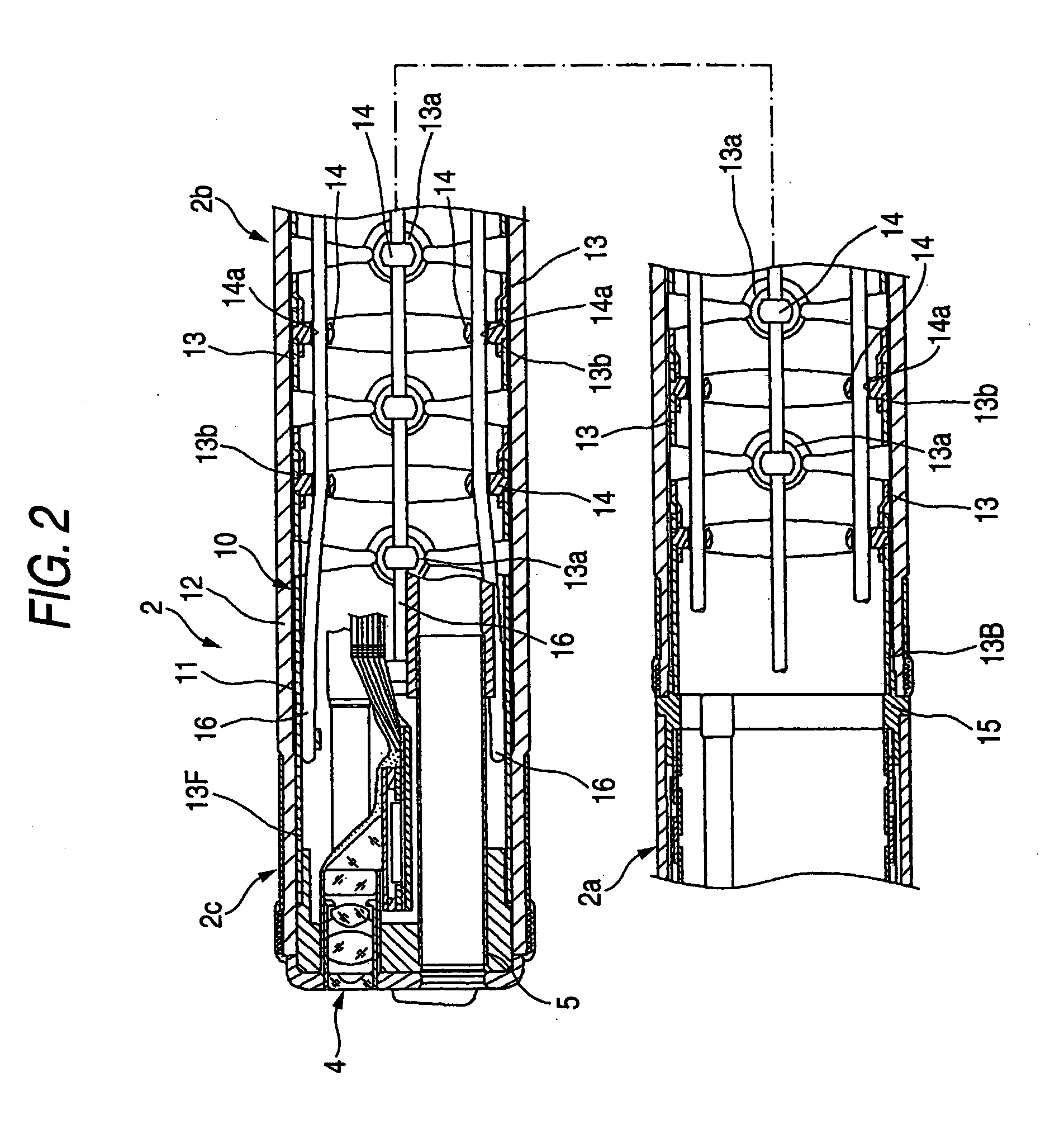

Endoscope angle portion

An endoscope angle portion comprises an angle portion structure. The angle portion structure includes angle ring units each of which comprises pivoting joint portions extending from its both ends and has a shape that is notched obliquely in directions away from the pivoting joint portions, and wherein adjacent ones of the angle ring units is pivotally joined to form the angle portion structure, wherein a first angle ring unit of the angle ring units has a larger length dimension than that of a second angle ring unit of the angle ring units, and the first angle ring unit has a smaller notch width of a notched portion than that of the second angle ring unit, the first angle ring unit being nearer a base end of the endoscope angle portion than the second angle ring unit.

Owner:FUJI PHOTO OPTICAL CO LTD

Endoscope angle portion

An endoscope angle portion comprises an angle portion structure. The angle portion structure includes angle ring units each of which comprises pivoting joint portions extending from its both ends and has a shape that is notched obliquely in directions away from the pivoting joint portions, and wherein adjacent ones of the angle ring units is pivotally joined to form the angle portion structure, wherein a first angle ring unit of the angle ring units has a larger length dimension than that of a second angle ring unit of the angle ring units, and the first angle ring unit has a smaller notch width of a notched portion than that of the second angle ring unit, the first angle ring unit being nearer a base end of the endoscope angle portion than the second angle ring unit.

Owner:FUJI PHOTO OPTICAL CO LTD

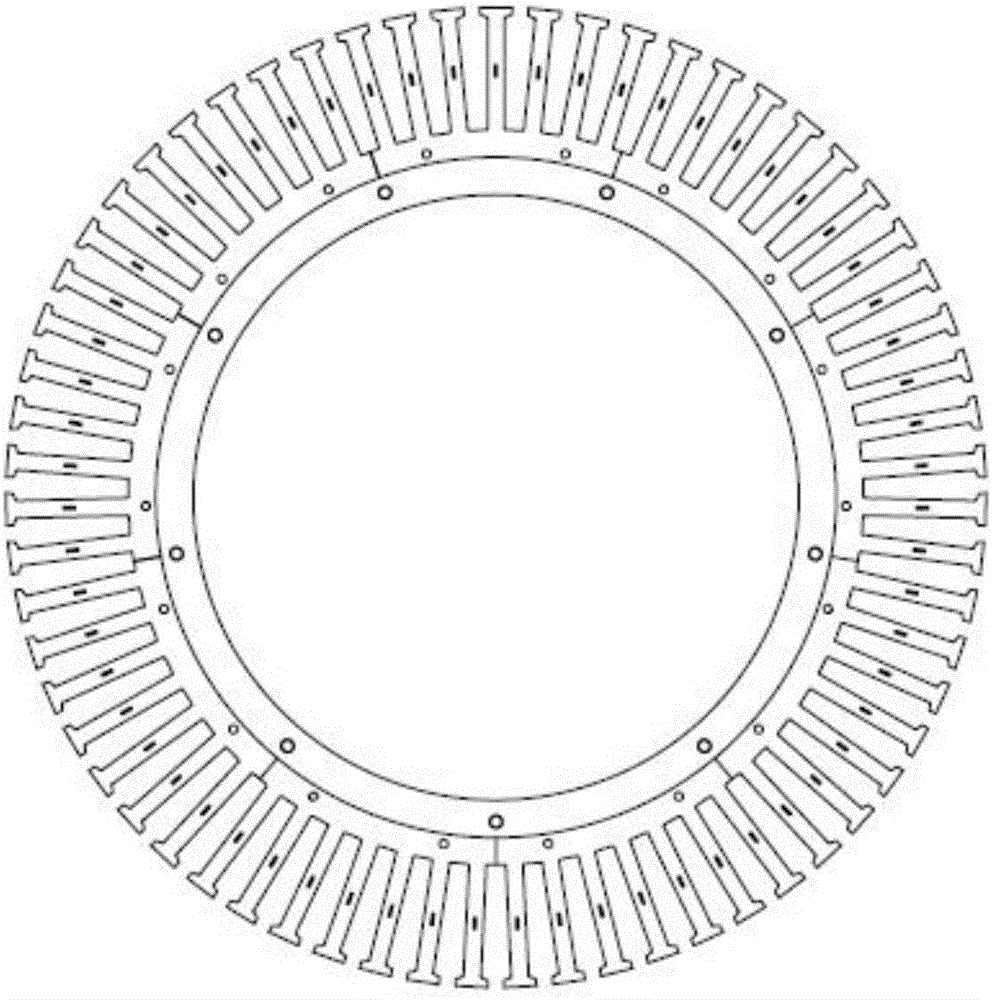

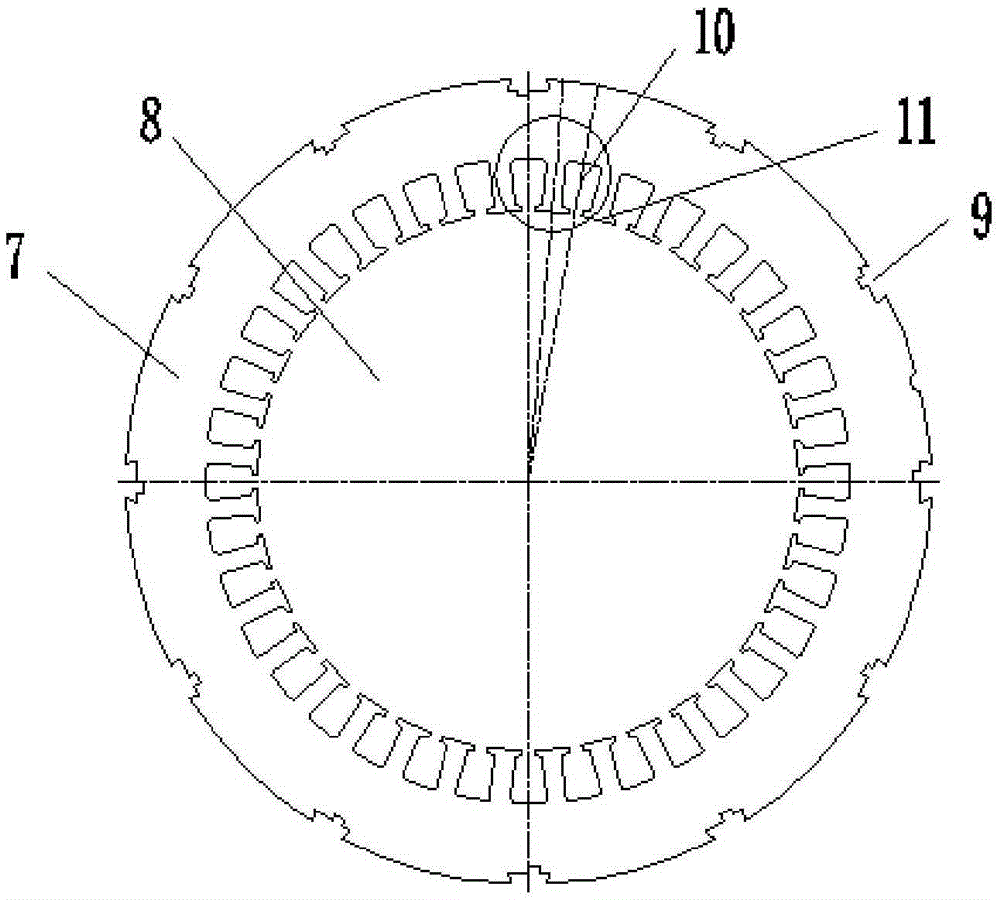

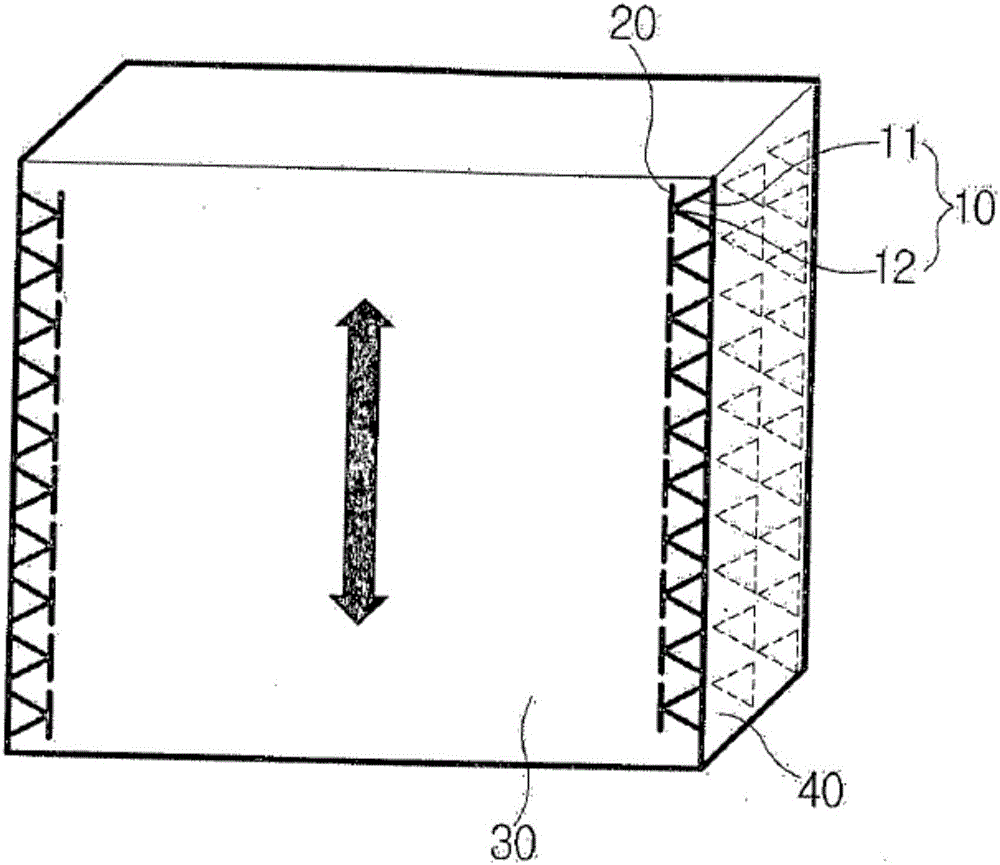

Stator core for an electric machine

InactiveCN102077448ASmall magnetic resistanceLow shape retentionMagnetic circuit stationary partsManufacturing stator/rotor bodiesManufacturing technologyElectric machine

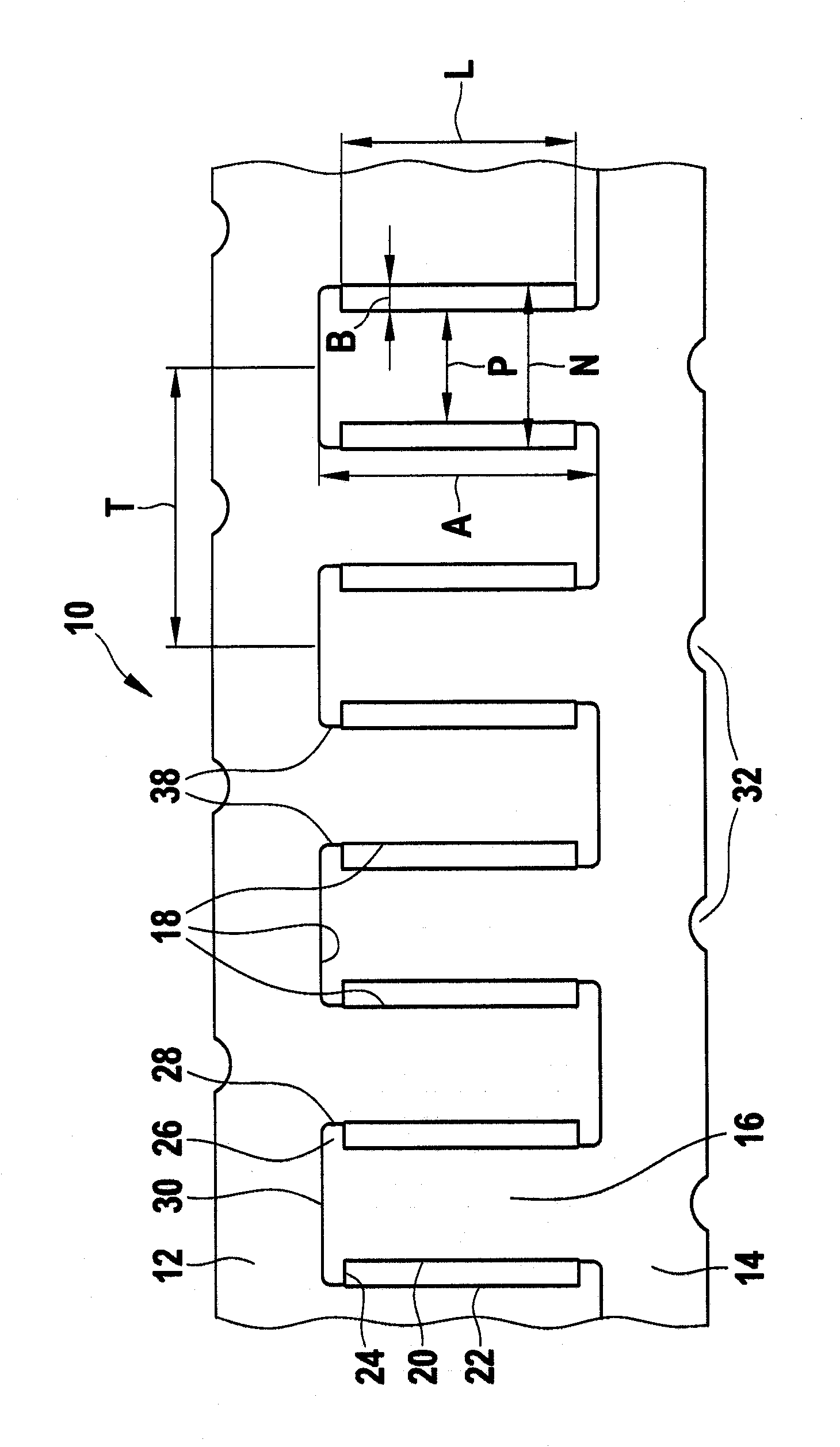

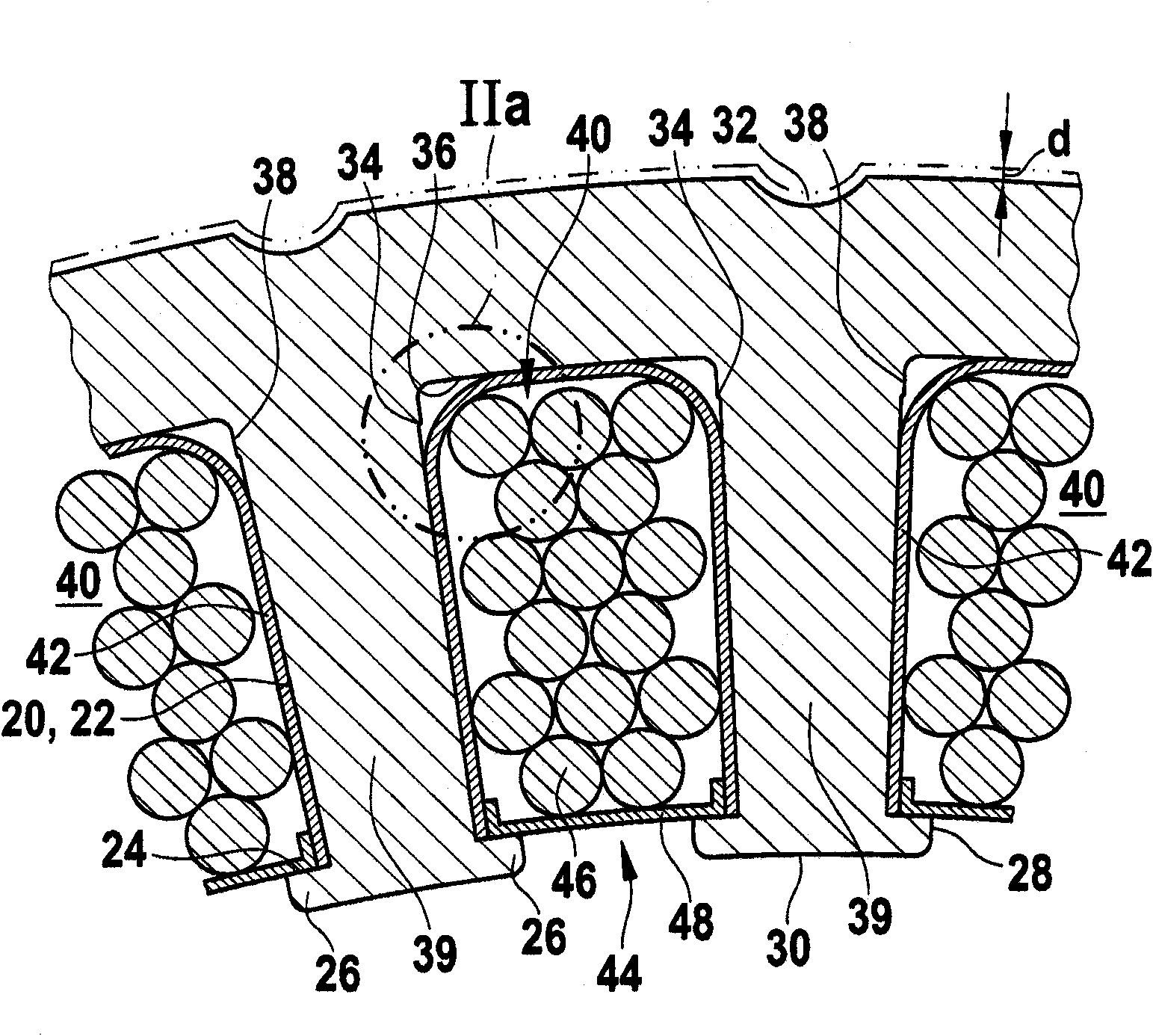

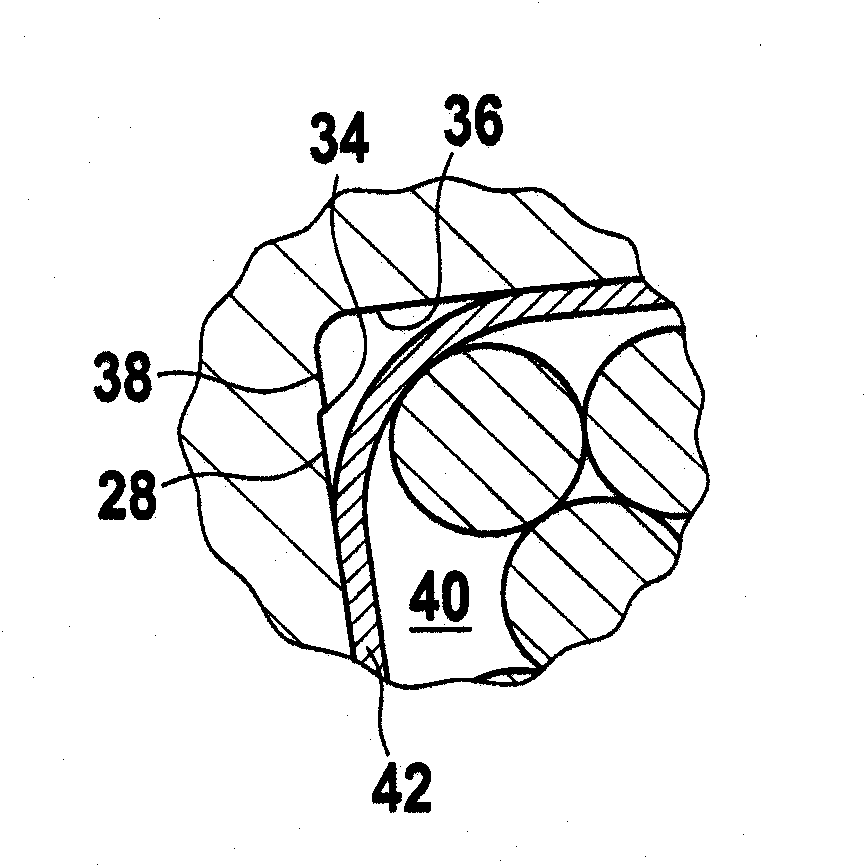

The invention relates to a stator core for an electric machine, in particular for the generator of a motor vehicle. Said stator core is laminated or wound from segments (12, 14) that are punched and / or cut out in a tooth-forming manner from a preferably strip-shaped magnetic steel sheet (10) and form a plurality of notches (40) and teeth (39). The region of the tooth flank (20) and the notch flank (22) is punched in such a way that the tooth width (P) and the notch width (N) are substantially constant in the unbent segments (12, 14) along the entire length (A) of the teeth. The ratio (alpha) between the tooth width (P) and the notch pitch (T) is greater than 0.38 and smaller than 0.5, thus minimizing magnetic resistance and limiting the amount of scrap to a level lying within the geometrical and production-related possibilities.

Owner:ROBERT BOSCH GMBH

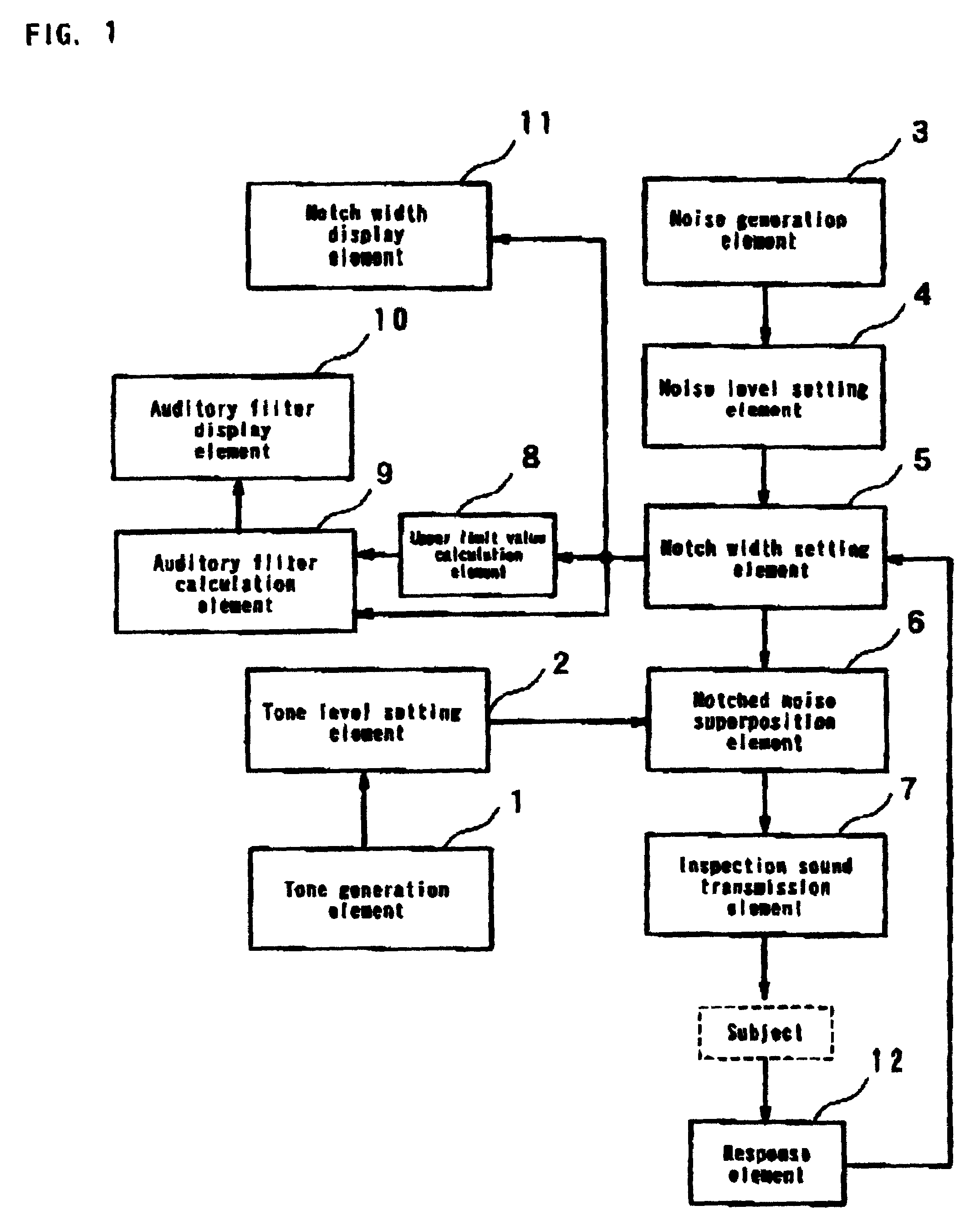

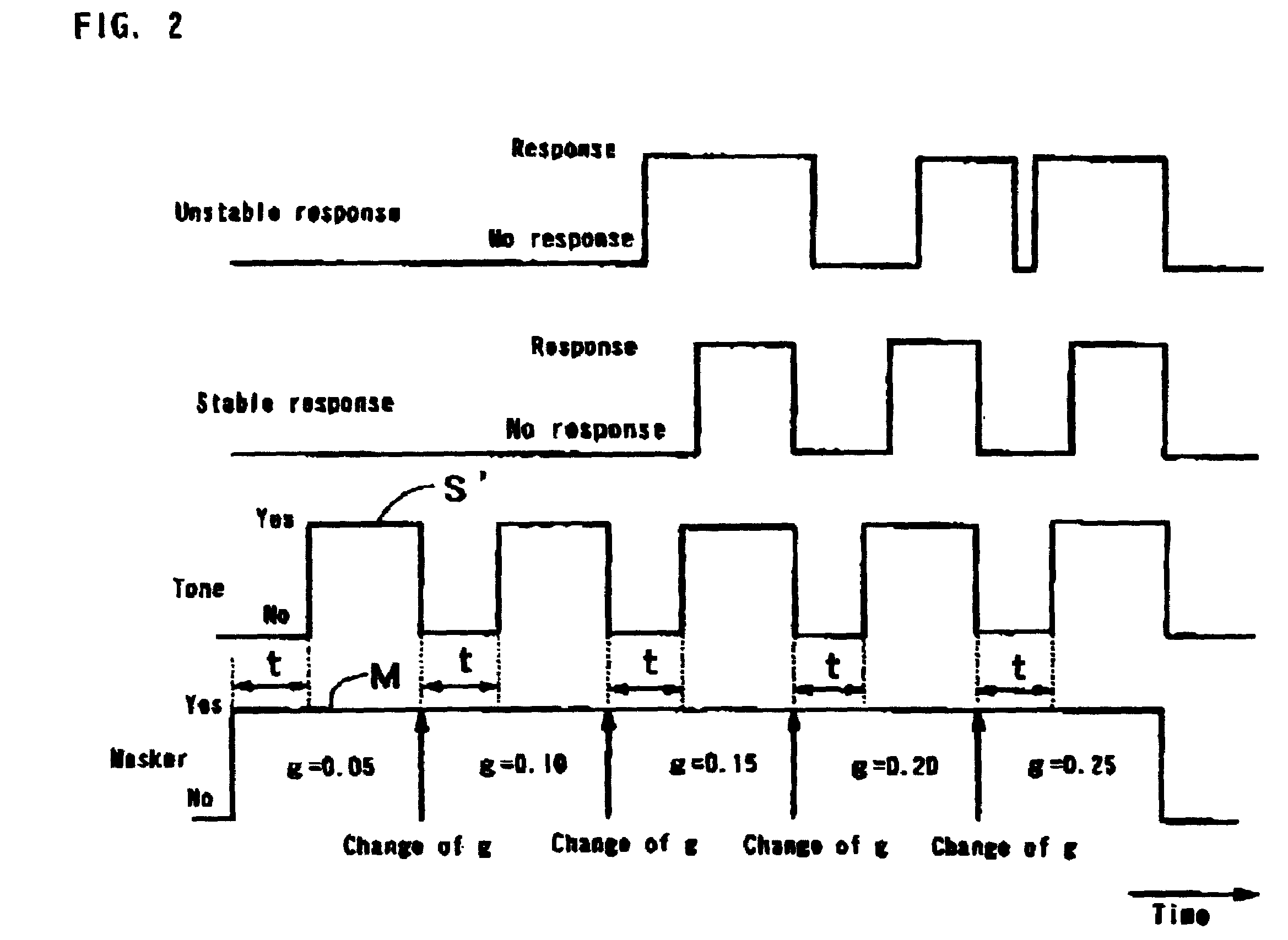

Method and apparatus for estimating auditory filter shape

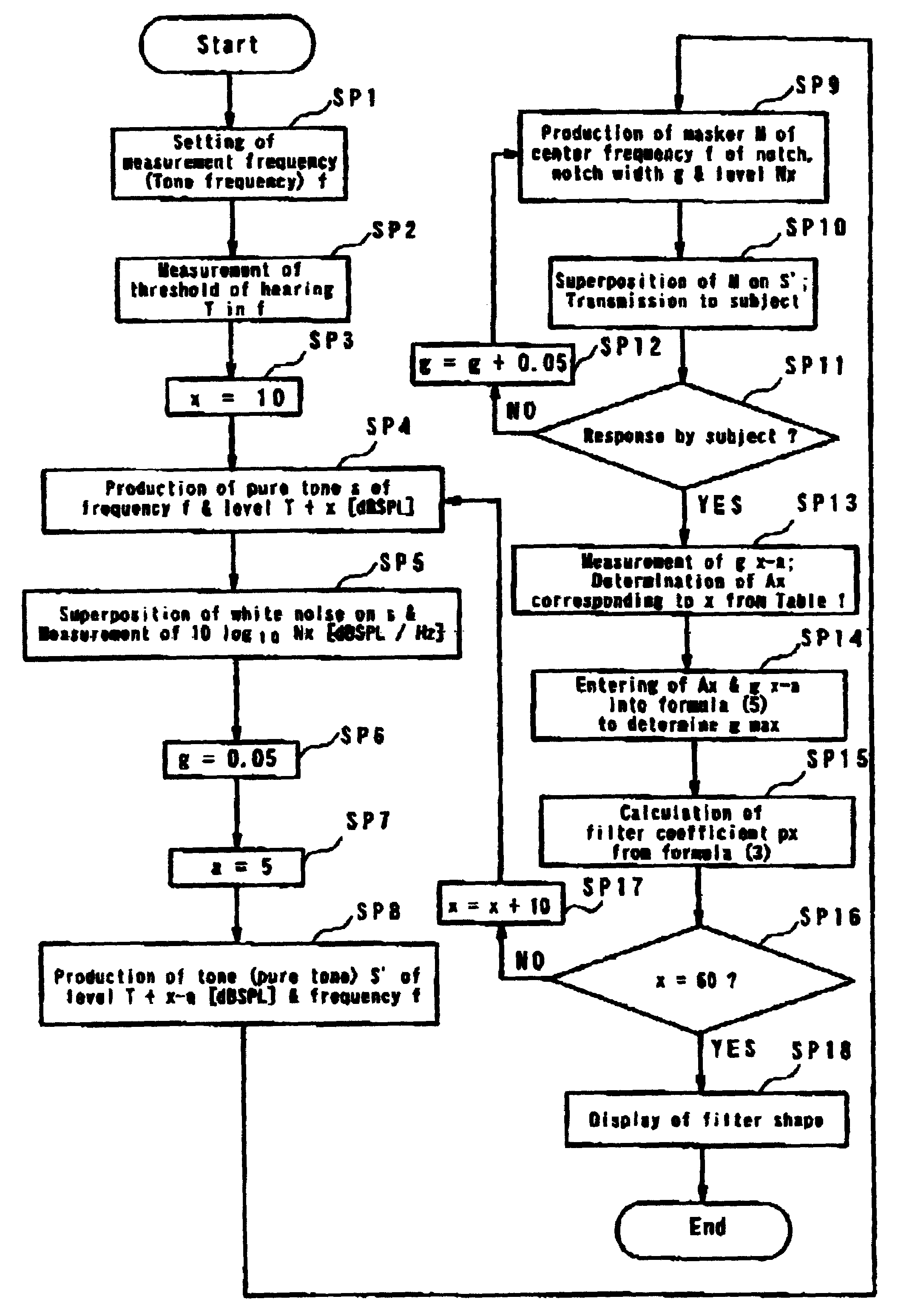

A method for estimating the shape of an auditory filter by finding a coefficient p of a roex (p, r) filter which is used as a model for the shape of the auditory filter is provided, which comprises the steps of: generating a tone S′; generating a masker of a notch width g and level Nx′ including in a notch the frequency f in which frequency characteristics of the external and middle ears of the subject are considered; transmitting to the subject a sound which superposes the masker on the tone S′; measuring the minimum notch width gx−a of the subject while varying the notch width g; calculating the coefficient p from an upper limit value gmax of the notch width g suitable for the subject and estimating the shape of the auditory filter from the coefficient p calculated above and the value x corresponding to the coefficient r.

Owner:RION COMPANY

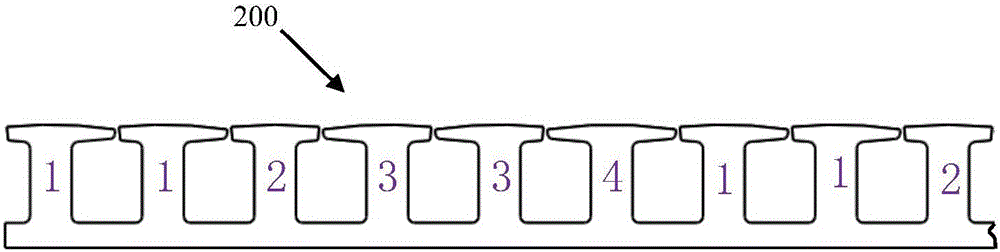

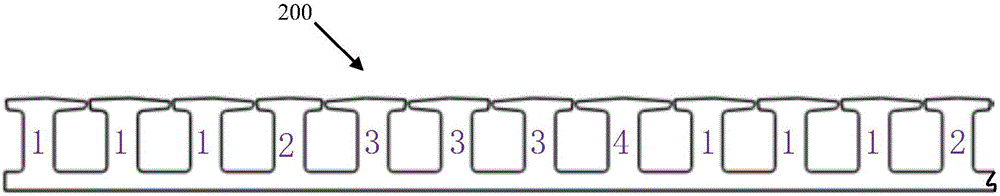

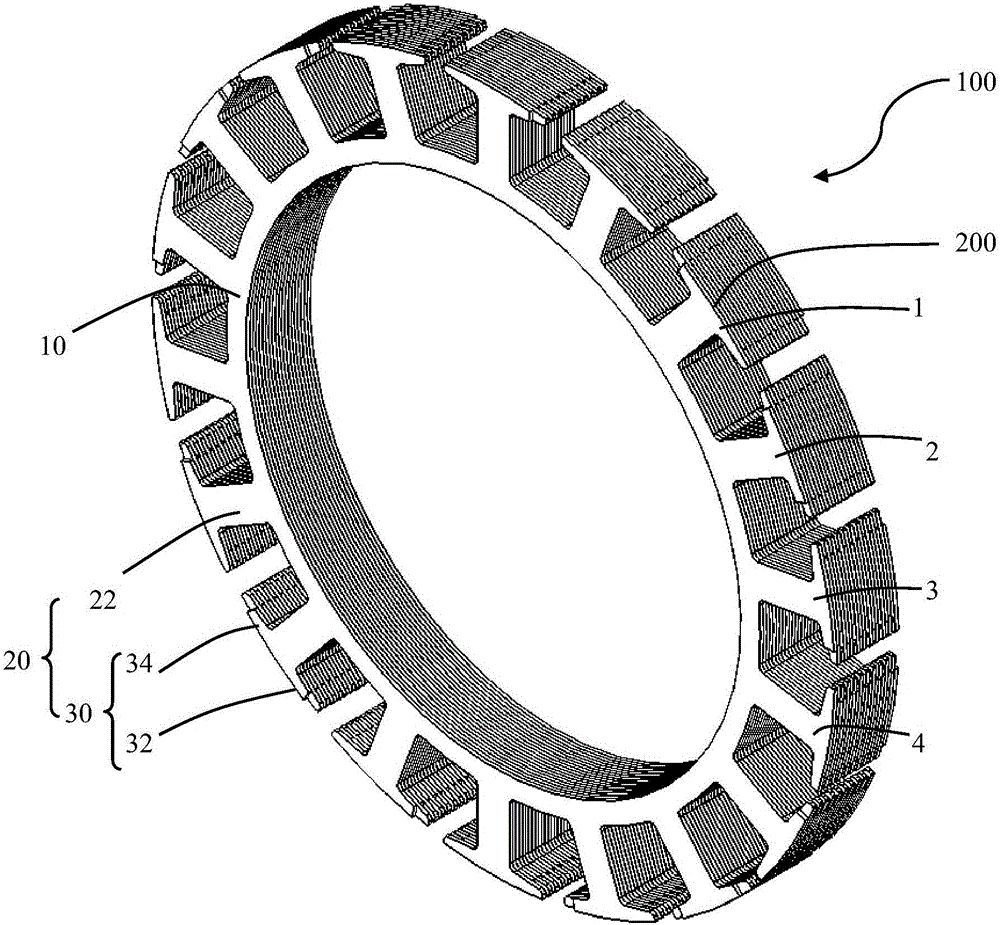

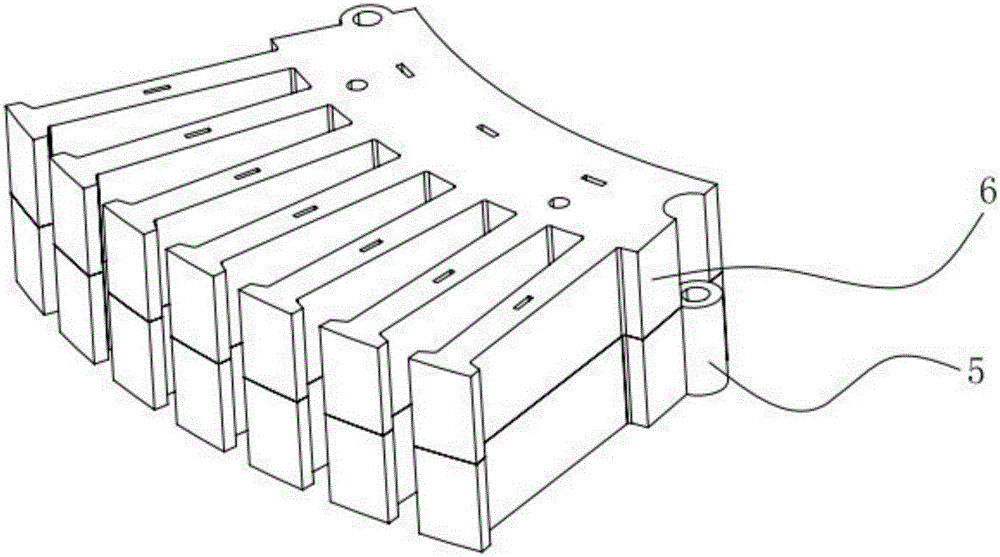

Magnetic core of motor and manufacturing method of magnetic core

ActiveCN106208428AMagnetic circuit rotating partsMagnetic circuit stationary partsLeft halfEngineering

The invention provides a magnetic core of a motor and a manufacturing method of the magnetic core. The magnetic core of the motor comprises a yoke part, teeth extending outwards from the yoke part and tooth crowns extending from the tail ends of the teeth along the circumferential direction, wherein each tooth crown comprises a left half tooth crown and a right half tooth crown; the magnetic core of the motor is formed by stacking multiple layers of first chips and multiple layers of second chips; each layer of chip comprises multiple groups of first-class teeth, second-class teeth, third-class teeth and forth-class teeth which are sequentially arranged; the left half tooth crowns of the first-class teeth are short tooth crowns and the right half tooth crowns are long tooth crowns; the left half tooth crowns and the right half tooth crowns of the second-class teeth are the short tooth crowns; the left half tooth crowns of the third-class teeth are the long tooth crowns and the right half tooth crowns are the short tooth crowns; the left half tooth crowns and the right half tooth crowns of the fourth-class teeth are the long tooth crowns; and the first-class teeth, the second-class teeth, the third-class teeth and the fourth-class teeth of the first chips are overlapped with the third-class teeth, the fourth-class teeth, the first-class teeth and the second-class teeth of the second chip respectively. By implementation of the magnetic core of the motor, the notch width can be reduced and the cogging torque can be reduced. By the manufacturing method provided by the invention, the material can be saved and the cost can be reduced.

Owner:JOHNSON ELECTRIC SHENZHEN

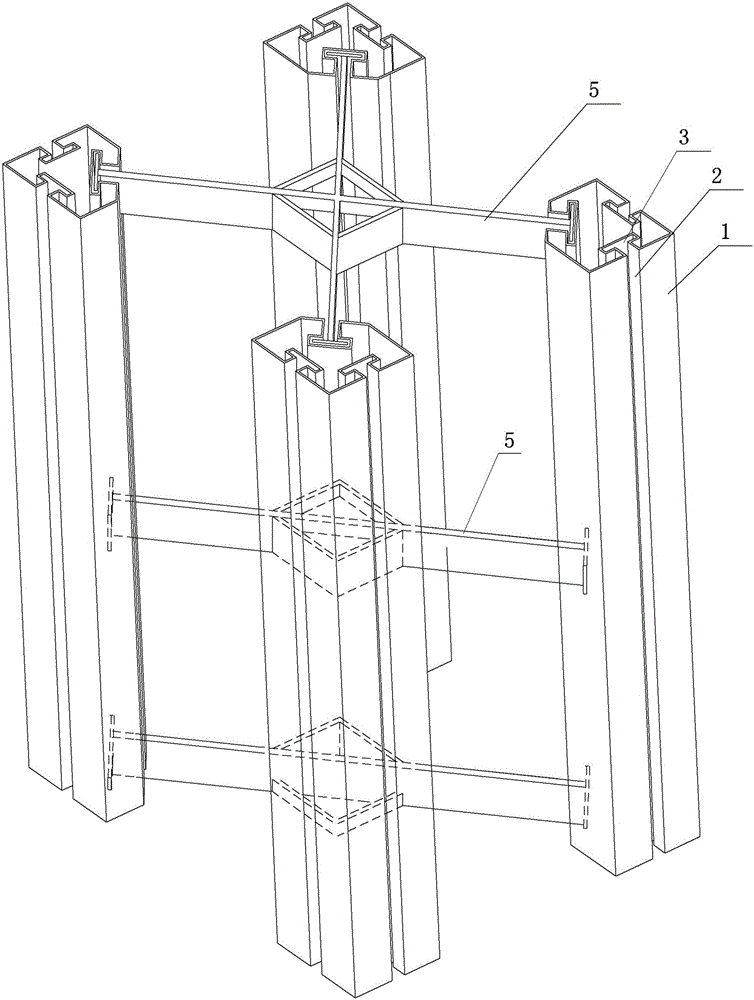

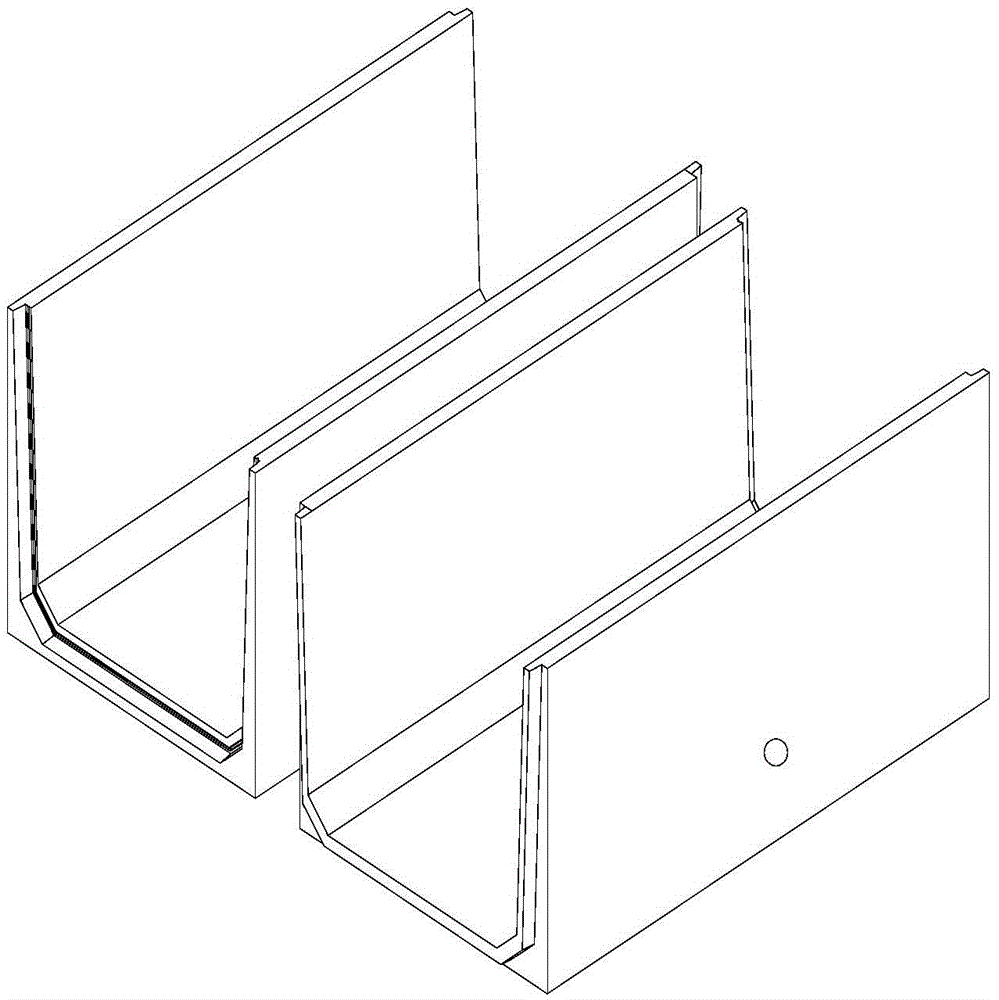

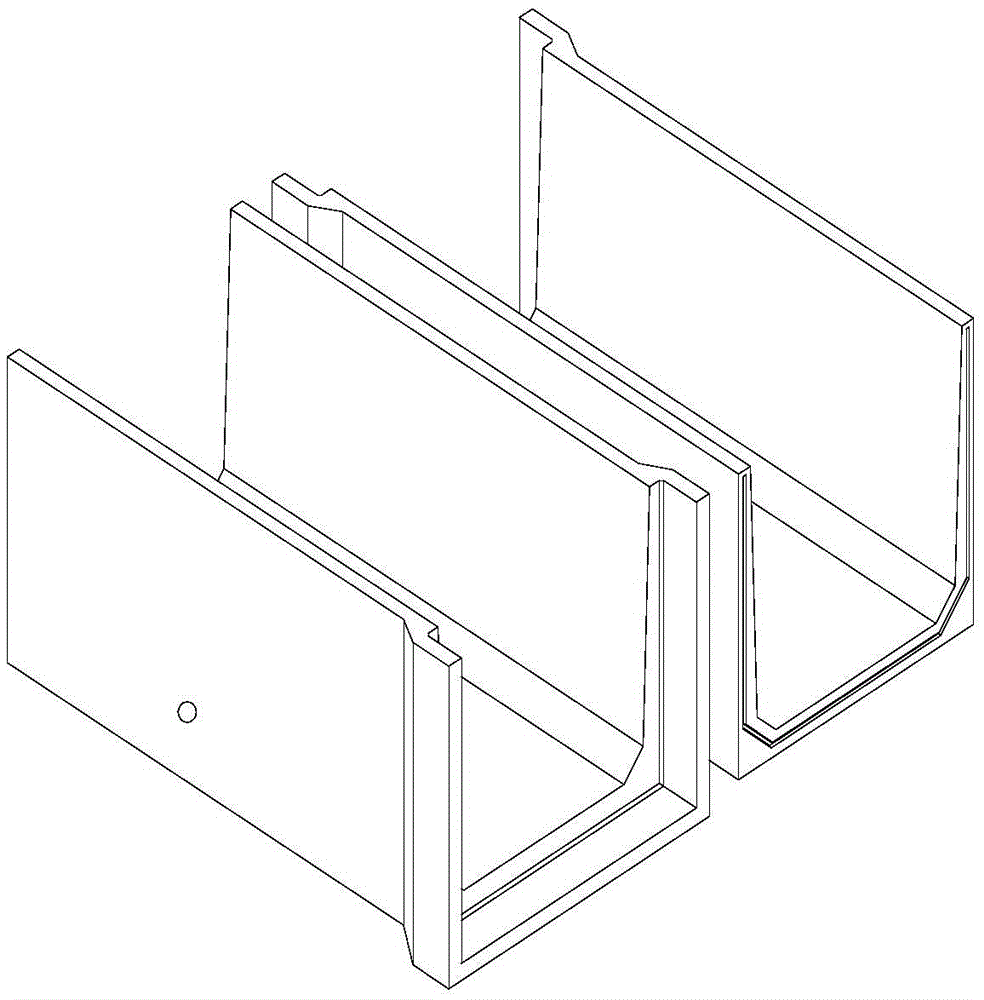

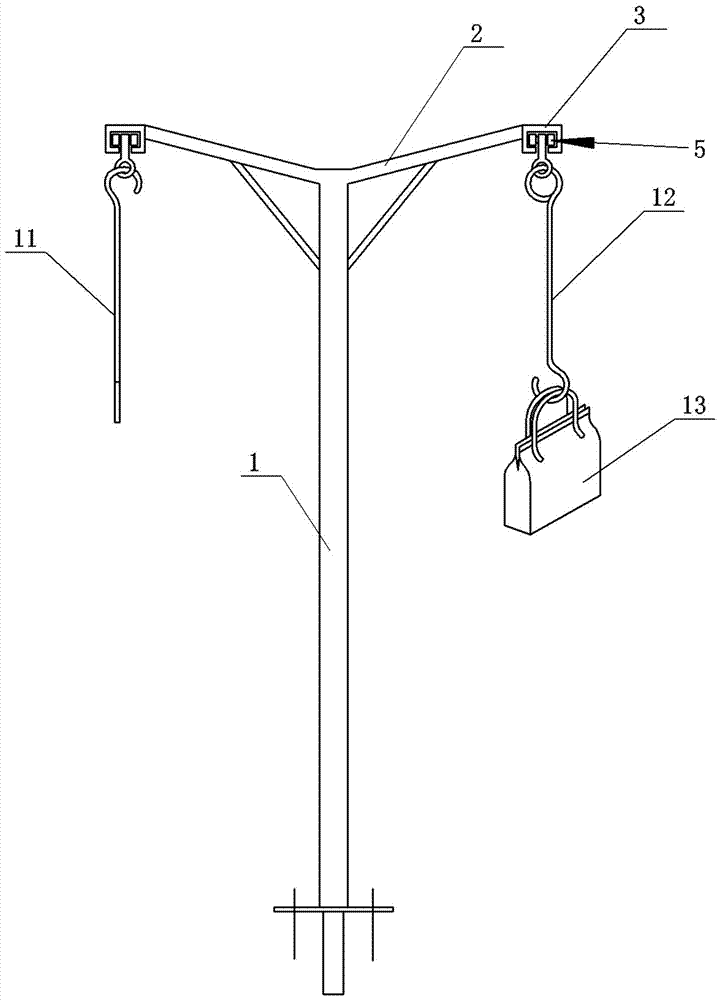

Sectional steel with concave-convex grooves at corner parts and inside connection combination post thereof

ActiveCN106760201AImprove bending resistanceIncreased torsional strengthStrutsPhotovoltaic energy generationCross connectionNotch width

The invention discloses sectional steel with concave-convex grooves at corner parts and an inside connection combination post thereof. The sectional steel is characterized in that a steel plate is bent and defined into four rectangular square steel pipe side surfaces; at least one top corner is made into an inclined surface; a bent and formed recessed notch is formed in the inclined surface; a bent and formed inside slide way which has the width being greater than the notch width and has the same direction as the notch is formed inside the notch; the sectional steel with concave-convex grooves at the corner parts are fixed together through connecting rods and are combined to form an inside crossed connection combination post. The fast and stable connection is realized by using the connecting rod with the inner sleeve plate; the construction speed is high; the effect is good, wherein through the structural design of the inside crossed connection combination post, the inertia moment can be greatly improved, so that the bending-resistant and twisting-resistant intensity of the square steel pipe can be improved.

Owner:HENAN AUSPIC TECH

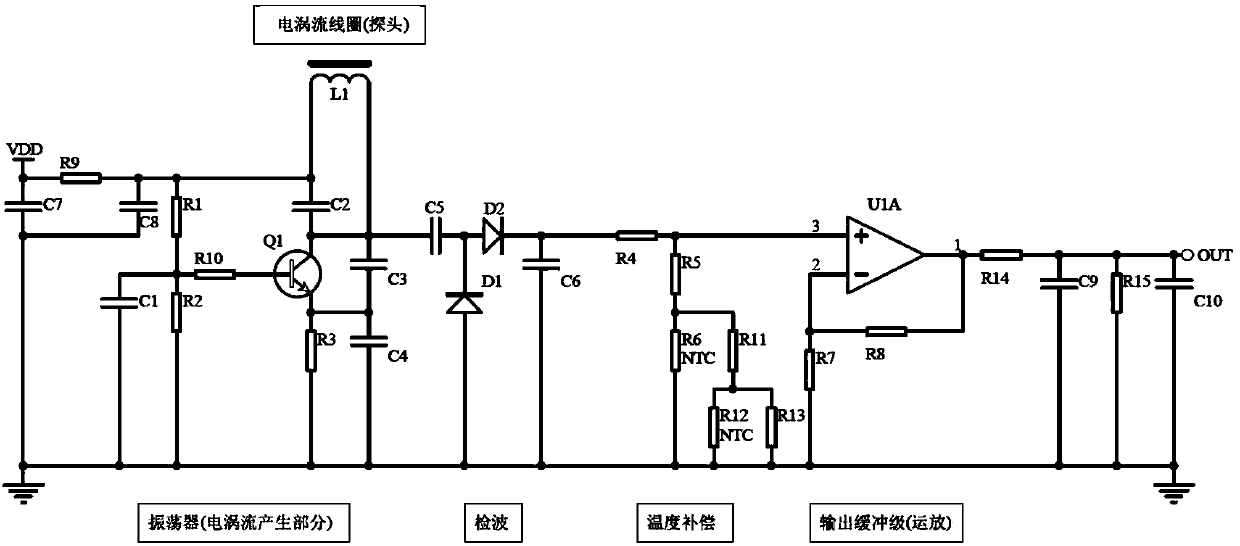

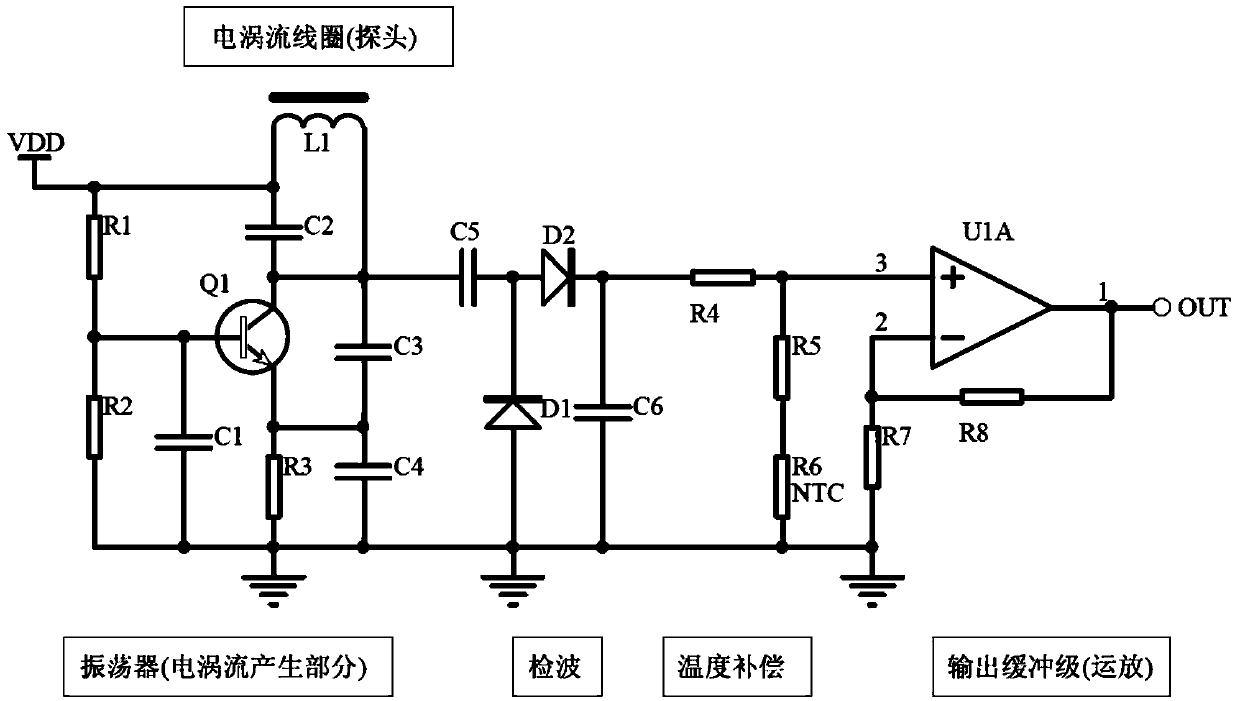

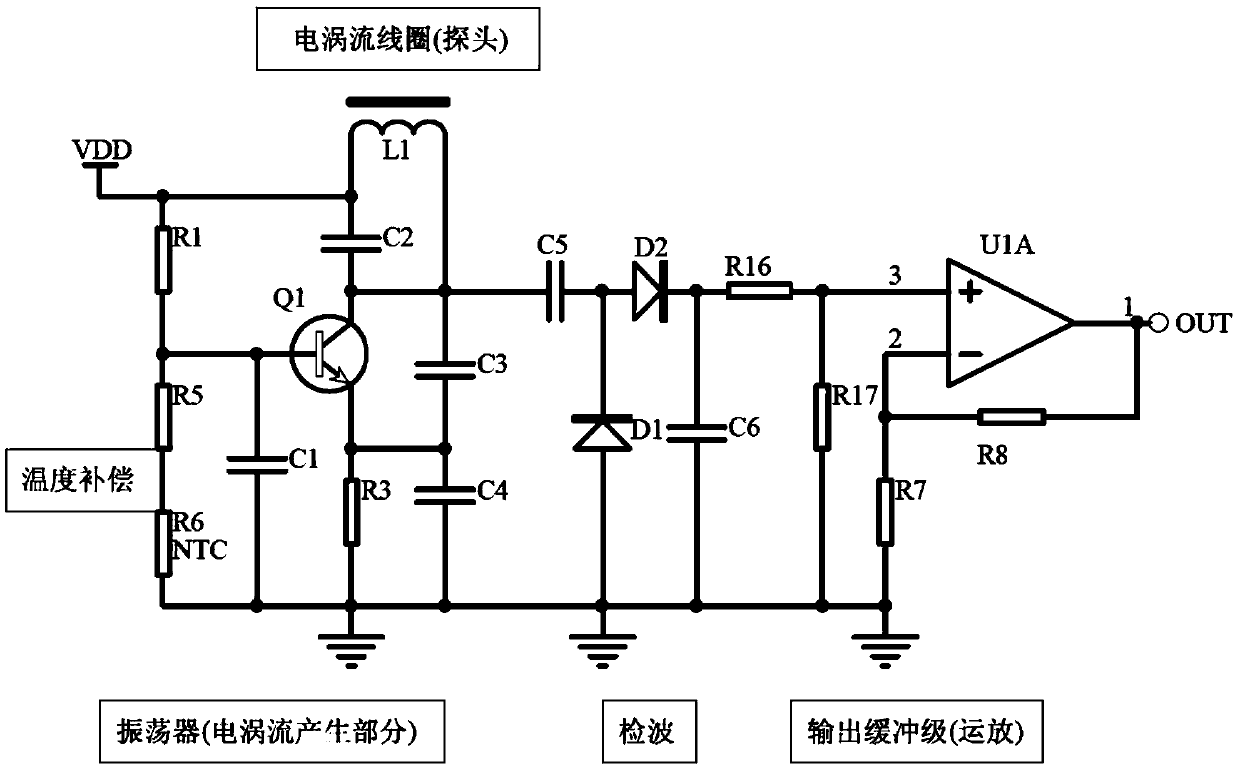

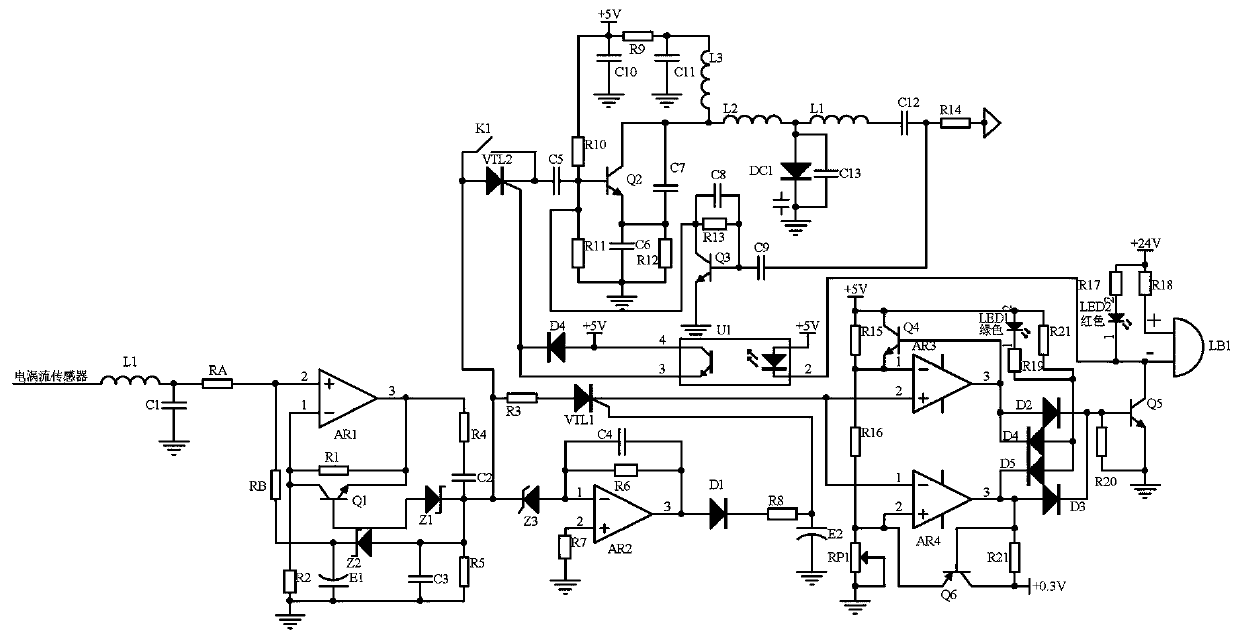

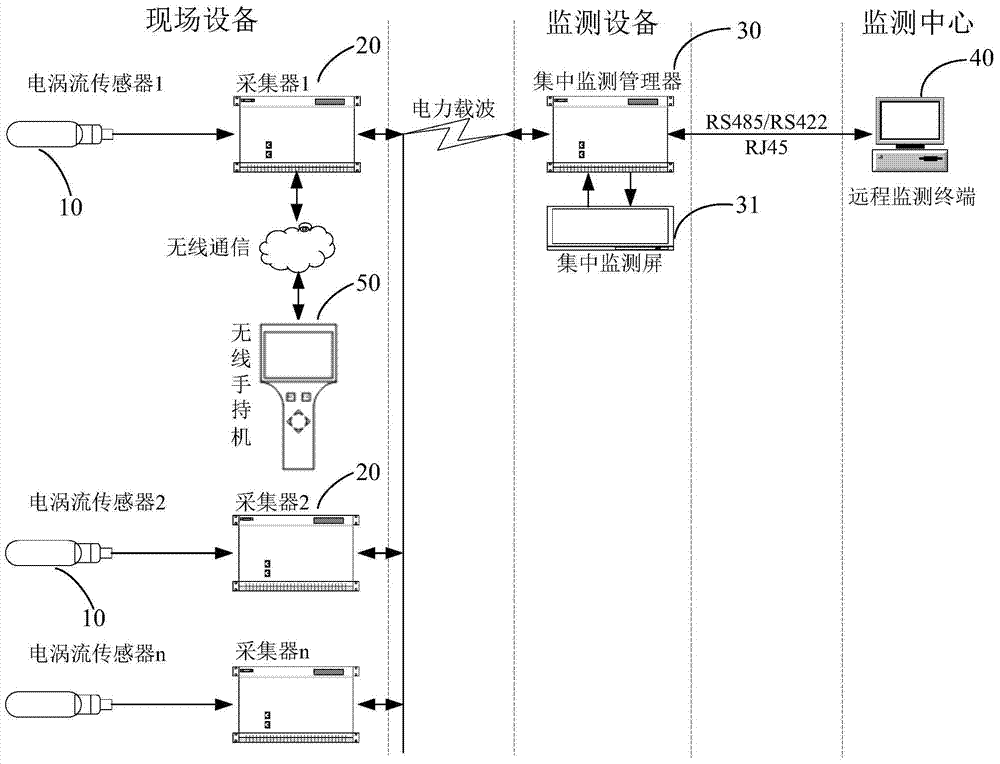

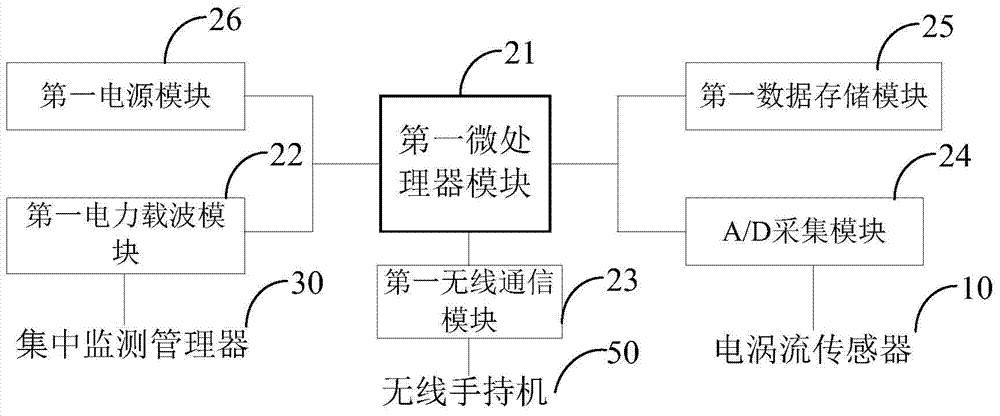

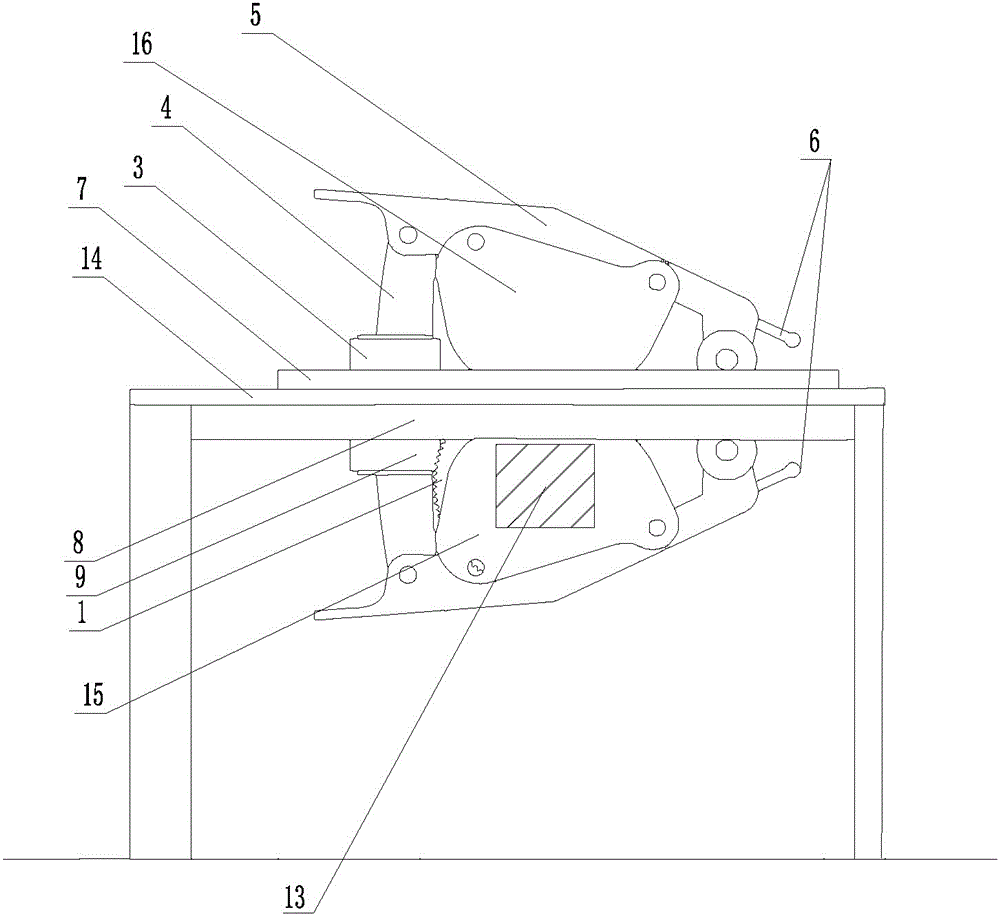

Switch machine indication bar notch width monitoring system and eddy current sensor thereof

ActiveCN104197821AAccurate measurement of gap widthHigh sensitivityUsing electrical meansElectrical conductorCurrent sensor

The invention discloses a switch machine indication bar notch width monitoring system and an eddy current sensor thereof. The eddy current sensor comprises an eddy current probe and an eddy current circuit; the eddy current circuit comprises an oscillator module, a detection module, a temperature compensation module and an output buffer module. The eddy current sensor is characterized in that high frequency oscillating current passes the eddy current probe, alternating magnetic field is generated in the head of the eddy current probe, the alternating magnetic field changes with moves of a metal conductor when the metal conductor moves in an effective range of the alternating magnetic field, a change in the alternating magnetic field is converted into a voltage or current change, the oscillator module is used for producing an oscillation signal and outputting the oscillation signal to the detection module, the detection module is used for rectifying and filtering an alternating-current voltage signal output by the oscillator module into a stable direct-current voltage signal, the temperature compensation module is used for compensating temperature, and the output buffer module is used for amplifying and outputting the higher-level direct-current voltage signal. The eddy current sensor allows a change in a gap between a check post and a notch of a check block to be acquired in real time.

Owner:SHANGHAI XINHAI XINTONG INFORMATION TECH CO LTD +1

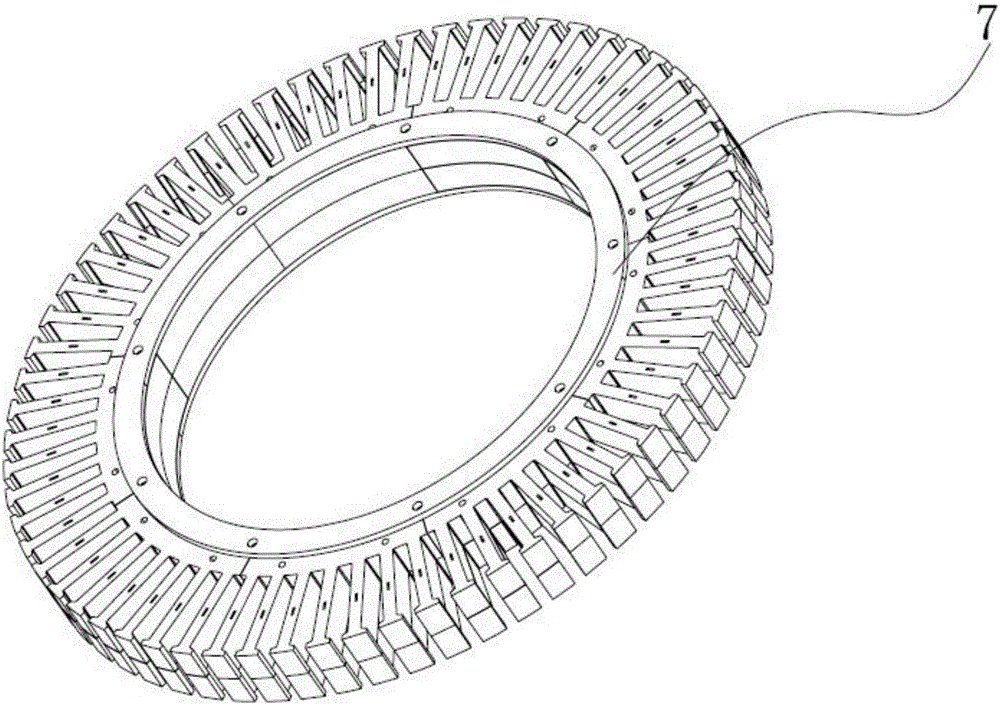

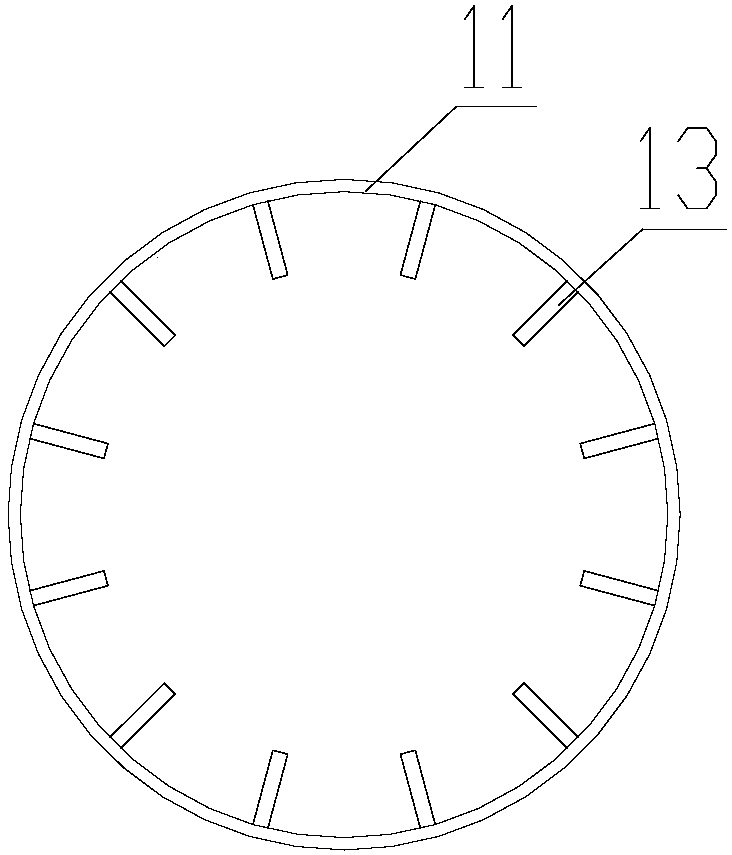

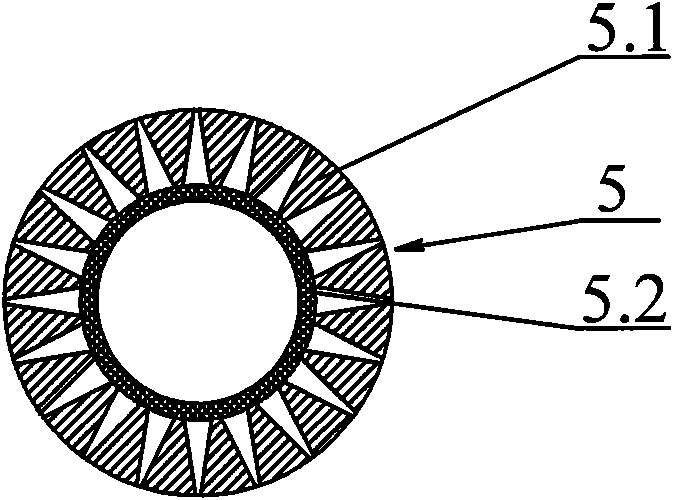

Outer-tooth and inner-stator structure of motor and manufacturing method of outer-tooth and inner-stator structure

InactiveCN106208434AIncrease profitGuaranteed tightnessMagnetic circuit stationary partsManufacturing stator/rotor bodiesPunch pressSilicon

The invention relates to an outer-tooth and inner-stator structure of a motor and a manufacturing method of the outer-tooth and inner-stator structure. The stator structure comprises silicon steel sheet stacks which are formed by sequentially superposing a plurality of silicon steel sheets, wherein the plurality of silicon steel sheet stacks are sequentially superposed to form stator splicing groups; the plurality of stator splicing groups are transversely butted in sequence to form an annular stator; each silicon steel sheet comprises an arc-shaped base part and one or more outer tooth parts; the outer tooth parts are uniformly arranged at the outer side of each arc-shaped base part; and the adjacent upper and lower silicon steel sheet stacks in the stator splicing groups are arranged in a manner that two ends are in opposite directions. The stator manufacturing method is simple, reliable and low in cost. The stator is assembled in a splicing manner, so that the utilization rate of the sheets can be greatly improved; processing can also be carried out by using a low-tonnage punch press; the cost of equipment is reduced; the automation degree is improved; each sub-part can also be wound and then assembled; and the outer-tooth and inner-stator structure is not limited by a notch width and is suitable for the stator with various requirements.

Owner:PHASE IND DESIGN NINGBO

Motor controller

InactiveUS7843159B2Constantly and stablyOscillation suppressionElectric motor controlElement comparisonControl systemMotor controller

A motor controller includes: a notch filter arranged inside a control system; an oscillation frequency estimating section which estimates an oscillation frequency component in a motor; and a notch control section which controls a notch filter so as to change a notch frequency and a notch width. The notch control section changes a frequency between an oscillation frequency and a notch frequency set in a notch filter as a new notch frequency, while changing a notch width to a new notch width such that the notch width is larger after the change than before the change.

Owner:PANASONIC CORP

A turnout switch machine indication rod fault monitoring system

InactiveCN110341754AImprove discriminationSimple structureUsing electrical meansRailway traffic control systemsInformation processingFrequency of optimum transmission

The invention discloses a turnout switch machine indication rod fault monitoring system. A signal collecting unit receives a signal of the notch width of a turnout switch machine indication rod detected by an eddy current sensor; the signal is subjected to amplification and conditioning by an in-phase amplifying circuit; and a transistor Q1 is set to reduce an abnormal high potential signal and anelectrolytic capacitor E2 is set to increase an abnormal low potential signal. When there is a tendency of abnormality the signal, the signal enters a fault discriminating unit, and whether the notchwidth of an indication rod is within 2+-0.5mm is judged by a double hysteresis comparator. When the signal is normal, a green indicator light is on. When the signal is abnormal, the red indicator light is on, and a horn alarm is activated. When the time of a timing switch K1 of a signal controllable transmission unit is arrived at or when the abnormality is judged, a signal output by an operational amplifier AR1 is initially subjected to frequency-modulation by an oscillation circuit to generate a high-frequency modulation signal which is further resonating with a resonance circuit to generate an optimal transmission frequency, and then the signal is subjected to frequency selection and fed back to the oscillating circuit. The signal is further stably transmitted to a remote monitoring terminal. The circuit structure is simple, which improves the timeliness of the abnormal information processing.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

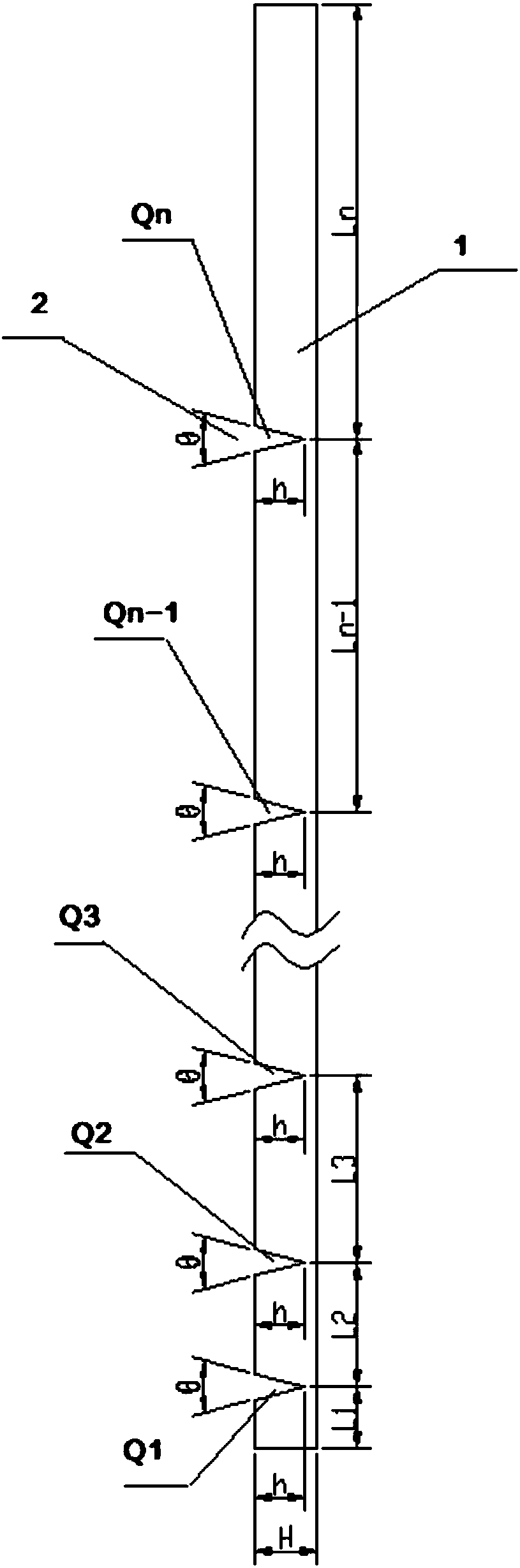

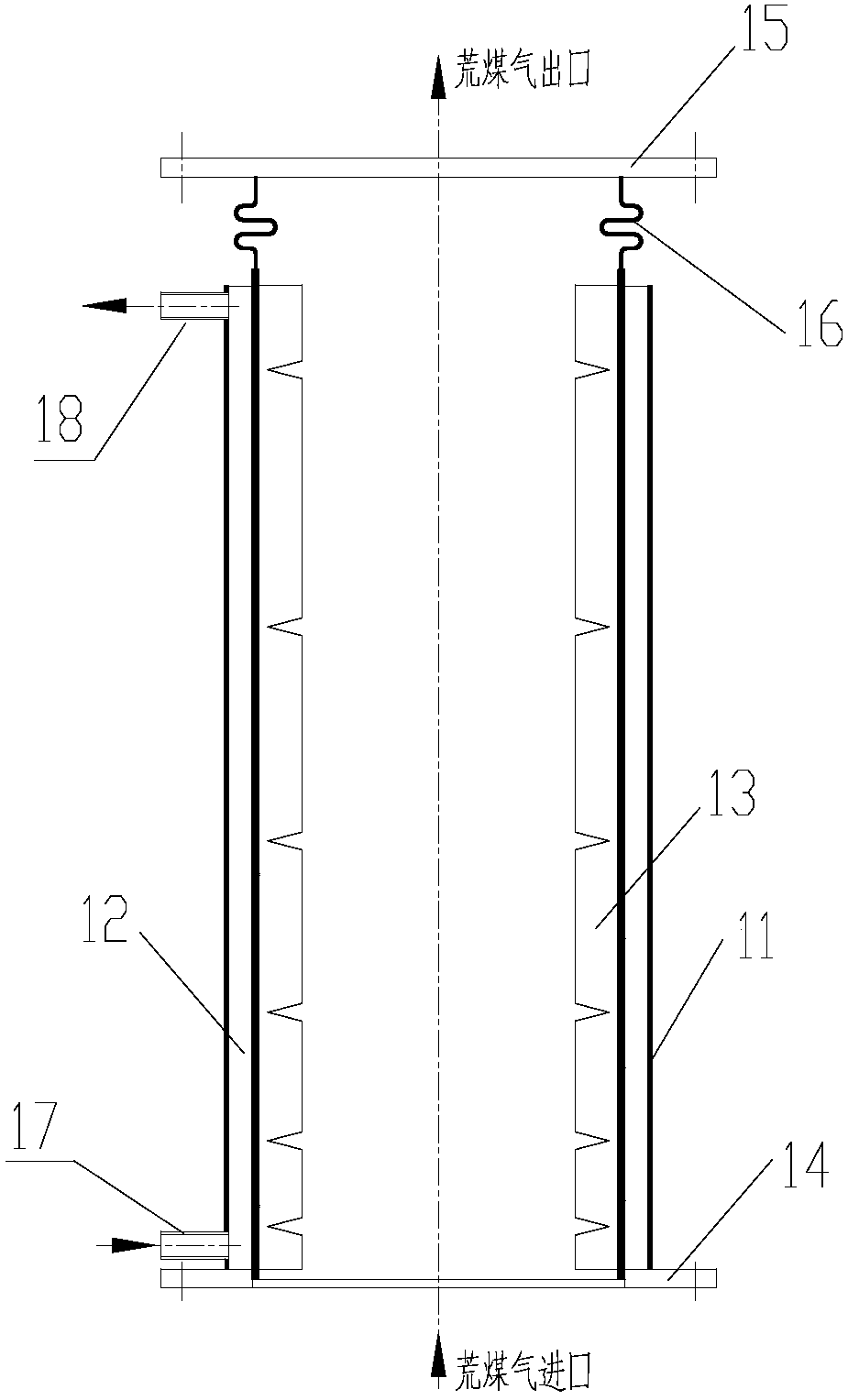

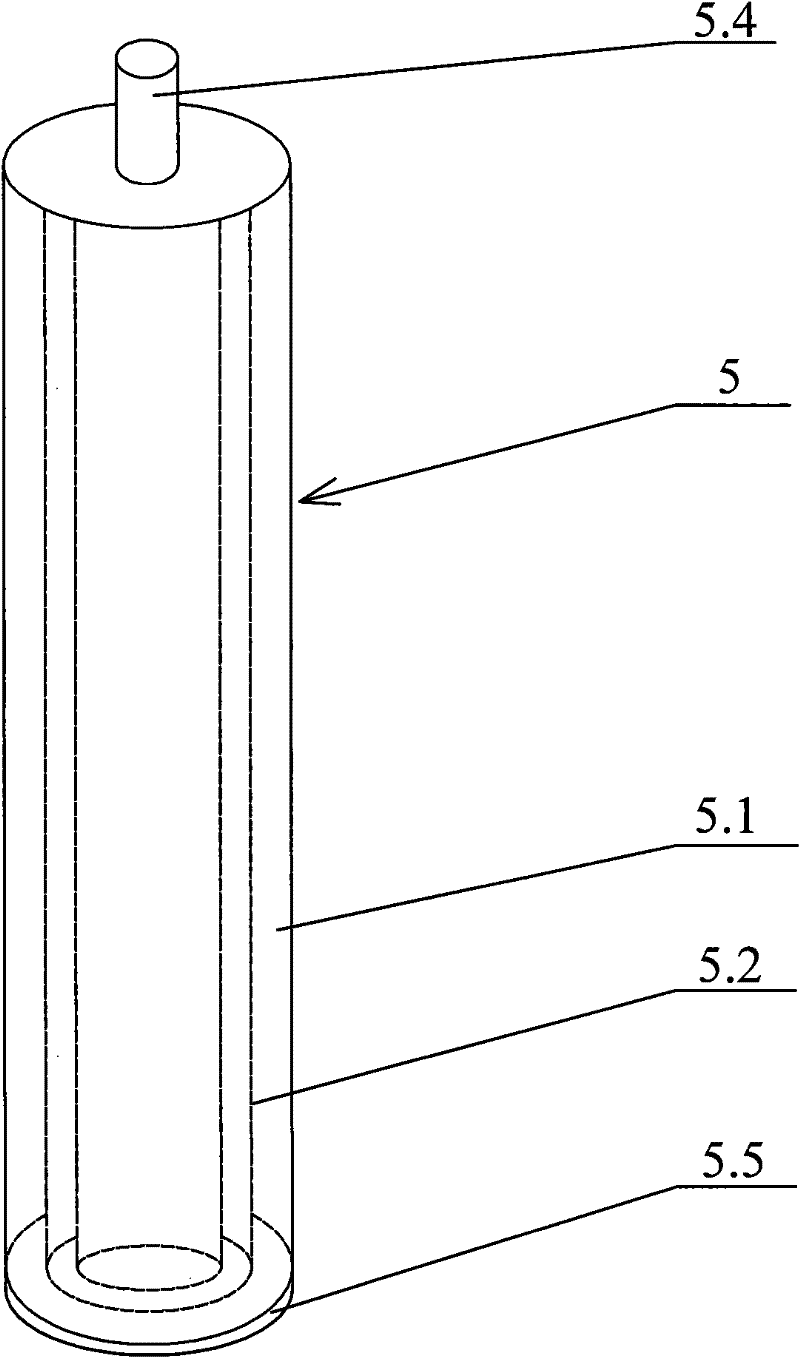

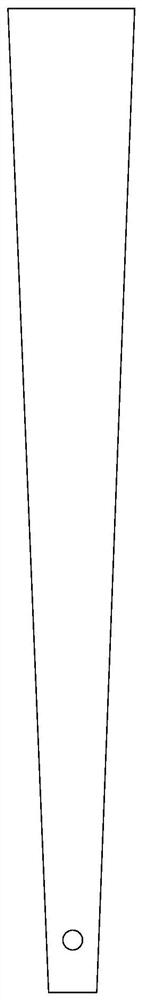

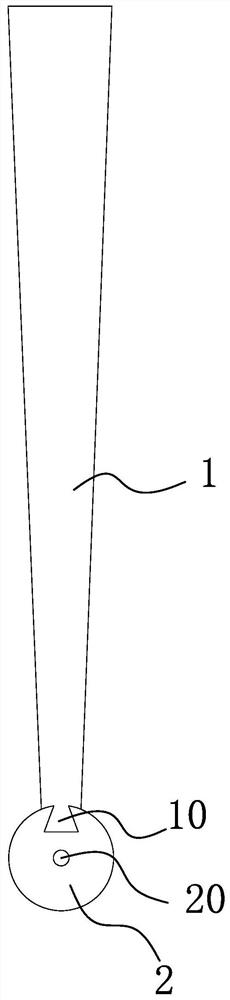

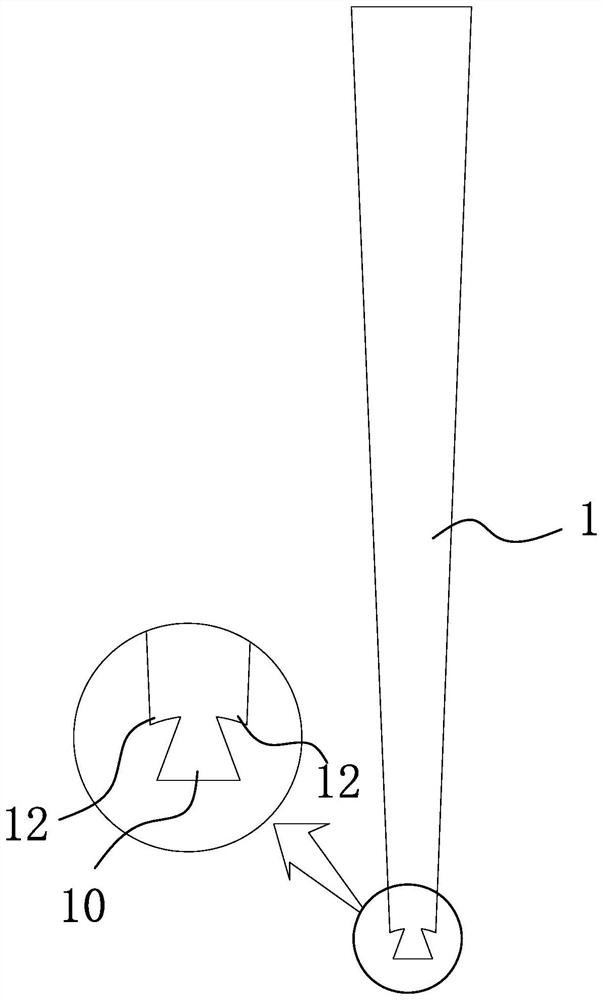

Straight fin for coke oven ascending pipe raw coke oven gas waste heat recycling and heat taking device and heat taking device

ActiveCN107560481ASimple structureLow costCoke oven safety devicesStationary conduit assembliesEngineeringCoke oven

The invention provides a straight fin for a coke oven ascending pipe raw coke oven gas waste heat recycling and heat taking device. The straight fin comprises a straight fin body (1) and a set of V-shaped notches (2) formed in the straight fin body (1). The depth h of the V-shaped notches (2) is smaller than the width H of the straight fin body (1). In the longitudinal direction of the straight fin body (1), the distances between the adjacent V-shaped notches (2) are increased from bottom to top. The invention further provides a heat taking device comprising the straight fin and a power generation device. The straight fin is simple in structure, low in cost and convenient to use, the heat transmitting performance of the raw coke oven gas side is greatly enhanced, and the wall face temperature is increased. Meanwhile, the width, the angle and the height-direction distance of the V-shaped notches in the top end of the straight fin are determined according to temperature field distribution during device usage, and when the device is used, the longitudinal swelling amount of the top end of the fin is smaller than or equal to the notch width, and after total expansion in the height direction, the straight fin is still kept in a flat rectangle and cannot disengage from the inner barrel wall, and the service life is greatly prolonged.

Owner:NANJING HUADIAN ENERGY SAVING & ENVIRONMENTAL PROTECTION EQUIP

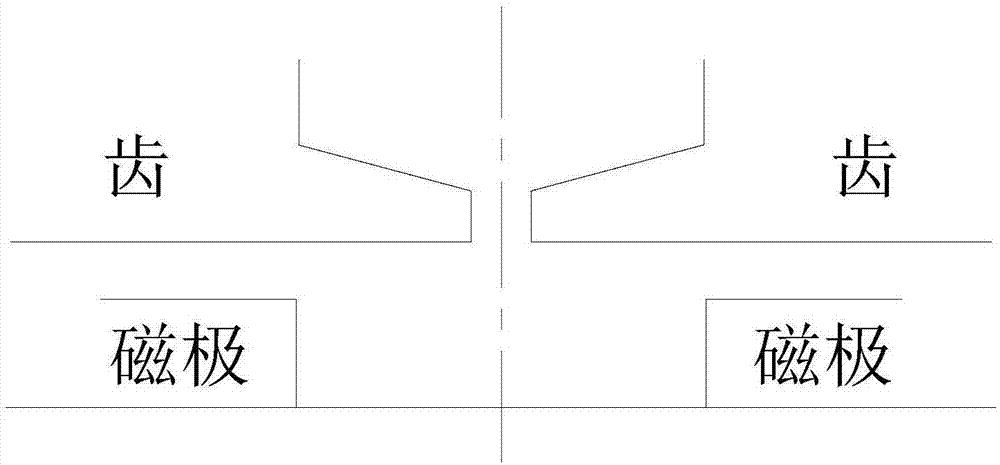

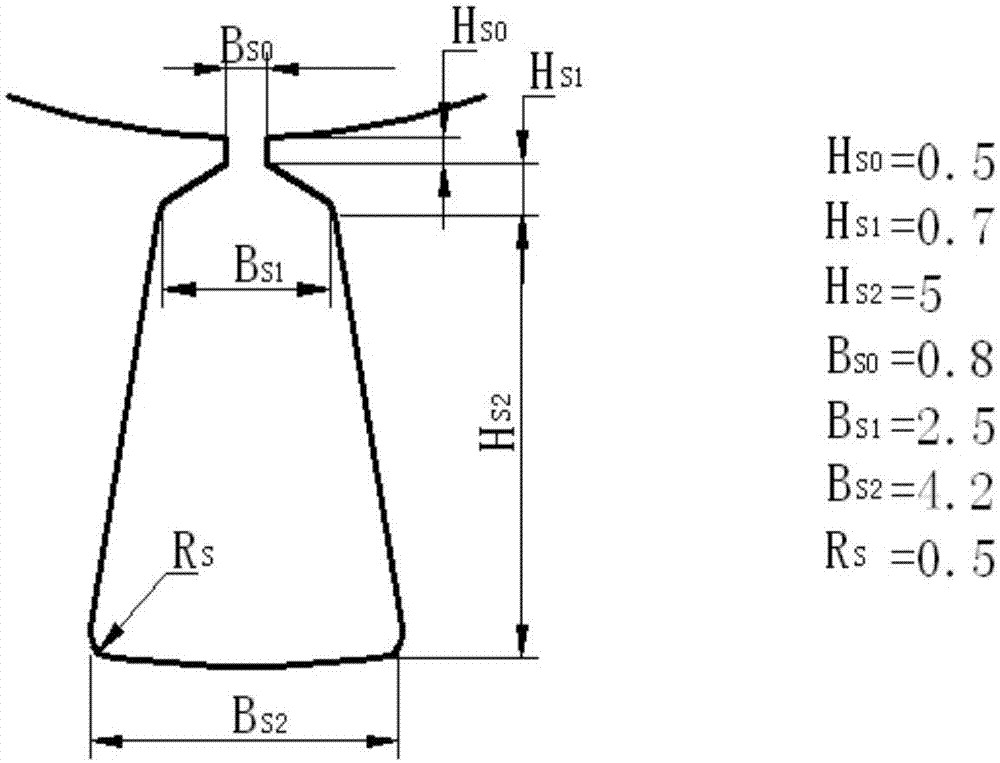

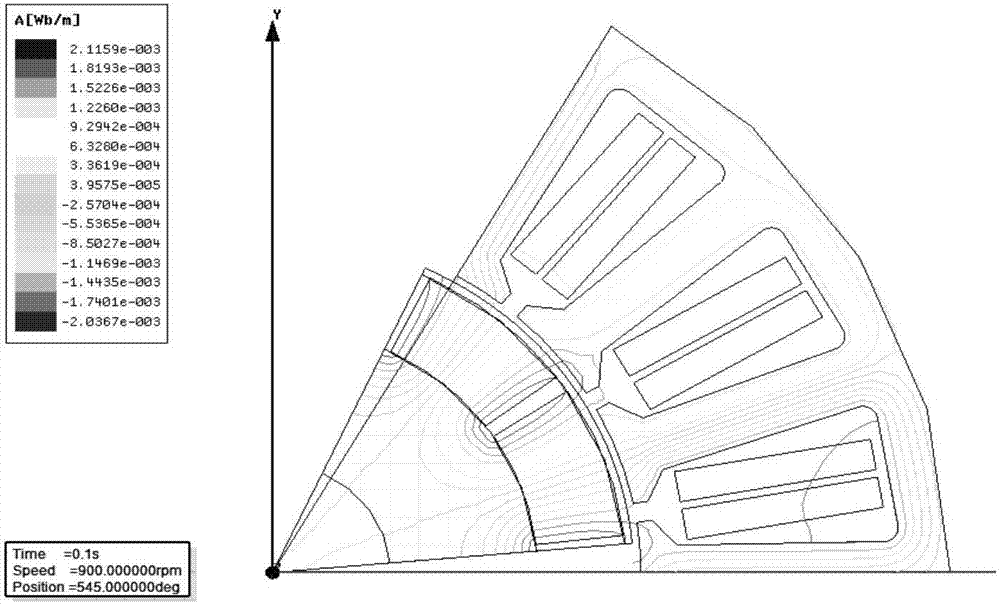

Cogging torque-based braking design method

ActiveCN107994739AImprove reliabilityGuaranteed performanceMagnetic circuit stationary partsManufacturing stator/rotor bodiesControl theoryDesign methods

The invention provides a cogging torque-based braking design method. The method comprises firstly applying an RMxprt model in Maxwell software to design a magnetic circuit scheme of a motor, and determining groove profile parameters of a motor stator; gradually increasing the motor stator notch width Bs0 in the software model, and observing the performance of the motor when the cogging torque meets the requirements; if the motor performance is reduced, gradually increasing the thickness of magnetic steel in the software model, so that the motor performance also meets the requirements while thecogging torque meets the requirements; finally importing RMxprt model design results into a 2D model in the Maxwell software to perform cogging torque and stator flux density verification, to confirmwhether the cogging torque reaches the requirements and whether the stator flux density is saturated; and if the requirements are not reached, readjusting the notch width and magnetic steel thickness, until the cogging torque and the stator flux density meet the requirements. According to the cogging torque-based braking design method, the defects of low brake reliability, mechanism redundancy, and heavy weight and the like are overcome, the reliability of a whole mechanism is improved while the motor performance is ensured, and the cogging torque-based braking design method is simple and convenient to design and easy to implement.

Owner:XIAN AEROSPACE PROPULSION TESTING TECH RES INST

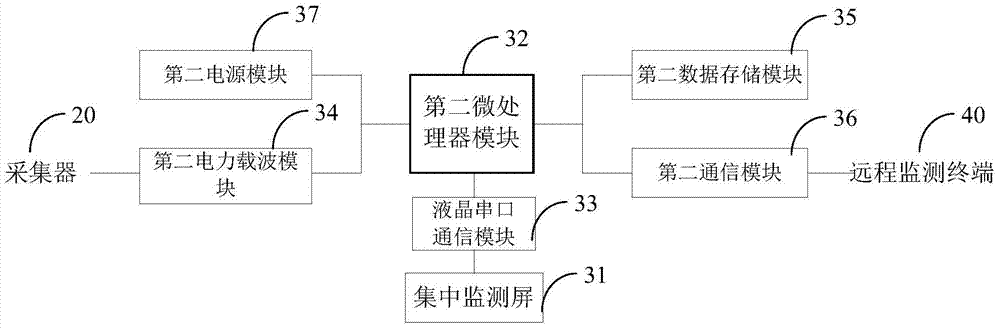

On-line real-time monitoring system for the gap width of switch switch machine

ActiveCN104197820BHigh sensitivityHigh resolutionUsing electrical meansElectricityInterference resistance

The invention discloses a system for online real-time monitoring of switch machine indication bar notch width. The system comprises eddy current sensors, collectors, a central monitoring manager and remote monitoring centers. Each eddy current sensor comprises an eddy current probe and an eddy current circuit; the eddy current probe is used for converting a gap between a check post and a notch of a check block into an eddy current signal, and the eddy current signal is processed by the eddy current circuit and output. The collectors are used for collecting data output by the eddy current sensors. The central monitoring managers are connected with the collectors through power cords and are used for receiving data collected by the collectors, in a power line carrier manner. The remote monitoring center is connected with one or multiple central monitoring centers and is used for receiving data transmitted by the central monitoring managers. The system has the advantages that stability and reliability are improved, false alarm rate and false negative rate are zero, the eddy current sensors are higher in reliability, sensitivity, resolution, response speed and interference resistance during long-term operation, and the system is suitable for various switch machines and various application environments.

Owner:赵建明 +1

Assembled rectangular reinforced concrete water saving tank

InactiveCN105421315AMeet structural requirementsPlay the role of sealing and anti-leakageConstructionsSoil drainageWater savingAnti freezing

The invention discloses an assembled rectangular reinforced concrete water saving tank. The outer contour of the cross section of a tank body is rectangular, and the inner contour is trapezoidal; the tank wall is a right trapezoid structure with narrow top and wide bottom; the outer side wall of the tank wall is a right-angled edge, and the connected place with the tank bottom is a right angle; and the inner side wall of the tank wall is an inclined edge, and the connected place with the tank bottom 2 is transited by chamfering or rounding. The ratio of the notch width to the tank depth is 1: 1-1: 0.5; the notch width is within 300-1200 mm; a sealing groove is formed in the end surface of one side of the tank body, and a joint is formed in the other side; and a reinforcement skeleton is prefabricated in the tank body. The assembled rectangular reinforced concrete water saving tank overcomes such technical difficulties as surface roughness, weak anti-seepage effect, waste of land resources, single structural size, incapability of satisfying the anti-freezing and anti-swelling requirements through mechanical performances, incapability of realizing reinforcement distribution, no economy and no environmental protection in a pressed U-shaped tank, further improves the durability, prolongs the service life of a channel from original 3-5 years to above 20 years, and is higher in superiority when being applied to cold regions and bad foundation soft soil layers.

Owner:TIANJIN HUICHUAN WATER CONSERVANCY ENG TECH DEV CO LTD

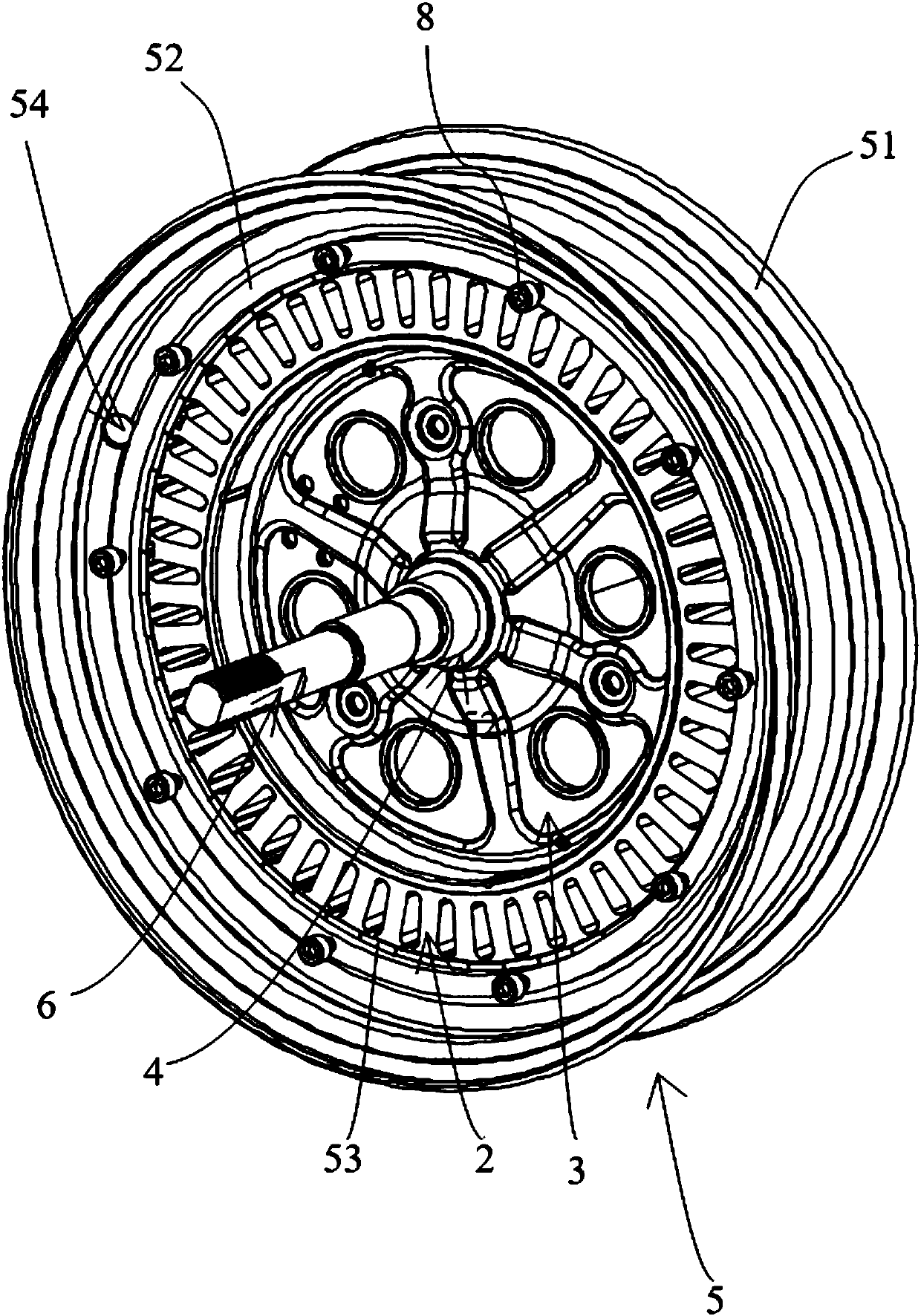

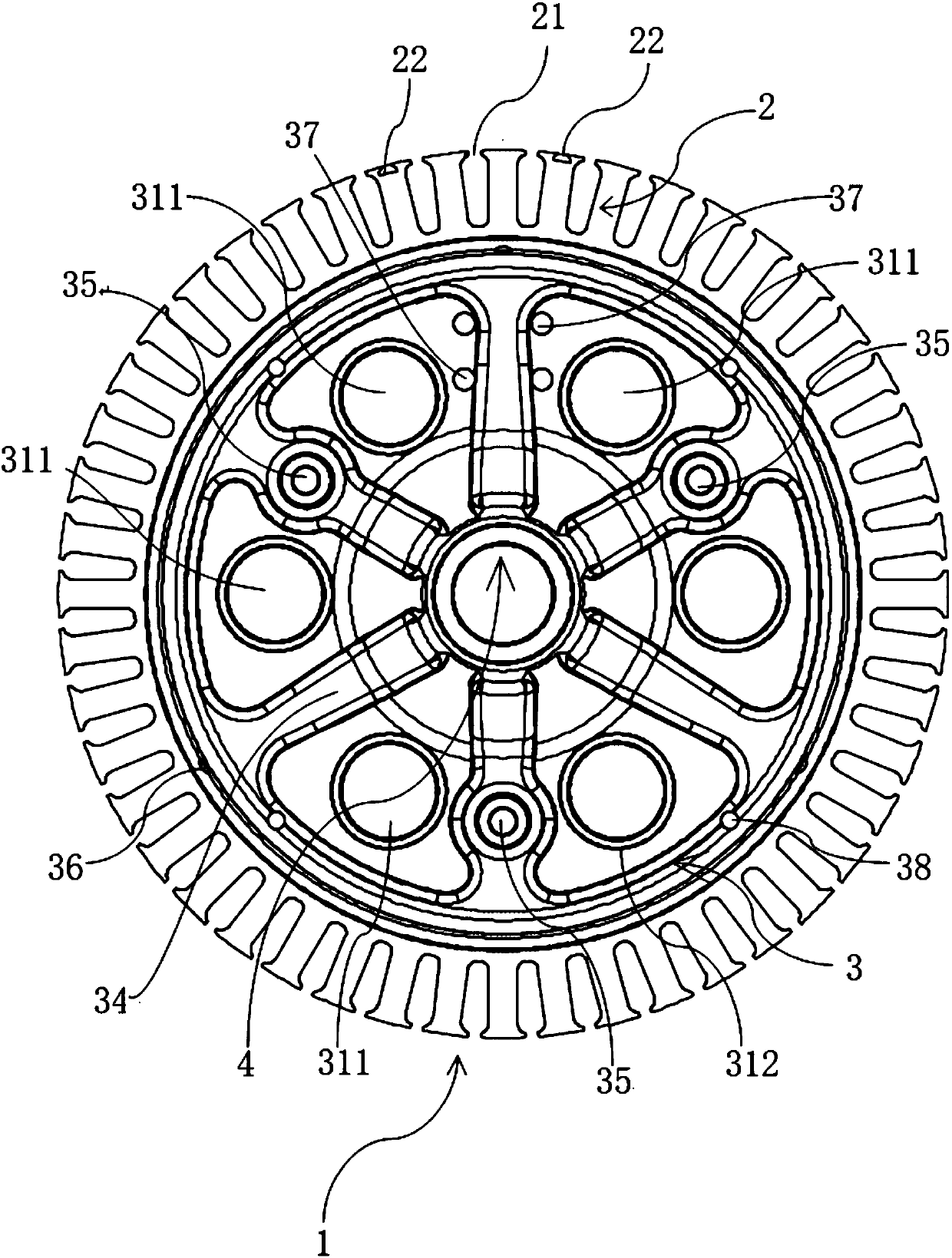

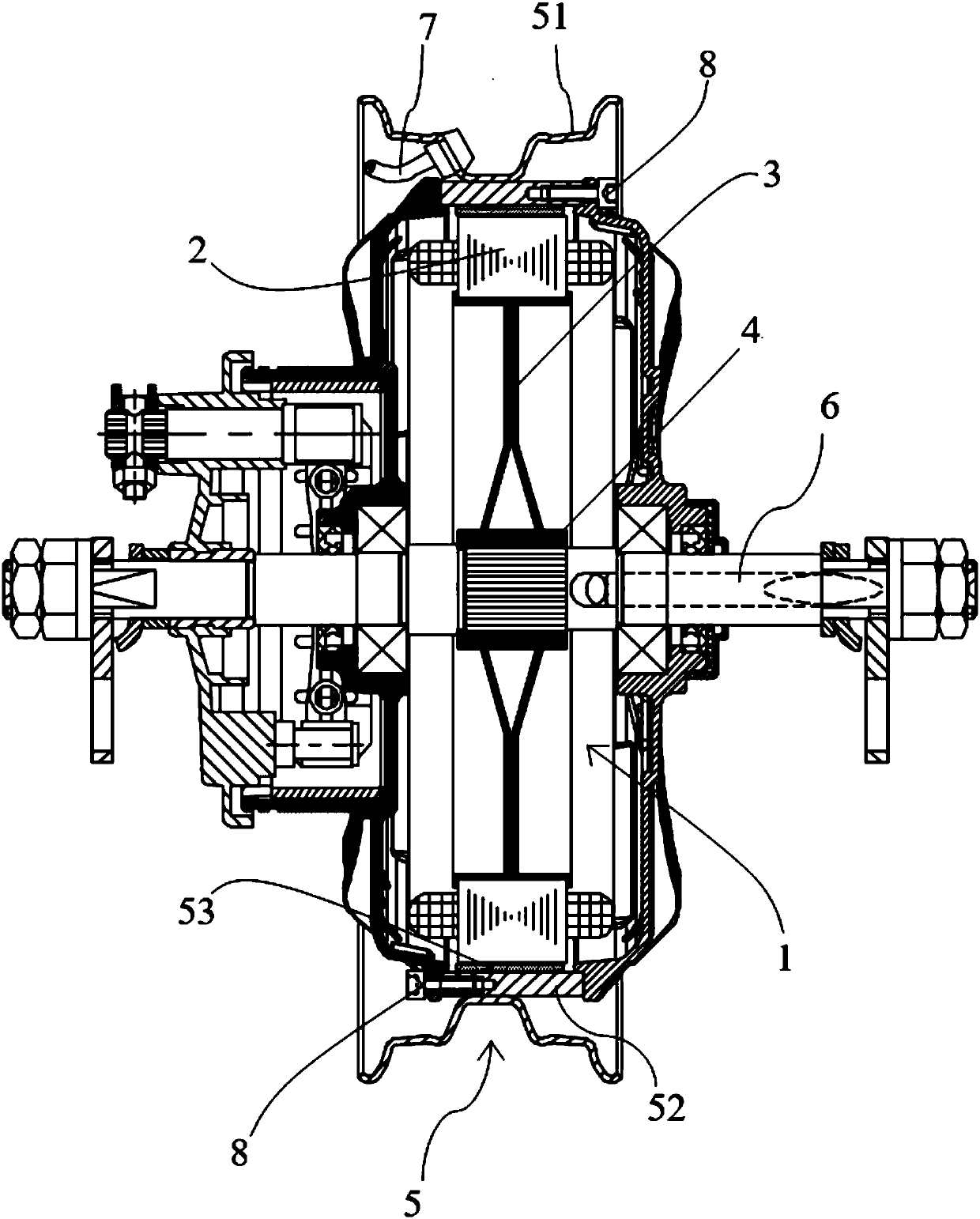

Hub motor for electric vehicle

PendingCN109995179AReduce cogging torqueHigh positioning accuracyElectric machinesMagnetic circuit stationary partsEngineeringElectric vehicle

The invention discloses a hub motor for an electric vehicle, which comprises a stator, a rotor and a connecting shaft, wherein the stator comprises an iron core and a bracket, the iron core is fixed on the bracket and is formed by laminating stator sheets in a spiral winding manner, and the notch width of a tooth socket, the outer diameter of the iron core, the thickness of the tooth lip of the iron core, the inner diameter of the iron core, the thickness of the yoke part of the iron core, the number of the tooth sockets of the iron core and the notch width of the stator sheet meet the following relation: the notch width of the tooth socket = pi x [the outer diameter of the iron core - 2 x the thickness of the tooth lip of the iron core - 2 x alpha x (the inner diameter of the iron core +the thickness of the yoke part of the iron core)] / the number of the tooth sockets of the iron core + the notch width of the stator sheet, wherein the value scope of alpha is 0.45~0.55, and the notch width value scope of the stator piece is 0~2 mm. The hub motor for the electric vehicle has the advantages that: the stator structure optimizes the tooth socket structure of the motor, improves the power density and the working efficiency of the motor, enhances the short-time overload capacity of the motor, reduces the temperature rise and the manufacturing cost of the motor, and prolongs the service life.

Owner:TAIZHOU JINYU ELECTROMECHANICAL

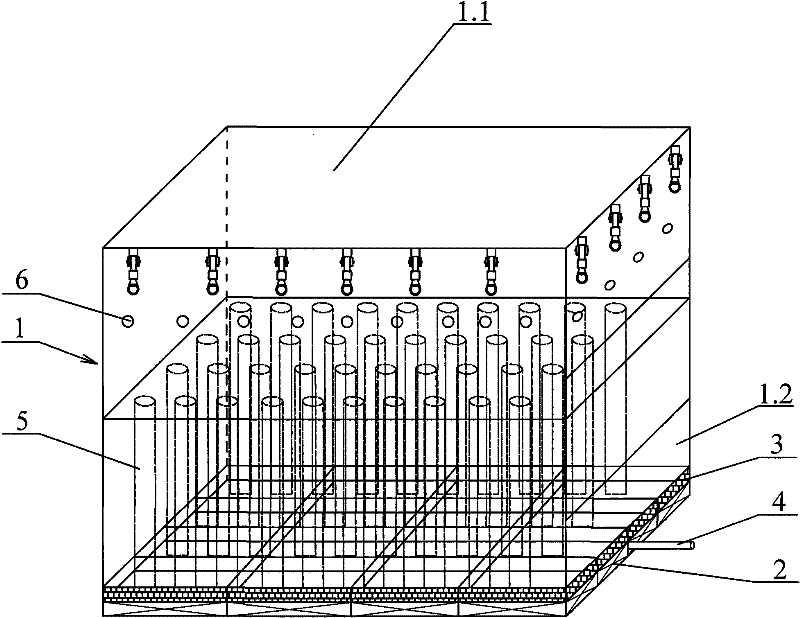

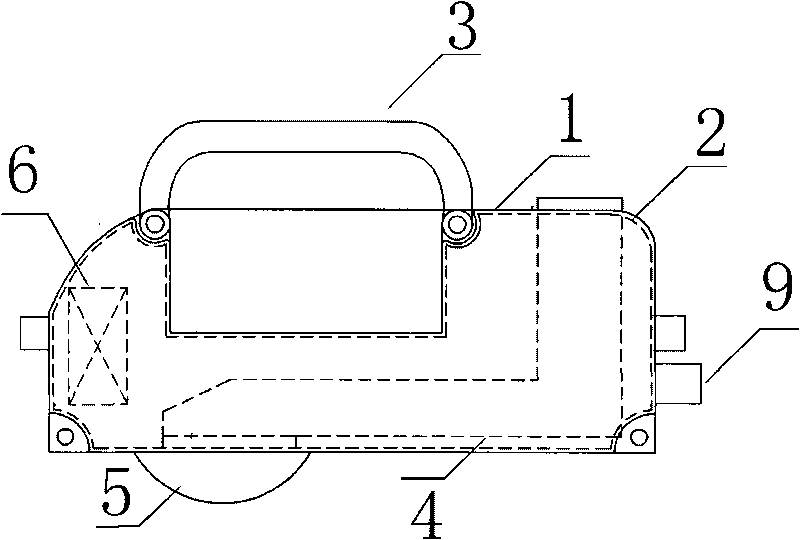

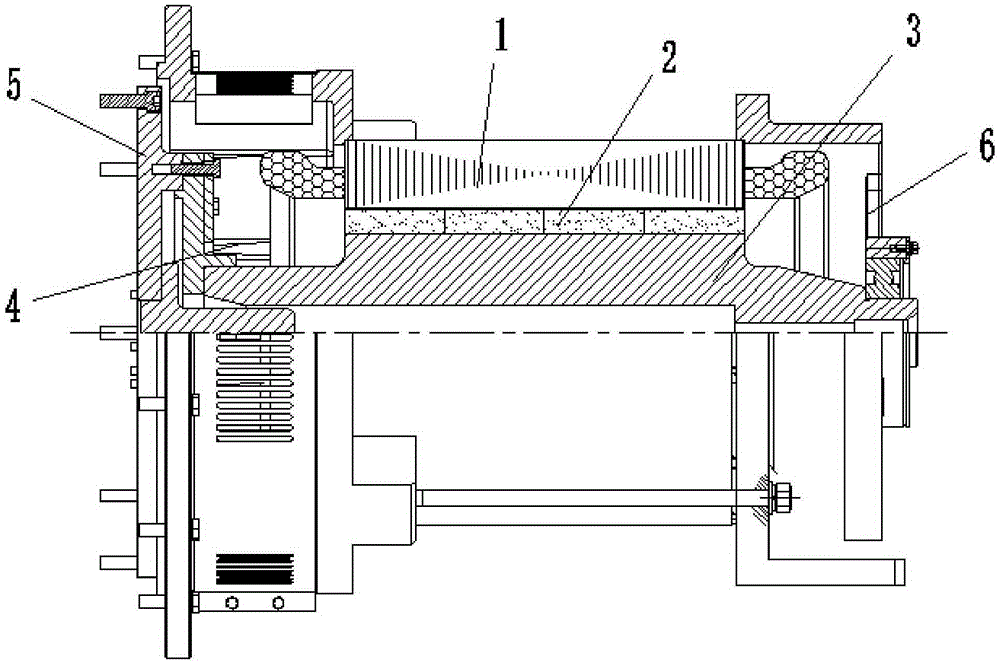

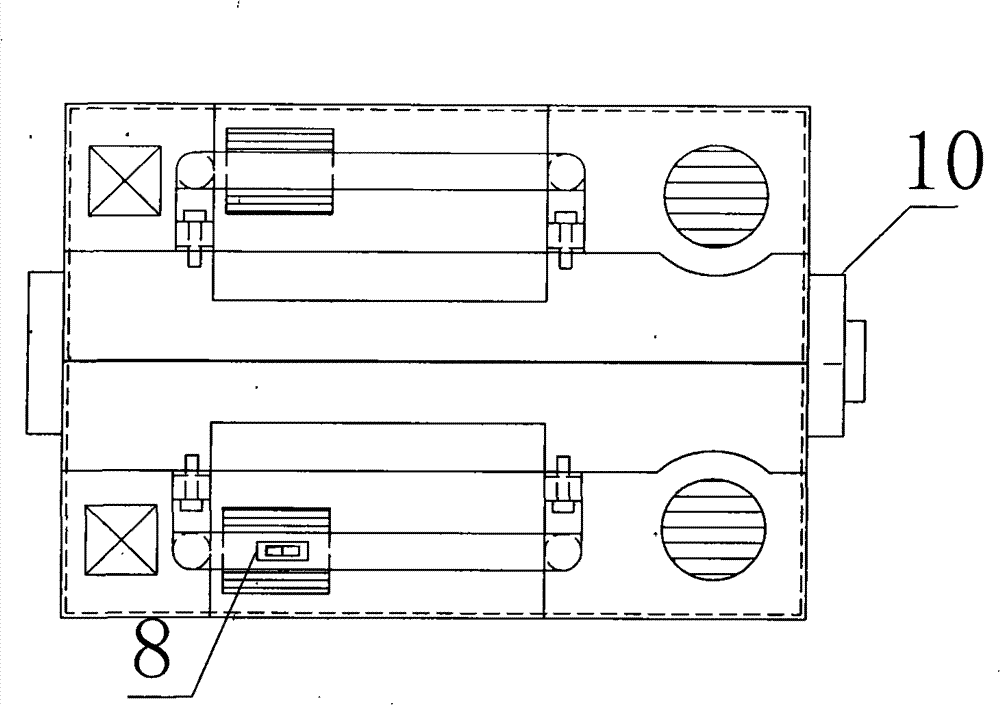

Roll immersed membrane capillary sludge deep dehydrator

InactiveCN101797451BReduce processing costsReduce moisture contentSludge treatment by de-watering/drying/thickeningStationary filtering element filtersCapillary filtrationAfter treatment

The invention relates to a roll immersed membrane capillary sludge deep dehydrator, comprising a sealed box, the box is provided with a movable cover, the bottom of the sidewall of the box is provided with a spoil disposal door, the upper surface of the base plate of the box is provided with a supporting frame, the supporting frame is provided with a filter body, the box under the filter body is provided with a discharging tube, the filter body is provided with a membrane capillary filtering device, the membrane capillary filtering device comprises a supporting barrel and a tubular filter cloth, the top of the supporting barrel is sealed, the bottom of the supporting barrel is a filter screen, the tubular filter cloth is arranged in the inner hole of the supporting barrel, the supporting barrel is opened with a filter tank, the notch width of the filter tank on the outer wall of the supporting barrel is less than the notch width of the filter tank on the inner wall of the supporting barrel. The invention is in operation, unit sludge treatment cost is less, treatment speed is fast, sludge moisture content after treatment is low, equipment is simple in structure, and operating cost is less.

Owner:WUXI DANI INTELLIGENT TECH

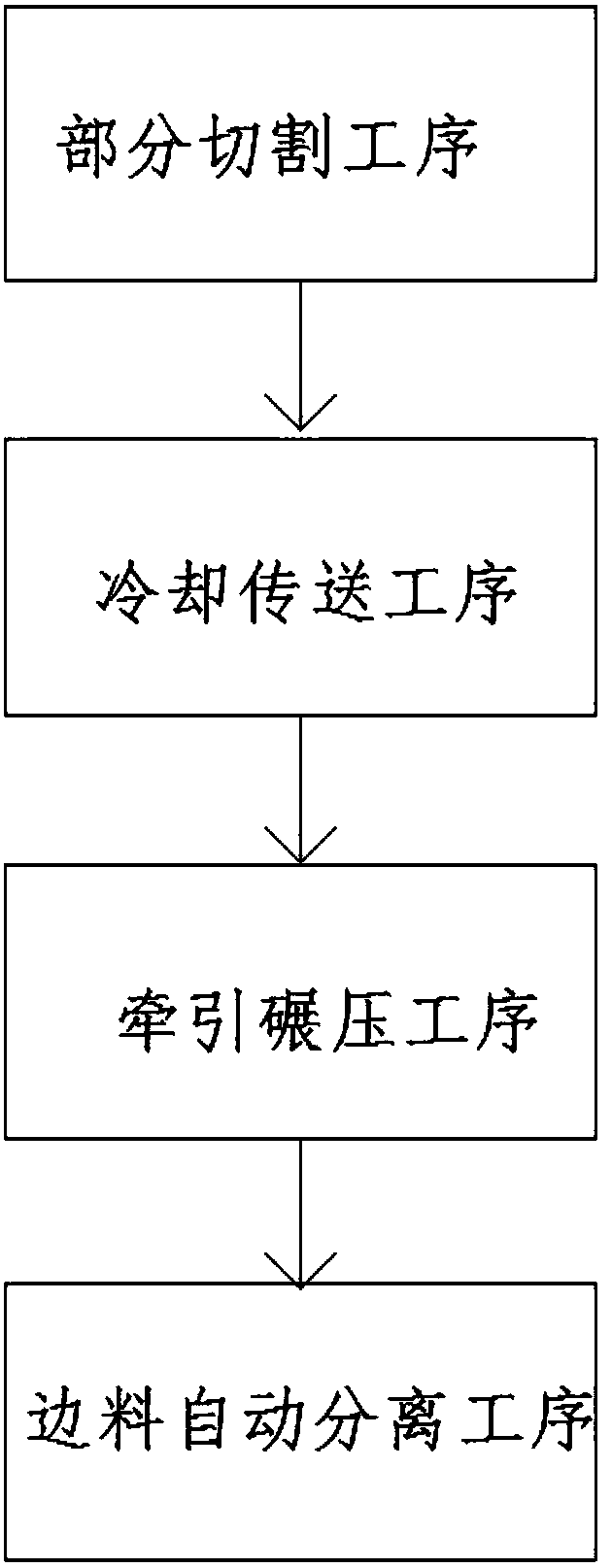

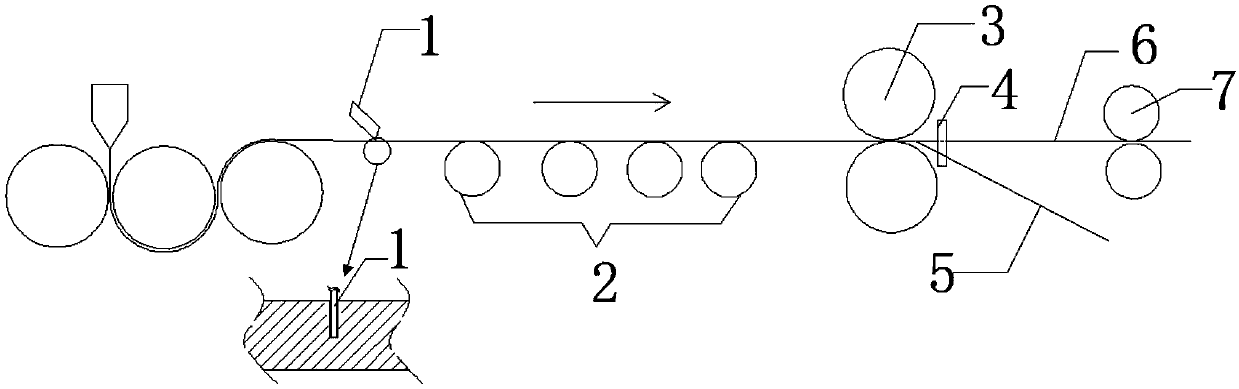

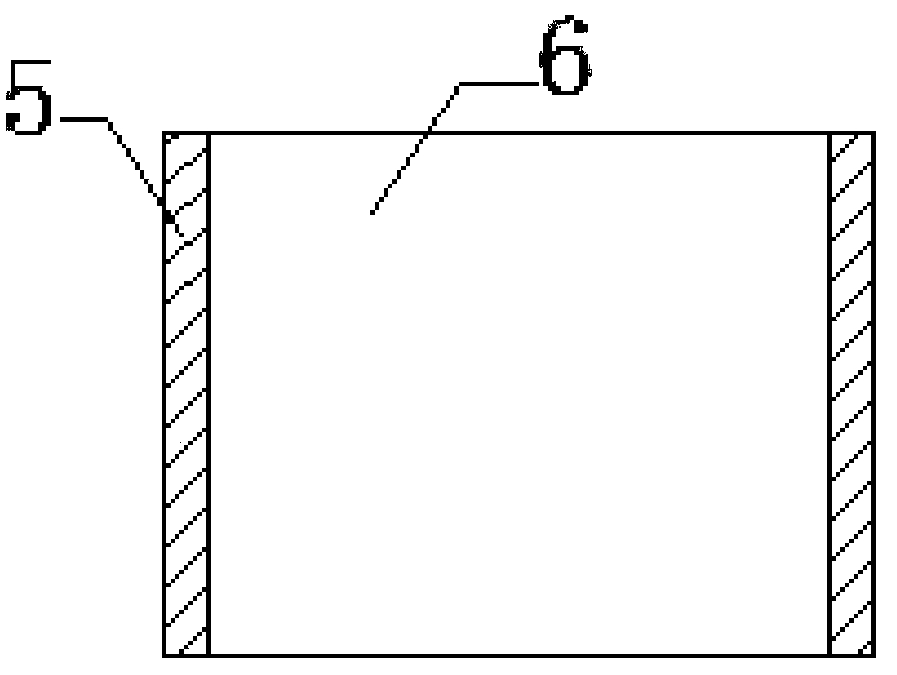

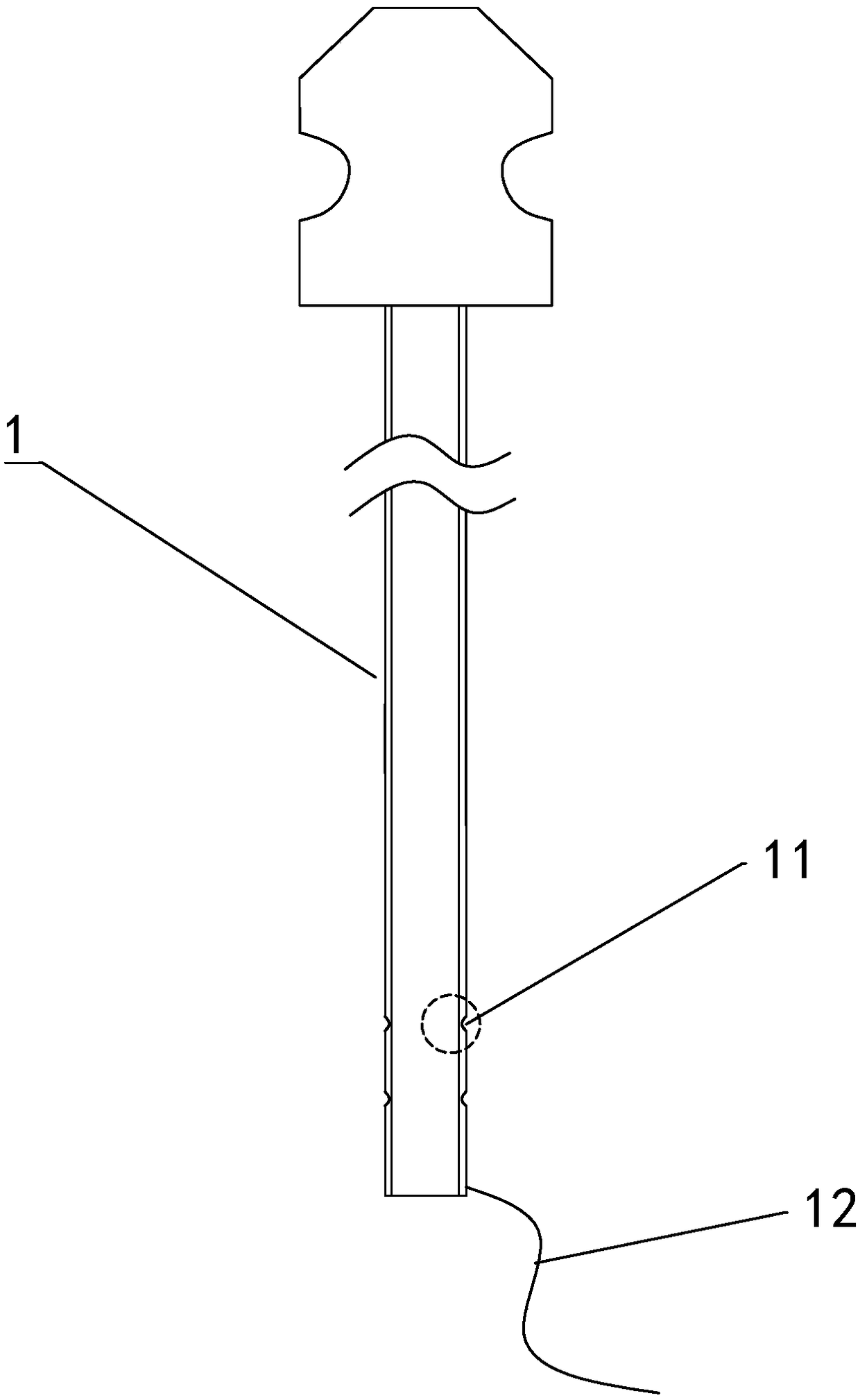

Automatic separation method and automatic separation device of cut edge material of optical diffusion plate

ActiveCN108032354ASeparation transition is smoothPrevent frontal impact deformationOptical articlesFlat articlesWorking environmentEngineering

The invention discloses an automatic separation method of a cut edge material of an optical diffusion plate. The automatic separation method comprises the specific implementation steps of partial cutting procedure, cooling conveying procedure, traction rolling procedure and edge material automatic separation procedure, wherein the edge material of the optical diffusion plate is subjected to non-penetrating partial cutting through an edge cutting device; a notch between the edge material and an optical diffusion plate body is subjected to depth extension during follow-up cooling and rolling; and the edge material and the optical diffusion plate body are automatically separated through an automatic separation device. The automatic separation device comprises a supporting cross rod and separation rods, wherein one separation rod is fixed to each of length ends of the supporting cross rod through welding; the distance between the outer sides of the two separation rods is equal to the widthdimension of the optical diffusion plate body; and the separation rods right face the notch of the optical diffusion plate. According to the automatic separation method and the automatic separation device, through the cutting mode, the notch width is decreased, sawing dust is avoided, the material utilization rate is increased, cleanliness of the optical diffusion plate is guaranteed while the working environment of a workshop is improved, input of manpower and material resources is reduced, and production cost is reduced.

Owner:SUZHOU SANXIN TIMES NEW MATERIAL CO LTD

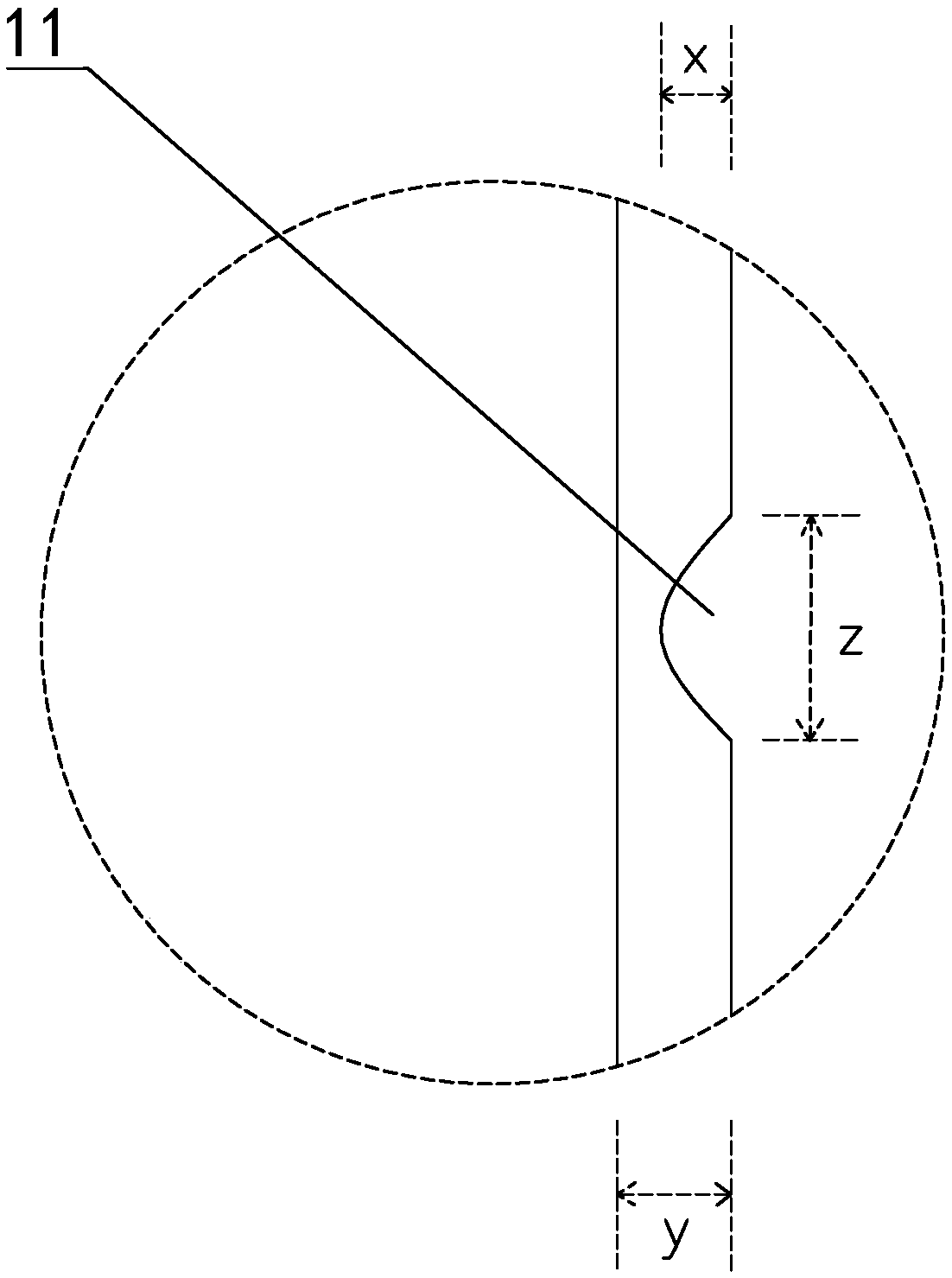

Easy-to-use vas deferens structure for pigs

The invention discloses an easy-to-use vas deferens structure for pigs, comprising a tube body, a recess is arranged on the tail tube wall of the tube body, the depth of the recess is x, the thicknessof the tube wall is y, and the notch width of the recess is z; The depth of the groove and the thickness of the pipe wall satisfy the formula shown in the description, that notch width of the grooveand the thickness of the pipe wall satisfy the formula shown in the description. By providing a sized groove at the end of the tube, the tail of the tube can be easily folded along the groove, which is very convenient. The vas deferens can be used for artificial insemination of pigs.

Owner:FOSHAN UNIVERSITY

Combined fan rib structure and assembling method

PendingCN113615944APrevent disengagementPlay a fixed connectionUmbrellasStructural engineeringMechanical engineering

The invention belongs to the technical field of fan manufacturing, and particularly relates to a combined fan rib structure and an assembling method. The technical problem that in the prior art, design is not reasonable is solved. The provided combined fan rib structure comprises a fan rib; a fan rib nail penetrating block, wherein a pin hole is formed in the fan rib nail penetrating block; a necking groove, which is formed in the fan rib nail penetrating block; a necking groove matching protruding block arranged at the rear end of the fan rib, wherein the notch width of the necking groove is smaller than that of the bottom of the necking groove, and the necking groove matching protruding block is matched with the necking groove to prevent the necking groove matching protruding block from being separated from the notch of the necking groove; and a restraining structure, which is arranged between the two sides of the necking groove matching protruding block and the groove wall of the necking groove and used for fixing the fan rib nail penetrating block relative to the necking groove in the thickness direction. The combined fan rib structure has the advantage that the problem of drilling cracking is solved.

Owner:陈爱兴

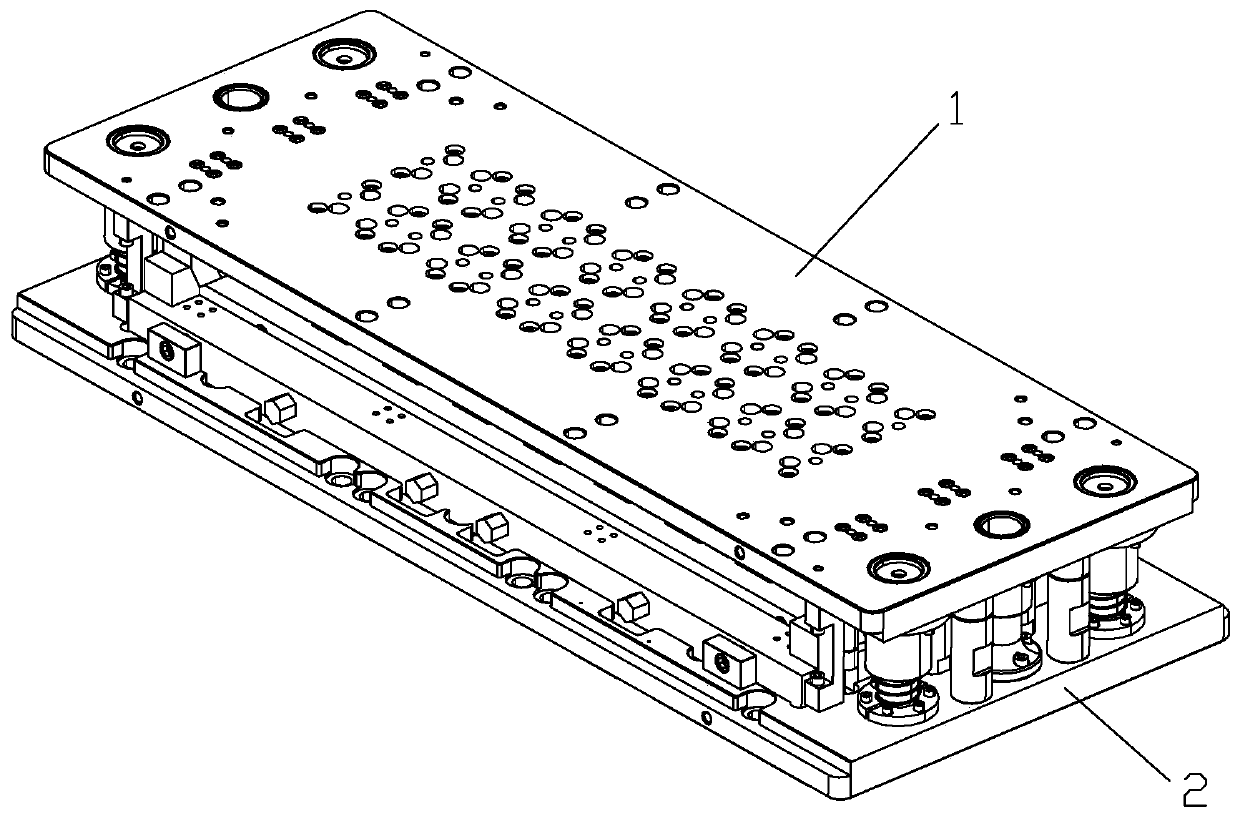

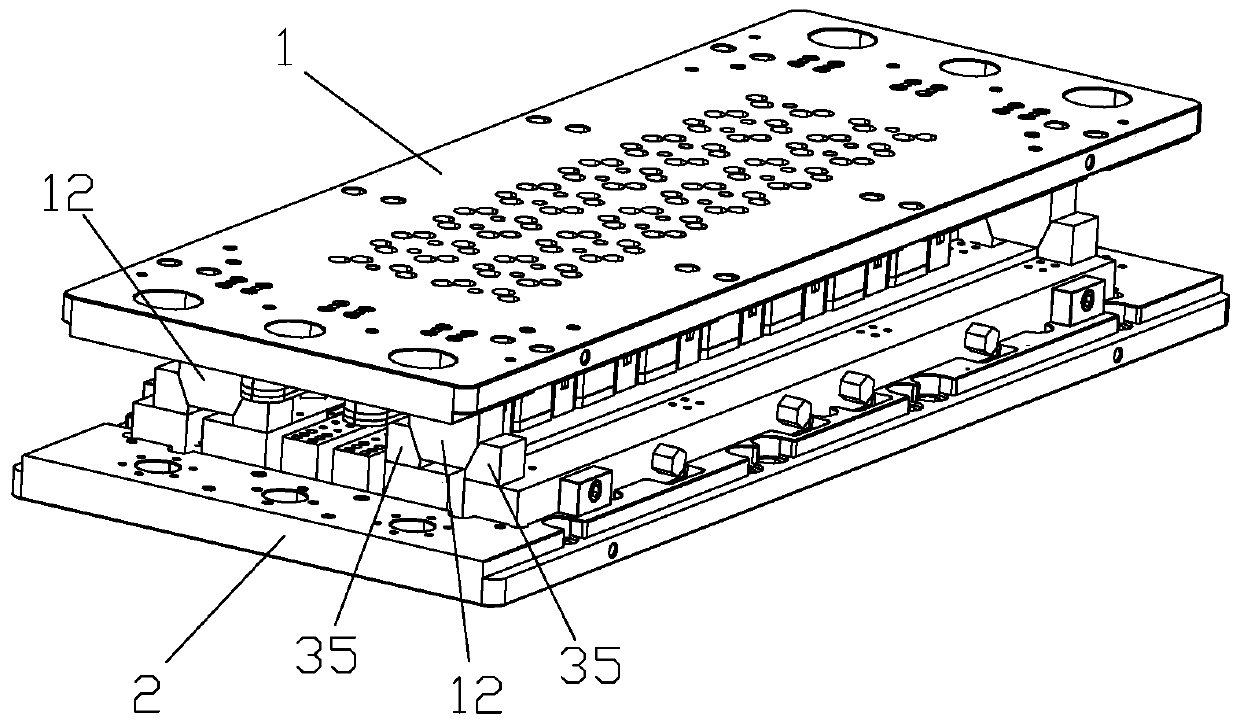

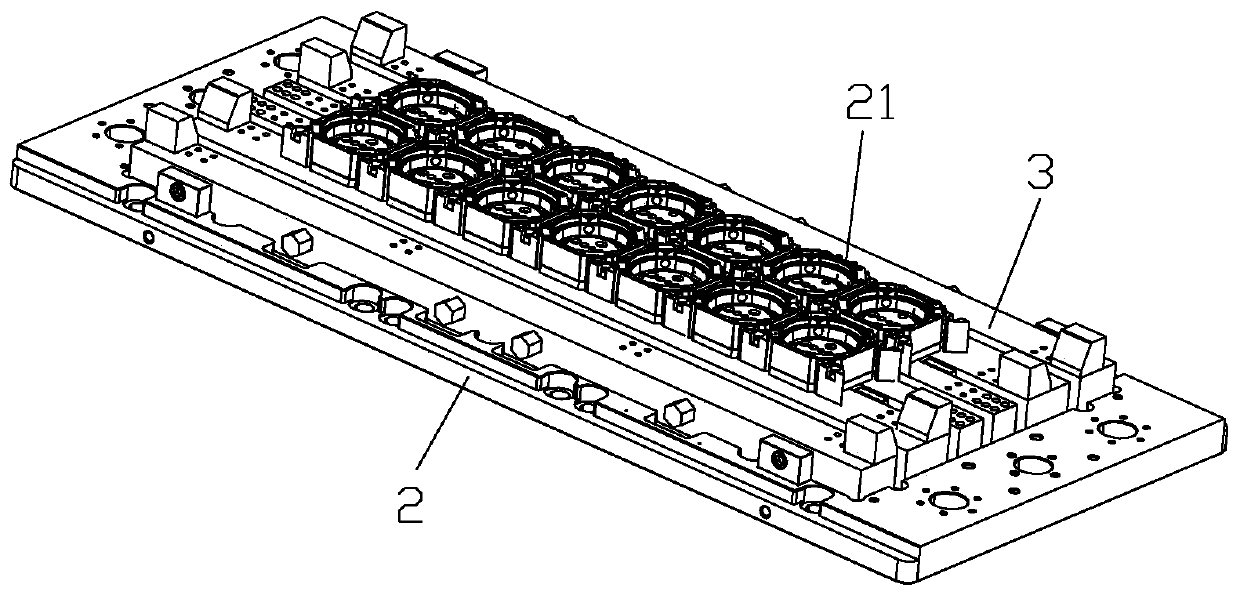

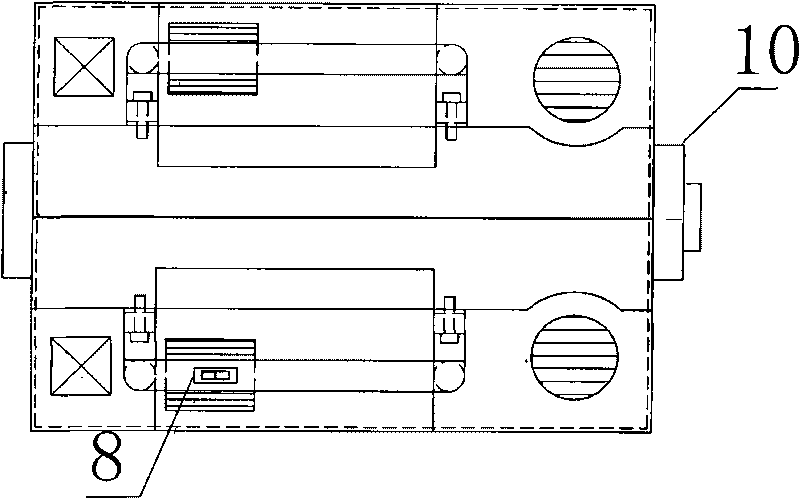

Punching die for clamping teeth of cup lid

ActiveCN109849107AExtended service lifeReasonable structureMetal working apparatusPunchingNotch width

The invention relates to a punching die for clamping teeth of a cup lid. An existing plain-end cutting knife is changed into a V-shaped or inverted-V-shaped pointed cutting knife, the clamping teeth are changed from plain-end teeth into V-shaped teeth or inverted-V-shaped clamping teeth, the pointed cutting knife can ensure that the cup lid is pierced during each punching, and the matching allowance between the V-shaped teeth or the inverted-V-shaped teeth and an edge opening of a cup body is large so that a better disengagement prevention effect is achieved; meanwhile, the structure of the punching die is also appropriately changed for solving the problem that the cutting knife is abraded, and the notch width can be adjusted and the service life of the cutting knife can be prolonged by increasing or decreasing gaskets; and the punching die has the characteristics of reasonable structure, good reliability and convenience in adjustment.

Owner:OTOR TECHNOLOGY CO LTD

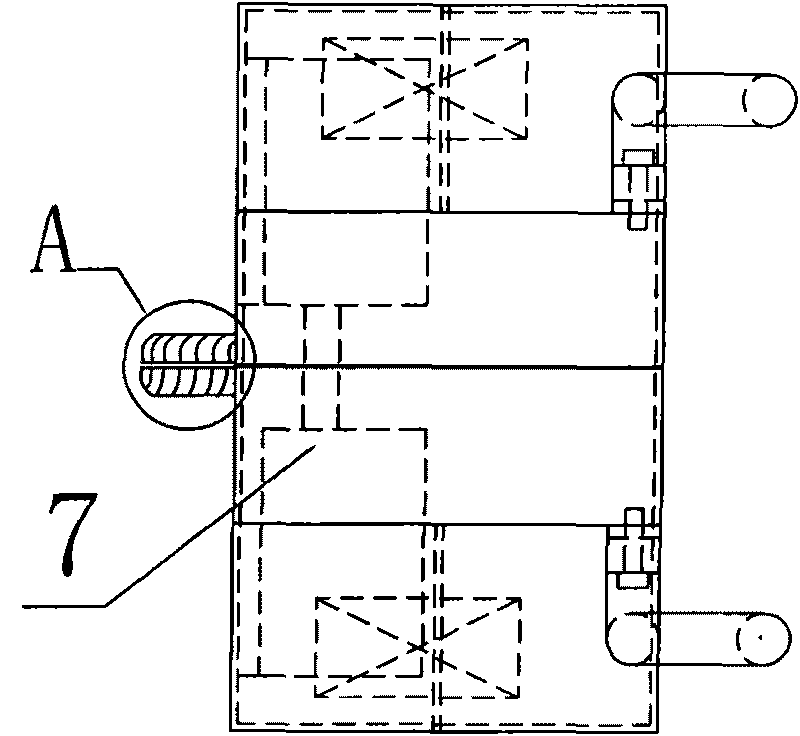

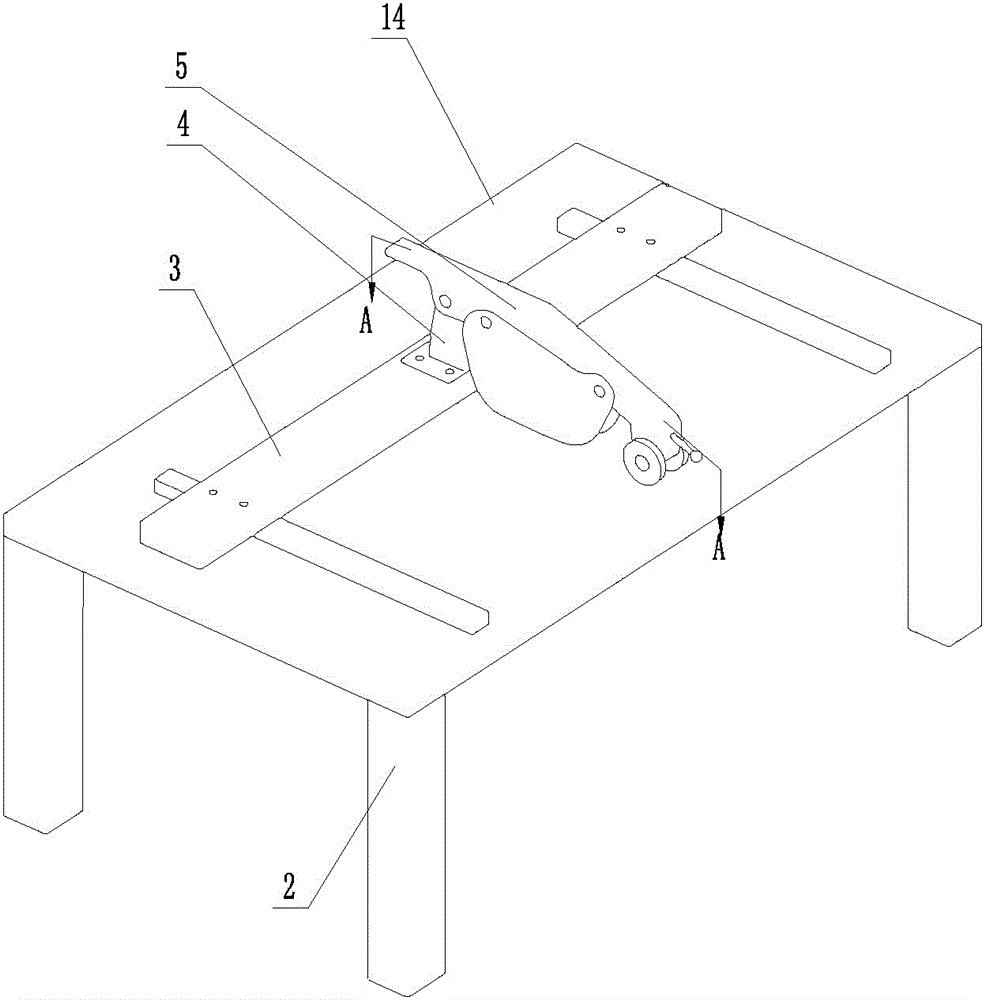

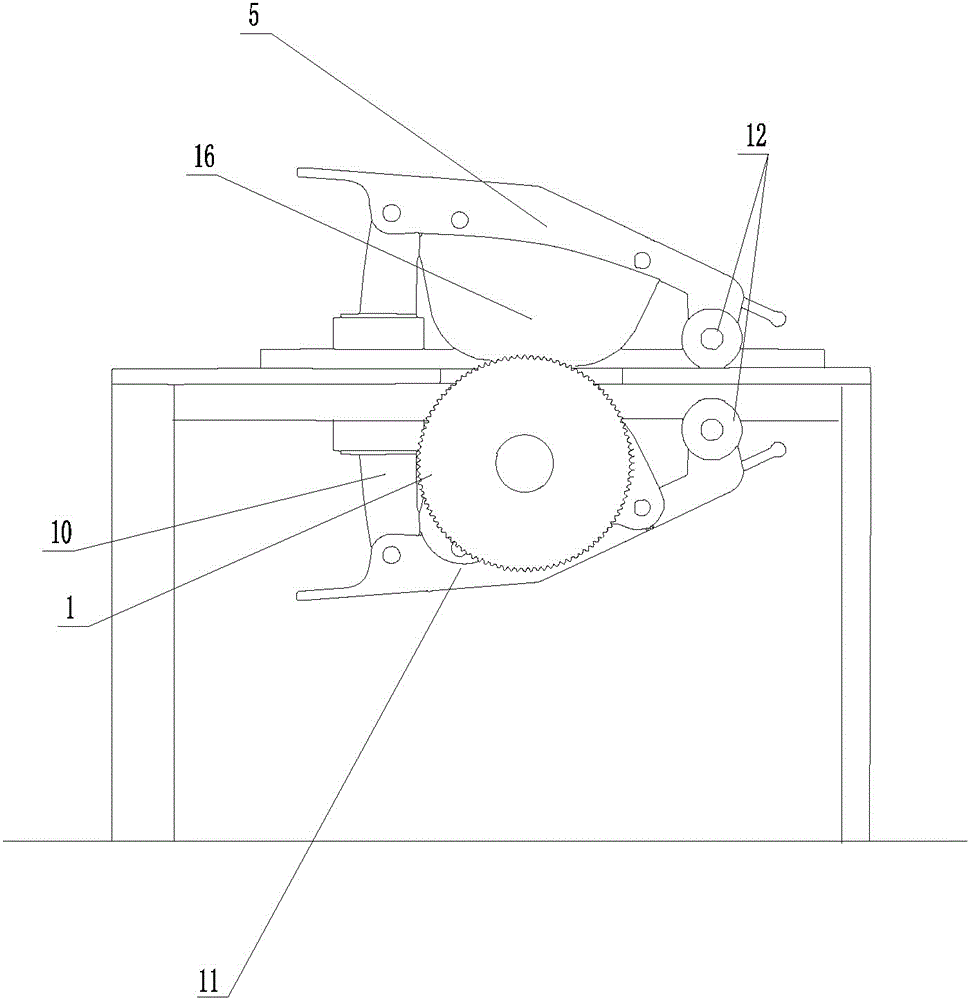

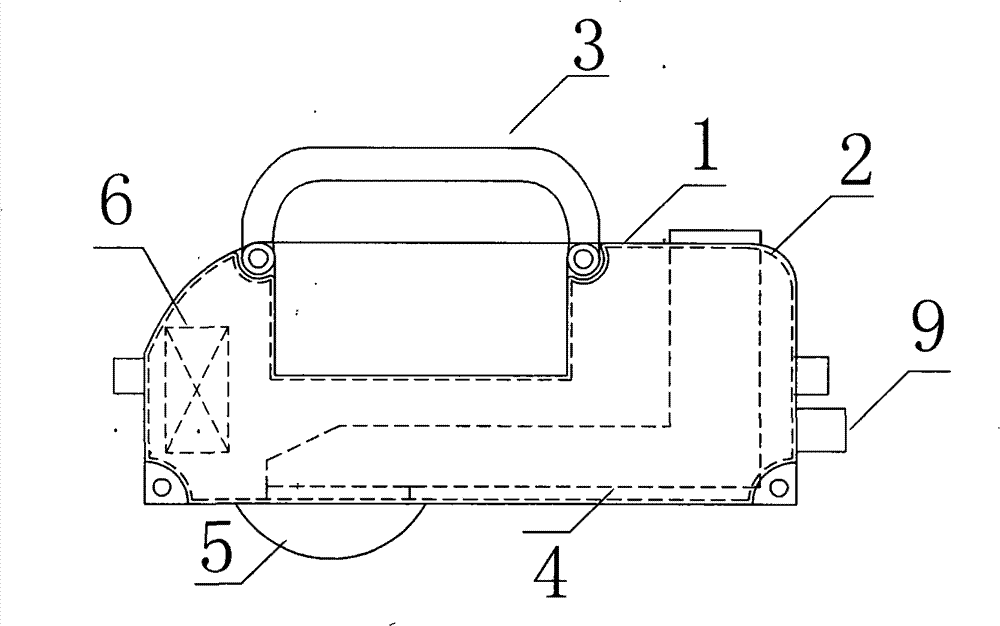

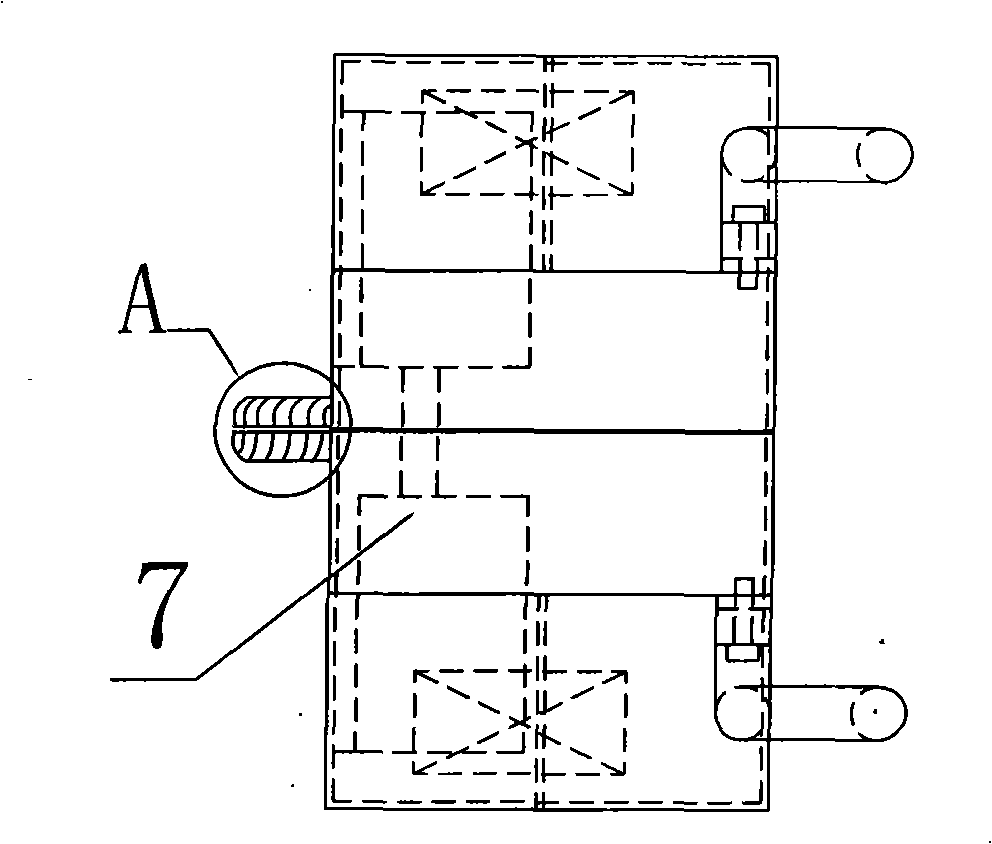

Dual-power mechanically-balanced notching and cutting method and multifunctional notching machine

The present invention provides a dual-power mechanically balanced multifunctional notching machine, which mainly solves the technical problem that when the conventional notching machine has a big power, heading mechanical force generated by a cutter is too big to keep the conventional notching machine held by hands, so the use of the conventional notching machine is not safe. The dual-power mechanically balanced multifunctional notching machine adopts a dual-power mechanically balanced method. Two symmetrical power systems are arranged in the machine; and the cutters rotate clockwise and counterclockwise respectively to notch half a notch in a width direction at the same time to form a complete notch width. The method and the notching machine have the advantages that: the rotation directions of the cutters are opposite, so the mechanical forces mutually counteract or balance, the heading mechanical force is small, the notching machine can be held by hands easily, the notching machine does not hurt human and has good safety and high power; and the method and the notching machine can notch all the architectural materials, including marbles, concrete and the like, overcomes the disadvantages of the traditional notching machine and has obvious effect.

Owner:郭宪民 +1

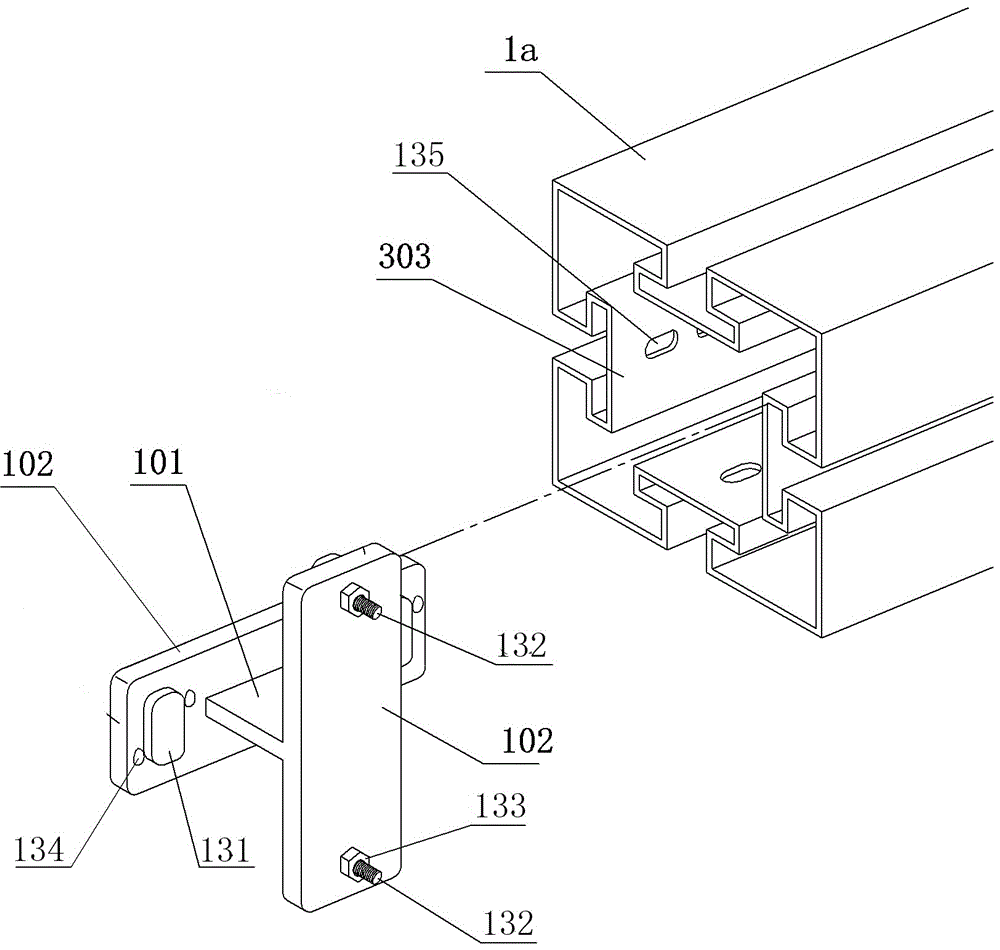

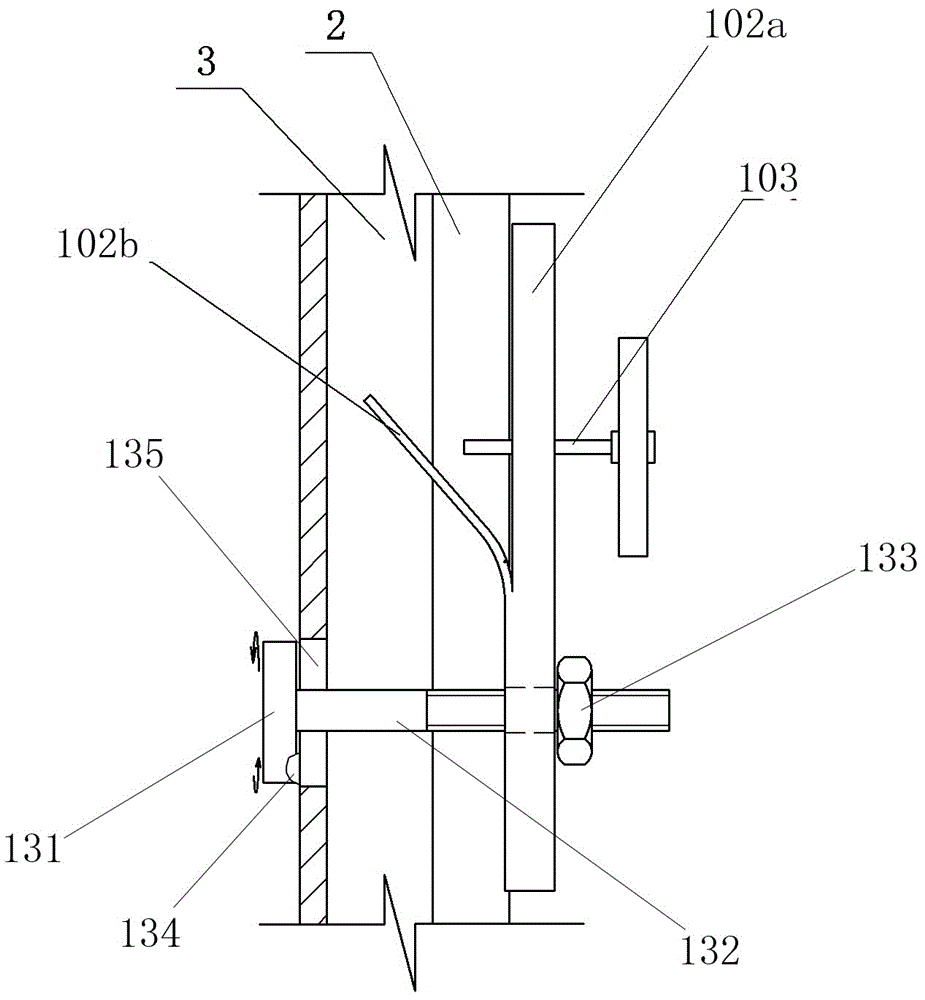

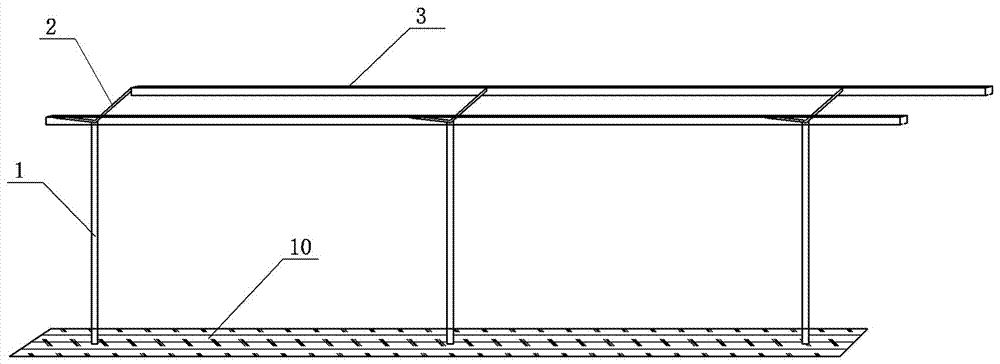

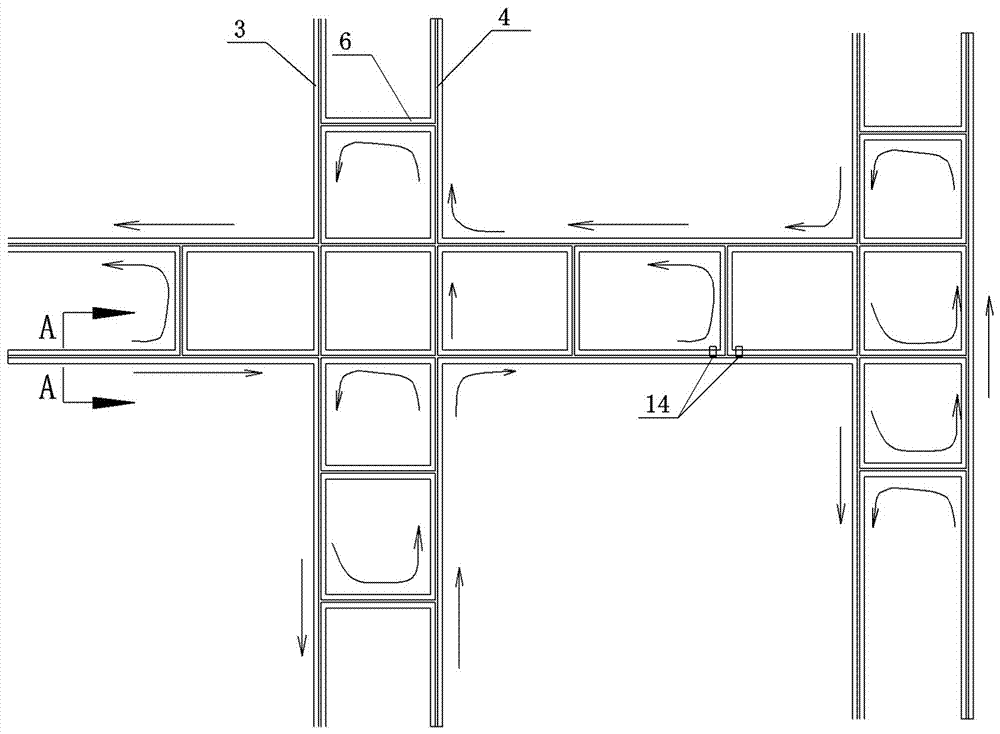

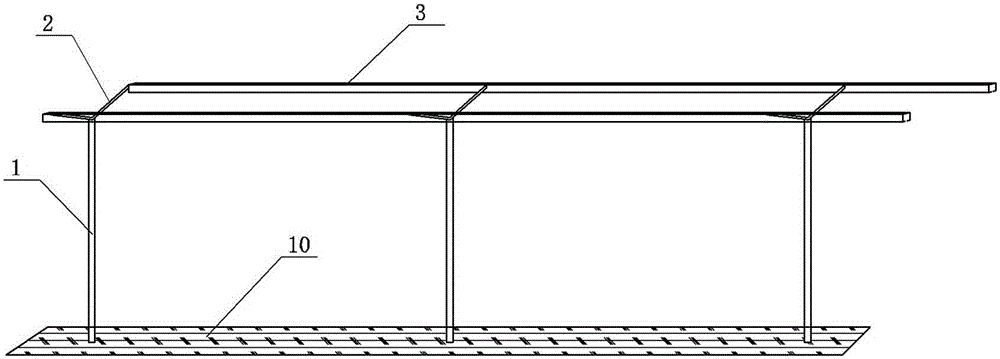

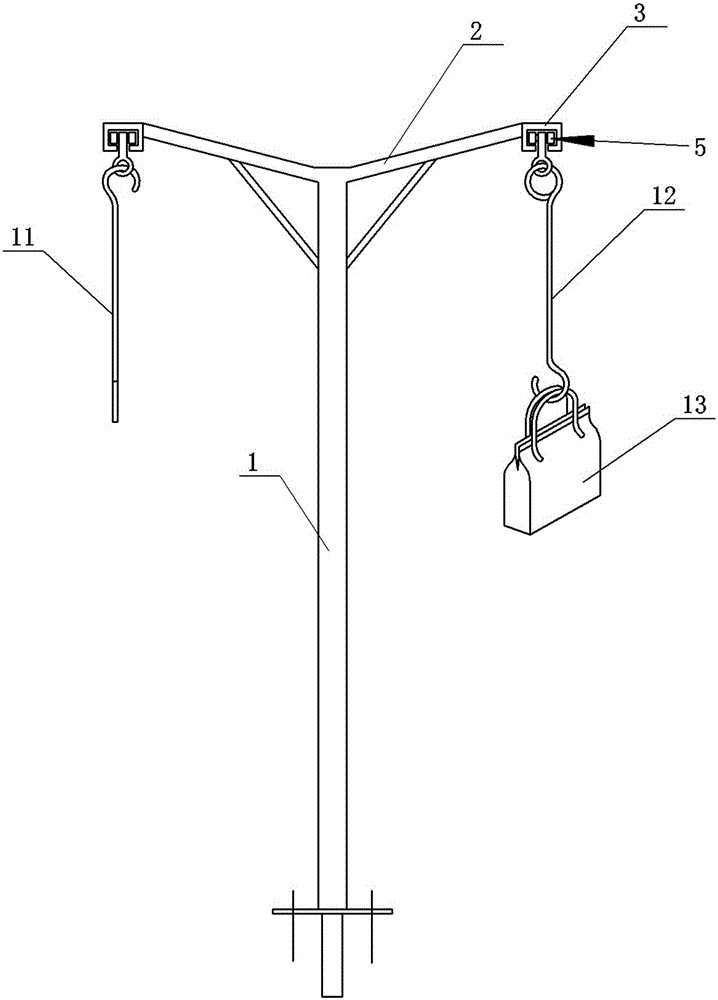

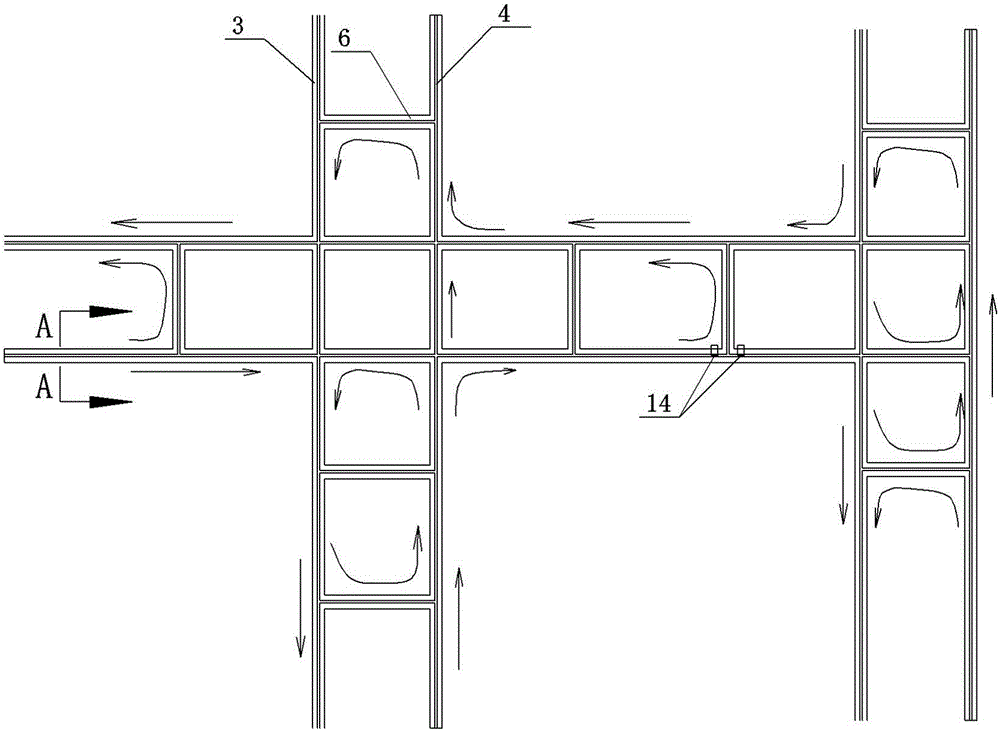

Guide rail street walking aid system

InactiveCN105185104BGood for self-careExtensive participation in social activitiesControl with pedestrian guidance indicatorWalking aidsEngineeringCantilever

The invention discloses a guide rail type street walking aid system. Columns are arranged at certain intervals on the sidewalk, cantilevers are arranged on each column, and continuous guide rails are arranged on the cantilevers of each column; guide grooves are arranged at the bottom of the guide rails, and the guide grooves The width of the inner cavity is greater than the width of the guide notch; a sliding mechanism is installed in the guide groove, and a suspension buckle is connected to the sliding mechanism. The present invention can provide a certain amount of assistance for the user, and can bear part of the weight of the user's lifting items. Providing a track walking aid on the sidewalk can provide the elderly with travel conditions that are conducive to exerting their self-care ability and provide opportunities for the elderly to participate in social activities extensively. It has the effect of guiding the blind, and the function of triggering the site information is designed on the track to provide travel directions, destination arrival reminders and other functions for the blind.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

200KW rare-earth permanent magnet generator

InactiveCN105429321AReduce volumeReduce weightMagnetic circuit stationary partsMagnetic sourcePunching

The invention discloses a 200KW rare-earth permanent magnet generator, which comprises a stator, a rotor core, a magnetic shoe, a front end cover and a rear end cover, wherein rare-earth neodymium iron boron is adopted by the magnetic shoe as a magnetic source body; the stator comprises a plurality of stator punching plates; a round hoe matched with the rotor core is formed in the middle part of each stator punching plate; cramp grooves are formed in the edge part of each stator punching plate; 36 coil slots are evenly distributed in each stator punching plate on an outer ring of each round hole; the coil slots are T-shaped; the notch widths of the coil slots are 6mm; a T-shaped coil tooth is formed between the adjacent coil slots; and the minimum vertical distance between the adjacent coil slots is 9mm. The generator optimizes armature reflection and reduces the motor demagnetization effect; the generator has relatively small size, relatively light weight and relatively high stability, simultaneously has ultra-strong continuous overload capacity (greater than 20%); the rated power of the unit is 200KW; the maximum load power is 230KW; the time of duration is 4 hours; and the 200KW rare-earth permanent magnet generator does not need to maintain basically and can be used in a severe environment for a long period of time.

Owner:CHONGQING ZHIREN ELECTRIC EQUIP

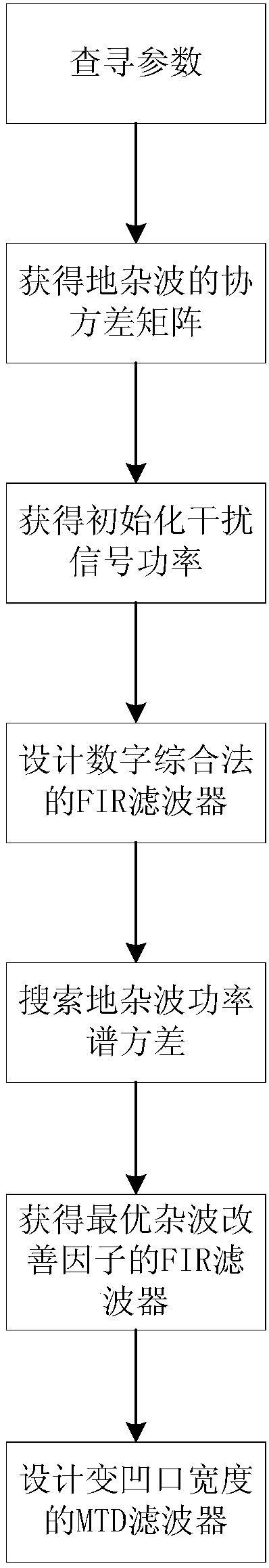

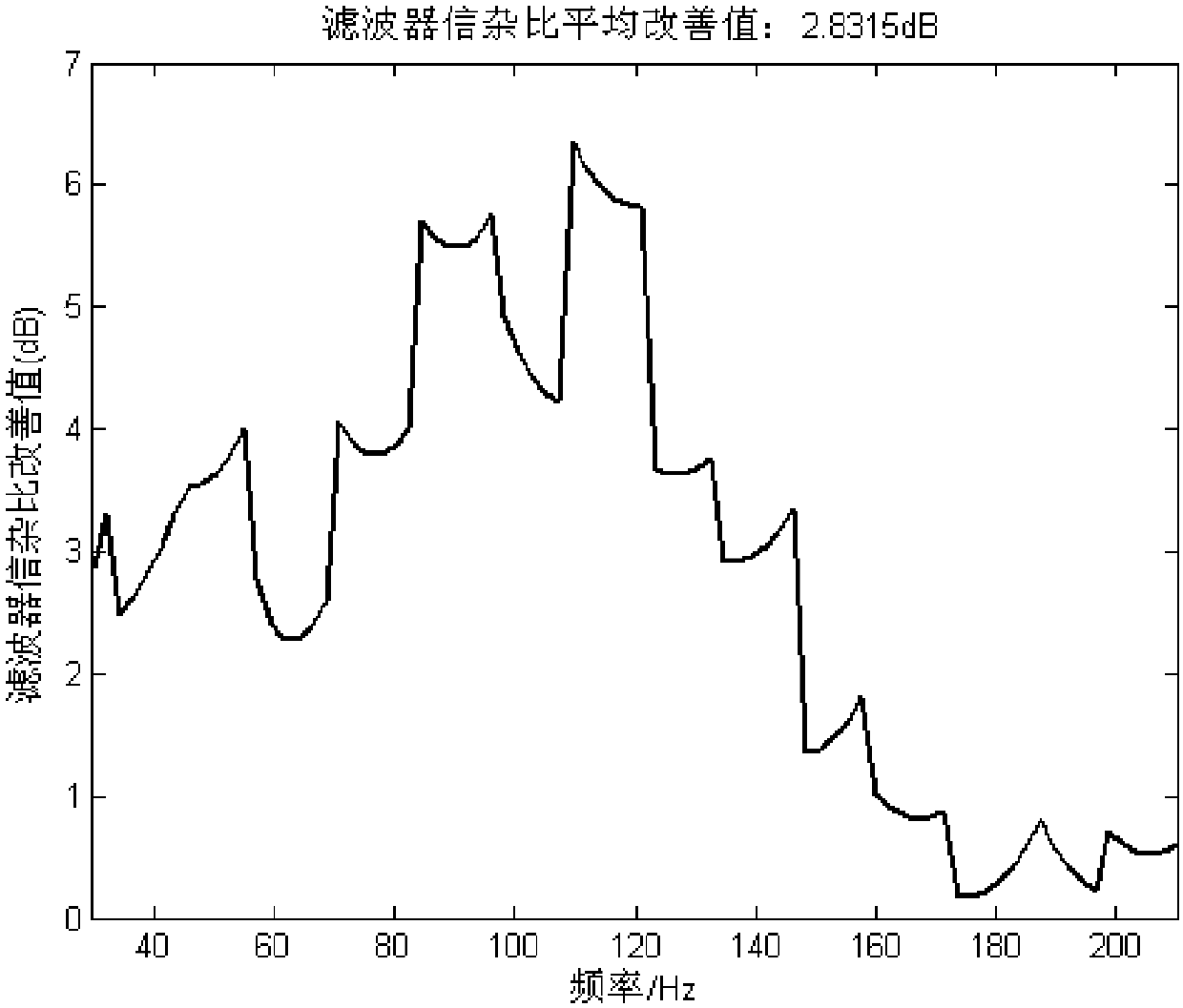

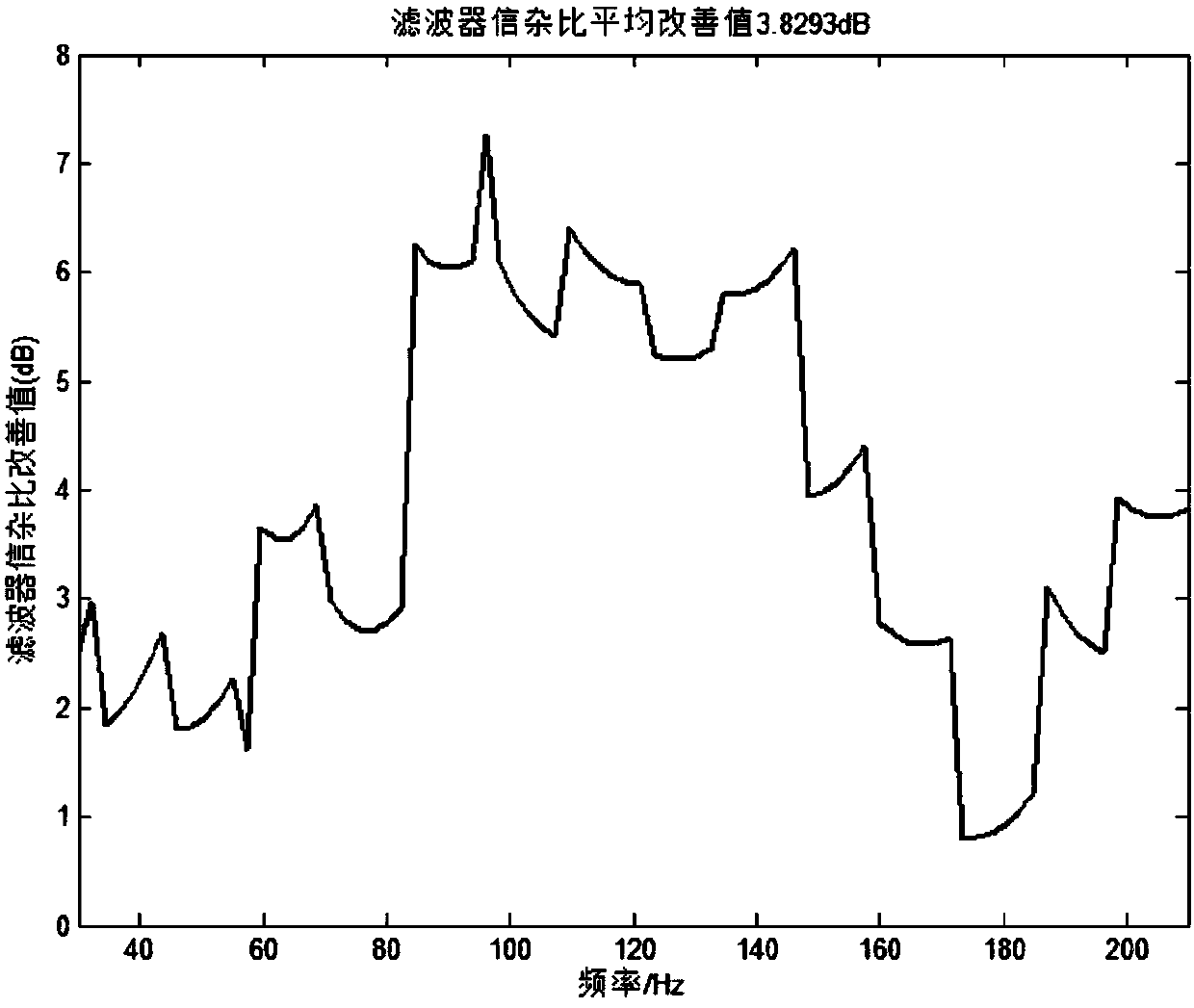

Design Method of Variable Notch Width MTD Filter Based on Prior Information

ActiveCN106093888BReduce filter lossImproved clutter suppression performanceWave based measurement systemsLow speedPrior information

The invention discloses a design method for a recess width variable MTD filter based on prior information. The method comprises the steps of 1) searching parameters; 2) obtaining a covariance matrix of ground clutters; 3) obtaining initialized interference signal power; 4) designing an FIR filter of a digit integrated method; 5) searching a power spectrum variance of the ground clutters; 6) obtaining an FIR filter of an optimal clutter improvement factor; and 7) designing the recess width variable MTD filter. According to the invention, the prior information of a radar surrounding scene is obtained, so that the clutter improvement factor of the output end of the filter is kept optimal. The problem that the recess width in the zero frequency position of the MTD filter is fixed in the prior art is solved. The MTD filter designed in the method has different expected recess widths for different central frequencies, and detection for low-speed movement objects is enhanced.

Owner:XIDIAN UNIV

Guide rail type street walking aid system

InactiveCN105185104AGood for self-careExtensive participation in social activitiesControl with pedestrian guidance indicatorWalking aidsEngineeringCantilever

The invention discloses a guide rail type street walking aid system; columns are arranged on a sidewalk at certain intervals; each column is provided with a cantilever having a continuous guide rail; the bottom of the guide rail is provided with a guide slot, and the cavity width of the guide slot is bigger than the notch width of the guide slot; a slide mechanism is arranged in the guide slot, and connected with a suspension ring. The guide rail type street walking aid system can provide certain power assistance for users, and can bearing partial weight of the user pulling objects; the track walking aid equipment on the sidewalk can help elder people to have travel ability by themselves, thus providing wide social activity participation opportunities for elder people; the guide rail type street walking aid system has blind guide effect; the track is provided with site information trigger type broadcast function, thus prompting walking direction and destination arrival information for blind people.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Circular saw for wooden door

PendingCN104526770AGuaranteed flatnessEasy post-processingCircular sawsCompression deviceCircular saw

The invention discloses wooden door processing equipment, in particular to a connecting structure of a circular saw for cutting wooden door edges and corners. The circular saw for the wooden door comprises a working platform used for holding a wood board, a circular saw blade arranged at one side of the working platform, and a compression device arranged at the other side of the working platform, and the compression device comprises a locating rod, a straight rod, an arc-shaped rod and a handle connected in sequence; the locating rod is placed on the wooden board, the straight rod is fixed on the locating rod, the arc-shaped rod is hinged to the straight rod, the handle is fixed on the arc-shaped rod, a propping plate is firmly arranged at each of two lateral surfaces of the arc-shaped rod, the lower edge of each propping plate is flat and straight, the lateral surfaces of the two propping plates are opposite, and the width between two propping plates is consistent with a preset door board notch width. The circular saw for the wooden door overcomes the disadvantage that the prior art forms an arc-shaped bump when cutting a notch, and the arc-shaped bump is not good for the later processing; a press device is arranged at the other side opposite to the circular saw to counteract deformation.

Owner:CHONGQING OFAN DOOR IND

Dual-power mechanically-balanced notching and cutting method and multifunctional notching machine

The present invention provides a dual-power mechanically balanced multifunctional notching machine, which mainly solves the technical problem that when the conventional notching machine has a big power, heading mechanical force generated by a cutter is too big to keep the conventional notching machine held by hands, so the use of the conventional notching machine is not safe. The dual-power mechanically balanced multifunctional notching machine adopts a dual-power mechanically balanced method. Two symmetrical power systems are arranged in the machine; and the cutters rotate clockwise and counterclockwise respectively to notch half a notch in a width direction at the same time to form a complete notch width. The method and the notching machine have the advantages that: the rotation directions of the cutters are opposite, so the mechanical forces mutually counteract or balance, the heading mechanical force is small, the notching machine can be held by hands easily, the notching machine does not hurt human and has good safety and high power; and the method and the notching machine can notch all the architectural materials, including marbles, concrete and the like, overcomes the disadvantages of the traditional notching machine and has obvious effect.

Owner:郭宪民 +1

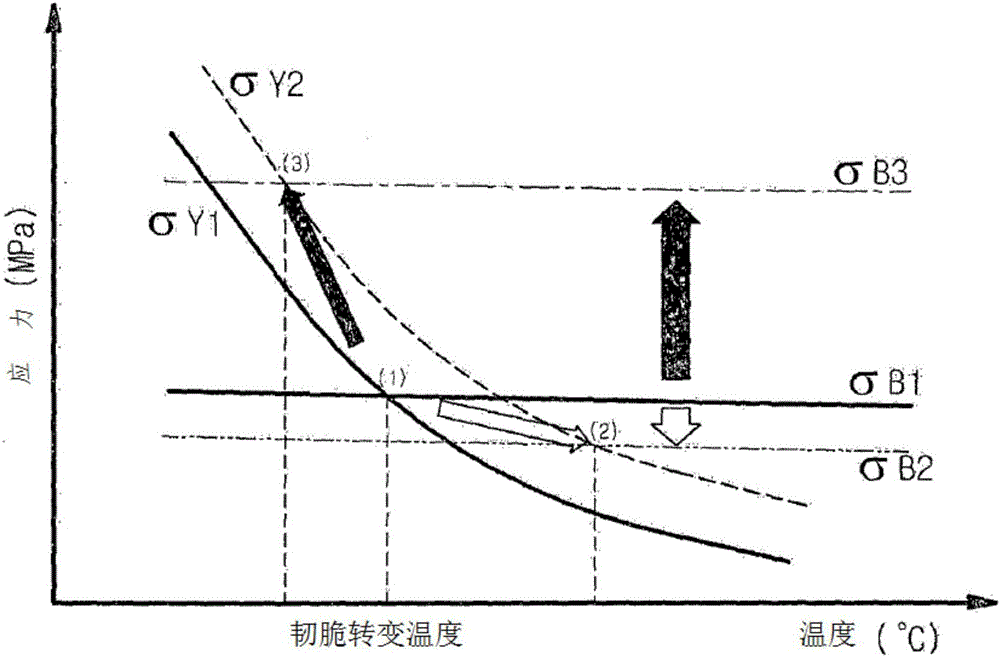

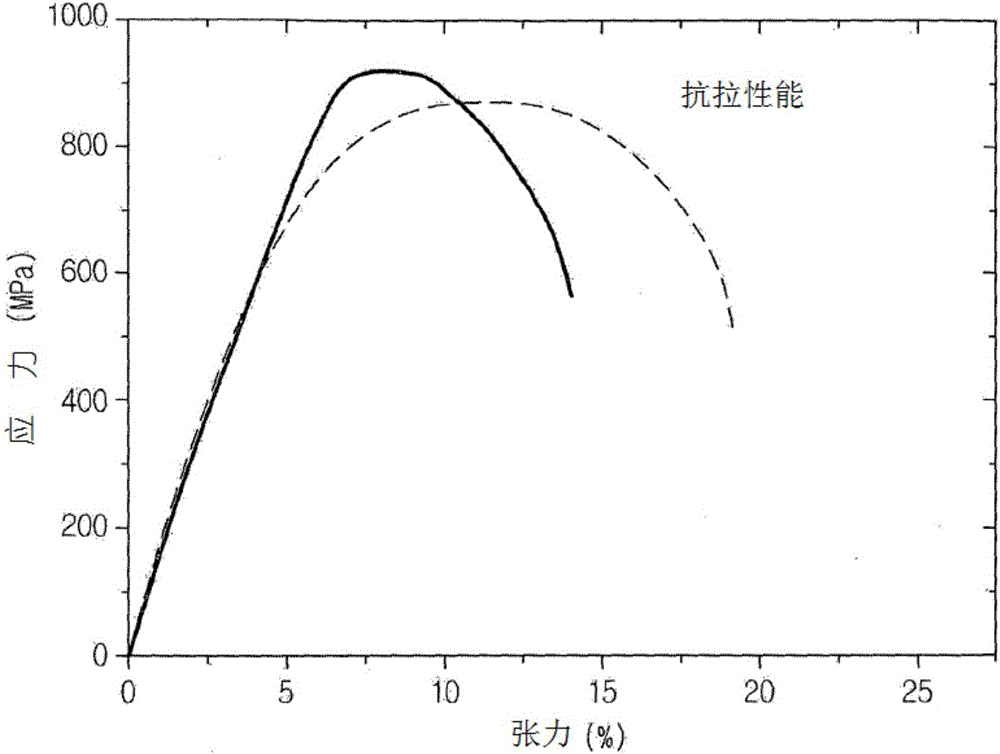

Metal material with improved low-temperature property and method for manufacturing same

The present invention relates to a metal material with an improved low-temperature property and a method for manufacturing the same, and the metal material is capable of being safely used at a low temperature by inducing a ductile fracture through an increase in fracture toughness at a low temperature. According to one embodiment of the present invention, provided are a metal material with an improved low-temperature property, in which at least one notch is recessed on a surface thereof and at least one fine crack is processed at a lower end of the notch that intersects with the notch in a notch width direction, and a method for manufacturing the same.

Owner:KOREA INST OF IND TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com