Combined fan rib structure and assembling method

A combined fan bone technology, applied in umbrellas, travel goods, clothing, etc., can solve the problems of fan bone cracking, difficult processing, narrow rear end width, etc., and achieve the effect of reasonable design and solving the problem of drilling cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

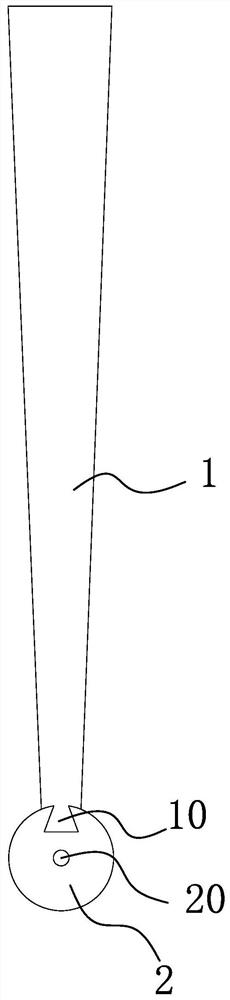

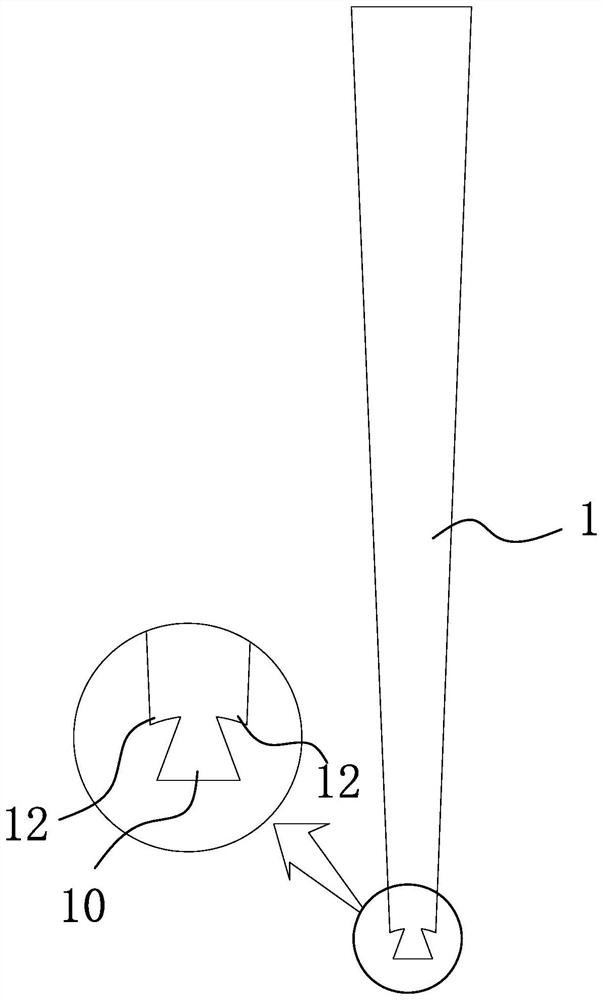

[0038] Such as Figure 2-Figure 4 As shown, this embodiment provides a combined fan bone structure including fan bone 1, fan bone nailing block 2, shrinkage groove 21, shrinkage groove matching protrusion 10 and restraint structure, the width of fan bone 1: the front end is wide, and the rear end is narrow .

[0039] The fan bone can be any one of the large side bone and the small side bone.

[0040] A pin hole 20 is provided on the fan bone nail block 2, and the pin hole 20 is a circular hole.

[0041] Shrinking groove 21 is arranged on the fan bone piercing block 2, and the shape of fan bone piercing block 2 is circular and prismatic or the like structure.

[0042] The shrinking groove and the protrusion 10 are arranged at the rear end of the fan rib 1 .

[0043] The notch width of the necking groove 21 is smaller than the groove bottom width of the necking groove 21, and the necking groove matching protrusion 10 matches the necking groove 21 to prevent the necking groove...

Embodiment 2

[0067] Based on the first embodiment, this embodiment provides a Wenwan folding fan, which has the combined fan bone structure described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com