Automatic separation method and automatic separation device of cut edge material of optical diffusion plate

A technology of light diffusing plate and automatic separation, applied in optical components, metal processing, flat products, etc., can solve problems such as waste of manpower, material resources, reduced product utilization, and environmental impact of workshops

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

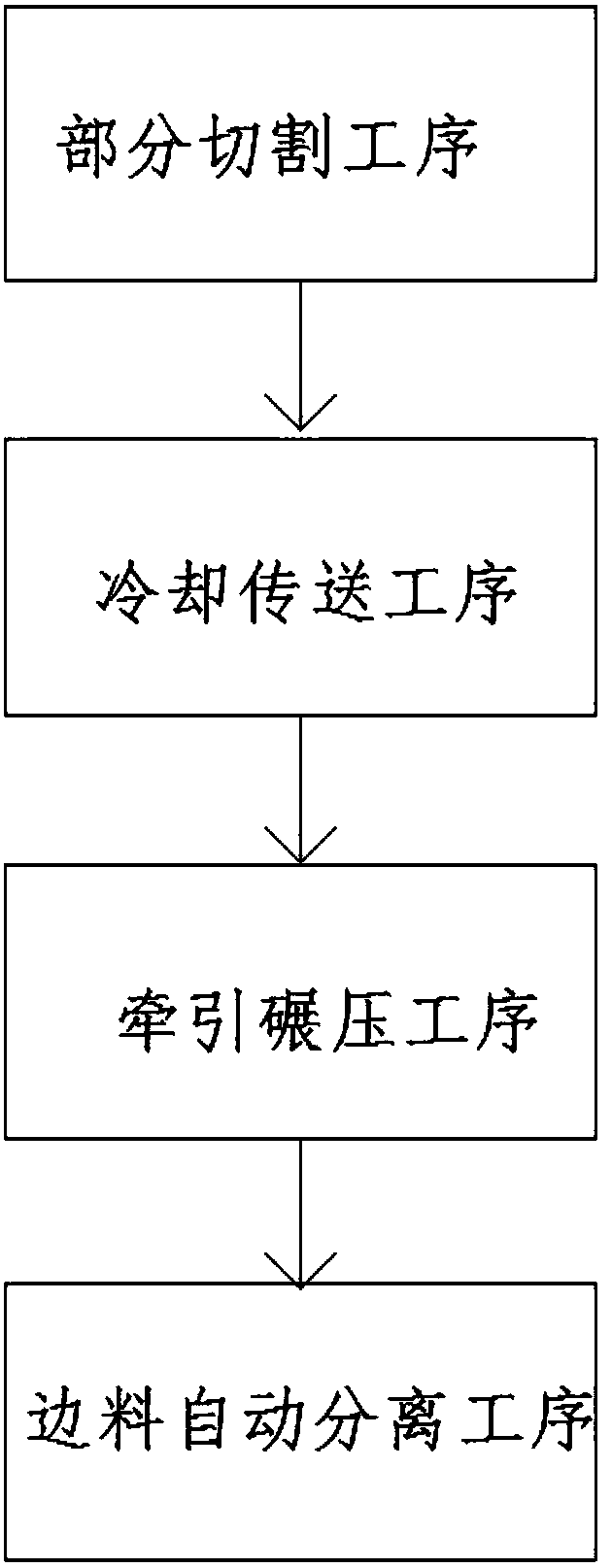

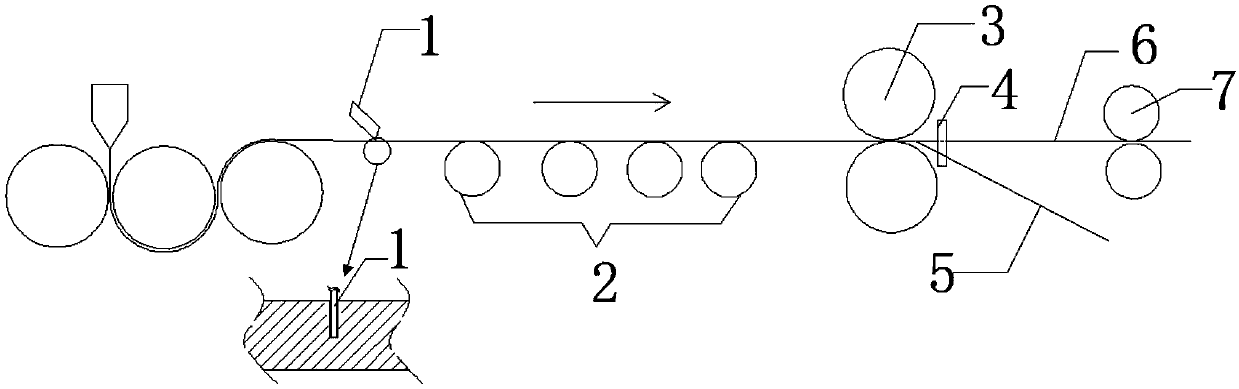

[0031] An automatic separation method for edge trimming of a light diffusion plate, specifically comprising:

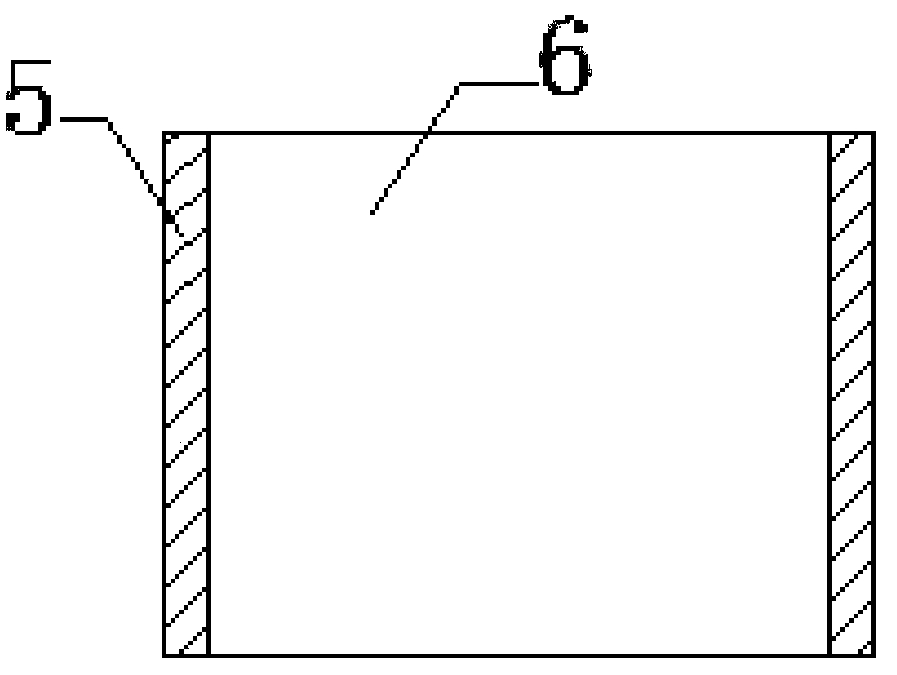

[0032] Partial cutting process: Use edge trimming device 1 to implement partial cutting process on the irregular edge material 5 on both sides of the width of the light diffusion plate after extrusion molding and surface embossing treatment, partial cutting is non-penetrating cutting, the depth of the cutting edge less than the thickness of the light diffuser. The light diffusion plate just formed is not cooled, so it is easy to cut with a thinner cutter.

[0033] Cooling and conveying process: passing the partially cut light diffusion plate through the cooling roller 2 for cooling and cooling treatment. According to the principle of thermal expansion and cold contraction, the light diffusion plates on both sides of the crack will undergo separation and contraction deformation, which will further tear the cutting edge of the knife.

[0034] Traction and rolling proc...

specific Embodiment example 2

[0040] An automatic separation method for edge trimming of a light diffusion plate, specifically comprising:

[0041] Partial cutting process: Use edge trimming device 1 to implement partial cutting process on the irregular edge material 5 on both sides of the width of the light diffusion plate after extrusion molding and surface embossing treatment, partial cutting is non-penetrating cutting, the depth of the cutting edge less than the thickness of the light diffuser. The light diffusion plate just formed is not cooled, so it is easy to cut with a thinner cutter.

[0042] Cooling and conveying process: passing the partially cut light diffusion plate through the cooling roller 2 for cooling and cooling treatment. According to the principle of thermal expansion and cold contraction, the light diffusion plates on both sides of the crack will undergo separation and contraction deformation, which will further tear the cutting edge of the knife.

[0043] Traction and rolling proc...

specific Embodiment example 3

[0049] An automatic separation method for edge trimming of a light diffusion plate, specifically comprising:

[0050] Partial cutting process: Use edge trimming device 1 to implement partial cutting process on the irregular edge material 5 on both sides of the width of the light diffusion plate after extrusion molding and surface embossing treatment, partial cutting is non-penetrating cutting, the depth of the cutting edge less than the thickness of the light diffuser. The light diffusion plate just formed is not cooled, so it is easy to cut with a thinner cutter.

[0051] Cooling and conveying process: passing the partially cut light diffusion plate through the cooling roller 2 for cooling and cooling treatment. According to the principle of thermal expansion and cold contraction, the light diffusion plates on both sides of the crack will undergo separation and contraction deformation, which will further tear the cutting edge of the knife.

[0052] Traction and rolling proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com