Roll immersed membrane capillary sludge deep dehydrator

An immersed membrane, deep dewatering technology, applied in dewatering/drying/concentrating sludge treatment, fixed filter element filter, filtration separation, etc. Simple, low sludge moisture content, low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

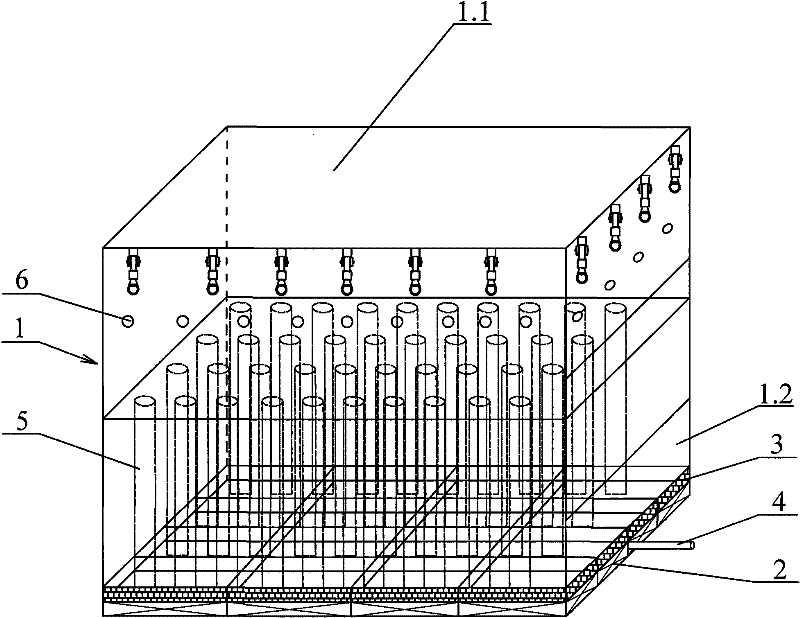

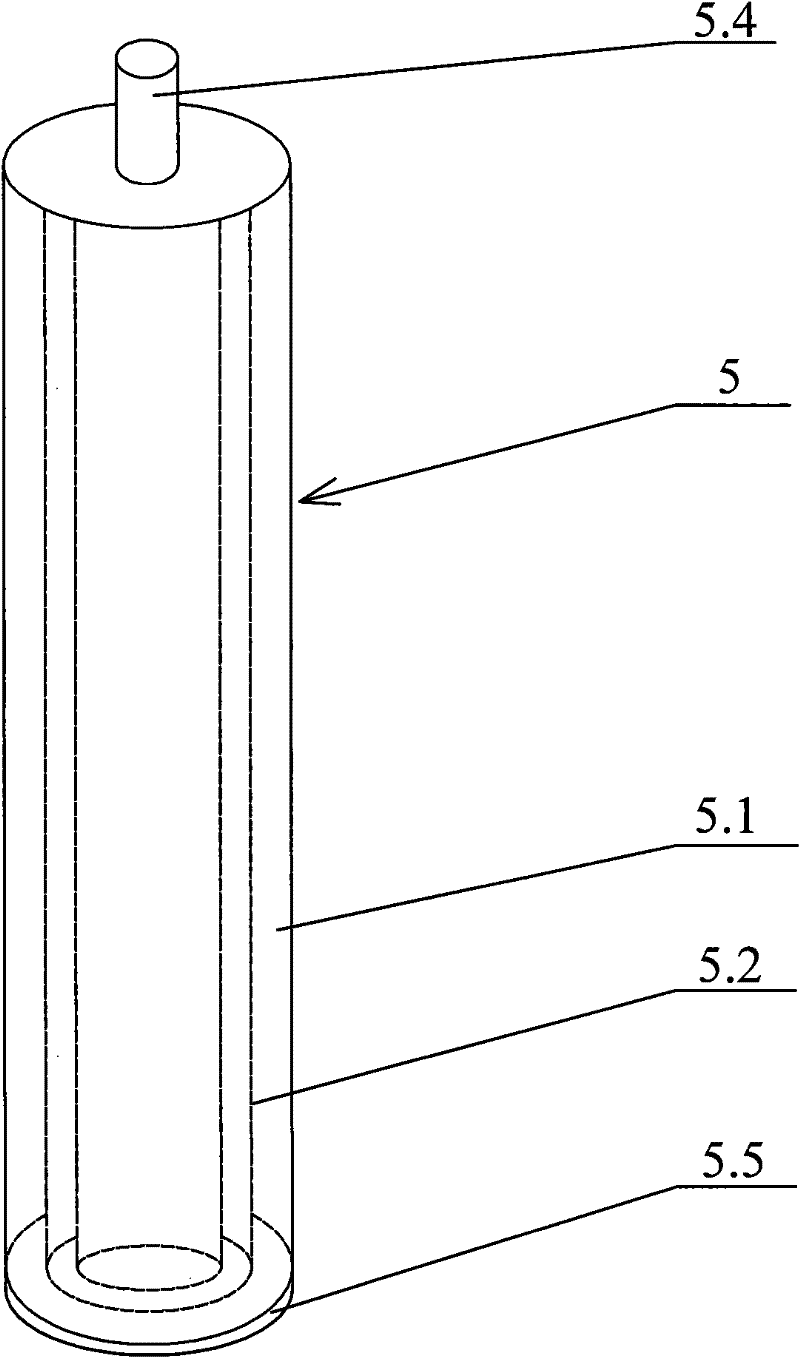

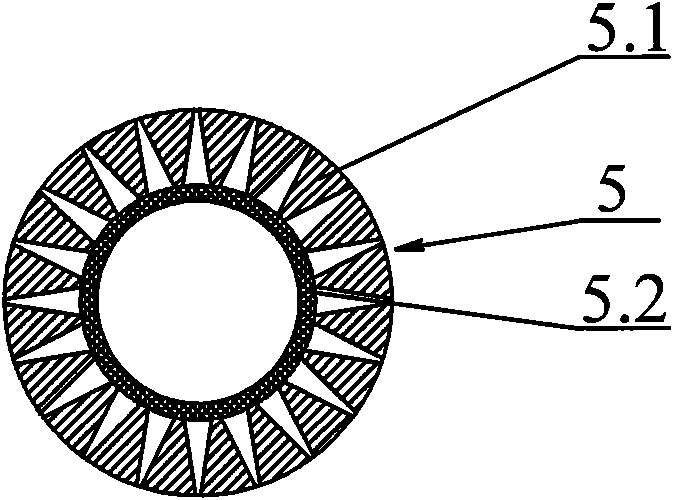

[0016] As shown in the figure, the roll-type submerged membrane capillary sludge deep dewatering device includes a sealed box 1, the box 1 has a movable cover 1.1, and a mud discharge door 1.2 is provided at the bottom of the side wall of the box 1. A support frame 2 is provided on the upper surface of the bottom plate of the box body 1, a filter body 3 is provided on the support frame 2, an outlet pipe 4 is provided on the box body 1 below the filter body 3, and a membrane capillary is provided on the filter body 3 The filter device 5 is provided with a compressed air inlet port 6 on the box body 1 above the membrane capillary filter device 5. The membrane capillary filter device 5 includes a support cylinder 5.1 and a tubular filter cloth 5.2, and a cylinder top of the support cylinder 5.1 Closed, the bottom of the support cylinder 5.1 is a filter screen 5.5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com