Straight fin for coke oven ascending pipe raw coke oven gas waste heat recycling and heat taking device and heat taking device

A waste heat recovery and raw gas technology, which is applied in the coke oven rising tube waste heat boiler power generation device, coke oven rising tube raw gas waste heat recovery heat extraction device with straight fins, coke oven rising tube waste gas waste heat recovery heat recovery device field, It can solve problems such as the separation of the straight fin and the wall of the cylinder, the failure of the heat transfer area of the straight fin, and the different expansion conditions, etc., and achieve the effect of low cost, simple structure and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

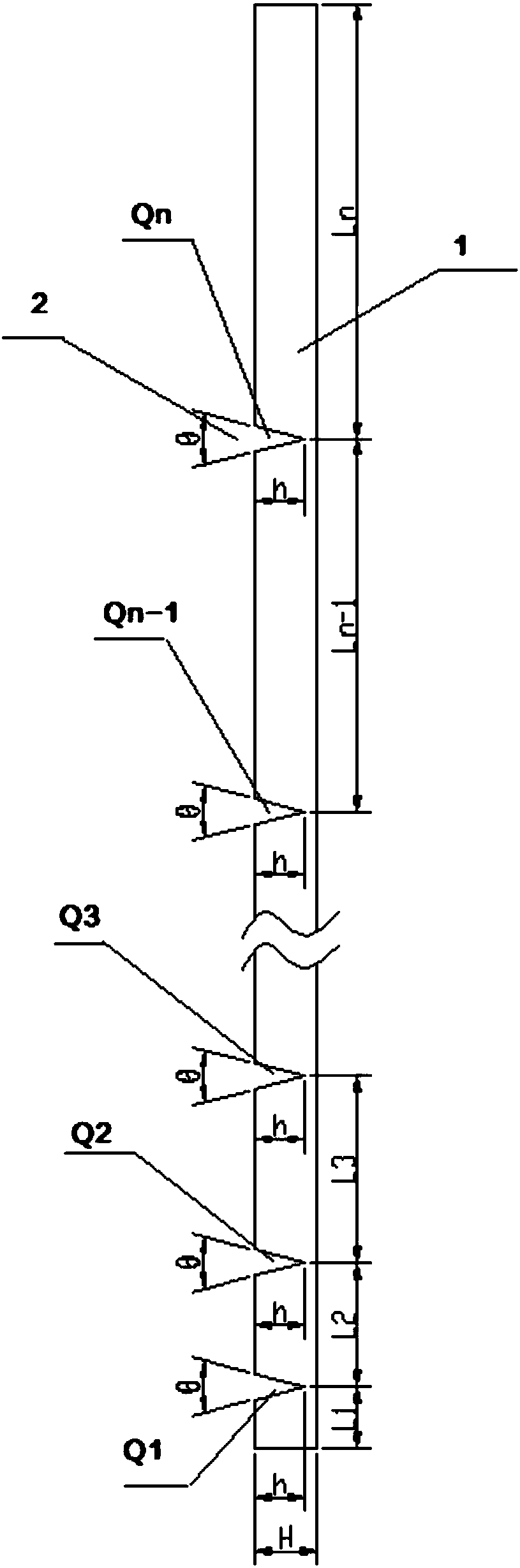

[0028] Straight fins for waste heat recovery device of waste gas in coke oven riser, see figure 1 , including a straight fin body (1) and a group of V-shaped cutouts (2) arranged on the straight fin body (1); the depth h of the V-shaped cutout (2) is smaller than that of the straight fin body (1) Width H; in the longitudinal direction of the straight fin body (1), the distance between adjacent V-shaped cutouts (2) increases from bottom to top.

[0029] In the longitudinal direction of the straight fin body (1), the set of V-shaped cutouts (2) are sequentially numbered Q1 to Qn-1 from bottom to top; the distance from Q1 to the bottom end of the straight fin body (1) is L1, The distance between adjacent V-shaped notches (2) is L2 to Ln-1 from bottom to top, and the distance from Qn-1 to the top is Ln; L1 to Ln form an arithmetic sequence, and optionally, the values of L1 to Ln increase evenly The purpose of the present invention can be achieved.

[0030] The opening angles θ...

Embodiment 2

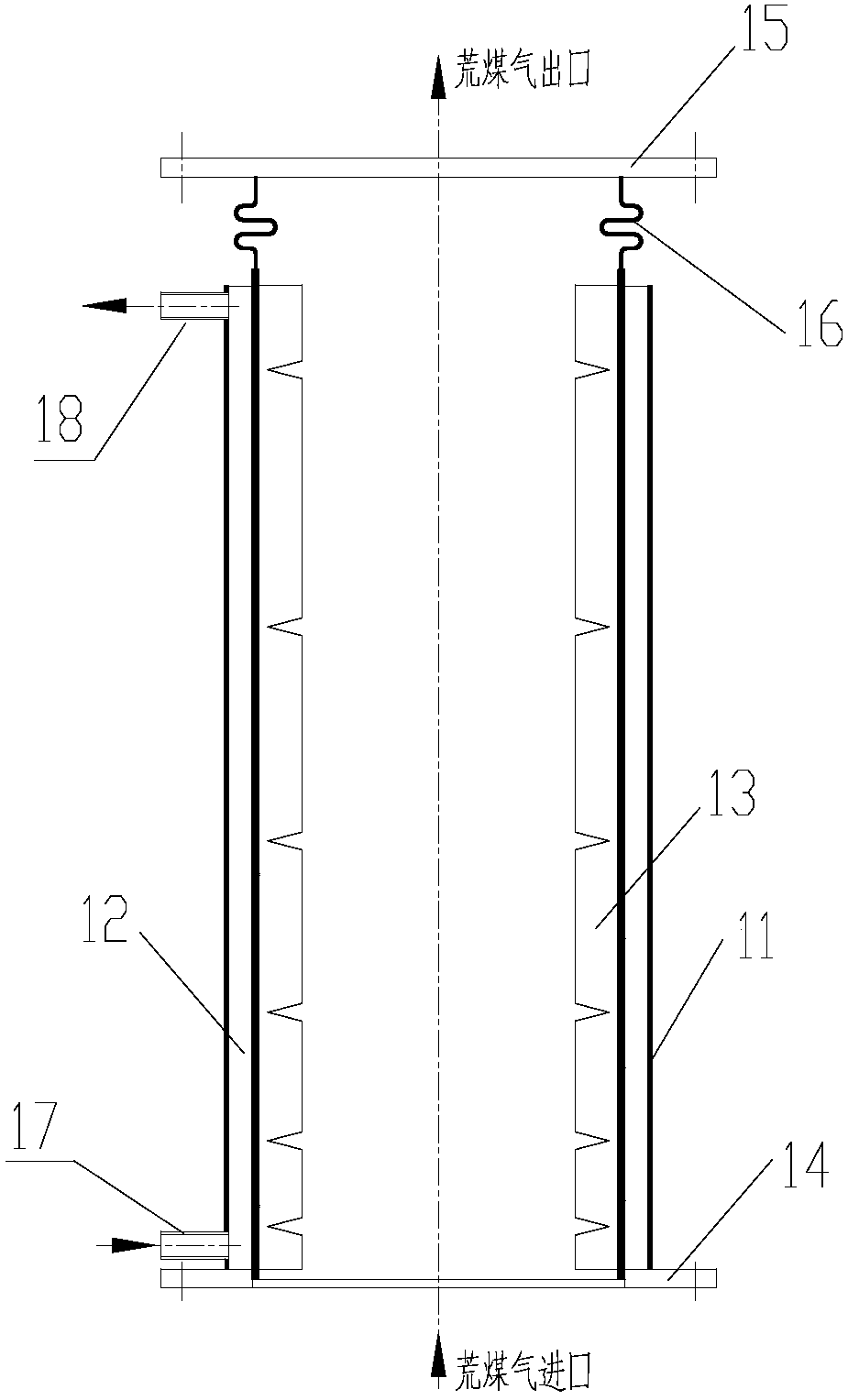

[0036] Coke oven riser waste gas waste heat recovery device, see figure 2, comprising a raw gas pipeline (11), a heat exchange tube (12), a group of straight fins (13) of embodiment 1; the heat exchange tube (12) is located on the outer wall of the raw gas pipeline (11); the described A group of straight fins (13) are arranged on the inner wall of the raw gas pipeline (11); the raw gas inlet of the raw gas pipeline (11) is provided with a lower flange (14), and the raw gas outlet is provided with an upper flange (15); the upper part of the raw gas pipeline (11) is provided with an expansion joint (16); the lower part of the heat exchange tube (12) is provided with a heat-taking medium inlet (17), and the upper part is provided with a heat-taking medium outlet (18) .

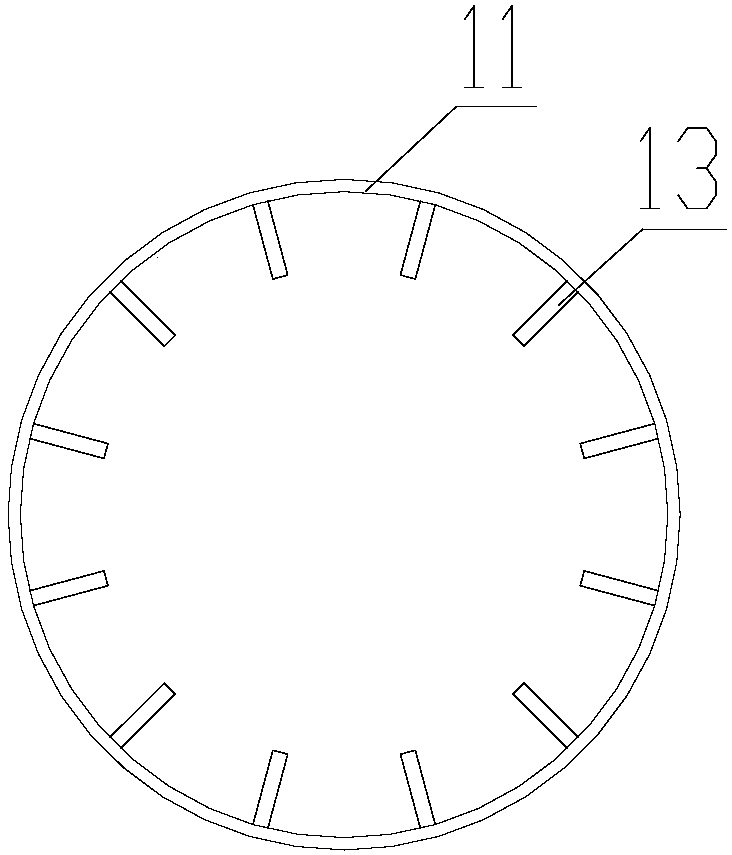

[0037] In the present invention, the set of straight fins (13) are vertically arranged at the same distance along the inner wall of the raw gas pipeline (11), see image 3 Optionally, whether the set of straig...

Embodiment 3

[0043] Coke oven rising tube waste heat boiler power generation device, see Figure 4 , including a waste heat boiler (22), a heat medium pump (23), a steam turbine (24), a water pump (25), a generator (26) and a set of coke oven riser gas waste heat recovery heat recovery device (21 ); the waste heat boiler (22) includes a hot coal pipeline and a steam-water circulation pipeline; The coal pipeline and the heat medium pump (23) are connected in sequence, and the heat medium pump (23) is connected with the heat medium inlet (17) of each coke oven rising pipe raw gas waste heat recovery heat recovery device (21); the waste heat boiler ( The steam-water circulation pipeline of 22), the steam turbine (24) and the water pump (25) are sequentially connected to form a loop; the generator (26) is connected to the steam turbine (24).

[0044] Taking 1.3 million tons / year coking as an example, the raw gas temperature is 800°C. At present, the temperature is lowered to 70°C by spraying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com