200KW rare-earth permanent magnet generator

A rare-earth permanent magnet and generator technology, applied in magnetic circuits, electrical components, electromechanical devices, etc., can solve problems such as reducing the efficiency of motor power generation, and achieve the effects of optimizing armature reflection, reducing demagnetization effects, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

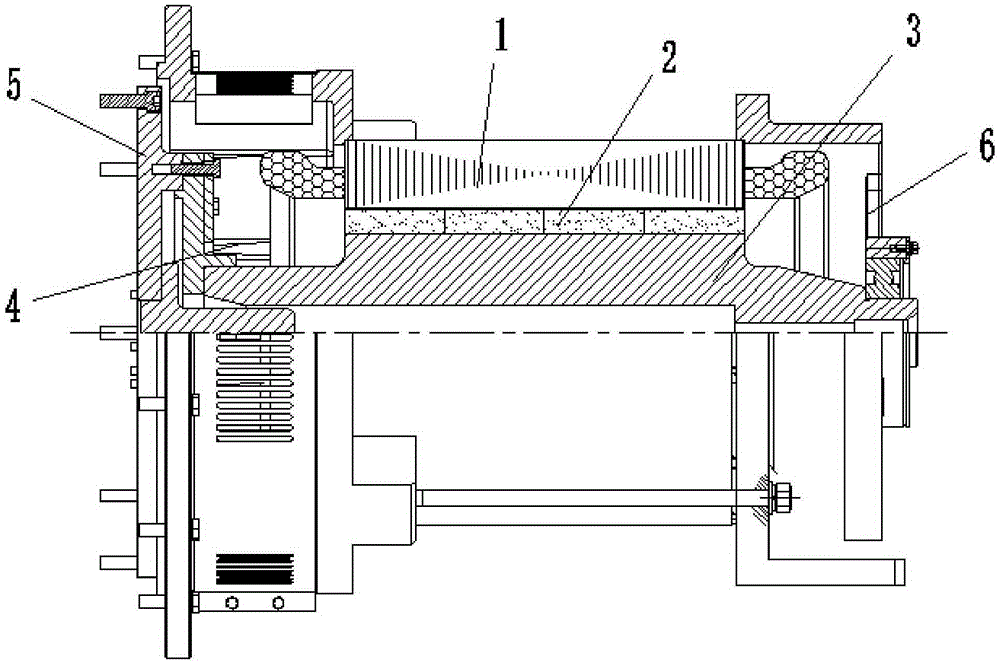

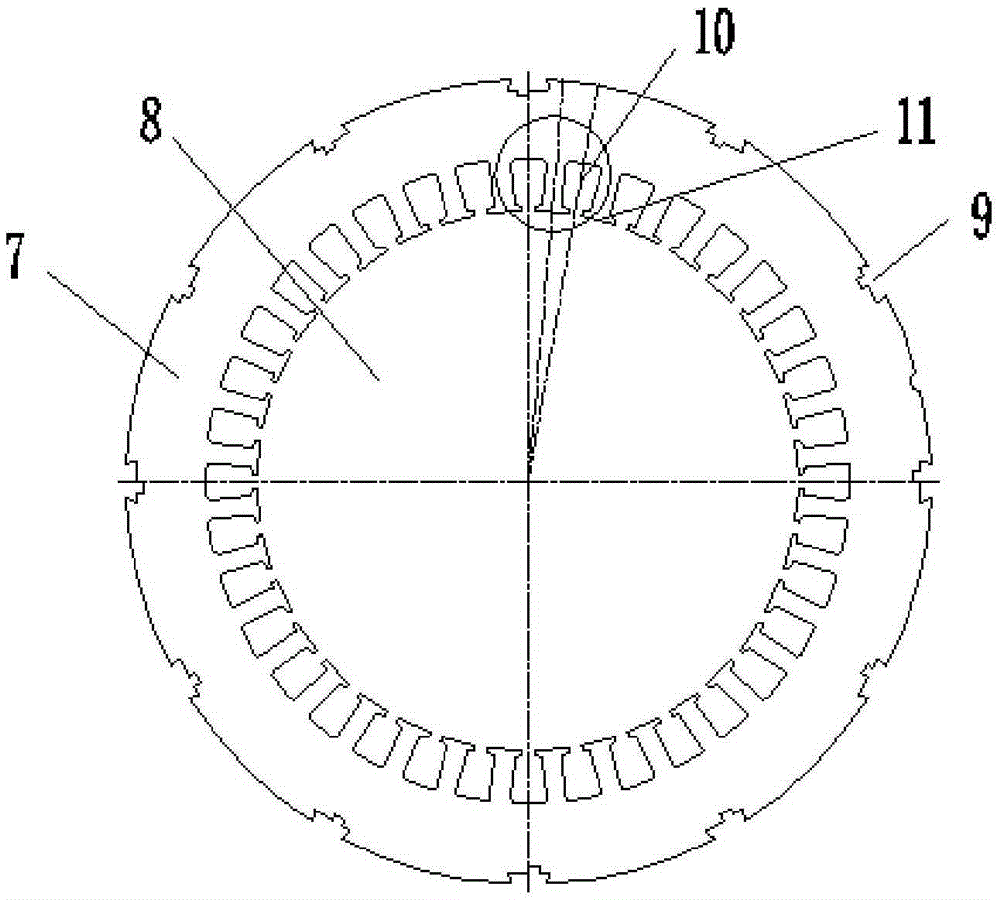

[0017] like figure 1 and figure 2 As shown, a 200KW rare earth permanent magnet generator in the embodiment of this city includes a stator 1, a rotor core 3, a magnetic tile 2, a front end cover 5 and a rear end cover 6, and the magnetic tile 2 uses rare earth NdFeB as a magnetic source body, the stator 1 is composed of several stator punches 7, the middle part of the stator punches 7 is provided with a circular hole 8 matching with the rotor core 3, and the edge of the stator punches 7 is provided with buckle slots 9, There are 36 coil slots 10 evenly distributed on the stator punching sheet 7 of the outer ring of the circular hole 8, the coil slots 10 are T-shaped, the slot width of the coil slots 10 is 6 mm, and a coil slot 10 is formed between adjacent coil slots 10. T-shaped coil teeth 11, the minimum vertical distance between adjacent coil slots 10 is 9mm. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com