A turnout switch machine indication rod fault monitoring system

A technology of fault monitoring and indicating rod, applied in the field of fault monitoring system of indicating rod of switch machine, which can solve the problem that abnormal information cannot be processed in time, cost and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

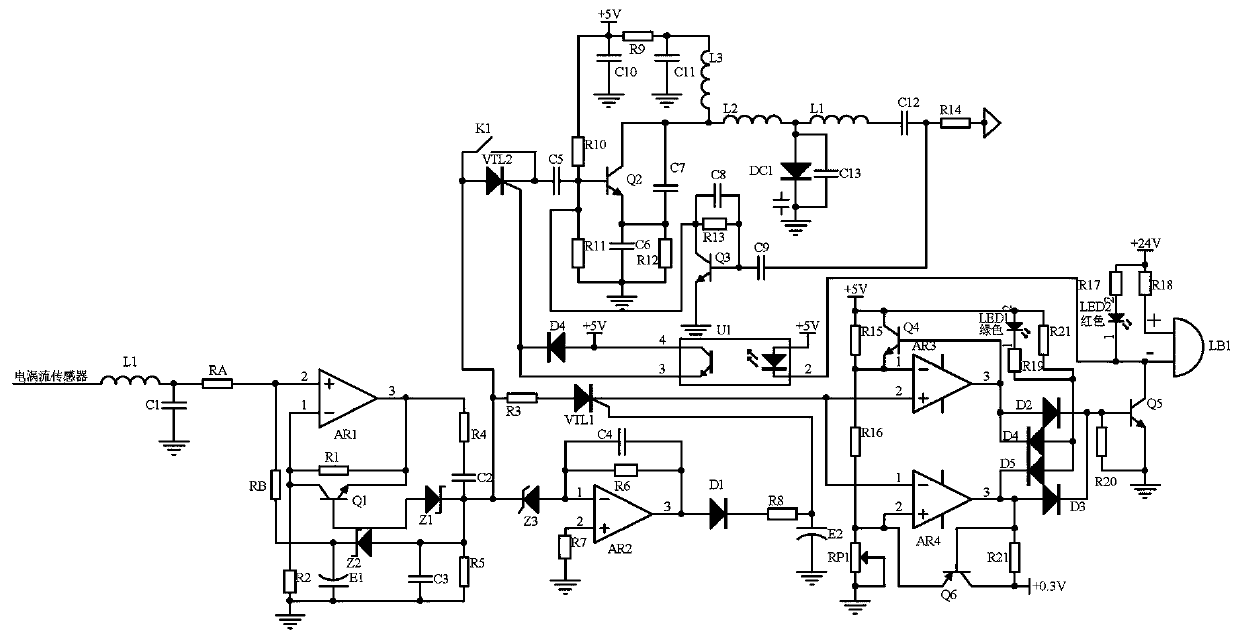

[0012] Embodiment 1, a fault monitoring system for a switch point machine display rod, the voltage corresponding to the gap width signal of the switch point machine display rod detected by the eddy current sensor is processed by the microprocessor module and transmitted to the remote monitoring terminal through the communication module To realize remote monitoring, this application transmits the gap width signal of the turnout switch machine indication rod detected by the eddy current sensor to the remote monitoring terminal after being processed by the signal acquisition unit, the fault discrimination unit, and the signal controllable transmission unit;

[0013] The signal acquisition unit receives the signal of the gap width signal of the turnout switch machine detected by the eddy current sensor. After filtering by LC, it enters the in-phase amplifying circuit composed of operational amplifier AR1, resistor R1, resistor R2, and resistor RA for amplification and conditioning. ...

Embodiment 2

[0014]Embodiment 2, on the basis of Embodiment 1, the signal acquisition unit receives the signal of the gap width signal of the turnout switch machine detected by the eddy current sensor, and after being filtered by the LC filter circuit composed of the inductance L1 and the capacitor C1, it enters the operational amplifier The in-phase amplifier circuit composed of AR1, resistor R1, resistor R2, and resistor RA performs amplification and conditioning. The amplification factor is determined by the resistance values of resistor R1 and resistor RA. The amplified signal is composed of resistor R4, resistor R5, capacitor C2, and capacitor C3. The RC frequency selection circuit selects the frequency, so that the frequency component of the stable DC voltage signal output by the eddy current sensor passes (because the detection module in the prior art only performs half-wave rectification through diode D1 and diode D2, capacitor C5 and capacitor C6 filter , is also the pulsating po...

Embodiment 3

[0015] Embodiment 3, on the basis of Embodiment 1, the fault discrimination unit receives the output signal of the signal acquisition unit, enters the operational amplifier AR3, the transistor Q4, the high threshold voltage (resistance R15, resistance R6, the voltage divider formed by the potentiometer RP1 The hysteresis comparator of the high threshold voltage composed of the circuit provided) judges whether the gap width of the pole is higher than the voltage 2.5+0.8V corresponding to 2+0.5mm, and enters the op amp AR4, transistor Q6, low threshold voltage (resistor R15, resistor R6 , Potentiometer RP1 composed of a voltage divider circuit provided) The low threshold voltage hysteresis comparator judges whether the rod gap width is lower than the voltage 2.5-0.8V corresponding to 2-0.5mm, higher than the low threshold voltage and the low and high thresholds When the voltage is low, the slight interference during high-low level conversion is eliminated, and the two hysteresis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com