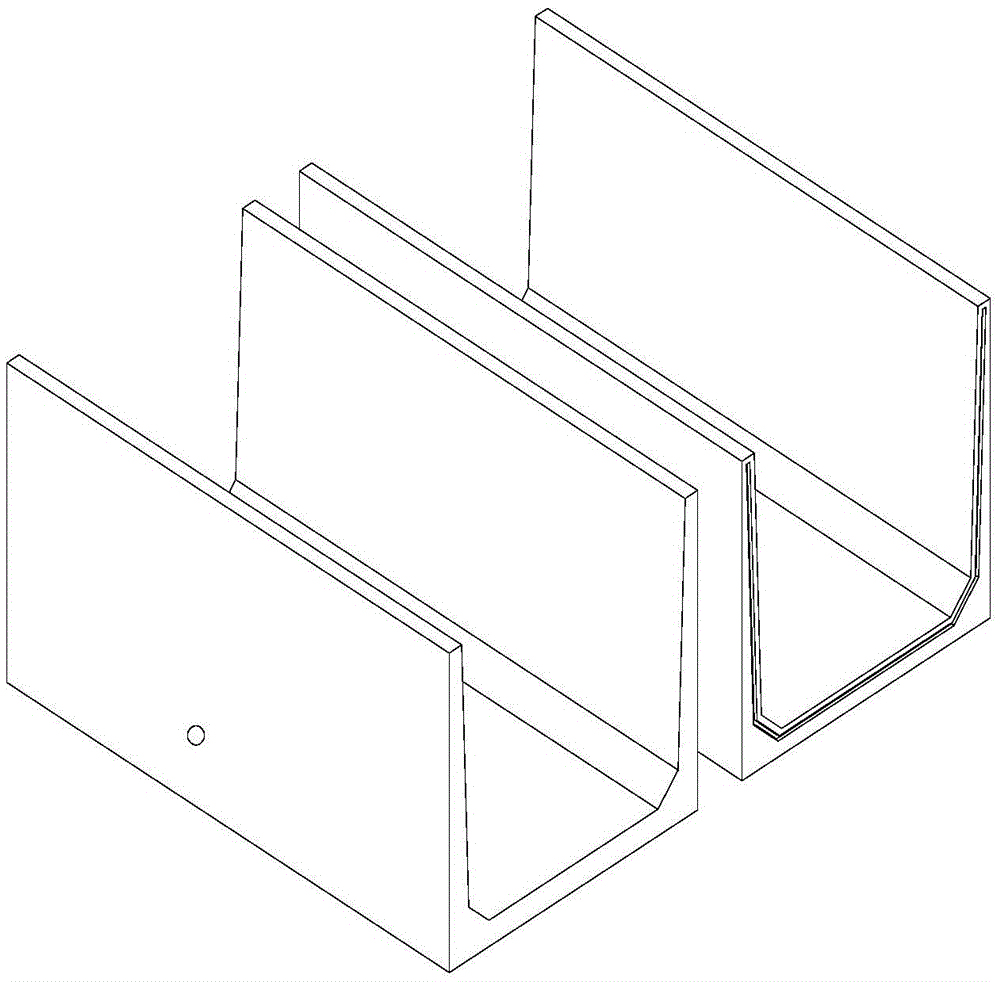

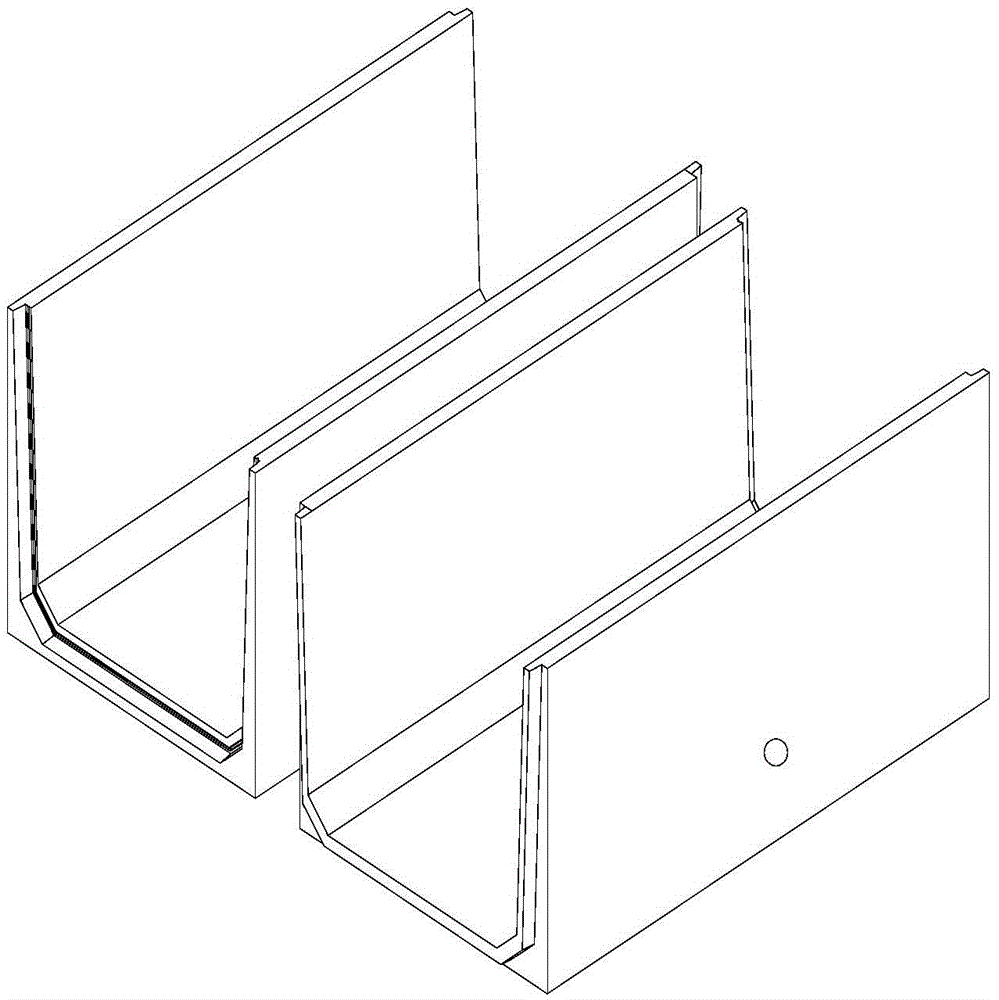

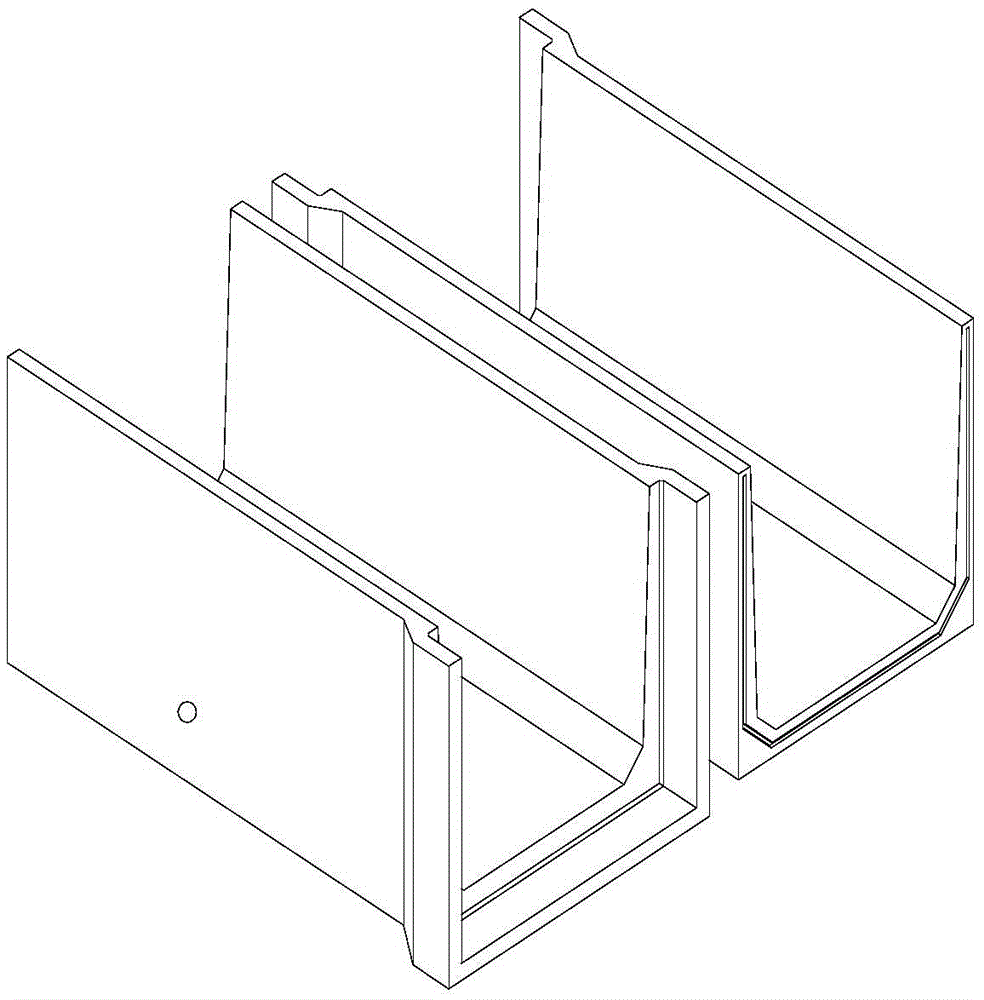

Assembled rectangular reinforced concrete water saving tank

A reinforced concrete, prefabricated technology, applied in soil drainage, irrigation pipes, applications, etc., can solve the problems of concrete cracking, large water flow resistance, energy waste, etc., to avoid cracking, improve strength, and improve the effect of durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

[0037] As shown in the figure: an assembled rectangular reinforced concrete water-saving tank, the outer contour of the cross section of the tank body is rectangular, the inner contour is trapezoidal, the tank wall 1 is a right-angled trapezoidal structure with a narrow top and a wide bottom, the outer side wall is a right-angle side, and the inner side wall It is a hypotenuse, its inclination angle 6 is 3-10°, the connection between the outer wall of the groove and the bottom 2 of the groove is a right angle; the connection between the inner wall of the groove and the bottom 2 of the groove adopts chamfering (r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com