Dual-power mechanically-balanced notching and cutting method and multifunctional notching machine

A technology of mechanical balance and slotting machine, which is applied in the direction of metal processing, etc. It can solve the problems of large mechanical force, unsafe use, and uncontrollable hands, so as to improve power, operate more stably and safely, and avoid labor-intensive problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

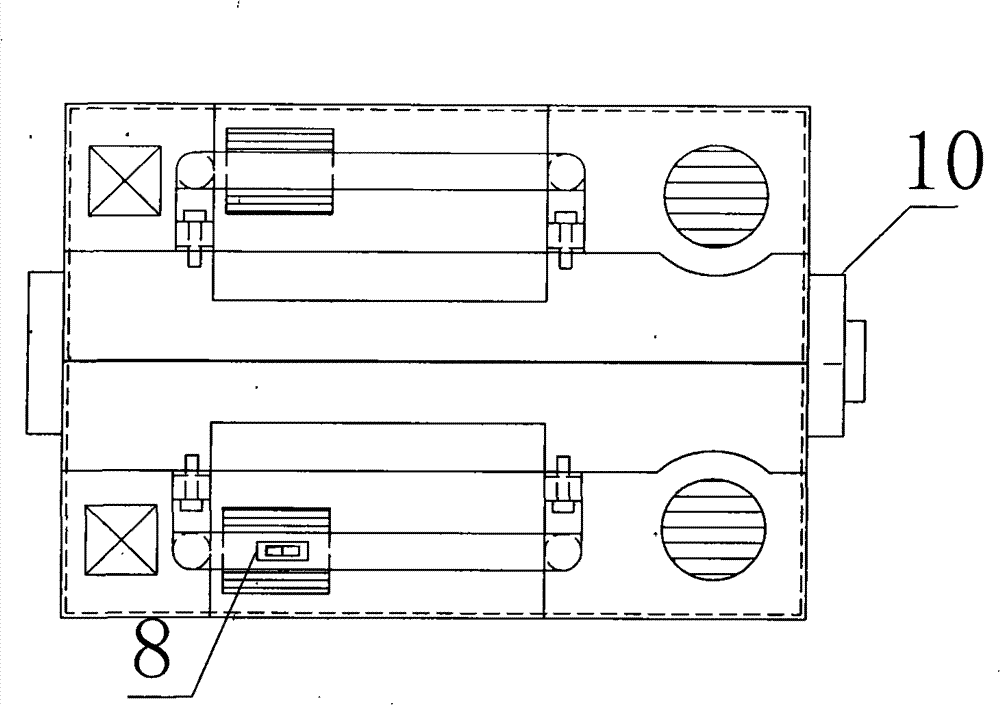

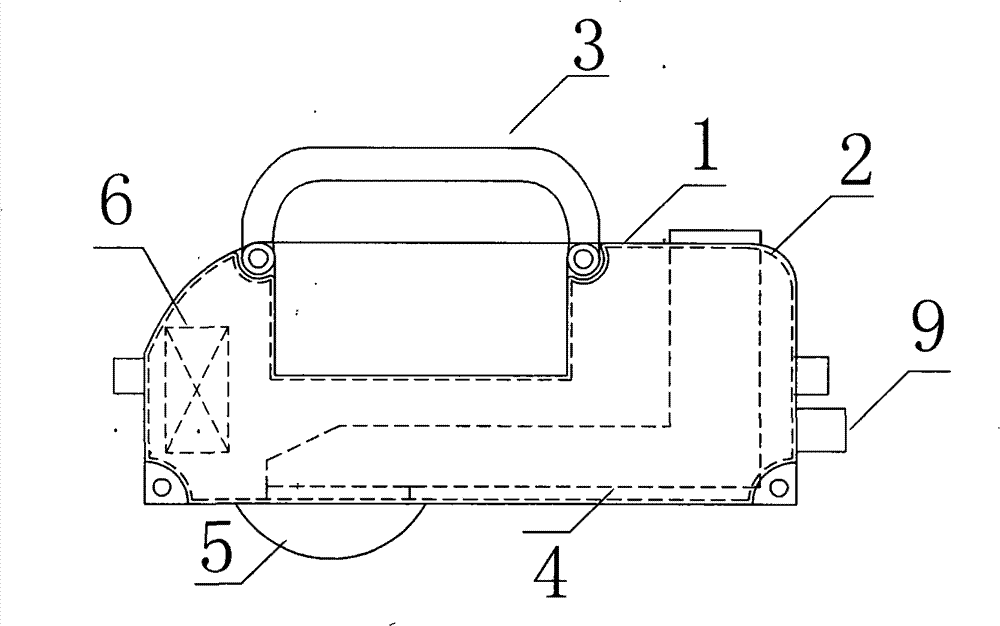

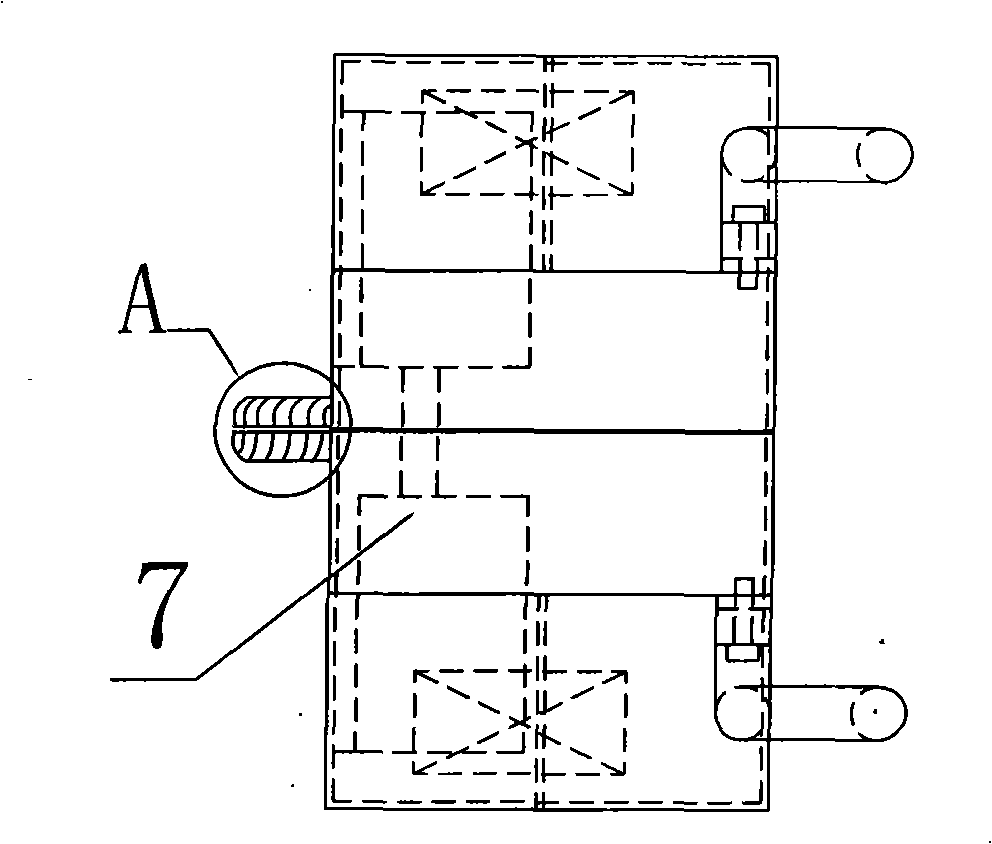

[0021] attached figure 1 , each digital part in 2,3,4 is as follows:

[0022] 1 Body (2); 2. Case (2); 3. Handle (2); 4. Motor (2); 5. Knife (2); 6. Lifting mechanism (2) ; 7, speed change mechanism (2 pieces); 8, power switch (1 piece); 9, ash collection port (1 piece); 10, lock buckle (respectively 1 piece before and after), wherein the parts with 2 pieces are all For the sake of simplicity, only one symmetrical part is marked in the figure. Ventilation louvers are provided in the casing 2 .

[0023] The method of the present invention simply means that there are two powers in one machine, each power has a cutter, each works independently, the cutter rotates one forward and one reverse, and slots at the same time. Groove width. Any power form can be adopted, and the multifunctional slotting machine of the present invention adopting the above-mentioned method uses a motor as power.

[0024] Such as figure 1 , 2, 3, the motor 4 is fixed on the body 1, the casing 2 firmly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com