Stator core for an electric machine

A technology of stator core and generator, applied in the field of stator core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

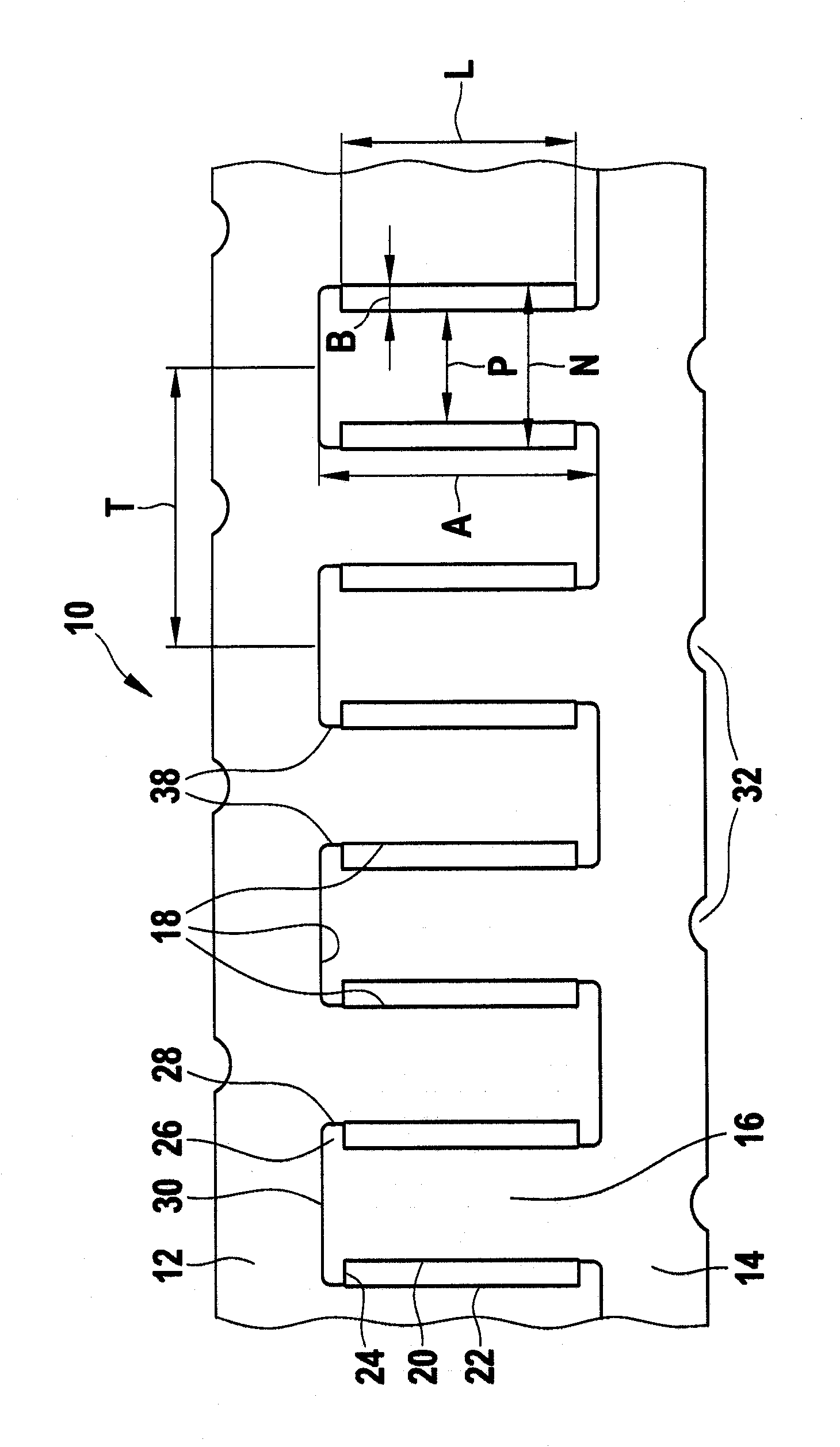

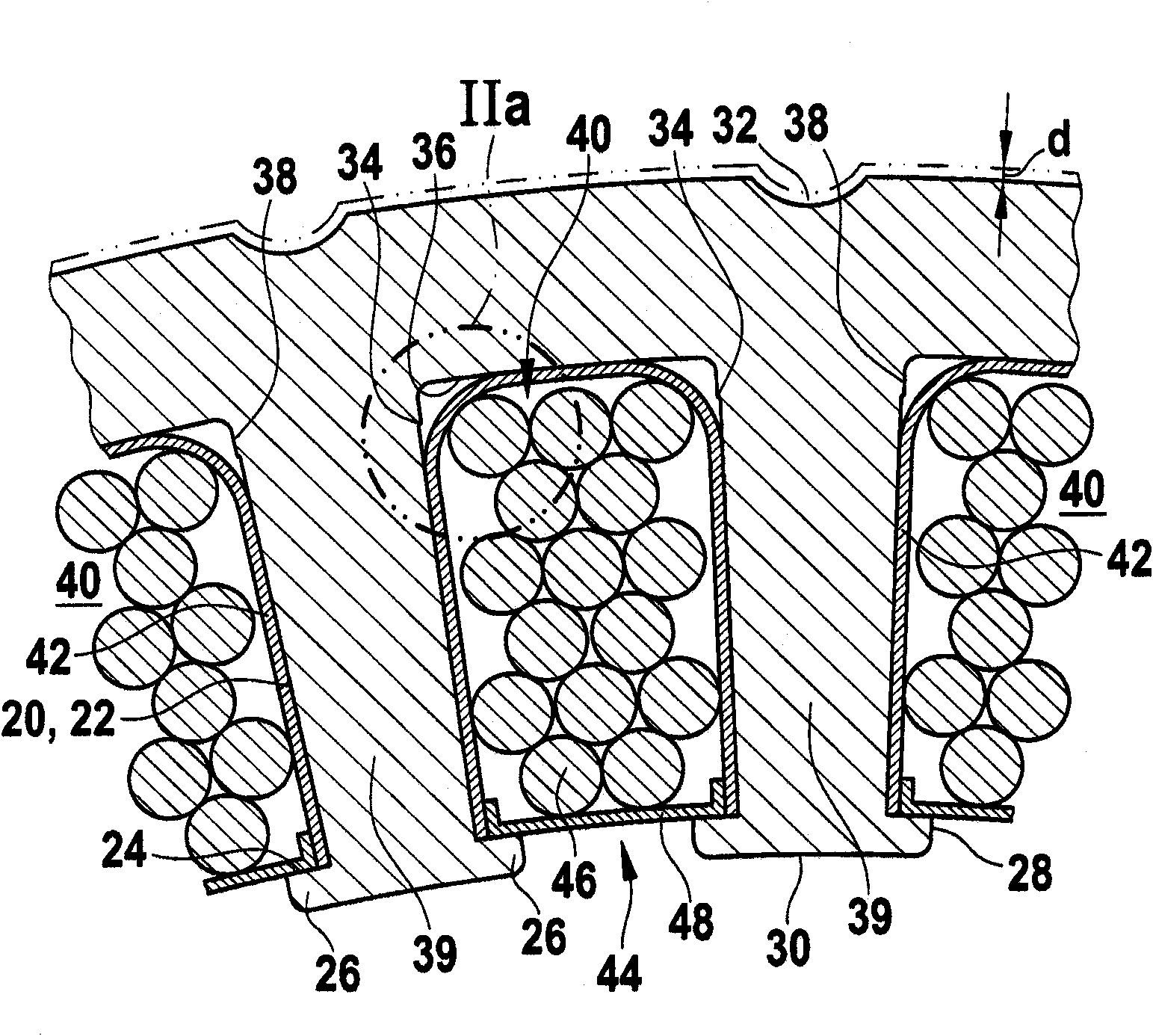

[0013] exist figure 1 10 denotes a strip made of electrical steel sheet which is partly stamped and partly cut into two intermeshing individual strips 12 and 14 . The strip 10 consists of a soft-magnetic electrical steel sheet suitable for the production of stator cores, such as is defined, for example, in DIN 46400 and is known in principle. The important principles of this steel sheet are the coercive magnetic field strength below 1000A / m, suitable alloy additions (especially Si, Ni, Co, Mo and other alloy additions) and special treatment processes such as hot rolling or cold rolling rolling, thereby obtaining advantageous soft magnetic properties on the one hand and favorable processing conditions on the other hand.

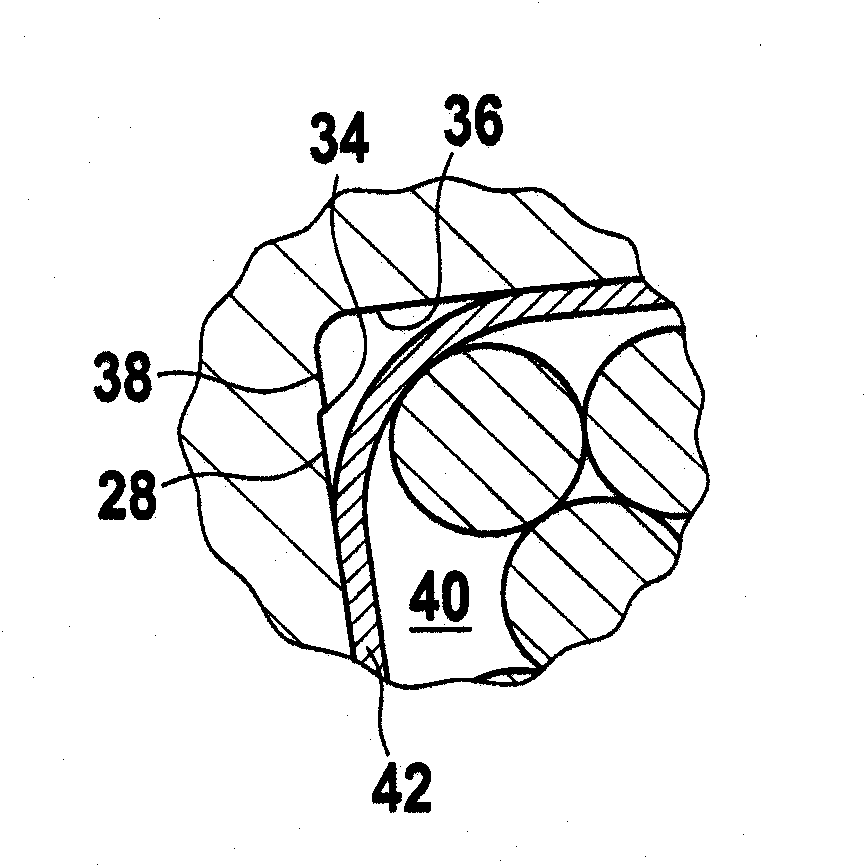

[0014] Through the separation process of the strip 10 , mirror-image individual strips engaging with each other are produced as lamellae 12 and 14 , which have pole-shaped elevations 16 and groove-shaped recesses 18 . In this case, the separation is carried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com