Metal material with improved low-temperature property and method for manufacturing same

A technology for metal materials and low-temperature characteristics, which is applied in the field of metal materials and their manufacturing to improve low-temperature characteristics, can solve the problems of simultaneously increasing strength and fracture toughness limitations, increasing manufacturing costs, and reducing applicability, so as to achieve high cost and improve low-temperature characteristics , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

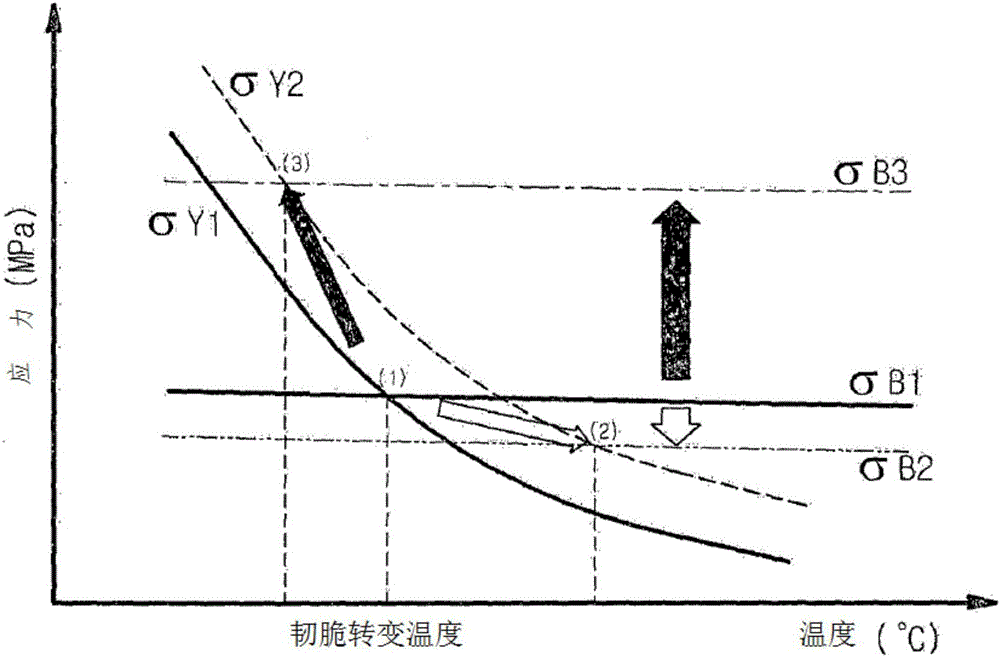

[0043] figure 1 It is a graph for explaining the temperature-stress of the ductile-brittle transition according to an embodiment of the present invention.

[0044] Generally, if the metal material is compressed by cold rolling or cold forging, then the figure 1 In the temperature-stress diagram shown, the yield strength curve moves to the right (σY1→σY2), the brittle strength line moves downwards (σB1→σB2), and the ductile-brittle transition temperature (DBTT; ductile-brittle transition temperature) ) Move from location (1) to location (2) and increase.

[0045] However, according to an embodiment of the present invention, the metal material with improved low-temperature characteristics, figure 1 As the yield strength curve shown moves to the right (σY1→σY2), the brittle strength line moves sharply upward (σB1→σB3), and the deflection-brittle transition temperature (DBTT) moves from point (1) to specific point (1). ) Moves to a low-temperature location (3), so that the strength and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com