Sectional steel with concave-convex grooves at corner parts and inside connection combination post thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

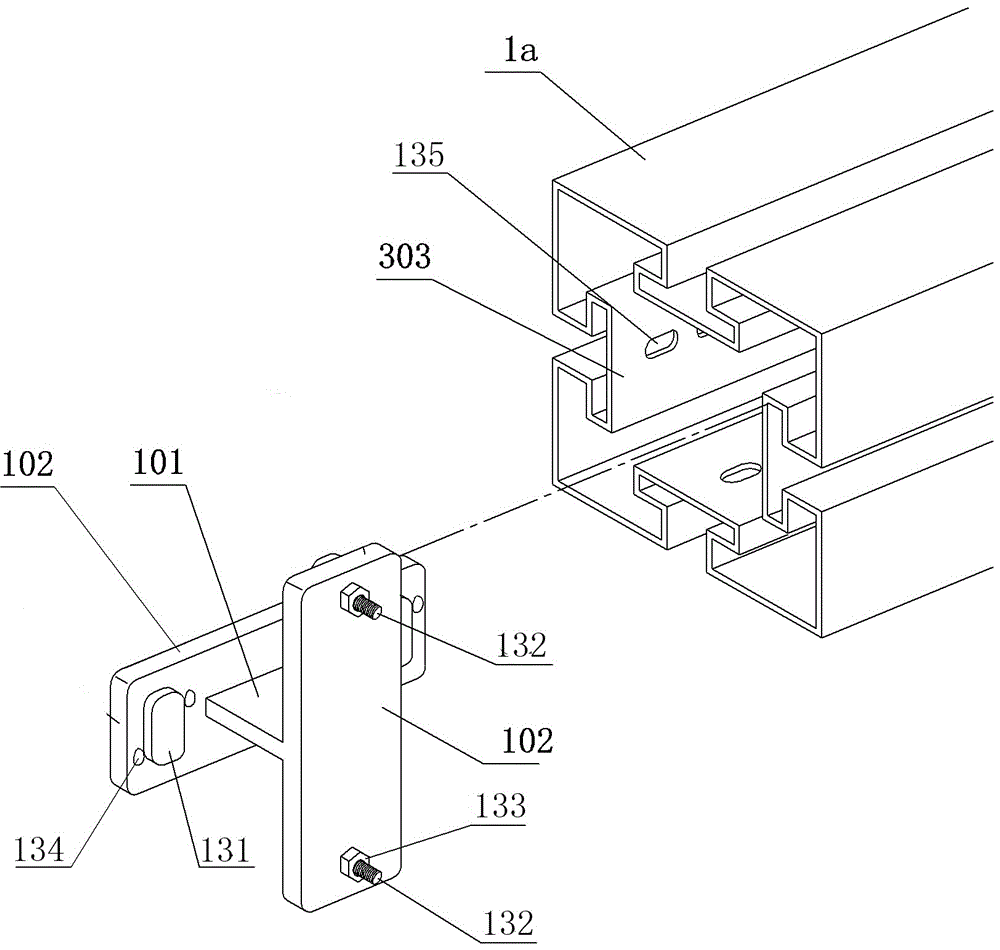

[0036] Embodiment 1: A kind of concave-convex channel steel at the corner, see figure 2 , bend the steel plate to enclose the four sides of the rectangular tube, and set a top corner as a bevel. At least one of the top corners is provided with a connecting weld of the steel plate. A concave notch formed by bending is provided on the inclined surface, and an internal slideway formed by bending in the same direction as the notch but wider than the width of the notch is arranged inside the notch; the notch includes two parts connected with the inclined surface The side of a notch; the internal slideway is a rectangular slideway, including two sideways of the slideway connected together, a bottom surface of a slideway and the top of two slideways; connect.

[0037] At the same time, in this embodiment, the other sides of the square tube are provided with a concave notch formed by bending, and an internal slide formed by bending in the same direction as the notch but with a widt...

Embodiment 2

[0038] Example 2: see Figure 4 and Figure 5 , On the basis of Example 1, a layer of cold-formed corrugated board can also be compounded and fixed on the bottom surface of the inner slideway. The cross section of the corrugation is a square corrugation, or a zigzag corrugation, or a curved corrugation.

Embodiment 3

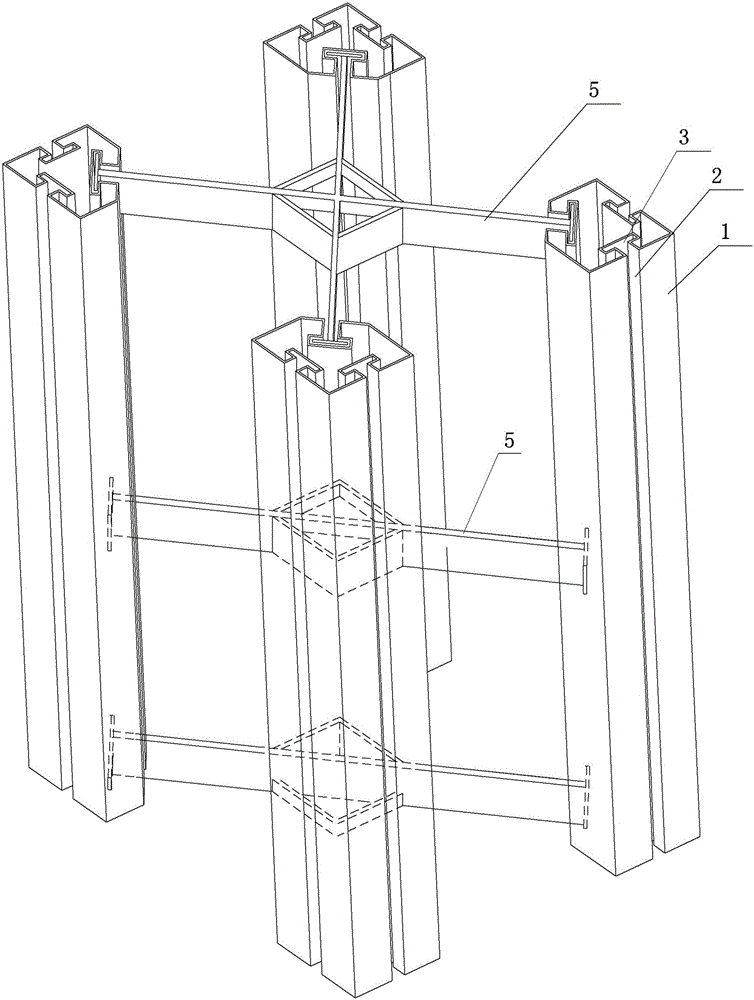

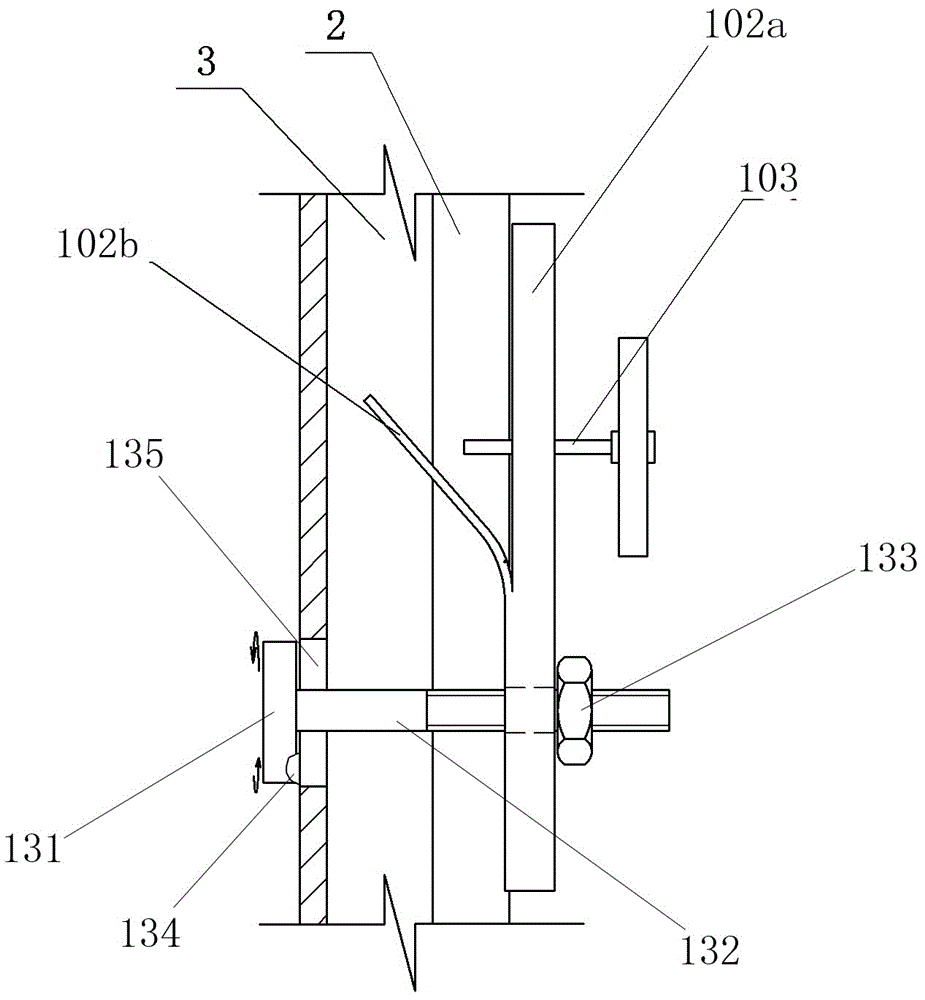

[0039] Embodiment 3: An internal fork-shaped connection composite column with concave-convex grooved steel at the corner, see Figure 1-Figure 4 , set four corners as described in embodiment 1 with concave-convex channel steel, the slope of each corner with concave-convex channel steel is on the inside, fixed together by connecting rods, the two ends of the connecting rods are respectively vertically connected with inner sleeves The symmetrical outer side of each inner cover plate is respectively inwardly cut, and the cut divides the edge of the inner cover plate into two parts: the inner plate and the outer plate; the cuts of the two inner cover plates are perpendicular to each other, and the inner plate Screw holes are arranged on the top and adjusting bolts are installed, and the end faces of the adjusting bolts are in contact with the inner surface of the outer plate. The middle parts of the connecting rods are combined into one through the connection of reinforcing rods. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com