Magnetic core of motor and manufacturing method of magnetic core

A manufacturing method and manufacturing method technology, applied in the direction of inductance/transformer/magnet manufacturing, magnetic core/yoke manufacturing, motor generator manufacturing, etc., which can solve the problems of large opening of the winding slot of the motor magnetic core and limitation of the length of the tooth crown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

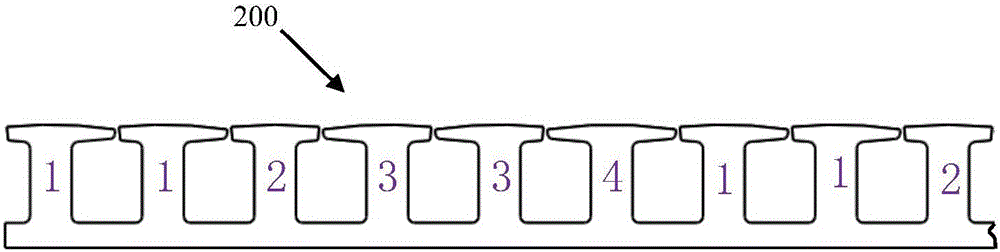

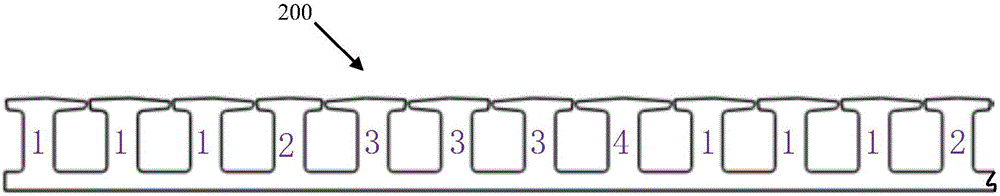

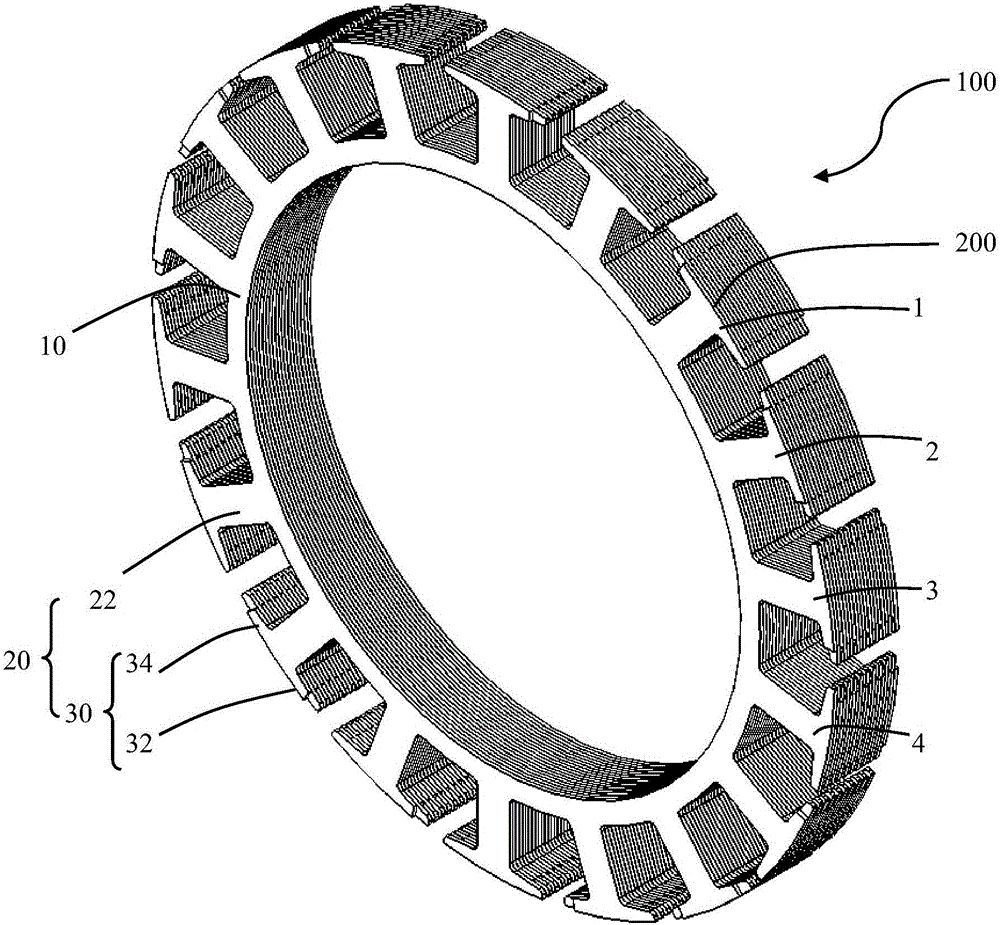

[0056] refer to figure 1 and figure 2 , an embodiment of the present invention provides a motor core 100, including an annular yoke 10, a tooth 20 protruding from the yoke 10, and a tooth extending circumferentially from the end of the tooth body 22 of the tooth 20. Crown 30. The tooth crown 30 of each tooth portion 20 includes a left half tooth crown 32 and a right half tooth crown 34, and the dimensions of the left half tooth crown 32 and the right half tooth crown 34 along the circumferential direction of the yoke 10 are respectively referred to as the left half tooth crown. length, the length of the right half crown. The motor magnetic core 100 is composed of several layers of chips 200 (see figure 2 ) superimposed. The motor magnetic core 100 is made of magnetically permeable material, preferably an iron core.

[0057] refer to figure 2 and image 3 , figure 2 The first layer of chips is formed by cutting off the second half of the last tooth set on the basis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com