Cross-shaped stirring drilling machine

A cross-mixing and drilling rig technology is applied in drilling equipment, earth-moving drilling, driving devices for drilling in wellbore, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

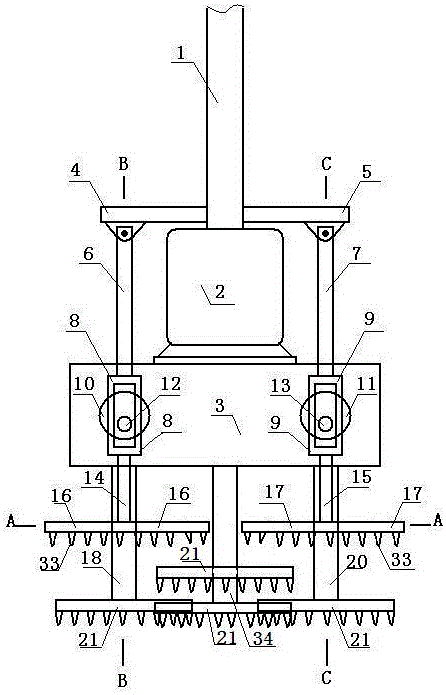

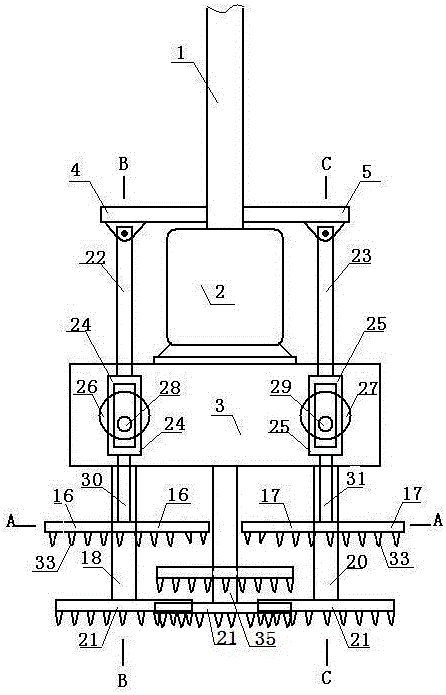

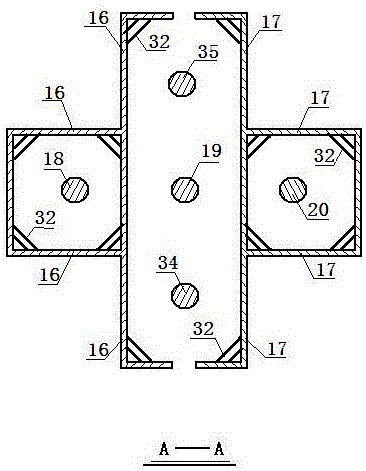

[0015] Accompanying drawing is a kind of specific embodiment of the present invention, and the fixed motor 2 upper end of this embodiment pressurizing rod 1 lower end, motor lower end is provided with total actuator 3, and total actuator lower end is provided with drilling rod one 18, drilling rod two 19. Three drilling rods 20, four drilling rods 34, and five drilling rods 35; five drilling rods are arranged in a cross, and a drill stirring head 21 is provided at the lower end of each drilling rod; and the left end of the support rod two are respectively fixed on the pressure rod; the front left part of the total actuator is provided with a wheel-10, and the wheel-one is eccentrically fixed on the horizontal axis-12, and the horizontal axis-one is inserted in the rectangular shape of the box one-8 In the middle hole, the upper end of the square frame one is fixed with the upper swing arm one 6, the upper end of the upper swing arm one hinges the left front part of the strut on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com