Punching die for clamping teeth of cup lid

A cup cover and stamping die technology, applied in the stamping die field, can solve the problem of insufficient clamping allowance between the inverted teeth and the cup rim, and achieve the effect of reasonable structure of the die and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

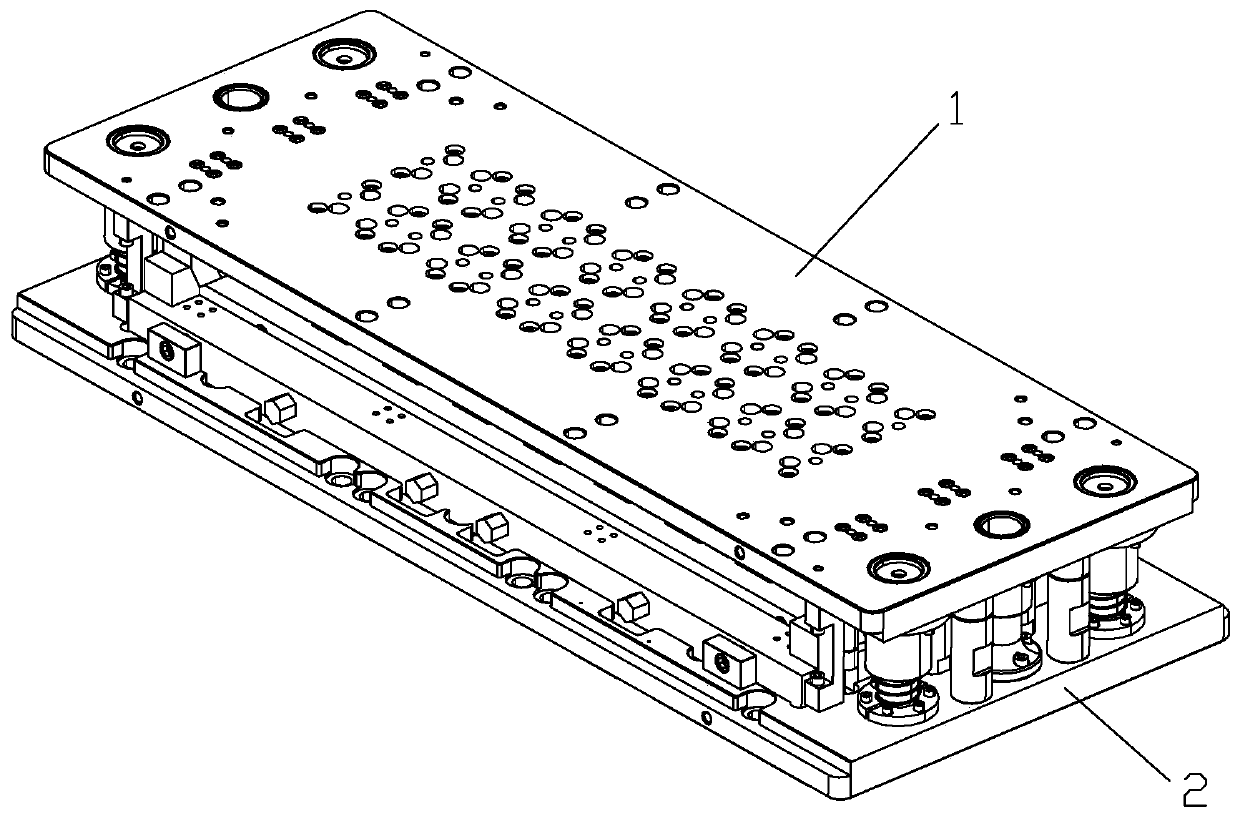

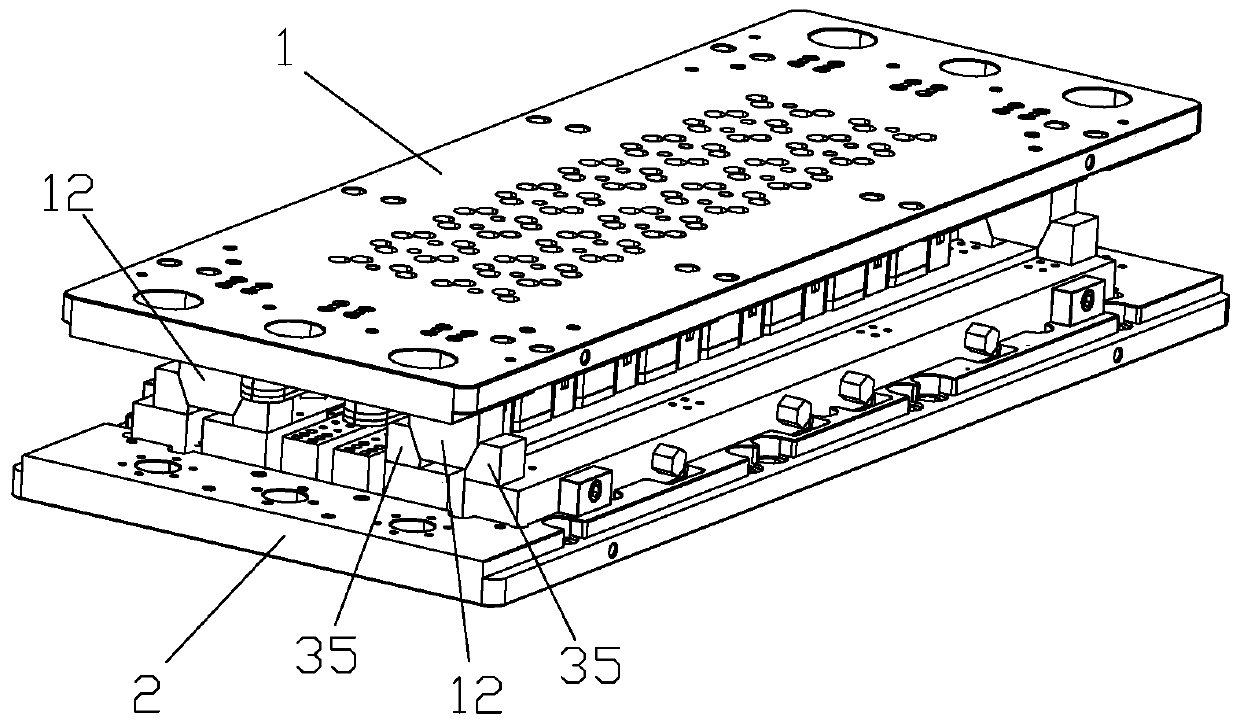

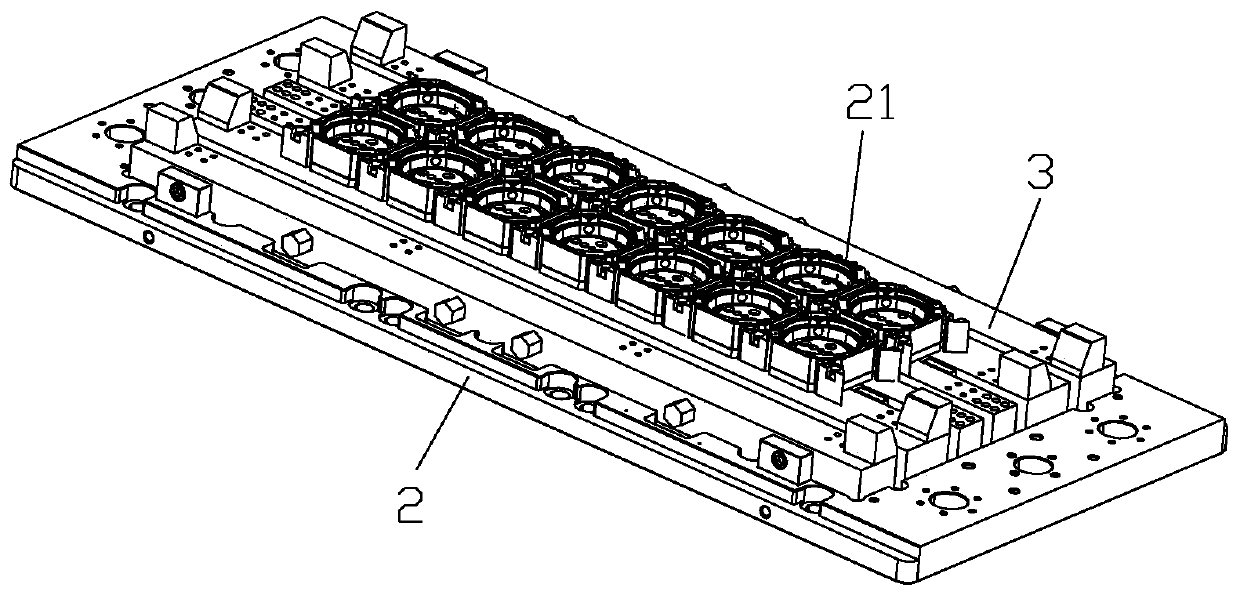

[0028] Such as Figure 1-11 As shown, a stamping die for a cup cover includes an upper template 1 and a lower template 2, the upper and lower mold groups are matched by guide posts and guide post sleeves, and several cores or pressure plates are arranged on the upper template 1 11. A number of cavities 21 corresponding to the cores or pressure plates are set on the lower template 2. The cavities 21 are arranged in one or several groups in a straight line, and slide plates are arranged on both sides of each group of cavities 21 arranged in a straight line. 3. A clamping push structure is provided between the slide plate 3 and the upper template, and the slide plate 3 is set on the lower template 2 through the guide rail 61 and the slider 62; the slide plate 3 is provided with a push block 30; the cavity 21 There is a guide groove 22 on the outside corresponding to the position of the push block 30, and a gap 23 is opened at the position corresponding to the guide groove 22 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com