Patents

Literature

30results about How to "Meet flexible needs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

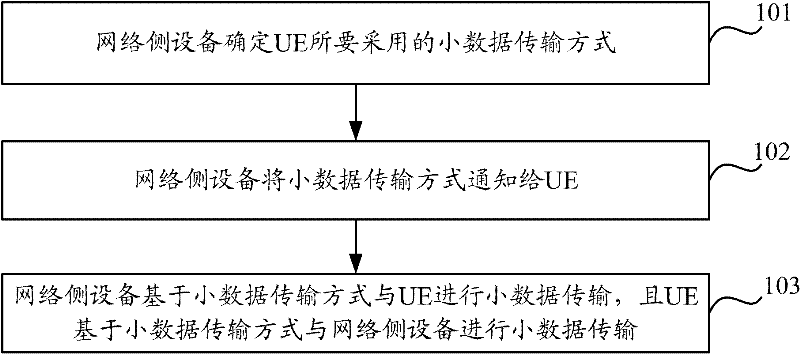

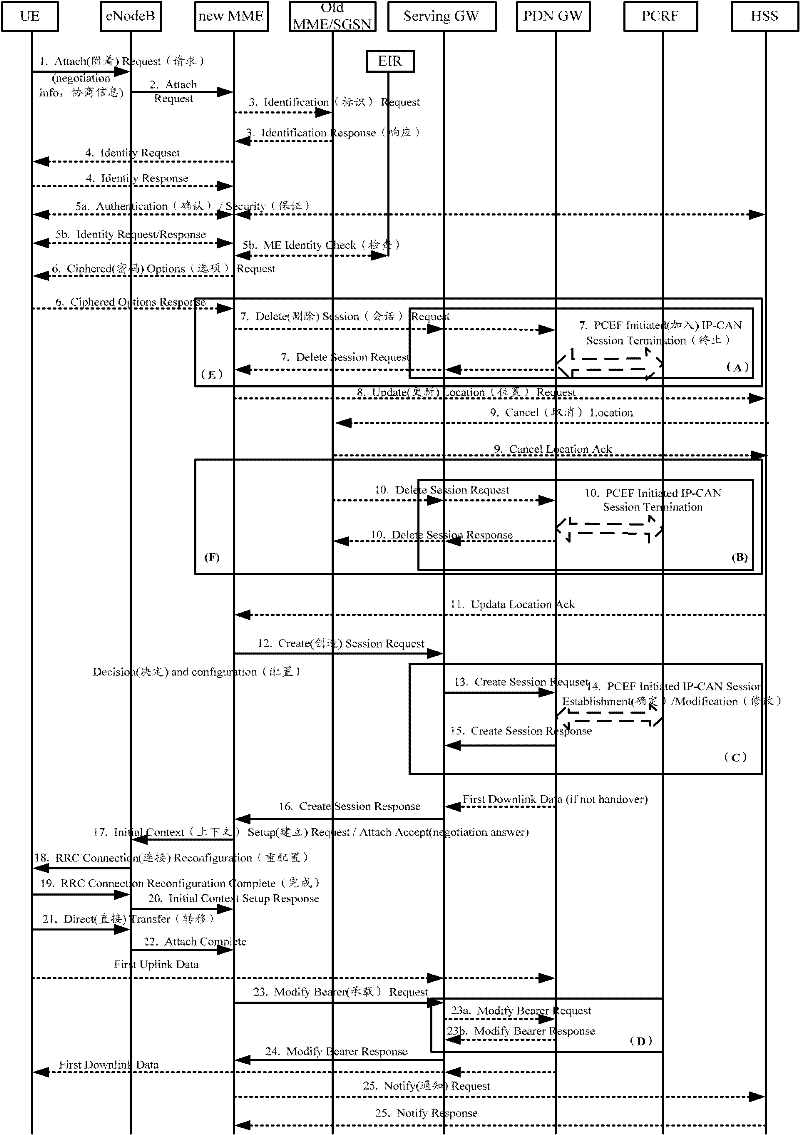

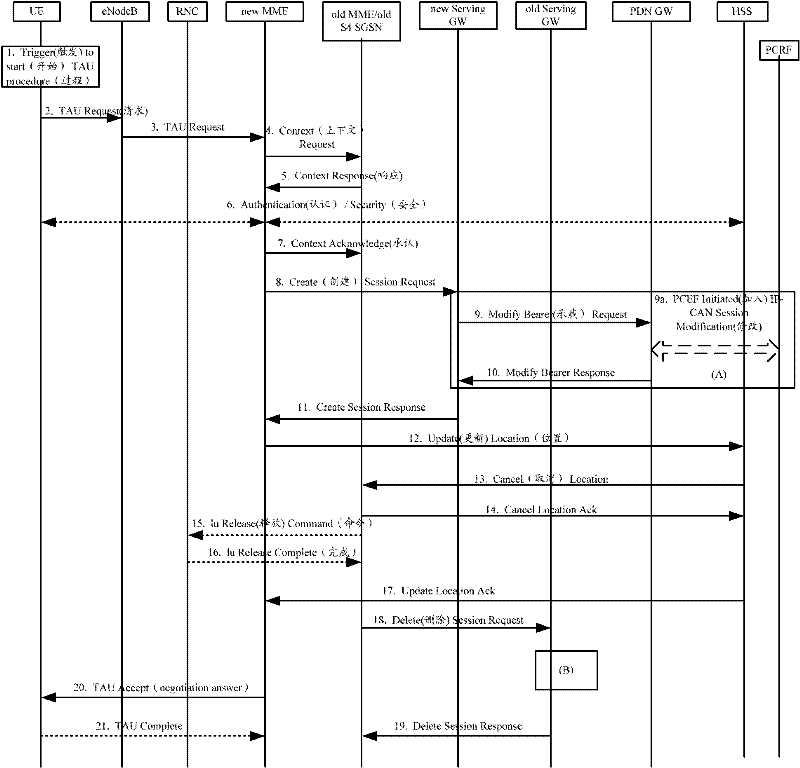

A small data transmission method and device

InactiveCN102271367AMeet the needs of transmissionMeet flexible needsNetwork traffic/resource managementSmall dataData transmission

The present invention discloses a small data transmission method and equipment. The method comprises: a network side device determines a small data transmission mode to be adopted by a user equipment; the network side device notifies the user equipment of the small data transmission mode ; The network side device performs small data transmission with the user equipment based on the small data transmission mode. In the embodiment of the present invention, a method for negotiating a small data transmission mode between the UE and the network side is proposed to meet the needs of small data transmission; and the existing processes and messages can be reused as much as possible, thereby simplifying the configuration of the operator. Meet users' flexible needs for small data transmission methods.

Owner:CHINA ACAD OF TELECOMM TECH

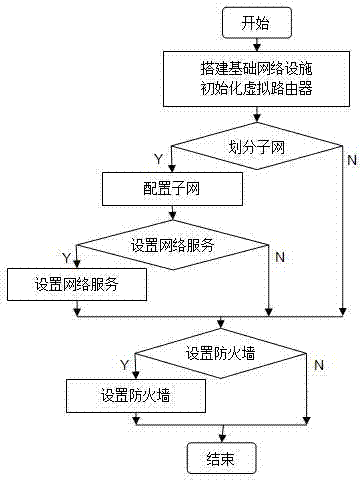

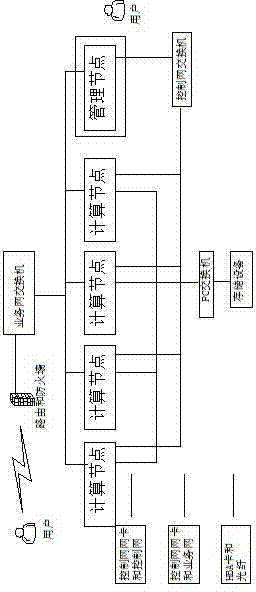

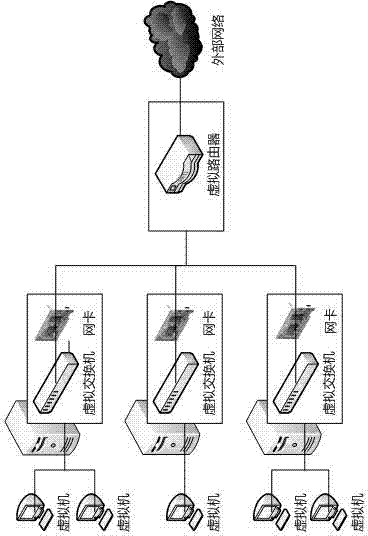

Cloud data center network deployment scheme based on virtual router

InactiveCN103595772AFlexible configurationNumber of flexible optionsData switching networksEngineeringNetwork management

The invention provides a cloud data center network deployment scheme based on a virtual router. By introducing the concept of a virtual exchanger and the virtual router which are independently developed, the network concept from the physics aspect is abstracted to the virtual aspect so that unified management can be carried out by webmasters conveniently and the network expense can be saved. The scheme includes the steps that firstly, a basic network environment is built; secondly, the virtual exchanger and the virtual router are deployed; thirdly, subnetting is carried out; fourthly, network services are configured, a network is scientifically partitioned into an external network, an internal network and a route network by in-depth investigation and research on network requirements of customers, and different levels of deployment schemes are made according to different network classifications. Flexibility requirements of customers are better met, at the same time, classified and hierarchical network management is achieved, deployment is more scientific and concise and management is facilitated.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

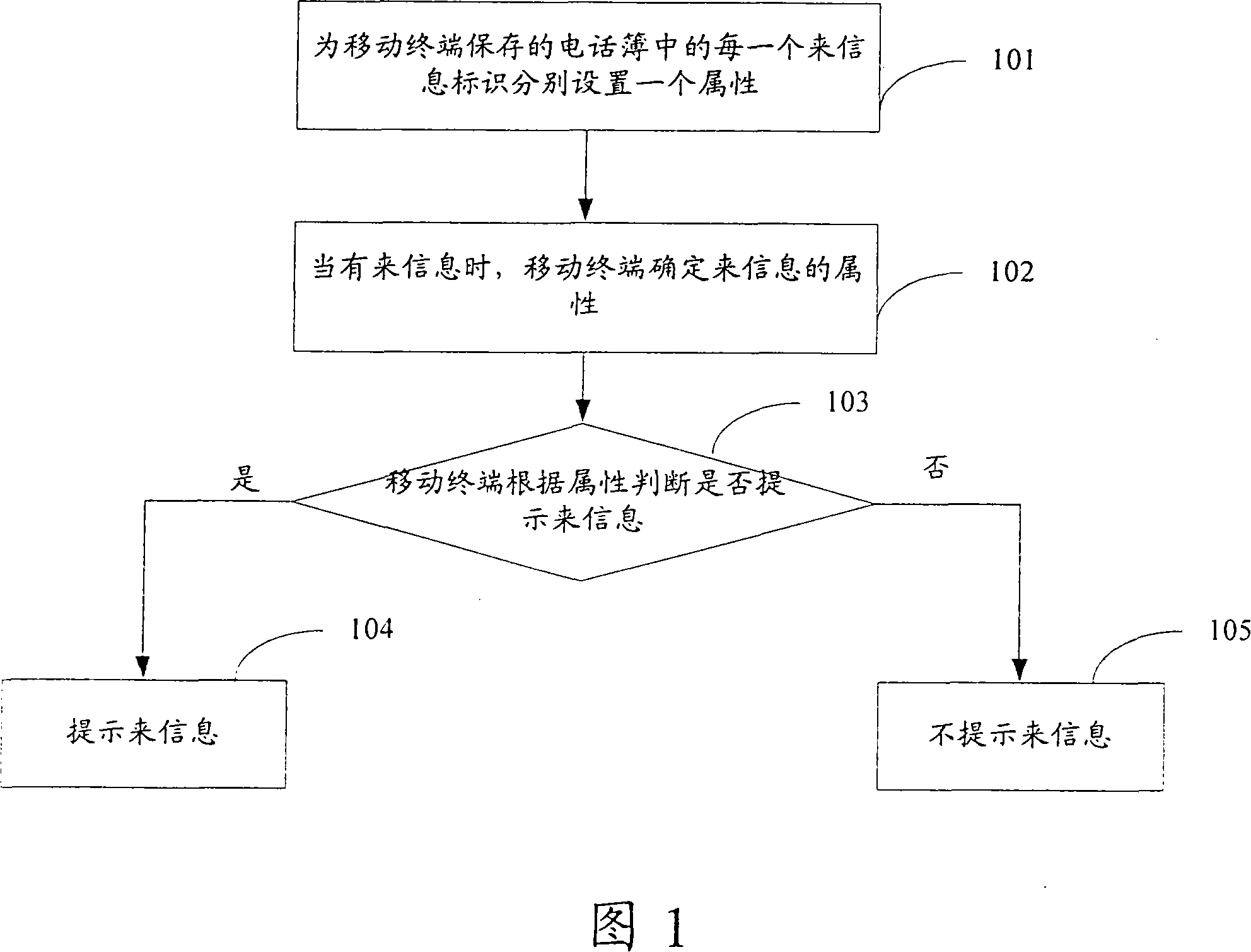

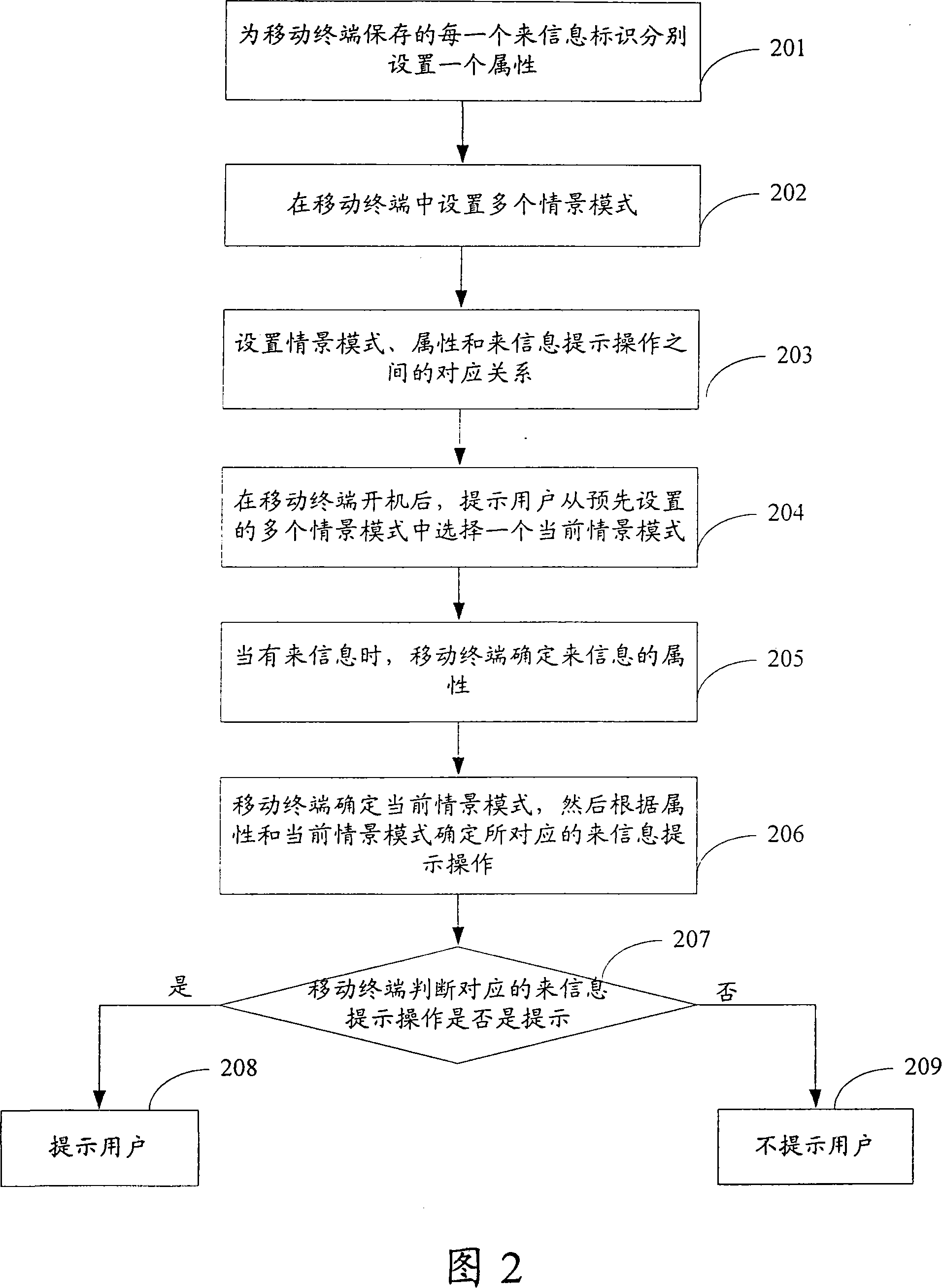

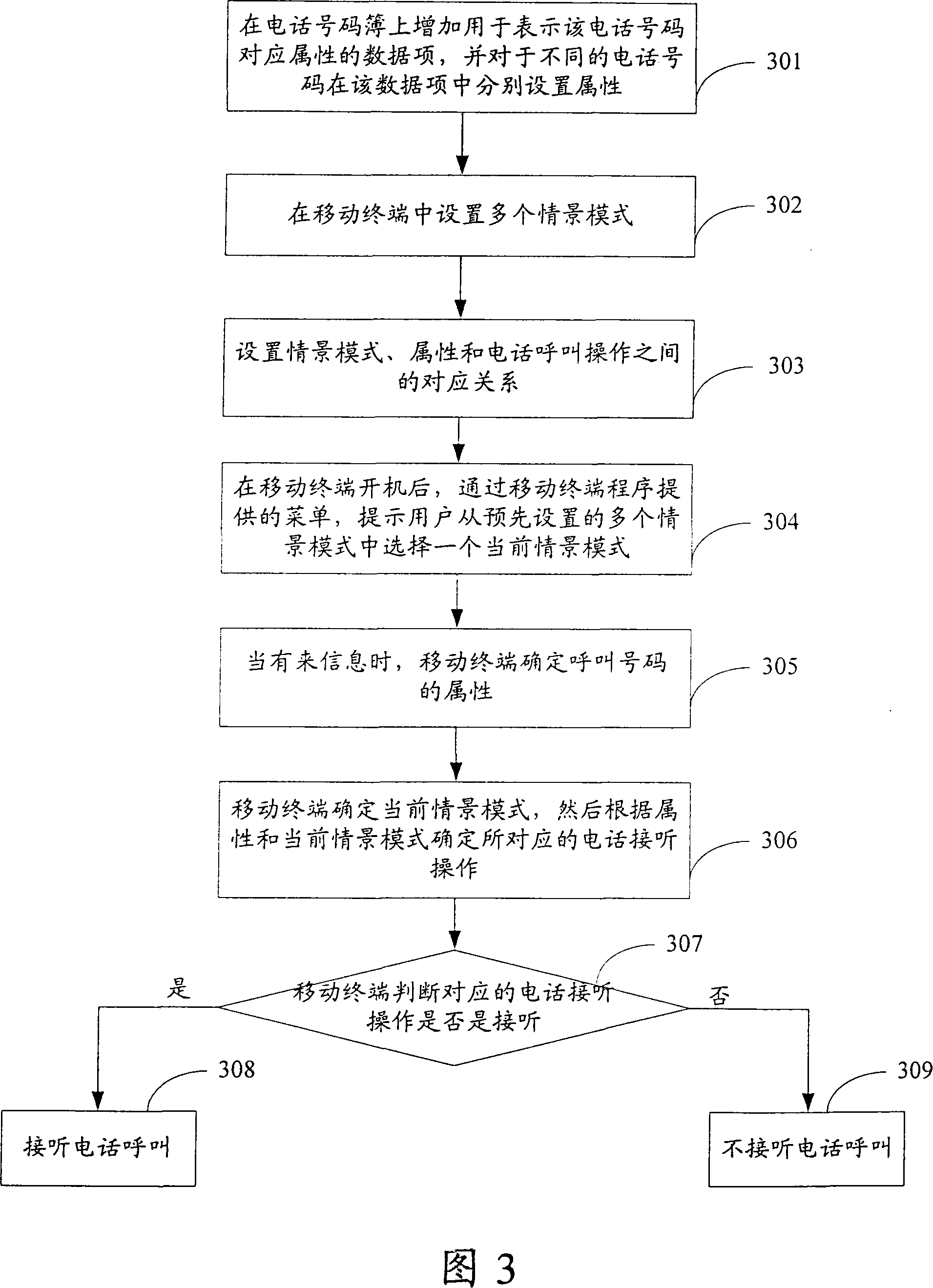

A method for realizing no disturbance service in mobile terminal

InactiveCN101150820ARealize Do Not Disturb ServiceEasy to implementCommmunication supplementary servicesRadio/inductive link selection arrangementsComputer engineering

Owner:HUAWEI TECH CO LTD

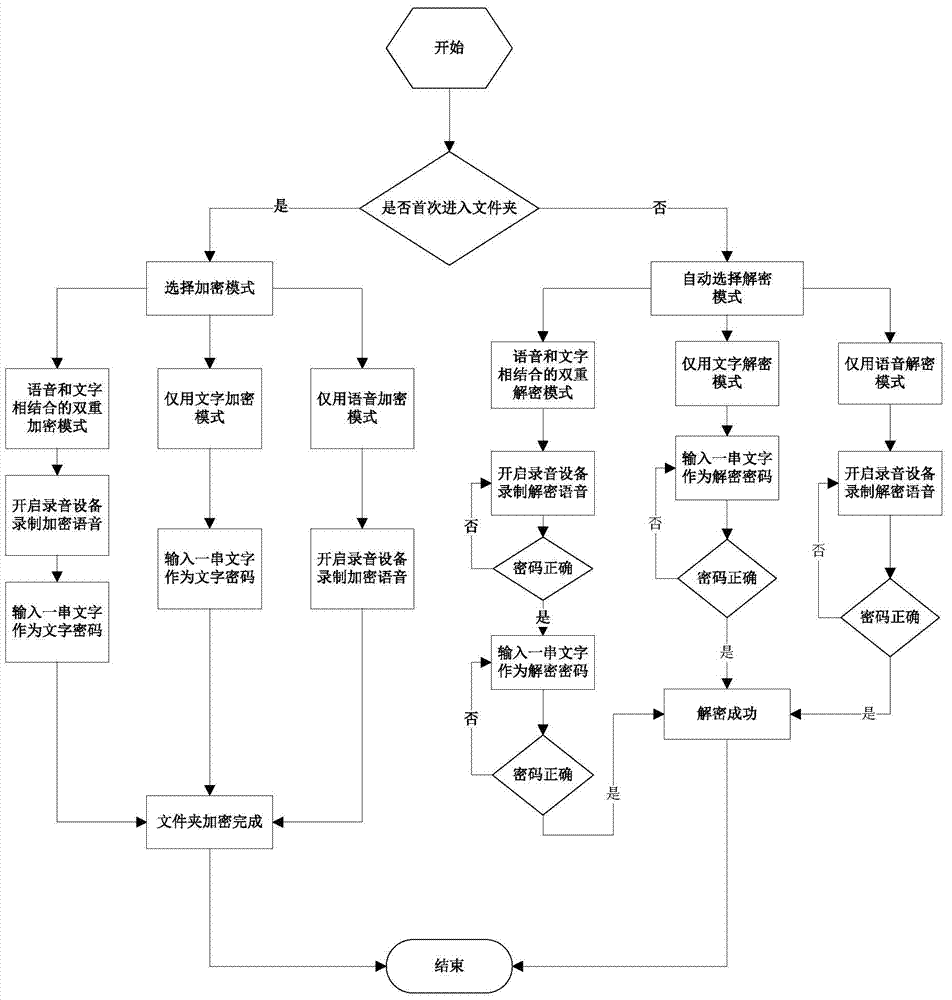

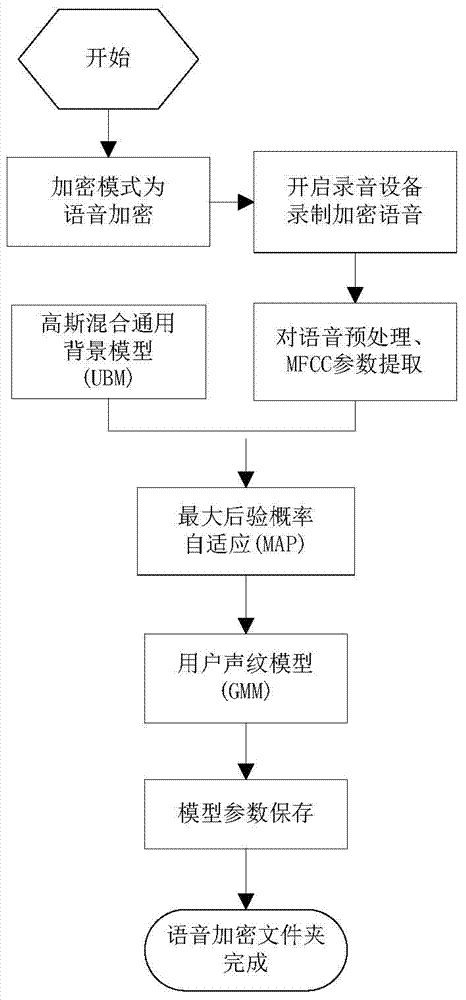

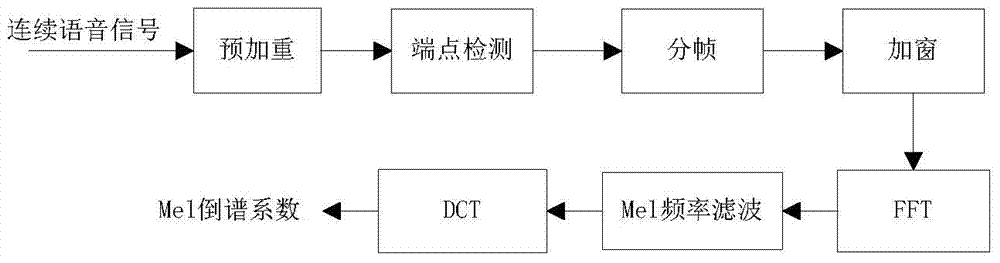

Folder encrypting method

InactiveCN104517066AImprove securityEasy to collectDigital data protectionDigital data authenticationComputer hardwarePassword

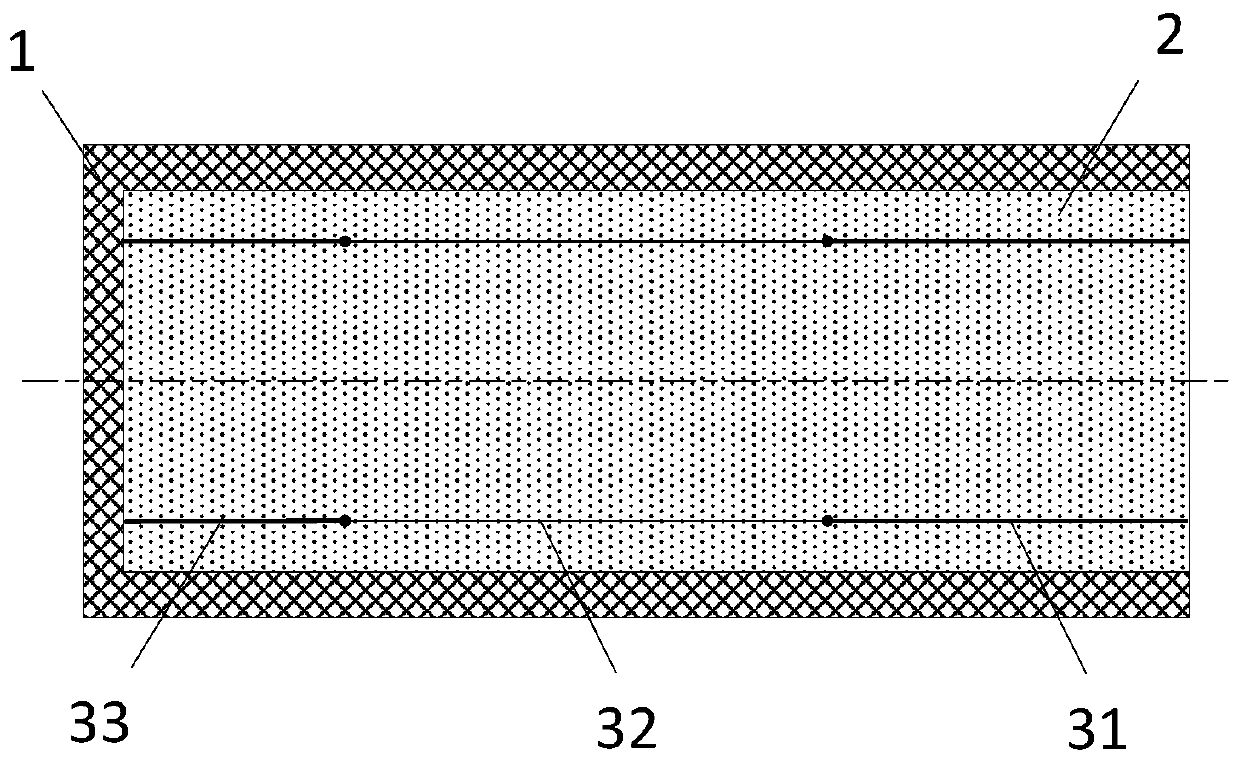

The invention provides a folder encrypting method, and specifically relates to a mode which combines the voiceprint encrypting technology and text passwords for authenticating the indentify of a folder user and confirming and distinguishing an accessor through the combination so as to ensure the security of information of the user folder, and relates to the technical field of information encrypting. The method involves a folder voice encrypting and decrypting module (1), a folder text encrypting and decrypting module (2), and a folder voice and text combined double-encrypting and decrypting module (3). The method is on the basis of the characteristics that voice signals are the natural properties of people, the voiceprint is unique and cannot be lost, and the voice is easily acquired, so that the safety and reliability are superior to the traditional digital or text encrypting mode; the user can flexibly and conveniently encrypt and decrypt; the mode method in combination of voiceprint encrypting and text encrypting, the text encrypting mode method and the voiceprint encrypting mode method are provided for selecting, so that the dual safety is provided to the folder encrypting, and meanwhile, the demand of the user on flexible encrypting modes is met.

Owner:SHANGHAI NORMAL UNIVERSITY

Geometric parameter optimization method for ball-end milling cutter based on co-simulation

InactiveCN108920844AReduce optimization costsMeet flexible needsGeometric CADDesign optimisation/simulationOptimal designGenetic algorithm

The invention discloses a geometric parameter optimization method for a ball-end milling cutter based on co-simulation. A ball-end milling cutter parameter solid model is established through UG, three-dimensional milling finite element simulation analysis is performed through ABAQUS, UG and ABAQUS joint simulation is integrated under an ISIGHT multidisciplinary design optimization platform, and modeling, simulation and control are integrated; design variables, objective functions and constraints of the geometric parameter optimization are determined according to characteristics of a workpiecematerial and the processing requirements, ball-end milling cutter geometric parameters are optimized by using a genetic algorithm, optimal design parameters are determined by fully utilizing process automation, the optimization design efficiency is improved, the ball-end milling cutter geometric parameter optimization cost is reduced, the flexible requirements of modern manufacturing are met, anda new way is provided for cutter geometric parameter optimization.

Owner:HARBIN UNIV OF SCI & TECH

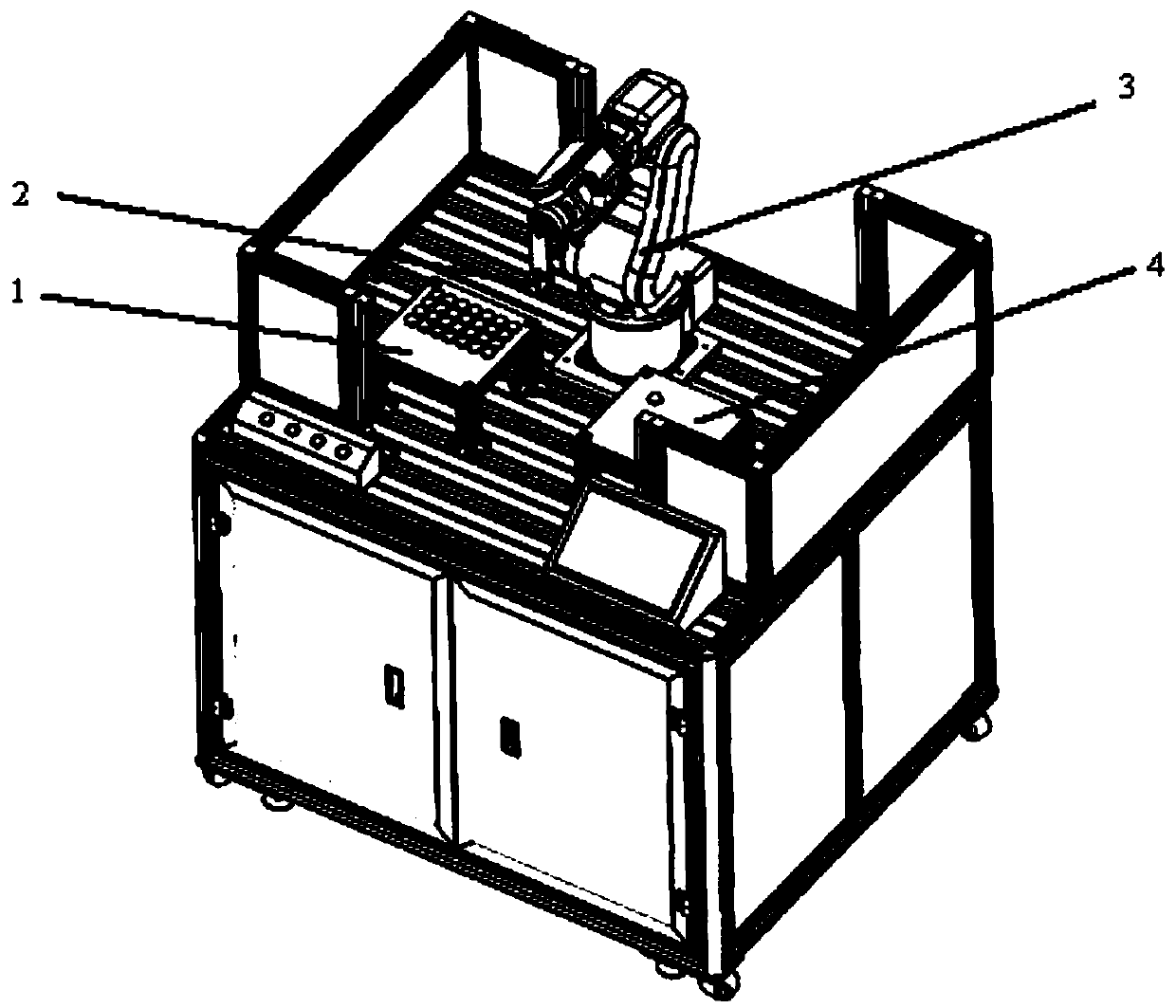

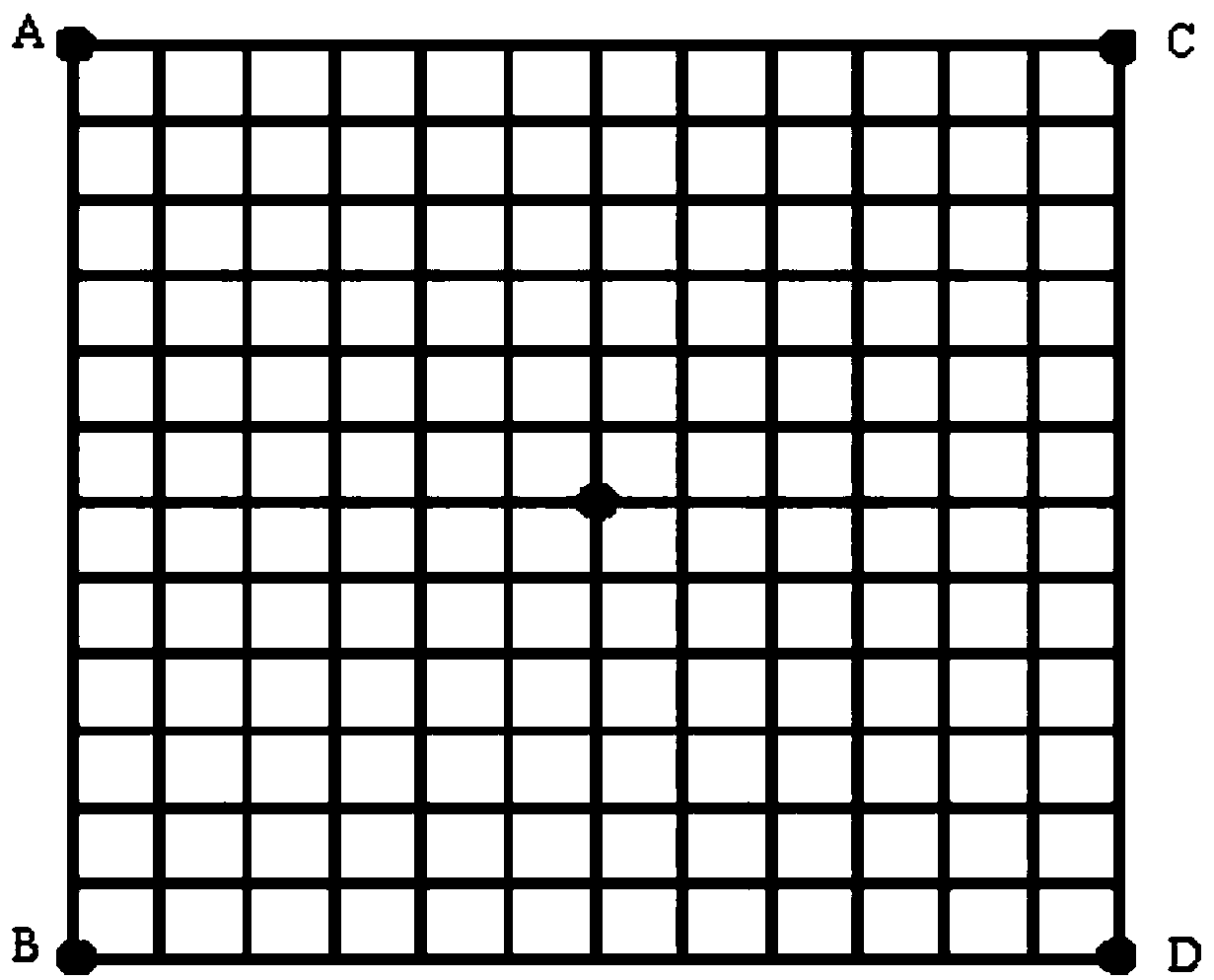

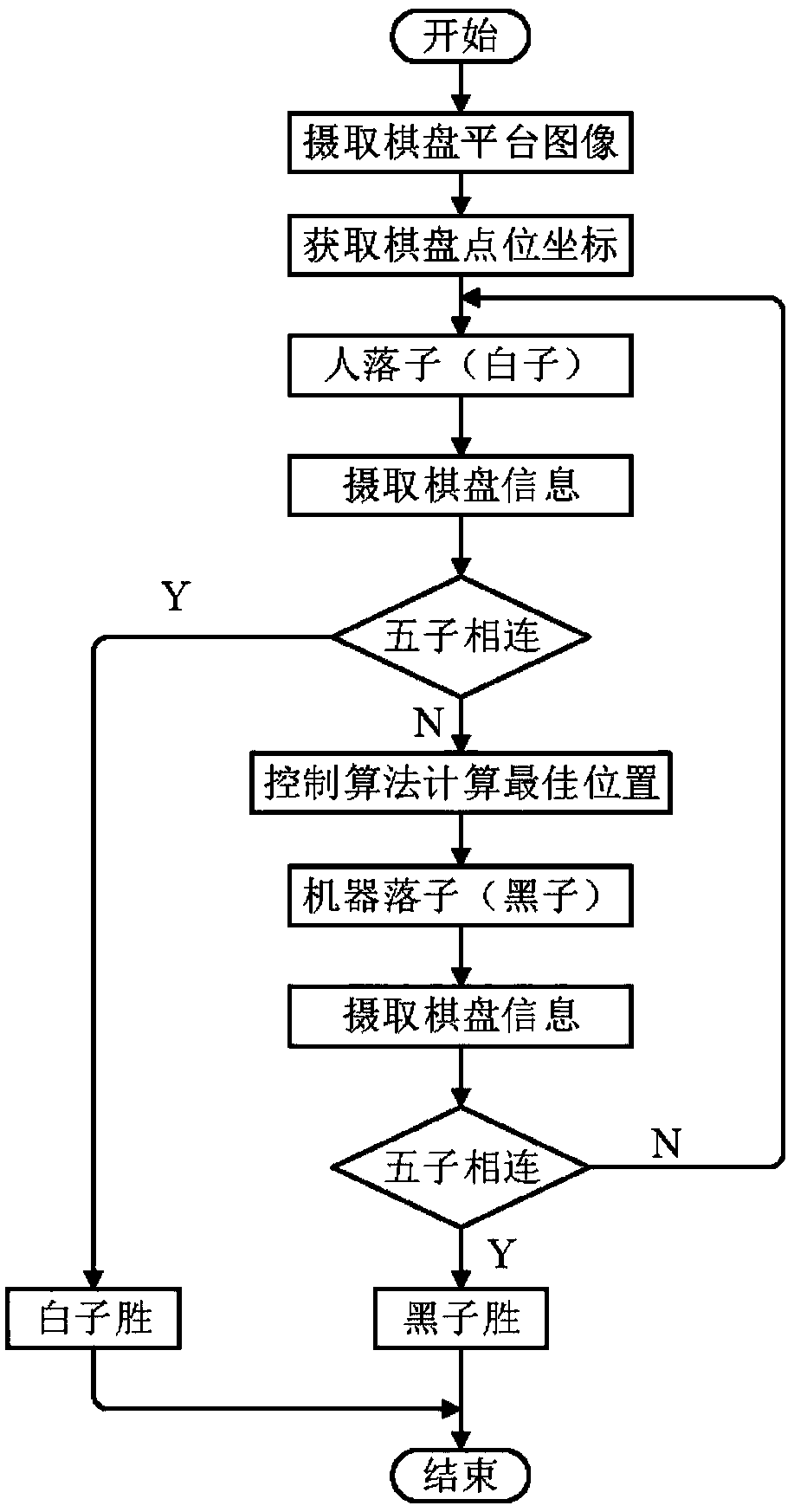

Control method of gobang robot

InactiveCN107813321AGuaranteed accuracyMeet flexible needsProgramme-controlled manipulatorComputer graphics (images)Man machine

The invention discloses a control method of a gobang robot, and belongs to the technical field of robot application. The control method comprises the steps that firstly, an industrial camera is used for shooting play chessboard image position information and obtaining coordinate information of various chess piece point positions on a chessboard; when man-machine playing is started, the industrialcamera is used for shooting the current chessboard chess piece distribution information, and in the same direction, if five continuously-connected white chess pieces or black chess pieces exist, it istreated that the white chess pieces or black chess pieces win; and if no five continuously-connected white chess pieces or black chess pieces exist, playing continues, meanwhile, the chessboard chesspiece distribution information is obtained in real time, the above operation is repeatedly conducted till one side wins, the game is over, and resetting is conducted. In the method, the six-axis industrial robot is adopted in the operation machine side, and the chess playing operation is achieved in combination with corresponding algorithms. The industrial camera is utilized in the method for intelligent detection, and the technical beneficial effects that the detection speed is high, the algorithm stability is high, and the recognition accuracy is high are achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

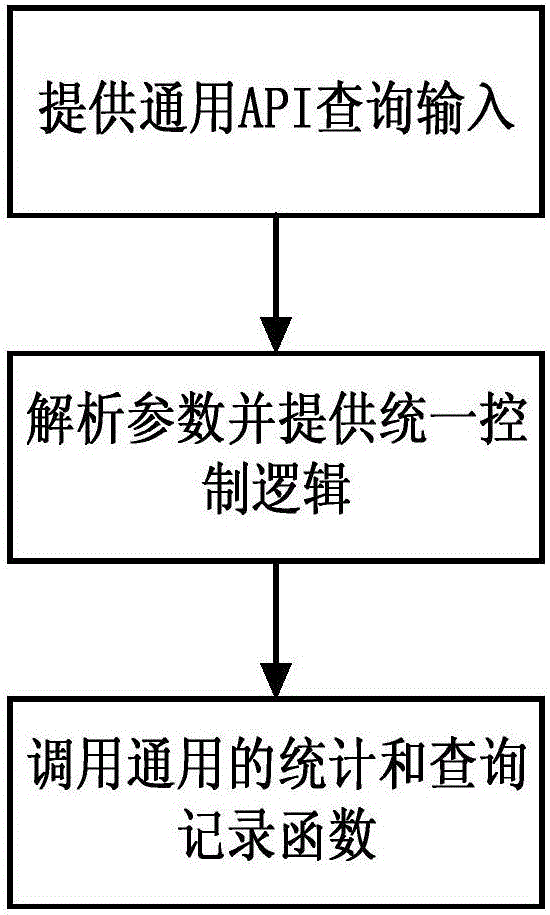

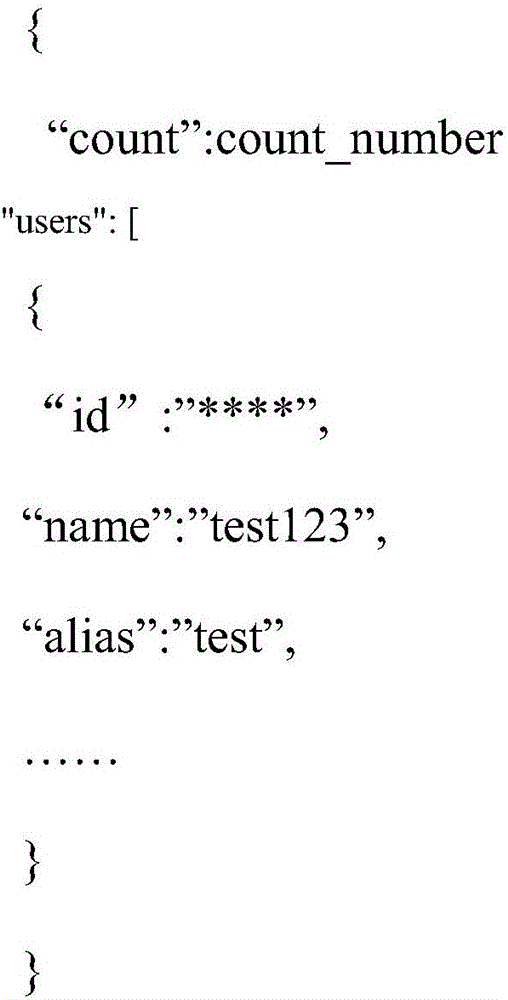

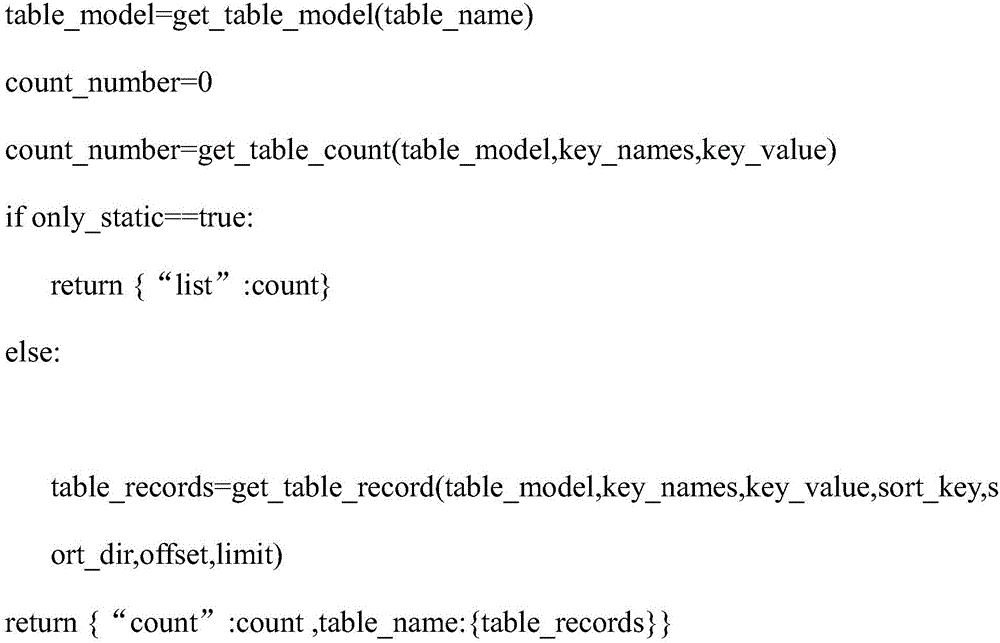

Universal API table query method

InactiveCN106708946AReduce the impactMeet flexible needsSpecial data processing applicationsInput formatData library

The invention relates to the technical field of databases, and in particular to a universal API table query method. The method mainly comprises the following steps of setting a universal API input format, so as to support fuzzy query according to keywords, provide statistical and page separation functions and support sorting according to a certain field; setting a uniform control logic, so as to only count record numbers or feed the record number and a detailed record list back; and packaging universal statistic and query record functions. Through the universal API table query method, the influences caused by the alternation of table structures to the table query are decreased, the efficiencies of development, test and integration are improved, and the flexible requirements, for the table query, of different businesses are satisfied at the same time.

Owner:G CLOUD TECH

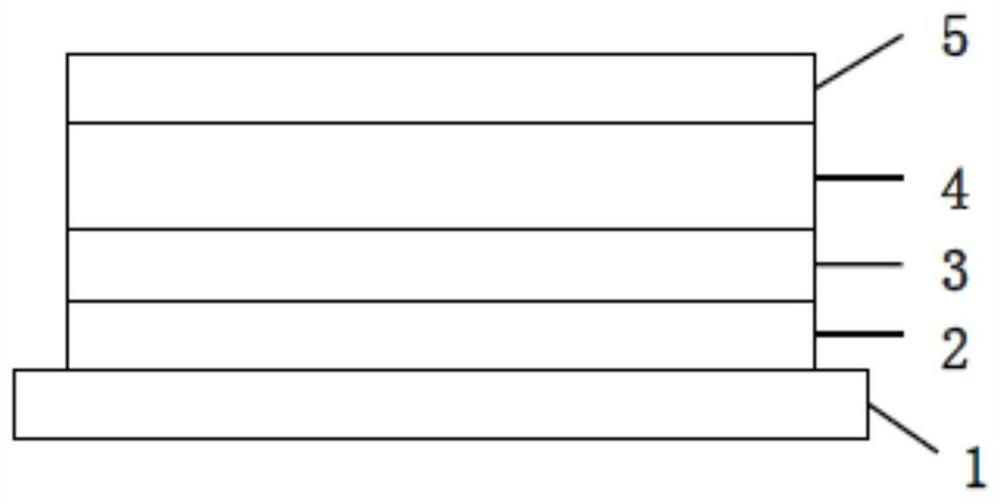

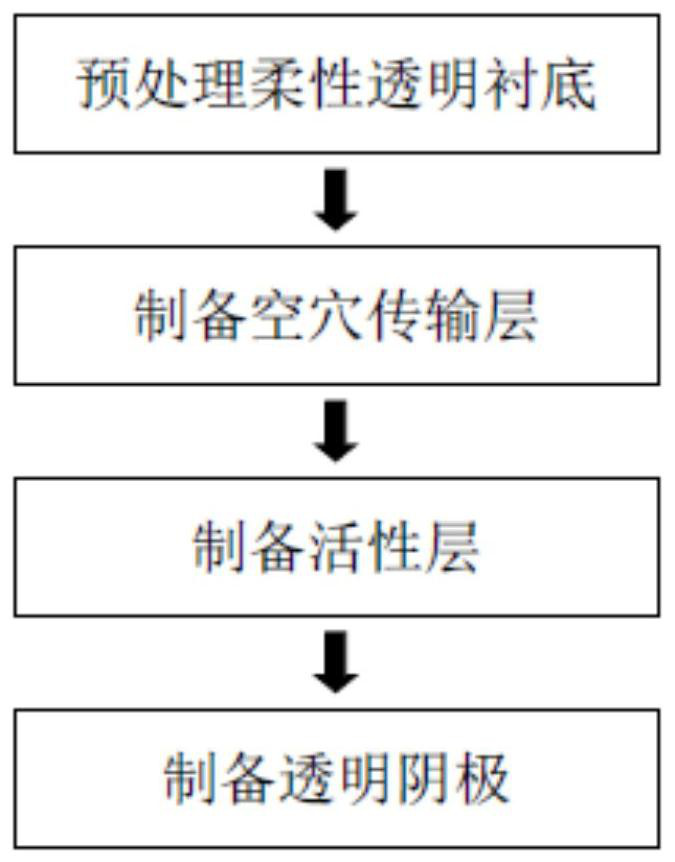

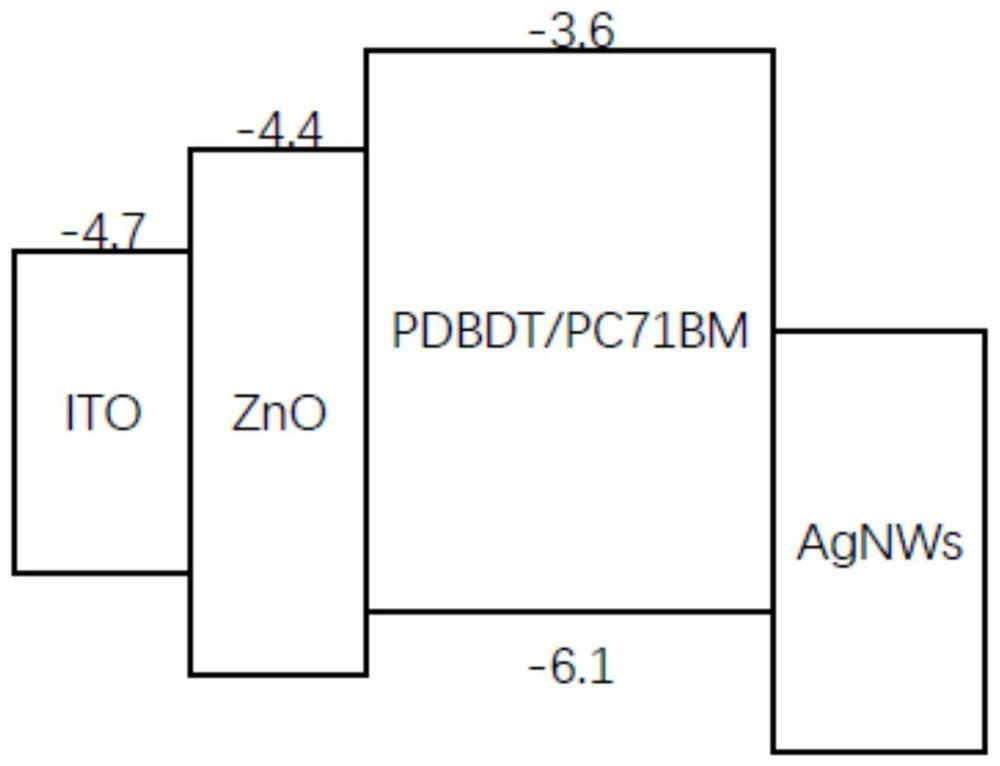

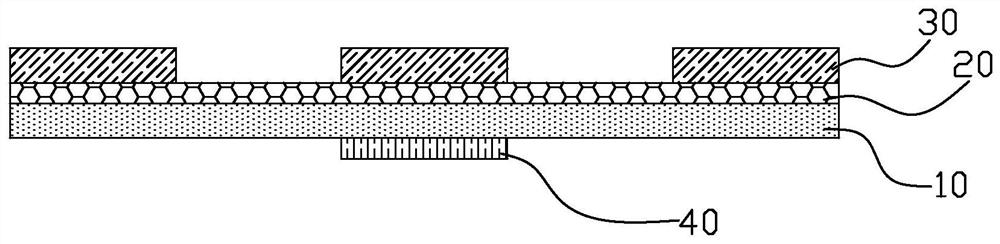

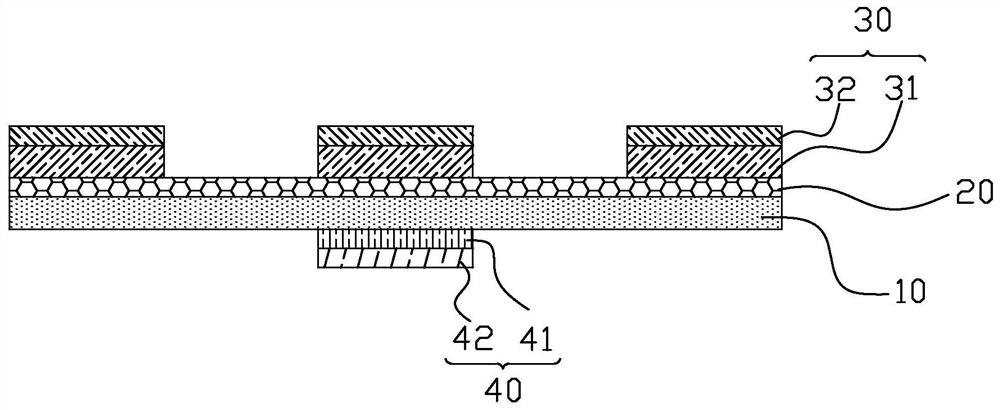

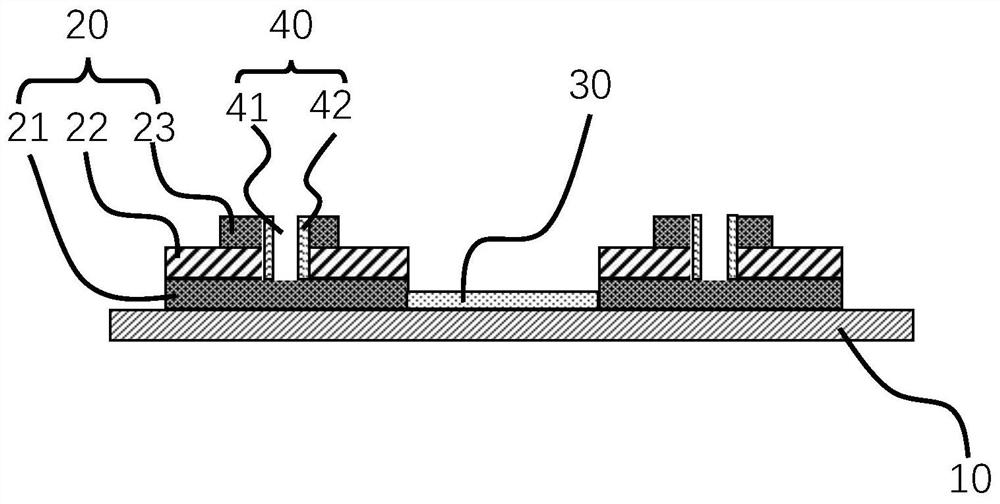

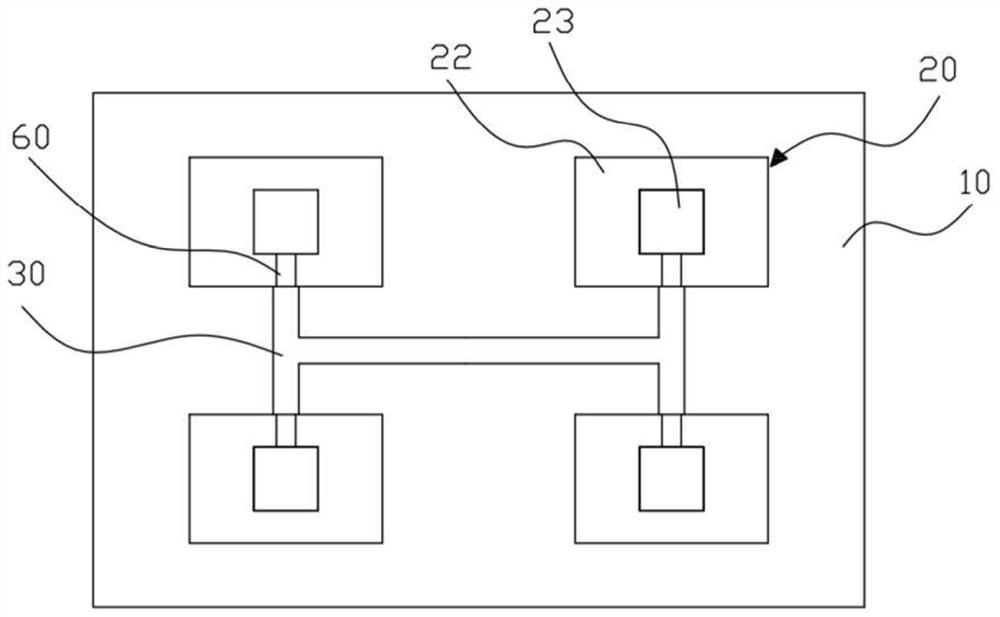

Flexible multiplication type organic photoelectric detector and preparation method

InactiveCN112271259ABi-directional transparencyEnhanced Tunneling InjectionSolid-state devicesSemiconductor/solid-state device manufacturingElectron donorHole transport layer

The invention discloses a flexible multiplication type organic photoelectric detector and a preparation method. The flexible multiplication type organic photoelectric detector comprises a flexible transparent substrate layer, a conductive anode layer, a hole transport layer, an active layer and a conductive cathode layer are sequentially stacked on the flexible transparent substrate layer, the active layer is a mixed film, the thickness of the mixed film ranges from 800 nm to 1200 nm, and materials for manufacturing the mixed film include but are not limited to an electron donor material and an electron acceptor material. The detector prepared by adopting the structure has the characteristic of high flexibility on the whole, can be applied to the field of wearable equipment, and has a practical value of miniaturization; by adjusting the mass ratio of the donor material to the acceptor material, a small amount of donor material is used as an electron trap, and electron tunneling injection is enhanced under the condition of reverse bias, so that the multiplication effect of the multiplication type device is achieved, and meanwhile, compared with a traditional multiplication type device, the detector has higher response speed.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

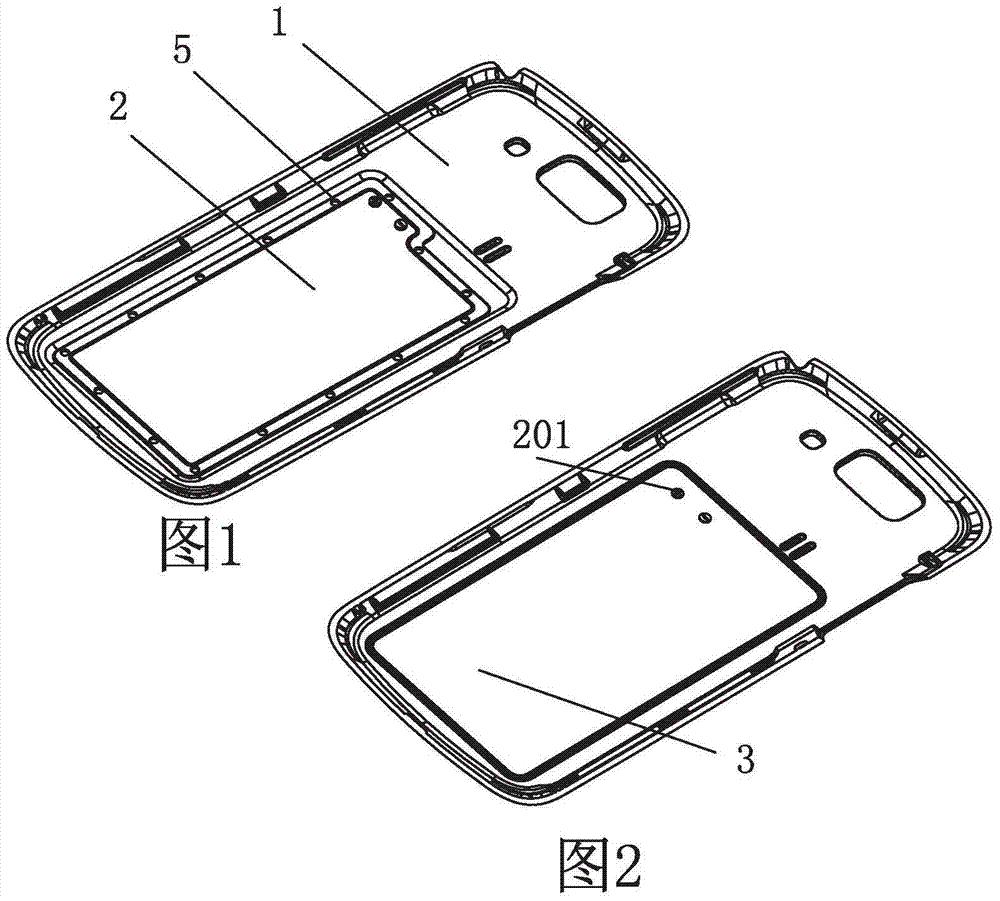

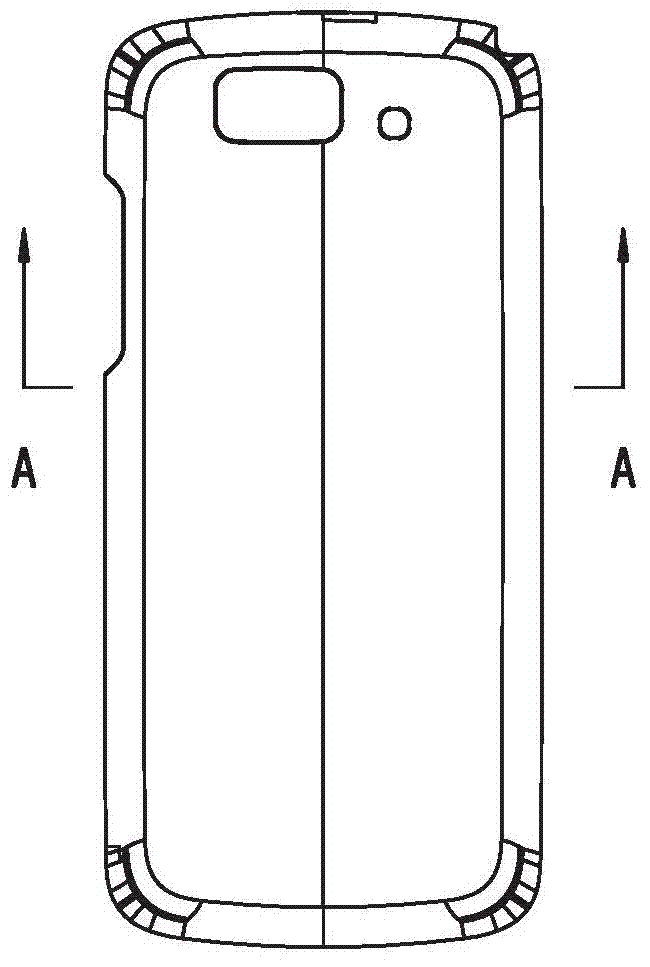

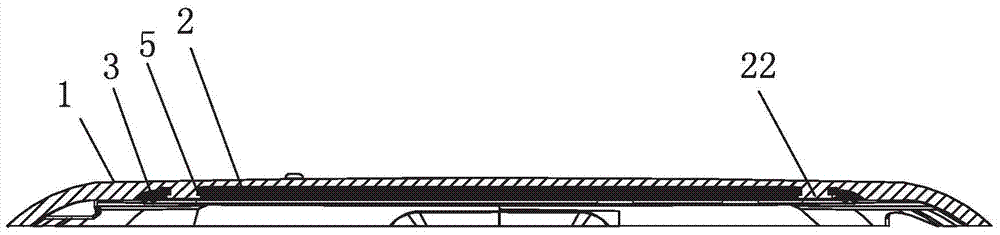

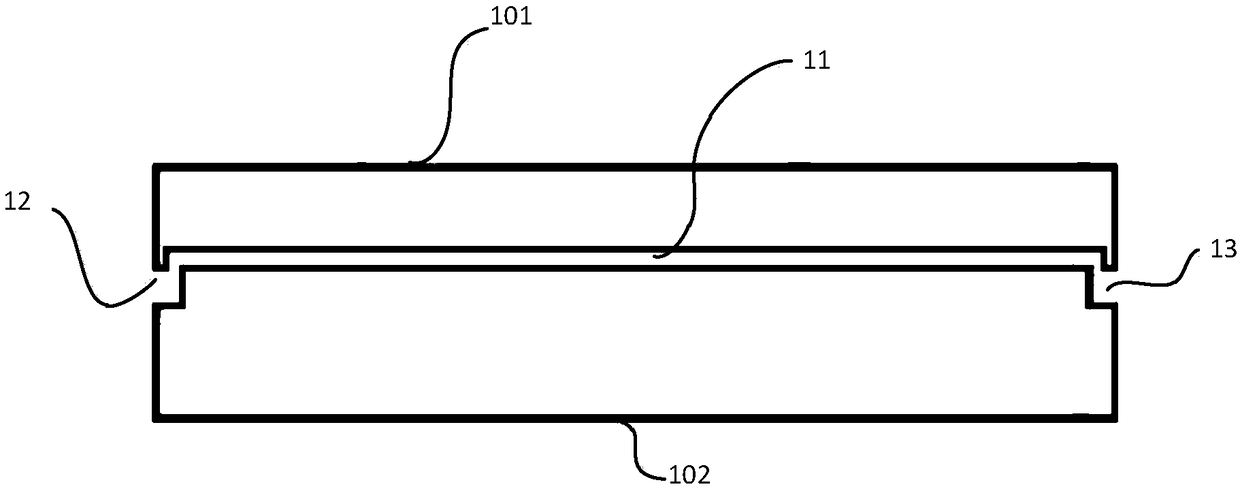

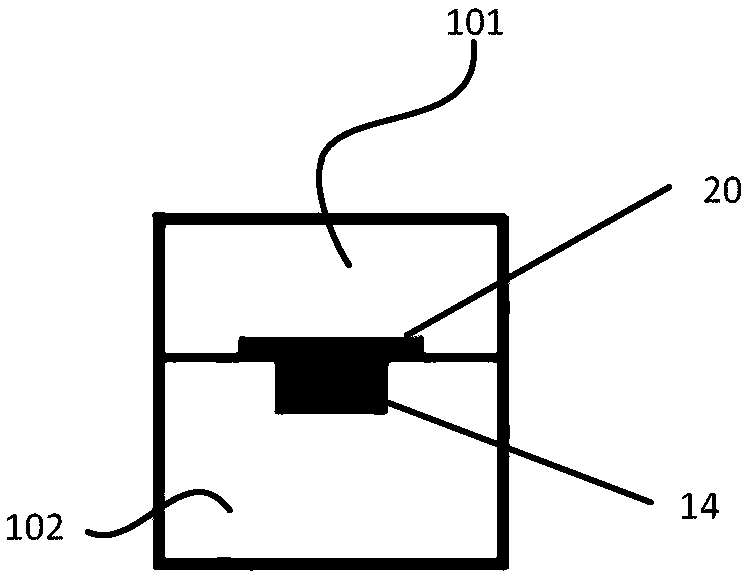

Ultra thin waterproof shell battery integrated molding structure, production equipment and production method

ActiveCN104333987AMeet flexibilityMeet needsSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringSilica gel

The invention discloses an ultra thin waterproof shell battery integrated molding structure, production equipment and a production method. The ultra thin waterproof shell battery integrated molding structure comprises a plastic shell and a flexible battery which is integrally injected and formed at the inner side of the plastic shell. The other side of the flexible battery opposite to the plastic shell is covered by waterproof silica gel which is provided with a feeding through hole. The production equipment comprises a first mould part and a second mould part which are used for molding and shaping and at least a third mould part for silica gel shaping. The second mould part is used for placing the flexible battery. The first mould part and the second mould part are combined to form an injection molding cavity. The second mould part is internally provided with a local cooling system corresponding to the placing area of the flexible battery, and the local cooling system is used for preventing the overhigh temperature of the flexible battery in the process of injection molding. According to the ultra thin waterproof shell battery integrated molding structure, the ultra thin integrated molding structure with good waterproof performance can be realized, the ultra thin integrated molding shell is flexible, and various surface process can be carried out at the same time.

Owner:DONGGUAN HUAQING OPTICAL TECH

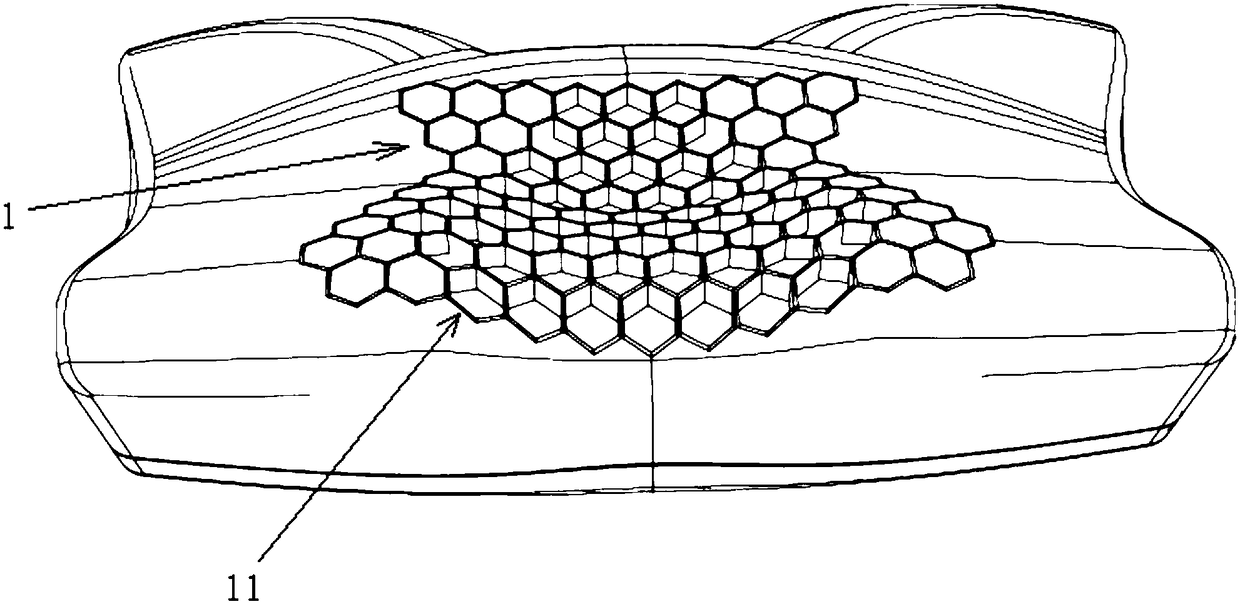

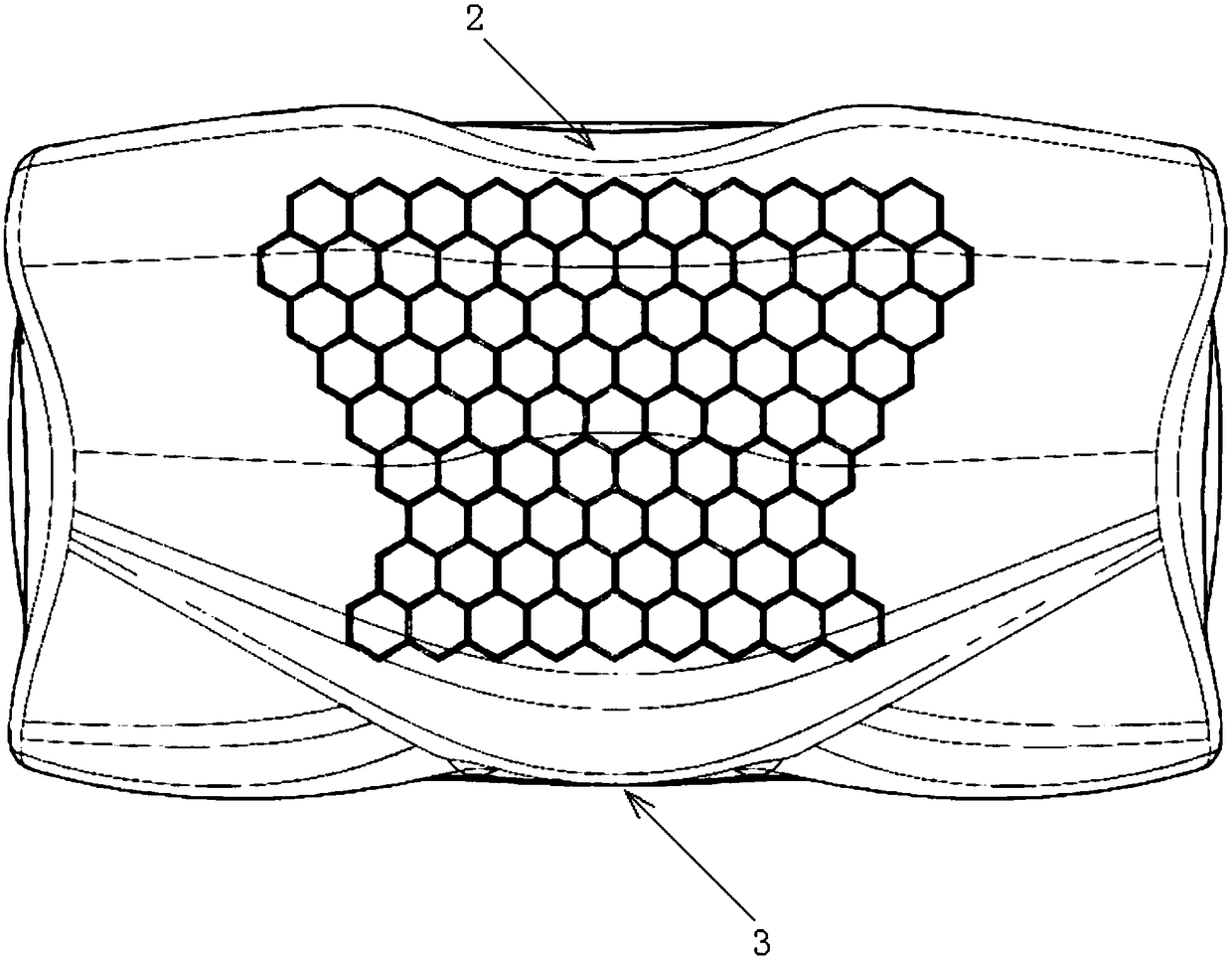

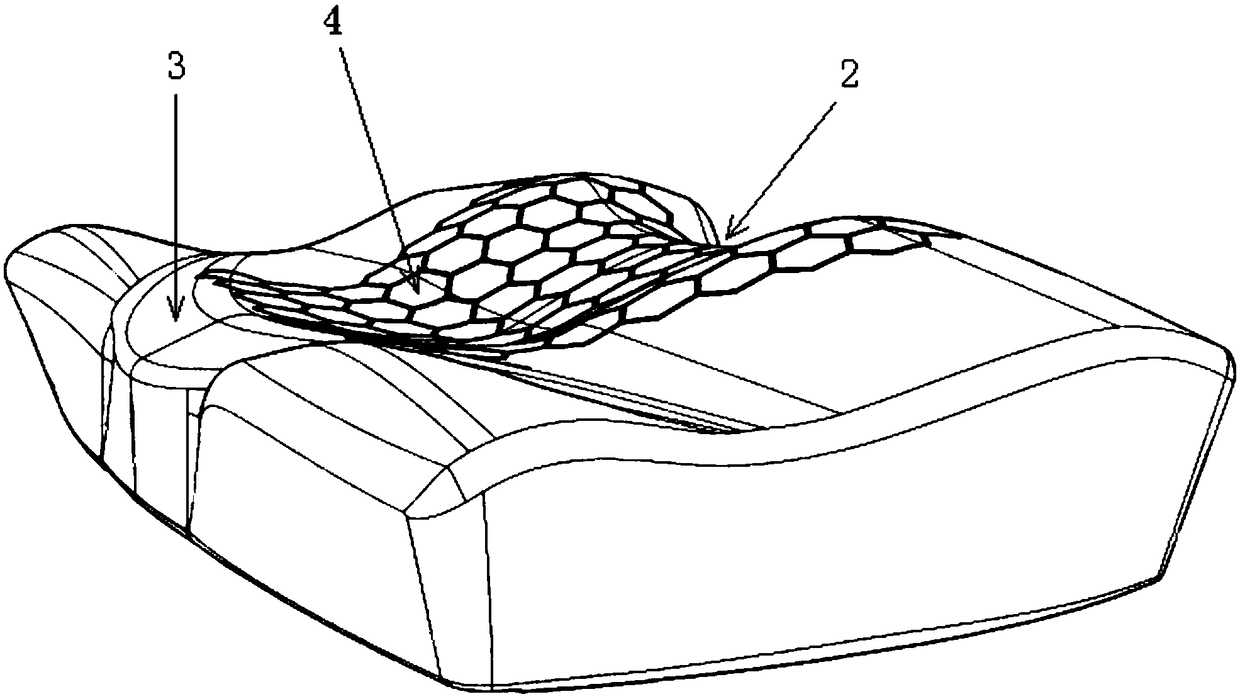

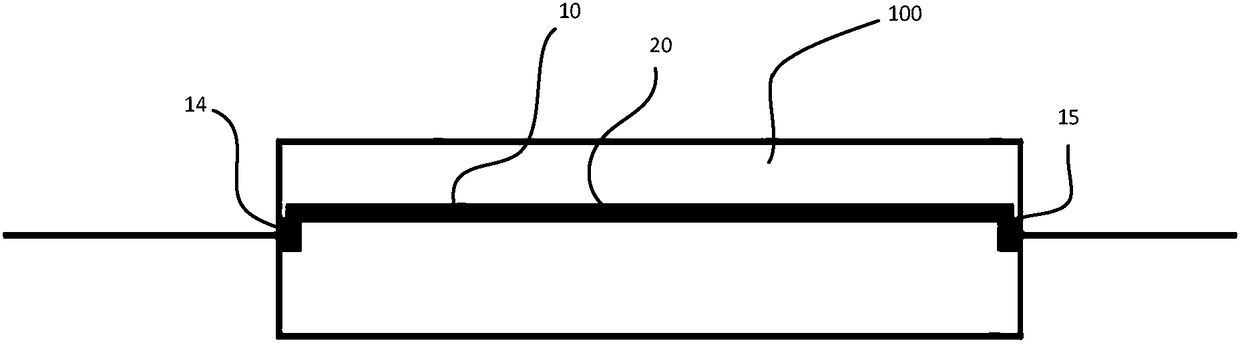

a pillow

Owner:江苏金太阳家用纺织品有限公司

Conductive connecting member and Wheatstone bridge

PendingCN108469548AMeet flexible needsMeet needsConnections to liquidResistance/reactance/impedenceElastomerElectrical resistance and conductance

The invention discloses a conductive connecting member and a Wheatstone bridge formed by the same. The conductive connecting member comprises an elastic body, a pipeline which penetrates through the opposite two sides of the elastic body and is formed in the elastic body, and the pipeline is composed of a pipe body and two pipe openings located at the two ends of the pipe body, wherein the two pipe openings are located at the lower portion of the pipeline body; liquid-phase metal / liquid-phase alloy is arranged in the pipe body; conductive sealing members for sealing the liquid-phase metal / liquid-phase alloy are arranged at the two pipe openings respectively. By forming a conductive resistor composed of the liquid-phase metal and the elastic body, a bendable and stretchable resistor with flexibility is provided, and the requirements on flexibility of the resistor and a flexible circuit can be met.

Owner:BEIJING DREAM INK TECH CO LTD

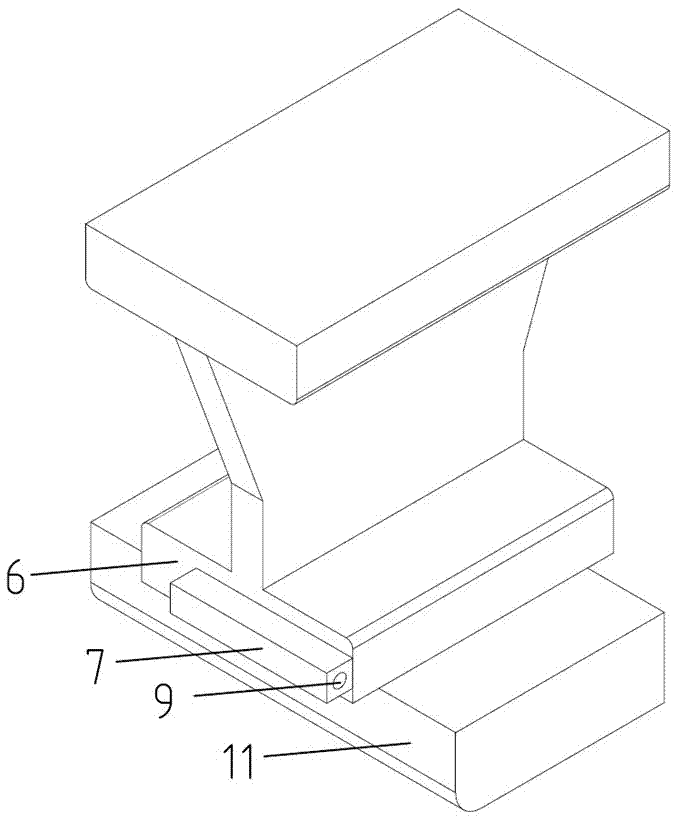

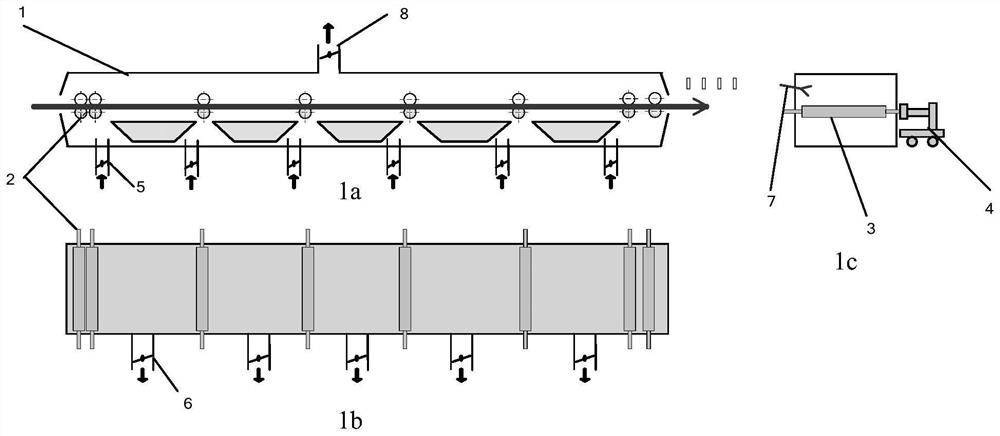

Flexible die mechanism for sheet metal pre-deformation

The invention relates to a flexible mold pressing mechanism for plate predeformation. The flexible mold pressing mechanism comprises a support frame and pressing head components; the support frame consists of two roller way plates symmetrically arranged, and a cushion plate; the roller way plates take the shape of channel steel; notches of the two roller way plates are opposite; rollers are uniformly distributed in each roller way plate in the length direction; the cushion plate is a strip plate, is arranged in the two roller way plates in the length direction, and is positioned above the rollers; the top surface of the cushion plate is connected with channel steel upper flat plates of the two roller way plates; the pressing head components include slide frames and mold heads; the longitudinal sections of the slide frames are I-shaped; the mold heads take the shape of rectangular blocks, and are transversely connected to the bottom surfaces of the slide frames; more than one pressing head components are matched and mounted in the support frame; the slide frames of the pressing head components can move along the rollers; and the mold heads of the pressing head components are positioned below the support frame. The distance of the pressing head components is adjustable to realize predeformation treatment of plates with different lengths.

Owner:ANHUI HELI CO LTD

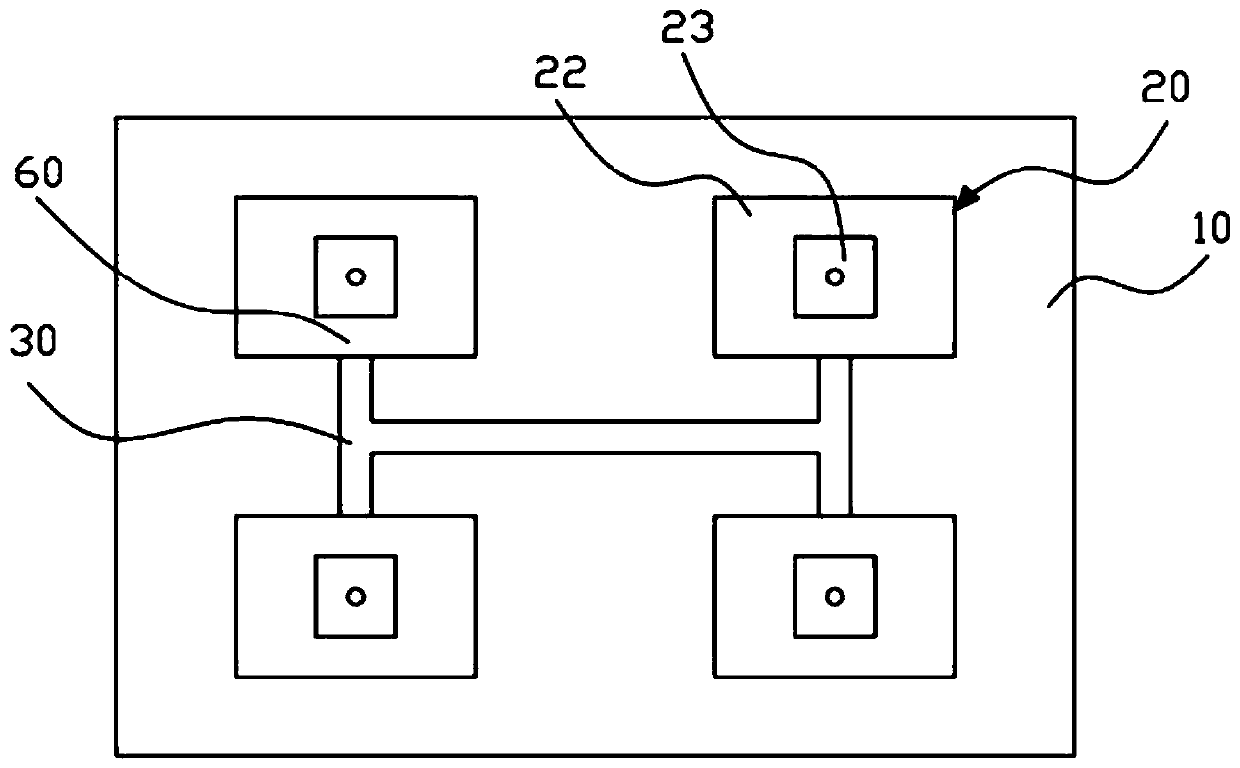

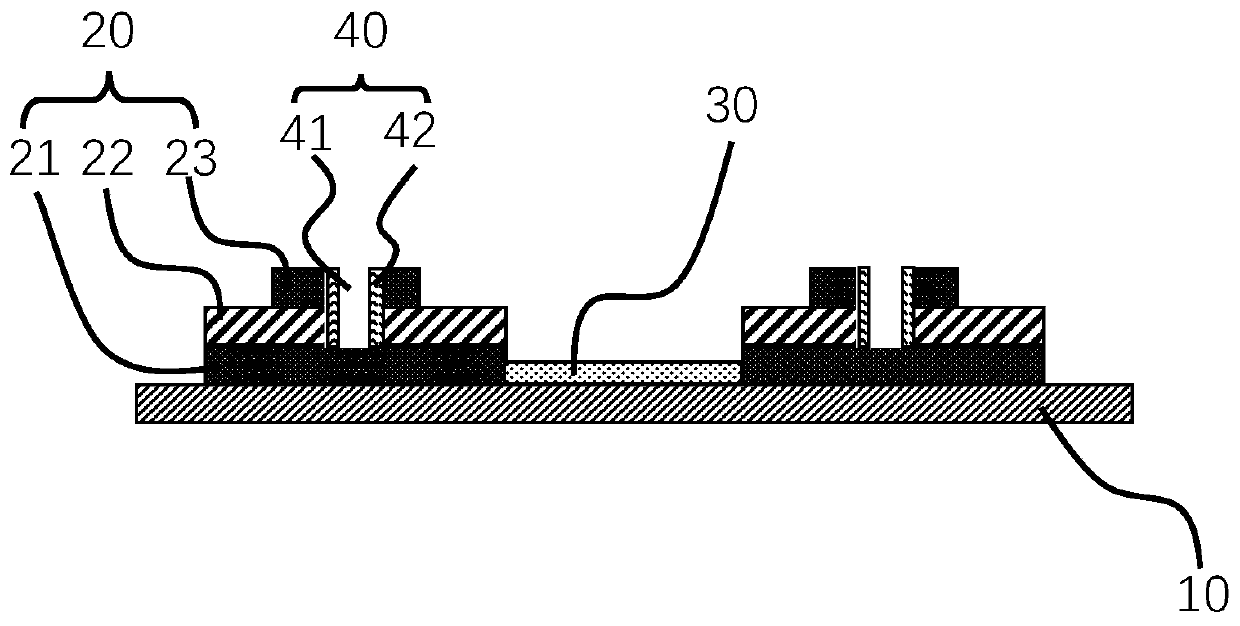

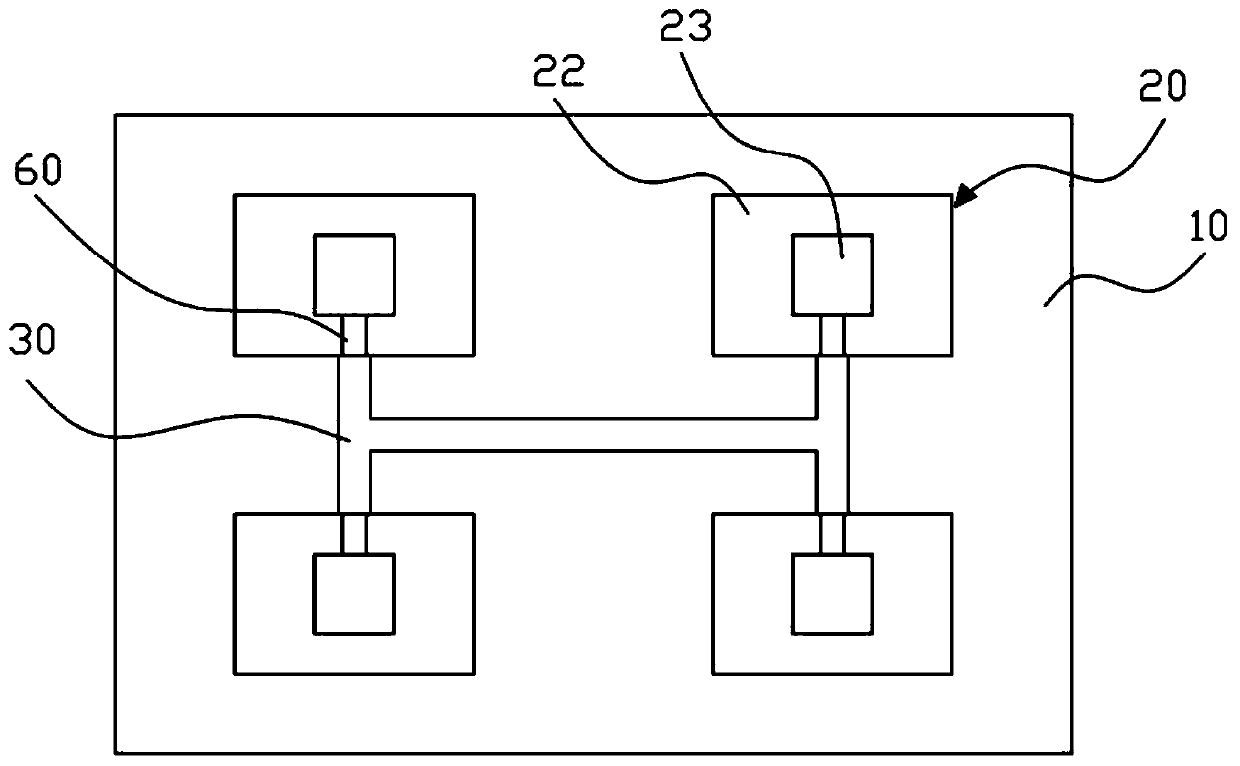

High-temperature-resistant flexible array antenna and manufacturing method thereof

ActiveCN110994167AElasticExcellent insulation performance and high temperature resistanceRadiating elements structural formsAntenna arrays manufactureMechanical engineeringSi substrate

The invention discloses a high-temperature-resistant flexible array antenna and a manufacturing method thereof. The antenna takes a flexible mica sheet as a substrate, a plurality of antenna units arearranged on the substrate and are electrically connected through a wire layer, and each antenna unit comprises a metal bonding layer, a chip and a metal pattern layer. The chip is fixed on the flexible mica sheet through the metal bonding layer, the metal pattern layer is arranged at one side, far away from the metal bonding layer, of the chip, and the metal bonding layer is electrically connected with the metal pattern layer. The high-temperature-resistant flexible array antenna can tolerate higher temperature and can be conformal with other objects easily, and the use space is greatly reduced.

Owner:INST OF FLEXIBLE ELECTRONICS TECH OF THU ZHEJIANG +1

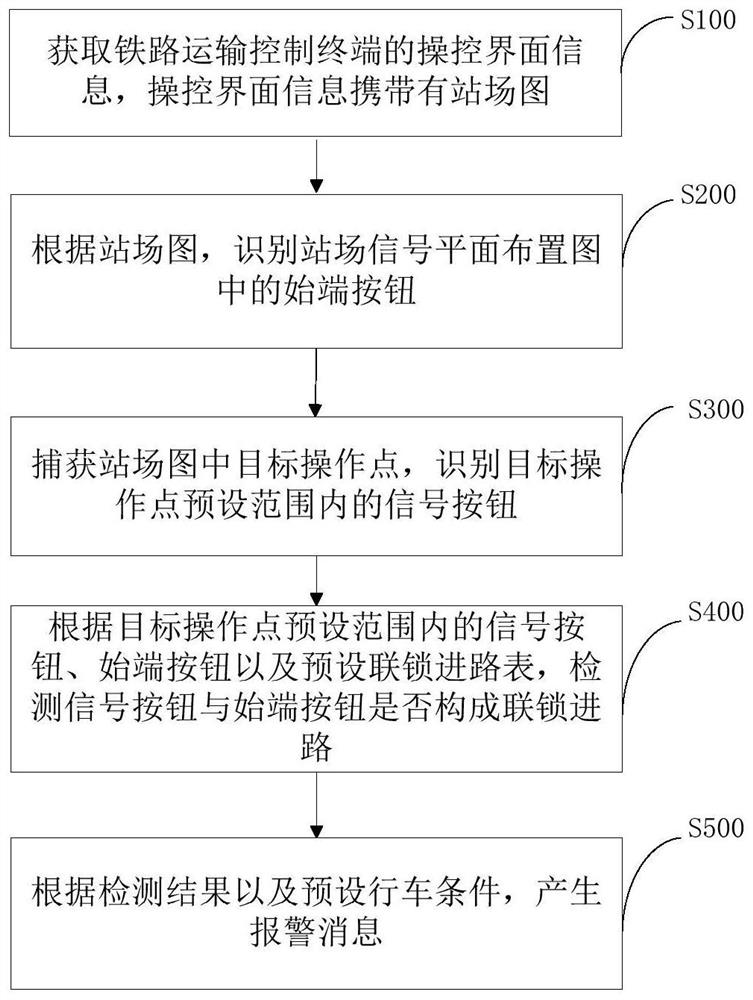

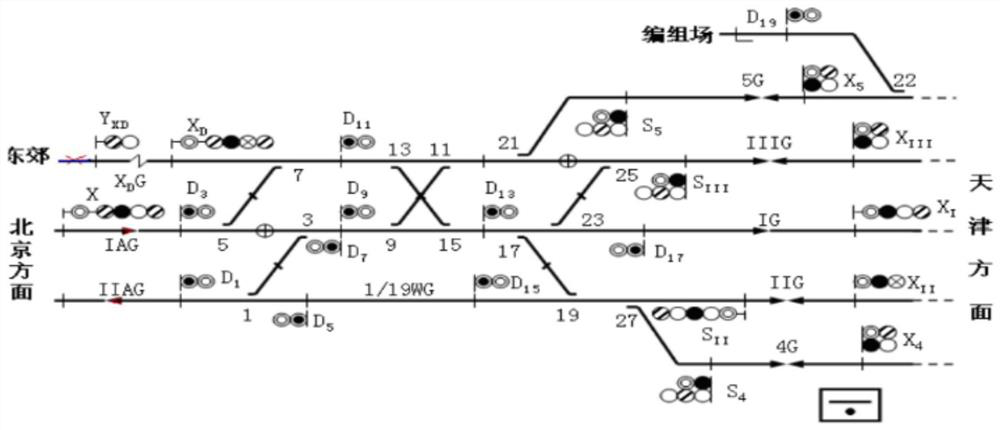

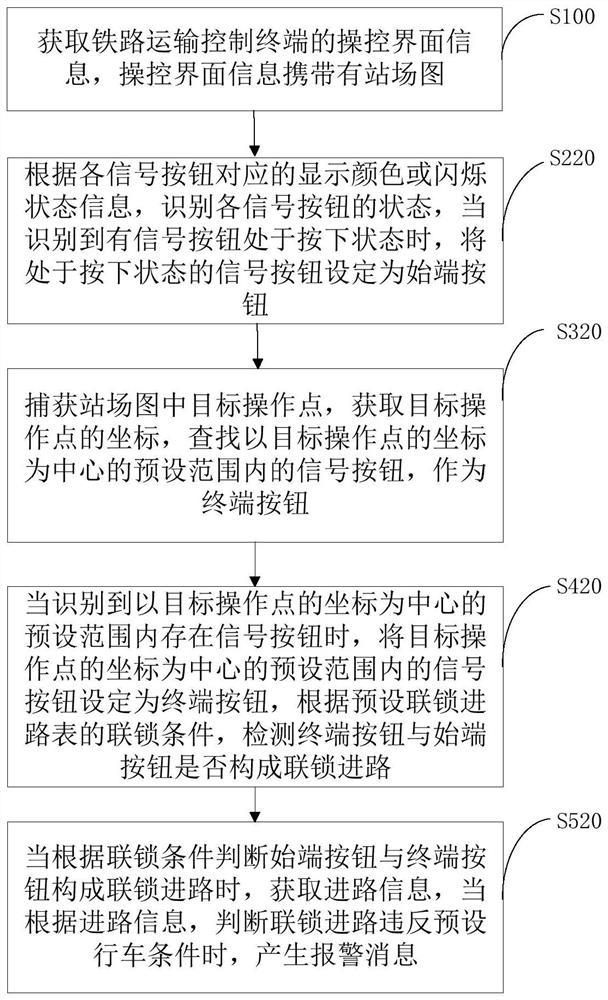

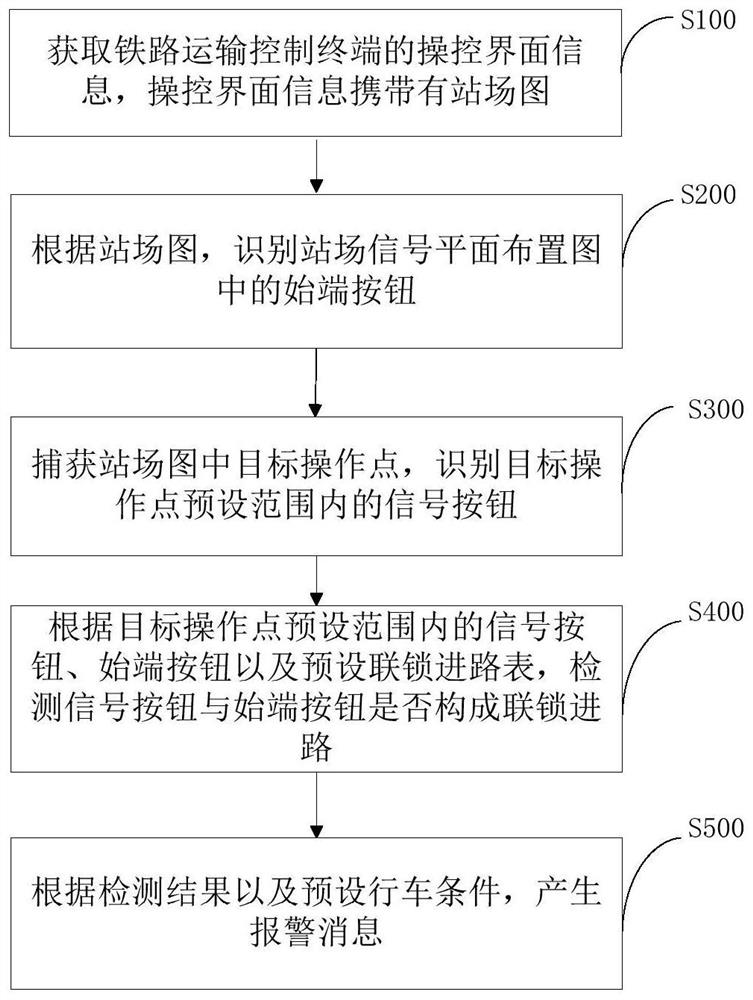

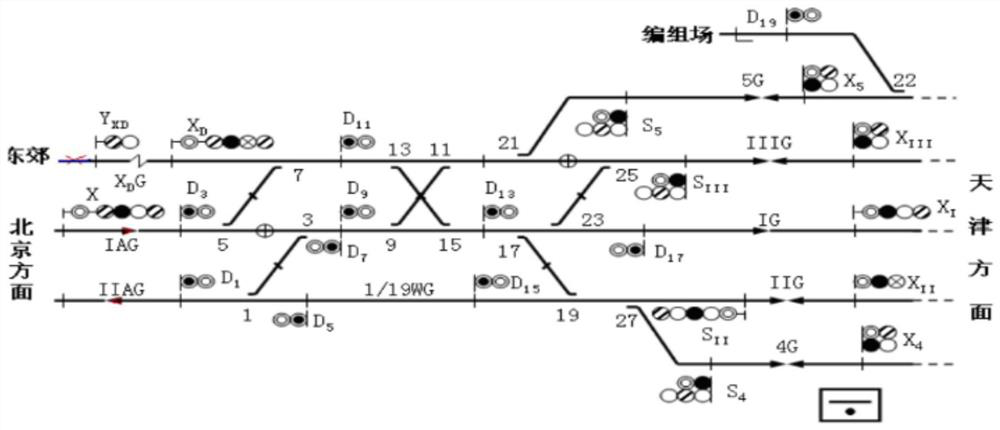

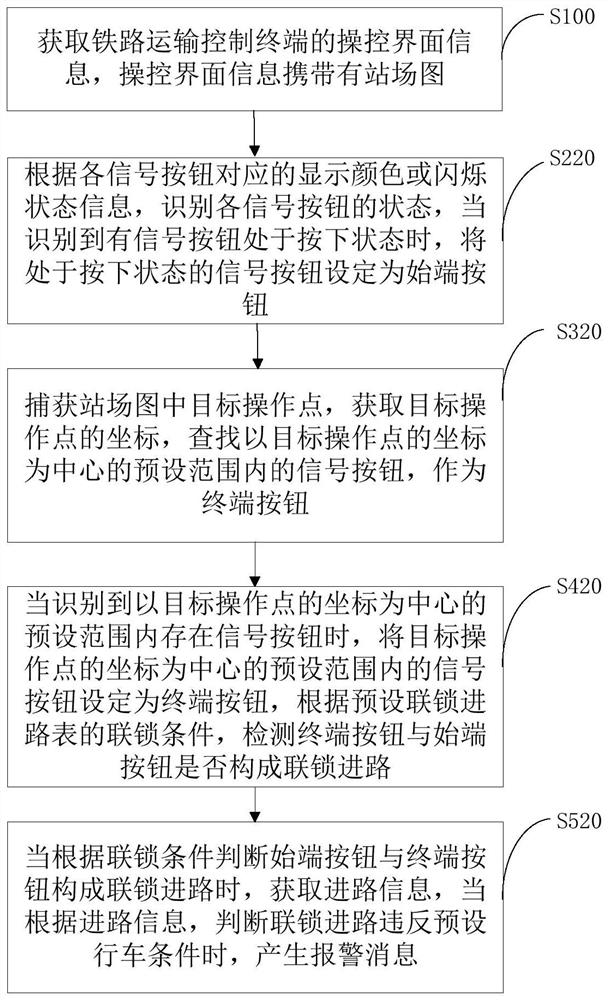

Station traffic operation control method, device, computer equipment and storage medium

ActiveCN111752423BSave resourcesMeet flexible needsInput/output processes for data processingAlarm messageSignaling system

The application provides a method, device, computer equipment, and storage medium for controlling station traffic operations. It acquires control interface information of a railway transportation control terminal. The control interface information carries a station map. According to the station map, it identifies the start point in the station map. Button, capture the target operating point in the station map, identify the signal button within the preset range of the target operating point, and detect the start end according to the signal button within the preset range of the target operating point, the state of the signal button and the preset interlocking route table Whether the button and the signal button constitute an interlocking route, an alarm message is generated according to the detection result and preset driving conditions. The above process, based on the image information of the station map and the position of the target operating point, can realize the alarm of wrong handling before or before the wrong handling of the route without interface with the signal system, which is convenient for the operator to check in time and Correcting route errors has the characteristics of saving resources and costs and meeting flexible needs.

Owner:上海睿栈科技有限公司

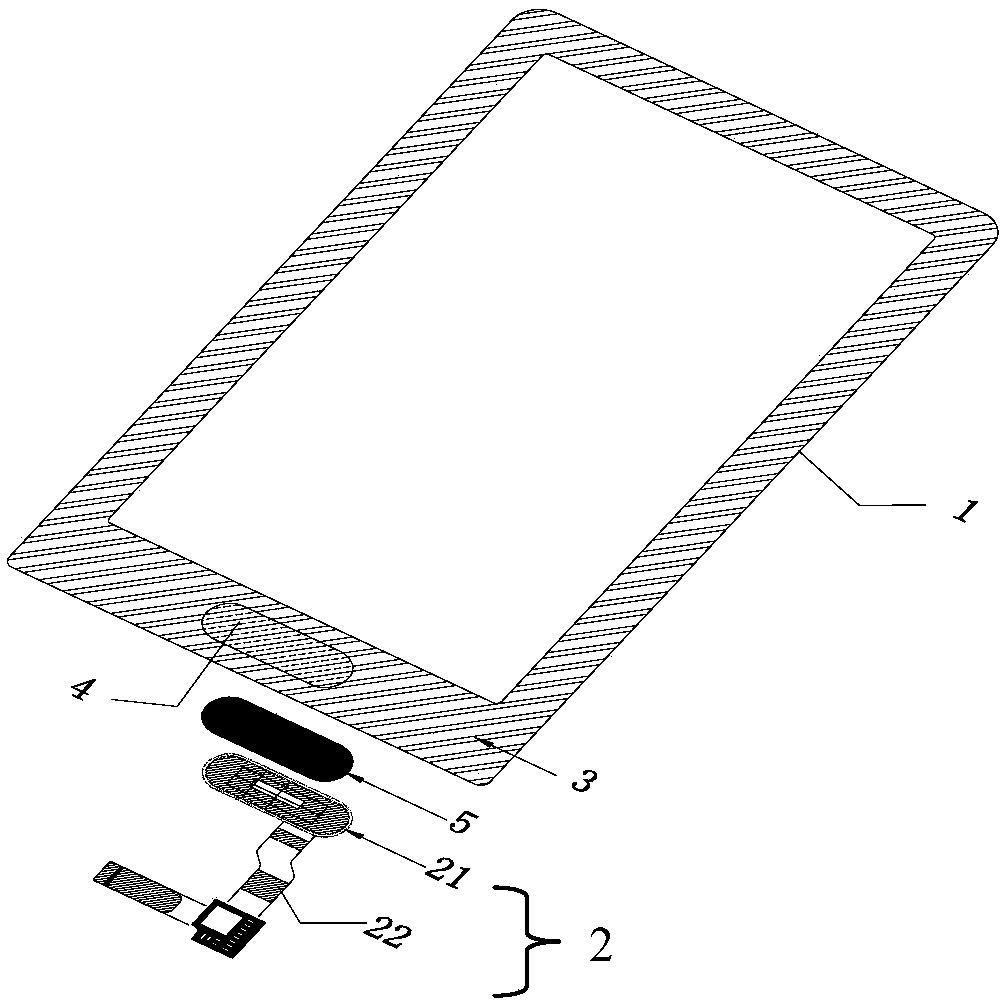

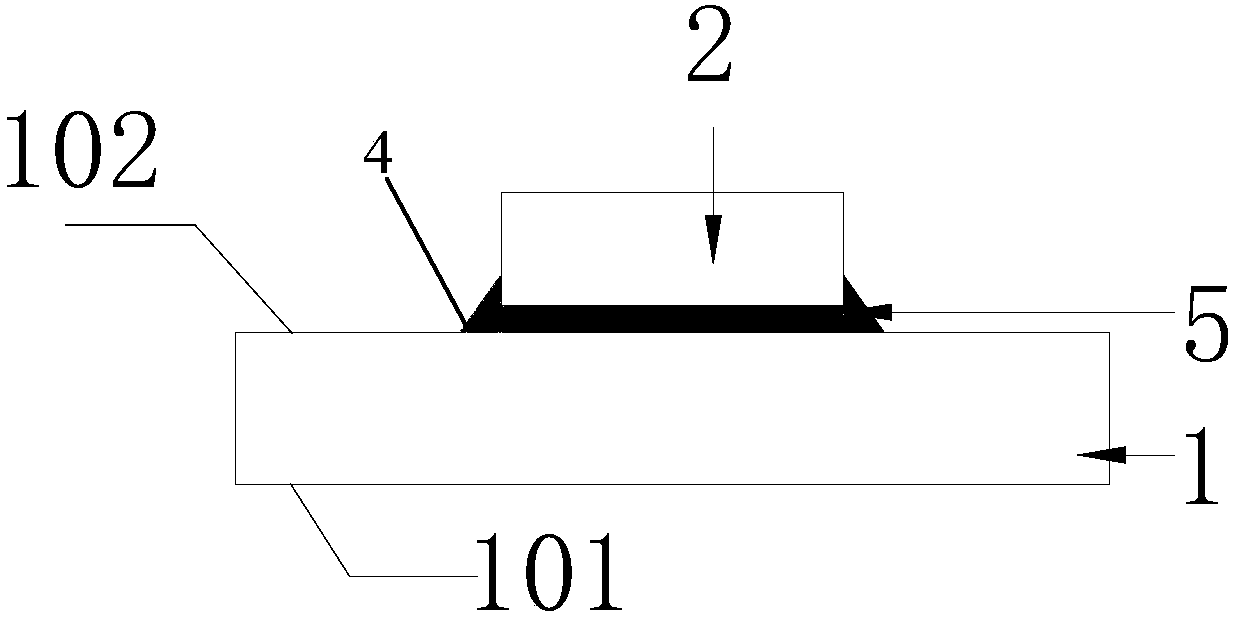

Touch screen and electronic equipment

PendingCN109725747AMeet flexible needsGood fingerprint touch functionCharacter and pattern recognitionInput/output processes for data processingEngineeringFlexible electronics

The invention provides a touch screen, which comprises a cover plate and a fingerprint identification module. The cover plate is a flexible plate, and the thickness of the cover plate is 0.023 [mu] m;0.2mm, the cover plate is divided into a screen visible area and a screen frame area, the cover plate comprises a first surface and a second surface which are oppositely arranged, the first surface is used for being touched by a user, the fingerprint identification module is arranged on the second surface of the cover plate, and the fingerprint identification module is located in the screen framearea of the cover plate. Compared with a traditional cover plate, the cover plate is a thin flexible plate and can be bent, the fingerprint recognition module can be attached to the back face of theflexible cover plate without manufacture of a through hole or a blind hole in the cover plate, the fingerprint recognition efficiency of the fingerprint recognition module is not affected, and the requirement of the flexible electronic touch screen for the fingerprint recognition function is met. The invention further provides electronic equipment adopting the touch screen.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

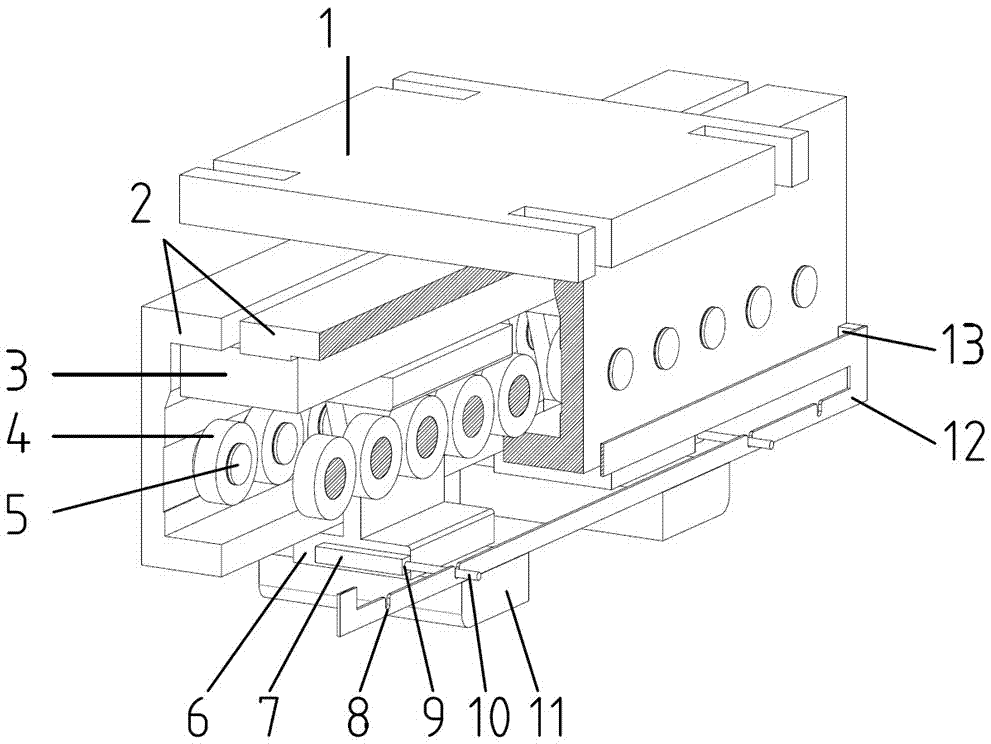

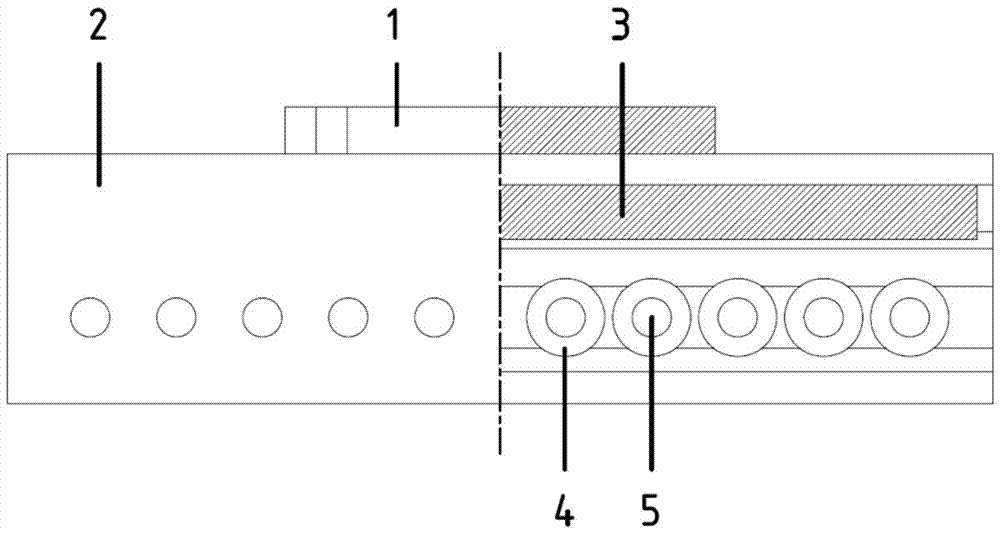

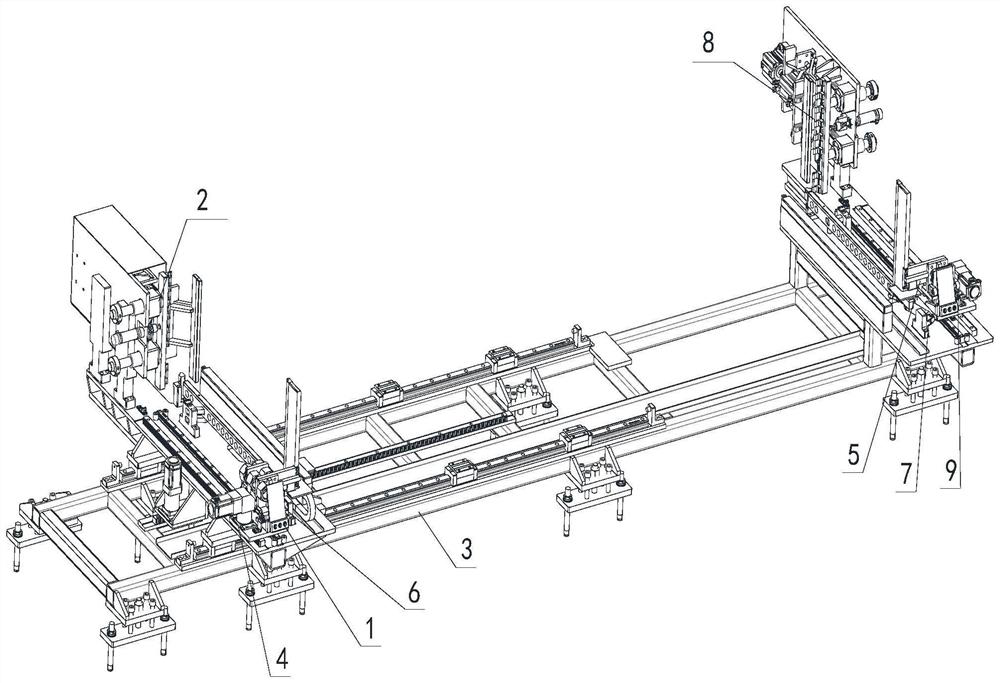

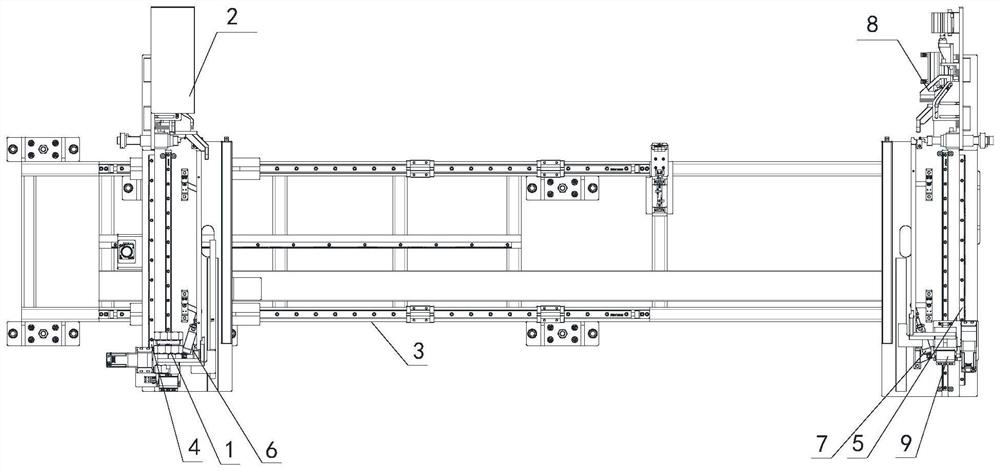

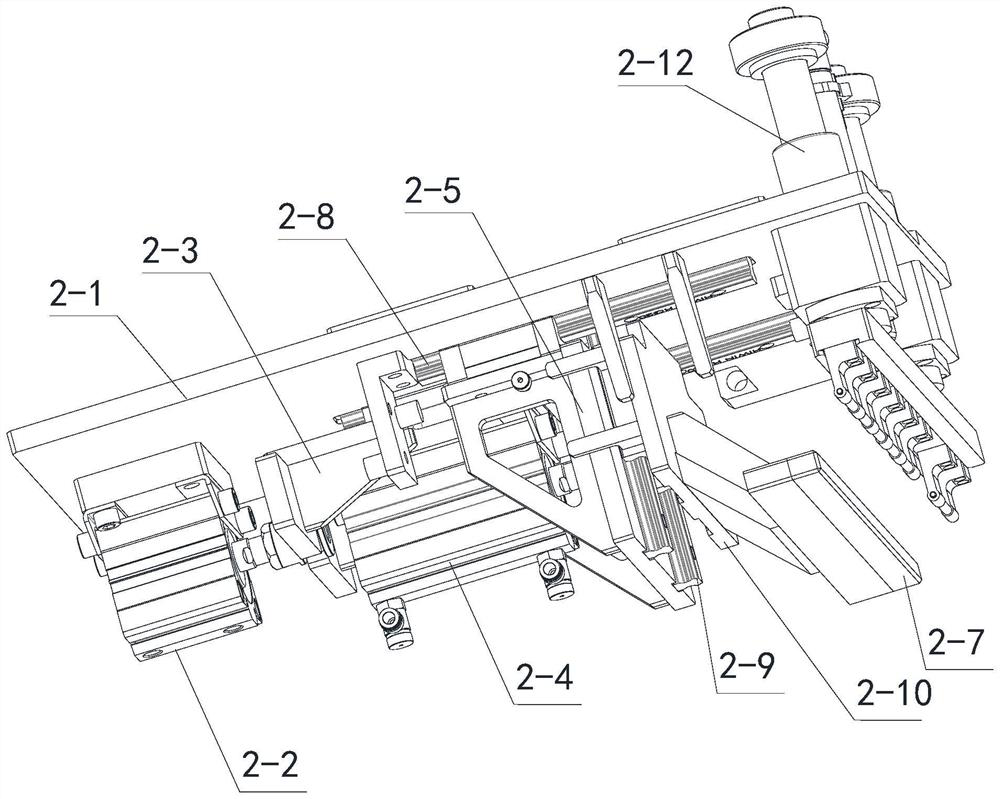

Flexible stirrup continuous feeding positioning machine and feeding positioning method

PendingCN114273829AFacilitate automated productionSolve automatic clampingWelding/cutting auxillary devicesWire networkControl engineeringMachine

The flexible stirrup continuous feeding and positioning machine comprises a control cabinet, a bottom frame, a left chain plate supporting mechanism and a right chain plate supporting mechanism, the left chain plate supporting mechanism and the right chain plate supporting mechanism are arranged on the bottom frame, and the left chain plate supporting mechanism is provided with a left alignment mechanism, a left pushing mechanism and a left positioning mechanism which are electrically connected with the control cabinet; the right chain plate supporting mechanism is provided with a right alignment mechanism, a right pushing mechanism and a right positioning mechanism which are electrically connected with the control cabinet, the left alignment mechanism and the right alignment mechanism are used for conducting left-right alignment on the stirrups, and the left pushing mechanism and the right pushing mechanism are used for pushing the stirrups. The left positioning mechanism and the right positioning mechanism are used for conducting double-position front-back positioning on the stirrup. The invention further provides a feeding positioning method of the flexible stirrup continuous feeding positioning machine. The stirrup automatic welding device solves the technical problems of automatic clamping, automatic feeding and automatic positioning of stirrups during automatic welding of the stirrup cage, and automatic production of the stirrup cage is facilitated. And the flexible requirements of length, height and diameter changes of the stirrup are met.

Owner:RBS PARTNERS S&T CO LTD

Flexible mold pressing mechanism for plate predeformation

The invention relates to a flexible mold pressing mechanism for plate predeformation. The flexible mold pressing mechanism comprises a support frame and pressing head components; the support frame consists of two roller way plates symmetrically arranged, and a cushion plate; the roller way plates take the shape of channel steel; notches of the two roller way plates are opposite; rollers are uniformly distributed in each roller way plate in the length direction; the cushion plate is a strip plate, is arranged in the two roller way plates in the length direction, and is positioned above the rollers; the top surface of the cushion plate is connected with channel steel upper flat plates of the two roller way plates; the pressing head components include slide frames and mold heads; the longitudinal sections of the slide frames are I-shaped; the mold heads take the shape of rectangular blocks, and are transversely connected to the bottom surfaces of the slide frames; more than one pressing head components are matched and mounted in the support frame; the slide frames of the pressing head components can move along the rollers; and the mold heads of the pressing head components are positioned below the support frame. The distance of the pressing head components is adjustable to realize predeformation treatment of plates with different lengths.

Owner:ANHUI HELI CO LTD

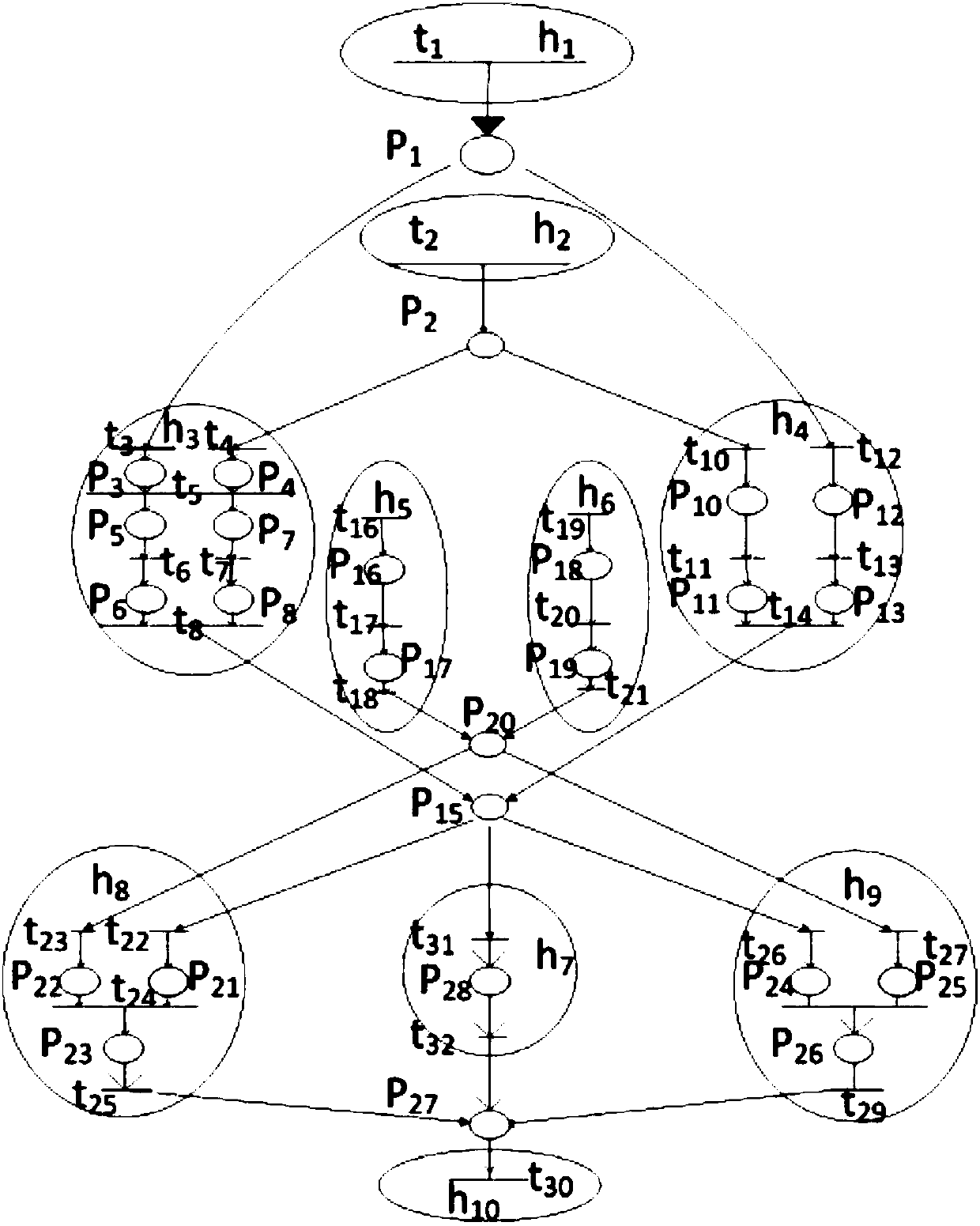

A fault-tolerant assembly control method for flexible small parts based on cooperative petri nets

ActiveCN105759615BOptimize the combination processMeet flexible needsAdaptive controlMathematical definitionFault tolerance

The invention discloses a fault-tolerant flexible small piece assembly control method based on a collaborative Petri network. The method comprises the following steps: 1, a Petri network model general mathematical definition is given; 2, a Petri network workflow for each sub product is described as an open-chain and acyclic Petri network workflow; 3, Petri network workflows between different sub products are combined and connected, || is defined to present a sub product combination, a different sub product Petri network combination completes a different assembly collaboration process control task, and a different target product task is completed; and 4, influences on the system by raw material supply failure by the assembly system and assembly execution action not in place are characterized by a fault-tolerant scale function F(C), F(C) contains a transition link G<C><*> for the collaborative Petri network; and raw material supply failure at a certain place p during the whole process shows that delta(p) is reduced at the place p, and robustness of the assembly system is ensured through controlling the size of delta(mc). The method of the invention has the advantages that the work flexibility is good, and fault tolerance can be controlled.

Owner:ZHEJIANG UNIV OF TECH

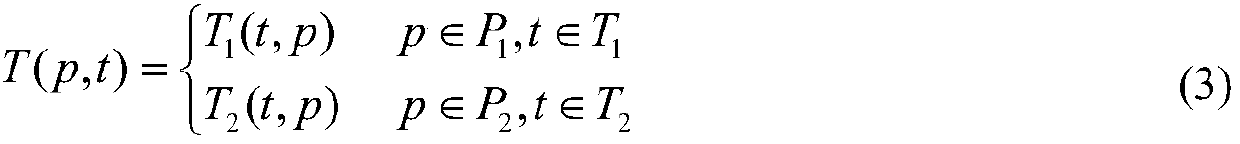

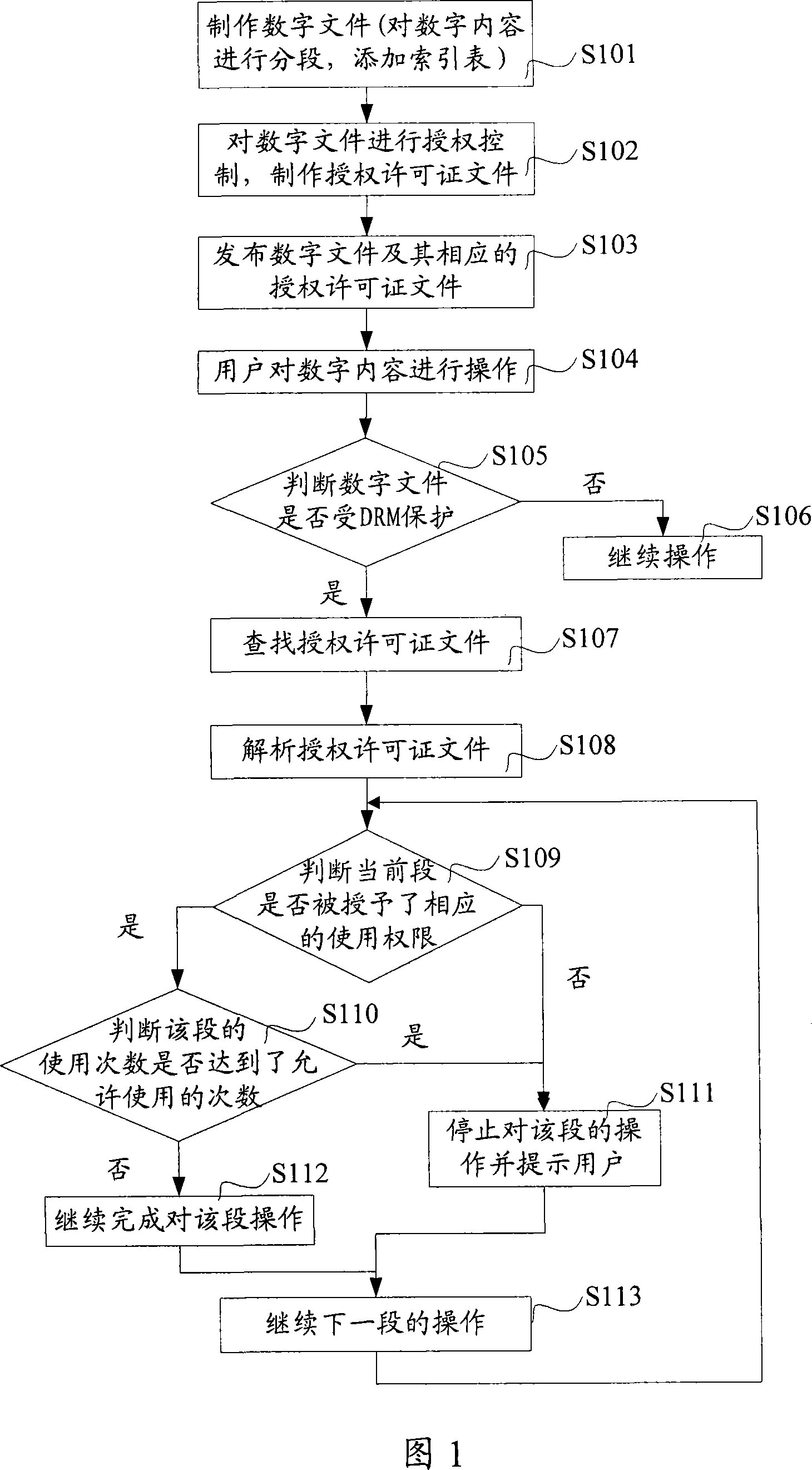

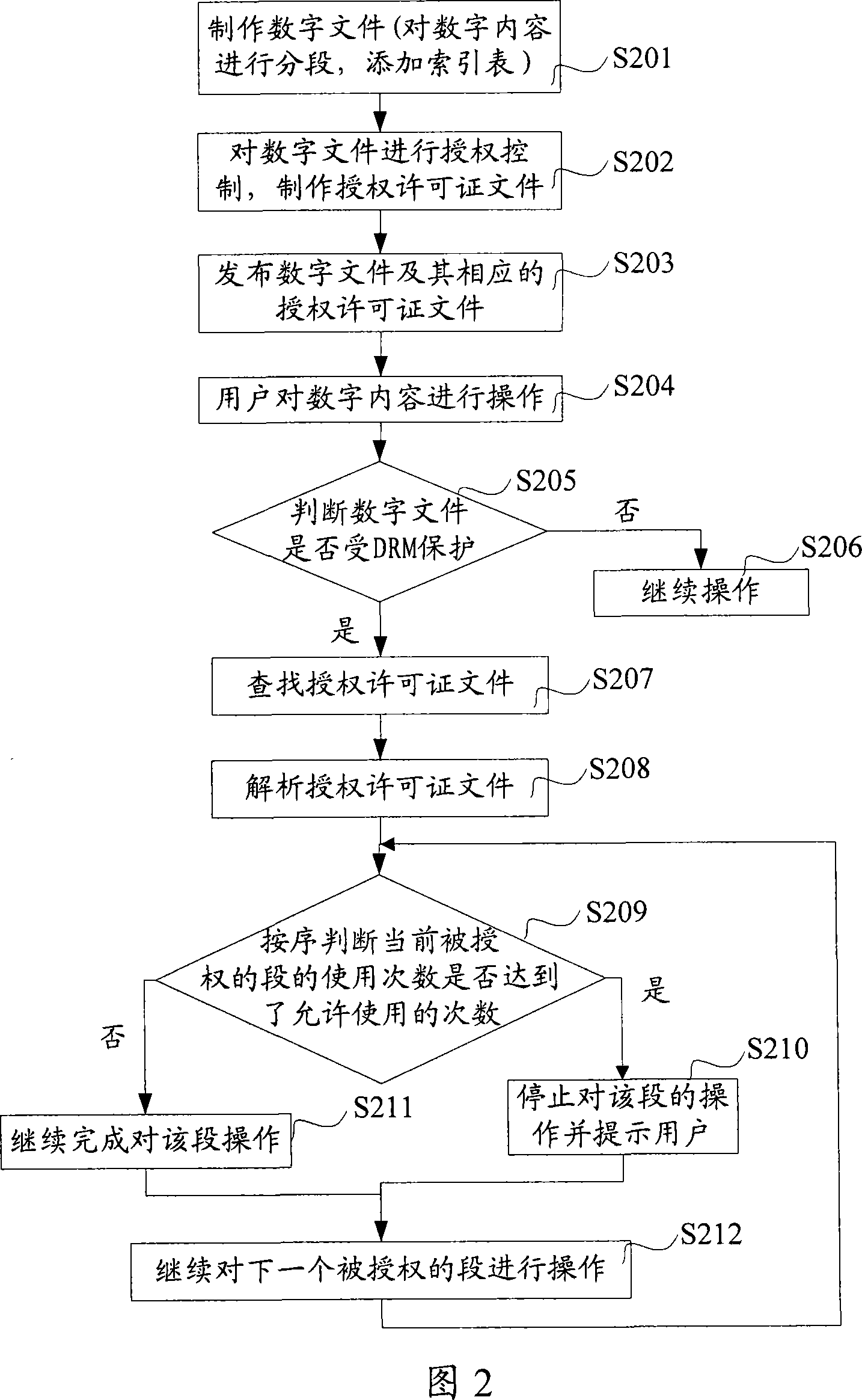

Method and system for implementing authorization management of digital contents

ActiveCN101196971BAvoid splittingMeet flexible needsProgram/content distribution protectionSpecial data processing applicationsDigital contentDigital rights management

The present invention discloses a method and system for realizing authorization management to digital contents, which is applied to the digital rights management technical field. The method comprises that: a file is segmented and added with index marks of segments by utilizing corresponding making tools according to different formats of the file. In an authorization license file, authorization control is performed to the segments according to business requirements. When a user uses reading / video software to perform operation, the software first examines whether the user has corresponding authority or not in the authorization license file according to the segment number of an operation object to be acquired; if the user has corresponding authority, the user is allowed to continue finishingthe operation and use the digital contents of the segment; if the user does not have corresponding authority, the present invention stops the operation to the segment and prompts the user.

Owner:PEKING UNIV +2

High temperature resistant adjustable frequency flexible antenna and manufacturing method thereof

ActiveCN110970720BRough surfaceRich surface roughnessSimultaneous aerial operationsRadiating elements structural formsDielectricThermodynamics

A high-temperature-resistant adjustable-frequency flexible antenna and a manufacturing method thereof. The high-temperature-resistant adjustable-frequency flexible antenna uses a flexible mica sheet as a flexible base layer, and a dielectrically adjustable ceramic film is arranged between the metal layer and the flexible mica sheet. Adjusting electrodes are arranged on the side of the flexible mica sheet away from the dielectrically adjustable ceramic film, so that the high temperature-resistant adjustable frequency flexible antenna can also adjust the operating frequency of the antenna while being able to withstand higher temperatures.

Owner:INST OF FLEXIBLE ELECTRONICS TECH OF THU ZHEJIANG +1

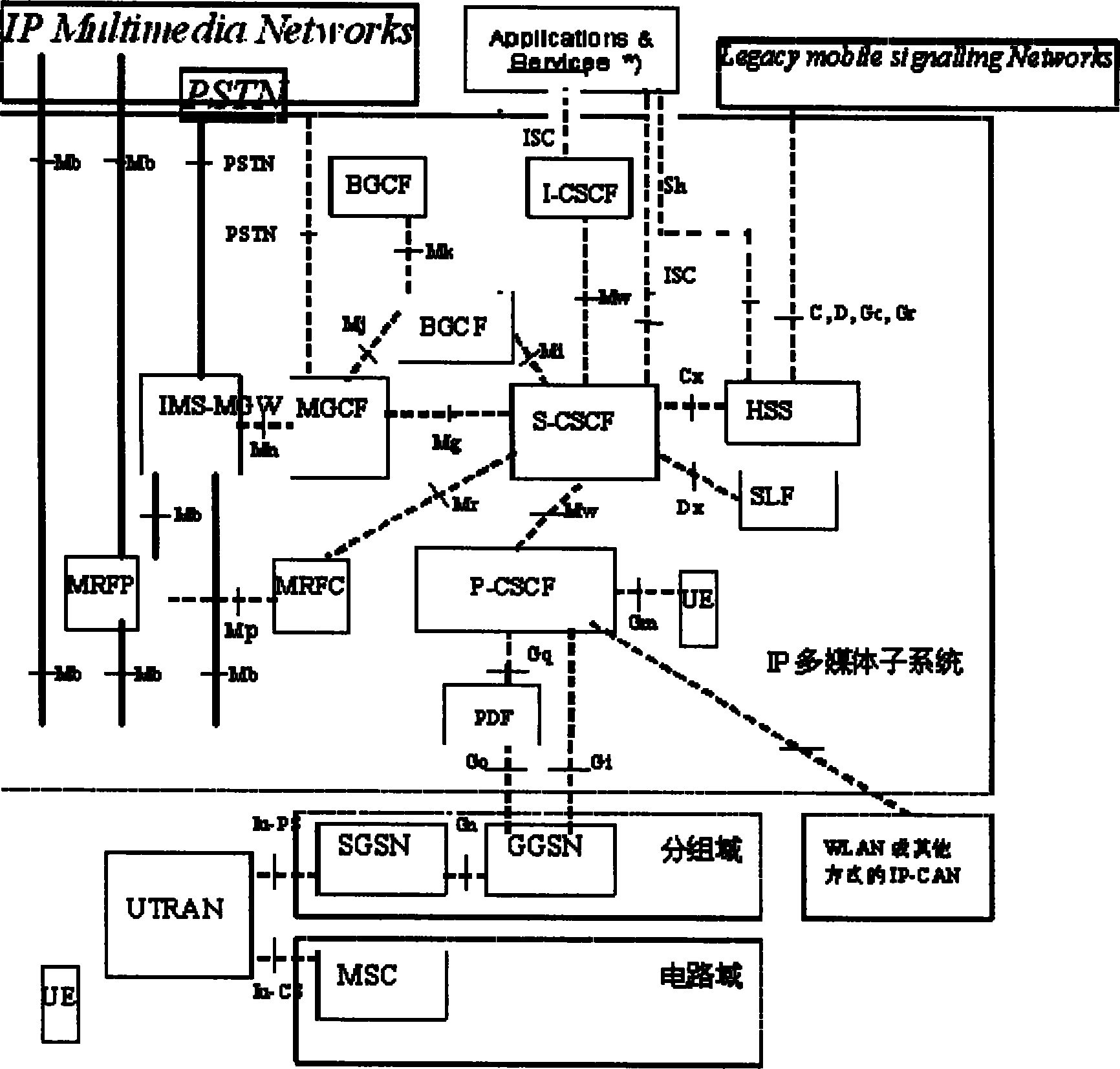

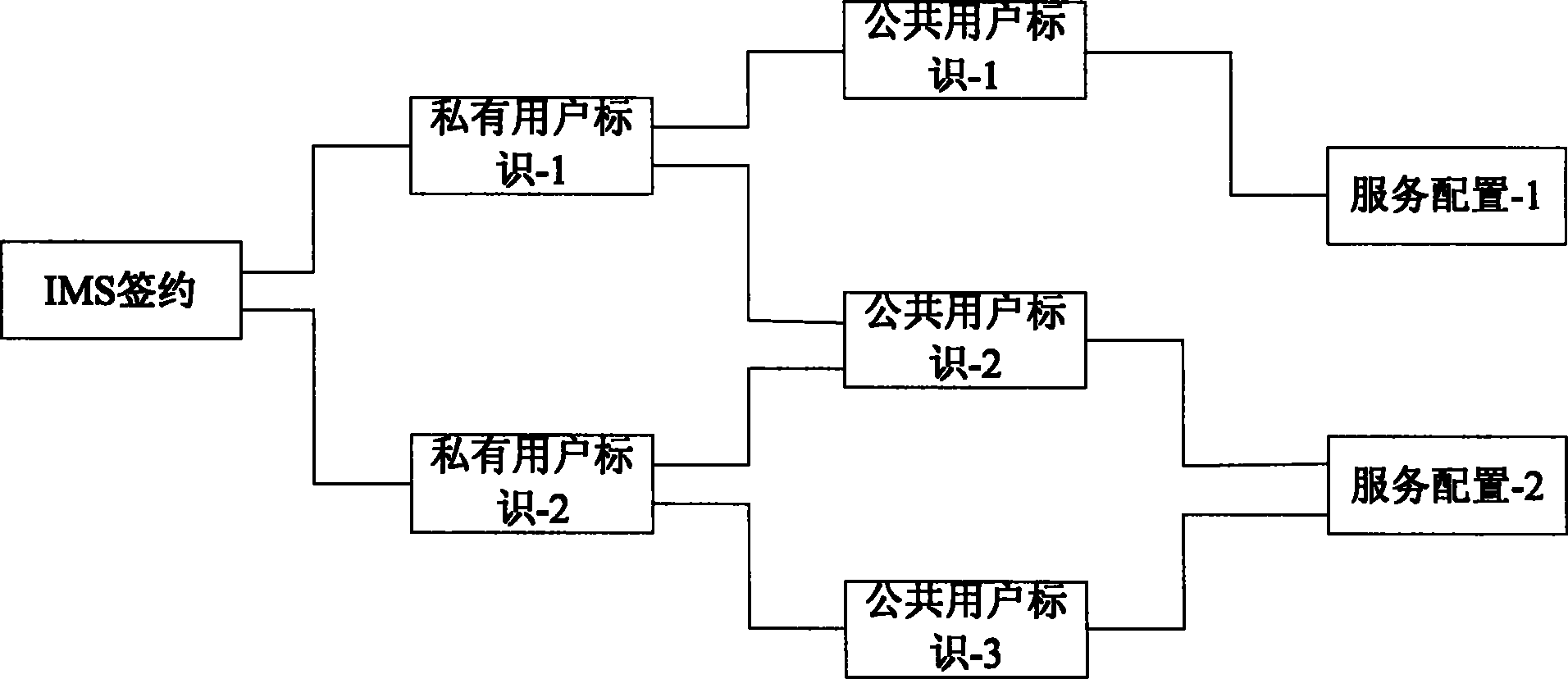

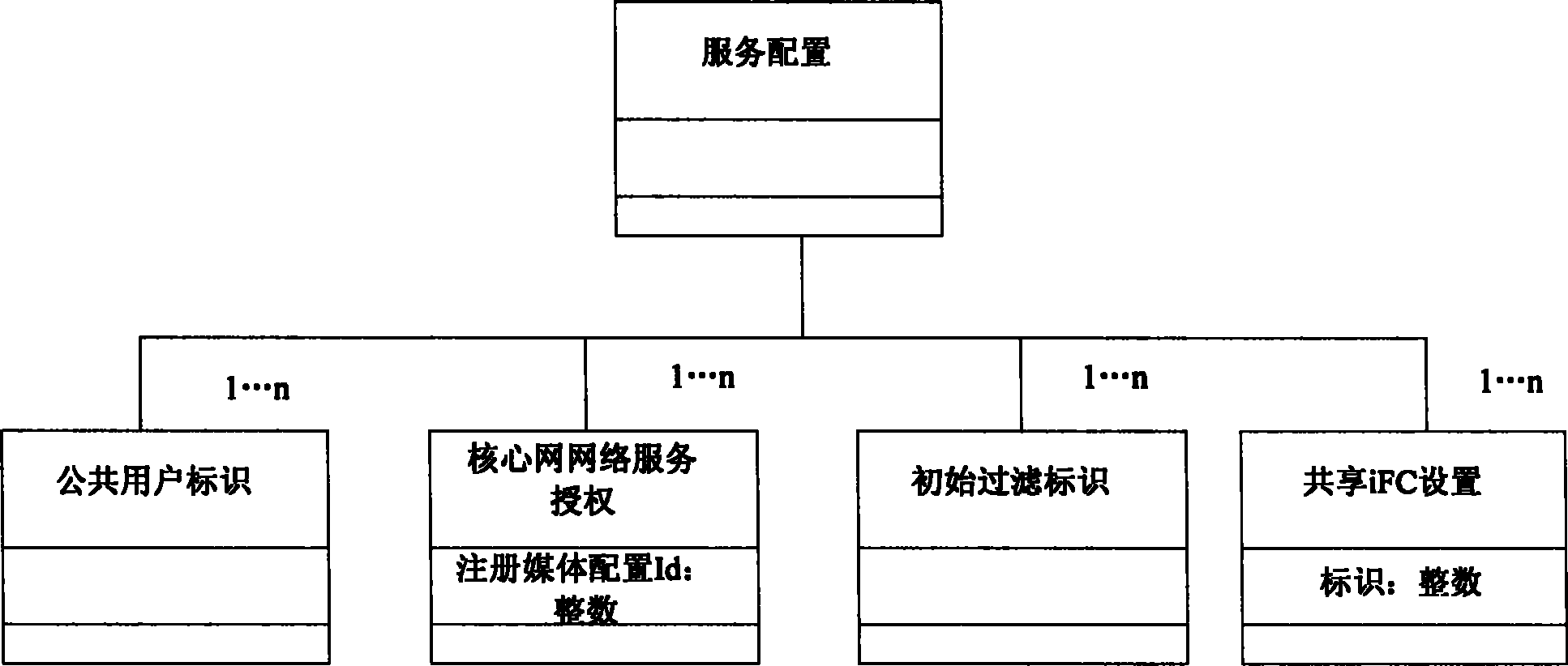

Method for sensing public user mark under service configuration in communication system

This invention relates to a method for sensing public user ID matched by service in a communication system including: an entity storing service matched information transmits at least one public ID message associated with a same service match to entities communicating with it, which get the ID message of at least one public user associated with the same service match from the information sent by the entity keeping the service match information, so that entities of S-CSCF, AS and UE can sense public user ID information associated with a same service match to realize related operation based on the method of dividing users based on the service match.

Owner:HUAWEI TECH CO LTD

High temperature resistant flexible array antenna and manufacturing method thereof

ActiveCN110994167BElasticRich surface roughnessRadiating elements structural formsAntenna arrays manufactureAdhesiveEngineering

A high-temperature-resistant flexible array antenna and a manufacturing method thereof. The antenna uses a flexible mica sheet as a substrate, and a plurality of antenna units are arranged on the substrate, and the plurality of antenna units are electrically connected through a wire layer. Each antenna unit comprises a metal bonding layer, a substrate and a metal layer, the substrate is fixed on the flexible mica sheet by the metal bonding layer, the metal layer is arranged on the side of the substrate away from the metal bonding layer, and the metal bonding The layer is electrically connected to the metal layer. While the high-temperature-resistant flexible array antenna can withstand higher temperatures, it can also easily conform to other objects, thereby greatly reducing the space used.

Owner:INST OF FLEXIBLE ELECTRONICS TECH OF THU ZHEJIANG +1

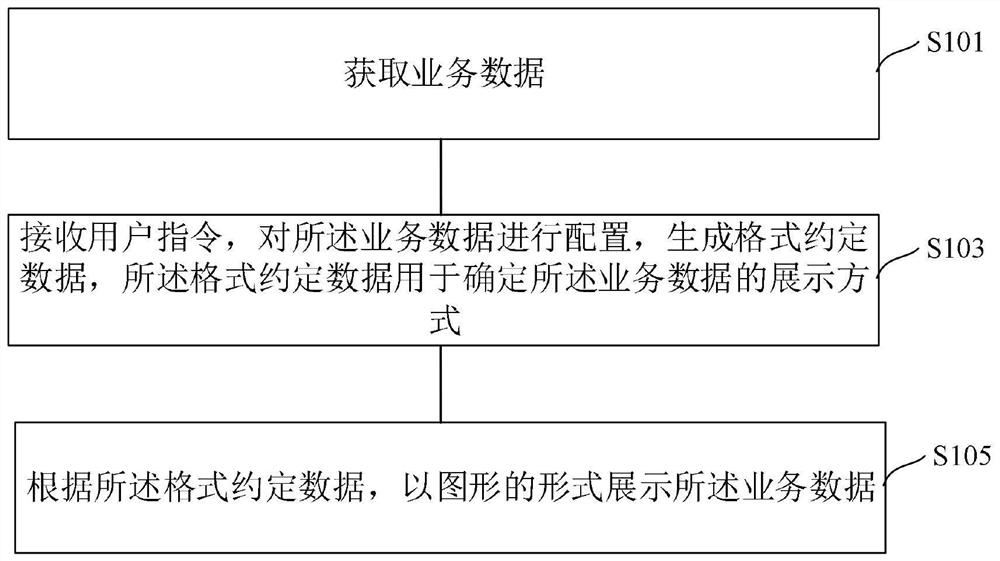

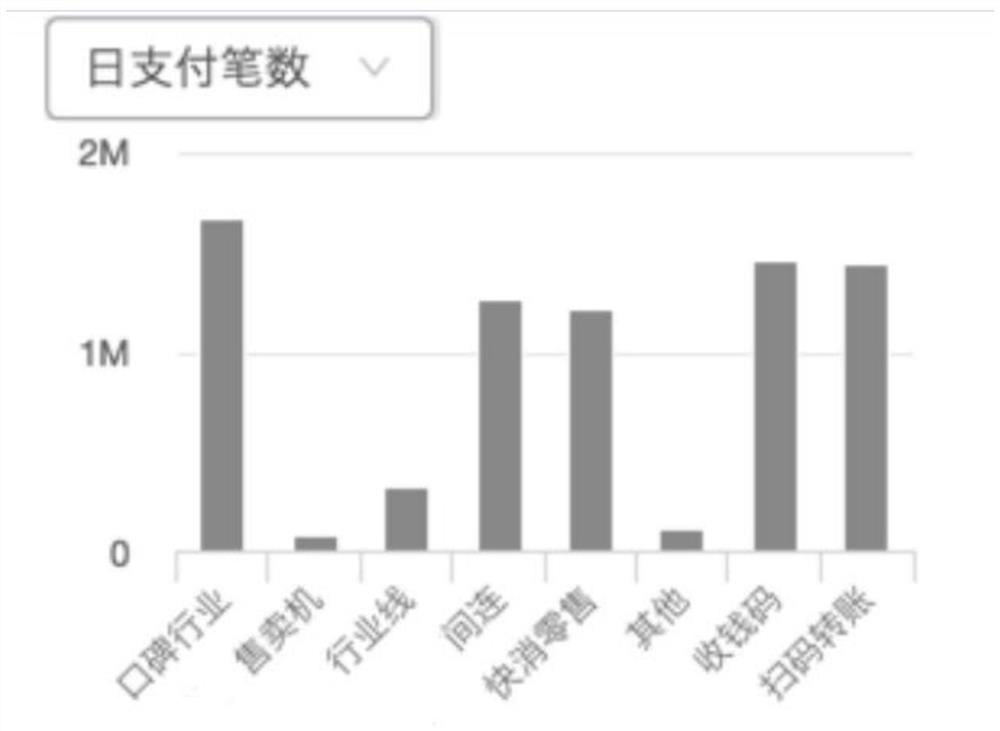

Data display method, device and equipment

PendingCN114780630AMeet flexible needsLow costVisual data miningStructured data browsingData displayData format

The embodiment of the invention discloses a data display method, device and equipment. In an application scene of big data, the display form, the data format and the authentication granularity of the data can be dynamically specified through dynamic configuration of the data display format, the data can be displayed in different formats according to actual requirements, various flexible requirements in the data scene are met, and the data display efficiency is improved. And the presentation layer only needs to perform universal processing presentation according to an agreed format. And if the service requirements are adjusted subsequently, the requirements can be met only by modifying the dynamic configuration without an independent release process.

Owner:ADVANCED NEW TECH CO LTD

Rapid switching system and method for production of acid pickling flat coil and black flat coil

The invention relates to a fast switching system and method for acid pickling flat coil production and black flat coil production, and belongs to the technical field of steel rolling, a wringing roller is adopted for acid pickling flat coil production, a black flat coil special roller is adopted for black flat coil production, and therefore the consumption of the wringing roller is reduced; and the quick switching between the wringing roller and the special roller for the black flat coil is realized through the quick roller changing device when the production modes are switched, so that the black flat coil is produced on the continuous pickling and leveling unit at low cost, the quick switching between the pickling and leveling coil production and the black flat coil production is also realized, and the roller changing time is shortened. In addition, the upper part of the acid tank is provided with a rapid flushing nozzle for flushing residual acid in the acid tank, so that the cover of the acid tank can be opened in a short time, the process conversion / adjustment time is shortened, and the production efficiency is improved.

Owner:CISDI ENG CO LTD

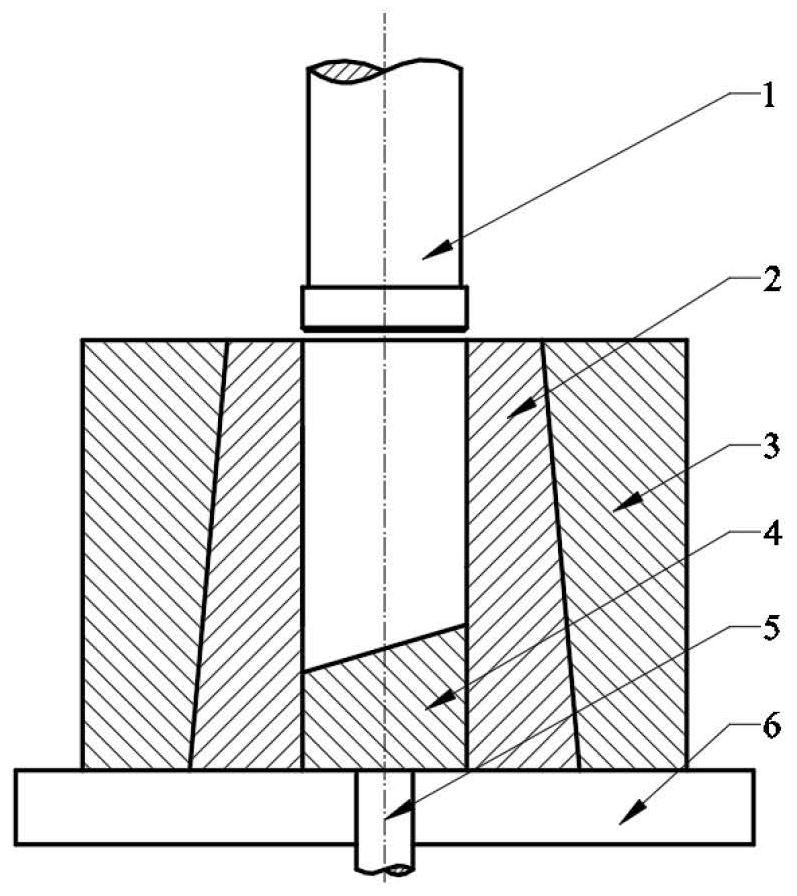

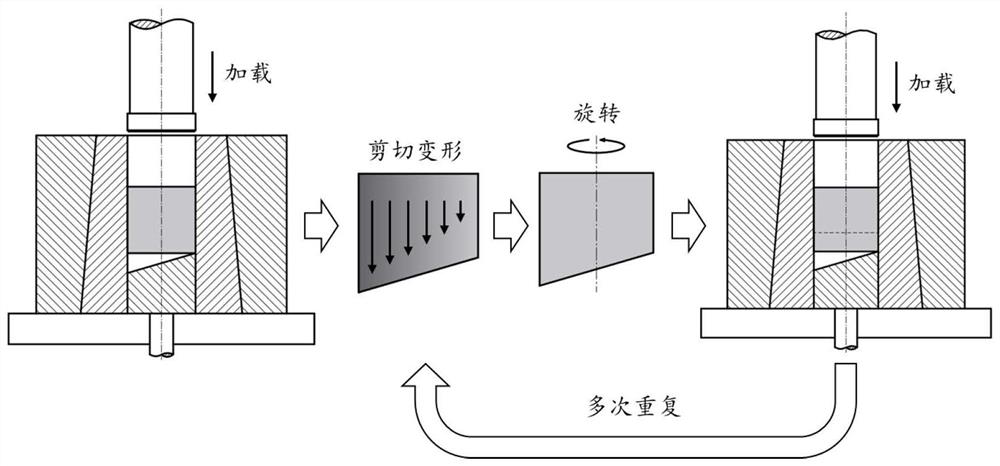

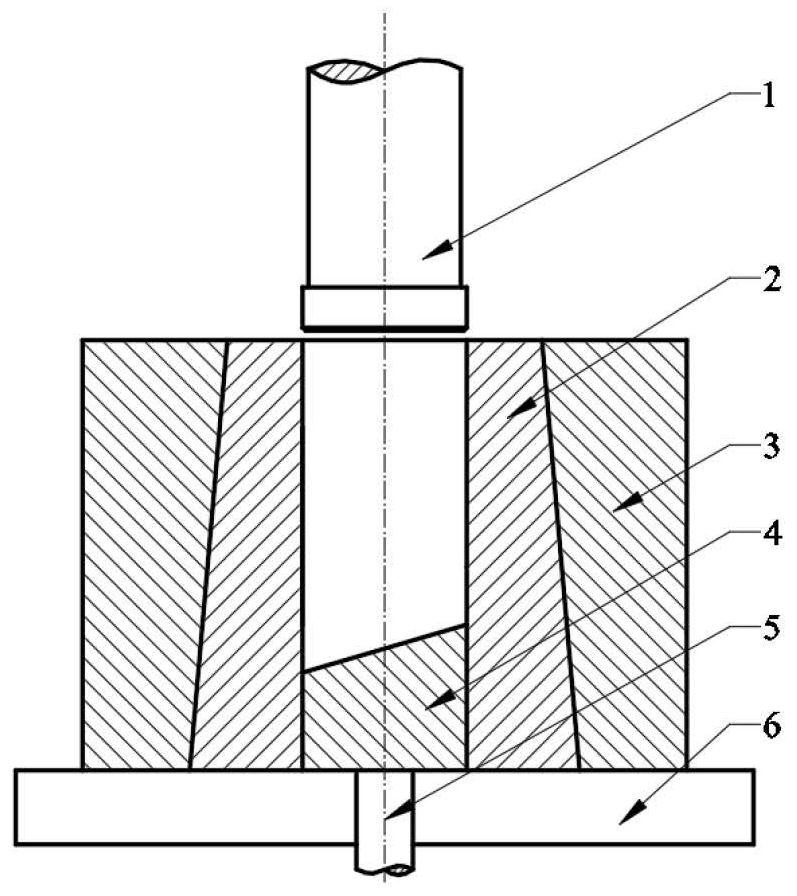

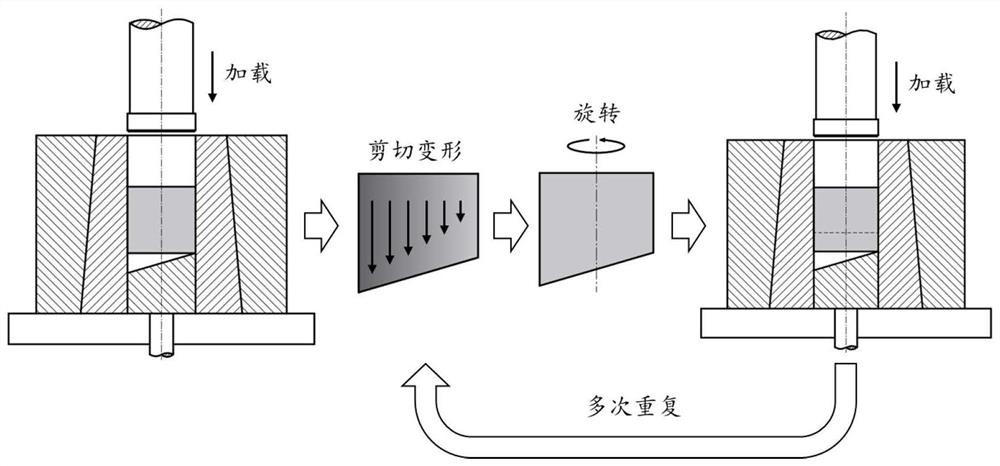

Method for refining titanium alloy microstructure through circular dislocation shearing and severe plastic deformation

The invention discloses a method for refining a titanium alloy microstructure through circular dislocation shearing and severe plastic deformation. Loading is carried out, so that a cylindrical metal blank is subjected to overall shear deformation at a certain temperature T (T is greater than T beta, and T beta is a beta phase transformation temperature) in a single-phase region under an isothermal deformation condition, then the blank is taken out, the blank is rotated by a certain angle along the axis of a loading direction (or rotated after the vertical direction of the cylindrical blank is adjusted) and then placed into a machining device again, a load is applied to enable the blank to generate shear deformation different from shear deformation in a last flowing direction, then the blank is taken out, rotated for a certain angle, and then is loaded again repeatedly , so that the blank is subjected to uniform shear deformation. According to the method, strain energy is accumulated in the titanium alloy blank through circular dislocation violent shear deformation, so that crystal grains in the titanium alloy blank are broken and dynamically recrystallized, the blank is deformed after being rotated by different angles for multiple times, the deformation uniformity of different positions of a component is improved, and equiaxial fine weak-texture beta-phase crystal grains are obtained.

Owner:HARBIN INST OF TECH AT WEIHAI

Station travelling operation control method and device, computer equipment and storage medium

ActiveCN111752423ASave resourcesMeet flexible needsInput/output processes for data processingAlarm messageRouting table

The invention provides a station travelling operation control method and device, computer equipment and a storage medium. The method comprises the steps of acquiring control interface information of arailway transportation control terminal, wherein the control interface information carries a station yard graph; according to the station yard graph, identifying a starting end button in the stationyard graph; capturing a target operation point in the station yard graph; and identifying a signal button in a preset range of the target operation point, detecting whether the starting end button andthe signal button form an interlocking route according to the signal button in the preset range of the target operation point, the state of the signal button and a preset interlocking route table, and generating an alarm message according to a detection result and a preset driving condition. According to the process, on the basis of the image information of the station yard graph and the positionof the target operation point, under the condition of not being connected with a signal system, mistaken handling alarm can be achieved before mistaken handling of the route, an operator can conveniently check and correct route errors in time, and the method has the advantages of saving resources and cost and meeting flexible requirements.

Owner:上海睿栈科技有限公司

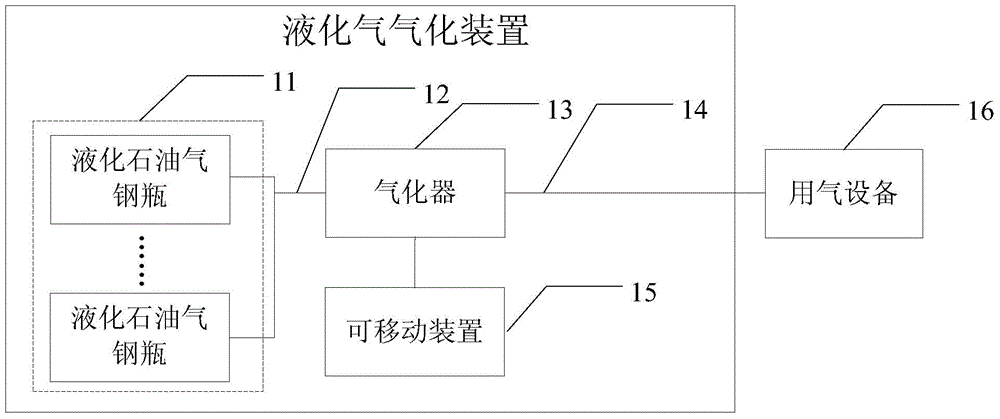

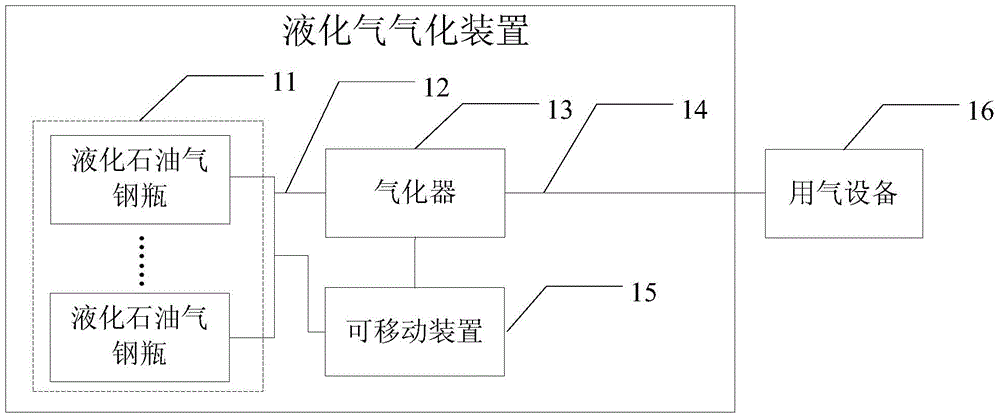

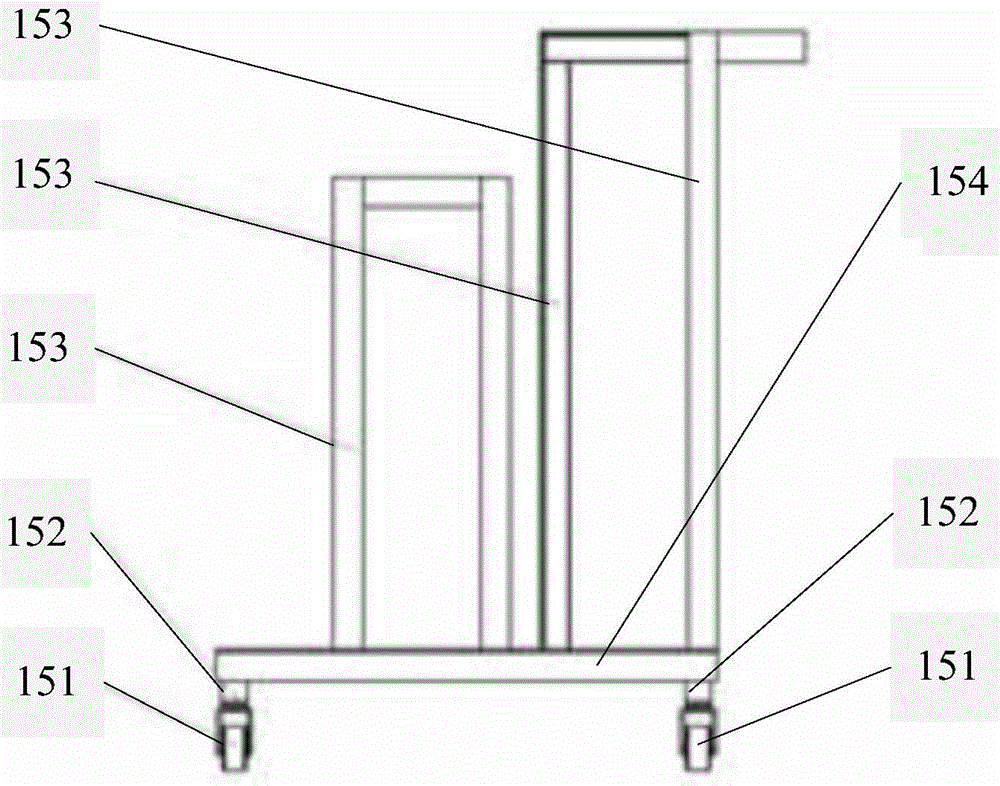

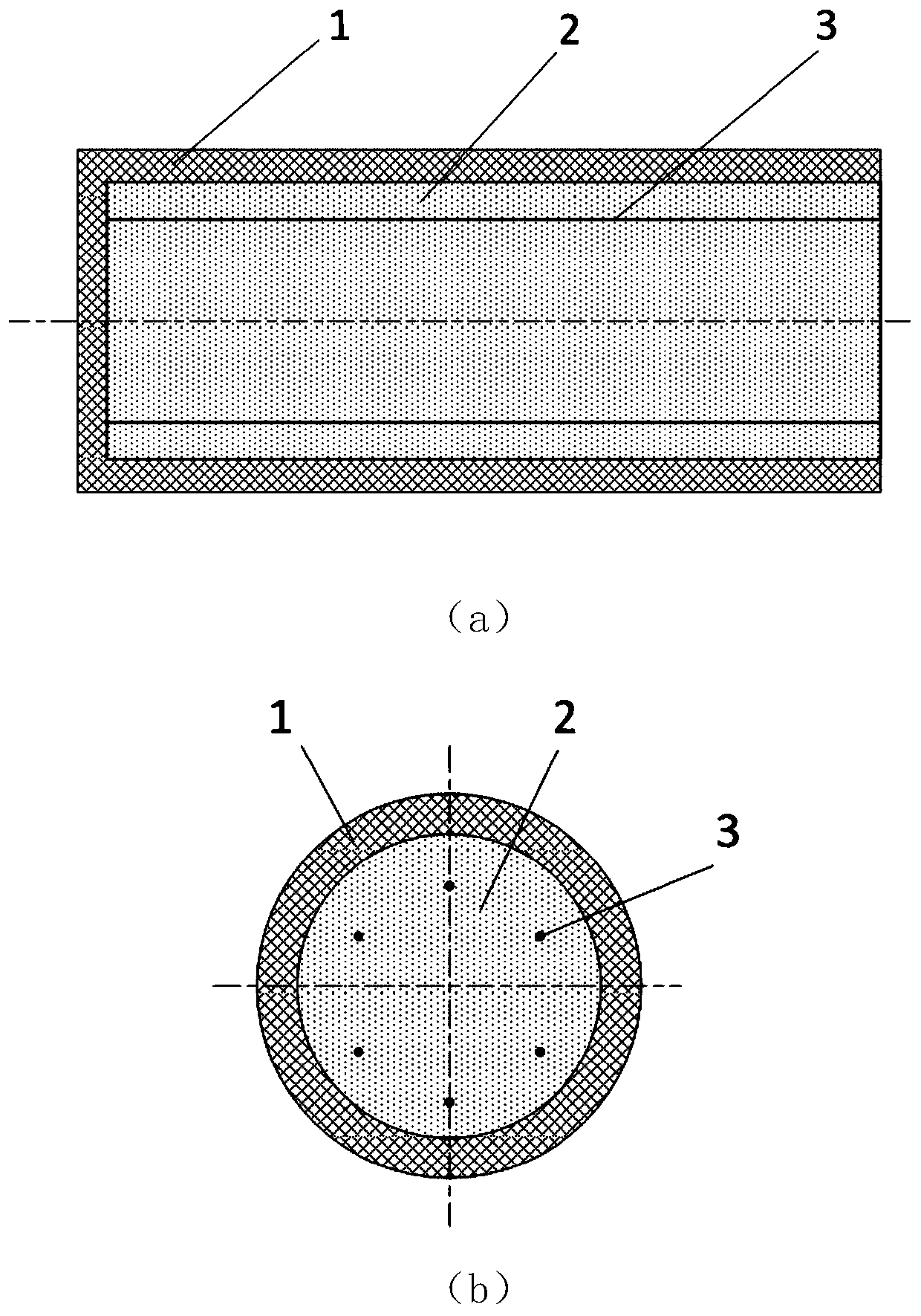

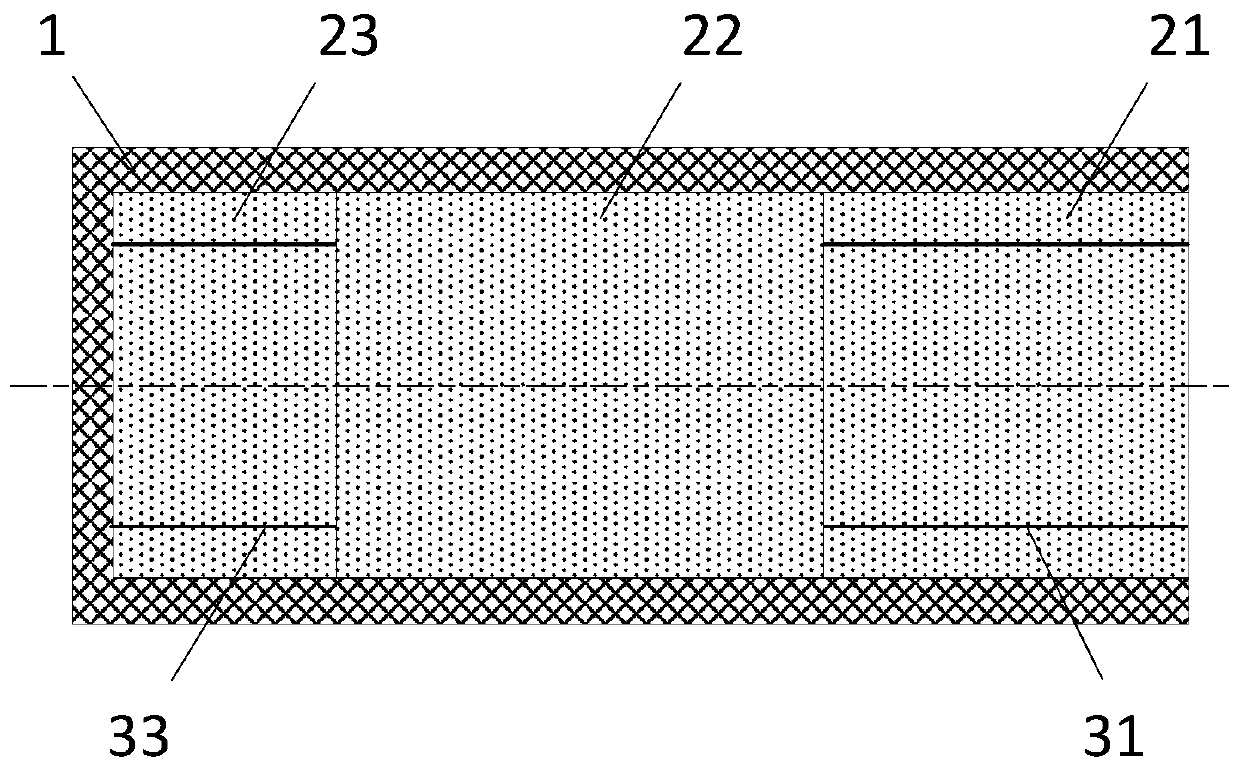

Gasification device for liquefied gas

InactiveCN104613310AFlexible and convenient to moveMeet flexible needsContainer filling methodsPressure vesselsBottleLiquid gas

The invention provides a gasification device for liquefied gas. The gasification device comprises at least one liquefied petroleum gas steel bottle, a gas inlet pipeline, a gasifier, a gas outlet pipeline and a movable device, wherein each liquefied petroleum gas steel bottle is connected with a gas inlet of the gasifier through the gas inlet pipeline, and a gas outlet of the gasifier is connected with the gas outlet pipeline; the gasifier is detachably arranged on the movable device and moves through the movable device. According to the gasification device for the liquefied gas provided by the invention, the gasifier arranged on the movable device can flexibly and conveniently move to any gas utilization place of a user, so that the gasification device for the liquefied gas can be used for gasifying liquefied petroleum gas at any gas utilization place of the user; meanwhile, due to gasification and large liquefied petroleum gas output capacity of the gasifier, the gasification device for the liquefied gas provided by the invention can meet gas utilization demands of the user on large gas utilization capacity and flexible gas utilization places.

Owner:KEDA MAS CLEAN ENERGY

An embedded composite metal wire end-burning charge

ActiveCN109973245BAvoid Bonding InterfacesMeet flexible needsRocket engine plantsStructural engineeringMechanical engineering

The invention discloses an embedded combined metal wire end-burning propellant. The embedded combined metal wire end-burning propellant comprises a cladding sleeve, a propellant grain, take-off metalwires, fixed connection wires and speed-up metal wires; the cladding sleeve is glued to the outside of the propellant grain; the take-off metal wires, the fixed connection wires and the speed-up metalwires are connected in sequence to form combined metal wires; and the combined metal wires are uniformly distributed in the propellant grain circumferentially with the axis of the propellant grain asthe center, and the end-burning propellant is formed. By means of the embedded combined metal wire end-burning propellant, the purpose that the different burning speeds are achieved at different speed-up multiples of the same type of propellant can be achieved.

Owner:北京灵动飞天动力科技有限公司

A Method for Refinement of Titanium Alloy Microstructure by Cyclic Dislocation Shear Large Plastic Deformation

The invention discloses a method for refining the microstructure of titanium alloy by cyclic dislocation shearing and large plastic deformation. Loading makes the cylindrical metal billet under the condition of isothermal deformation, at a certain temperature T in the single-phase region (T>T β ,T β β phase transition temperature) undergoes overall shear deformation, and then the billet is taken out, rotated at a certain angle along the axis of the loading direction (the cylindrical billet can also be rotated after adjusting the up and down directions) and put into the processing device again, and the billet is subjected to a different load. For the shear deformation in the last flow direction, the billet is then repeatedly taken out and rotated at a certain angle before loading again, so that the billet undergoes uniform shear deformation. This method accumulates strain energy inside the titanium alloy billet through cyclic dislocation and severe shear deformation, so that the internal grains are broken and dynamic recrystallization occurs, so that the billet is deformed after multiple rotations at different angles, and the deformation at different positions of the component is improved. property, obtaining equiaxed, fine and weakly textured β-phase grains.

Owner:HARBIN INST OF TECH AT WEIHAI

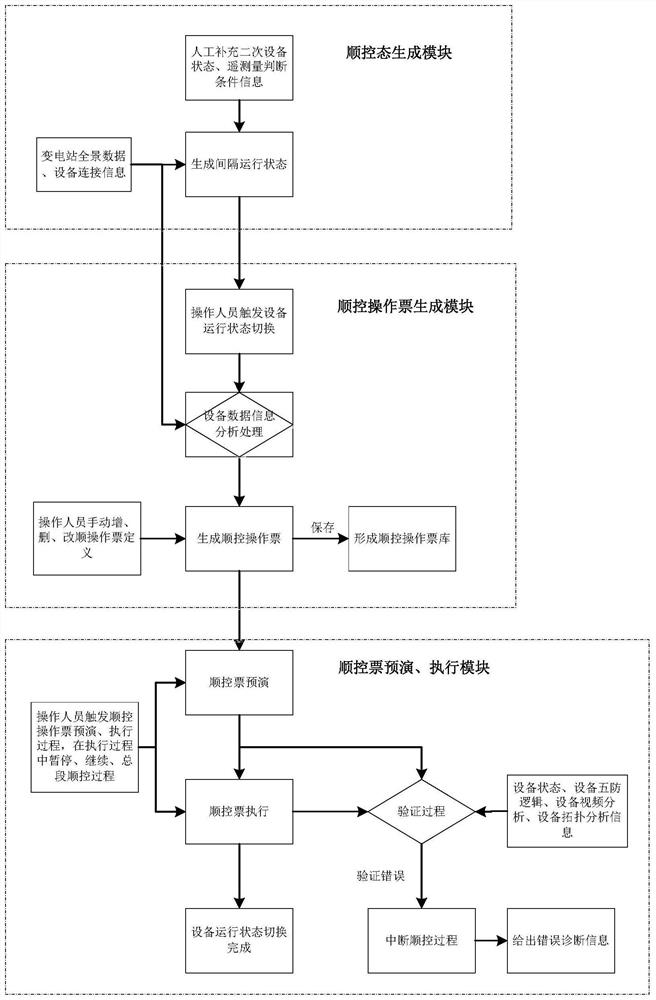

An intelligent sequential control system and method based on panoramic data in substations

ActiveCN109617241BEasy to switchReliable switching operationCircuit arrangementsInformation technology support systemSequence controlControl system

An intelligent sequential control system and method based on panoramic data in a substation. The intelligent sequential control system is composed of three modules, which are the sequential control state generation module, the sequential control operation ticket generation module, and the sequential control operation ticket preview and execution module. The sequential control state generation module divides the operating state of the substation into numerous interval sequential control states by analyzing the panorama data in the substation. The sequence control operation ticket generation module obtains the sequence control state definition generated by the sequence control state generation module, and assists the operator to generate the sequence control operation ticket for the operation state switching process in the station. The sequence control ticket rehearsal and execution module simulates the sequence control ticket rehearsal and executes the sequence control ticket process to complete the operation state switching process in the station. Based on the intelligent sequence control system and method of the present invention, the workload of operators is reduced, and the difficulty of work of operators is reduced, which is of great significance for improving the operation efficiency in the substation and ensuring the safe and reliable operation of the power system.

Owner:BEIJING SIFANG JIBAO AUTOMATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com