A Method for Refinement of Titanium Alloy Microstructure by Cyclic Dislocation Shear Large Plastic Deformation

A technology of large plastic deformation and microstructure, used in metal material processing equipment and processing fields, can solve the problems of uneven deformation, high sensitivity of microstructure deformation history, differences in microstructure characteristics, etc., and achieve the effect of refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

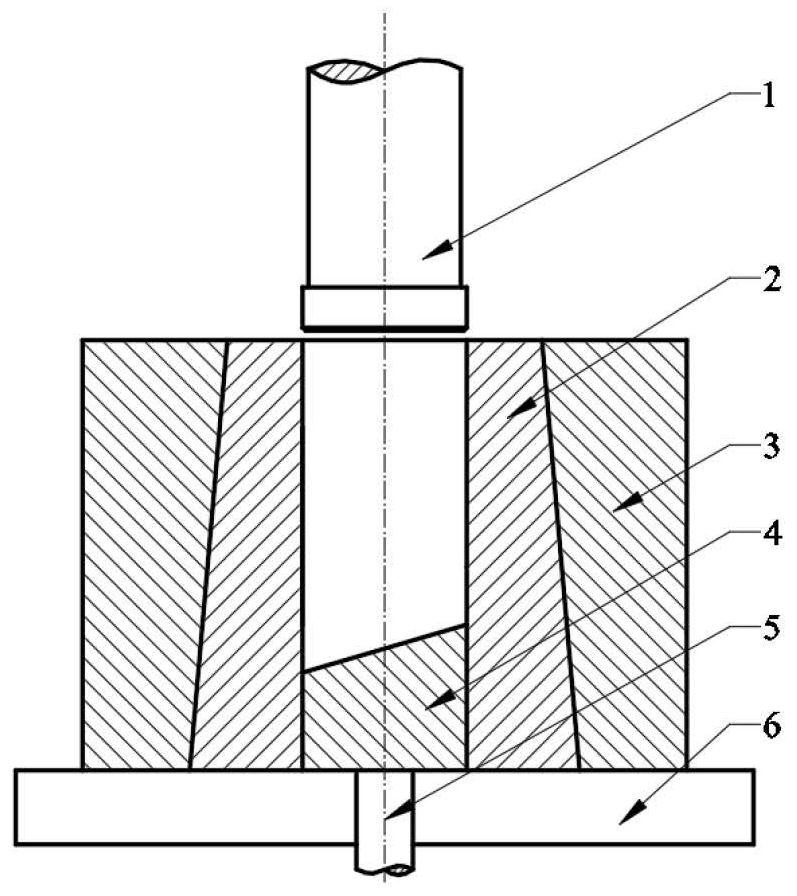

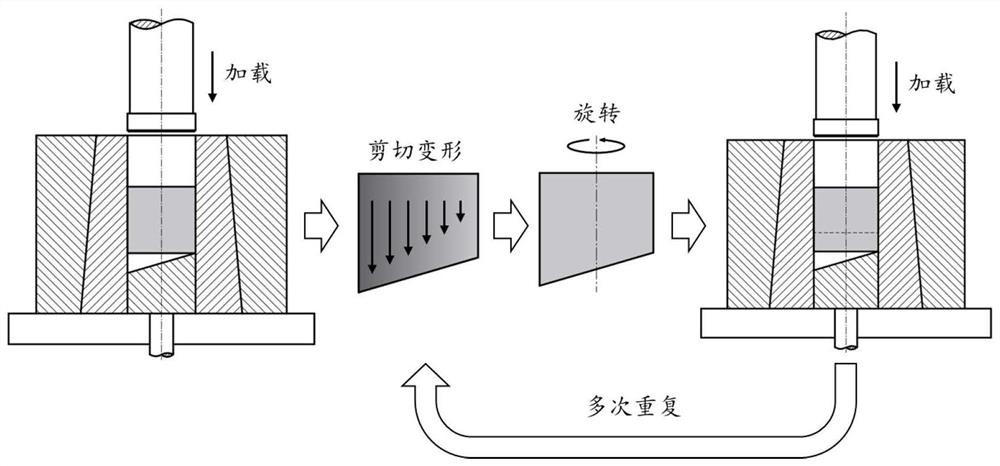

[0065] Step 1. Machining and assembling a deformation device for metal blank deformation.

[0066] The deformation device includes a punch 1, a die 2, a die cover 3, a push rod 5, an inclined pad 4 and a lower template 6, and the die cover 3 and the lower template 6 are fixedly connected, and the die 2 is located in the In the mold cover 3, the inside of the die 2 is a cylindrical cavity with an inner diameter of d=50mm, and the inclined pad 4 is located at the bottom side of the die cavity of the die 2; the edge of the die 2 is provided with chamfers, The punch 1 is cylindrical, and the punch 1 is matched with the cavity, the slope pad 4 is a stepped slope, the thickness of the slope pad 4 is different on both sides, and the angle of the slope is 10 °, the punch 1, the die 2, and the inclined pad 4 are all made of superalloy materials.

[0067] Step 2, heating the metal blank and keeping it warm,

[0068] The cylindrical metal billet Ti-55531 titanium alloy was heated to 90...

specific Embodiment approach 2

[0078] Step 1. Machining and assembling a deformation device for metal blank deformation.

[0079] The deformation device includes a punch 1, a die 2, a die cover 3, a push rod 5, an inclined pad 4 and a lower template 6, and the die cover 3 and the lower template 6 are fixedly connected, and the die 2 is located in the In the mold cover 3, the inside of the die 2 is a cylindrical cavity with an inner diameter of d=40mm, and the inclined pad 4 is located at the bottom side of the die cavity of the die 2; the edge of the die 2 is provided with chamfers, The punch 1 is cylindrical, and the punch 1 is matched with the cavity, the slope pad 4 is a stepped slope, the thickness of the two sides of the slope pad 4 is different, and the angle of the slope is 15 °, the punch 1, the die 2, and the inclined pad 4 are all made of superalloy materials.

[0080] Step 2, heating the metal blank and keeping it warm,

[0081] The cylindrical metal billet Ti-1023 titanium alloy was heated to ...

specific Embodiment approach 3

[0091]Step 1. Machining and assembling a deformation device for metal blank deformation.

[0092] The deformation device includes a punch 1, a die 2, a die cover 3, a push rod 5, an inclined pad 4 and a lower template 6, and the die cover 3 and the lower template 6 are fixedly connected, and the die 2 is located in the In the mold cover 3, the inside of the die 2 is a cylindrical cavity with an inner diameter of d=30mm, and the inclined pad 4 is located at the bottom side of the die cavity of the die 2; the edge of the die 2 is provided with chamfers, The punch 1 is cylindrical, and the punch 1 is matched with the cavity, the slope pad 4 is a stepped slope, the thickness of the slope pad 4 is different on both sides, and the angle of the slope is 20 °, the punch 1, the die 2, and the inclined pad 4 are all made of superalloy materials.

[0093] Step 2, heating the metal blank and keeping it warm,

[0094] The cylindrical metal billet Ti-55511 titanium alloy was heated to 900...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com