An embedded composite metal wire end-burning charge

A composite metal and metal wire technology, which is applied in jet propulsion devices, rocket engine devices, machines/engines, etc., can solve the problems of low production efficiency, unfavorable production organization, and single wire specifications, so as to improve production efficiency and reliability , the effect of meeting flexible needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

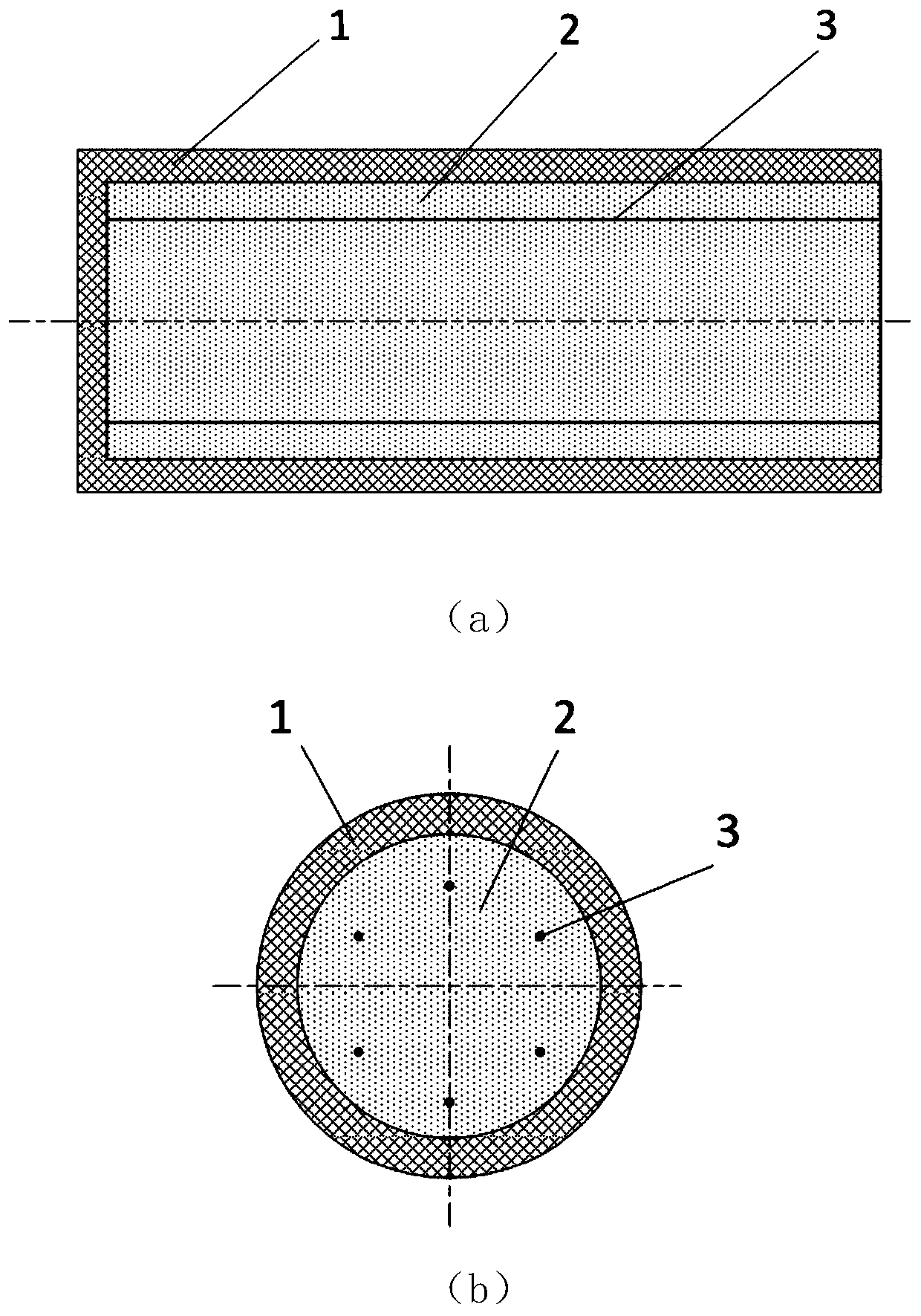

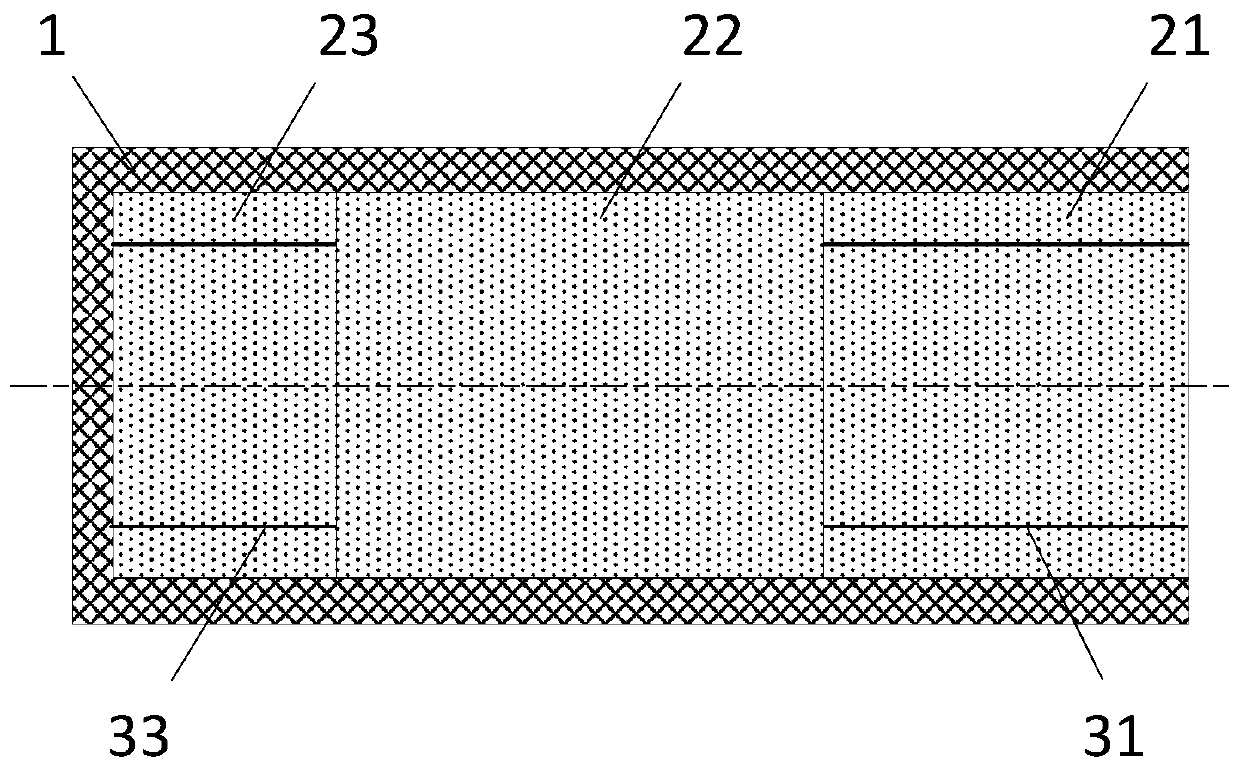

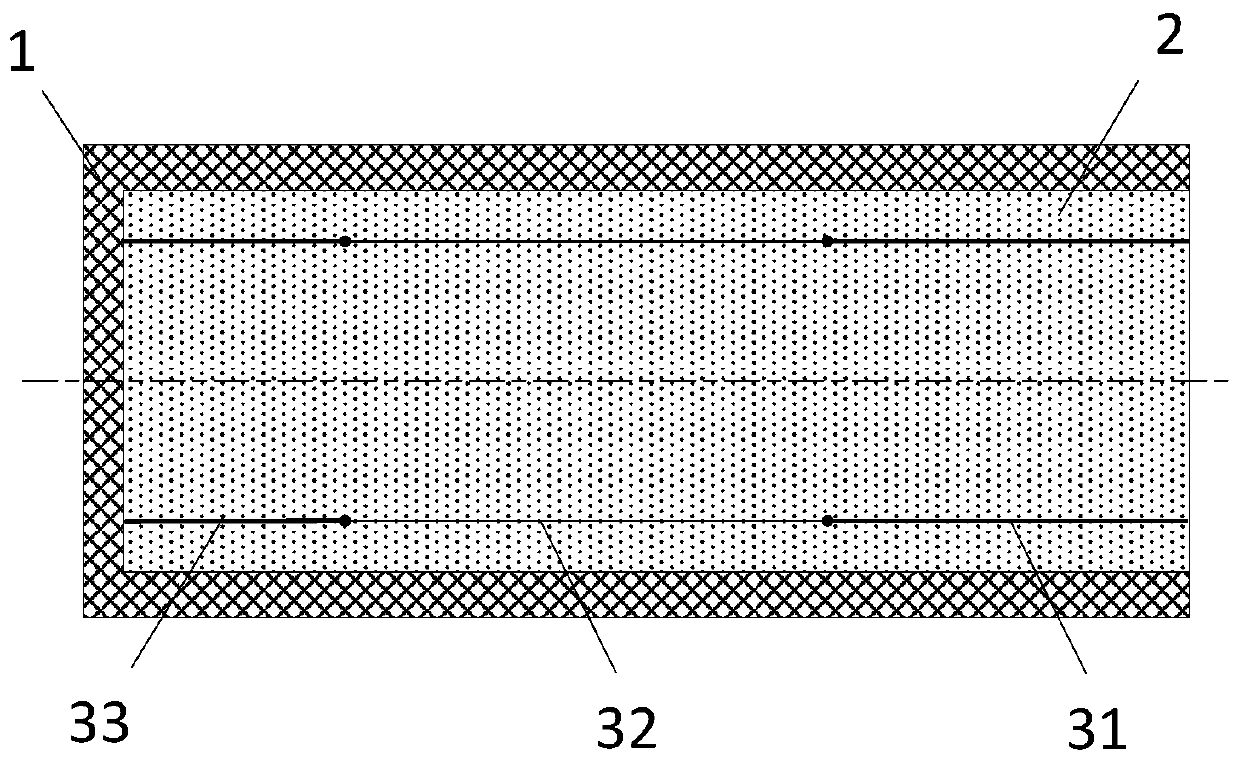

[0019] Traditional three-thrust end-fired powder embedded with metal wire such as figure 2 As shown, it is composed of a covering sleeve 1, a take-off grain 21, an endurance grain 22, an acceleration grain 23, a take-off silver wire 31 and an acceleration silver wire 33. Among them, the take-off grain 21, the endurance grain 22, and the acceleration grain 23 have the same diameter and the same propellant formula, all of which are three-component hydroxybutylene propellants with a basic burning rate of 25mm / s (6.86MPa). The left end of the take-off grain 21 The surface is bonded to the right end surface of the endurance grain column 22, the left end surface of the endurance grain column 22 and the right end surface of the acceleration grain column 23, and all contact surfaces between the three and the covering sleeve 1 are bonded and fixed. The take-off p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com