Ultra thin waterproof shell battery integrated molding structure, production equipment and production method

A technology of waterproof casing and forming structure, applied in the direction of sealed casing, structural parts, battery pack components, etc., can solve the problems of fashionable and novel appearance of flexible wearable devices, no integrated molding process, difficult surface treatment process, etc. The effect of better hand feeling, reducing the thickness of the mobile phone and increasing the battery area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

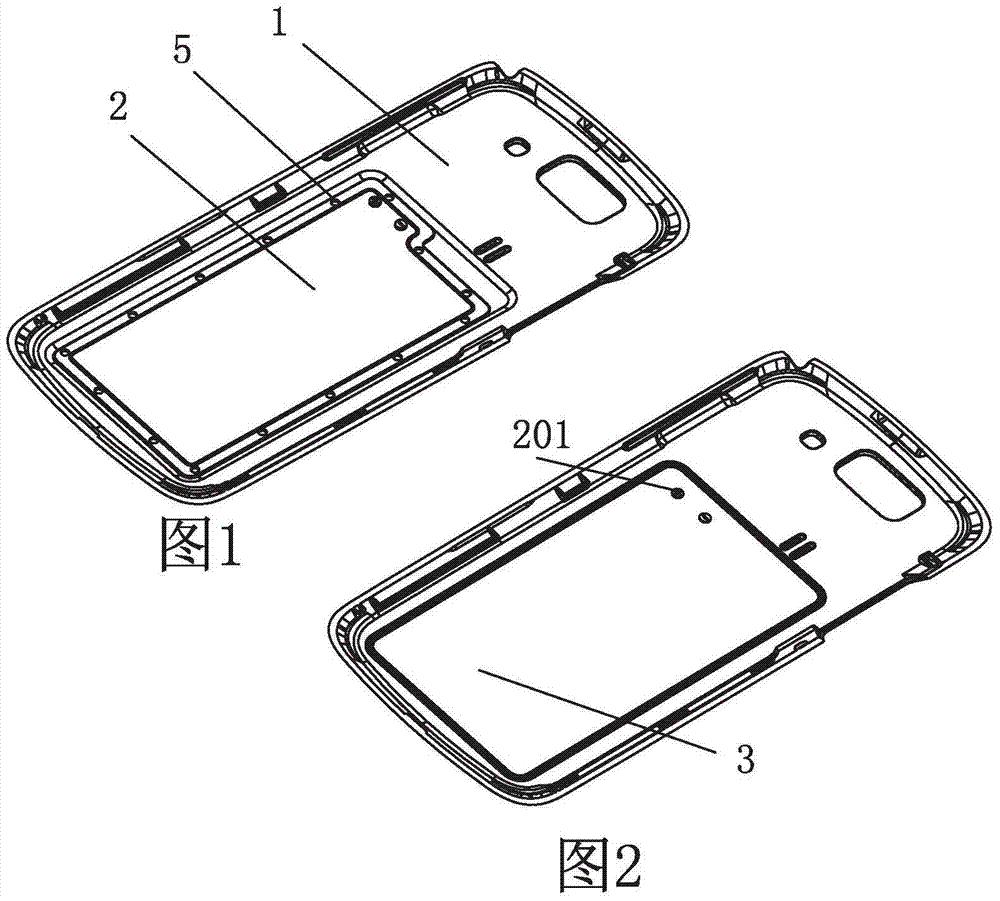

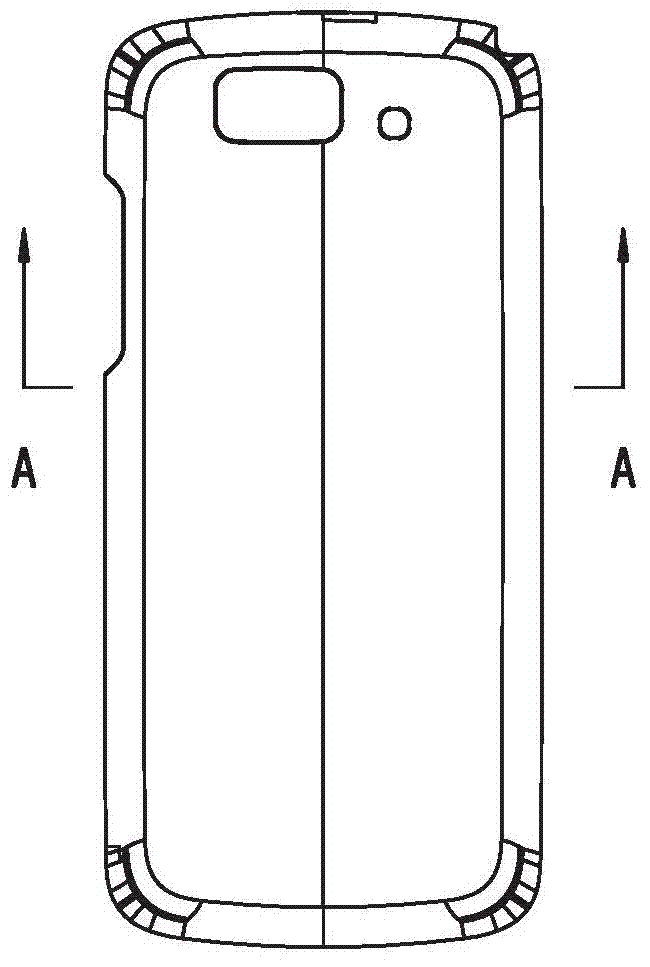

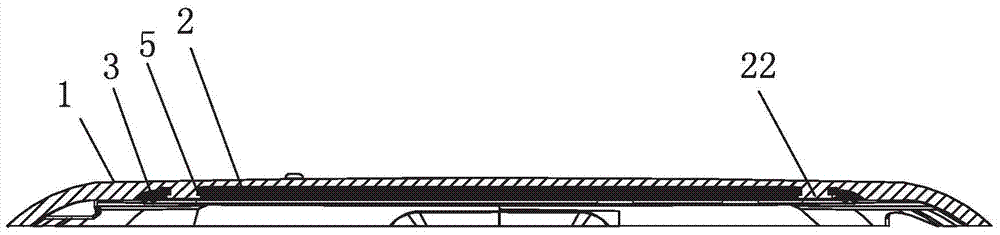

[0049] refer to Figure 1 to Figure 4 , in one embodiment, the ultra-thin waterproof case battery integral molding structure includes a plastic case 1 and a thin-walled flexible battery 2 integrally injection-molded inside the plastic case 1, and the other side of the flexible battery 2 opposite to the plastic case 1 One side is covered with waterproof silica gel 3, and the waterproof silica gel 3 is provided with a feeding through hole. The electrode of the flexible battery 2 exposes an electrical contact 201 through the feeding through hole, and the electrical contact can be used to communicate with the main board installed in the casing electrical connection. The overall thickness of the flexible battery 2 can be as thin as about 0.36mm-0.60mm. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com