A device for removing burrs from the slot of an external spline

A technology for deburring and external splines, which is applied in the direction of grinding machine parts, manufacturing tools, grinding feed movement, etc., can solve the problems of high cost and high work intensity of operators, and achieve good deburring and maintain precision Effects with quality, guaranteed precision and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Describe technical scheme of the present invention in detail below in conjunction with accompanying drawing:

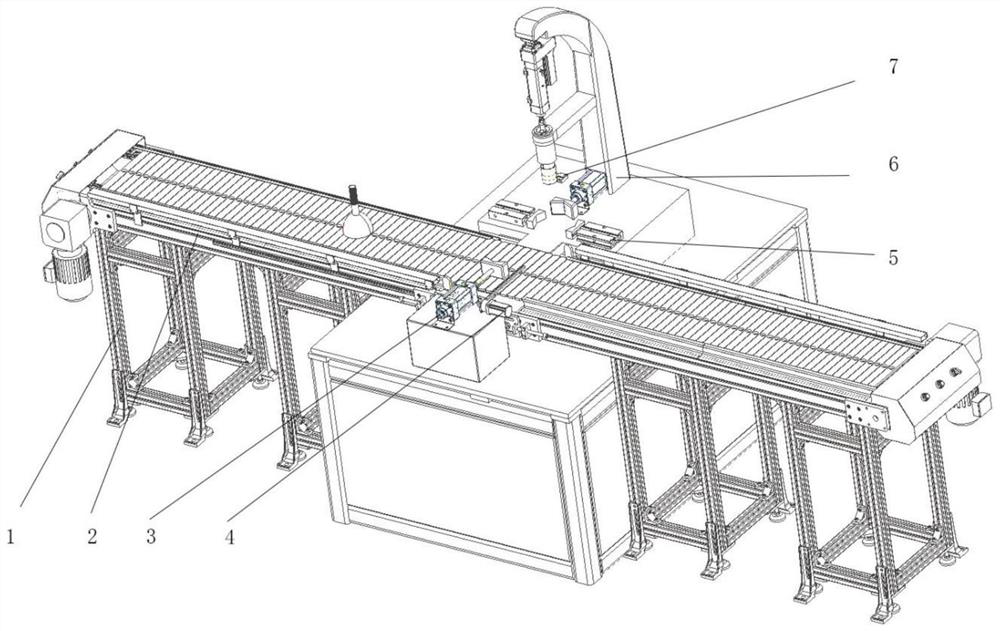

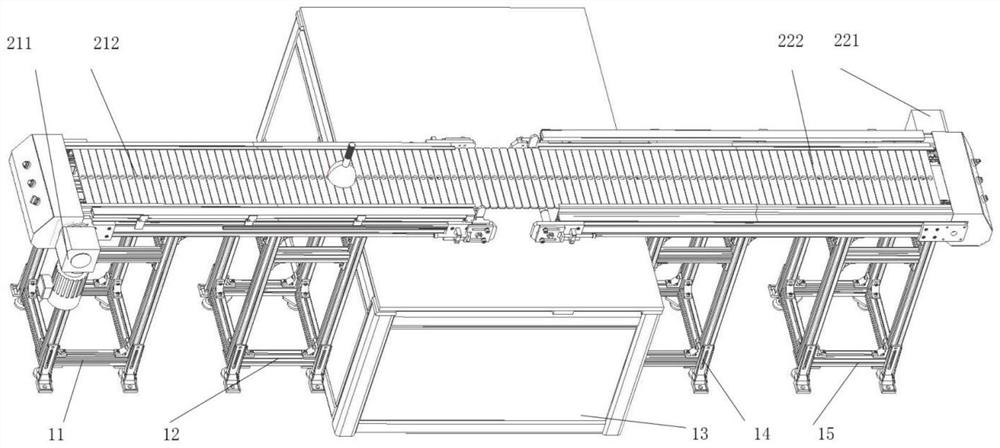

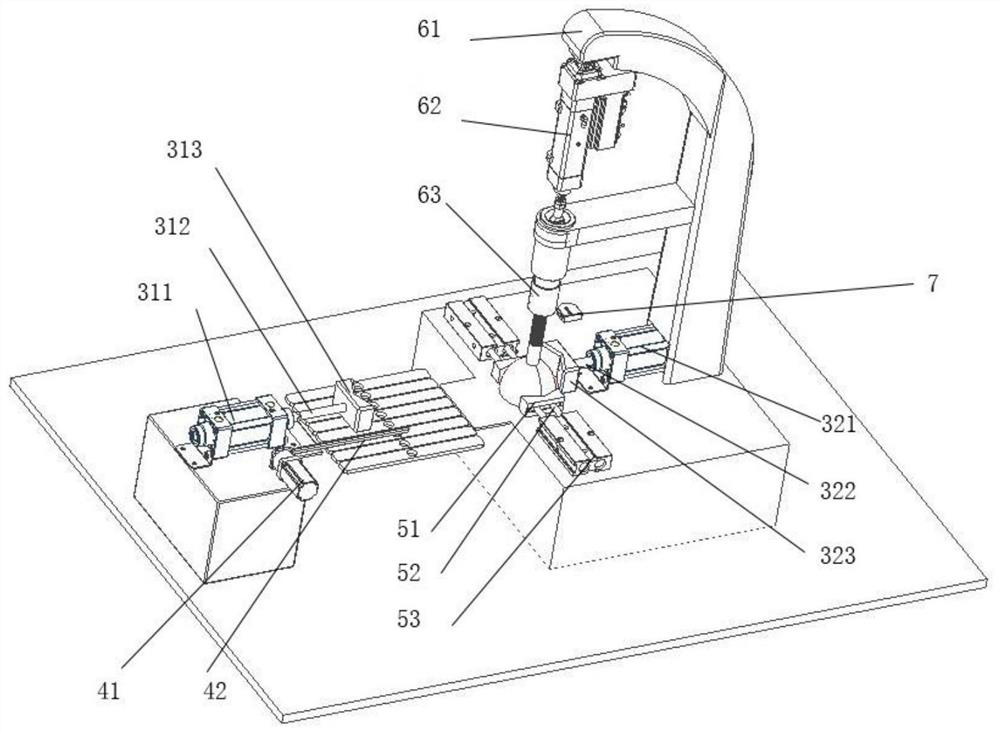

[0025] like figure 1 , image 3 As shown, a device for removing burrs from the slot of an external spline includes a stage 1 , a conveyor belt 2 , a feeding mechanism 3 , a limit mechanism 4 , a clamping mechanism 5 , an actuator 6 , and a detection mechanism 7 . The conveyor belt 2 is horizontally installed on the stage 1; the feeding mechanism 3, the limit mechanism 4, the clamping mechanism 5, the actuator 6, and the detection mechanism 7 are respectively fixed on the main stage 13 of the stage 1 by bolts. The arrangement direction of the feeding mechanism 3 is perpendicular to the conveyor belt 2, and is used to push the workpiece onto or off the conveyor belt; the limiting mechanism 4 is located on the side of the feeding mechanism 3, and is used to limit the workpiece. The clamping mechanism 5 is located behind the conveyor belt 2 and is used for clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com