Concrete pumping movable arm and concrete spreader comprising same

A technology for concrete pumps and movable arms, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve the problems of wasting sites, pollution, heavy workload and labor intensity, and meet the needs of expansion and contraction. The overall structure is simplified and convenient. The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

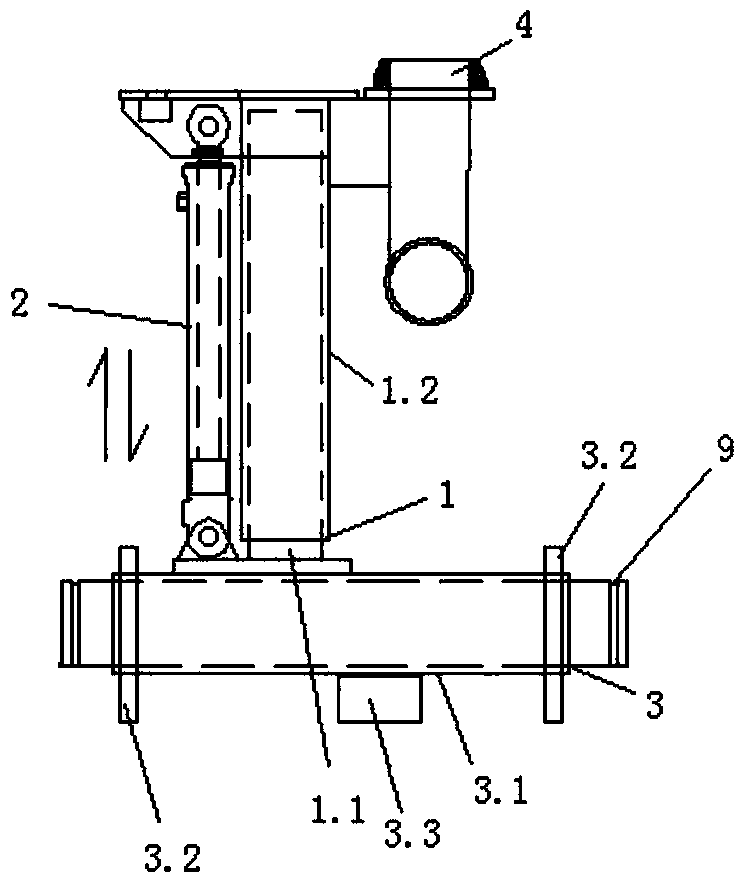

[0030] see figure 1 ( figure 1 Middle: the telescopic mechanism is in the retracted state, and the bidirectional arrow is the telescopic direction of the telescopic mechanism), a movable arm for concrete pumping, including a movable arm 1, a telescopic control part 2 that drives the movable arm 1 to perform telescopic movement, and drives the movable arm 1. A rotation control part 3 for rotating the movable arm 1 .

[0031] The movable arm 1 includes a guide post 1.1 and a guide sleeve 1.2, the lower end of the guide post 1.1 is fixed on the rotation control part 3, and the lower end of the guide sleeve 1.2 is sleeved on the upper end of the guide post 1.1 , and the concrete output end 4 is fixed on the guide sleeve 1.2.

[0032] The telescopic control part 2 includes a group of telescopic mechanisms (at least two groups of telescopic mechanisms arranged side by side can also be used according to the actual situation), and the telescopic mechanisms are telescopic along the c...

Embodiment 2

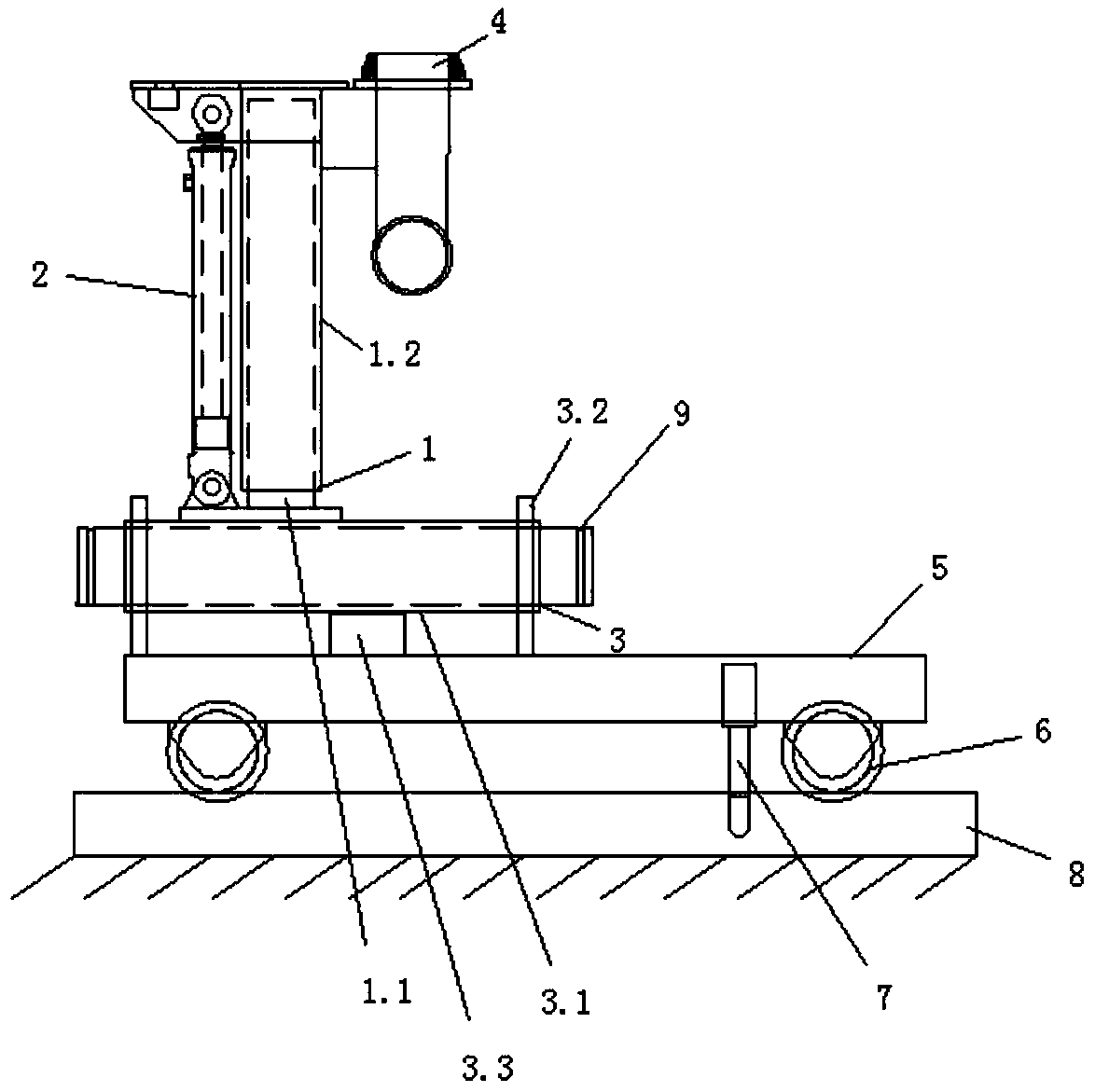

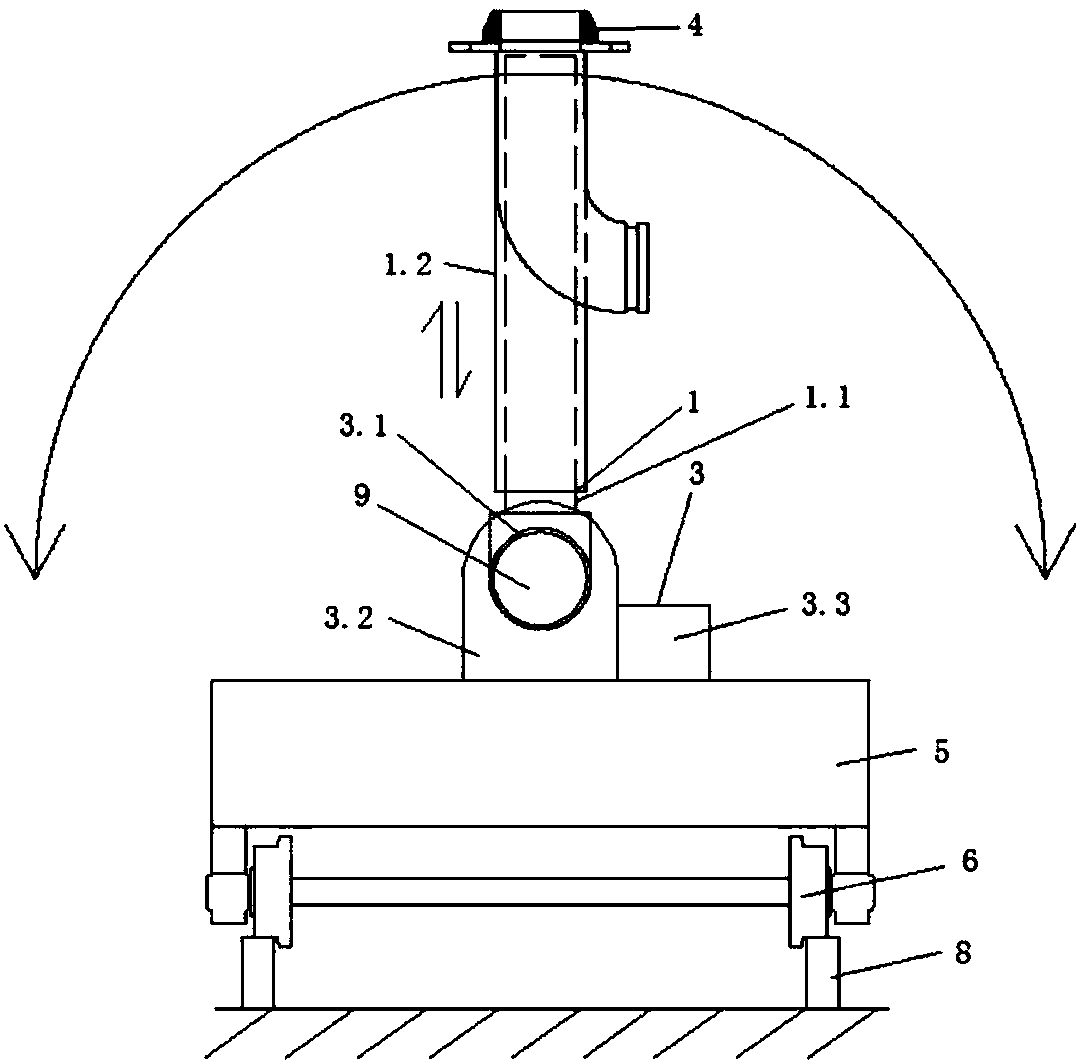

[0038] see figure 2 with image 3 ( image 3Middle: The arc arrow indicates the swing direction of the movable arm, and the straight double arrow indicates the telescopic direction of the telescopic mechanism; figure 2 with image 3 Middle: the telescopic mechanism is in the retracted state), a concrete placing machine, the detailed structure is: including the car body 5, the traveling mechanism 6, the locking mechanism 7, the concrete pumping movable arm as described in Embodiment 1, and the concrete pumping arm connected to the concrete The pipeline (not shown) of the output end 4 and the concrete pumping mechanism and the console (not shown).

[0039] The support base 3.2 is arranged on the upper surface of the car body 5, and it includes two sets of support bodies arranged side by side. The end is the point of force, which can realize rotation along its central axis.

[0040] The running gear 6 matches the running track 8 (the running track 8 here can be arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com