Parameter selection method adopting onboard control moment gyroscope group vibration-isolating platform

A technology for controlling moment gyroscopes and vibration isolation platforms, applied in attitude control and other directions, can solve the problems of satellite space waste, limited ability to improve stand-alone performance, no analysis, etc., to achieve improved attitude stability, save launch costs, and save space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for parameter selection of an on-board control moment gyroscope group vibration isolation platform can be accomplished through the following steps:

[0040] Step 1: For a satellite with a mass of 1000kg, four control moment gyroscopes are used as actuators on the satellite to complete the attitude stability control. The mass of each control moment gyroscope is 19kg. In combination with the above parameters, the radius R of the upper platform 2 and the lower platform 3 of the vibration isolation platform is selected as 150mm, and the formula It can be calculated that the platform height of the vibration isolation platform H≈106.1mm, through the formula Calculate the nominal rod length l of each strut 4 of the vibration isolation platform 0 ≈183.7mm.

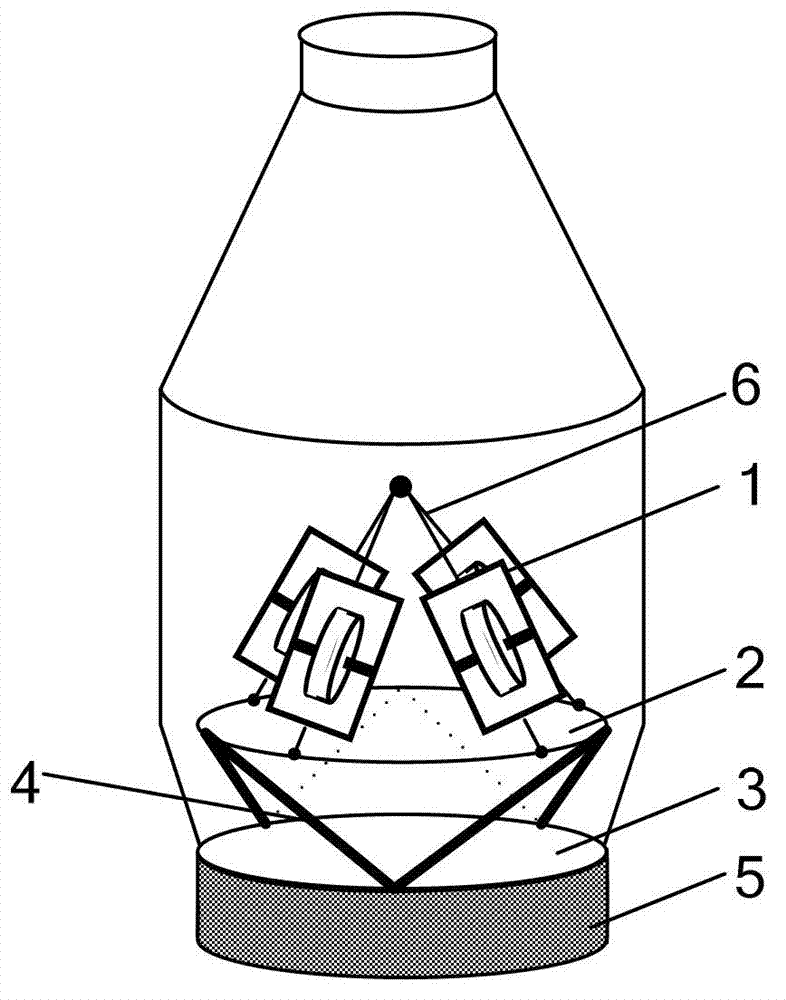

[0041] Step 2: adopt the form of a satellite body 5 connected to a plurality of control moment gyroscopes (CMGs) on a vibration isolation platform, such as figure 1 shown. The control moment gyroscope group 1...

Embodiment 2

[0093] The selection of the maximum loss factor different from that in Example 1 and the small value added by inferring the undamped natural frequency from the vibration isolation frequency, the selection of the parameters involved in the vibration isolation platform can be completed through the following steps:

[0094] Wherein, step 1 to step 4 are equivalent to step 1 to step 4 in embodiment 1;

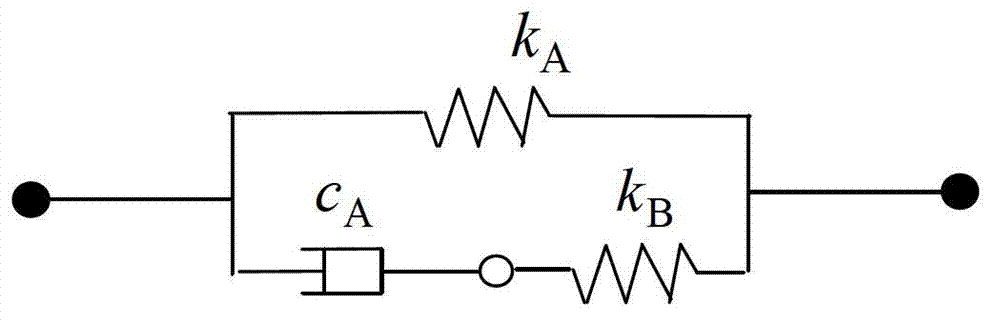

[0095] Step 5: According to the vibration isolation frequency of the vibration isolation platform obtained in step 3, it is known that the vibration isolation frequency is slightly smaller than the undamped natural frequency ω 0 , then add 1.3Hz to the vibration isolation frequency obtained in step 3, as the undamped natural frequency ω of the vibration isolation platform 0 , ω 0 =13Hz; select the maximum loss factor η max , let η max =0.4, then by the known η max by expression It can be solved to get α, α=1.48, by can be further obtained k ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com