Patents

Literature

174results about How to "Overcome waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

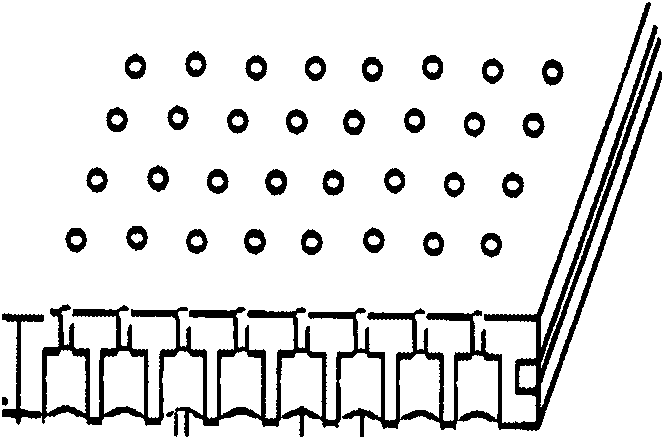

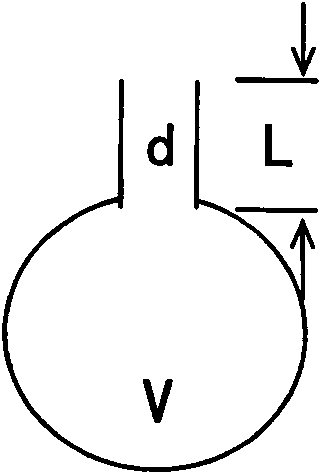

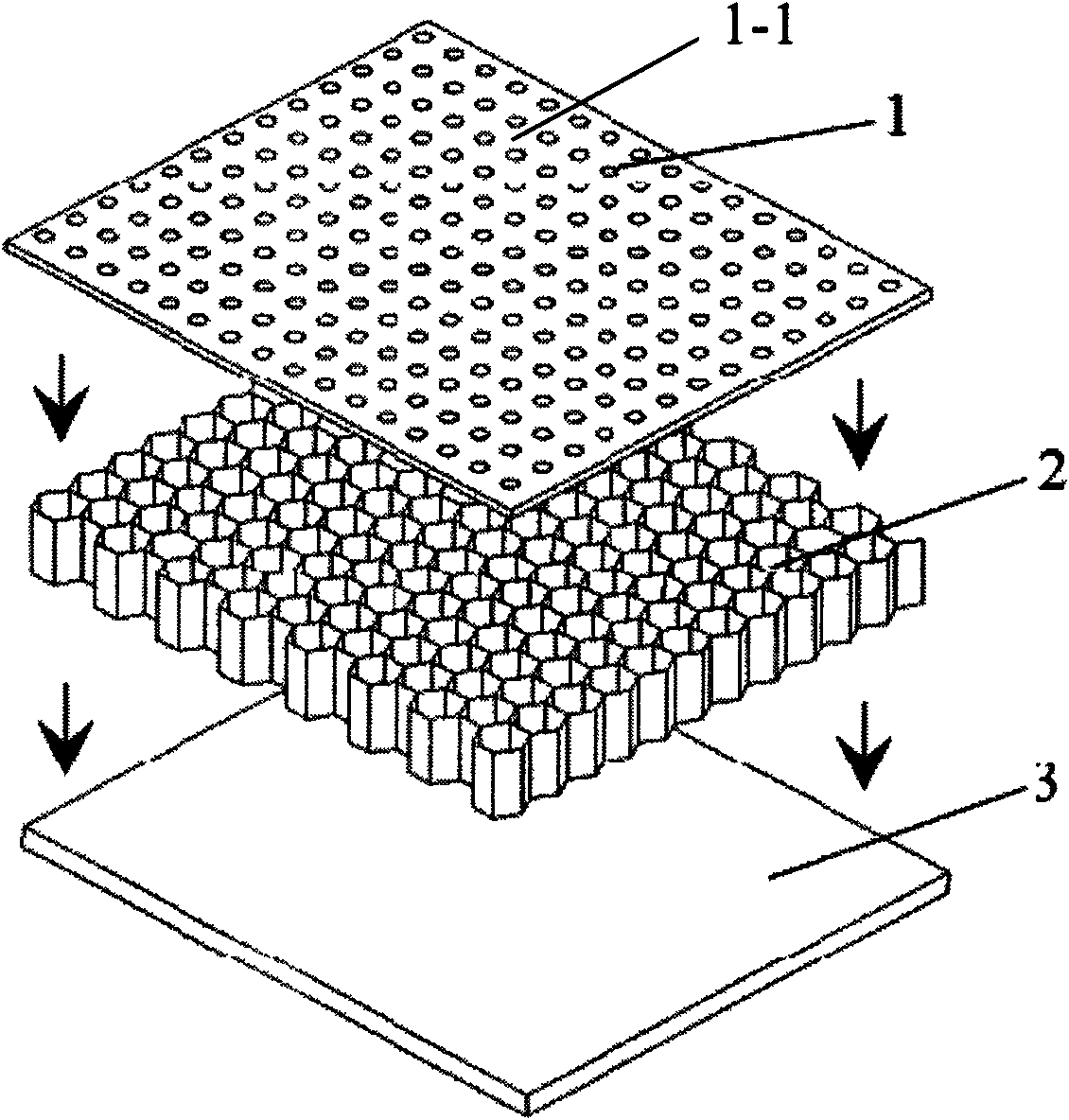

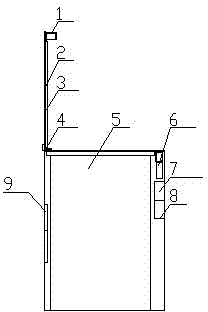

Multiple helmholtz resonator parallel cellular sandwich wood sound absorption plate

InactiveCN101962980AOvercome wasteStrong pressure resistanceCovering/liningsLayered productsCell cavityHelmholtz resonator

The invention relates to a multiple helmholtz resonator parallel cellular sandwich wood sound absorption plate, belonging to the field of sound absorption technologies. The invention solves the problems of small chamber volume ratio, narrow sound absorption frequency band and poor sound absorption effect in the traditional sound absorption panels. Technical essential is characterized in that a sandwich layer is a cellular sandwich layer; the cellular sandwich layer is formed from splicing a plurality of cylinder bodies with hexagonal cross sections; an inner cavity of each hexagonal cylinder body is a cell cavity chamber; the chamber volume ratio of the sandwich layer is larger than 90%; the area of perforation shape surrounded by contour lines of each perforation is less than a half of the hexagonal area of corresponding sandwich layer; and each small through hole on a panel is communicated with the cell cavity chamber at the corresponding position of the sandwich layer. The invention has wider sound absorption frequency band and better medium high frequency sound absorption performance, and the sanding wave tube method sound absorption coefficients respectively reach 0.8, 0.9 and 0.7 at 500Hz, 1000Hz and 2000Hz. In addition, the invention also has the characteristics of light weight, high ratio of strength to weight, good decorative effect, and the like; and wood resources can be saved, preparation process is simple, and cost is low.

Owner:NORTHEAST FORESTRY UNIVERSITY

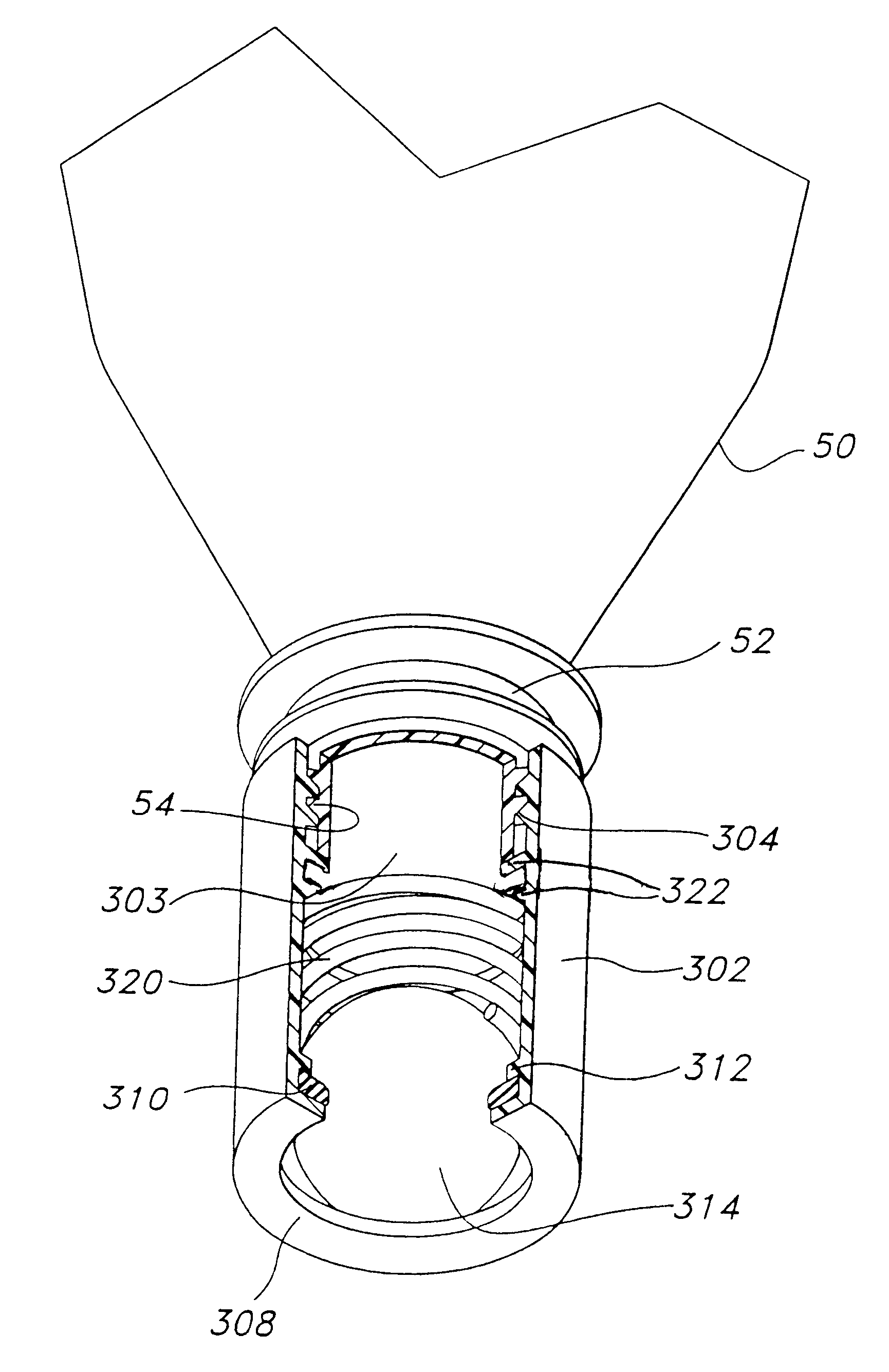

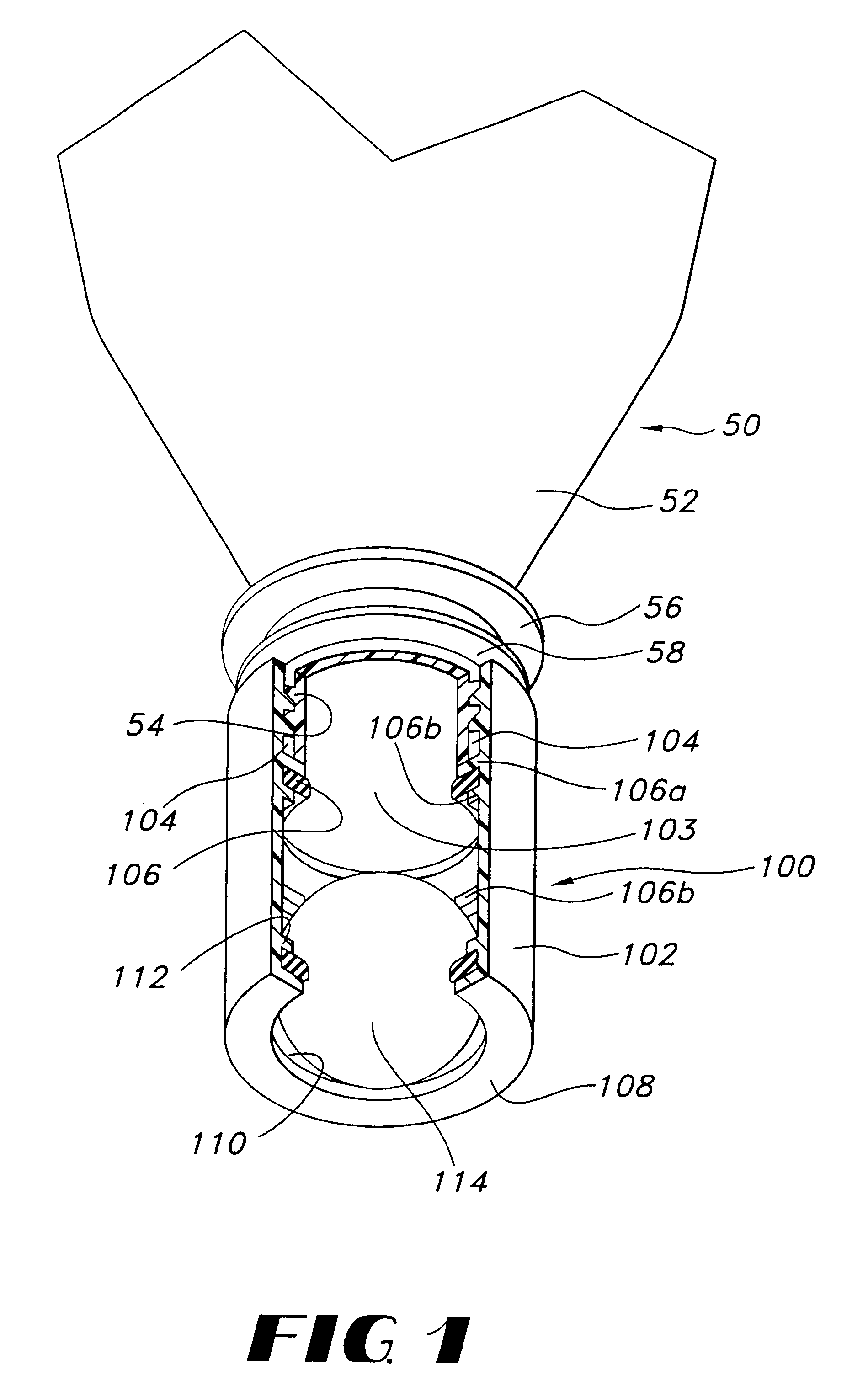

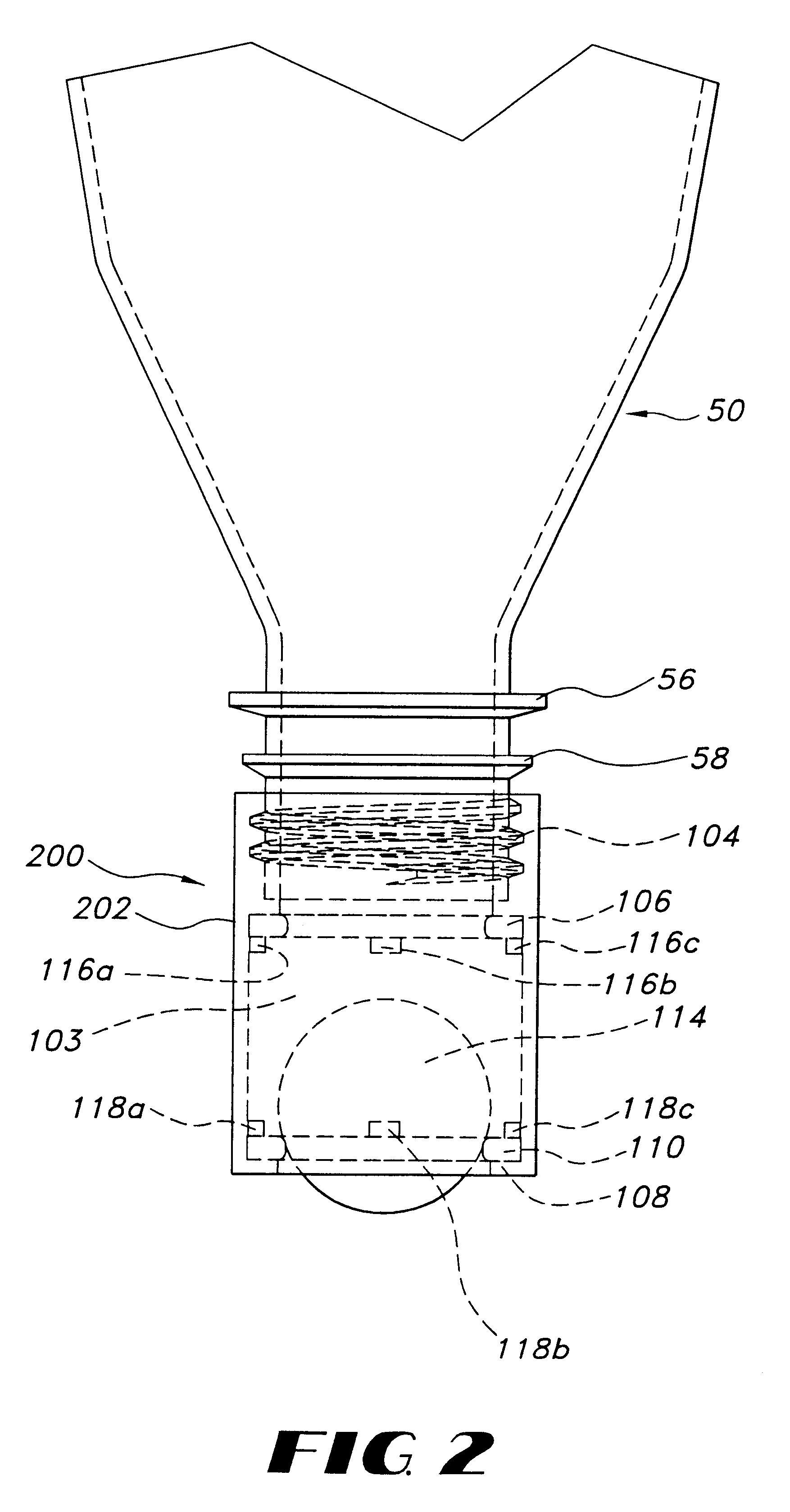

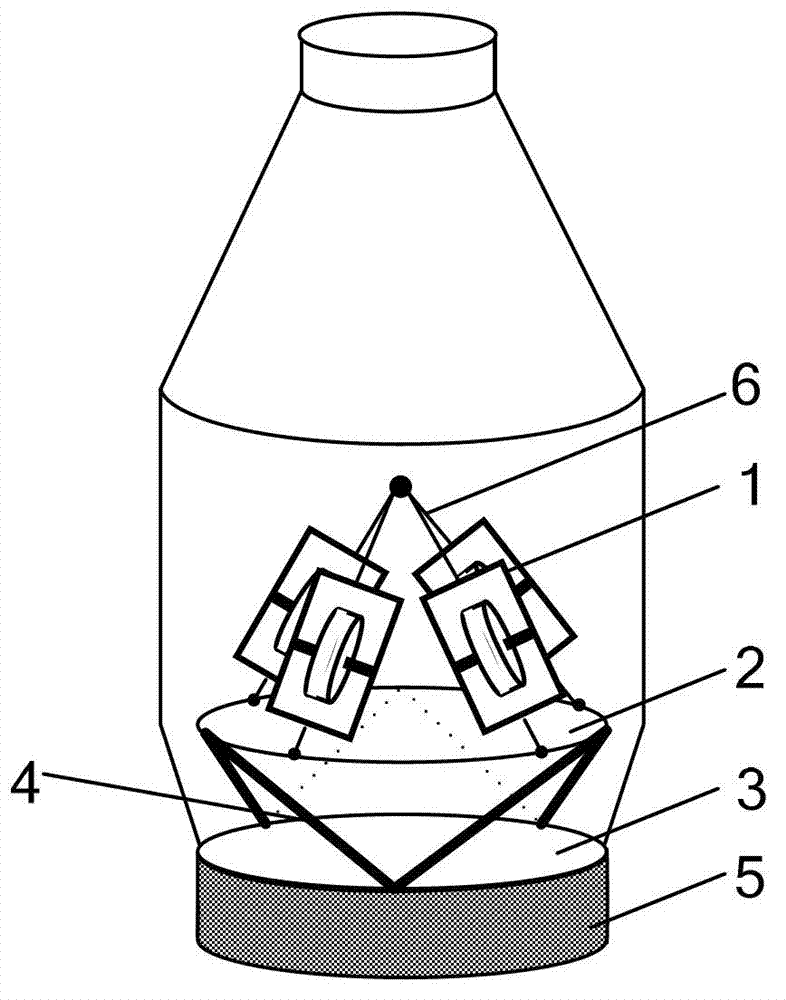

Pet drinking aid device

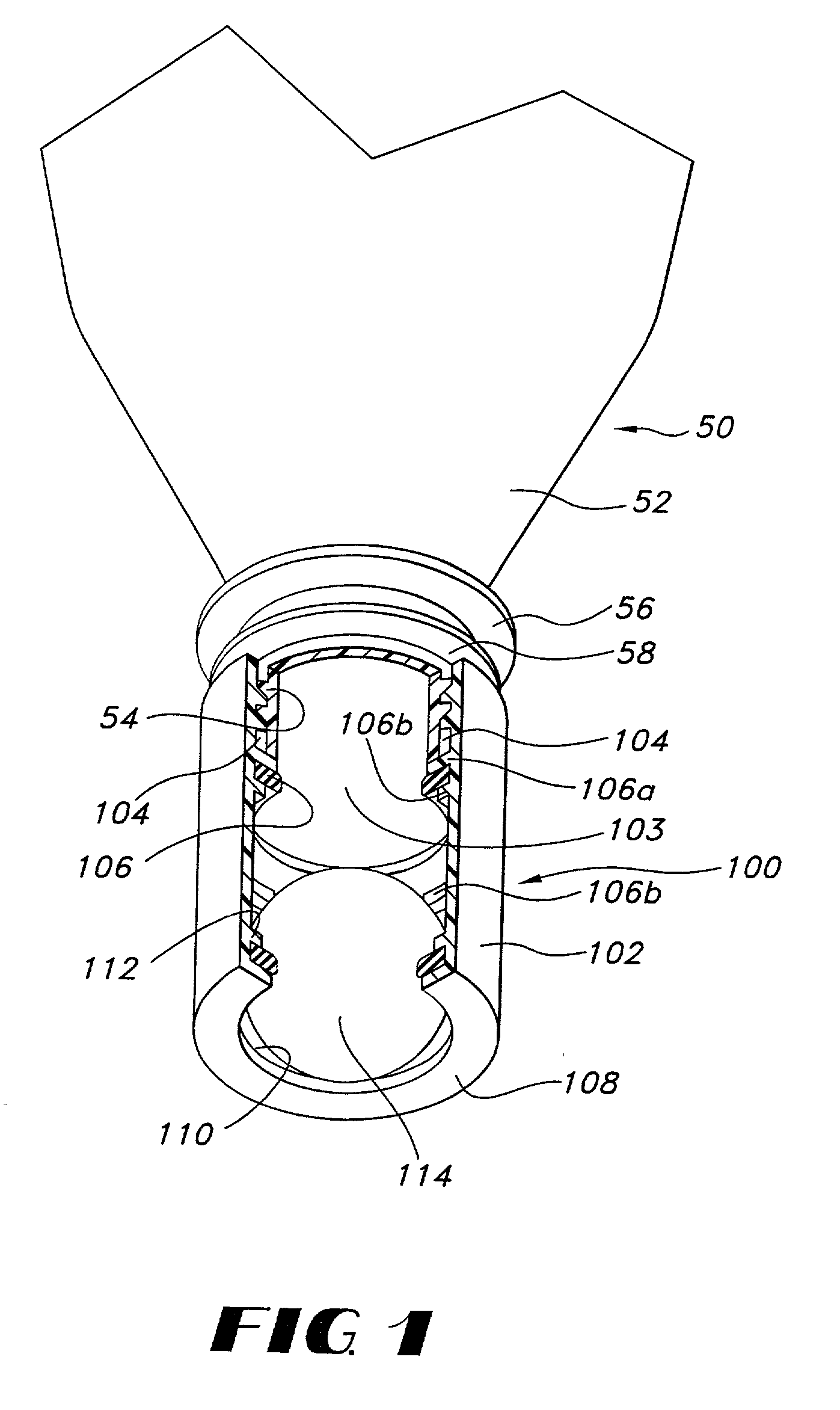

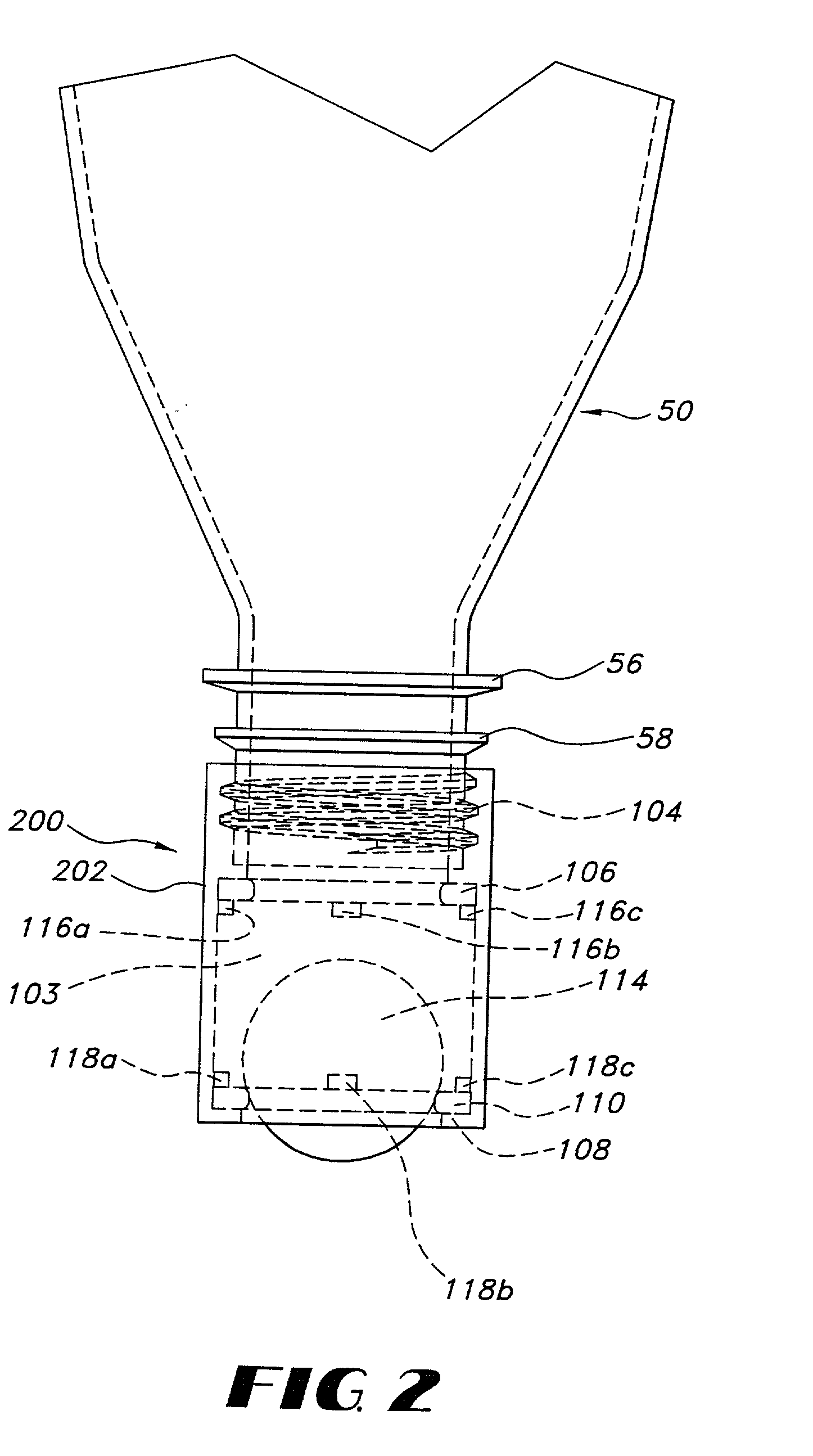

InactiveUS6718912B2Restricts and moderates flow of fluidImprove sealingAnimal watering devicesAnimal housingPhysical medicine and rehabilitationPhysical therapy

A pet drinking aid includes a cap defining an axial passage therewithin. Preferred embodiments of the cap include securing means for detachably securing the cap to a fluid container and an inwardly directed flange. The securing structure may include helical threads, an elastomeric sleeve or the like. The cap further includes a ball positioned within the axial passage of said cap and, in a preferred embodiment a biasing structure mounted relative to the cap within the axial passage. The biasing structure advantageously engages the ball to bias the ball toward the inwardly directed flange. The ball is preferably captured within the axial passage between the inwardly directed flange and the biasing structure, and the ball is capable of rotatable movement and limited axial movement against the bias of the biasing structure. The biasing structure may include a compression spring, a foam member or the like. In an alternative embodiment, the biasing means is omitted and the cap includes an inwardly directed ridge extending from the cap's inner surface at an axial location intermediate the first and second ends of the cap.

Owner:MEDIALORE

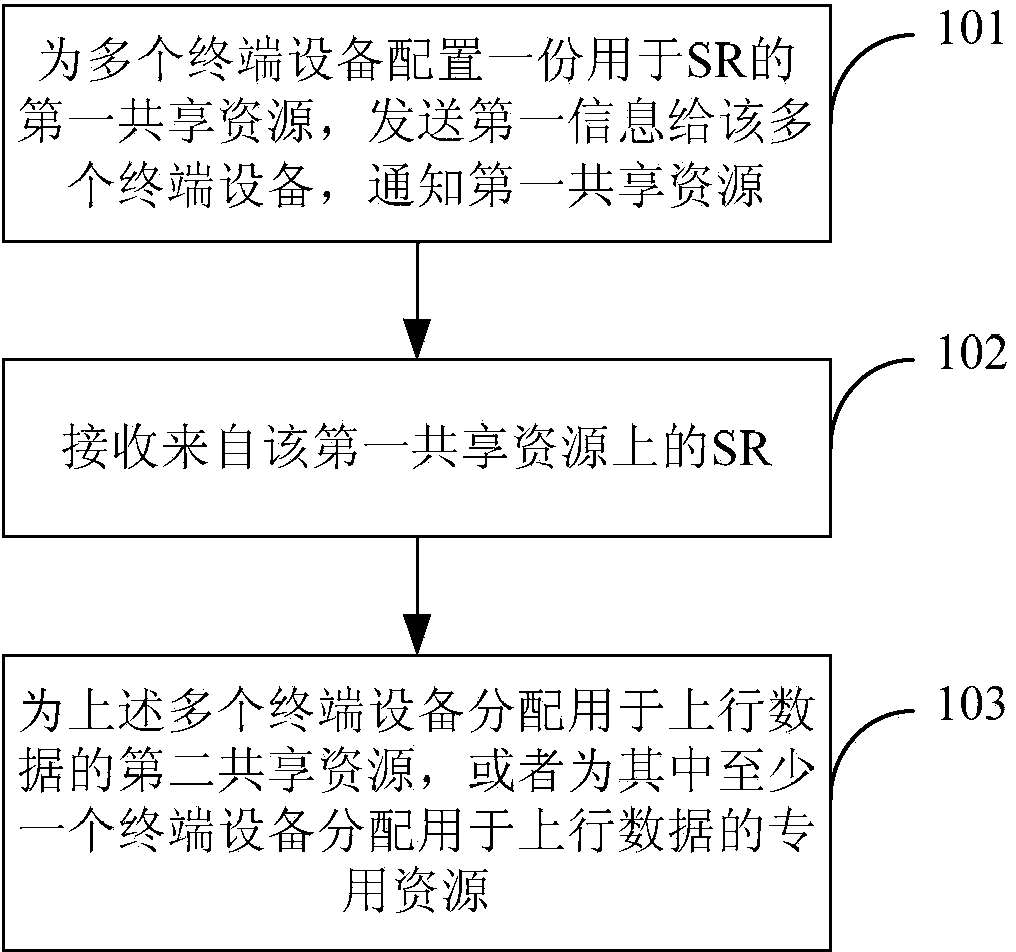

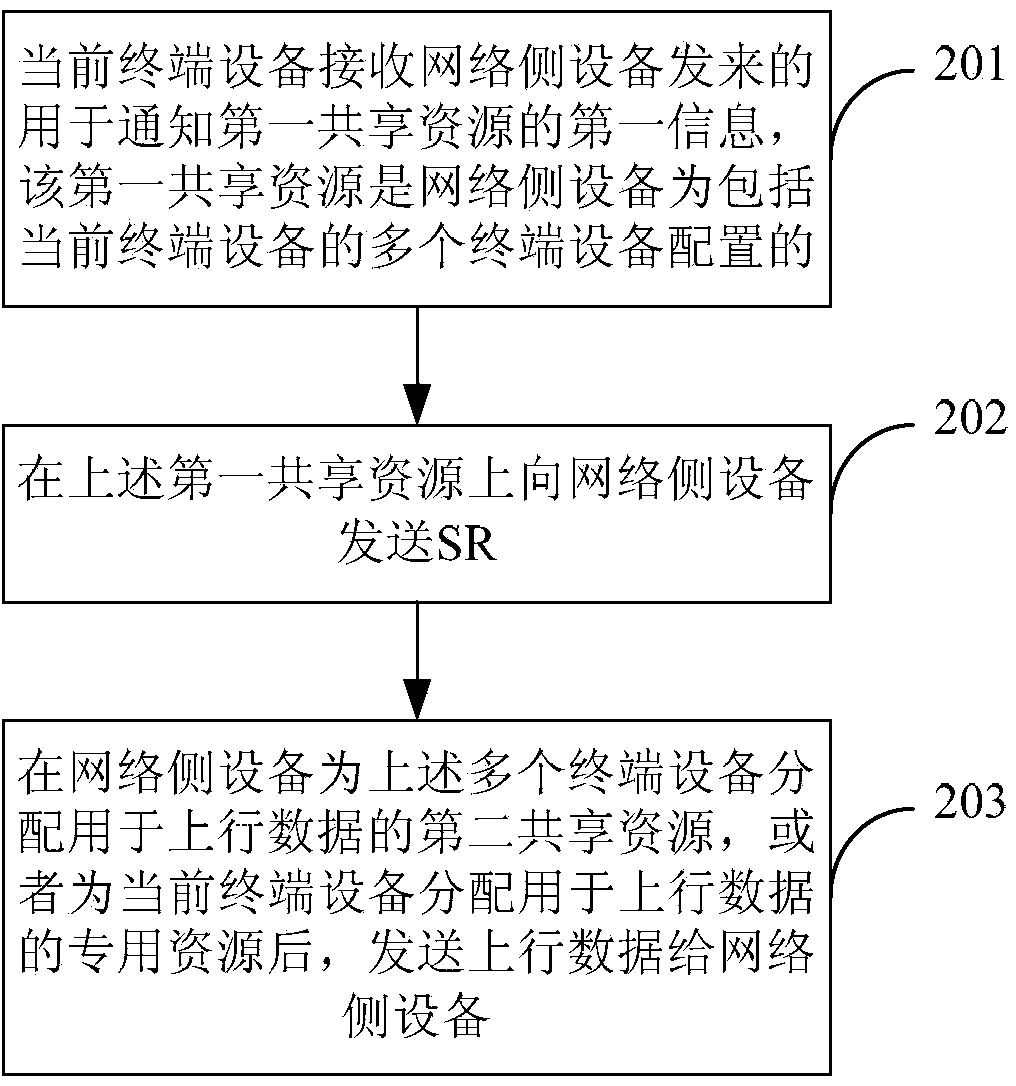

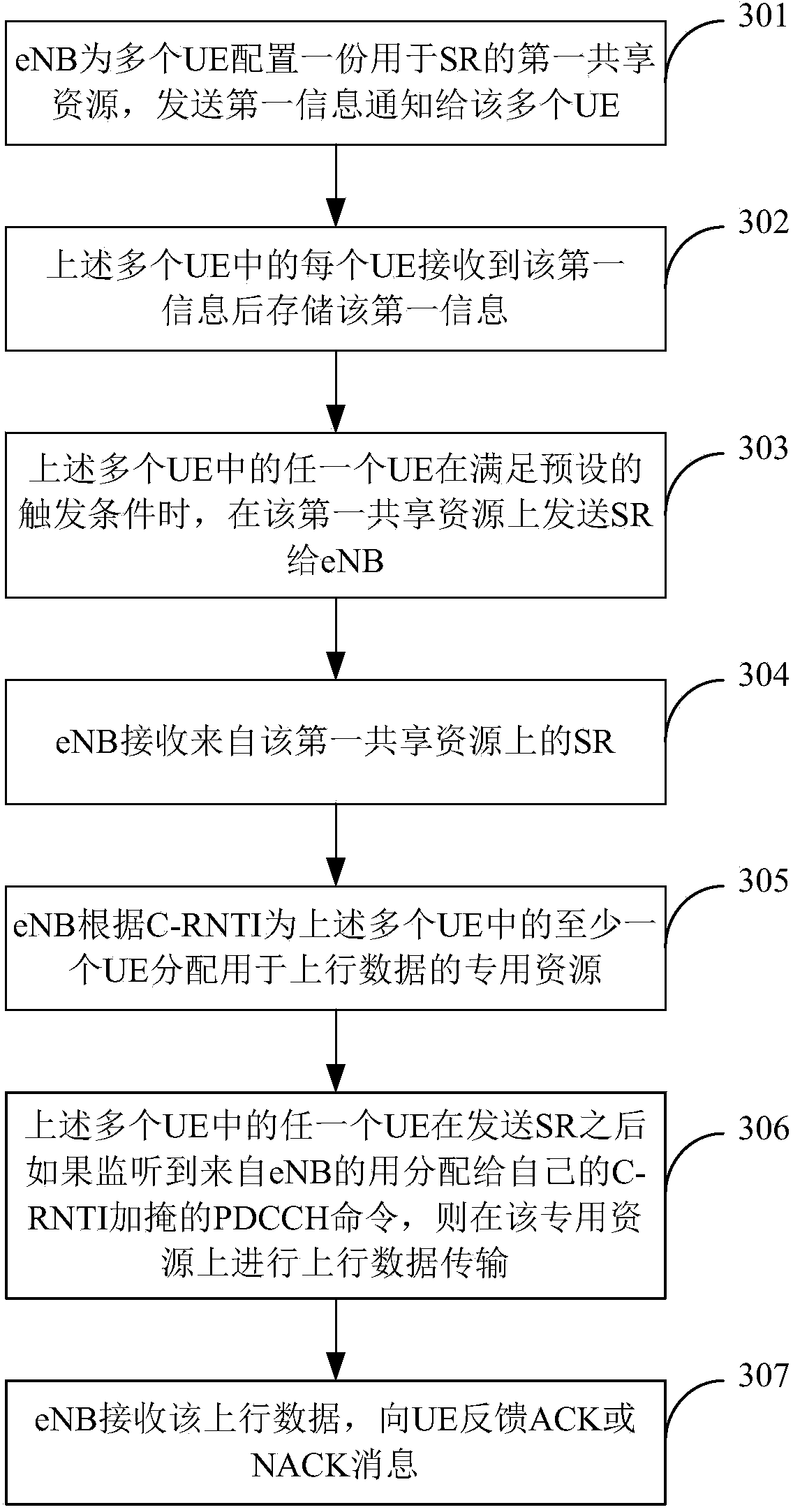

Schedule requesting method and device

ActiveCN103796320AImprove sending success rateOvercome wasteWireless communicationComputer moduleTerminal equipment

The invention discloses a schedule requesting method, network side equipment, terminal equipment and a system and belongs to the technical field of communication. The method comprises the steps that a first sharing resource for SR is configured, and first information messages are sent to a large amount of terminal equipment; the SR on the first sharing resource is received; and a second sharing resource of uplink data is distributed for the terminal equipment, or a special resource of the uplink data is distributed for one piece of the terminal equipment. The network side equipment comprises a configuration module, a receiving module and a distributing module. The terminal equipment comprises a receiving module, a requesting module and a sending module. The system comprises the network side equipment and first terminal equipment. Uplink data resource waste is avoided, the using rate of the uplink data resources is improved, and the sending success rate of the uplink data is improved.

Owner:HUAWEI TECH CO LTD

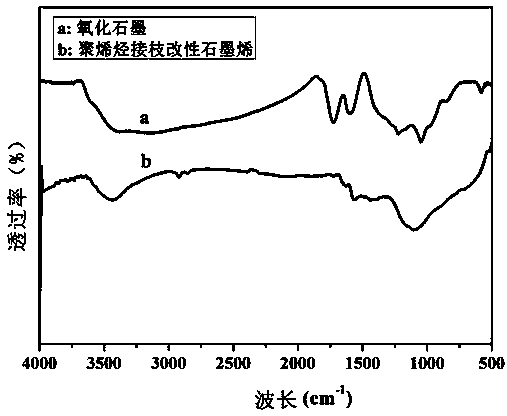

Polyolefin/graphene nanocomposite and preparation method thereof

ActiveCN104098816AGood dispersionOvercome wastePigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsPolymer scienceGraphene nanocomposites

The invention discloses a polyolefin / graphene nanocomposite. According to the invention, two-dimensional nano-material graphene is used as a reinforcing agent, and through graft modification of polyolefin, polyolefin grafted-modified graphene is formed and uniformly dispersed in a polyolefin material. A preparation method for the polyolefin / graphene nanocomposite comprises the following steps: functionalized modification of graphene; preparation of polyolefin grafted-modified graphene; and preparation of the polyolefin / graphene nanocomposite. The preparation method overcomes the problems of easy agglomeration and difficult dispersion of graphene in graphene-enhanced non-polar polymers; in the prepared polyolefin / graphene nanocomposite, graphene is uniformly distributed; and the polyolefin / graphene nanocomposite has excellent flame retardation performance and mechanical properties.

Owner:HEFEI GENIUS NEW MATERIALS

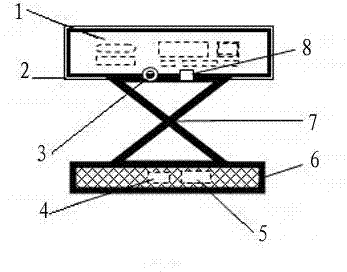

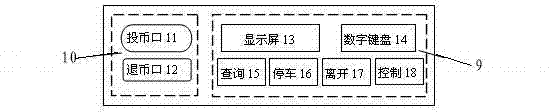

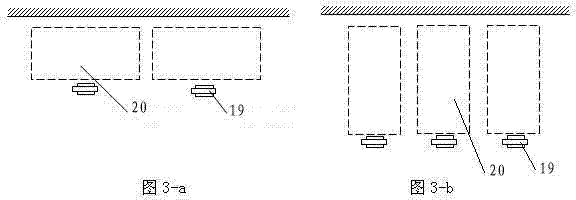

Shared type intelligent parking spot lock and control method thereof

InactiveCN103195281AIncrease the use of functionsAchieve safety protectionApparatus for meter-controlled dispensingParkingsWireless controlControl cell

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Automobile special material produced by utilizing recovered plastic

The invention relates to an automobile special material produced by utilizing recovered plastic, comprising the recovered plastic, polypropylene, polyolefin elastomer, filler, coupling agent, antioxygen and toner, wherein the recovered plastic comprises PP plastics, such as a PPR tube, a washing machine cylinder, a battery jar, a bumper, an outdoor air-conditioning shell and the like. The produced automobile special material can be used for bumpers, splash guards, instrument boards, door interior trimming panels, automobile lamp holders and the like, can greatly lower raw material cost, eliminates resource wastage and environment pollution problems to a certain degree and realizes circular economy and low-carbon development.

Owner:中塑汇鑫科技发展有限公司

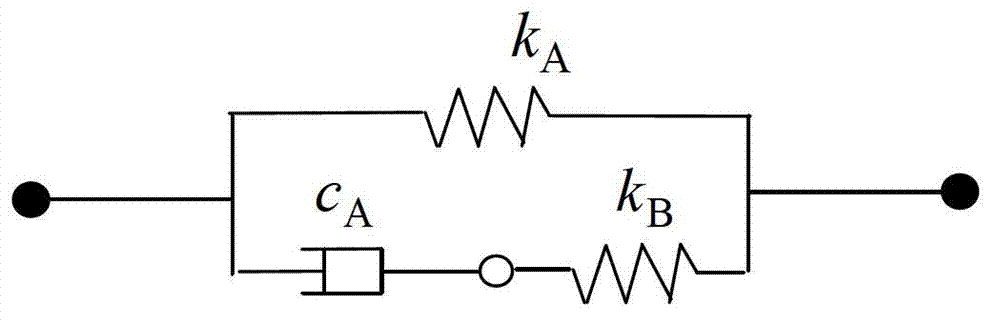

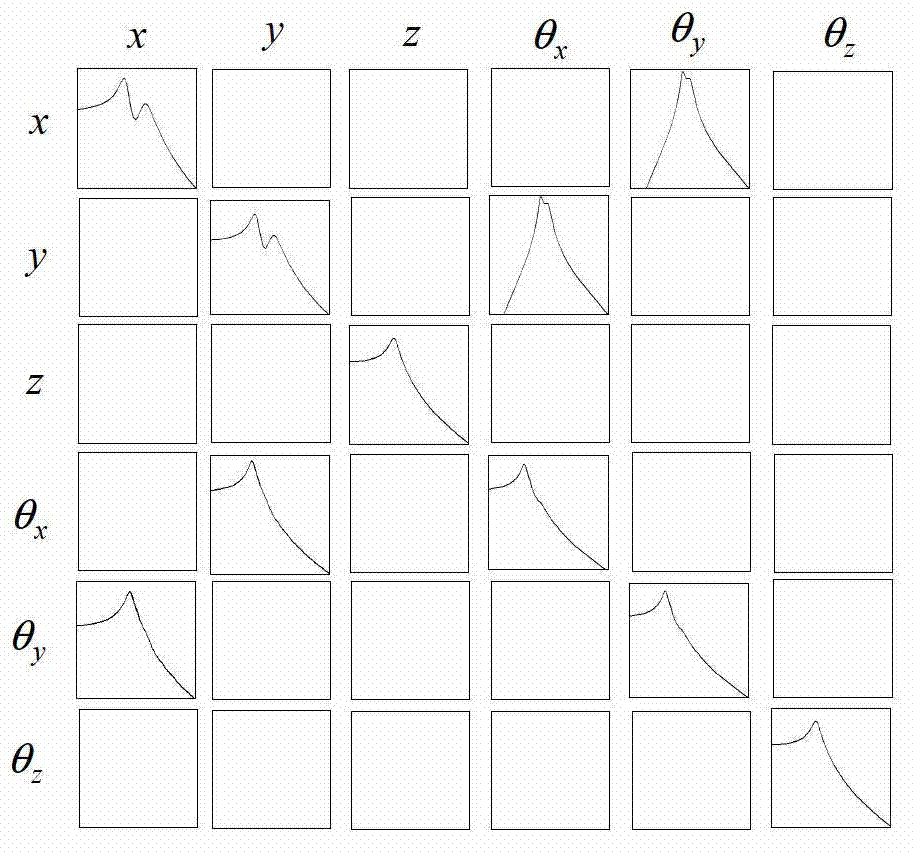

Parameter selection method adopting onboard control moment gyroscope group vibration-isolating platform

InactiveCN102778891AOvercome wasteAchieve vibration isolationAttitude controlSpacecraft attitude controlEngineering

The invention relates to a parameter selection method adopting an onboard control moment gyroscope group vibration-isolating platform and belongs to the field of the attitude control and the vibration and shaking control of a spacecraft. (1) an idea of the cube vibration-isolating platform is adopted, the cube vibration-isolating platform is arranged between a configuration consisting of a plurality of control moment gyroscopes and a satellite body and the high frequency vibration caused by a plurality of control moment gyroscopes is isolated to the greatest extent; and (2) by reasonably selecting parameters of the onboard control moment gyroscope group vibration-isolating platform, the problem of effectiveness loss of other onboard systems, which is caused after the vibration-isolating platform is applied on a satellite, is avoided.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

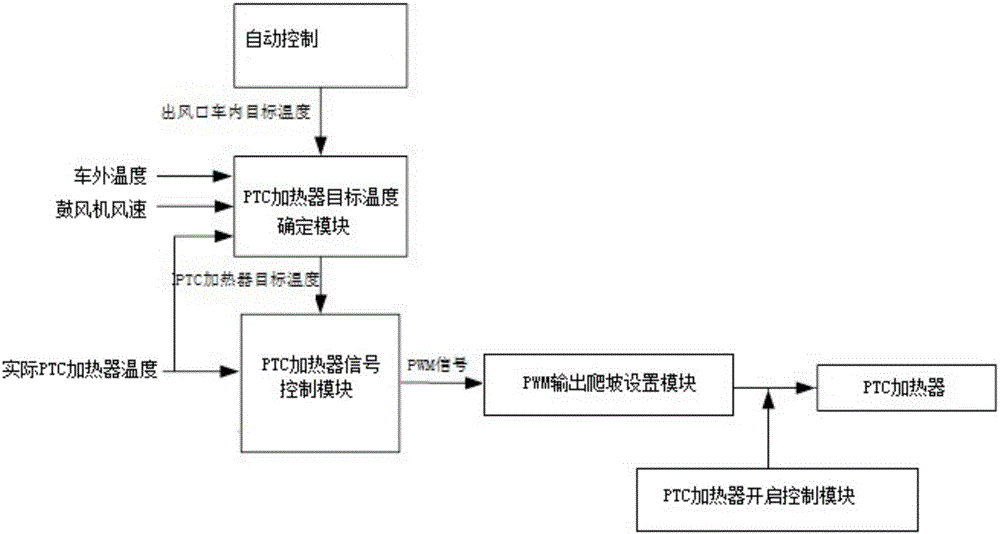

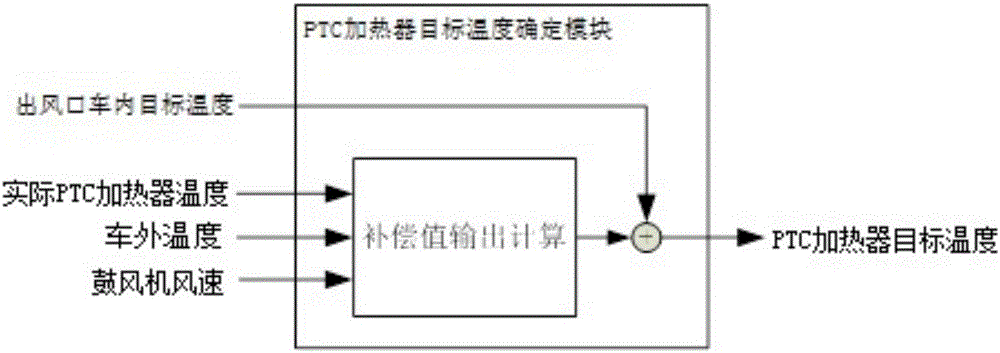

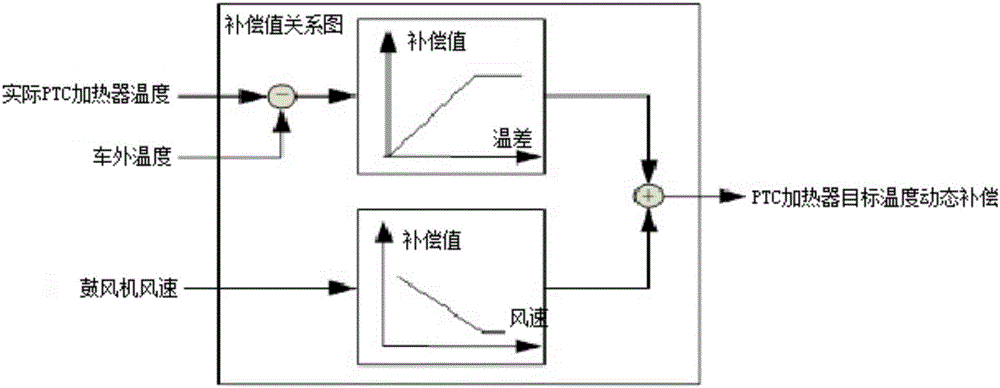

PTC heater control system and method for automobile air conditioner controller

ActiveCN106166934AOvercome resource waste and safety hazardsGuaranteed energy savingAir-treating devicesVehicle heating/cooling devicesHigh pressureControl system

The invention provides a PTC heater control system and method for an automobile air conditioner controller. The PTC heater control system comprises a PTC heater target temperature determining module, a PTC heater signal control module, a PWM output climbing setting module and a PTC heater switching-on control module. The PTC heater target temperature determining module is used for superposing a first temperature compensation value and a second temperature compensation value with an air outlet automobile internal target temperature as a basic value so as to determine the target temperature of a PTC heater. The PTC heater signal control module is used for setting the PWM duty cycle of the PTC heater with a PI control method. By regulating the target temperature of the PTC heater in real time, the energy conservation of an automobile air conditioner system is guaranteed to the maximum; meanwhile, a whole automobile high-voltage power supply system, the PTC heater and an air conditioner case plastic shell are effectively protected, and the use safety of the automobile air conditioner system is guaranteed.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

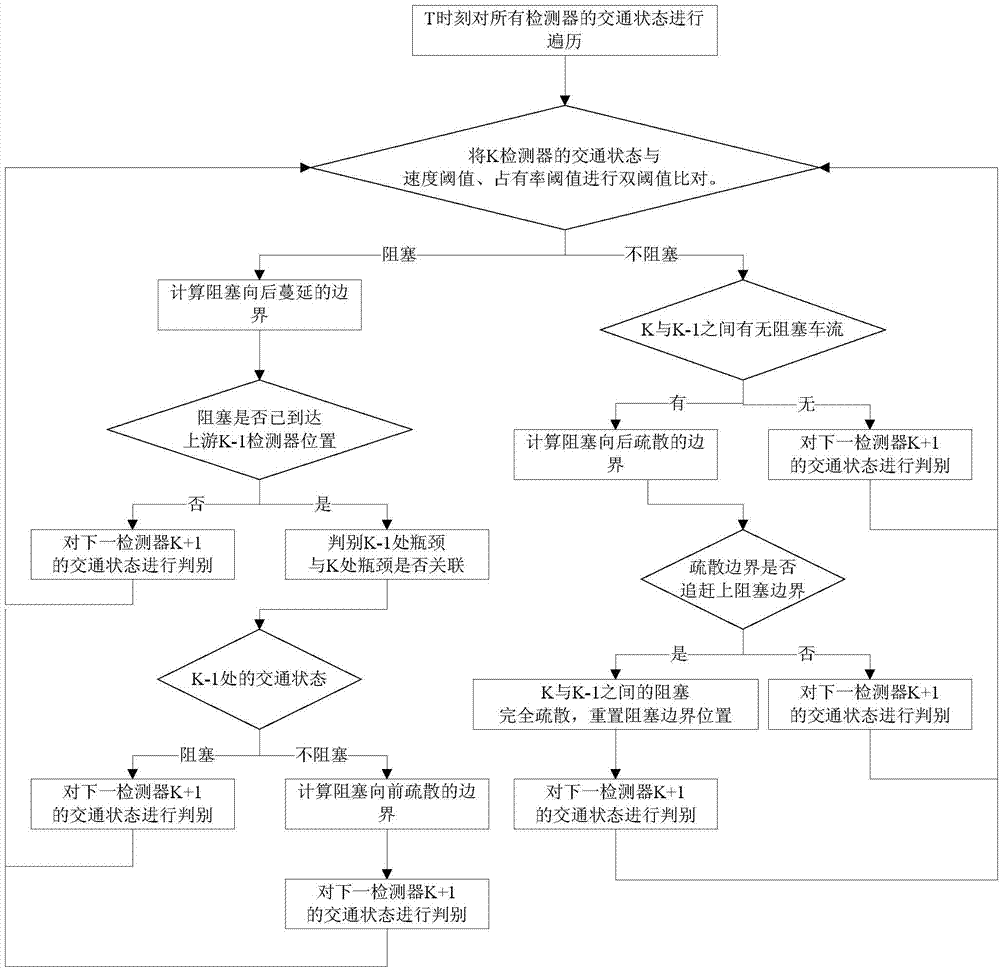

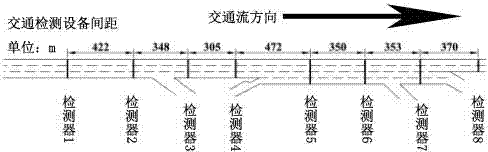

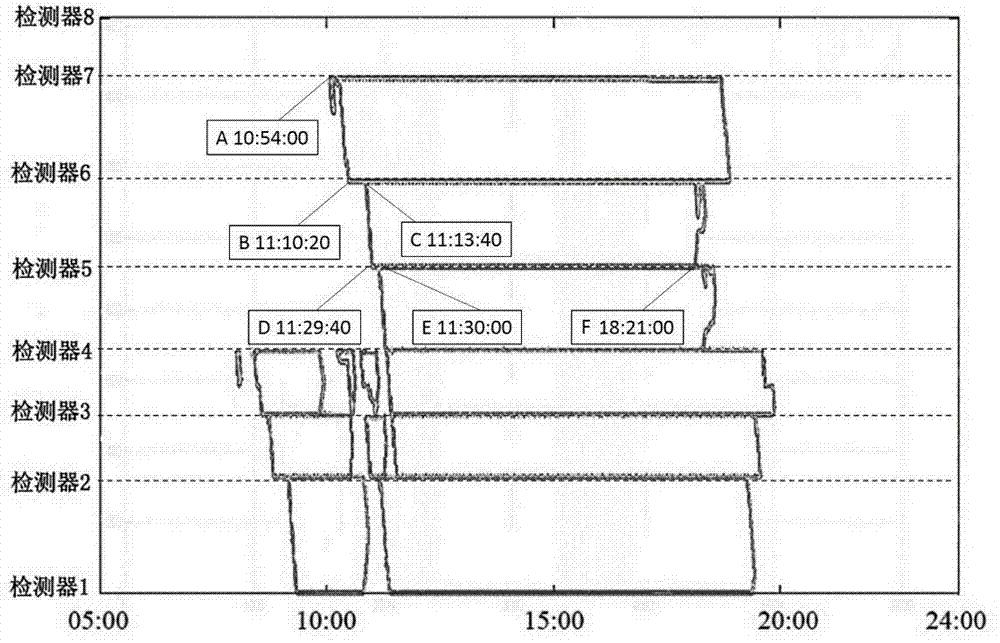

High-grade road multi-bottleneck-point congestion evolution space-time range identification method

ActiveCN104778835AFull and comprehensive analysisImprove accuracyDetection of traffic movementTraffic flowTime space

The invention discloses a high-grade road (highway and city expressway) multi-bottleneck-point congestion evolution space-time range identification method and aims to overcome the defect that in existing road bottleneck congestion evolution range identification, mutual influence among multiple bottlenecks cannot be identified. The method comprises the steps of: firstly, carrying out traversing and operation on data in time and space on the basis of data acquired by traffic flow detection equipment in a multi-bottleneck region; according to a traffic flow theory building algorithm, carrying out real-time operation and reproduction on boundaries of traffic flow congestion and dissipation and simultaneously, identifying and judging relevance among bottleneck points in the region; and finally, obtaining a complete congestion evolution space-time range in the multi-bottleneck-point region.

Owner:TONGJI UNIV

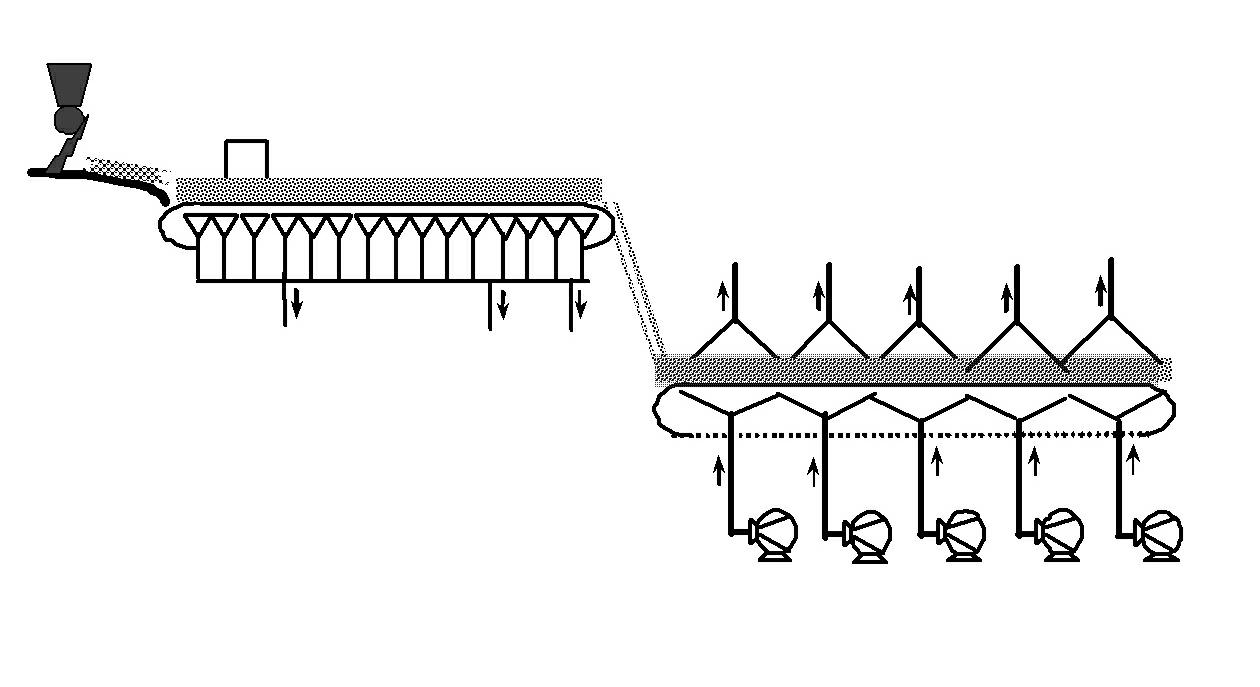

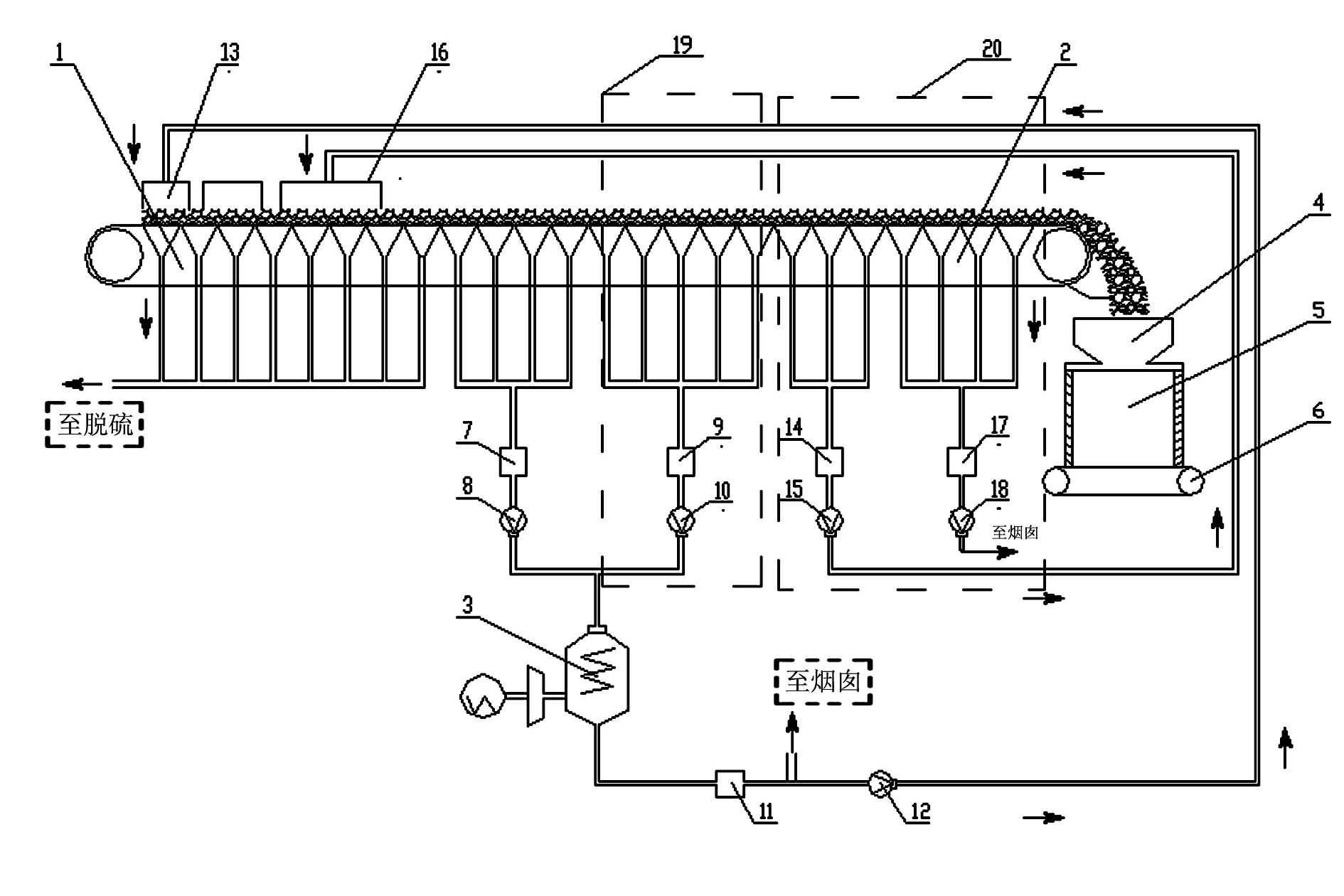

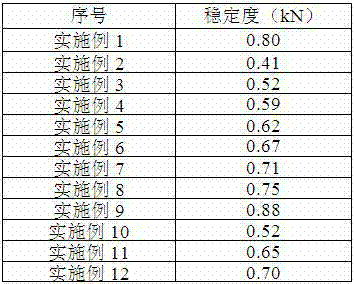

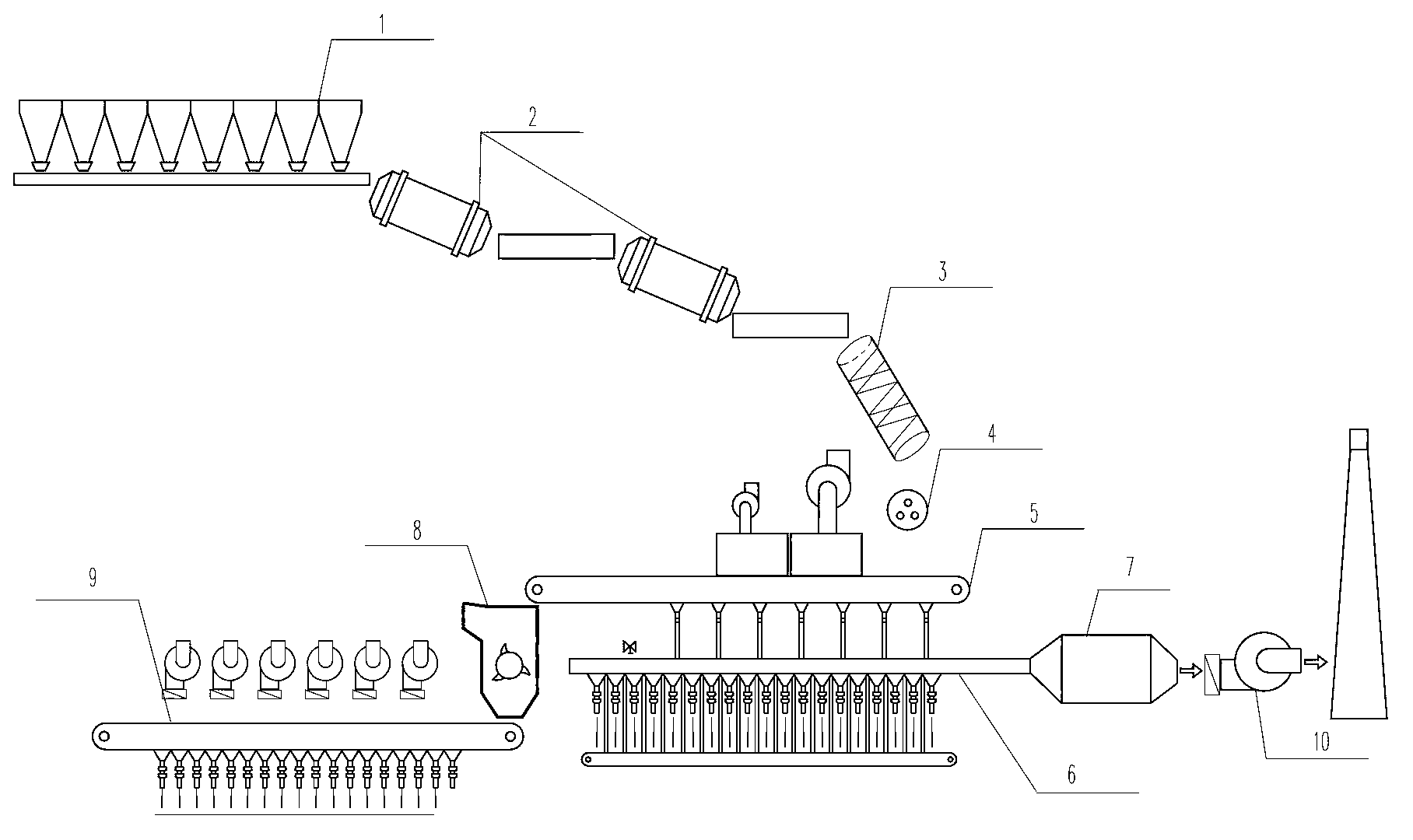

Sintering and cooling integrated method for efficiently recovering and utilizing waste heat resources and device thereof

InactiveCN102384664AOvercome the problem of sensible heat wasteOvercoming the \"quantity\" of waste heatIncreasing energy efficiencyWaste heat treatmentThermodynamicsFlue gas

The invention relates to a sintering and cooling integrated method for efficiently recovering and utilizing waste heat resources and a device thereof. The method has the steps that the length of a sintering machine is doubled; the front half part of a sintering ore cooling section is set as a cooling section I, and the back half part of the sintering ore cooling section is set as a cooling section II; a gravitational crusher and an assistant cooling device are equipped below the tail part of the cooling section; after sintering ore passes through a sintering area of the device, pulverized coal completely enters the cooling section to be cooled and then falls into the crusher; flue gas at the tail part of the sintering machine, which has a high temperature, a high oxygen content and a low sulfur content, and flue gas at the cooling section I are led into a waste heat boiler to produce medium-pressure steam; the steam is merged into a steam pipe network or is used to generate electricity; low temperature flue gas part getting out of the waste heat boiler is led into the head part of the sintering machine to preheat the sintering ore; and the high temperature part of low temperature flue gas in the cooling section II is led into a table top of the sintering machine to conduct hot air sintering. By adopting the method, the waste of sensible heat of the sintering ore is reduced, the waste heat recovery and utilization rate is high, energy consumption of a sintering procedure is effectively reduced, and the method is suitable for being popularized and applied to the technical field of the recovery and the utilization of waste heat resources in the metallurgical process.

Owner:NORTHEASTERN UNIV

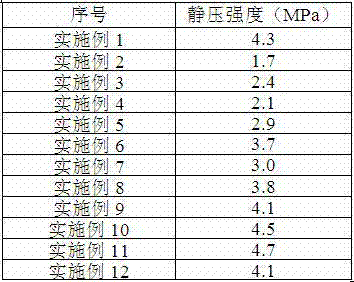

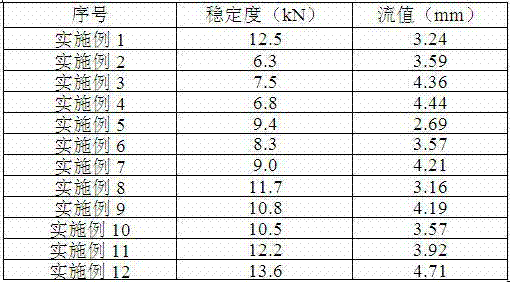

Emulsified asphalt concrete material cured by microwave heating and its preparation method

InactiveCN102295445AOvercome wasteOvercoming the problem of low early strengthRoads maintainencePavement maintenancePortland cement

The invention discloses a microwave heated and cured emulsified asphalt concrete material and a preparation method thereof. The emulsified asphalt concrete comprises the following components by mass: 79%-88% of basalt or limestone aggregate, 3%-6% of limestone mineral powder, 1%-4% of ordinary portland cement, 8%-11% of microwave heated and demulsified emulsified asphalt. The preparation method consists of the steps of: mixing the aggregate, mineral powder and cement at normal temperature for 1min, adding the microwave heated and demulsified special emulsified asphalt, and mixing the mixture for 2min, spreading out and pre-pressing the mixture to compactness of 50%, conducting microwave heating to a temperature above 50DEG C and implementing demulsification for draining, continuing heating the mixture to a temperature above 100DEG C, and carrying out final pressing, thus obtaining the concrete material. The method of the invention employs demulsification for draining after microwave heating as well as final pressing for curing, so that the demulsification time of the emulsified asphalt is controllable, and the pavement performance of the emulsified asphalt concrete is greatly improved. Being green and environmentally friendly as well as construction convenient, the method provided in the invention is suitable for application of the emulsified asphalt concrete to high-grade pavement layers, rapid pavement maintenance, asphalt concrete factory prefabrication, and other fields.

Owner:CHANGAN UNIV

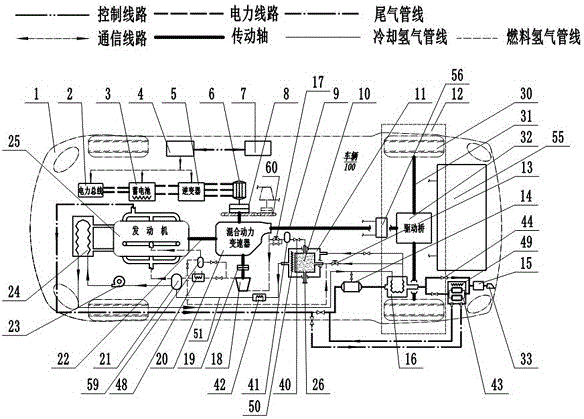

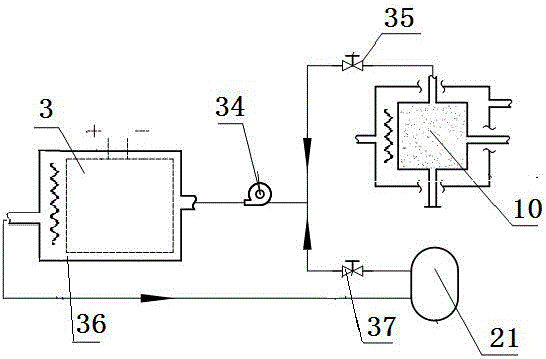

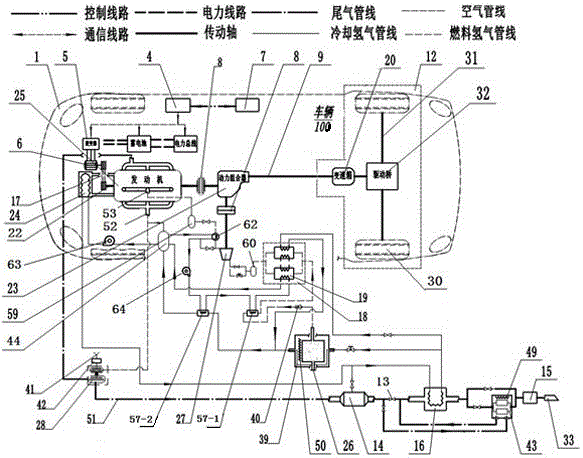

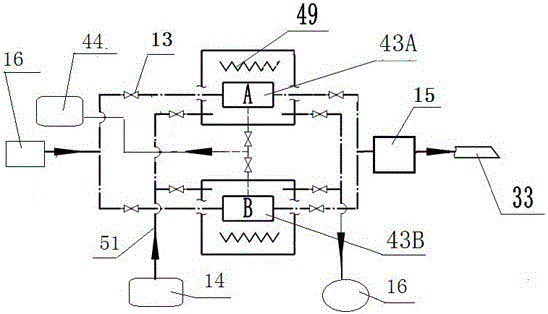

Hybrid power system with waste heat recovery function and environment air purification function and for hydrogen vehicle

ActiveCN106627090AImprove efficiencyFunction increaseHybrid vehiclesAir-treating devicesAtmospheric pollutionRecovery function

The invention relates to a hybrid power system with a waste heat recovery function and an environment air purification function and for a hydrogen vehicle. The hybrid power system with the waste heat recovery function and the environment air purification function and for the hydrogen vehicle comprises a vehicle body, a transmission system, a hydrogen fuel engine, a hybrid power transmission, a metal hydride storage tank, a turbine, a catalyst, a high-pressure surge tank, a hydrogen buffering tank and the like. The metal hydride storage tank is connected to an inlet of the turbine through the high-pressure surge tank. An outlet of the turbine is connected to an inlet of the hydrogen fuel engine through the hydrogen buffering tank or a high-pressure hydrogen buffering tank. An outlet of the hydrogen fuel engine is connected to a discharge outlet through the catalyst, a tail gas heat exchanger, a residual hydrogen absorption unit and a tail gas zero-stage purifier. The hydrogen fuel engine is connected with the hybrid power transmission through a power output shaft. According to the hybrid power system with the waste heat recovery function and the environment air purification function and for the hydrogen vehicle, the hydrogen fuel engine, the turbine and an exhaust gas waste heat recovery and purification system are combined to form the hybrid power system for the automobile, chemical energy of hydrogen is sufficiently used, various kinds of heat energy in the process is recovered, and the working efficiency of the power system is improved; and atmospheric pollution is avoided, the environment air is purified, and protection of the natural environment is facilitated.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

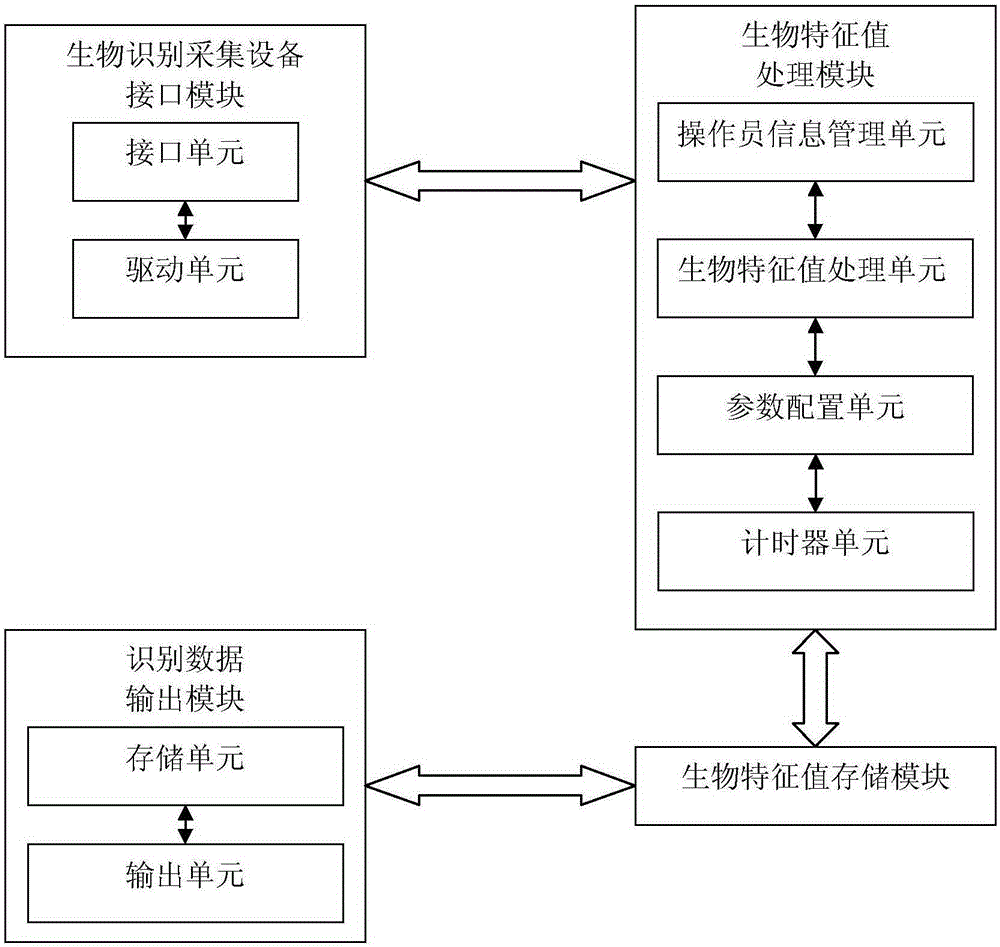

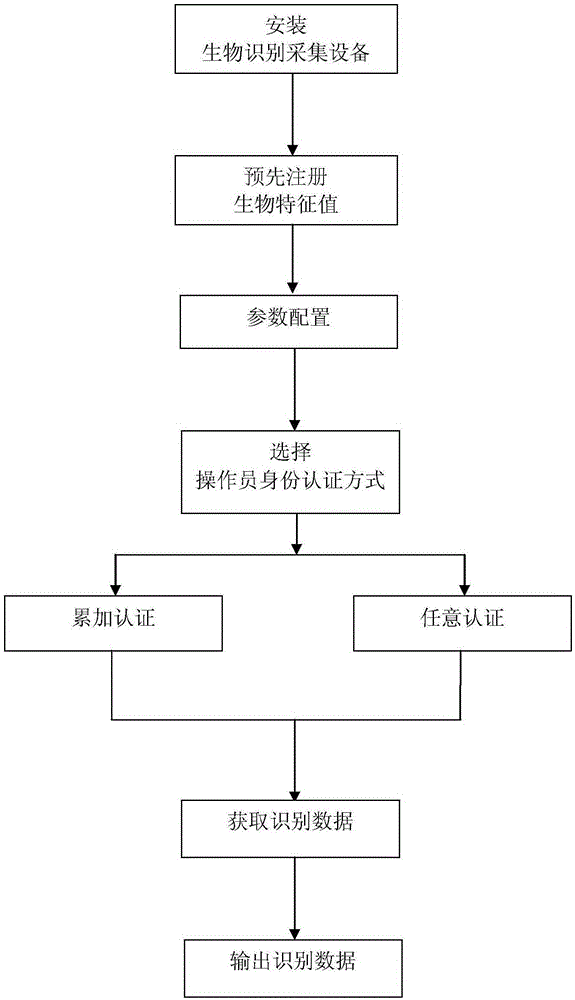

Multi-model biological recognition general platform and multi-model biological recognition identity authentication method

ActiveCN105160302AOvercome the shortcomings of limited applicationOvercome lossAcquiring/recognising eyesDigital data authenticationPattern recognitionComputer module

The invention discloses a multi-model biological recognition general platform and a multi-model biological recognition identity authentication method. Highly-integrated middleware technologies are achieved by means of a computer terminal. The platform comprises a biological recognition collection equipment interface module, a biological characteristic value processing module, a biological characteristic value storage module and an identification data output module. The method comprises the following steps of installing biological recognition collection equipment; registering biological characteristic values in advance; performing parameter configuration; selecting an operator identity authentication mode; accumulating authentication; performing random authentication; obtaining identification data; and outputting identification data. The invention collects biological characteristic information with the combination of single-mode or multi-mode biological recognition collection equipment which is widely applied to identity authentication, and can be widely applied to application systems for identity authentication, control, display and alarm, and gather, statistics and analysis.

Owner:西安凯虹电子科技有限公司

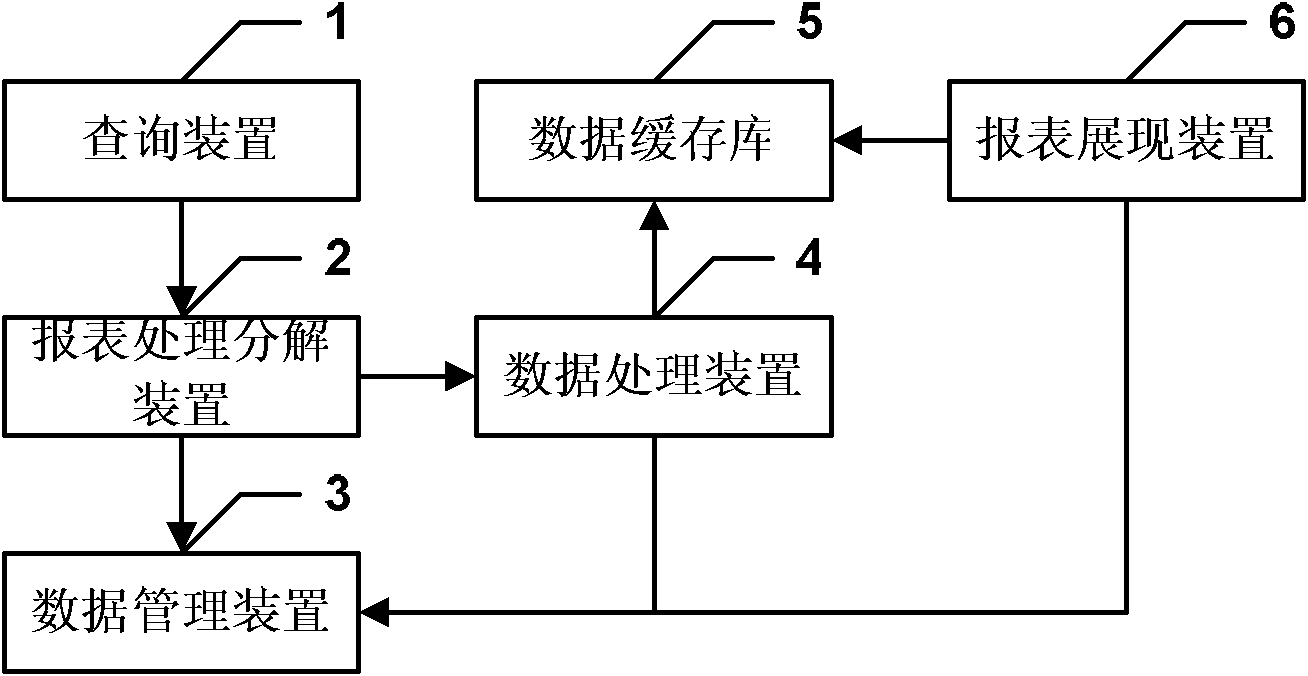

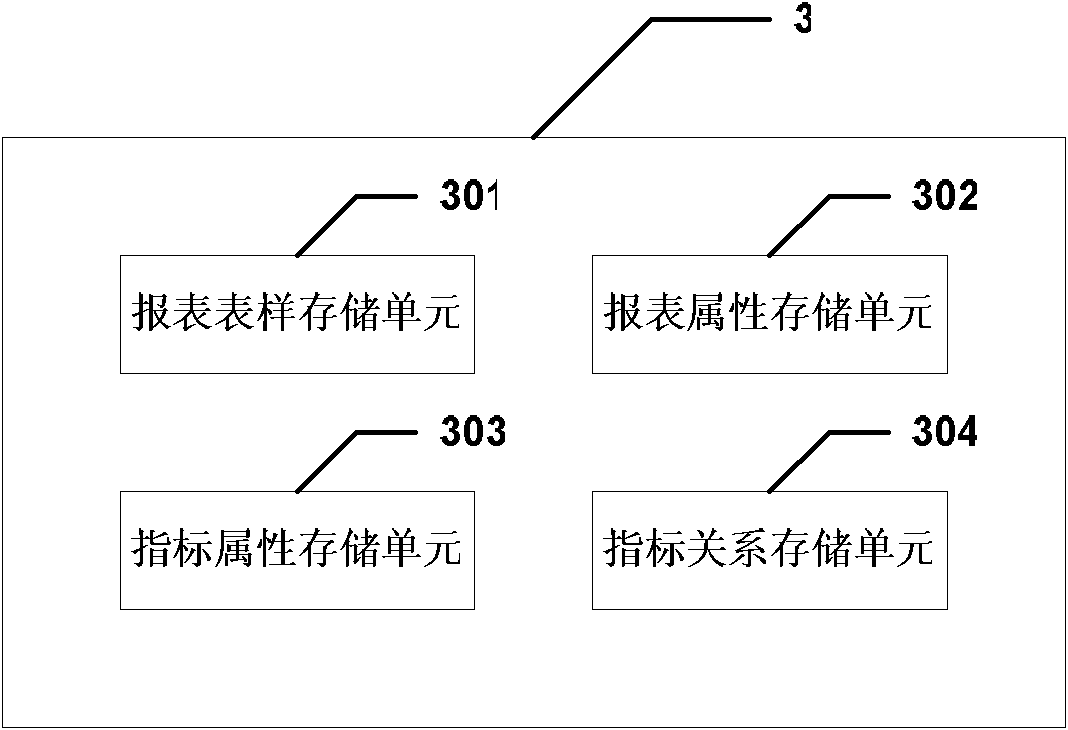

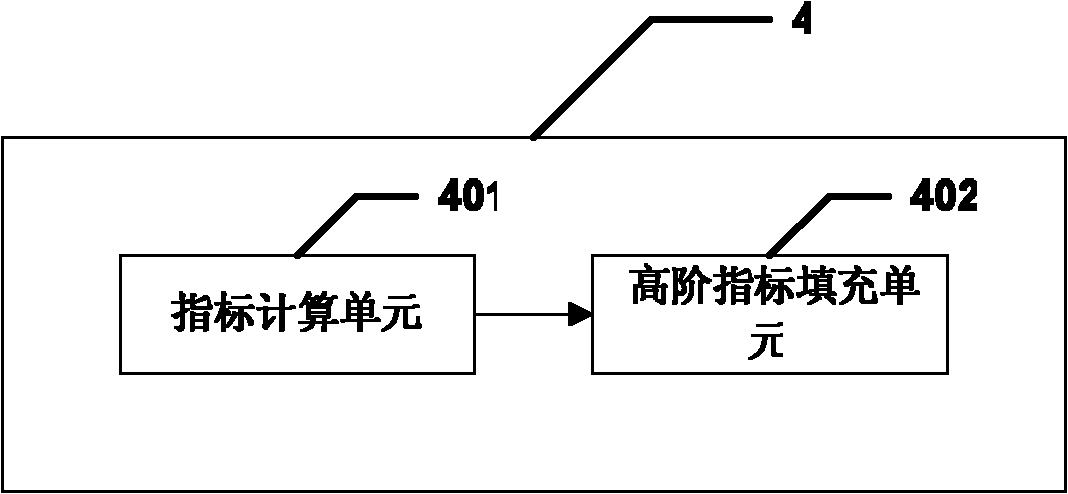

Device and method for realizing data dynamic cache

ActiveCN102024062AOvercome wasteAchieve sharingSpecial data processing applicationsManagement unitData management

The invention discloses a device and a method for realizing data dynamic cache. The device comprises an inquiry unit, a report processing decomposer, a data management unit, data processing unit, a data cache library and a report displaying unit wherein the report processing decomposer receives a report inquiry command input by the inquiry unit, decomposes the command into a plurality of index inquiry commands contained in the command, and then forms a string of inquiry command stream and transmits the same to the data processing unit; the data processing unit is used for carrying out index calculation in accordance with the string of inquiry command stream, calculating the higher-order index of an index result layer by layer in accordance with the index result, filling the high-order index dynamically, and storing the obtained report data in the data cache library; and the report displaying unit is used for displaying the report in accordance with the data in the data cache library and a report sample in the data management unit. The device and the method for realizing the data dynamic cache can be used to overcome the problems of repeated data processing and storage in the processing of the report data, and waste of system resources caused by low data processing efficiency and redundant storage.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

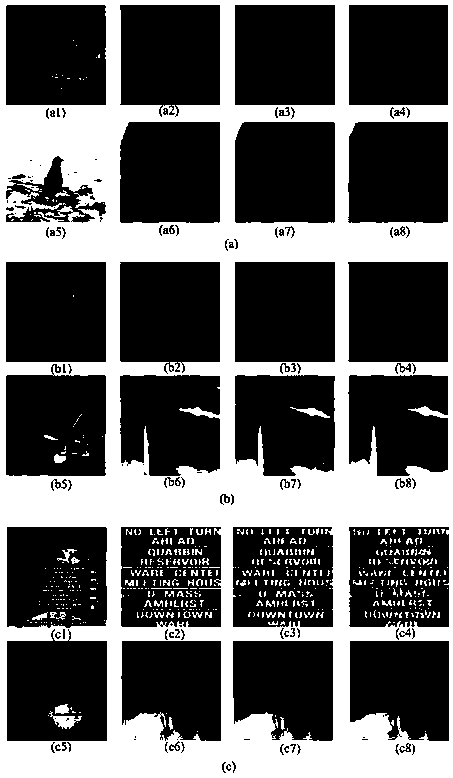

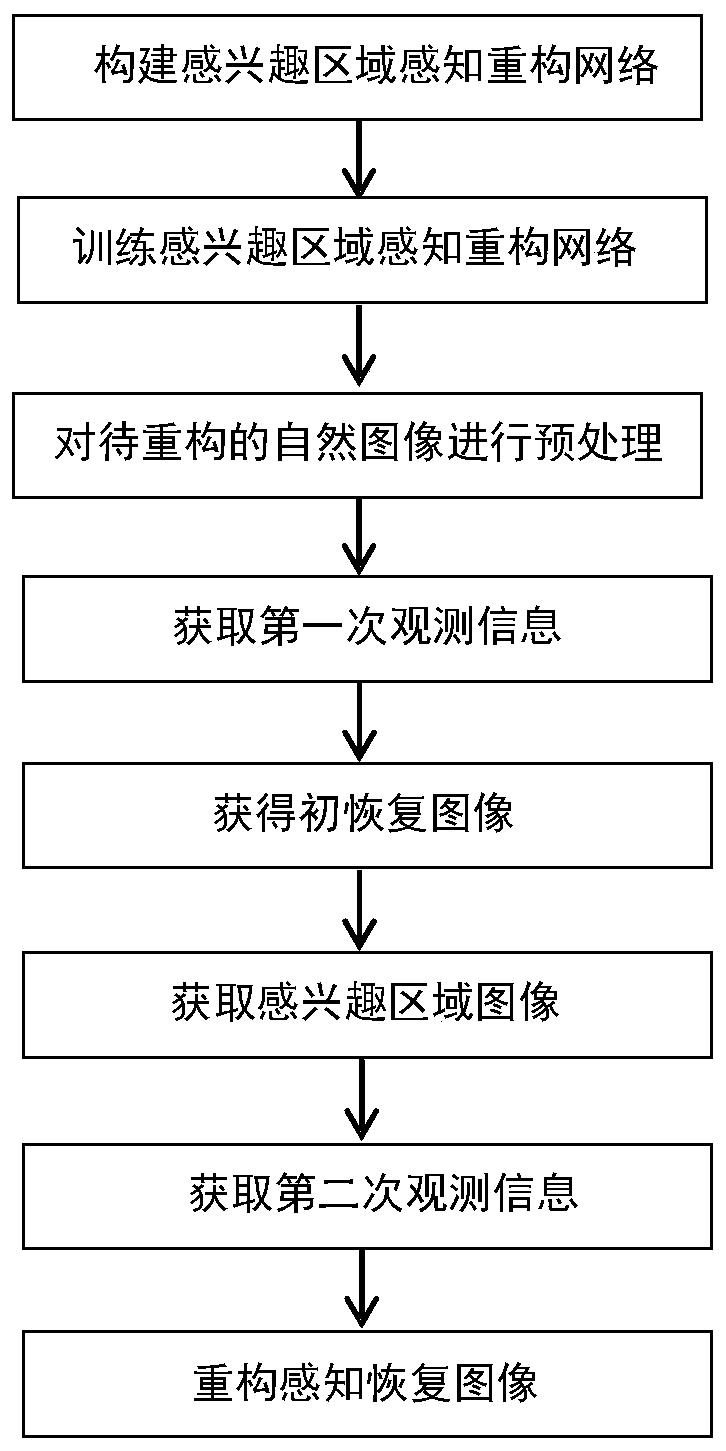

A region-of-interest compressed sensing image reconstruction method based on deep learning

ActiveCN109949257AOvercome the problem that the time complexity is very high and affects the speed of the algorithmImprove rebuild speedImage enhancementGeometric image transformationReconstruction methodPattern perception

The invention discloses a region-of-interest compressed sensing image reconstruction method based on deep learning, which overcomes the problem of low reconstruction quality of an interested region inan image under limited observation resources in the existing compressed sensing image reconstruction method, and comprises the following implementation steps of: (1) constructing an interested regionsensing reconstruction network; (2) training a region-of-interest perception reconstruction network; (3) preprocessing the natural image to be reconstructed; (4) obtaining first observation information; (5) obtaining an initial recovery image; (6) obtaining a region-of-interest image; (7) obtaining second observation information; And (8) reconstructing the perception recovery image. According tothe method, more observation resources are distributed to the region of interest by using a twice observation method, and the texture details of the region of interest in the reconstructed image are clear.

Owner:XIDIAN UNIV

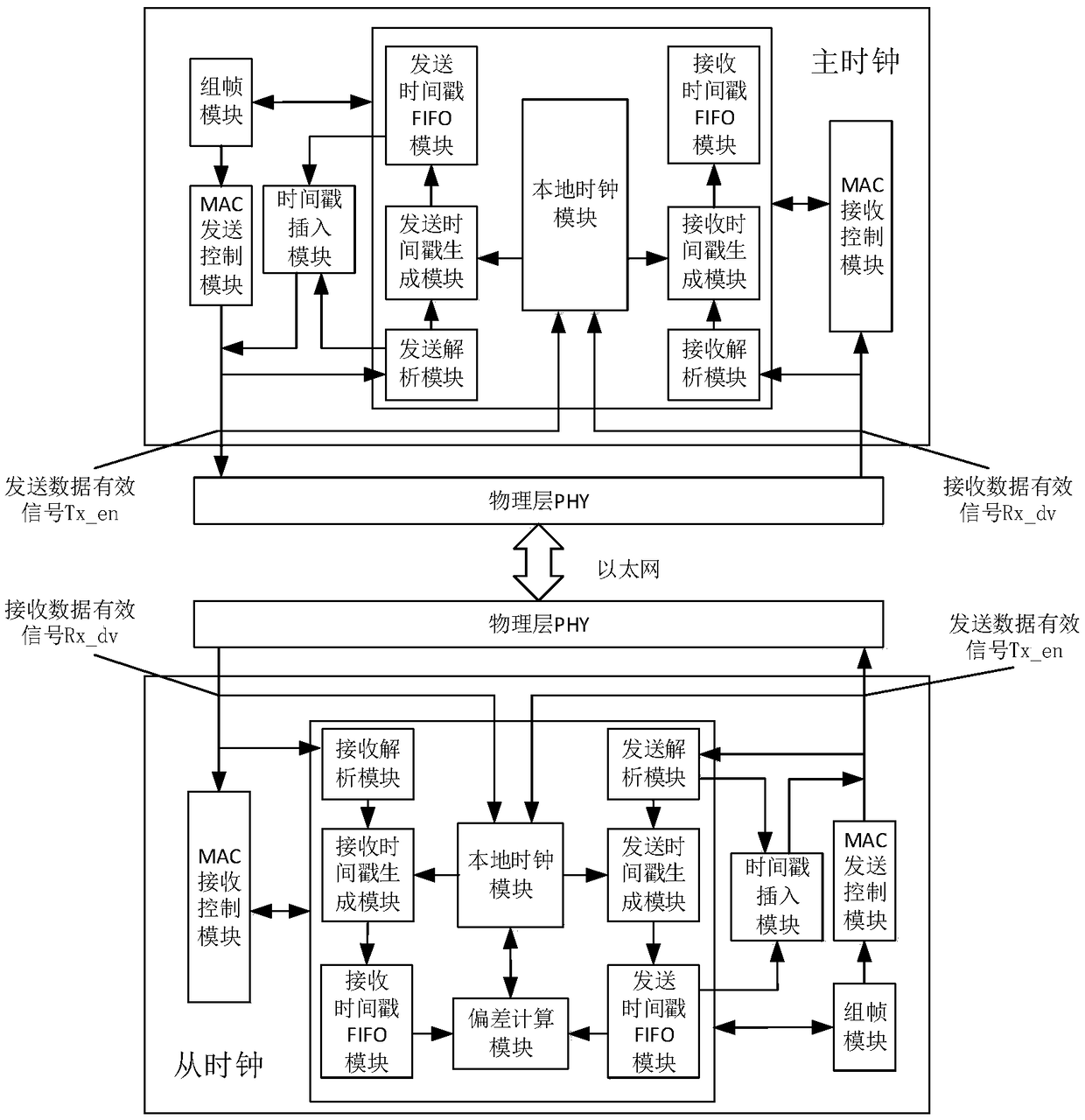

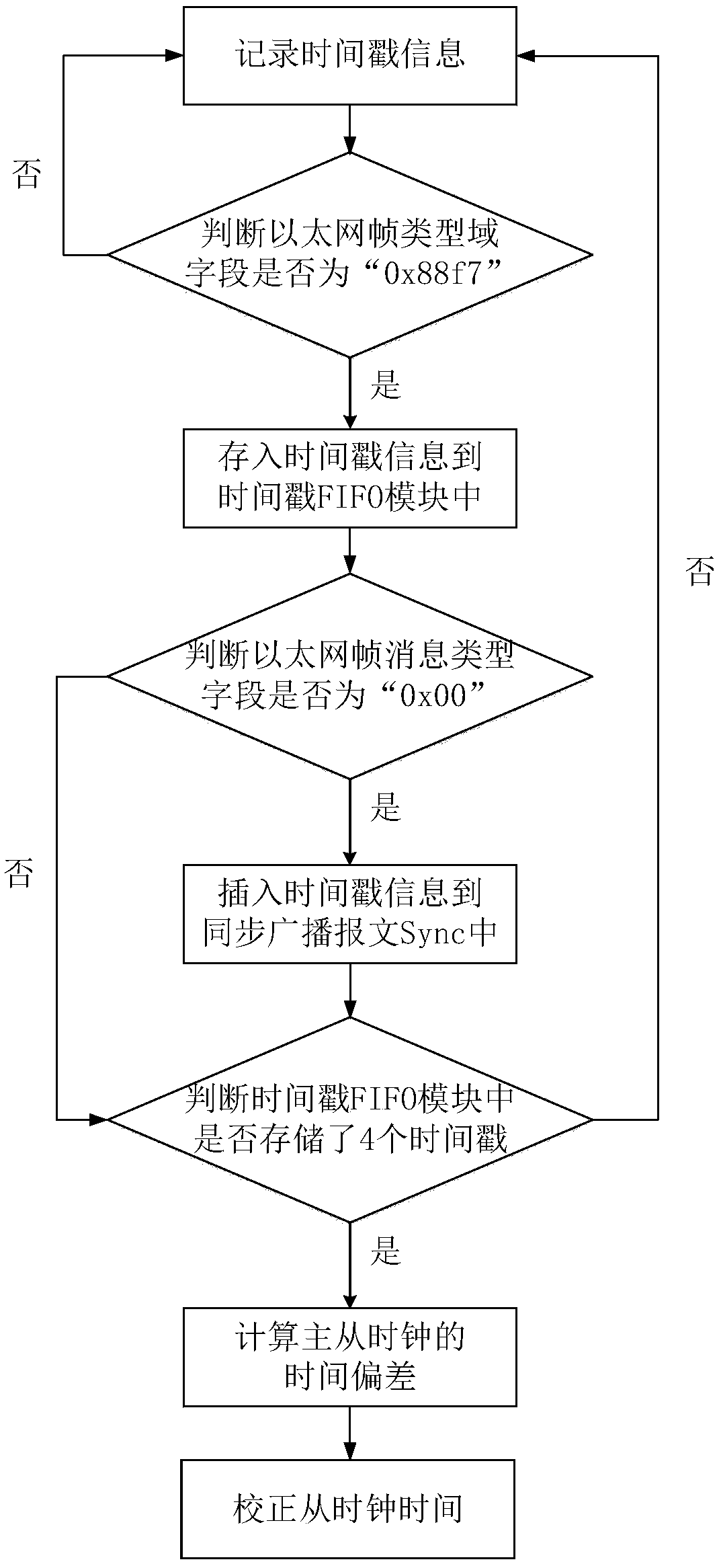

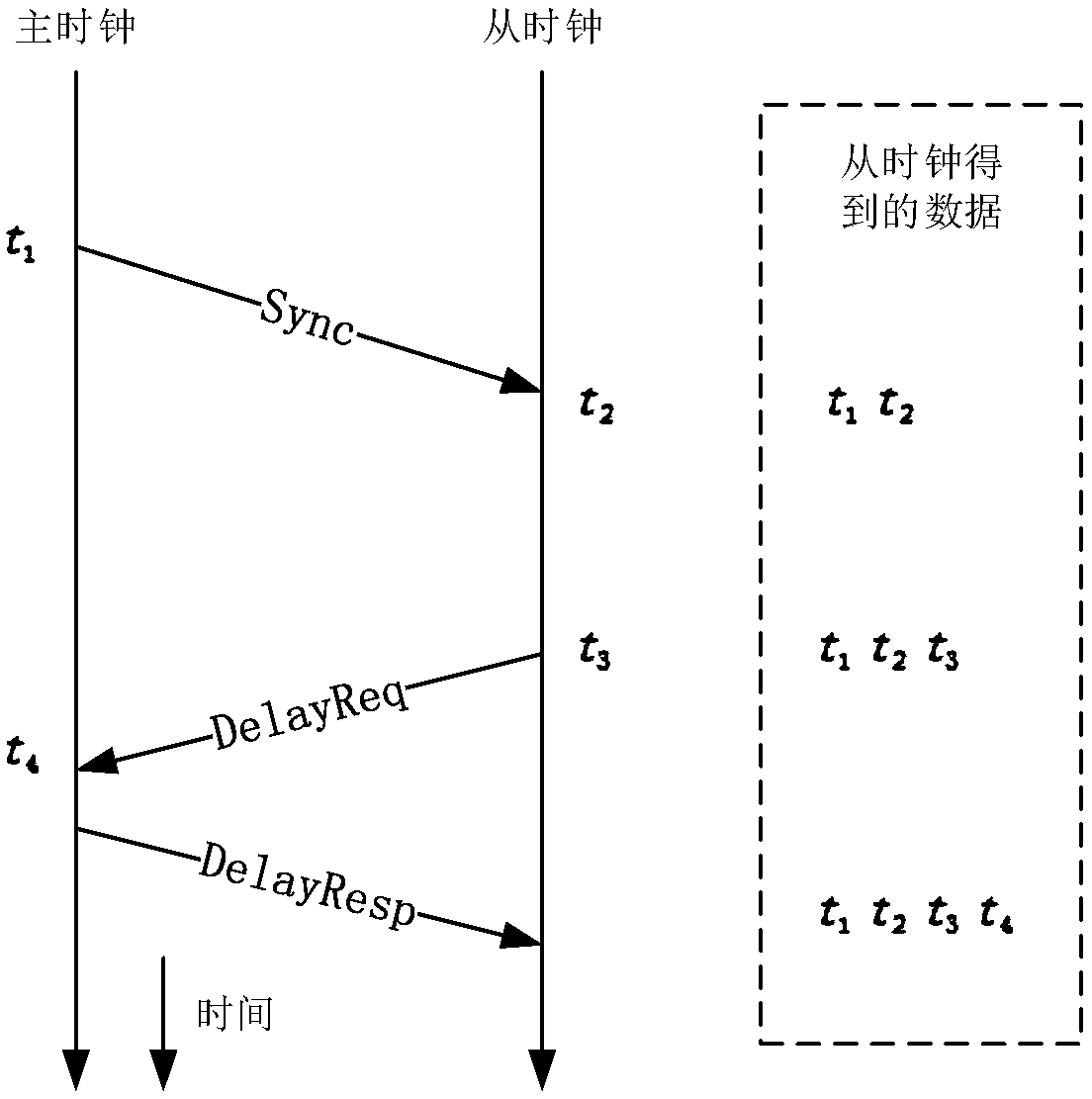

Universal full-hardware one-step 1588 clock synchronization device and method

ActiveCN108650051ALow hardware requirementsEliminate latency uncertaintyTime-division multiplexRecording durationTime deviation

The invention relates to a universal full-hardware one-step 1588 clock synchronization device and method. The device comprises a framing module, an MAC transmission control module, an MAC receiving control module, an analysis module, a timestamp generation module, a first-in first-out queue timestamp FIFO module, a local clock module, a deviation calculation module and a timestamp insertion module. The method of the invention includes the following steps: recording timestamp information, identifying synchronous messages, storing the timestamp information, identifying synchronous broadcast messages Sync, inserting the timestamp information, calculating the time deviation of master-slave clocks, and correcting the time of the slave clock. According to the scheme of the invention, a hardware-only one-step synchronization method is adopted, effective data signals ctrl at a reduced gigabit media independent interface (RGMII) between a data link layer MAC and a physical layer PHY are adoptedto collect accurate timestamp information, and thus the universality and synchronization accuracy of the system can be improved.

Owner:XIDIAN UNIV

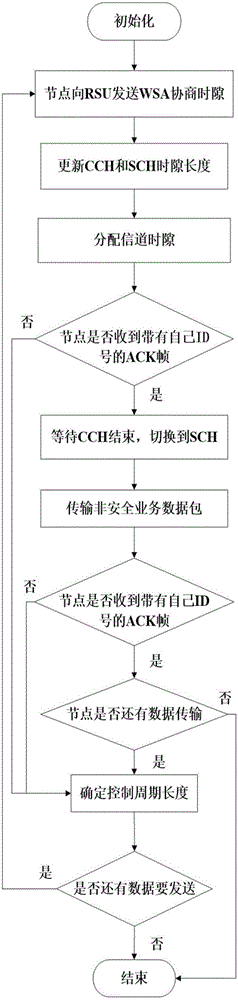

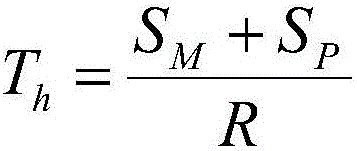

Method for combination of multichannel MAC protocol and TDMA in IOV

ActiveCN106060944AIncrease profitImprove throughputError prevention/detection by using return channelSignalling characterisationThe InternetControl channel

The invention discloses a method for combination of a multichannel MAC (Media Access Control) protocol and TDMA (Time Division Media Access) in IOV (Internet of Vehicles), which overcomes the problems of low time slot utilization rate of a control channel CCH and a service channel SCH and high expense of channels in the prior art. The specific thought of the method is as follows: firstly , setting channel initialization; then, by a roadside unit RSU, negotiating time slot with a node, updating the time slot length of the control channel CCH based on a feedback condition of the node, and maintaining time slot distribution of two channel lists; and finally switching to the service channel SCH for data transmission. According to the method for combination of the multichannel MAC protocol and the TDMA in the IOV, as the roadside unit RSU controls the time slot length of the control channel CCH and the time slot distribution, the problems of low utilization rate of the channel and high channel expense under the condition of a varying vehicle density can be avoided efficiently, the throughput of the channel is increased , and the channel expense is reduced.

Owner:XIDIAN UNIV

Aquasol self-adhesive elastic bandage and manufacturing method thereof

The invention relates to an aquasol self-adhesive elastic bandage which comprises aquasol and elastic fabric, and the formula of the aquasol is as follows: 62 to 90 percent of emulsion adhesive, 0.1 to 10 percent of tackifier, 0.5 to 20 percent of softener, 0.001 to 2 percent of age inhibitor, 0.1 to 5 percent of environmental-friendly additive and 0.1 to 1 percent of colorant; the elastic fabric is one type of elastic cotton fabric, elastic chemical fiber fabric, elastic chemical fiber / cotton blended fabric; the manufacturing process comprises the following steps that: first, mixing the aquasol by the component, then selecting one type of the elastic cotton fabric, the elastic chemical fiber fabric, the elastic chemical fiber / cotton blended fabric as the backup fabric, putting the mixed aquasol into gluing equipment, uniformly applying the aquasol onto the prepared elastic fabric through rolling, spray coating, roll coating, scrape coating and extrusion coating processes, and manufacturing aquasol self-adhesive elastic bandage products with various specifications through a rolling device. The products manufactured through the method have the advantages of good air permeability, comfortable feel, no mildew after long-termed storage, convenient use and the like.

Owner:SUZHOU MEDSPORT PROD

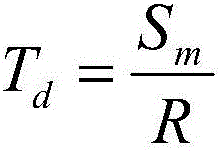

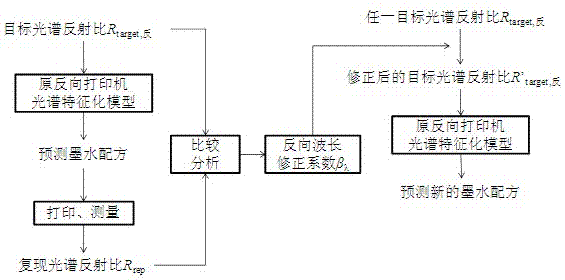

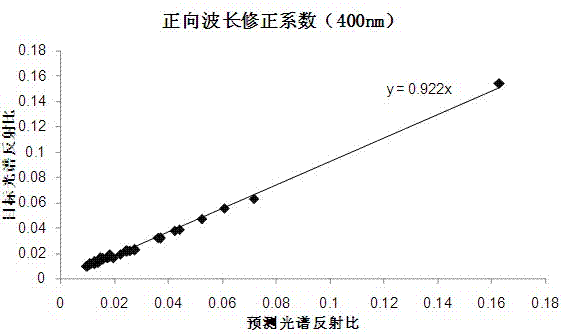

Method of correcting printer spectrum characterization model

InactiveCN102180003AReduce precisionOvercome wasteCharacter and pattern recognitionColor/spectral properties measurementsGamutLength wave

The invention discloses a method of correcting a printer spectrum characterization model. The method can substantially improve the situation that precision of a spectrum characterized model is reduced due to changes of printing environment, such as ink, paper, temperature, air humidity, etc, and the method is applicable to a plurality of printer spectrum characterized model. The method comprises selecting 20 to 50 correcting samples (reflectivity of ink formula to spectrum) which basically cover colour gamut of the printer, printing and measuring under a new printing environment, after comparative analysis, obtaining corresponding correction factors of forward wavelength and reverse wavelength to correct an input or output parameter of the original spectrum characterized model, and finally realizing a precise prediction of the original forward and reverse spectrum characterized model under the new printing environment. The method avoids cost and inconvenience brought by remodeling, meanwhile overcomes the problem that the precision of the model is substantially reduced due to changes of printing environment. Besides, the method is easy to implement.

Owner:ZHEJIANG UNIV

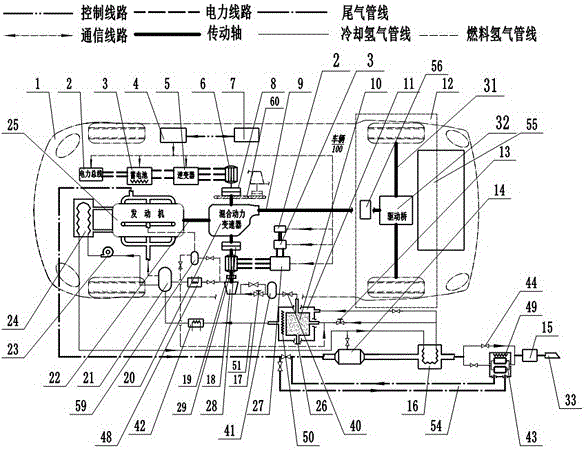

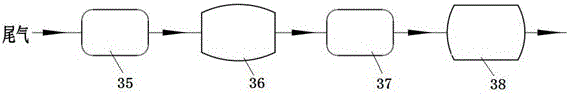

Hydrogen energy vehicle power system for ambient air purification

ActiveCN106837529AOvercome wasteOvercome environmental pollutionInternal combustion piston enginesFuel supply apparatusPower combinerEngineering

The invention relates to a hydrogen energy vehicle power system for ambient air purification. The hydrogen energy vehicle power system comprises a transmission system, a hydrogen fuel engine, a metal hydride storage tank, a hydrogen compression unit, a hydrogen stabilized tank, an inverter, a, electric-generator, an expansion machine, a storage battery and an exhaust gas disposal system. The storage battery is electrically connected with a power bus and the inverter, and the inverter is electrically connected with the electric-generator; the metal hydraulic storage tank is connected with the hydrogen fuel engine through the hydrogen compression unit and the hydrogen stabilized tank, and an exhaust outlet of the hydrogen fuel engine is connected with the exhaust gas disposal system through a turbo charger; the hydraulic fuel engine or / and the number one electric-generator is / are connected with a power combiner, the expansion machine is connected with the power combiner, and the power combiner is connected with the transmission system through a transmission shaft. By the combination of the hydrogen fuel engine with the electric-generator, operation efficiency of the hydrogen energy vehicle power system is improved; by recycling exhaust heat, atmospheric pollution is reduced, and natural environment is favorably protected.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

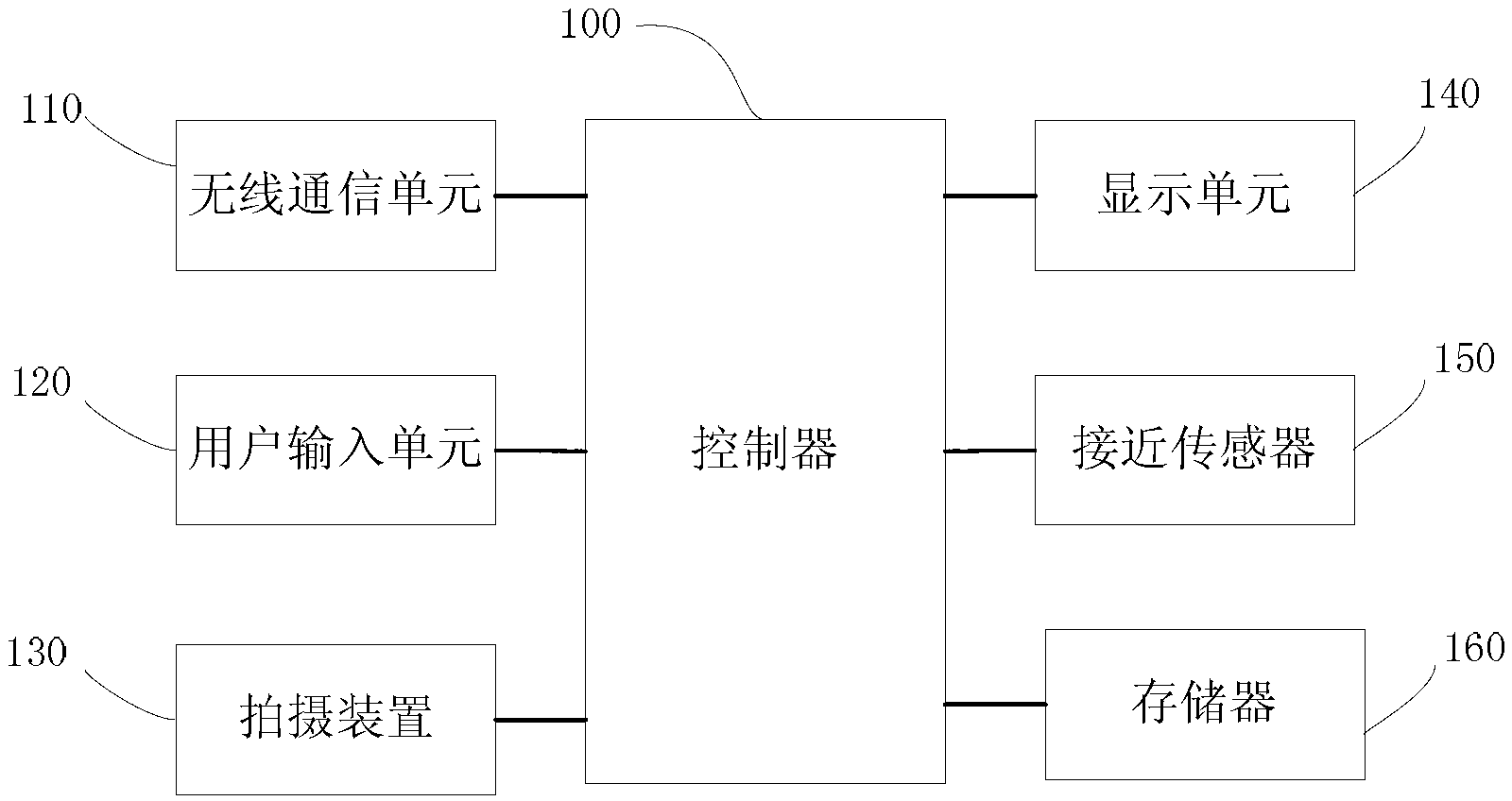

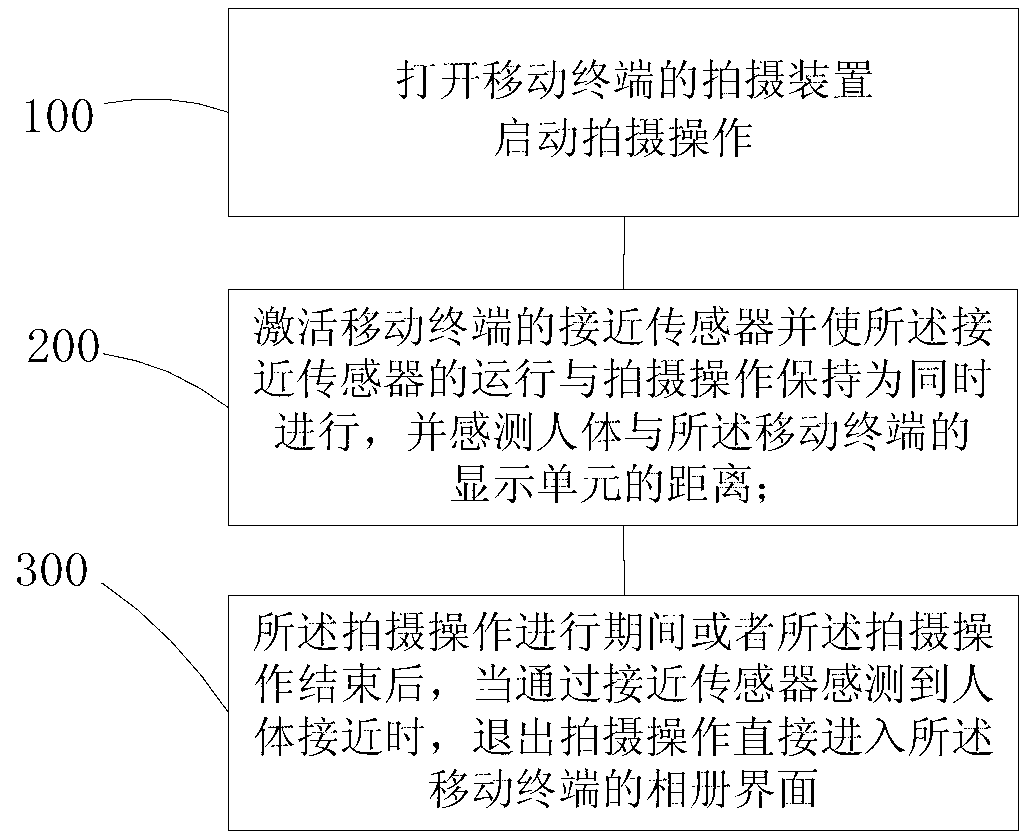

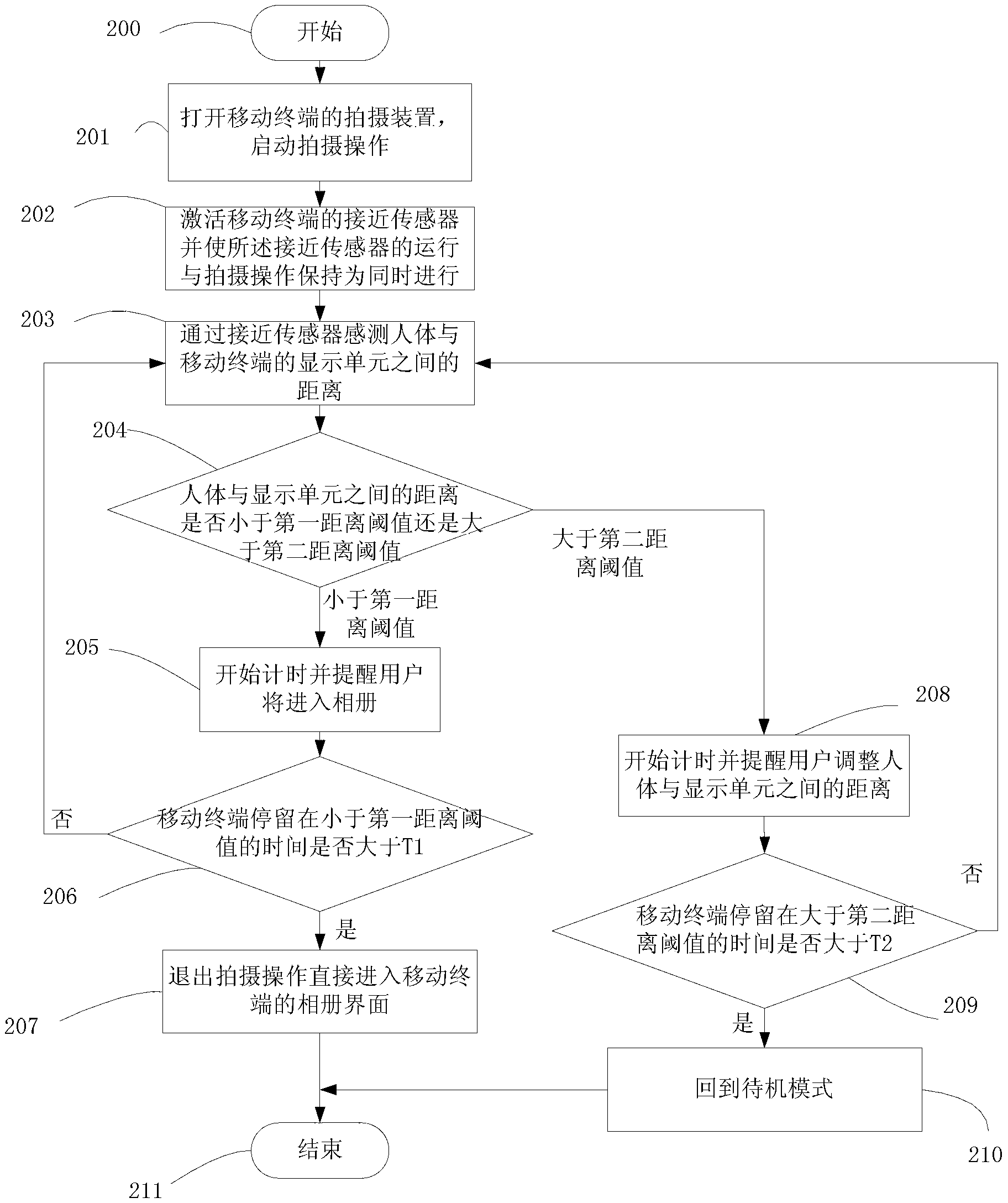

Method and device which enter into photo album interface from shoot interface of mobile terminal

ActiveCN103024182AOvercome Battery WasteOvercome wasteSubstation equipmentProximity sensorComputer engineering

The invention discloses a method and device which utilize a proximity detector to enable a shoot interface to directly enter into a photo album interface and a mobile terminal. The method comprises the steps of: opening a shooting device of the mobile terminal, starting shooting operation; activating the proximity detector of the mobile terminal and enabling running and shooting operation of the proximity detector to be simultaneous, and sensing distance between a human body and a display unit; and after shooting pictures, when sensing approaching of a human body through the proximity detector, quitting shooting operation and directly entering into the photo album interface of the mobile terminal. By means of the method and device which utilize the proximity detector to enable the shoot interface to directly enter into the photo album interface and the mobile terminal, after users uses the mobile terminal to shoot, the users can directly enter into the photo album interface of the mobile terminal without performing a plurality of manual operations, and during photo album reading, the shooting program is automatically quitted, and accordingly the problem of battery electric quantity waste caused by backstage running of the shooting program is solved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

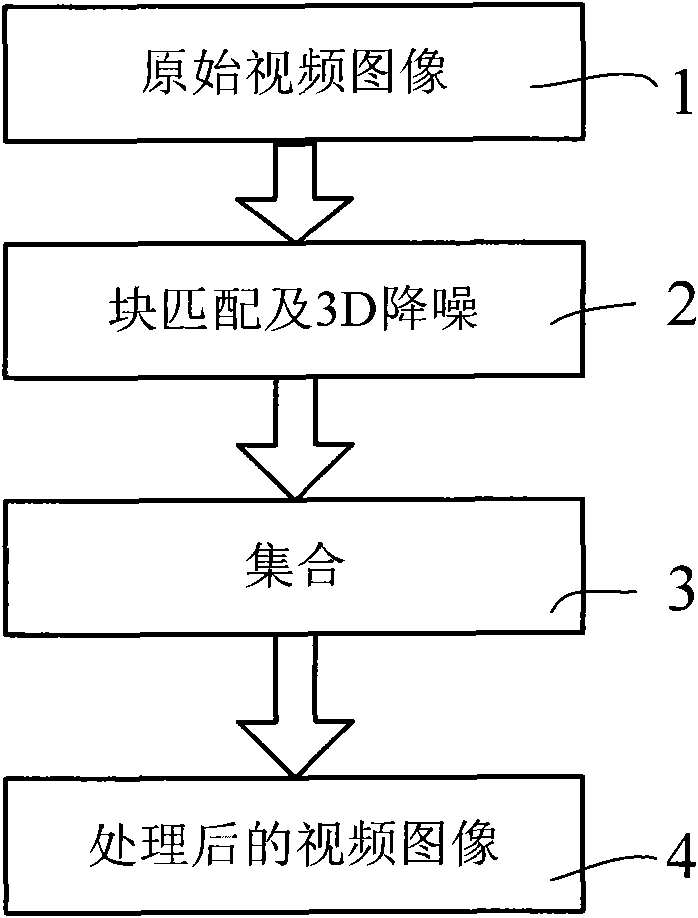

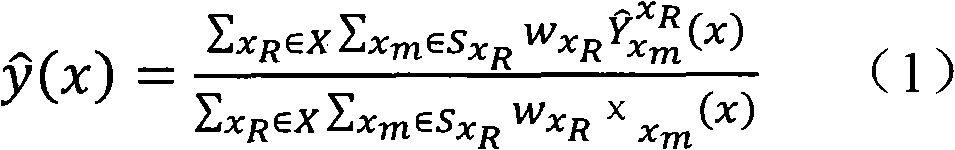

Integrated method suitable for real-time processing of BM3D

ActiveCN101895676AEliminate duplicate visitsSave bandwidthTelevision system detailsColor television detailsControl flowImaging processing

The technical problem to be solved by the invention is to provide a BM3D integration method. The method comprises the following steps: a, after 3D denoising processing, storing image processing information according to a line index or a column index; and b, reading the image processing information of a specific frame at a storing position from the storing position, reconstructing the image processing information of the specific frame and completing image reconstruction. The method realizes BM3D real-time integration processing by optimizing a BM3D integration process. In the method, the data structure and control flow are simple enough to be realized by software easily, and multiprocessor can be used for parallel processing. In addition, the method also makes the chip realization easy, is favorable for satisfying the high throughout needs for high-definition and multipath processing and realizes the video image BM3D real-time processing.

Owner:SHANGHAI FULLHAN MICROELECTRONICS

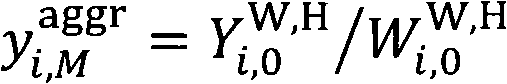

Pet drinking aid device

InactiveUS20030233985A1Improve sealingLarge spacingAnimal watering devicesAnimal housingPhysical medicine and rehabilitationPhysical therapy

A pet drinking aid is disclosed that includes a cap defining an axial passage therewithin. Preferred embodiments of the cap include securing means for detachably securing the cap to a fluid container and an inwardly directed flange. The securing means may include helical threads, an elastomeric sleeve or the like. The cap further includes a ball positioned within the axial passage of said cap and, in a preferred embodiment, biasing means mounted relative to the cap within the axial passage. The biasing means advantageously engages the ball to bias the ball toward the inwardly directed flange. The ball is preferably captured within the axial passage between the inwardly directed flange and the biasing means, and the ball is capable of rotatable movement and limited axial movement against the bias of the biasing means. The biasing means may include a compression spring, a foam member or the like. In an alternative embodiment, the biasing means is omitted and the cap includes an inwardly directed ridge extending from the cap's inner surface at an axial location intermediate the first and second ends of the cap.

Owner:MEDIALORE

Sample storage barrel and intelligent management system

ActiveCN104504787AOvercome wasteEnsure safetyIndividual entry/exit registersControl signalElectromagnetic lock

The invention discloses a sample storage barrel and an intelligent management system, and relates to the technical field of sample storage and management. The storage barrel is provided with a latch hook on a barrel lid, and an electromagnetic lock and a control part on a barrel body, wherein the electromagnetic lock is matched with the latch hook. The control part comprises a control module, a power supply module and an IC card. The system comprises a rotary worktable, a sealing material tube, the storage barrels, weighing sensors, a door opening mechanism and a door closing mechanism. The storage barrels are sequentially arranged on a rotary plate of the rotary worktable; the sealing material tube is mounted on a panel of rotary worktable; the weighing sensors are mounted on a base of the rotary worktable; both the door opening mechanism and the door closing mechanism are mounted on a side surface of the rotary worktable. All control signals of component driving elements are connected with an upper computer, and all motion parts are under the uniform control of control signals of the upper computer. The system can prevent samples from being changed by people, and improve the sample storage safety. The samples are prevented from being changed by people, and the safety of the samples in storage is improved.

Owner:国能南京煤炭质量监督检验有限公司 +1

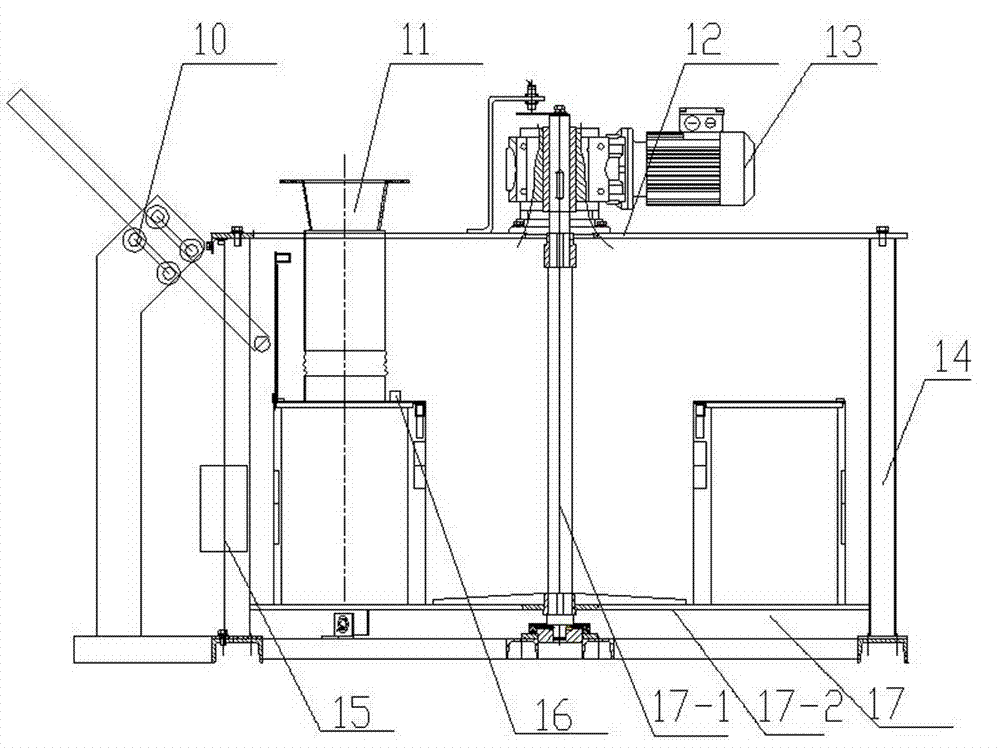

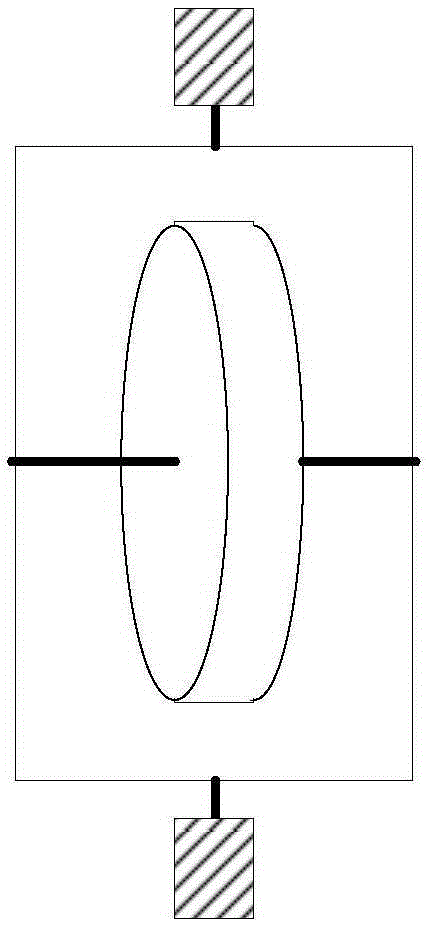

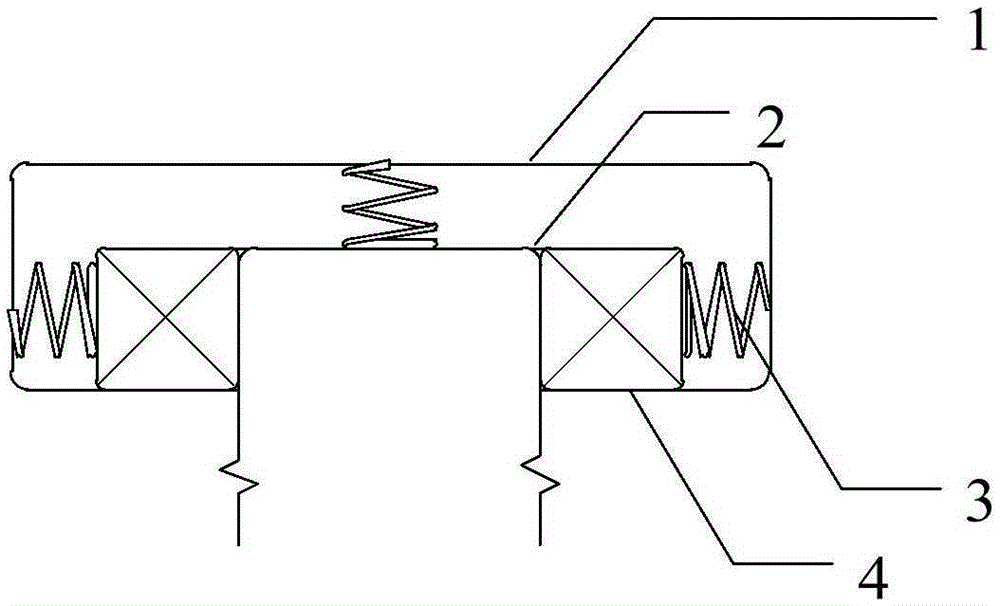

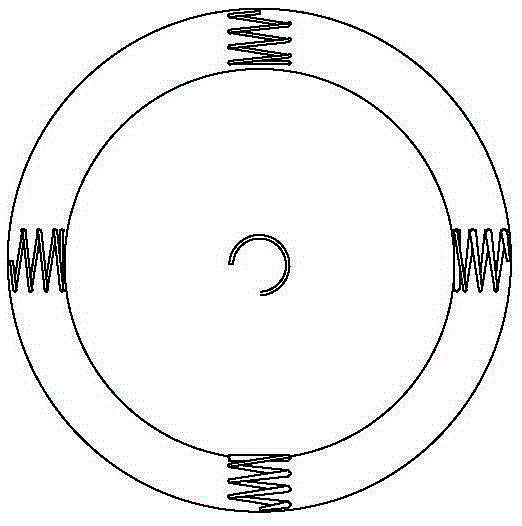

Apparatus and method of improving spacecraft attitude stability

The invention relates to an apparatus and method of improving spacecraft attitude stability, belonging to the spacecraft attitude dynamics and vibration inhibition field. The framework bearing of each SGCMG is provided with a vibration isolation element; each vibration isolation element includes a plurality of metal springs respectively in connection with the internal wall and the external wall of the vibration isolation element through spherical hinges. The internal wall of the vibration isolation element sleeves the framework bearing of an SGCMG so as to be in connection with the framework bearing of the SGCMG; the external wall of the vibration isolation element is directly in fixed connection with a satellite body. The vibration isolation elements can effectively solve the vibration problem of an SGCMG, and possess a decoupling characteristic so as to effectively and rapidly realize the parameter design of vibration isolation elements; in addition, the vibration isolation elements can greatly improve satellite attitude stability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Convenient barbecue seasoning and preparation method thereof

The present invention belongs to the field of condiment, and particularly relates to a convenient barbecue spice and preparation method thereof. The barbecue spice comprising the ingredients in terms of parts by weight as follows: 15-20 parts of cumin powder, 10-20 % part of white pepper powder, 6-10 parts of capsicum powder, 6-10 parts of Sichuan pepper powder, 6-10 parts of aniseed powder, 6-10 parts of ginger, 6-10 parts of garlic, 6-10 parts of sesame, 6-10 parts of shallot, and 6-15 parts of salt. The barbecue spice of the invention tasted delicious and is easy to carry, which is ideal for barbecue flavoring.

Owner:周大红

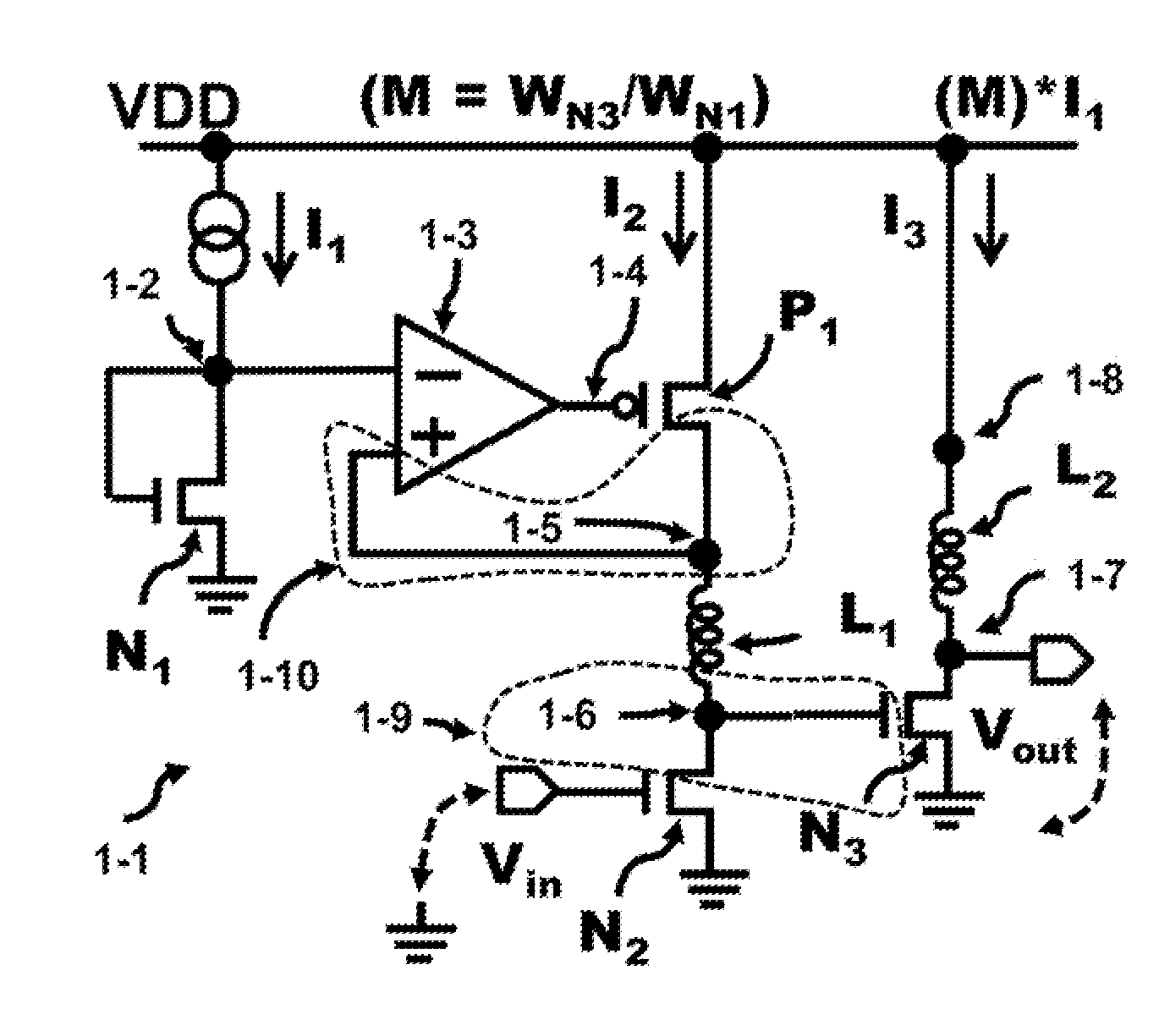

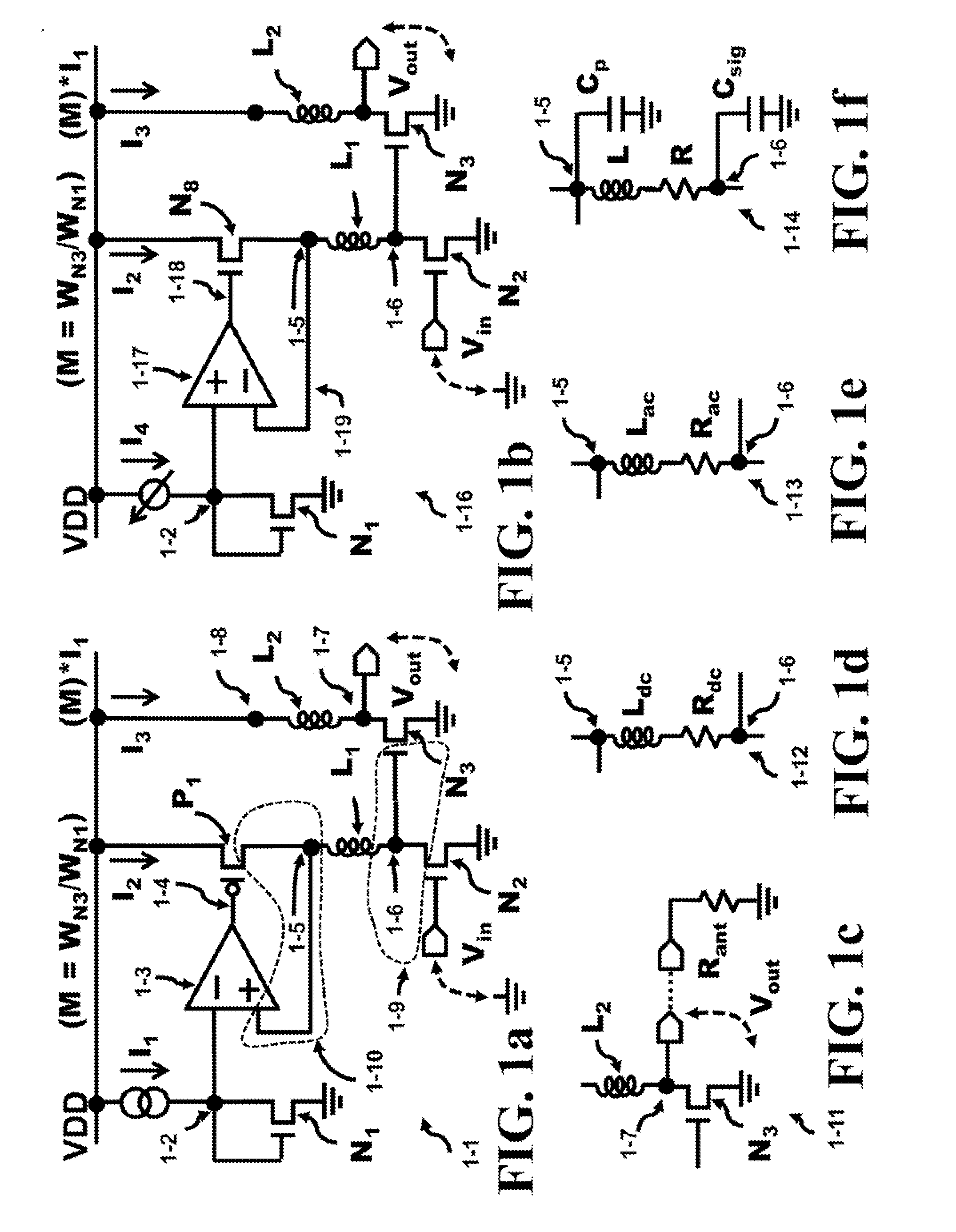

Direct Coupled Biasing Circuit for High Frequency Applications

ActiveUS20120319673A1Overcomes wasteful useDistance minimizationNear-field transmissionAmplifier modifications to reduce temperature/voltage variationParasitic capacitanceDirect coupling

This invention eliminates the need for “capacitor coupling” or “transformer coupling,” and the associated undesirable parasitic capacitance and inductance associated with these coupling techniques when designing high frequency (˜60 GHz) circuits. At this frequency, the distance between two adjacent stages needs to be minimized. A resonant circuit in series with the power or ground leads is used to isolate a biasing signal from a high frequency signal. The introduction of this resonant circuit allows a first stage to be “directly coupled” to a next stage using a metallic trace. The “direct coupling” technique passes both the high frequency signal and the biasing voltage to the next stage. The “direct coupling” approach overcomes the large die area usage when compared to either the “AC coupling” or “transformer coupling” approach since neither capacitors nor transformers are required to transfer the high frequency signals between stages.

Owner:TENSORCOM

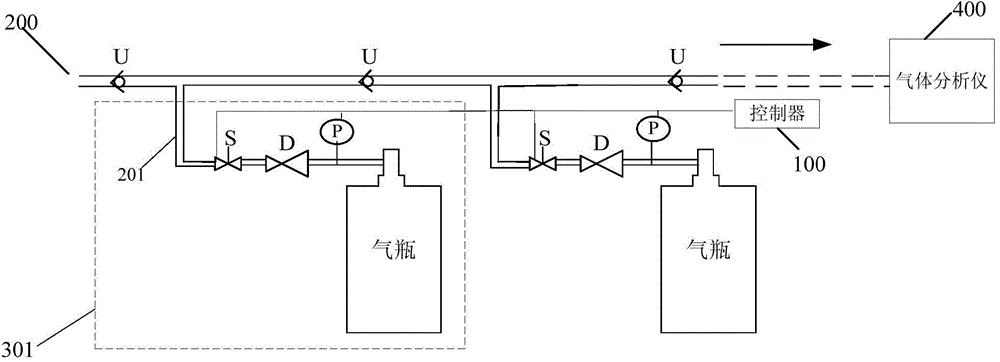

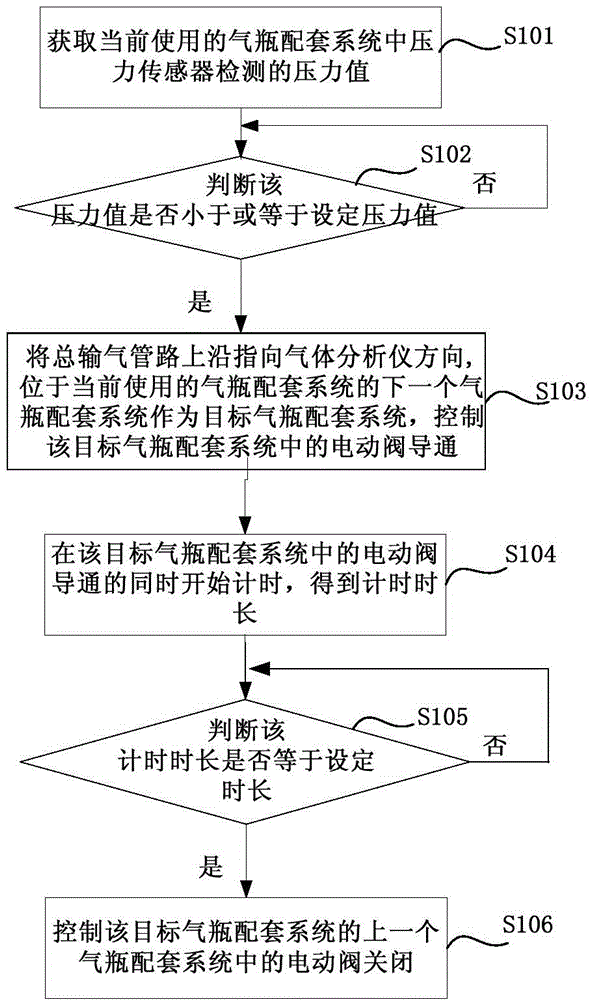

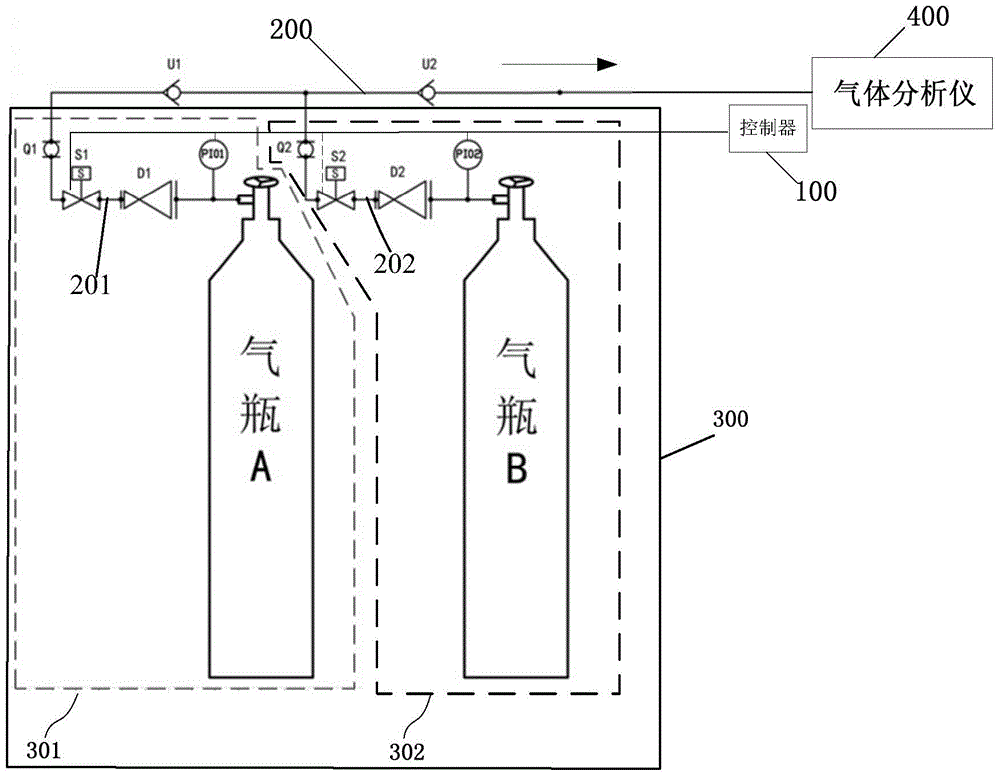

Gas supply device and method of gas analyzer

ActiveCN104792923AAccurate replacementOvercome wasteChemical analysis using combustionSupporting systemGas cylinder

The embodiment of the invention discloses a gas supply device and a gas supply method of a gas analyzer. The gas supply device is used for supplying gas to the gas analyzer, and comprises a controller, a gas conveying main pipeline and a plurality of gas bottle supporting systems, wherein the gas conveying main pipeline is communicated with the gas analyzer; the gas bottle supporting systems are sequentially distributed along the gas conveying main pipeline; each gas bottle supporting system comprises a gas bottle, a gas conveying branch pipeline, an electrically-operated valve, a pressure reducing valve and a pressure sensor. By presetting the using sequence of the gas bottles, when the used gas bottle reaches a switching condition, the controller switches the gas bottle, and sends out an alarm signal which indicates that the pressure of the gas bottle is low, so that compared with manual switching operation, the switching way provided by the invention is more accurate and reliable; the problem that waste of gas bottle resources or insufficient gas supply caused by the manual switching operation is solved; the labor cost and the time cost are greatly saved.

Owner:ELECTRON CO LTD

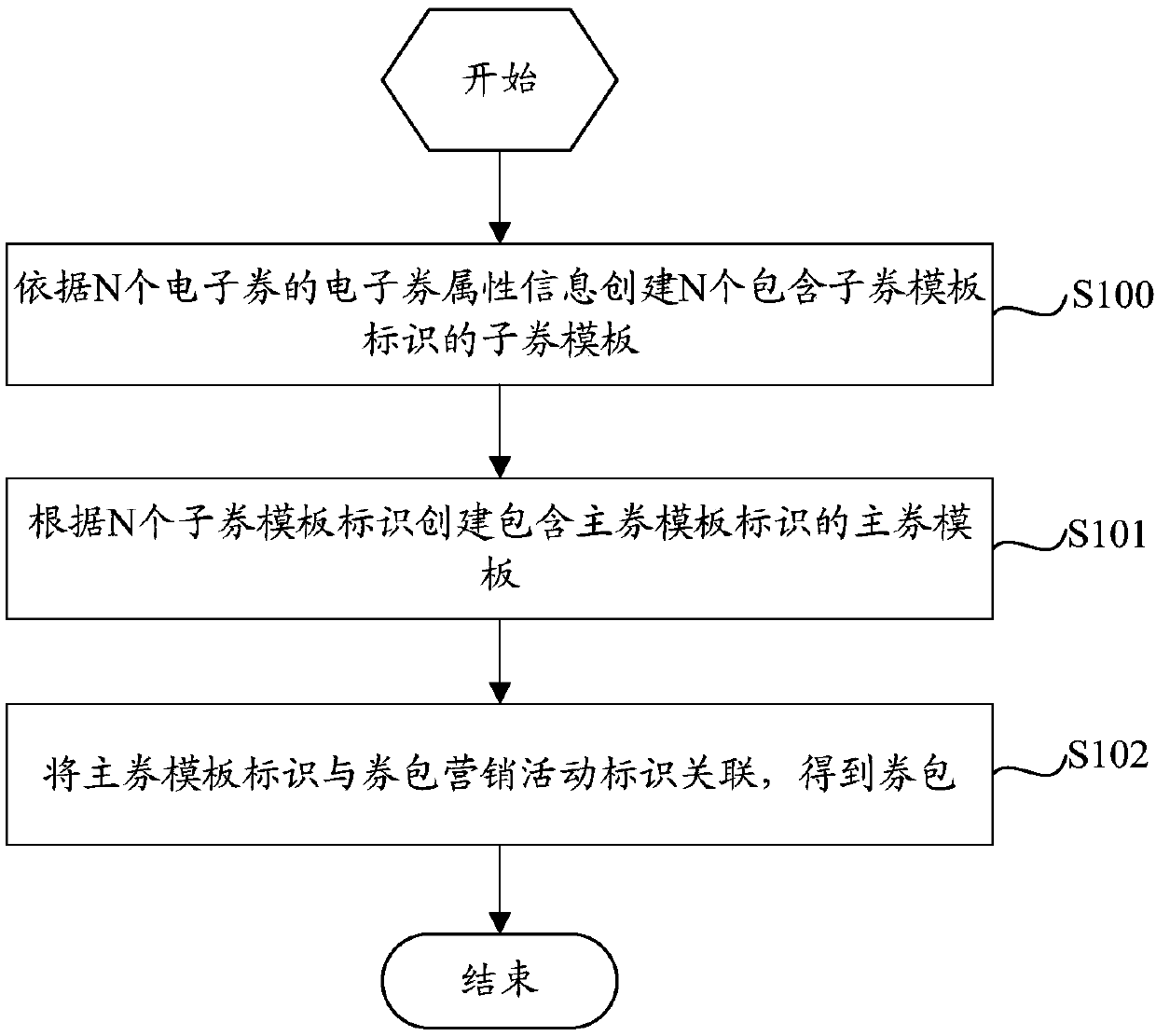

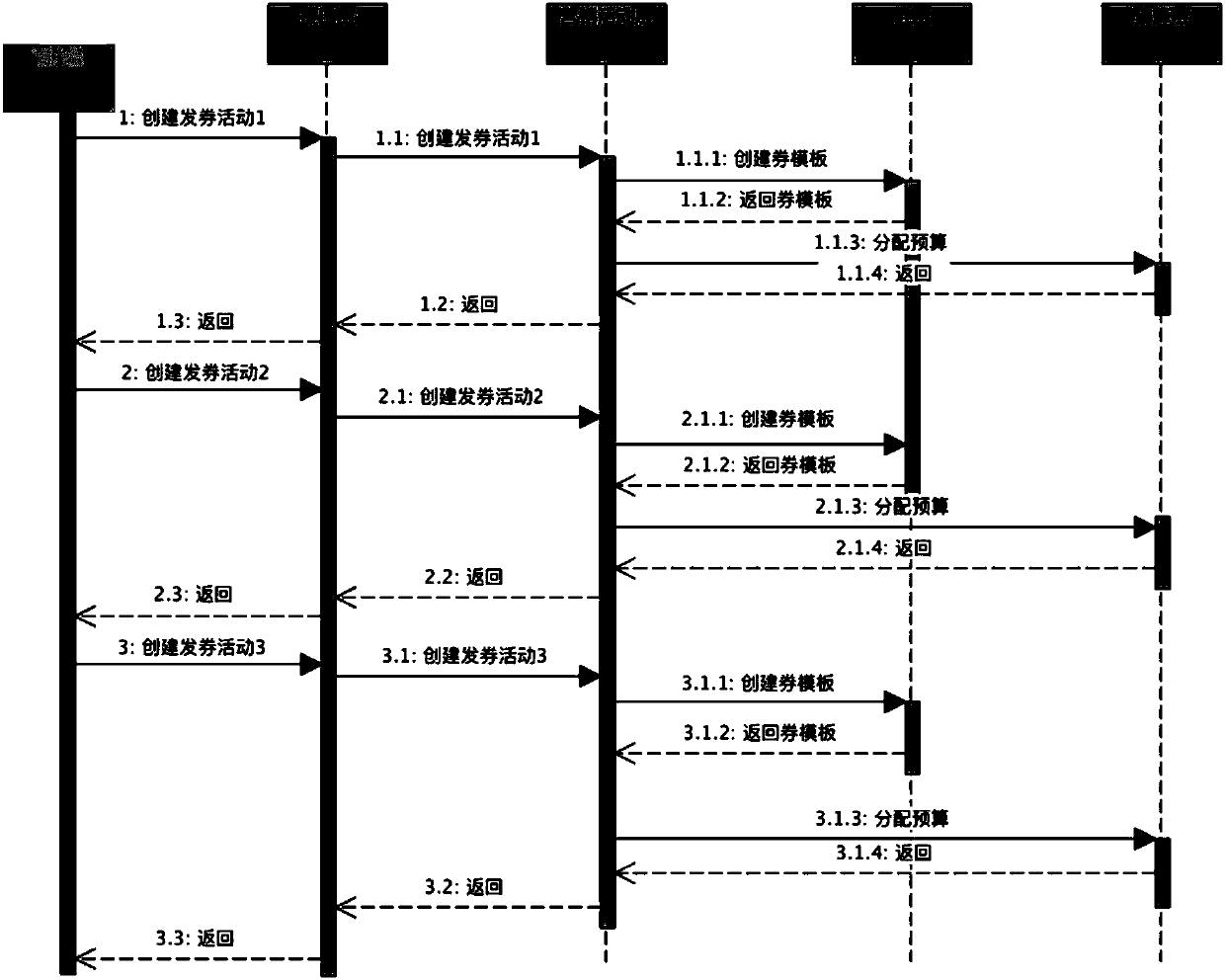

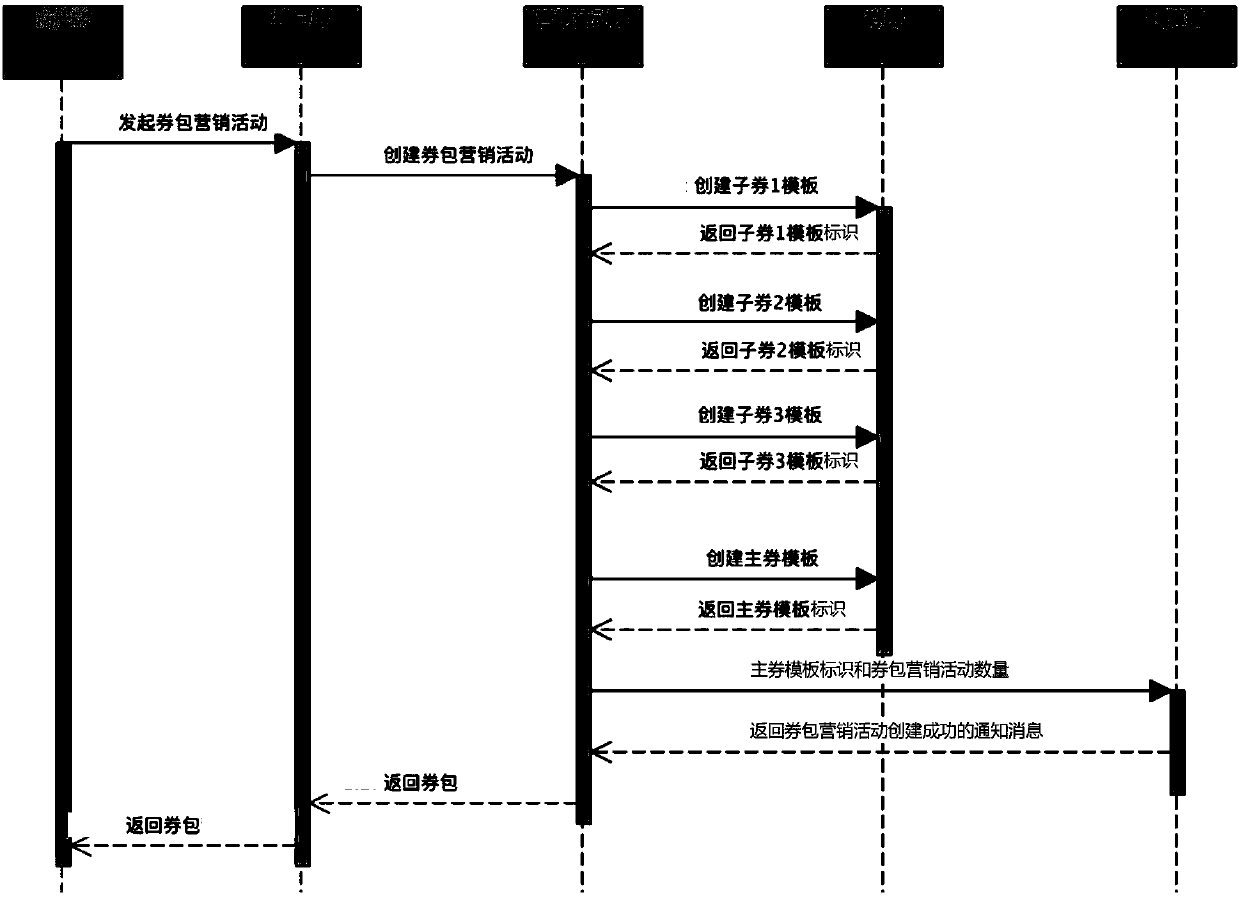

Method and device for creating coupon package, and method and device for obtaining coupon package

The invention discloses a method and device for creating a coupon package, and a method and device for obtaining a coupon package. The method for creating a coupon package comprises: N sub coupon templates including sub coupon template identifiers are created based on electronic coupon attribute information of N electronic coupons; according to the N sub coupon template identifiers, a main coupontemplate including a main coupon template identifier is established; and the main coupon template identifier is associated with a coupon package marketing activity identifier to obtain a coupon package, the N sub coupon templates are associated, the main coupon template is associated with the sub coupon templates for follow-up electronic coupon management. Besides, because the main coupon templateidentifier is associated with the coupon package marketing activity identifier and the coupon package is obtained, the user is able to obtain multiple electronic coupons only by clicking a taking button once when taking electronic coupons, so that a phenomenon of taking electronic coupons one by one is avoided and a problem that too many resources of the server side are occupied because of multi-times taking request sending to the server side and thus the resources of the server side are wasted is solved.

Owner:KOUBEI SHANGHAI INFORMATION TECH CO LTD

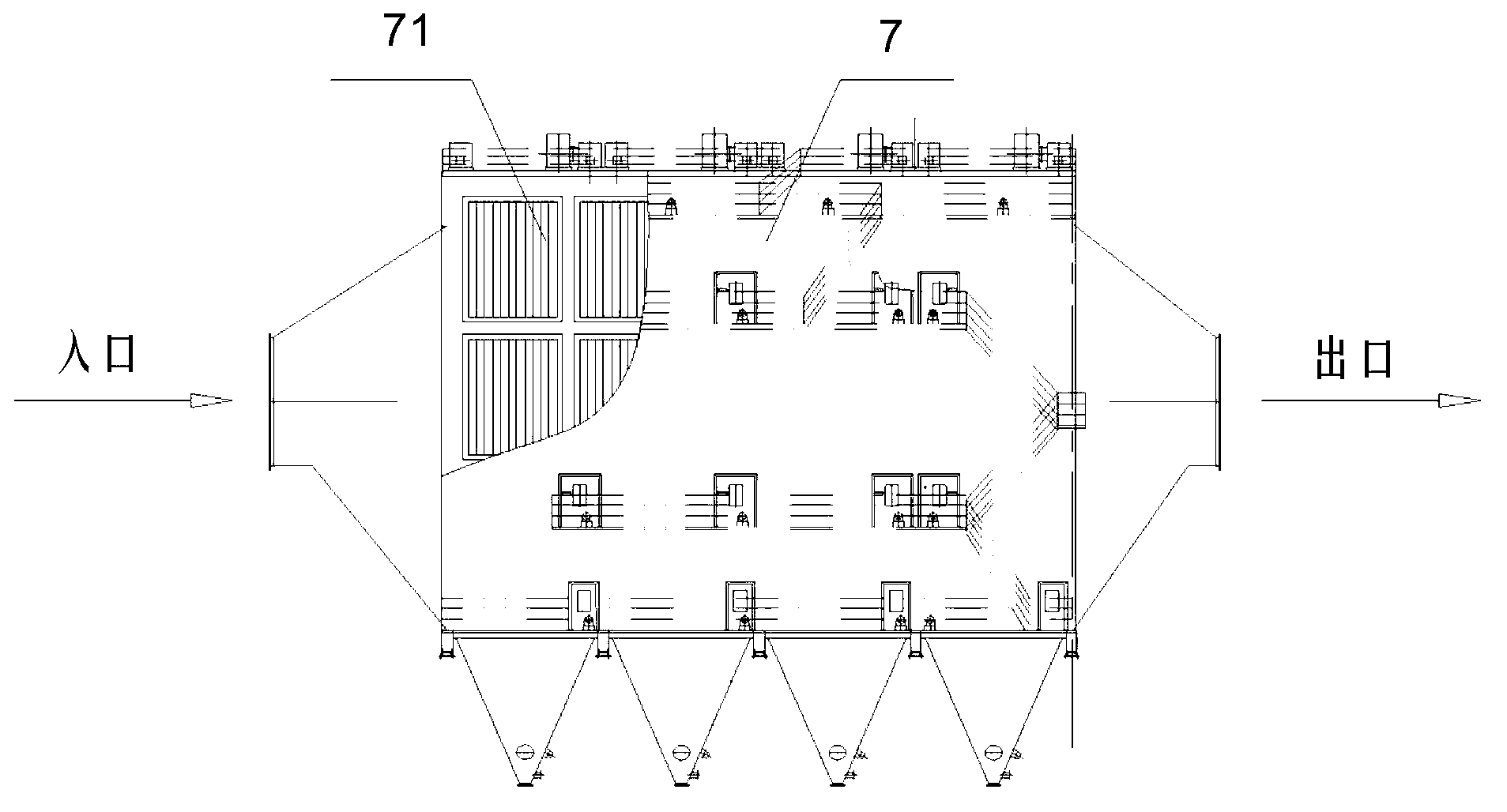

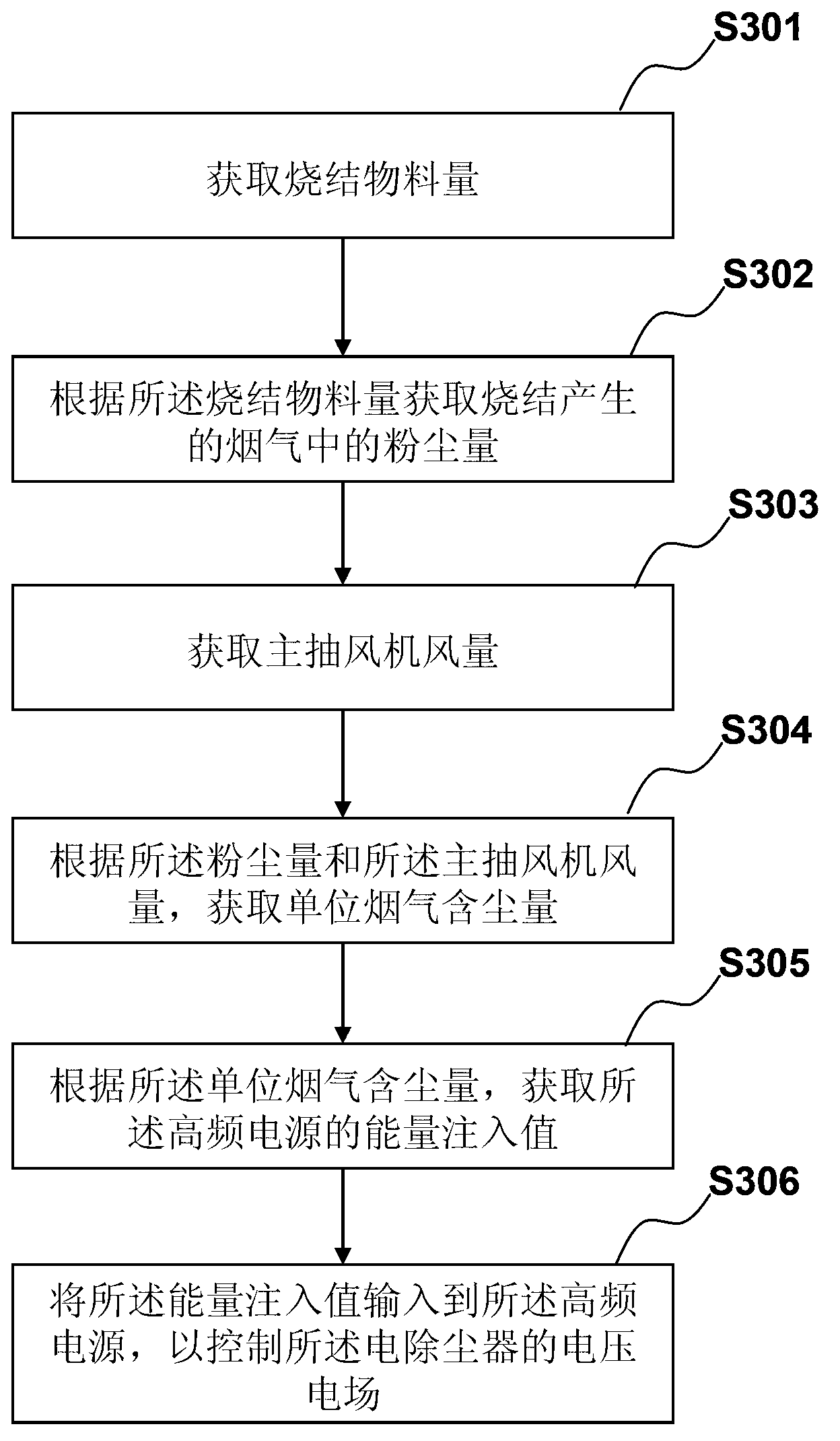

Control method and device of electric precipitator in sintering system

The embodiment of the invention discloses a control method and device of an electric precipitator in a sintering system. The electric precipitator comprises a high-frequency power source. The control method comprises the following steps of: acquiring the quantity of sintered materials; acquiring the dust capacity in exhaust gas generated in sintering according to the quantity of the sintered materials; acquiring the air quantity of a main exhaust fan; acquiring a dust content of unit exhaust gas according to the dust capacity and the air quantity of the main exhaust fan; acquiring the energy adding value of the high-frequency power source according to the dust content of the unit exhaust gas; and inputting the energy adding value into the high-frequency power source to control a voltage electric field of the electric precipitator. According to the control method and device of the electric precipitator in the sintering system, the energy adding value is regulated to control and regulate the voltage electric field of the electric precipitator by acquiring actual working condition data such as the quantity of the sintered materials and the air quantity of the main exhaust fan, and the electric precipitator can efficiently run in an energy-saving manner, thereby solving the problem of electric energy waste because the field handling capacity of the exhaust gas of the electric precipitator does not reach a designed handling capacity in an actual production process, and reducing the energy consumption of dust extraction.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com