Emulsified asphalt concrete material cured by microwave heating and its preparation method

A technology of emulsified asphalt and microwave heating, which is applied in construction, roads, road repairs, etc. It can solve problems such as difficulty in realization, failure to open traffic as soon as possible, difficulties in emulsifiers and emulsification stabilization additives, etc., and achieve easy and convenient construction and compaction The quality is easy to control and the effect of breaking through the limitation of heat preservation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the preparation of emulsified asphalt mixture, based on the total mass of the mixture, aggregate accounts for 84%, mineral powder accounts for 4%, cement accounts for 3%, and emulsified asphalt accounts for 9%; the gradation (mass ratio) is shown in Table 1.

[0035] Table 1 Aggregate grading table

[0036]

[0037] Raw material selection:

[0038] Aggregate: Basalt aggregate produced in Zhejiang, with a density of 2.821g / cm 3 , Adhesion to asphalt is grade 4, crush value is 10.1%, particle size is 0.075mm~9.5mm, continuous gradation;

[0039] Mineral powder: Limestone ore powder produced in Jingyang, Shaanxi, with a density of 2.711g / cm 3 , The hydrophilic coefficient is 0.83;

[0040] Cement: P.O42.5R cement produced by Shaanxi Qinling Cement Co., Ltd., with qualified stability and strength grade meeting the requirements of "General Portland Cement Standard" (GB175-2007).

[0041] Emulsified asphalt with microwave heating demulsification: the stability is less than 2% for 5 d...

Embodiment 2~12

[0048] The raw materials and their mass mixing ratios of the concrete in Examples 2-12 are shown in Table 3. The concrete was produced according to the preparation method described in Example 1, and the demulsification time and final molding temperature are shown in Table 4.

[0049] Table 3 The mass ratio of concrete raw materials (%)

[0050]

[0051] Table 4 Demulsification temperature and final pressure temperature of concrete

[0052]

[0053] Test example:

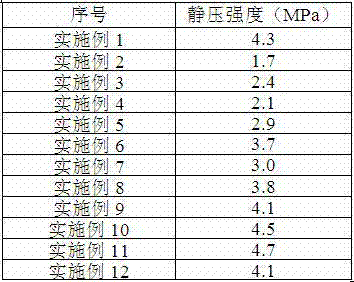

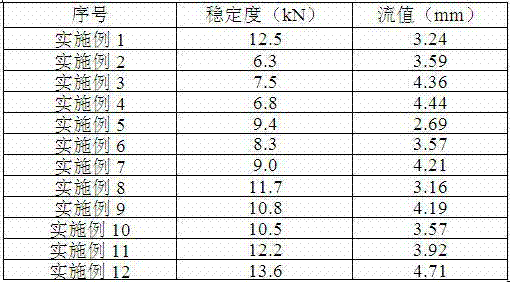

[0054] The emulsified asphalt mixture specimens formed in Examples 1-12 were placed at room temperature for 3 days, and the road performance test was carried out with reference to "Test Regulations for Highway Engineering Asphalt and Asphalt Mixtures" (JTJ052-2000).

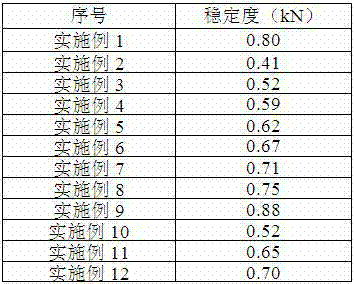

[0055] Determination of Marshall stability

[0056] Using a Marshall compactor, the hammer weight is 4536g, and the free fall height is 457.2mm. According to the degree of compaction, the initial compaction is 25 times on both sides of the specimen to reach 50% ...

Embodiment 13

[0076] According to the concrete raw material ratio in Example 1, Example 13 was prepared according to the conventional emulsified asphalt concrete production method. The curing age was the same as that of Example 1. The road performance is shown in Table 9.

[0077] Table 9 Results of concrete road performance test

[0078]

[0079] Table 9 shows that, compared with emulsified asphalt concrete prepared by conventional production methods, the road performance of emulsified asphalt concrete heated by microwave is greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com