Patents

Literature

128results about How to "Realize green construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

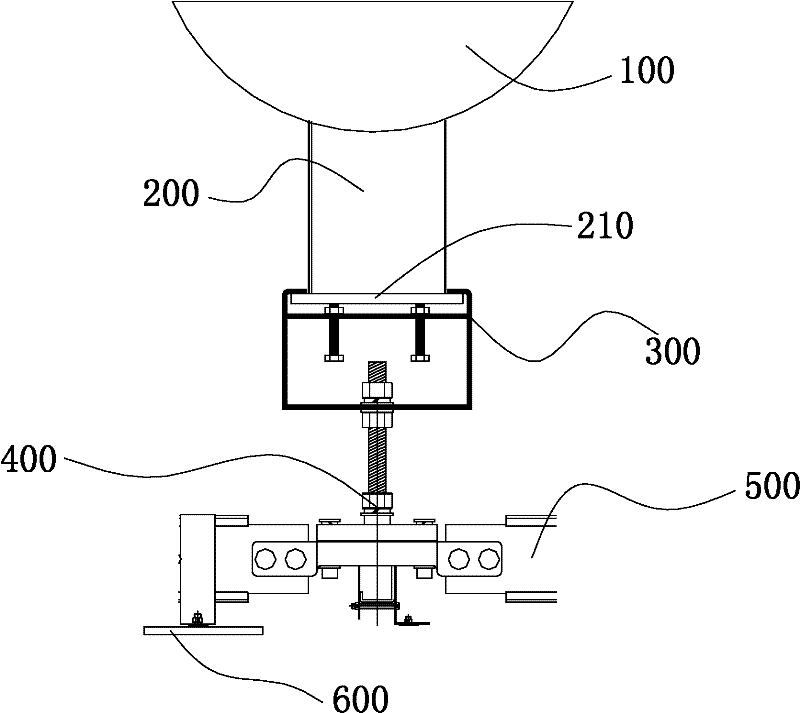

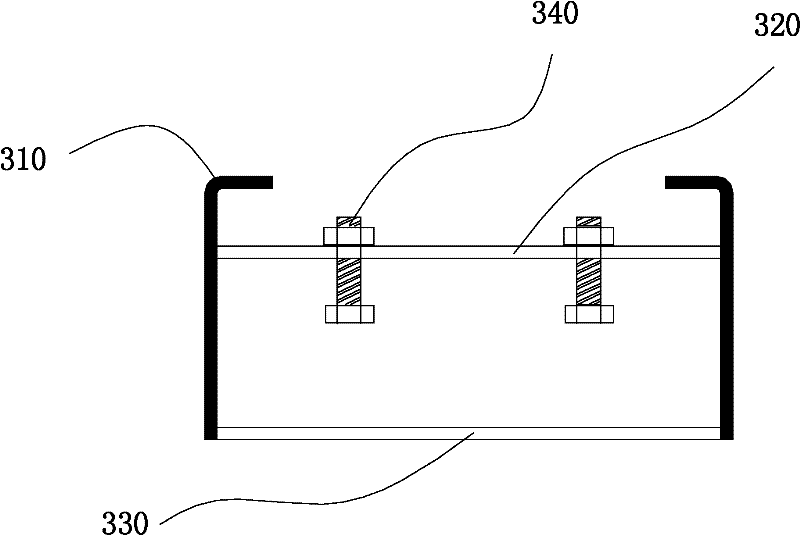

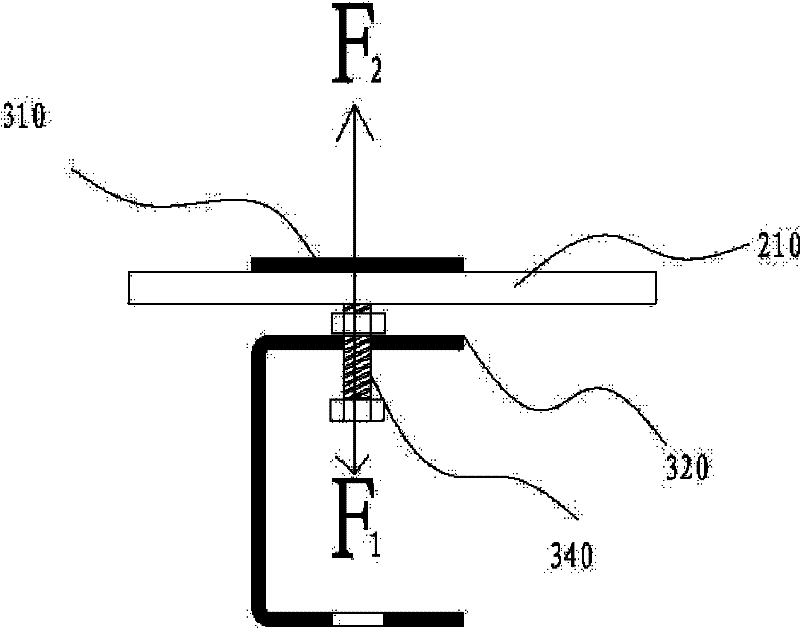

Ceiling system applicable to large-span space steel structure and construction method thereof

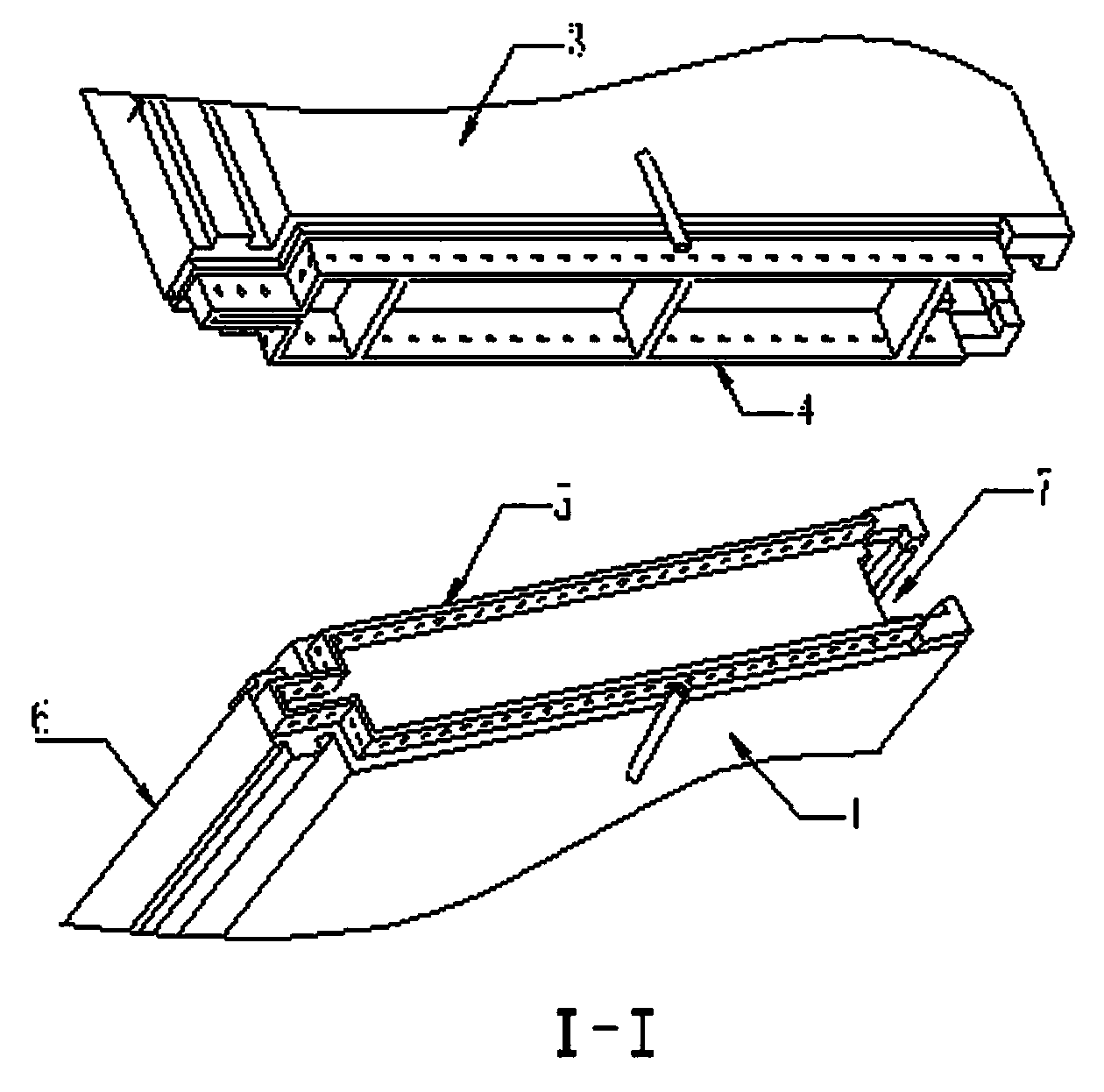

The invention discloses a ceiling system applicable to a large-span space steel structure and a construction method thereof. The ceiling system comprises a ceiling mounting plate, an adjustable mounting base, a three-dimensional adjustable hoisting tray, a ceiling joist and a panel, wherein the adjustable mounting base is connected with the ceiling mounting plate through a fastener and a fixing part rather than welding, therefore, the traditional grid lower chord ball welding ceiling method is changed, potential safety hazards caused by overhead welding can be avoided, green construction is realized, the construction error effect of a three-dimensional adjustable digestive grid lower chord ball can be achieved; meanwhile, the three-dimensional adjustable hoisting tray can rotate in all directions, the structure of a main joist is adjustable horizontally, can be adapted to the curve change of a space steel structure roof, can absorb deformation and structure mounting errors of a grid structure generated under the action of static and dynamic loads. The ceiling system disclosed by the invention has the advantages of reliable structure, simpleness in mounting, light weight, no need of wielding, good durability, high economical efficiency and the like and also has great innovation, a high promotion value and strong market competitiveness.

Owner:广东省建筑装饰工程有限公司

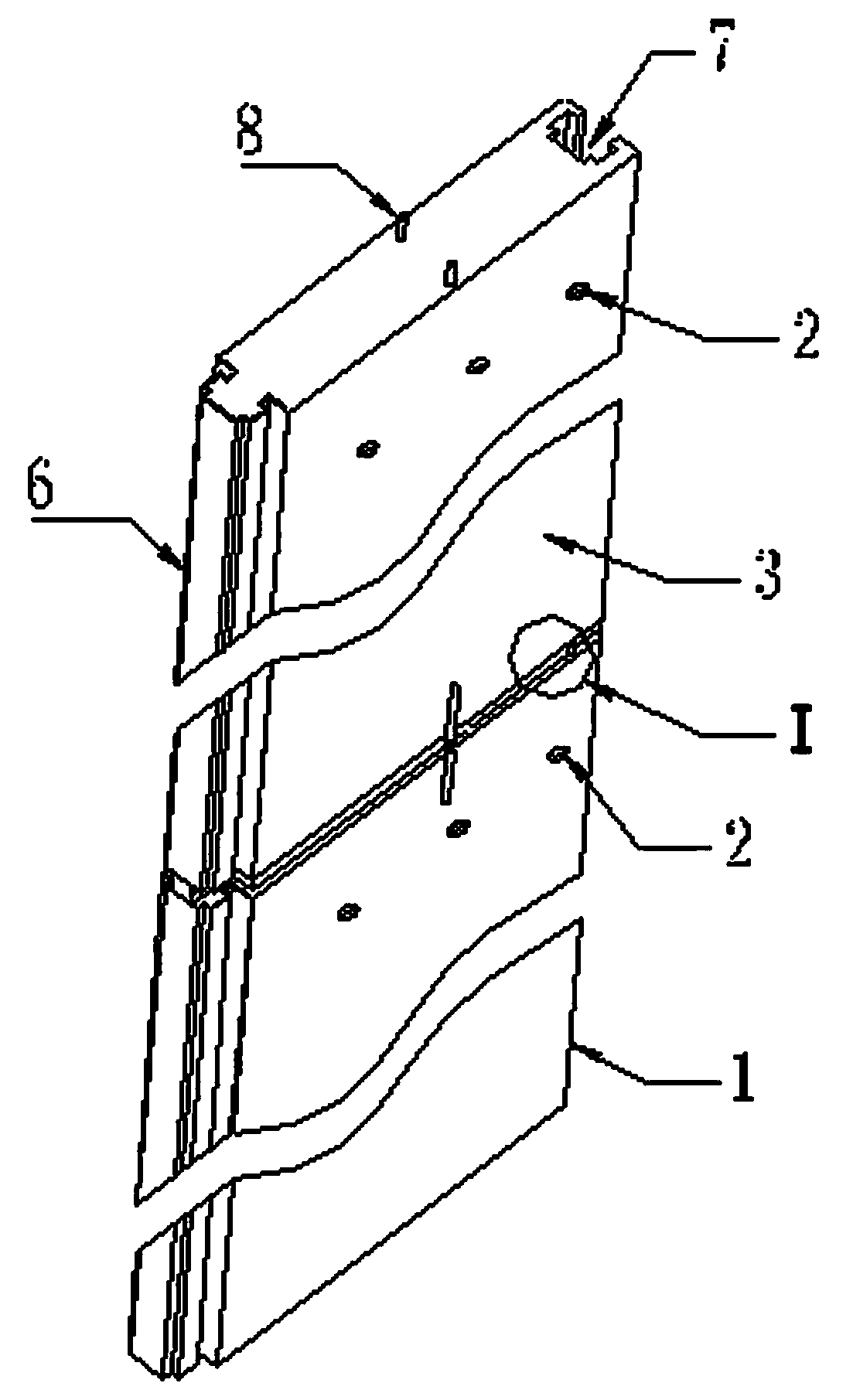

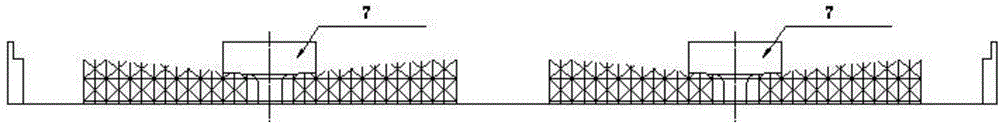

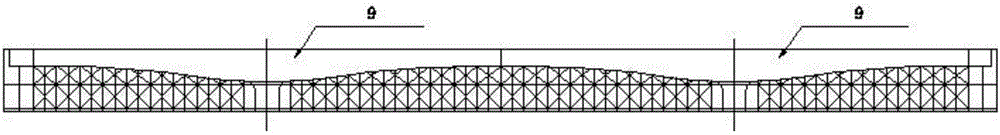

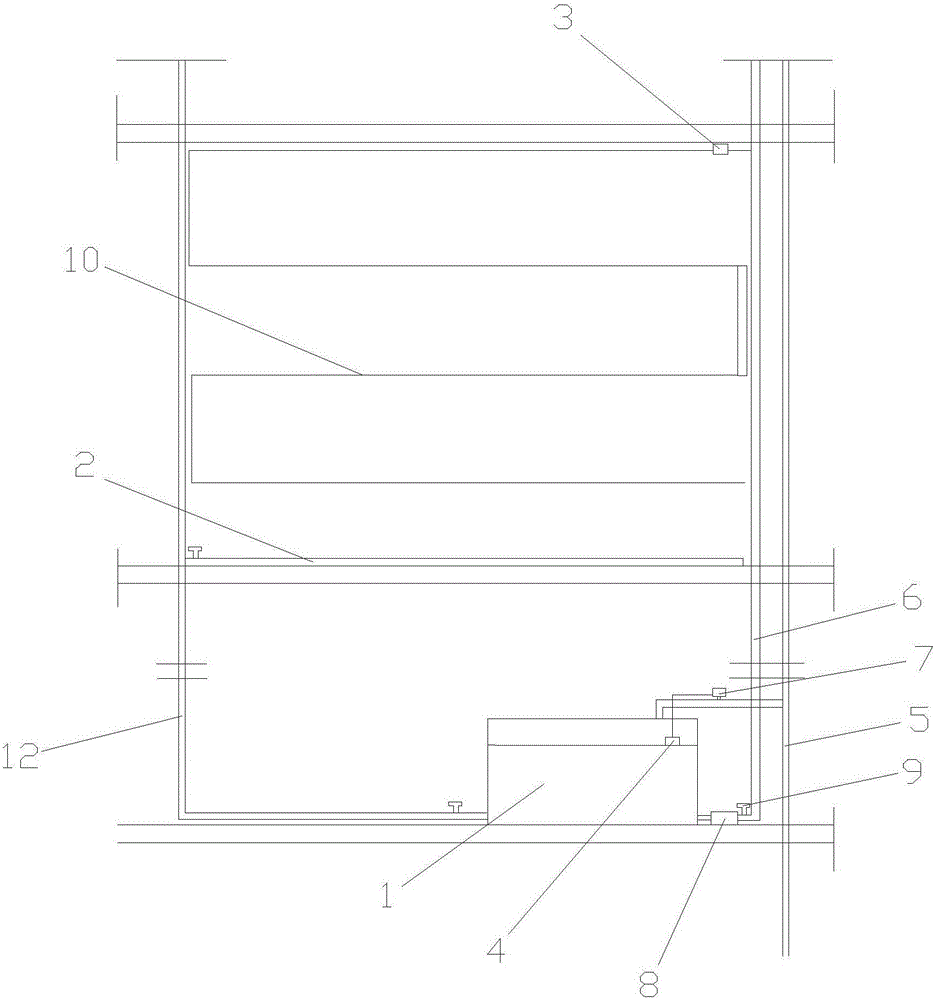

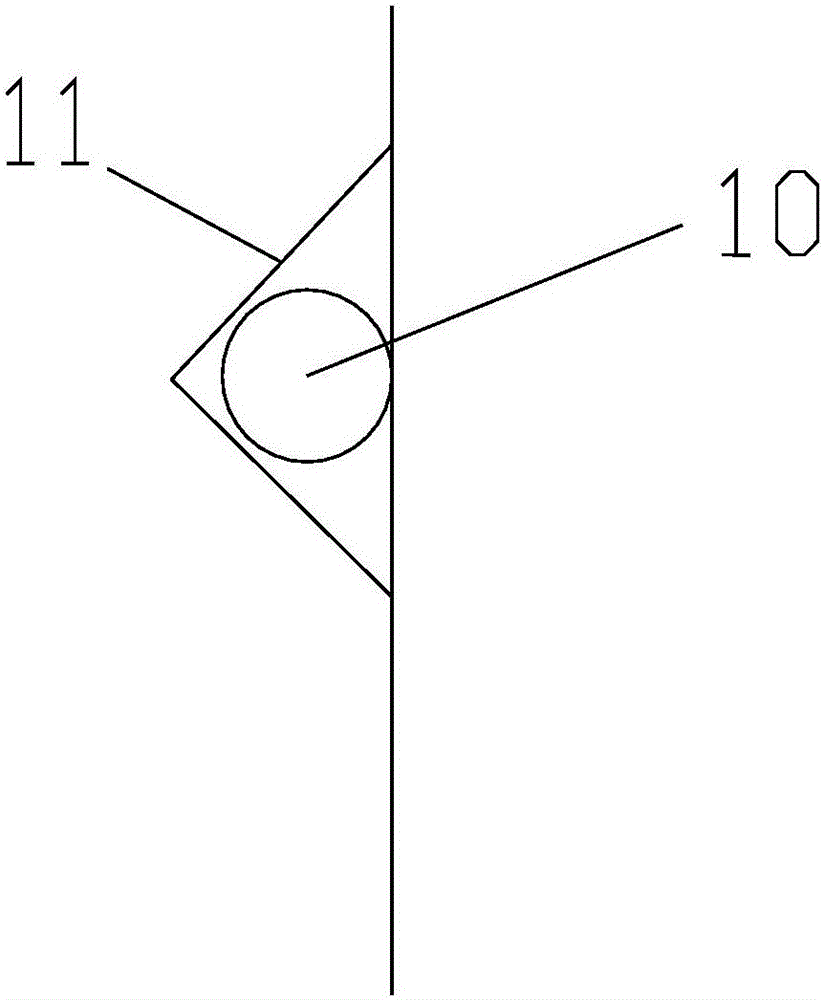

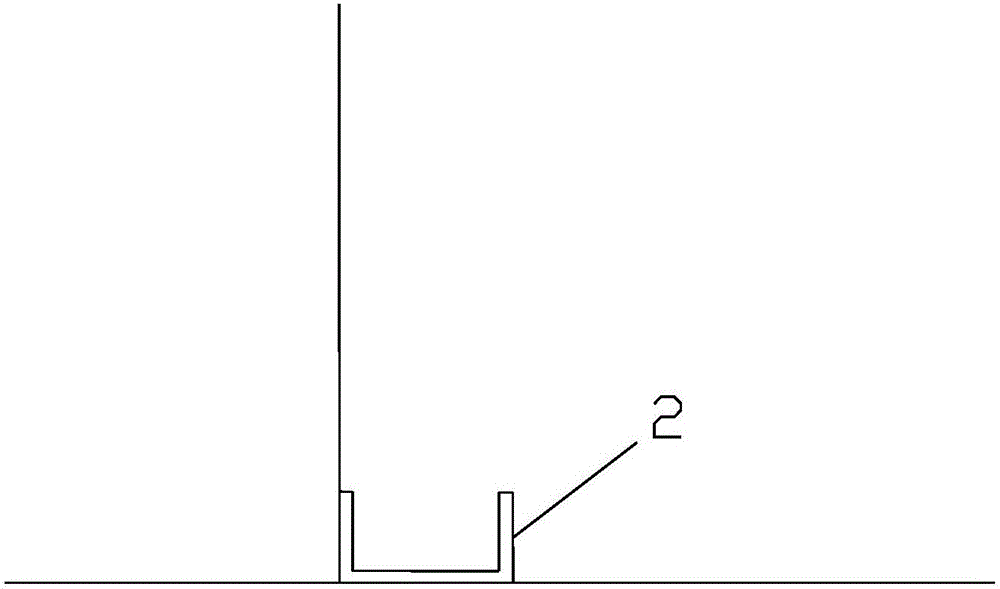

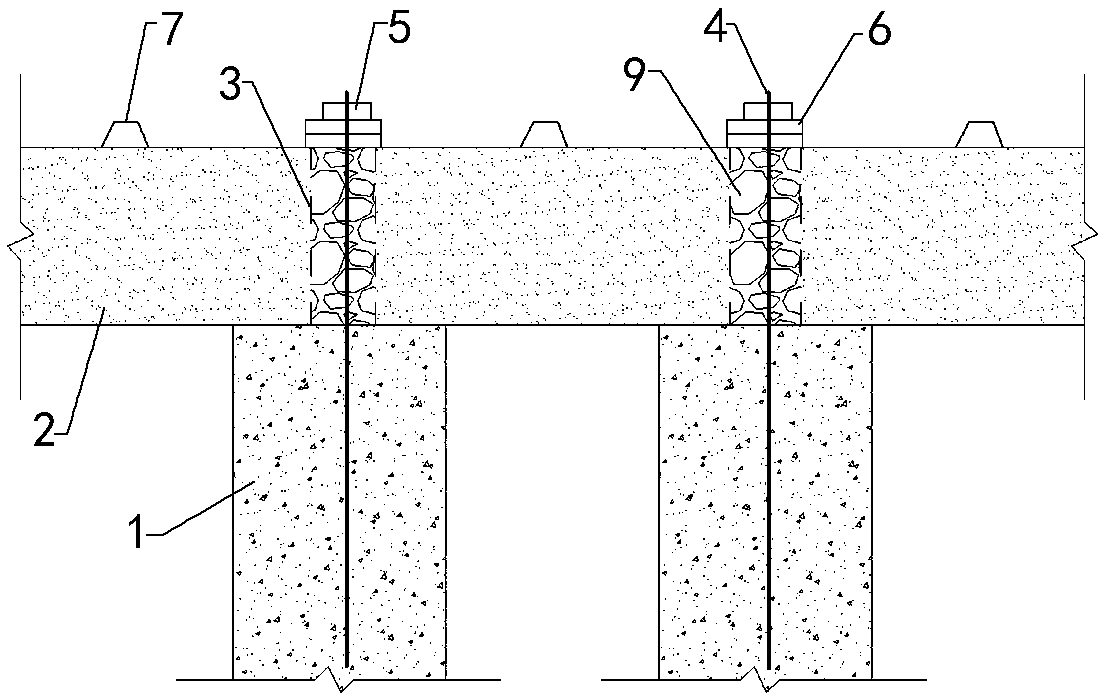

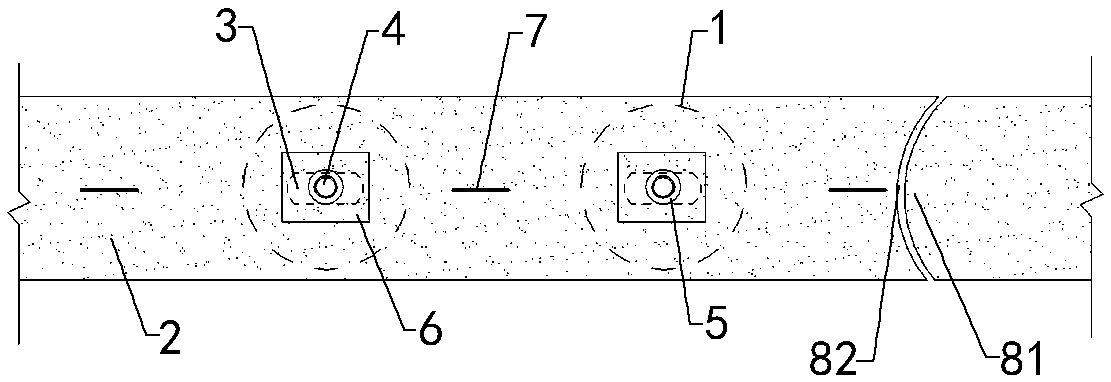

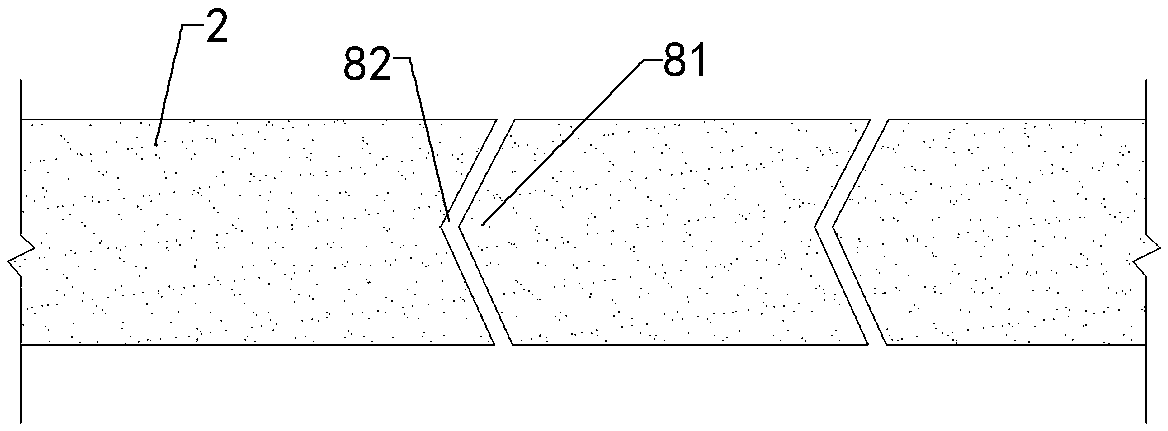

Underground construction constructed in assembled mode and construction method of underground construction

InactiveCN103397660ARealize the industrialized construction of underground buildingsRealize standardized productionArtificial islandsUnderwater structuresSlurry wallFloor slab

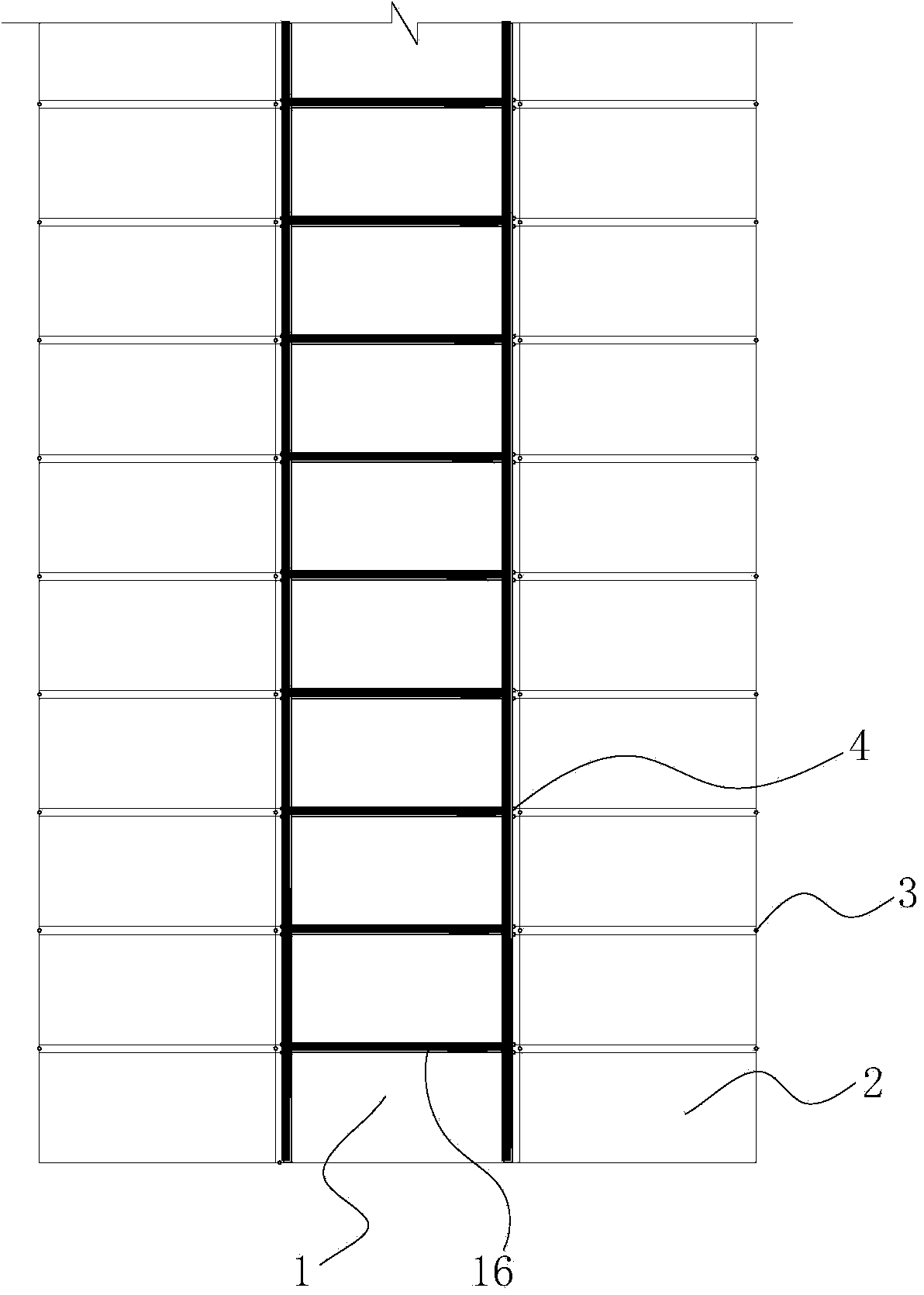

The invention discloses an underground construction constructed in an assembled mode and a construction method of the underground construction. The underground construction mainly comprises prefabricated underground diaphragm walls, steel latticework stand columns, prefabricated piles, prefabricated main beams, section steel secondary beams and first layer prefabricated prestress floor slabs, wherein the prefabricated underground diaphragm walls, the steel latticework stand columns, the prefabricated piles, the prefabricated main beams, the section steel secondary beams and the first layer prefabricated prestress floor slabs are assembled and constructed in a prefabricated mode and prefabricated in a factory. The upper prefabricated underground diaphragm wall and the lower prefabricated underground diaphragm wall are connected through bolts. The left prefabricated underground diaphragm wall and the right prefabricated underground diaphragm wall are connected in a plug pin mode. Upper sections and lower sections of the prefabricated piles are connected through pile end embedded steel plates in a welded mode. The steel latticework stand columns are connected with the upper sections of the prefabricated piles through bolts. The prefabricated main beams are connected through main beam connection node bolts. The section steel secondary beams are connected with the prefabricated underground diaphragm walls and the prefabricated main beams through bolts. According to the underground construction constructed in the assembled mode and the construction method of the underground construction, temporary construction materials and labor cost are reduced, construction efficiency is improved through on-site mechanized construction, and the composite engineering cost is lower compared with a traditional construction method; top plates of an underground structure of the underground construction are formed quite fast, therefore, the original ground state can be recovered quickly, noise and dust pollution on a construction site are reduced greatly, and environment-friendly construction is realized truly.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

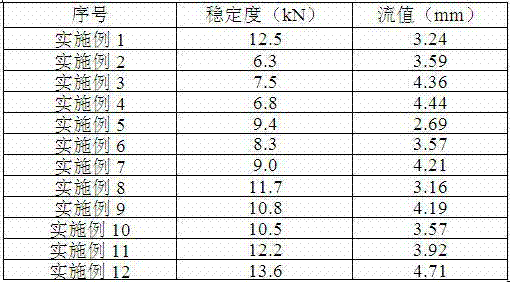

Emulsified asphalt concrete material cured by microwave heating and its preparation method

InactiveCN102295445AOvercome wasteOvercoming the problem of low early strengthRoads maintainencePavement maintenancePortland cement

The invention discloses a microwave heated and cured emulsified asphalt concrete material and a preparation method thereof. The emulsified asphalt concrete comprises the following components by mass: 79%-88% of basalt or limestone aggregate, 3%-6% of limestone mineral powder, 1%-4% of ordinary portland cement, 8%-11% of microwave heated and demulsified emulsified asphalt. The preparation method consists of the steps of: mixing the aggregate, mineral powder and cement at normal temperature for 1min, adding the microwave heated and demulsified special emulsified asphalt, and mixing the mixture for 2min, spreading out and pre-pressing the mixture to compactness of 50%, conducting microwave heating to a temperature above 50DEG C and implementing demulsification for draining, continuing heating the mixture to a temperature above 100DEG C, and carrying out final pressing, thus obtaining the concrete material. The method of the invention employs demulsification for draining after microwave heating as well as final pressing for curing, so that the demulsification time of the emulsified asphalt is controllable, and the pavement performance of the emulsified asphalt concrete is greatly improved. Being green and environmentally friendly as well as construction convenient, the method provided in the invention is suitable for application of the emulsified asphalt concrete to high-grade pavement layers, rapid pavement maintenance, asphalt concrete factory prefabrication, and other fields.

Owner:CHANGAN UNIV

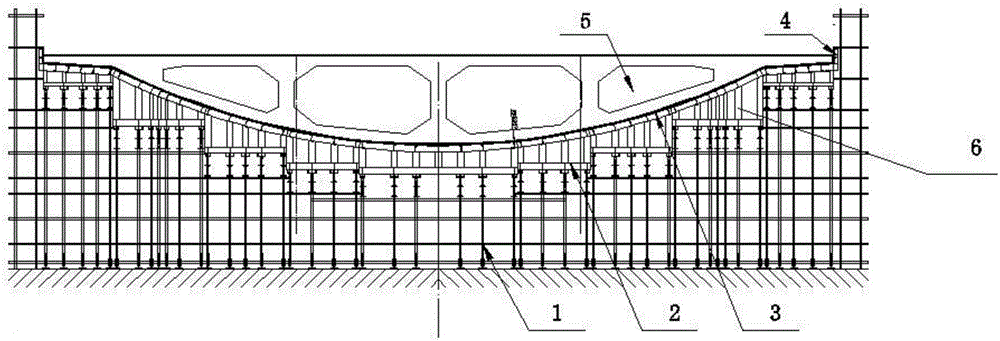

Prestressed concrete variable cross-section fish-bellied type continuous box girder construction method

ActiveCN105714684APrevent movementReduce usageBridge erection/assemblyBridge materialsPre stressEngineering

The invention discloses a prestressed concrete variable cross-section fish-bellied type continuous box girder construction method. According to the method, a formwork assembly part, steel bar binding and preserved hole setting part and box girder bottom plate and web plate concrete casting part in the existing prestressed concrete variable cross-section fish-bellied type continuous box girder construction method are improved. The construction difficulty is reduced, so that the construction of a prestressed concrete variable cross-section fish-bellied type continuous box girder becomes simple; the operation is simple.

Owner:CHINA FIRST METALLURGICAL GROUP

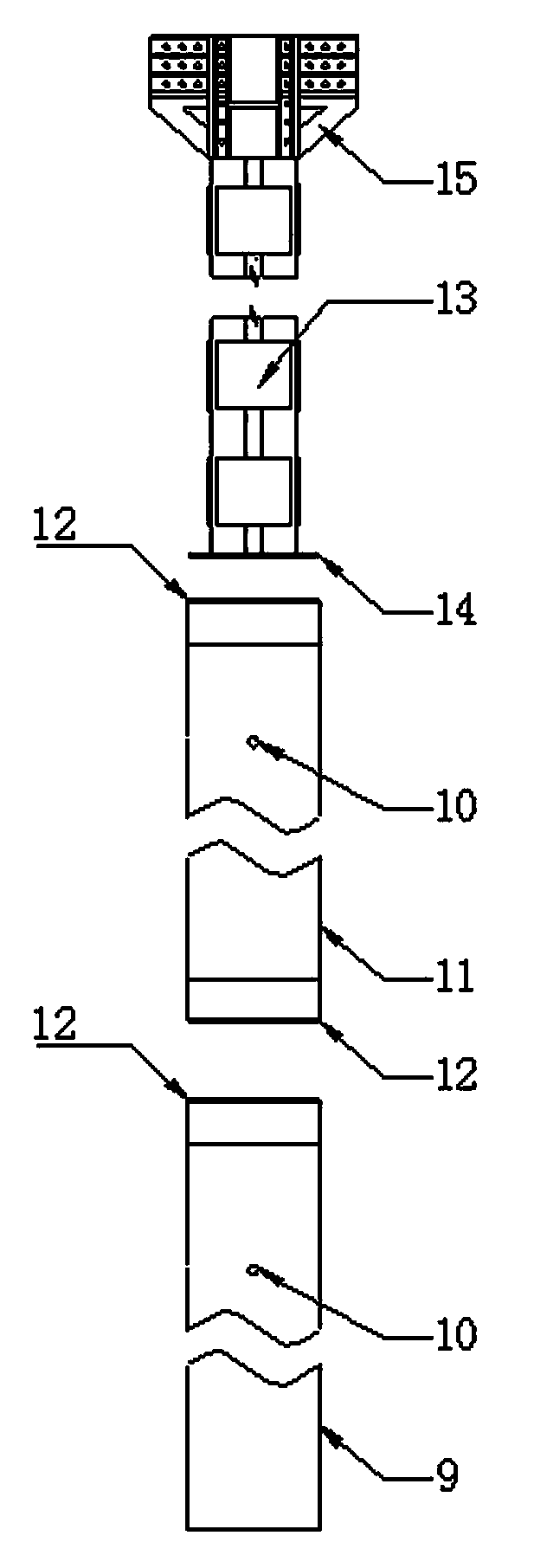

Automatic spraying maintenance system for concrete vertical member employing circulating water supply

The invention discloses an automatic spraying maintenance system for a concrete vertical member employing circulating water supply. The automatic spraying maintenance system comprises a water tank, a water collecting tank and a timing control valve, wherein a water level sensor is arranged in the water tank; the water tank is connected with a power supply main pipe and a main water supply stand pipe; a water level control valve is arranged on the main water supply stand pipe and is connected with the water level sensor; a water pump and a check valve are arranged on the main water supply stand pipe; the water pump is connected with the timing control valve; the main water supply stand pipe is connected with more than one spray pipe; the timing control valve is arranged on the spray pipe; and the spray pipe is in an S shape. According to the automatic spraying maintenance system for the concrete vertical member employing circulating water supply, the strength and the compactness of concrete can be ensured; the apparent quality of the concrete is improved; and a crack is prevented.

Owner:ZHONGQI JIAOJIAN GRP

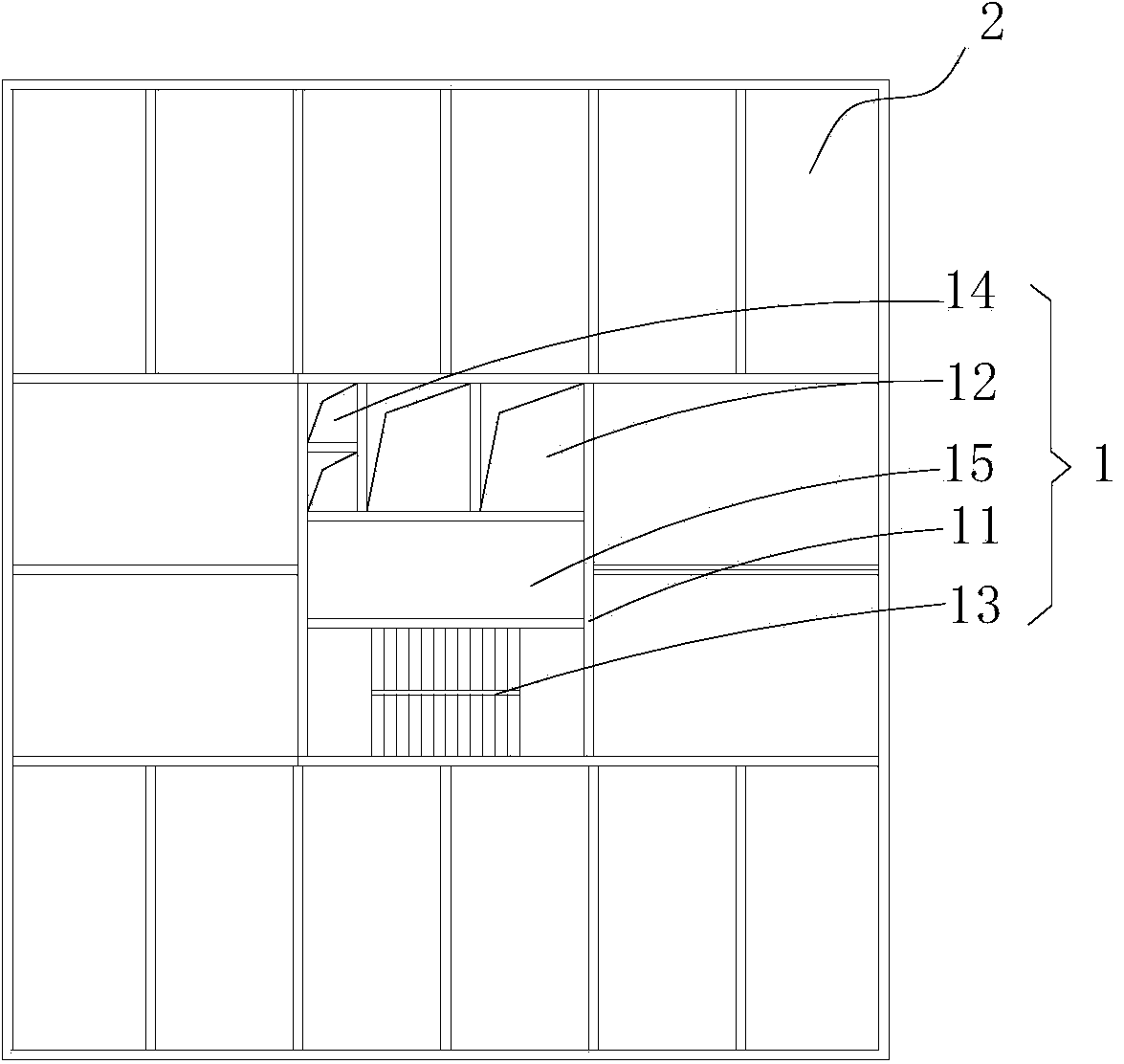

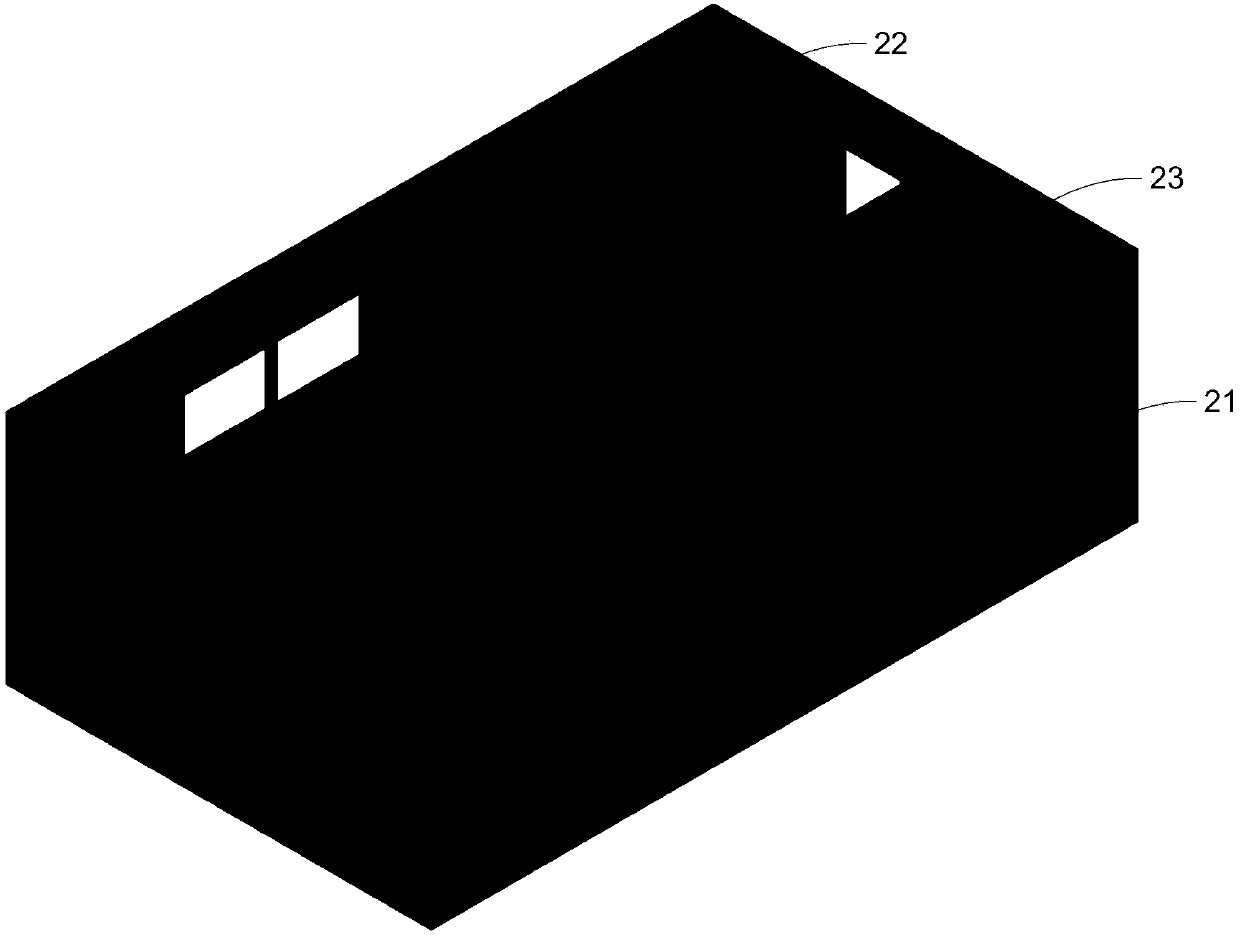

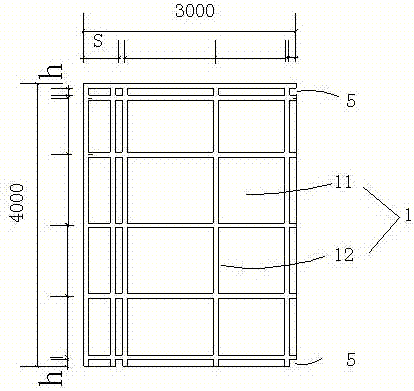

Building module and middle/high-layered modularized building with building module

InactiveCN104088366AMeet the requirements of energy saving and environmental protectionIncrease build heightBuilding constructionsComputer moduleModularity

The invention provides a building module and a middle / high-layered modularized building with the building module. The building module comprises a frame, a top plate, a bottom plate, wall bodies and connecting parts, wherein the top plate, the bottom plate and the wall bodies are respectively arranged on the top surface, the bottom surface and the side surfaces of the frame; the wall bodies comprise outer walls, inner walls and insulating layers arranged between the outer walls and the inner walls; the wall bodies are provided with doors and windows; the connecting parts are used for connecting adjacent building modules and connecting the building modules with core cylinders when the building modules surround core cylinder stacking of the middle / high-layered modularized building. By adopting the building module, the industrialization degree of a building is improved, the construction period of the building is shortened, environmental-friendly construction is achieved, the construction garbage and the constriction dust can be effectively controlled in the construction process, and thus the energy is saved and the environment is protected; large-scale intensive production is achieved, and the construction quality is improved.

Owner:CIMC MODULAR BUILDING DESIGN RES DEVCO

High bridge pier self-lifting outer frame over-form construction technology

ActiveCN105839543ARealize cycle upliftAvoid it happening againBridge structural detailsBridge erection/assemblySupporting systemUpper floor

The invention discloses a high bridge pier self-lifting outer frame over-form construction technology which is simple in construction, high in construction safety and high in construction efficiency. The over-form construction technology comprises the following steps that firstly, formworks are installed, and upper layer concrete and lower layer concrete are poured; secondly, outer support systems and telescopic devices are installed; thirdly, the lower layer formworks are detached, lifted and installed; fourthly, the outer support systems are lifted; fifthly, the telescopic devices freely side downwards to an upper layer formwork system to be connected with formworks of the upper layer formwork system. The over-form construction technology is easy to operate, quality is controlled more easily, the speed is higher, cost is lower, and safety is higher.

Owner:CHINA 19TH METALLURGICAL CORP

Integrated construction method for board wall formwork and support formwork in restricted area

InactiveCN105926815AShorten construction timeShorten the timeWallsForms/shuttering/falseworksBasementEngineering

The invention relates to the technical field of building construction, in particular to an integrated construction method for a board wall formwork and a support formwork in a restricted area. A support pile is used as a shear wall outer mold, basement foundation outer wall steel bars are bound after waterproof treatment of the vertical faces of a fender post group, and then pull screws are connected between an inner side formwork and waterproof bolts; and then a basement foundation outer wall is subjected to concrete pouring. Operation is simple and rapid, the construction time of a formwork reinforcing system and construction engineering time are shortened, diversification of reinforcing of building formworks is promoted, efficiency is improved, the construction period is shortened, and the quality and performance of buildings are ensured.

Owner:东晟兴诚集团有限公司

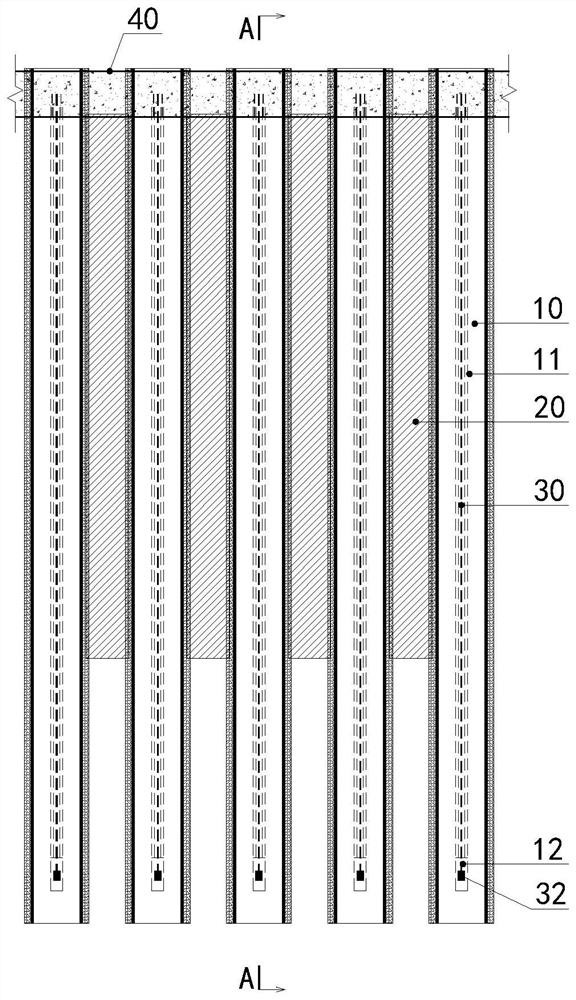

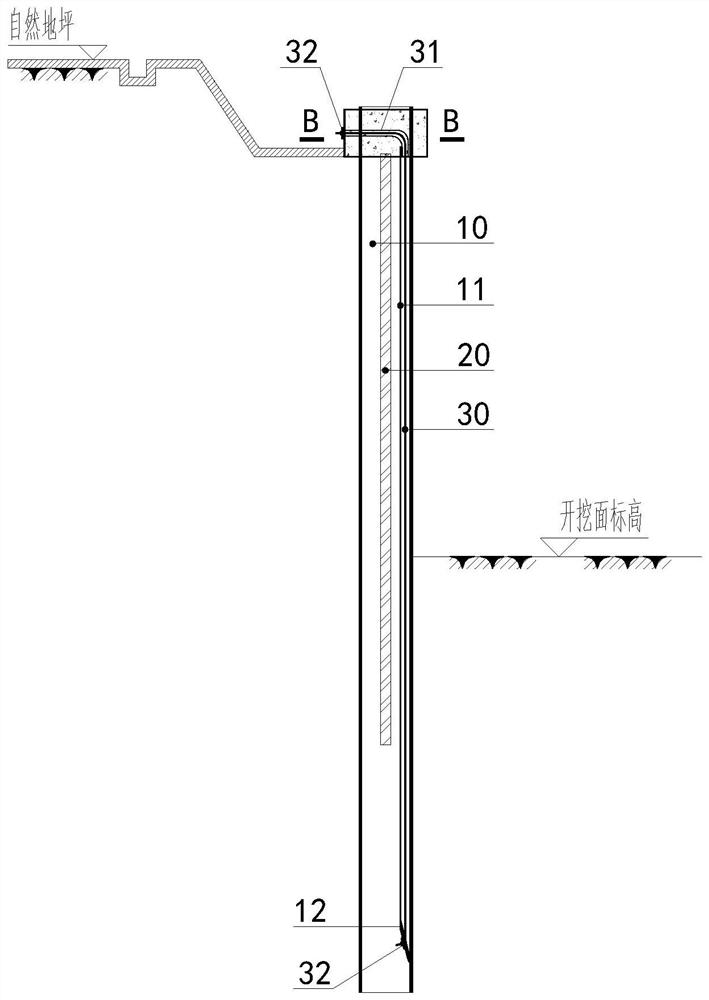

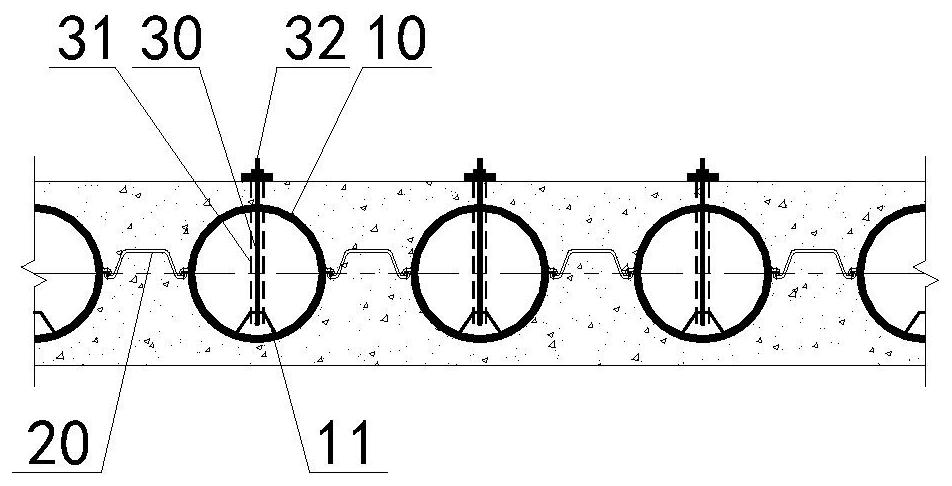

Prestressed PC construction method combined steel pipe pile foundation pit supporting structure and construction method thereof

The invention discloses a prestressed PC construction method combined steel pipe pile foundation pit supporting structure and a construction method thereof, relates to the technical field of geotechnical engineering foundation pit supporting, and aims at the problems that an existing PC construction method combined steel pipe pile supporting structure needs to be combined with a supporting system to be used, the construction cost is increased, and the construction period is prolonged. The structure comprises at least one row of steel pipe piles which are arranged in parallel at intervals; fixed end anchorage devices are arranged at the bottoms of the inner walls of the row of steel pipe piles close to the excavation surface of a foundation pit; every two adjacent steel pipe piles are connected through at least one Larsen steel sheet pile in a buckled mode; capping beams are arranged at the tops of each row of steel pipe piles; and one end of a prestressed steel strand is anchored to the fixed end anchorage device, and the other end is anchored to the coping beam. According to the construction method, the adjacent steel pipe piles are connected through the Larsen steel sheet piles in a buckled mode, the capping beams are constructed at the tops of the steel pipe piles, sleeves are pre-buried, the prestressed steel strands are tensioned, the top ends of the steel pipe piles are anchored to the soil facing side of the capping beam, after construction of the underground structure is completed, the steel pipe piles and the Larsen steel sheet piles are pulled out, and gaps are filled through grouting.

Owner:SHANGHAI CONSTRUCTION GROUP +1

Self-elevating outer frame turning device for bridge high pier

ActiveCN105839542BRealize cycle upliftAvoid it happening againBridge structural detailsBridge erection/assemblySupporting systemSupport system

Owner:CHINA 19TH METALLURGICAL CORP

Microwave heating super early strength cement concrete pavement repair material and preparation method thereof

InactiveCN102408216AShorten the setting timeDoes not seriously affect late strengthCeramic shaping apparatusSuperplasticizerSodium sulfate

The invention discloses a microwave heating super early strength cement concrete pavement repair material and a preparation method thereof. The repair material contains the following constituents: cement, siliceous dust, fly ash, microfine heavy calcium carbonate, high-efficiency water reducing agent, calcium oxide, calcium chloride and sodium sulfate in the weight ratio of 1 : 0.1 : 0.1 : 0.1 : 0.005 : 0.012 : 0.03 : 0.01, and water consumption is 40% of mass sum of the constituents. The preparation method comprises the following steps of: according to the proportion, adding the raw materials and the water to a cement paste mixer and mixing for 60s, and forming by using a plastic mould; covering a plastic film on the surface of the formed test piece; counting from the moment of adding water for mixing, and testing initial setting time and final setting time in microwave heating process; heating the formed test piece by microwave to 50 degrees centigrade, and stopping heating; and when the surface temperature of the test piece is reduced to 40 degrees centigrade, reheating to 50 degrees centigrade by microwave, repeating like this, and stopping and testing related performance of the test piece after two hours, wherein the test result shows that the repair material has short setting time, high early strength, strong bonding capacity and dry narrow and can meet the requirements on traffic restoring after two hours.

Owner:CHANGAN UNIV

High bridge pier self-lifting outer frame over-form device

ActiveCN105839542ARealize cycle upliftAvoid it happening againBridge structural detailsBridge erection/assemblySupporting systemEngineering

The invention discloses a high bridge pier self-lifting outer frame over-form device which is simple in structure, can enhance over-form safety and improves over-form efficiency. The over-form device comprises outer support systems, telescopic devices, an upper formwork system and a lower formwork system. The upper formwork system is located above the lower formwork system. The upper formwork system and the lower formwork system both comprise a layer of formworks forming a high bridge pier pouring cavity. The outer surface of the formworks of the upper formwork system and the outer surface of the formworks of the lower formwork system are both provided with reinforcing transverse back ridges. The reinforcing transverse back ridges on every two adjacent formworks are connected through reinforcing transverse back ridge connecting pieces, so that the reinforcing transverse back ridges tightly hold the outer surface of the upper layer formwork system. The upper end and the lower end of each formwork in the upper layer formwork system are both provided with one outer support system. Each outer support system comprises a crank arm beam, a straight beam and a vertical guide column. The over-form device is easy to operate, quality is controlled more easily, the speed is higher, cost is lower, and safety is higher.

Owner:CHINA 19TH METALLURGICAL CORP

Method for conducting construction sample plate guiding with BIM technology

InactiveCN106088598AReduce usageReduce generationBuilding material handlingArchitectural engineeringConstruction waste

The invention discloses a method for conducting construction sample plate guiding with a BIM technology. The BIM technology is applied, the three-dimensional and intuitive characteristics of the BIM technology are utilized, and a construction sample plate is digitized and virtualized, so that construction sample plates in a traditional mode are replaced. If the sample plate needs to be adjusted, only a model of the sample plate needs to be modified, and no extra charges are produced in the whole process, so that not only is the cost reduced, but also the material using amount and the construction waste producing amount are decreased, green construction is achieved, and materials are saved; and the construction materials are quantized according to the size of a BIM model, so that the construction waste producing amount is decreased, and meanwhile the construction cost is reduced.

Owner:CHINA MCC17 GRP

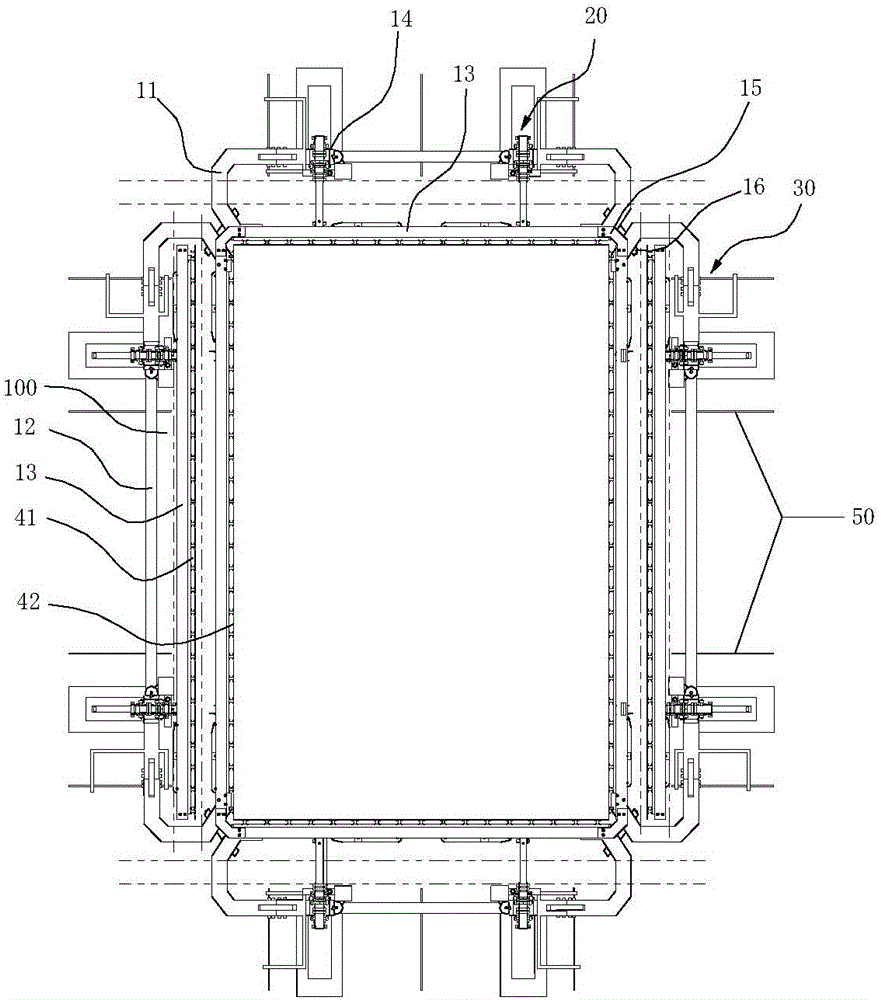

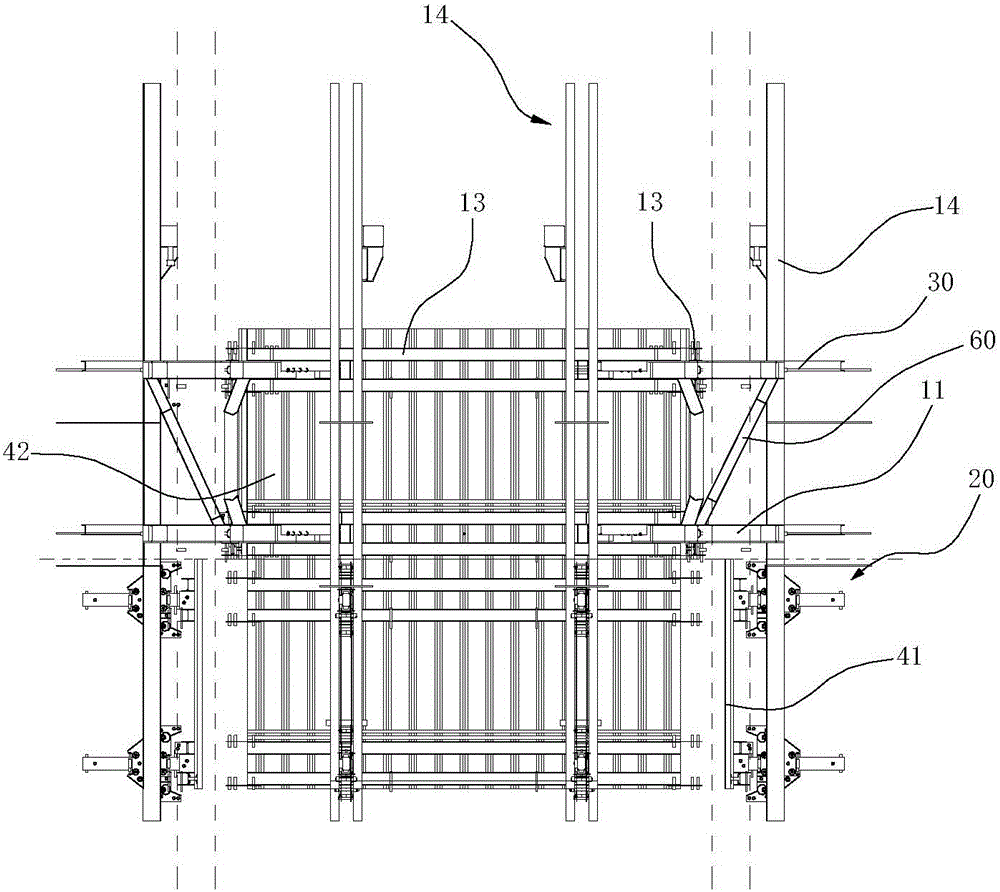

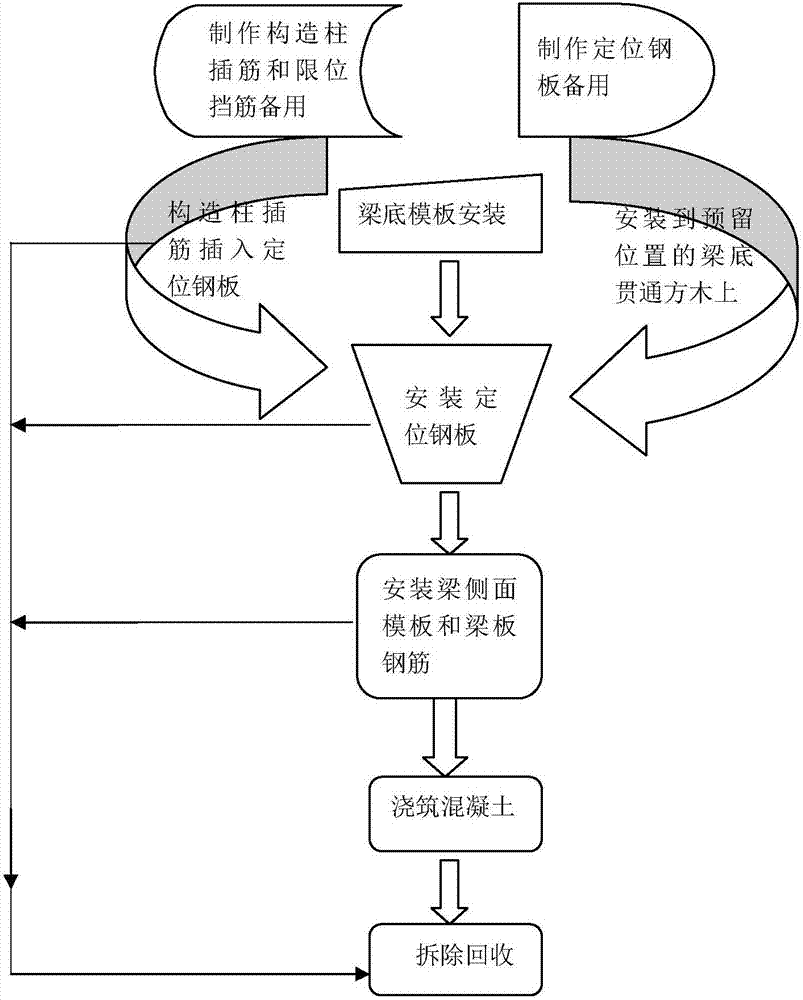

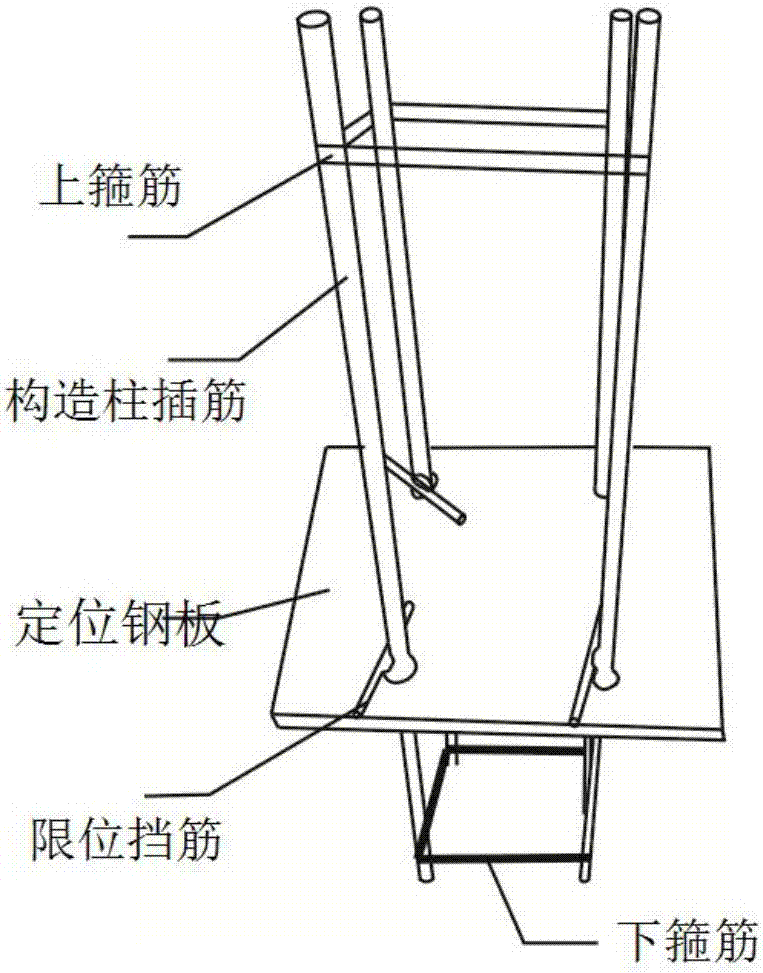

Construction method for wall-body constructional column joint bar

ActiveCN107083804AAvoid post-plantationSave the construction cost of planting barsForms/shuttering/falseworksSheet steelSteel bar

The invention provides a construction method for a wall-body constructional column joint bar. The construction method is used in the engineering construction process of a major structure of wall-body construction of constructional engineering, a positioning steel plate serves as a concrete pouring bottom mould, and pre-buried constructional column joint bar holes are evenly formed in the four directions of the positioning steel plate; and pre-buried constructional column joint bars penetrate through the holes, lower stirrups and upper stirrups are arranged at the bottoms and on the upper portions of the pre-buried constructional column joint bars correspondingly to conduct limiting and fixing, constructional column joint bar limiting block ribs are pre-buried on the positions of the holes to ensure the integral structure to be stable, and the positioning steel plate serves as the concrete pouring bottom mould, and concrete pouring is conducted from the upper stirrups down. By adopting the construction method, rear planted steel bars are avoided, the construction cost of steel bar planting is saved, the construction quality can be more ensured, and green construction is achieved.

Owner:THE FOURTH OF CHINA CONSTR SEVENTH ENG

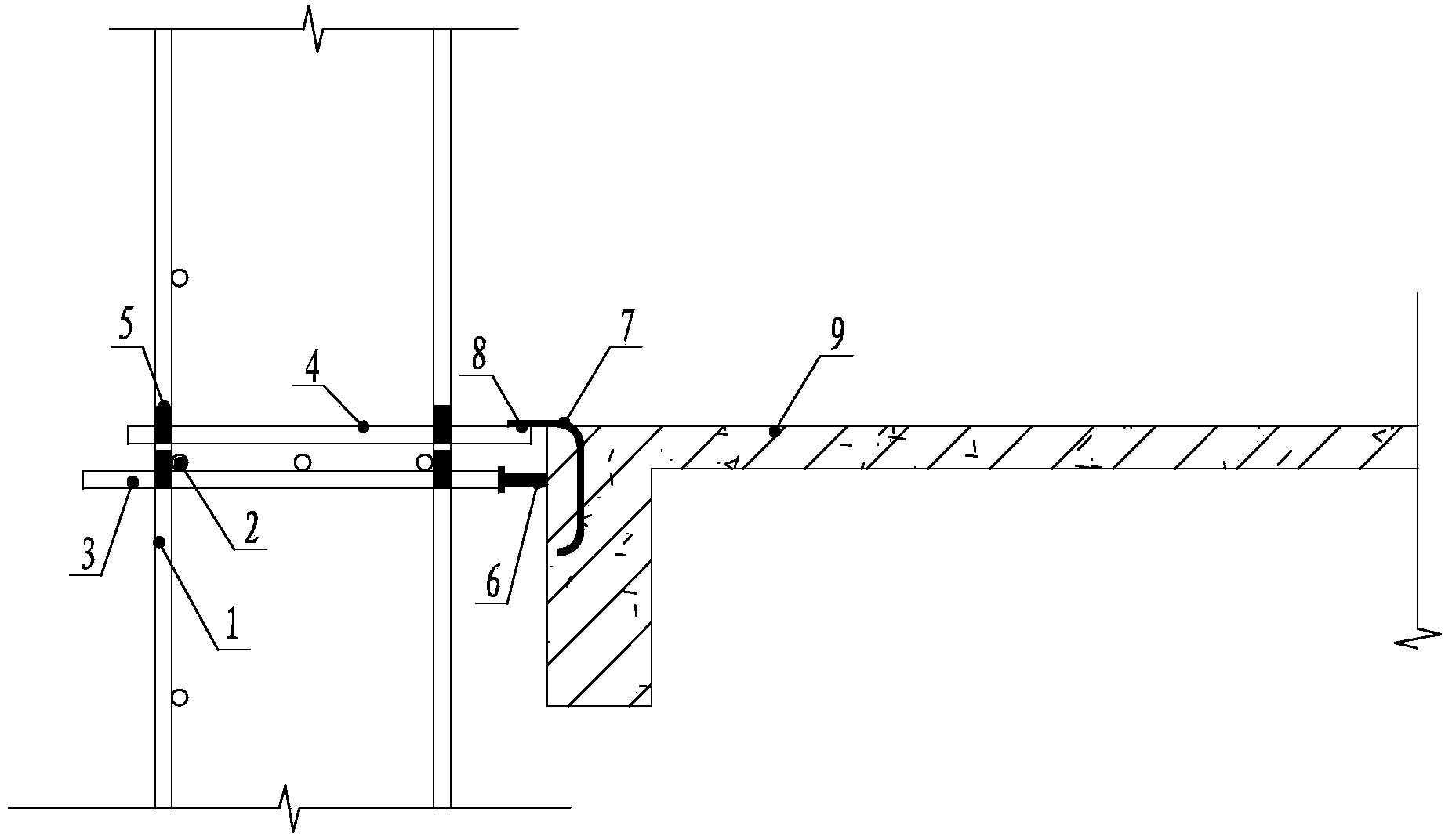

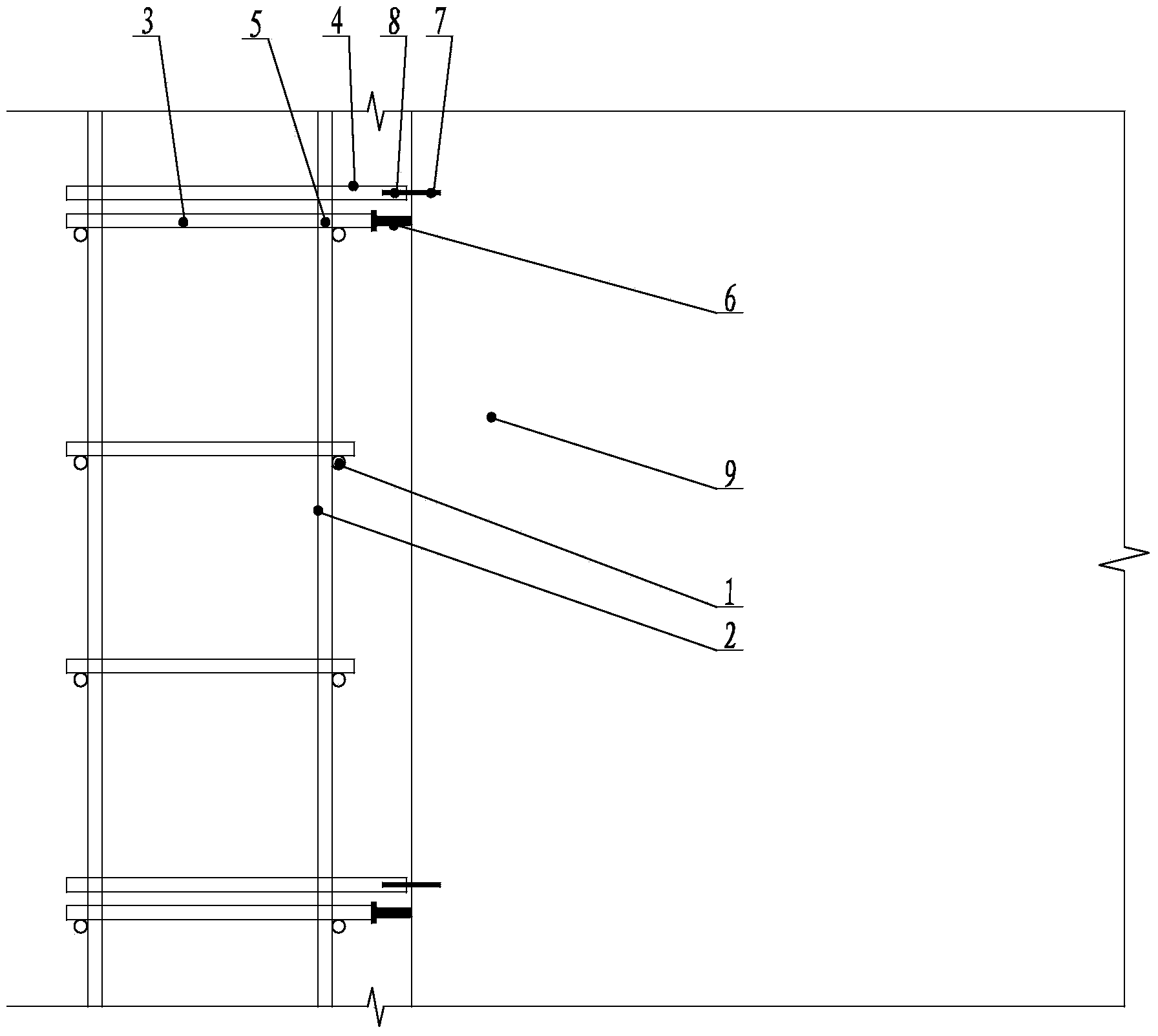

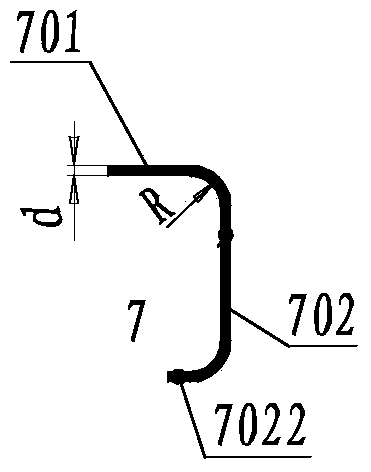

Inserted type outer frame L-type steel wall connecting piece structure free of scaffold hole and construction method thereof

InactiveCN103452304AImprove construction progressEasy constructionBuilding material handlingScaffold accessoriesReinforced concreteRebar

The invention discloses an inserted type outer frame L-type steel wall connecting piece structure free of a scaffold hole and a construction method thereof and relates to a construction device and a construction method thereof. The wall connecting piece structure comprises an outer frame and a wall connecting piece, wherein the outer frame is mainly composed of an upright column, a large cross rod and a small cross rod; the wall connecting piece comprises a wall connecting rod and L-type steel, one end of the wall connecting rod is connected with the upright column of the outer frame, the other end of the wall connecting rod is welded with the short side of the L-type steel, and the long side of the L-type steel is embedded in a main body reinforced concrete structure. The construction method comprises the steps that A, the wall connecting piece is manufactured in an off-site manner; B, the outer frame is mounted; C, the wall connecting piece is mounted; D, the main body structure concrete is poured; E, the wall connecting piece is connected with the outer frame; F, the wall connecting piece is dismantled; G, outer wall repairing is carried out; H, the outer frame is dismantled. According to the inserted type outer frame L-type steel wall connecting piece structure free of the scaffold hole and the construction method thereof, the position of the wall connecting piece is not needed to be changed for the second time, and the construction progress is accelerated; no wall holes and scaffold holes are penetrated, the risk of outer wall leakage is reduced, the safety performance is high, material is saved, and the wall connecting piece structure is applicable to connecting an edge beam, a shear wall, a column position with the outer frame.

Owner:广西建工第五建筑工程集团有限公司

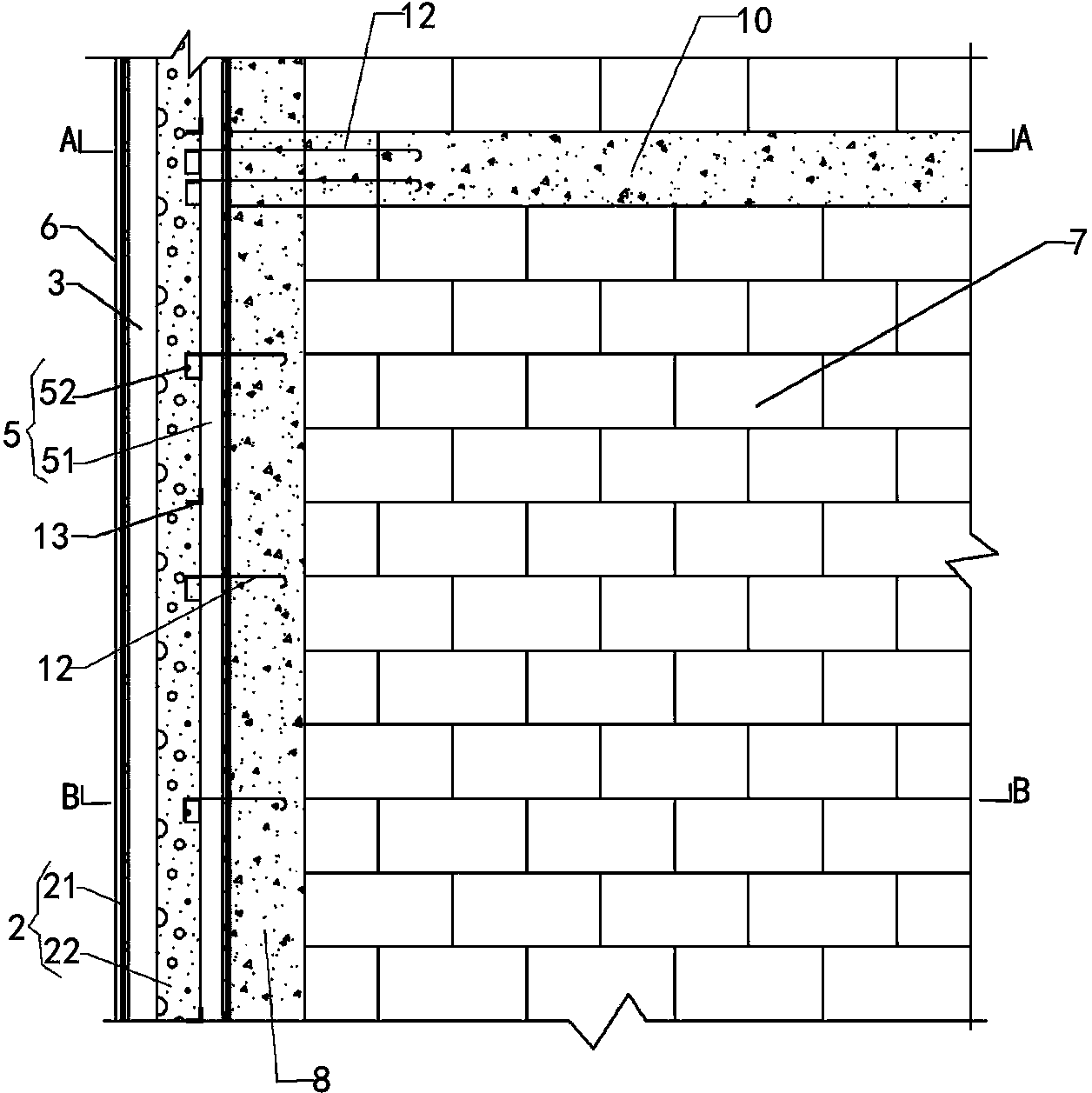

Building envelope inner and outer wall anti-seismic and sound insulation anti-cracking integrated structure and construction method thereof

InactiveCN103883022AImprove insulation effectLow costWallsBuilding material handlingIsolation effectKeel

Disclosed are a building envelope inner and outer wall anti-seismic and sound insulation anti-cracking integrated structure and a construction method of the structure. An outer wall is connected with the outer side of a frame column to form an integrated building envelope surrounding the frame column, one part of the frame column is embedded in the outer wall, the outer wall is a cast-in-place sandwich wall, the outer wall is filled with light porous inorganic core materials, a lightgage steel joist in the core materials is anchored with face plates on the two sides, the outer wall is connected with the inner wall through connecting ribs, and a reinforcing keel is arranged on the connecting portion. According to the structure, containment and heat preservation are integrated, connection between the cast-in-place light inorganic heat preservation composite outer wall and the constructed inner wall is successfully achieved, the good heat preservation, sound isolation and deformation anti-cracking treatment is achieved, industrial wastes are recycled to be used as raw materials to form nonflammable inorganic foam heat preservation slurry, and due to the rich porous structure in the slurry, the slurry has the excellent heat preservation and sound isolation effects. According to the structure and the method, form removal is not required, construction is easy, the forming speed is high, maintenance is not needed, flexible and continuous casting can be achieved, the building construction efficiency is improved by 30 percent, and the cost is reduced by more than 10 percent.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

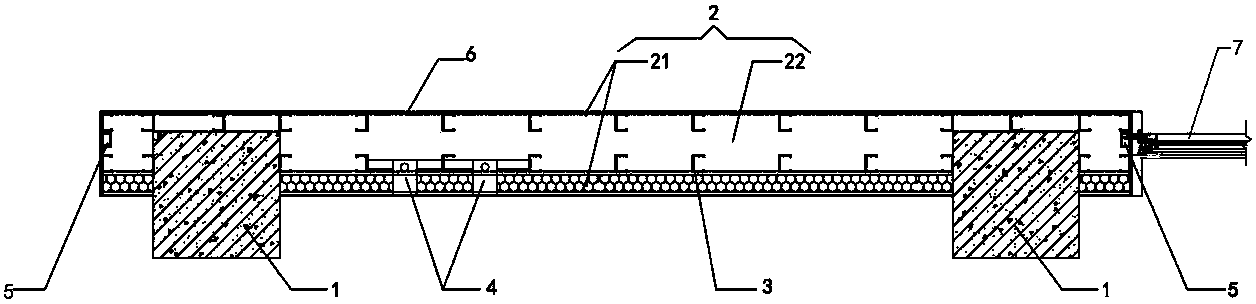

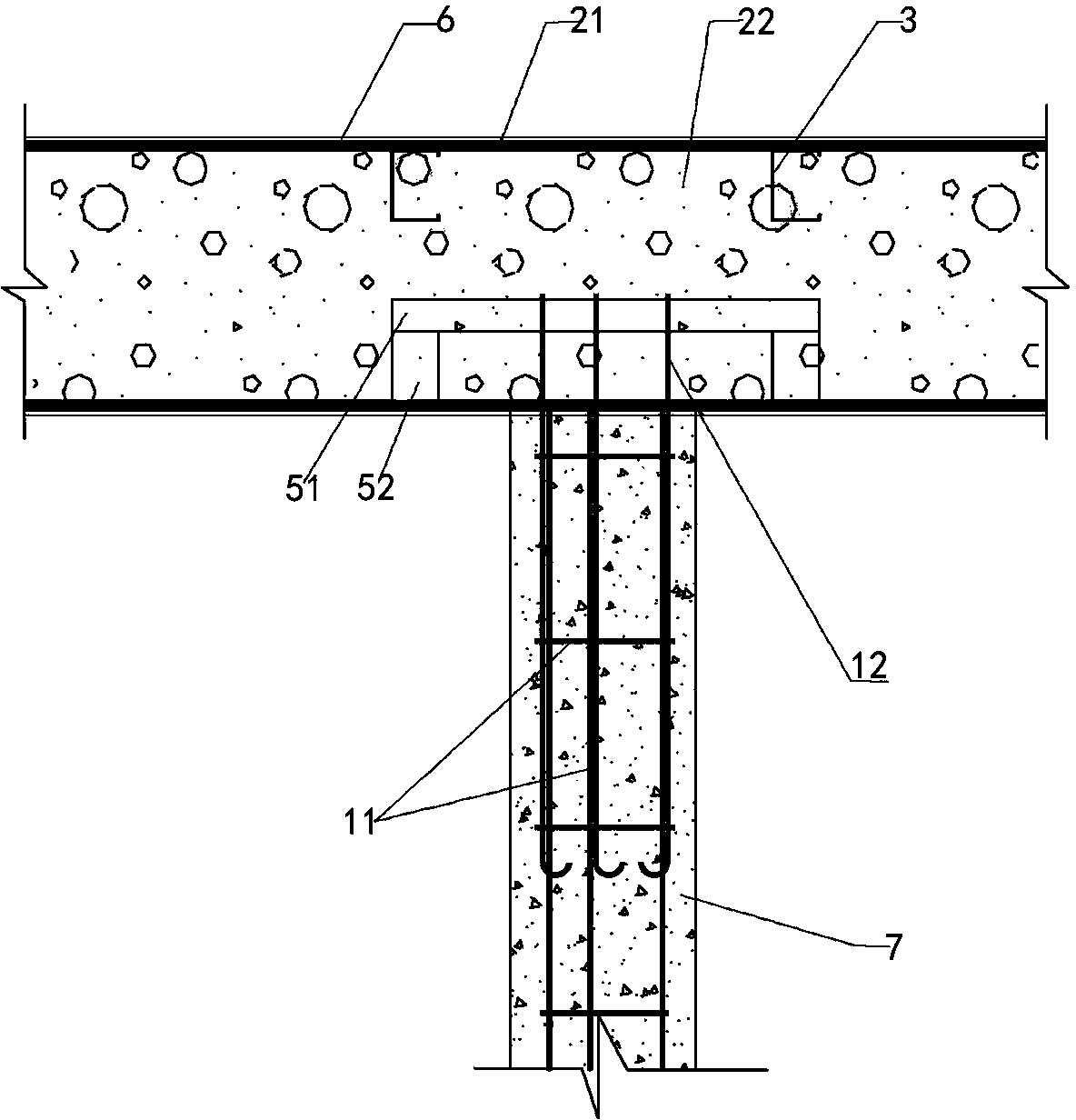

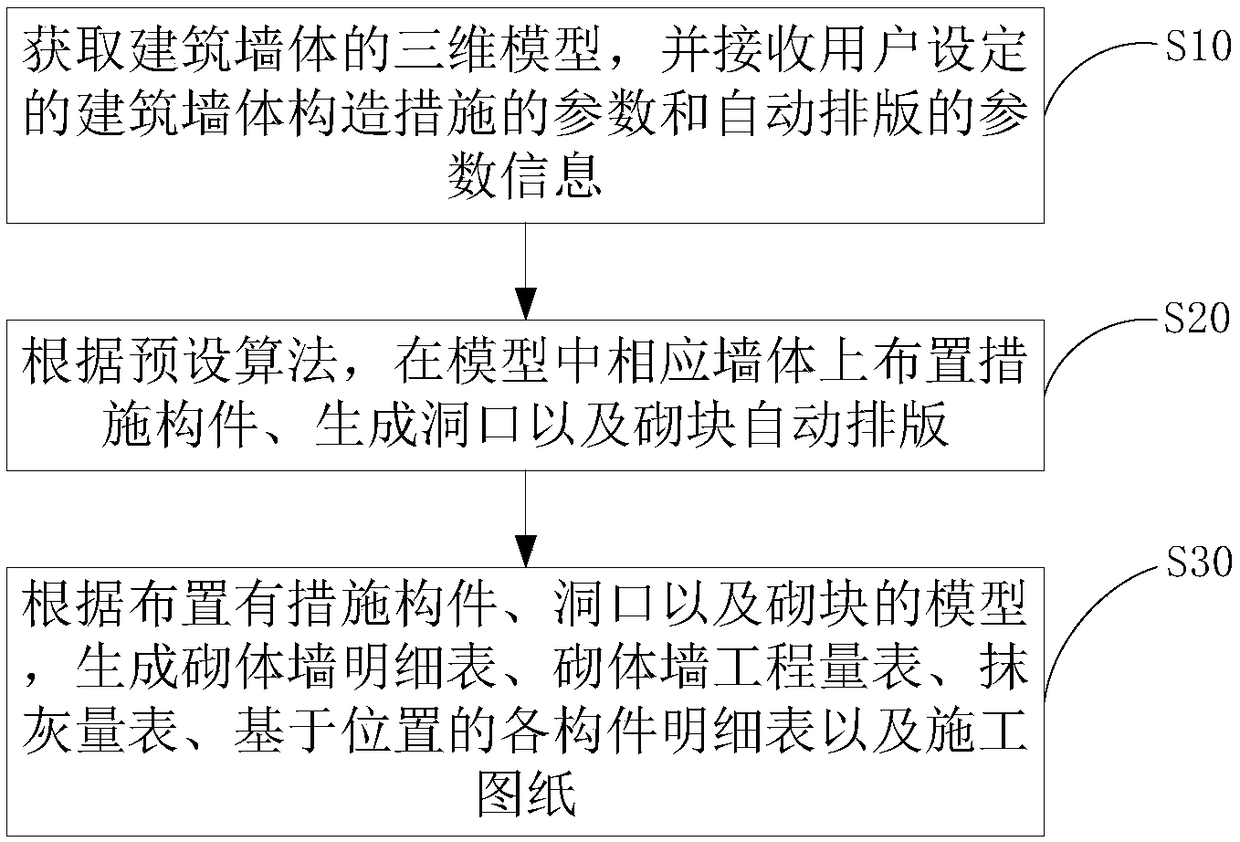

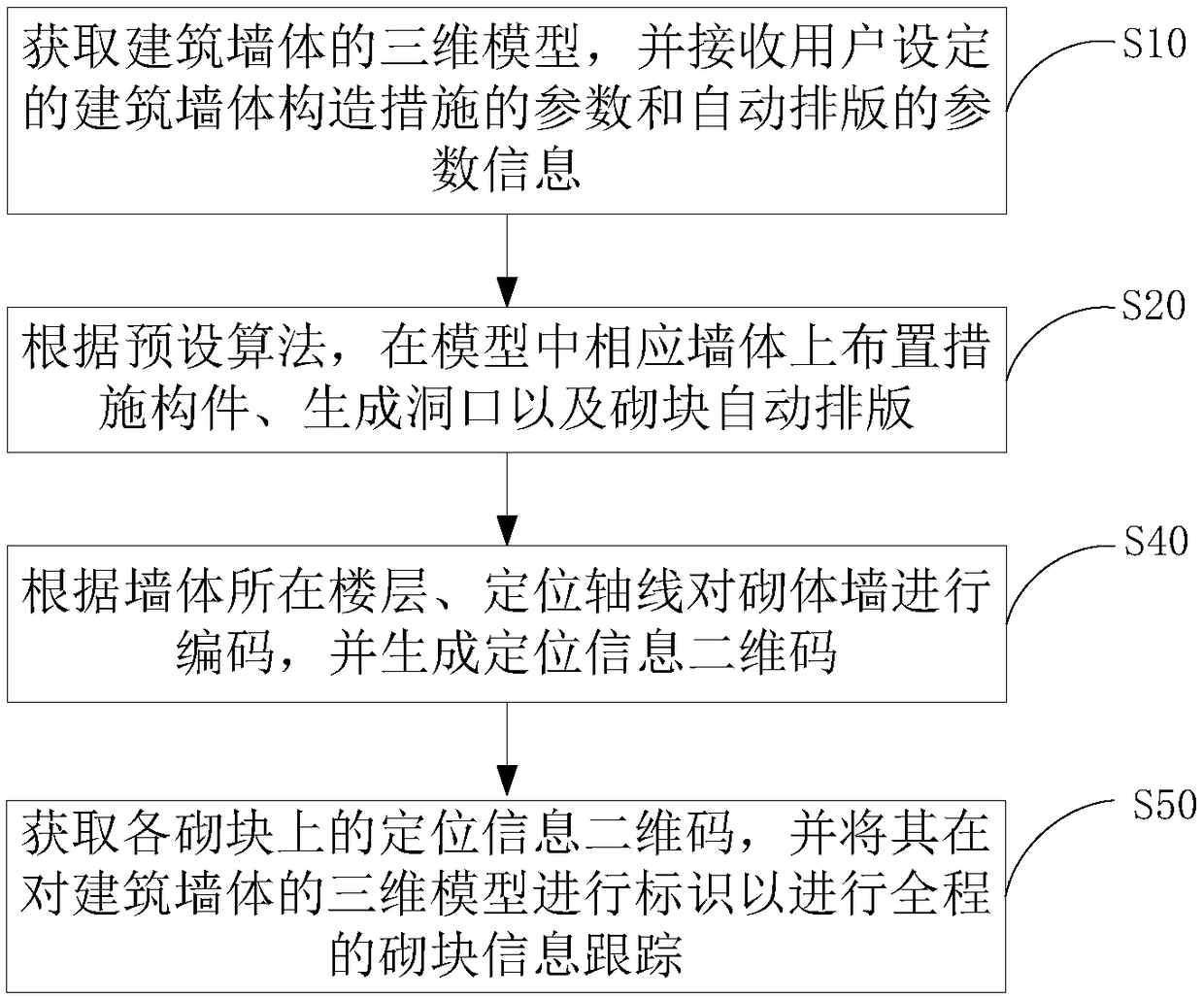

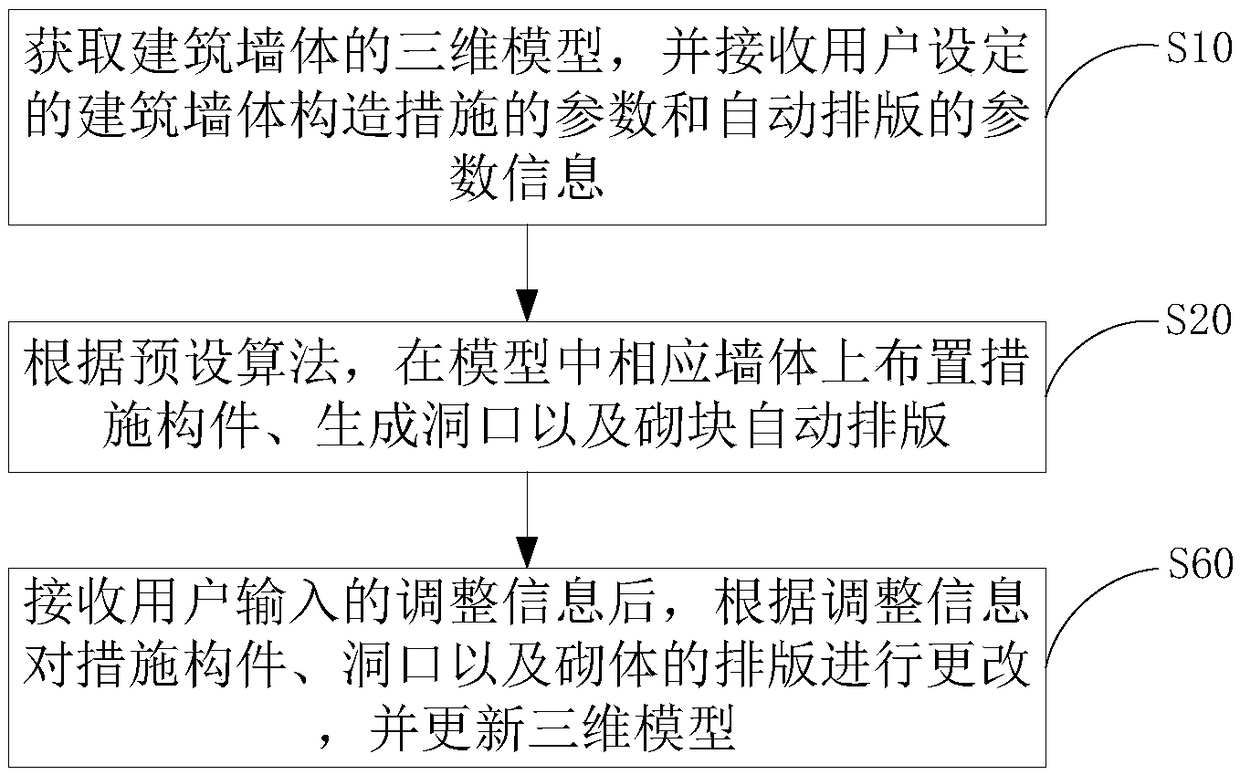

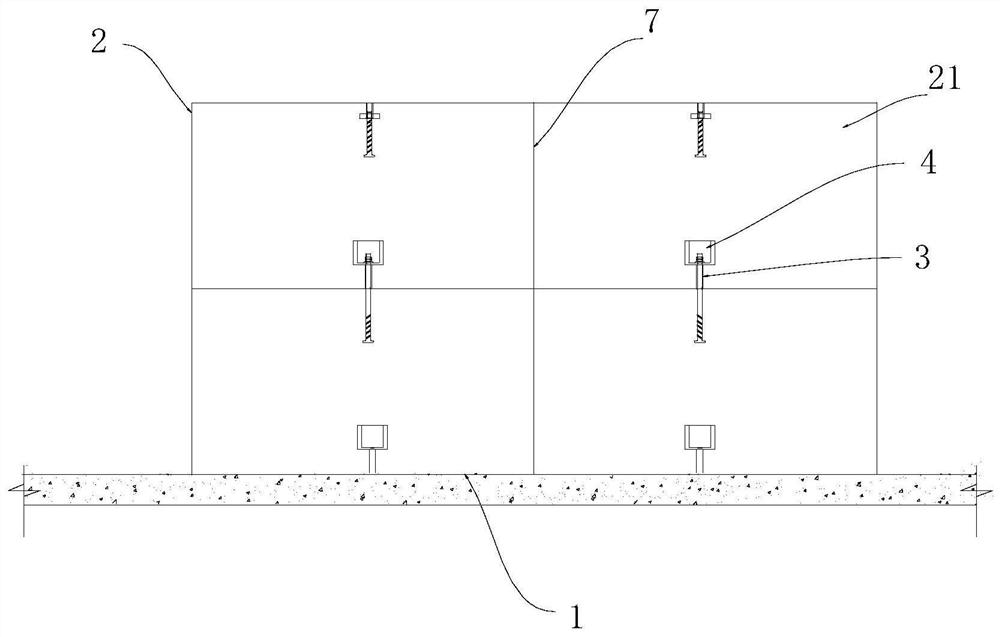

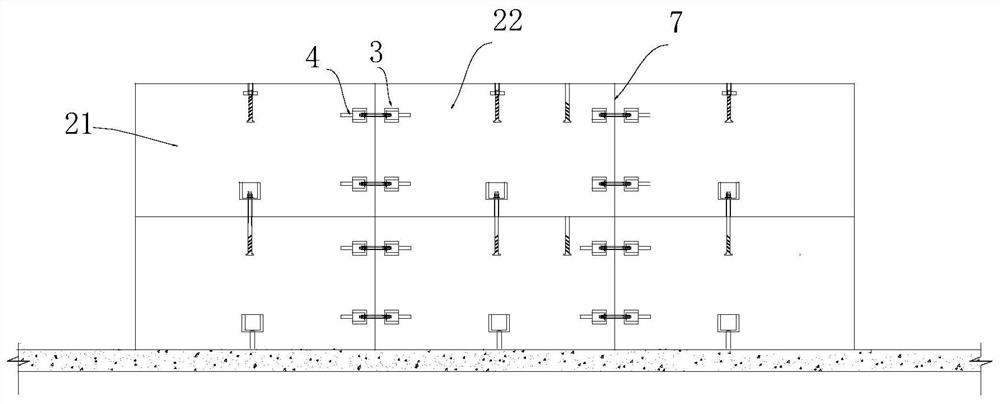

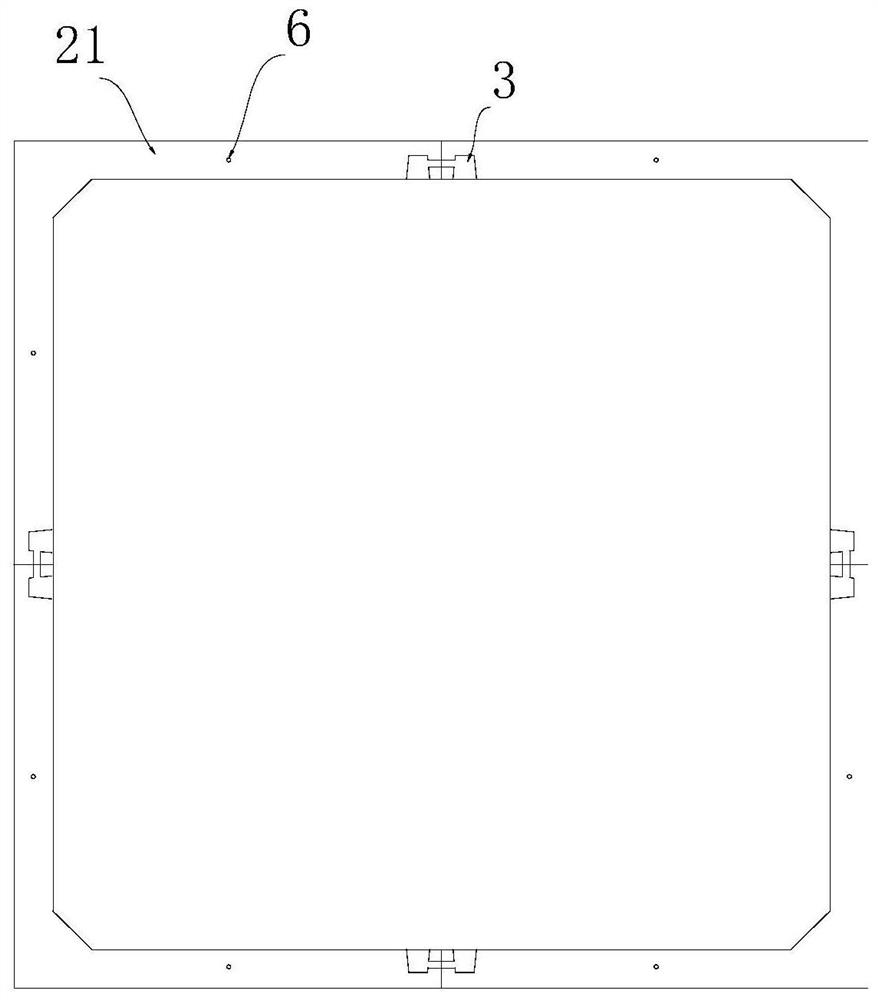

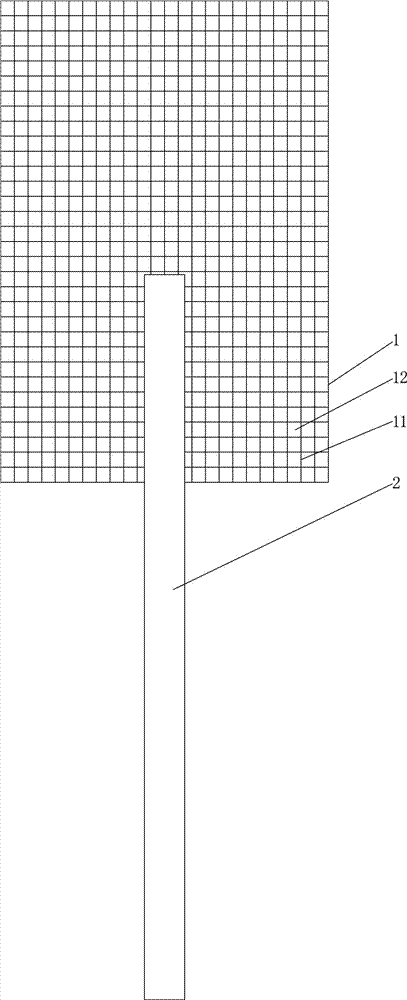

Intelligent masonry design method and device based on BIM

InactiveCN108647404AEnable smart designRealize green constructionGeometric CADSpecial data processing applicationsNumerical controlDesign methods

The invention discloses an intelligent masonry design method based on BIM. The method comprises the following steps that a three-dimensional model of building walls is acquired, and building wall construction measure parameters set by a user and automatically-typeset parameter information are received; according to a preset algorithm, measure component arrangement, hole generation and automatic building block typesetting are conducted on the corresponding walls in the model; and according to the model with measure components, holes and building blocks, a masonry wall engineering quantity bill,a plastering quantity bill, a location-based component list and a construction drawing are generated. According to the intelligent masonry design method based on BIM, transmission of BIM informationis utilized, a factory conducts machining by means of the BIM data by adopting numerical control cutting equipment, the loss of the building blocks is reduced while convenience is brought to buildingblock construction, and meanwhile the exported charts are used for indicating construction, so that the construction quality is improved.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

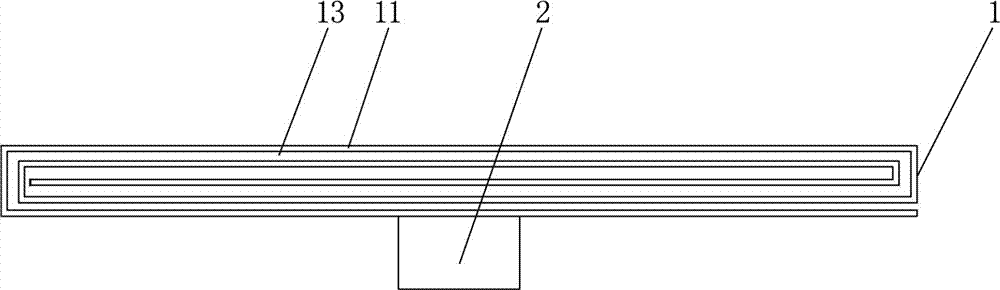

Prefabricated assembly type water tank and assembly method,

PendingCN111809951AQuality improvementHigh dimensional accuracyBuilding material handlingBuilding insulationsEcological environmentArchitectural engineering

The invention discloses a prefabricated assembly type water tank and an assembly method, and belongs to the field of liquid storage tanks. The prefabricated assembled type water tank comprises a watertank bottom plate and prefabricated components arranged on the water tank bottom plate, wherein the prefabricated components comprise the plurality of groups of L-shaped components arranged on the water tank bottom plate and the vertical plate-type components arranged between the transversely adjacent L-shaped components; and connecting bolts are arranged between the L-shaped components and the vertical plate-type components. The prefabricated assembled type water tank absorbs the advantages of the assembly type construction technology to form a modular, standard and large-scale production technology and a standard assembling technology, under the condition of meeting a certain degree of strength, durability and stability, the construction period is shortened to the maximum extent, the construction efficiency is improved, the ecological environment is protected, and the noise pollution of a construction site is reduced; and meanwhile, the construction efficiency of the pre-drilling engineering is improved, and the problem that the construction period of the pre-drilling engineering is short for a long time is solved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Fully-prefabricated pile top crown beams capable of being recycled, and construction method thereof

The invention relates to the technical field of pile top crown beams, and discloses fully-prefabricated pile top crown beams capable of being recycled, and a construction method thereof. The crown beams are arranged at the tops of supporting piles, and are sequentially spliced to connect the adjacent supporting piles; the crown beams are provided with anchorage holes corresponding to connecting anchor cables pre-buried in the tops of the supporting piles, and the connecting anchor cables vertically upwards penetrate through the anchorage holes and are locked and fixed through anchorage devices; and the two ends of the crown beams are provided with connecting convex parts and connecting concave parts, wherein the connecting convex parts and the connecting concave parts are mutually matched,and the adjacent crown beams are clamped and aligned through the connecting convex parts and the connecting concave parts. Cast-in-place construction is avoided, mounting saves the time and labor, the construction efficiency is high, environmental protection is achieved, the fully-prefabricated pile top crown beams can be reused after being recycled, and the construction cost is low.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

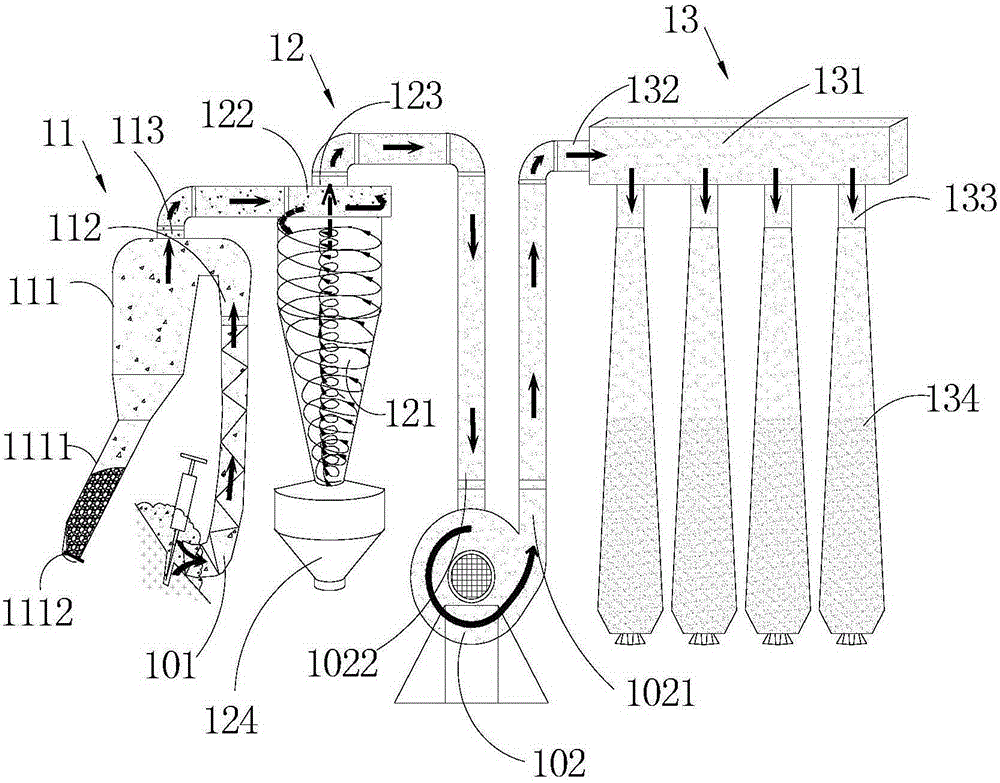

Rock static blasthole drilling dust reduction device

ActiveCN105370313AAvoid pollutionReduce pollutionDust removalFire preventionWorking environmentStatics

The invention relates to the technical field of a dust reduction device, and discloses a rock static blasthole drilling dust reduction device. The rock static blasthole drilling dust reduction device comprises an adsorption device and a filtering device, wherein the adsorption device is used for adsorbing dust in a rock static blasthole drilling part; the filtering device is used for sequentially filtering dust adsorbed by the adsorption device in a classified way; the adsorption device comprises an adsorption pipe and a power source; a pipe opening of the adsorption pipe is aligned with a position of a hole opening of a static blasthole; the power source forms negative pressure in the filtering device; the adsorption pipe is connected with the filtering device; the power source is formed in the filtering device; power is provided through the power source; an adsorption pipe is used and is put in the position of the hole opening of the static blasthole for dust adsorption; and the dust is transmitted to the position of the filtering device to be filtered and collected in a classified way. The problem of dust pollution generated during rock static blasthole drilling is solved; field operation personnel are enabled to be in a good work environment; the pollution of construction on surrounding environment is reduced; green construction is realized; the structure is simple; the practicability is high; the dust reduction effect is good; the operation is simple and convenient; the rock static blasthole drilling dust reduction device is favorable for site safe and civilized construction; and the use cost is low.

Owner:SHENZHEN GONGKAN GEOTECHN GRP

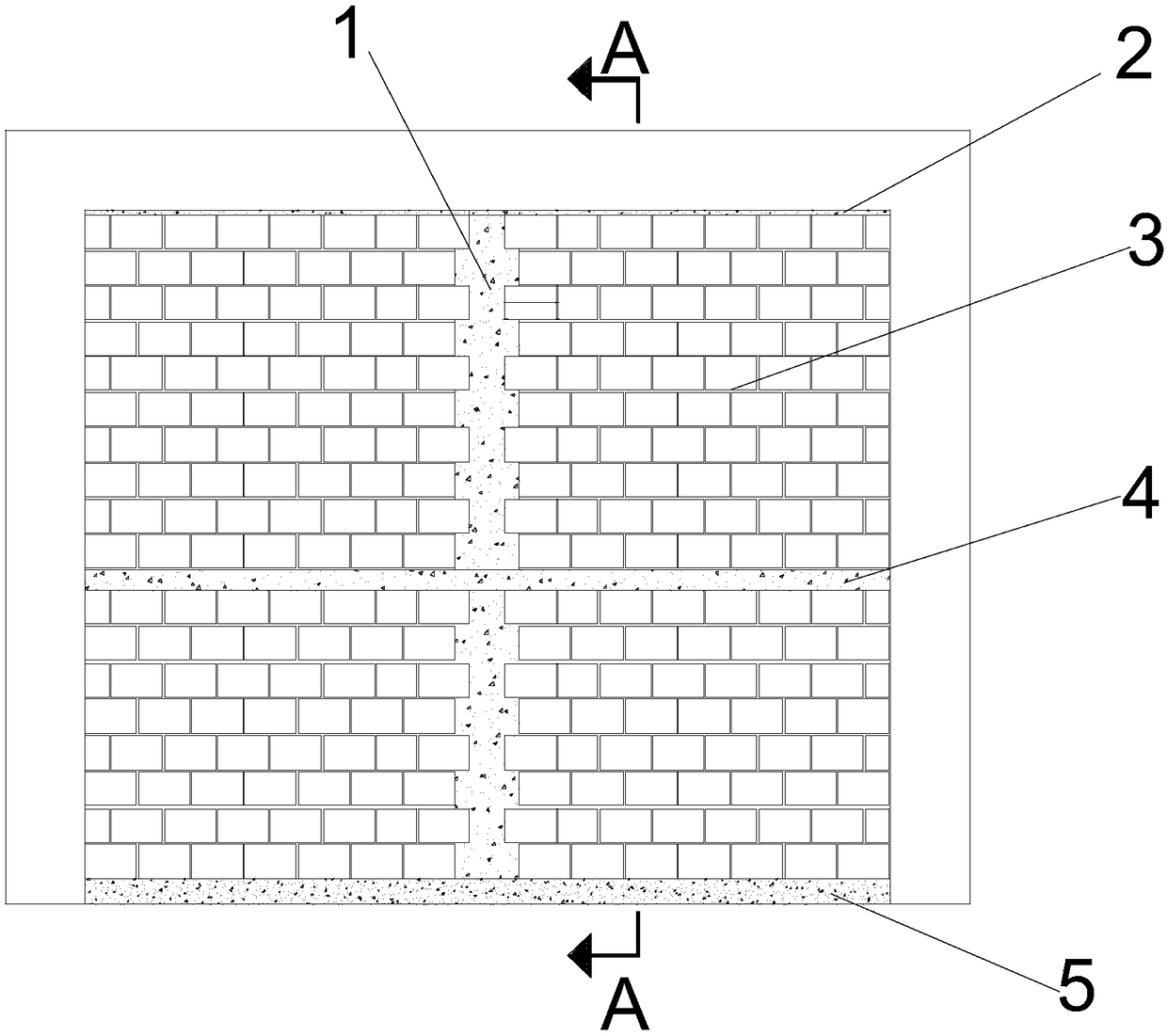

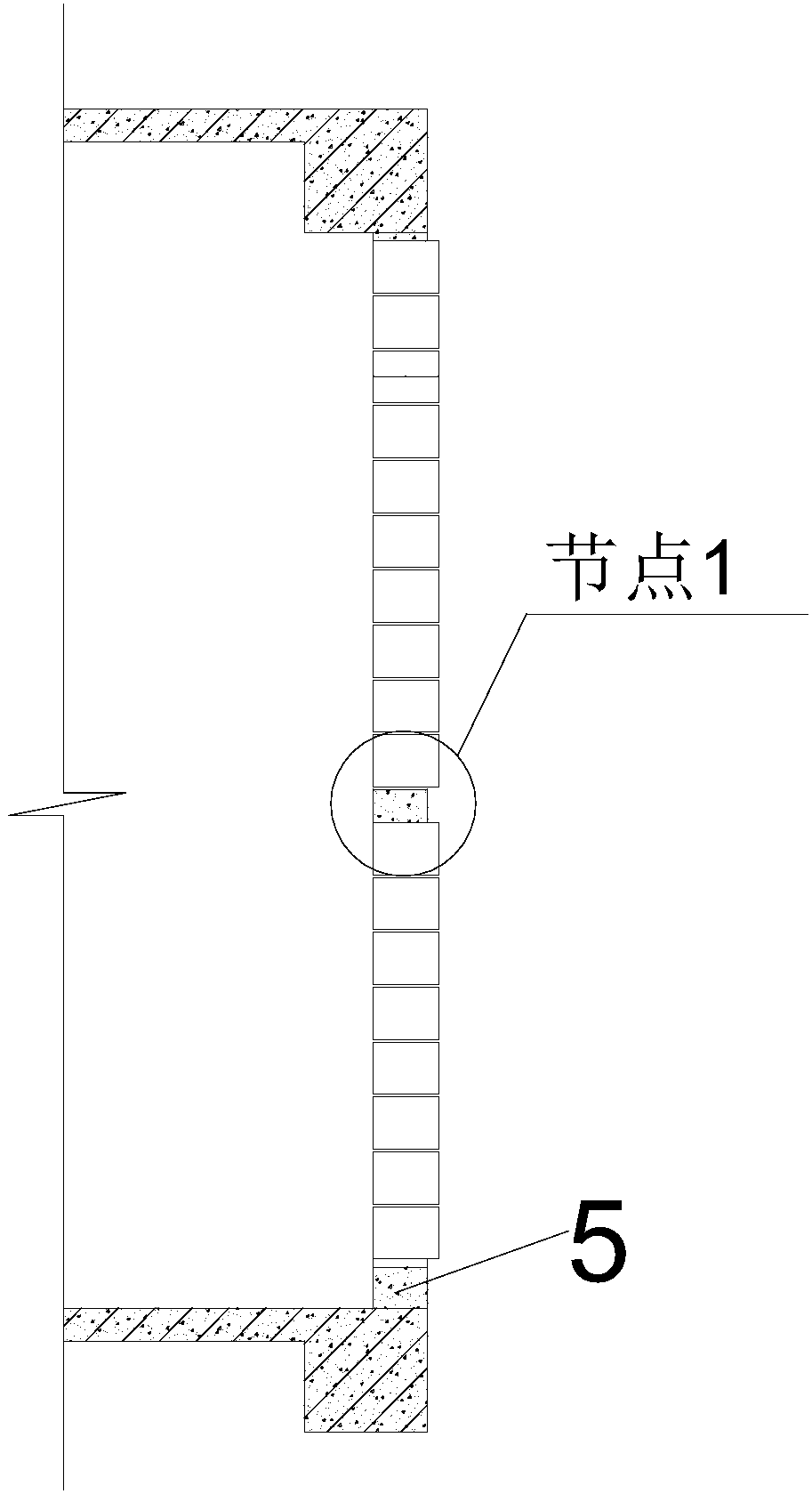

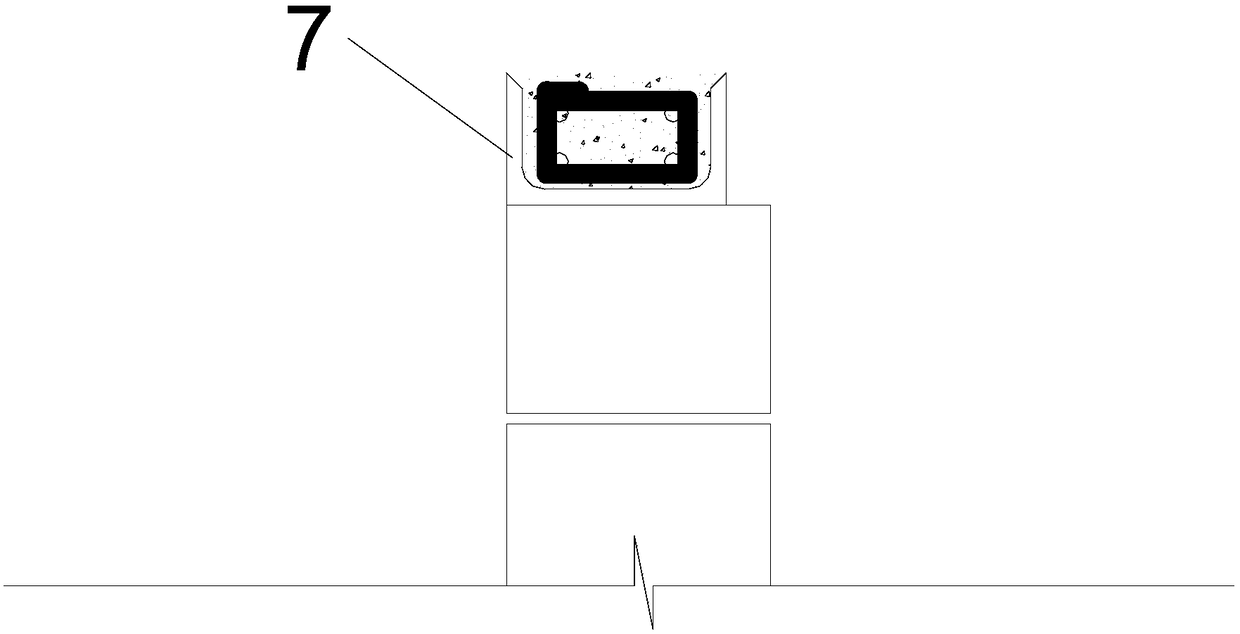

Formwork-erecting-free self-heat-insulation brick wall construction method

The invention discloses a formwork-erecting-free self-heat-insulation brick wall construction method. The formwork-erecting-free self-heat-insulation brick wall construction method comprises the following steps that plain concrete flanging is poured; bricks are arranged, and ribs are planted; a self-heat-insulation wall body on the lower portion of a waist beam is built; the waist beam is built; waist beam concrete is poured; a self-heat-insulation wall body on the upper portion of the waist beam is built; and meanwhile, an outer frame of a constructional column is built through U-shaped bricks, the upper portion of the wall body is subjected to horizontal top plugging, heat-insulation plates are pasted, and then cover surface plastering construction is conducted. In the building process of heat-insulation bricks, heat-insulation plate mounting spaces are reserved at the positions needing the heat-insulation plates to be pasted, so that the heat-insulation plates is flush with the outer wall surface of the wall body after being mounted at the cold bridge position, wall body rendering at the later stage is facilitated, and the problems of hollowing and cracking are relieved.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

High-strength repairing material for concrete cracks and construction method of high-strength repairing material

The invention discloses a high-strength repairing material for concrete cracks. The high-strength repairing material comprises the following raw materials in parts by weight: 40-50 parts of ground waste concrete powder aggregate, 6-8 parts of fine sand, 20-25 parts of polyvinyl chloride ethyl ester, 8-10 parts of gypsum powder, 10-15 parts of a resin curing agent and 15-20 parts of water. A construction method of the high-strength repairing material for the concrete cracks comprises the following construction steps: (1) preparing the repairing material; (2) cleaning the cracks; (3) preprocessing the cracks; (4) filling the cracks; and (5) carrying out maintenance. The high-strength repairing material has the advantages that the raw material source is wide, the economic cost is low, the connection strength is high, the cracking is avoided, and the construction is simple and convenient.

Owner:QINGDAO XINHUAYOU CONSTR GROUP

Plastering construction method for wall base layer

The invention provides a plastering construction method for a wall base layer. The plastering construction method sequentially comprises the following steps that (1) the surface of a wall is cleaned; (2) water is sprayed on the surface of the wall to make the wall surface moist; (3) a slurry patting device is used to pat cement mortar on the wall surface, a roughening layer is formed and composed of a plurality of bulges which are distributed on the surface of the wall; (4) screeding is conducted on the roughening layer, and then plastering mortar is smeared to form a plastering layer, (5) after plastering by 3-4 hours, water is sprayed on the plastering layer for being moist, (6) after the plastering layer is initially set, glue is brushed on the surface of the plastering layer, cut plastic thin film is paved from top to bottom, so that the plastering layer is covered with the plastic thin film, and the plastering layer is cured; and (7) the plastic thin film is peeled off after film curing is finished. With adoption of the plastering construction method for the wall base layer, the plastering layer can be firmly bonded with the wall, shrinkage and cracking of the plastering layer can be effectively avoided, and the construction cost can be greatly reduced.

Owner:广东省第二建筑工程有限公司

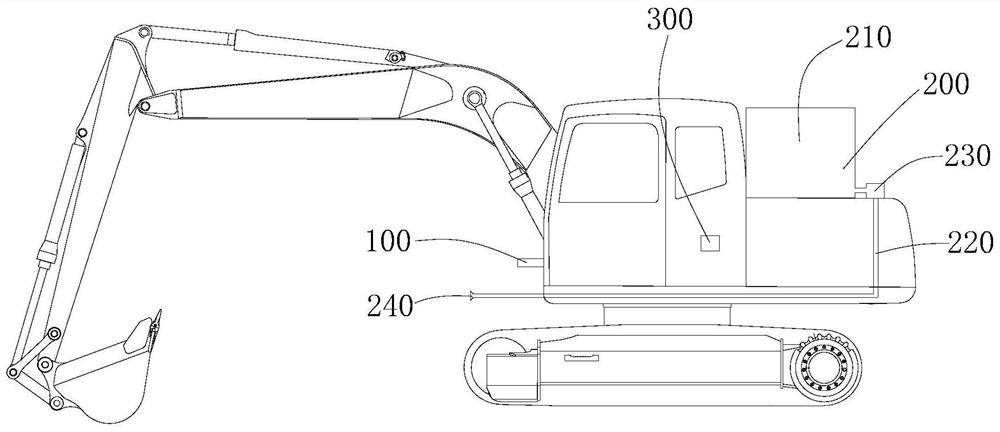

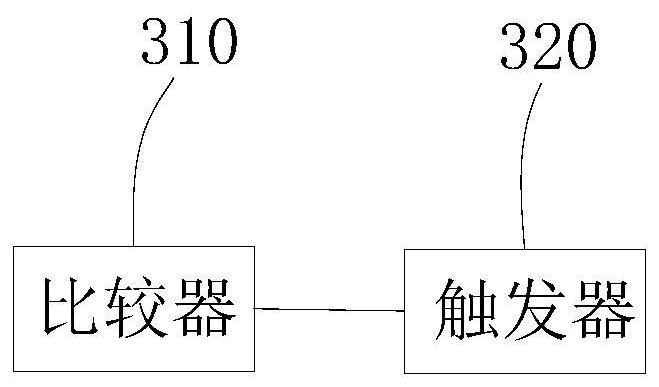

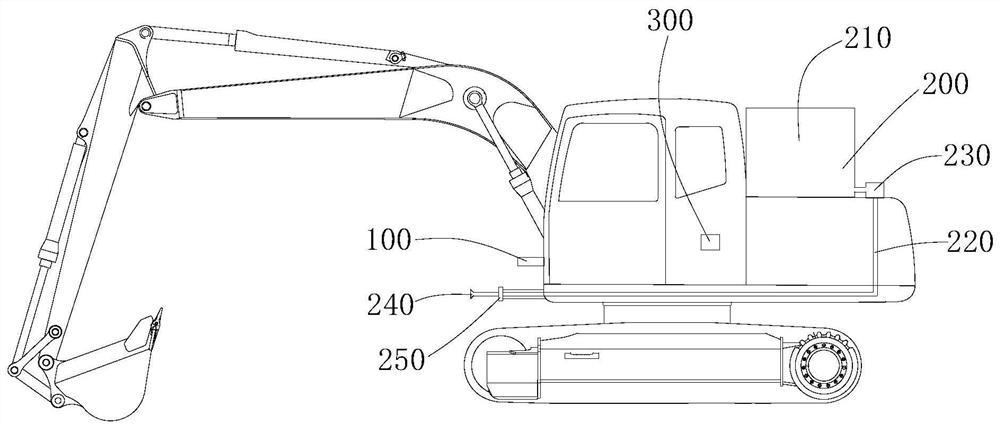

Automatic dust removal system and excavator

InactiveCN112575830ARealize automatic controlReduce the impact on physical healthUsing liquid separation agentMechanical machines/dredgersDust controlEnvironmental engineering

The invention provides an automatic dust removal system and an excavator, and relates to the technical field of excavator equipment. The automatic dust removal system comprises a dust sensor used fordetecting the dust concentration in the environment; a spraying device used for spraying to the environment so as to reduce the dust concentration; and a controller, wherein the controller is respectively connected with the dust sensor and the spraying device so as to obtain the dust concentration and control the spraying device to carry out spraying operation according to the dust concentration.The automatic dust removal system is applied in the excavator to realize automatic control of the spraying device according to the dust concentration, so that the dust concentration in the construction environment of the excavator is reduced, and the influence of dust on the health of on-site constructors is reduced.

Owner:SANY HEAVY MACHINERY

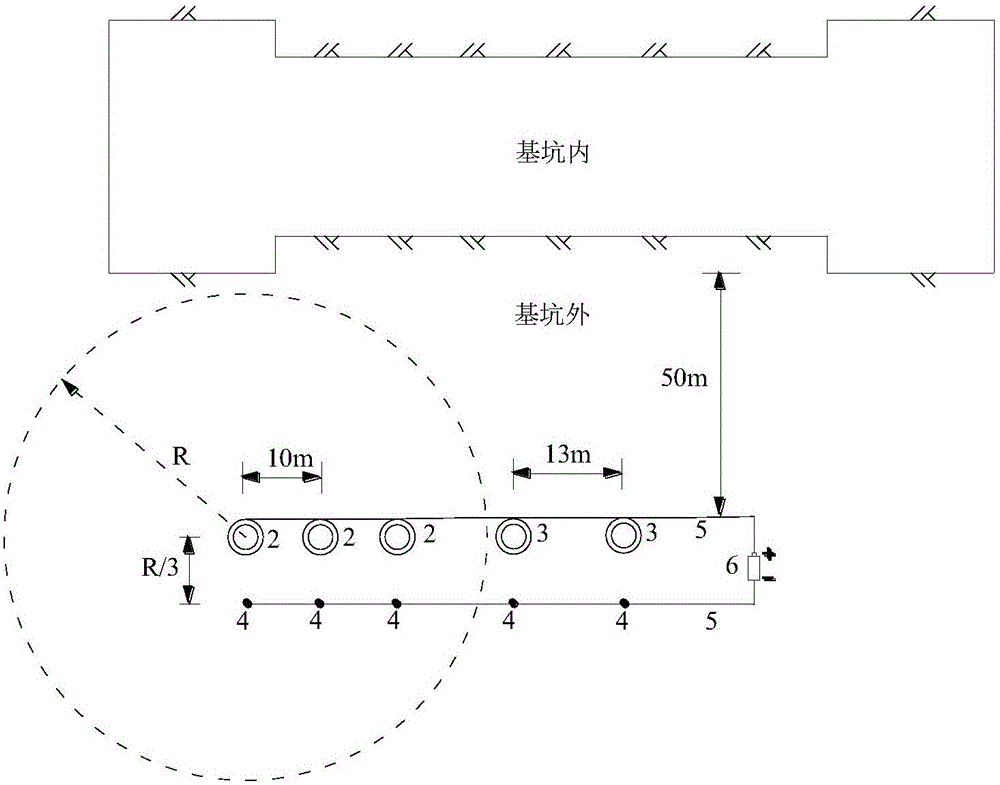

Recharge well construction method adopting electroosmosis

ActiveCN106245621AImproved permeabilityAccelerated dissipationIn situ soil foundationSoil preservationTube wellAnode

The invention discloses a recharge well construction method adopting electroosmosis. The method comprises the following steps: determining groundwater level depth and soil layer lithologic distribution of a recharge field; according to a recharge target aquifer, constructing multiple recharge tube wells on the same side outside a foundation pit, performing a pumping test and a recharge test on the recharge tube wells to determine a permeability coefficient, a recharge influence radius and a recharge quantity; further determining a recharge scheme according to results of the pumping test and the recharge test, and constructing other recharge tube wells outside the foundation pit in the recharge field; arranging electrodes in positions certain distances away from the corresponding recharge tube wells and on one sides, away from the foundation pit in the recharge field, of the recharge tube wells; connecting the recharge tube wells through wires to form a recharge tube well conductive circuit, connecting the electrodes to form an electrode conductive circuit, connecting the recharge tube well conductive circuit with a power cathode, and connecting the electrode conductive circuit with a power anode. With adoption of electroosmosis, the permeability of soil mass around the recharge wells is improved, dissipation of recharge water is accelerated, and interference in the groundwater environment can be reduced.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

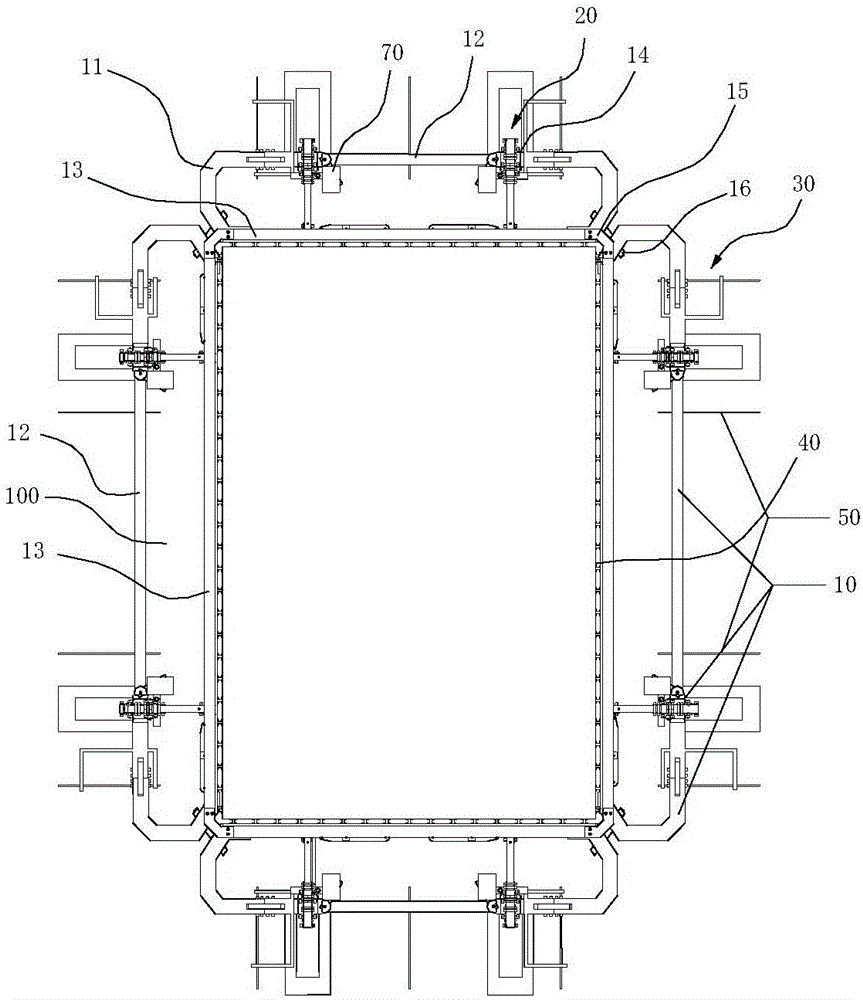

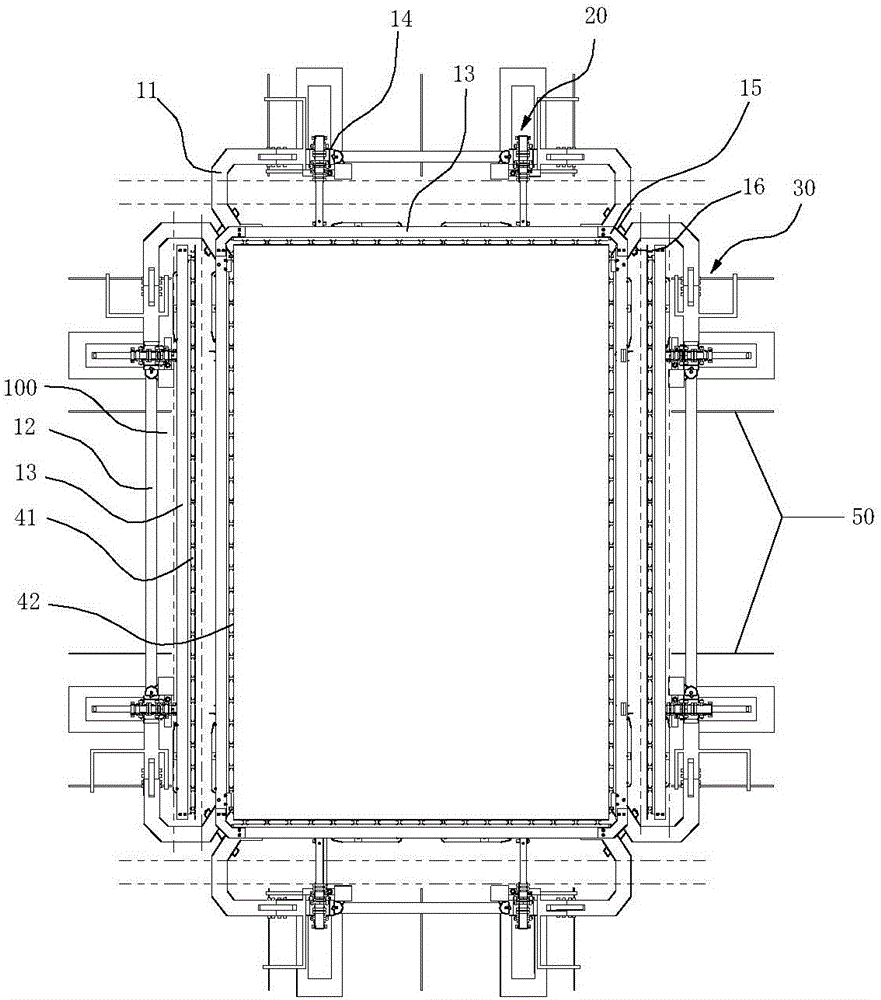

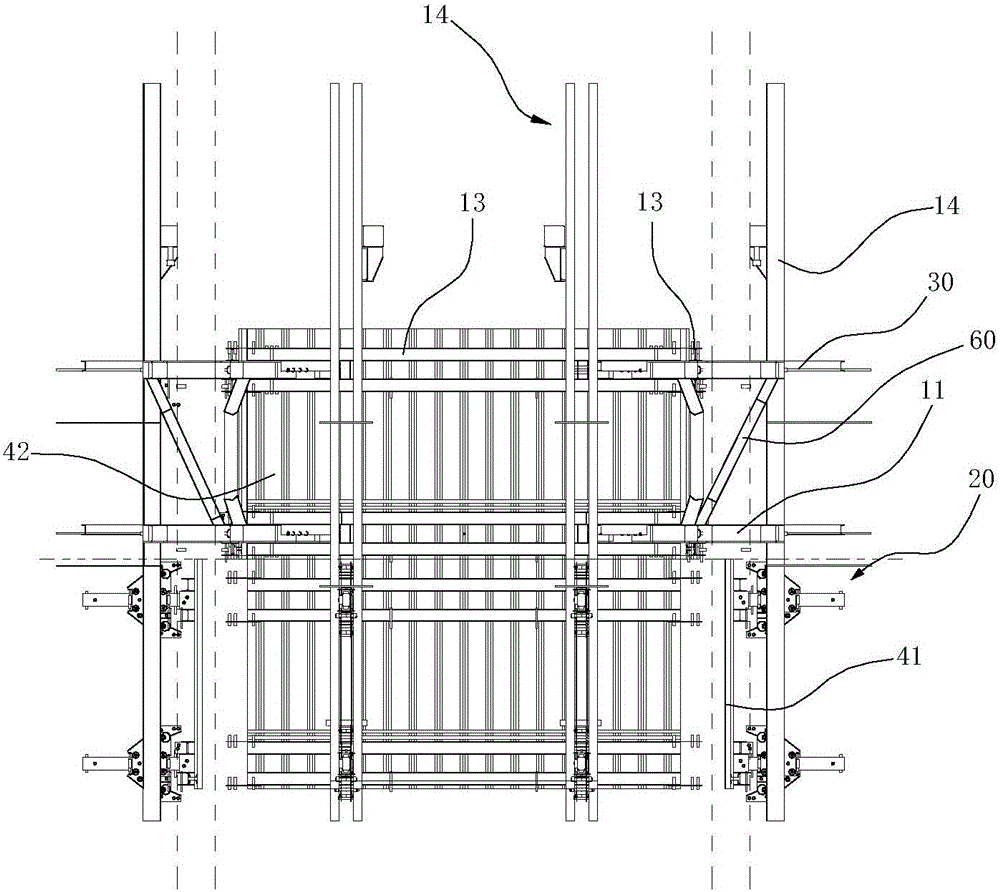

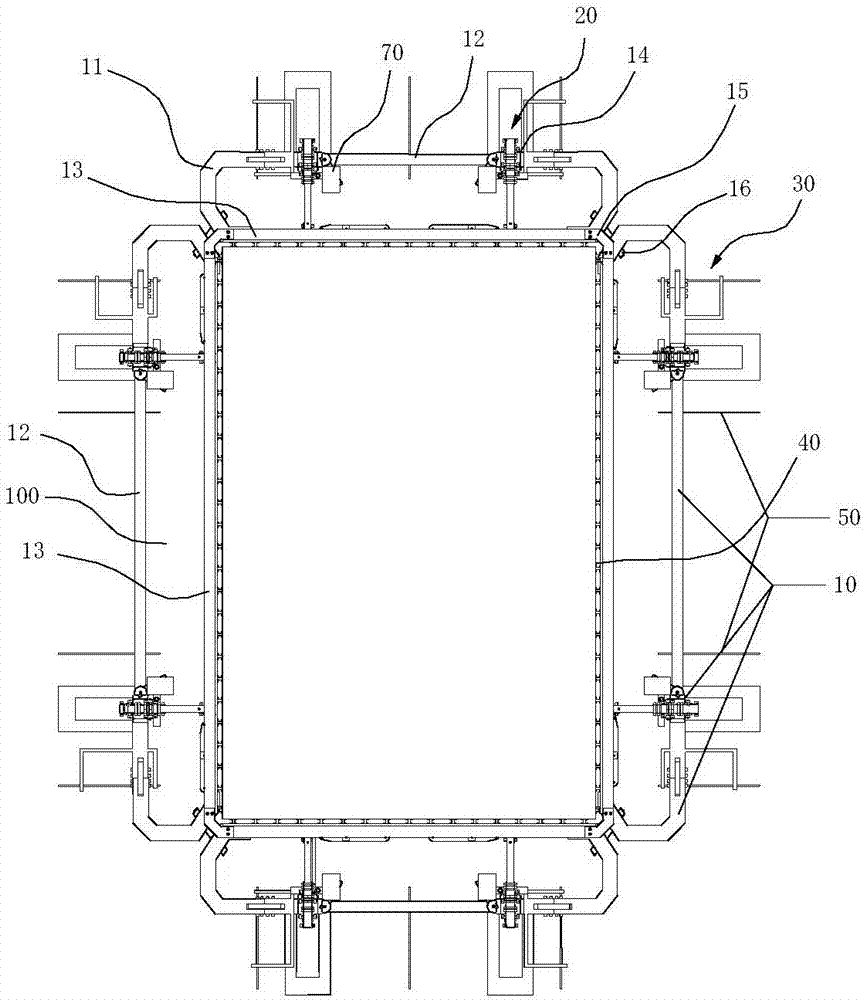

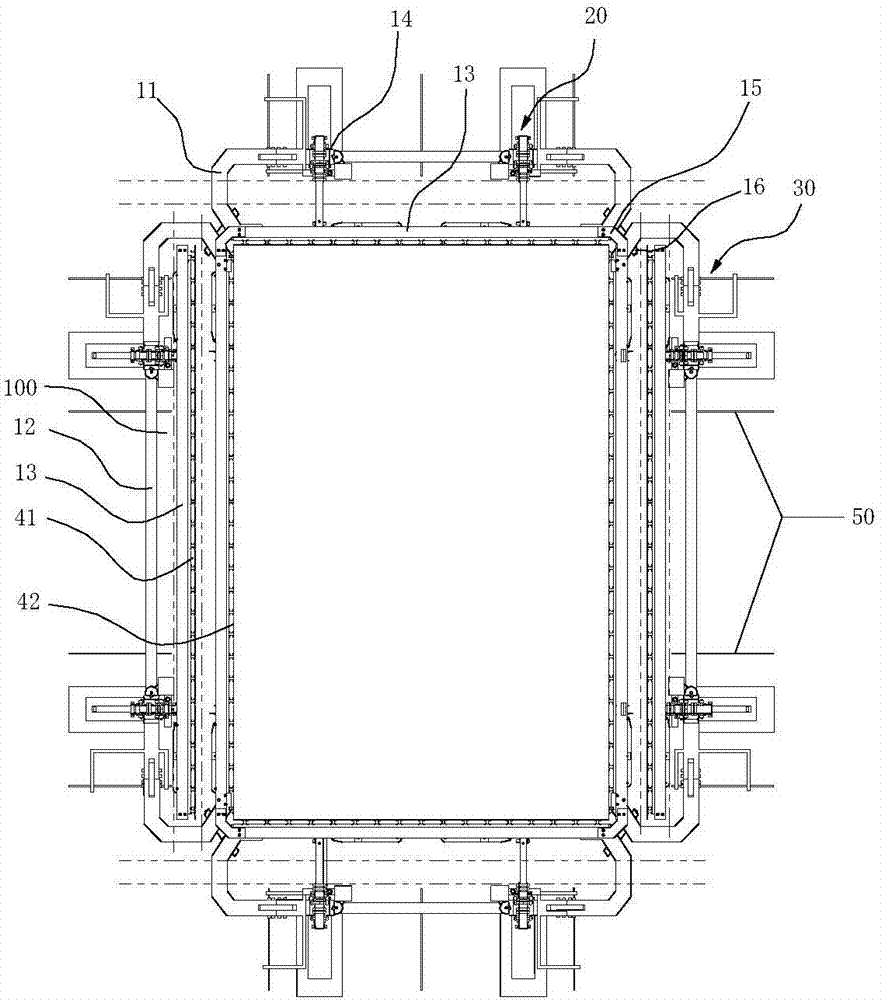

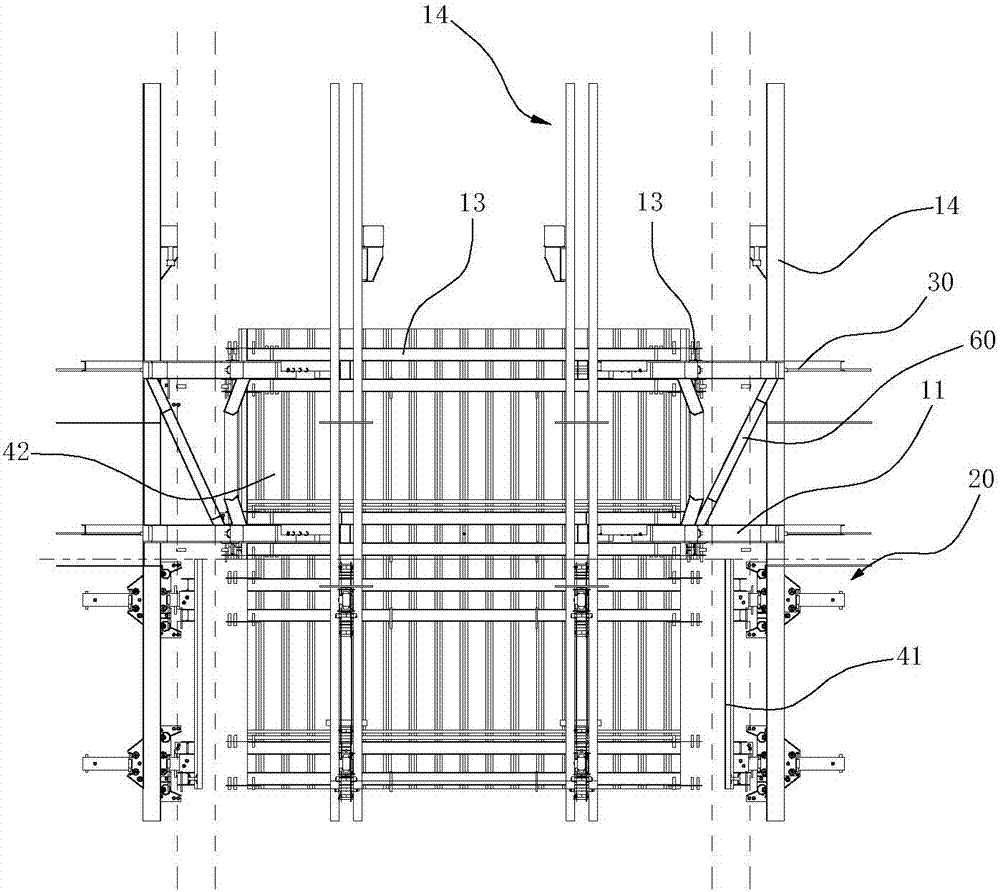

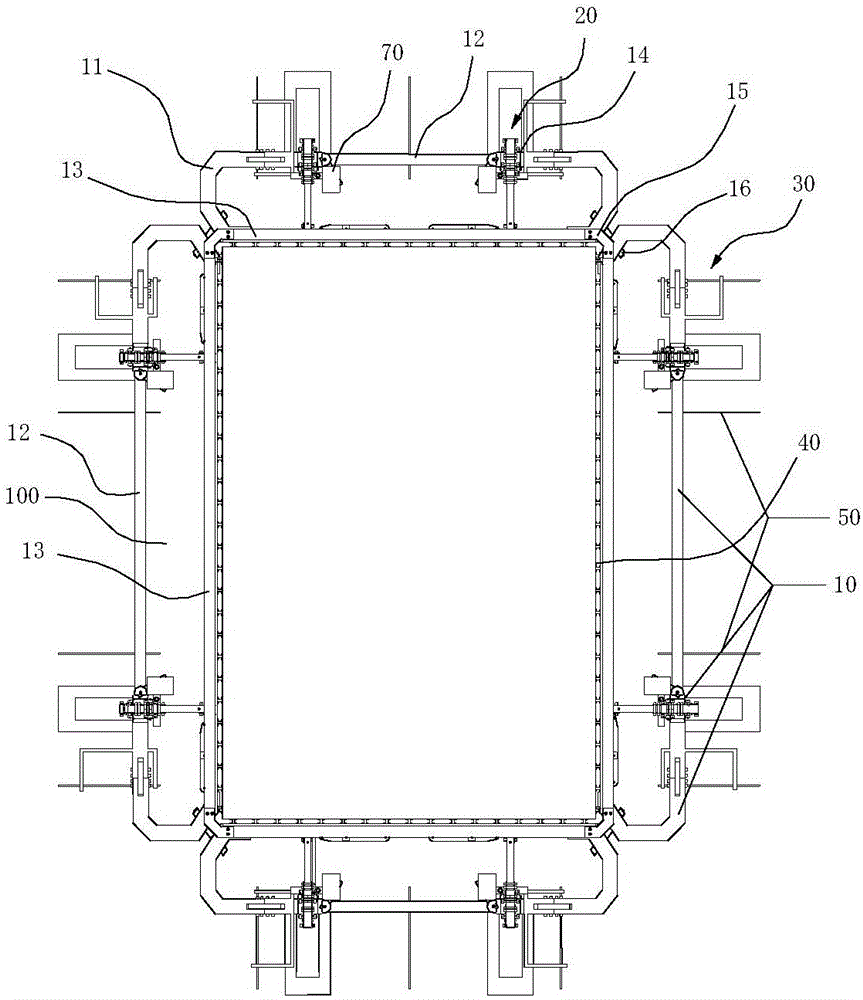

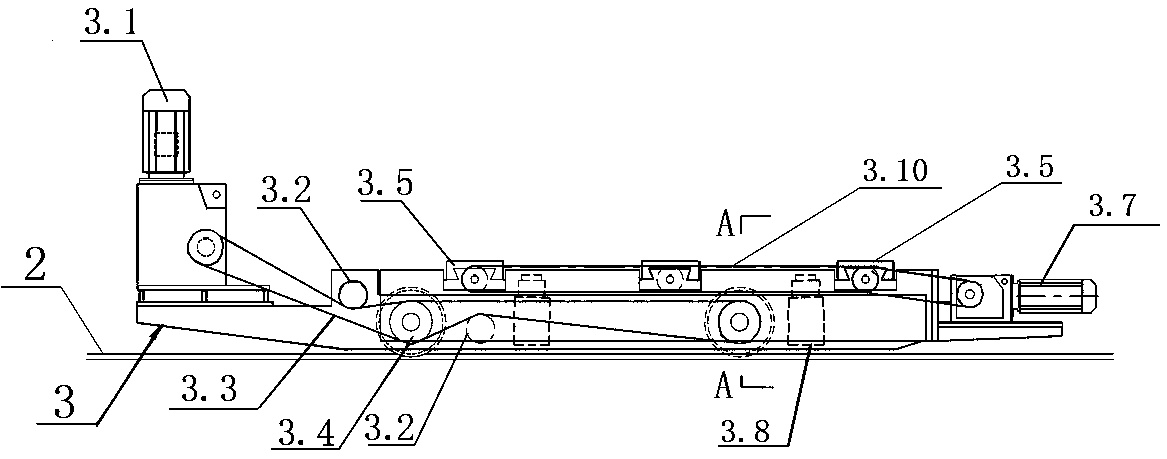

Transportation and assembling equipment system for prefabricated components and construction method of transportation and assembling equipment system

PendingCN108343087AImprove assembly construction efficiencyReduce workloadArtificial islandsUnderwater structuresVertical displacementUltimate tensile strength

The invention provides a transportation and assembling equipment system for prefabricated components and a construction method of the transportation and assembling equipment system. The transportationand assembling equipment system comprises guide rails, transport assembling equipment, at least two vehicle bodies and connecting beams; each vehicle body is connected to the corresponding guide railin a rolling mode and comprises a vehicle body structure, a traveling system and an aligning system; the vehicle body structures comprise top buckling plates and bottom buckling plates, and the top buckling plates and the bottom buckling plates are jointly spliced into a hollow box body with the cross section being rectangular; the traveling systems are mounted on the vehicle body structures fordriving the vehicle body structures to move along the guide rails; the aligning systems are mounted on the vehicle body structures for adjusting vertical displacement and transverse displacement of to-be-transported prefabricated components; and the prefabricated components are placed on the top buckling plates of the vehicle body structures, and transporting and mounting work of the prefabricatedcomponents is completed through the vehicle body structures, the traveling systems and the aligning systems. According to the transportation and assembling equipment system for the prefabricated components, the technical problems that as for a traditional construction method, the heavy hoisting operation quantity is large, many potential safety hazards occur, the occupied space of hoisting operation is large, the labor intensity of aligning splicing operation is high, and splicing precision is poor are solved.

Owner:BCEG CIVIL ENG +1

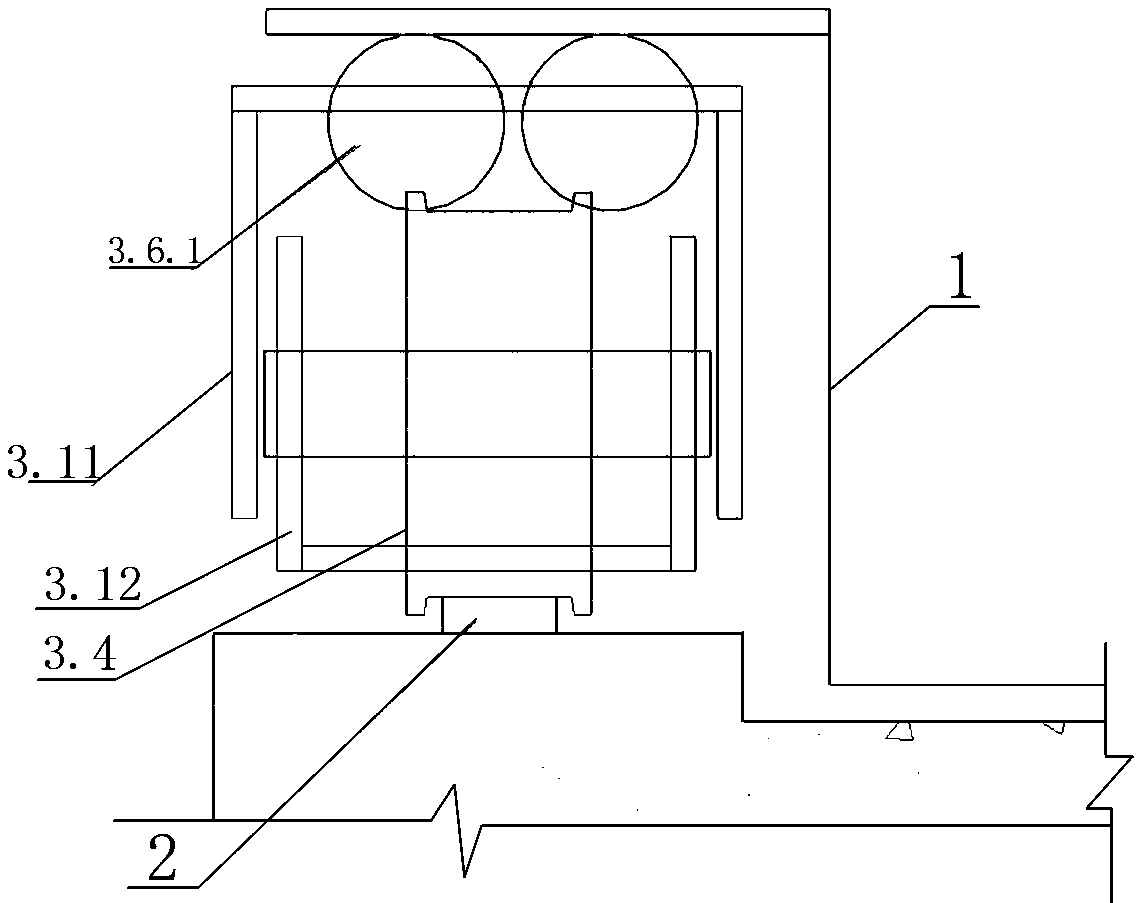

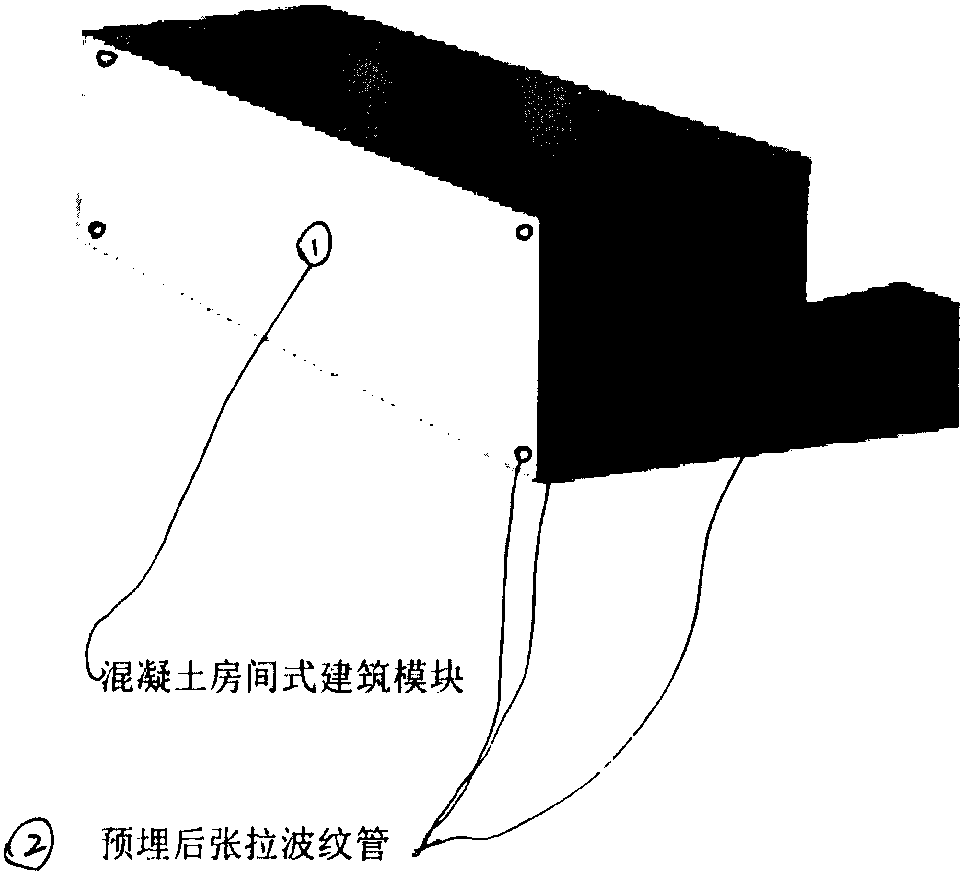

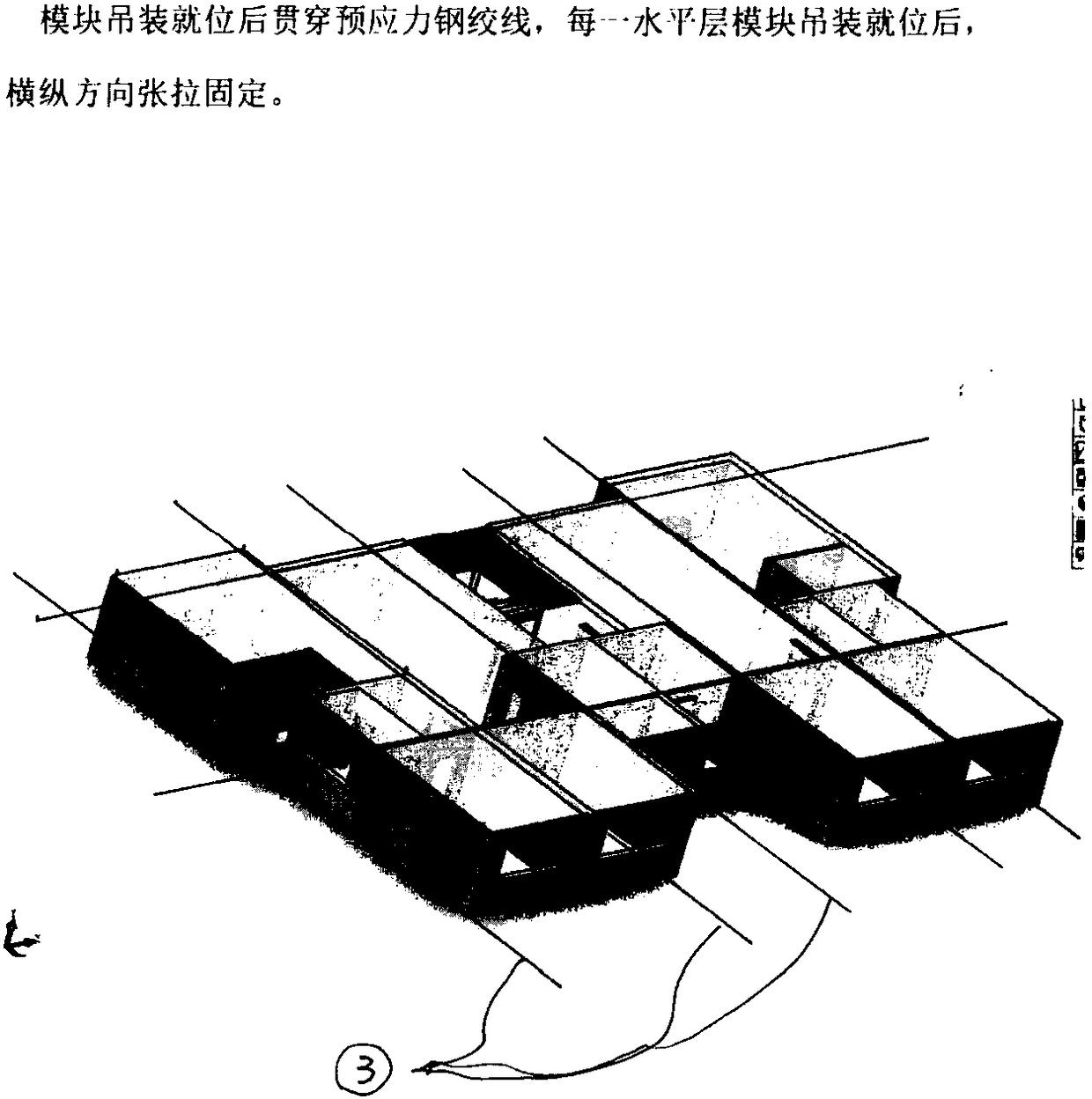

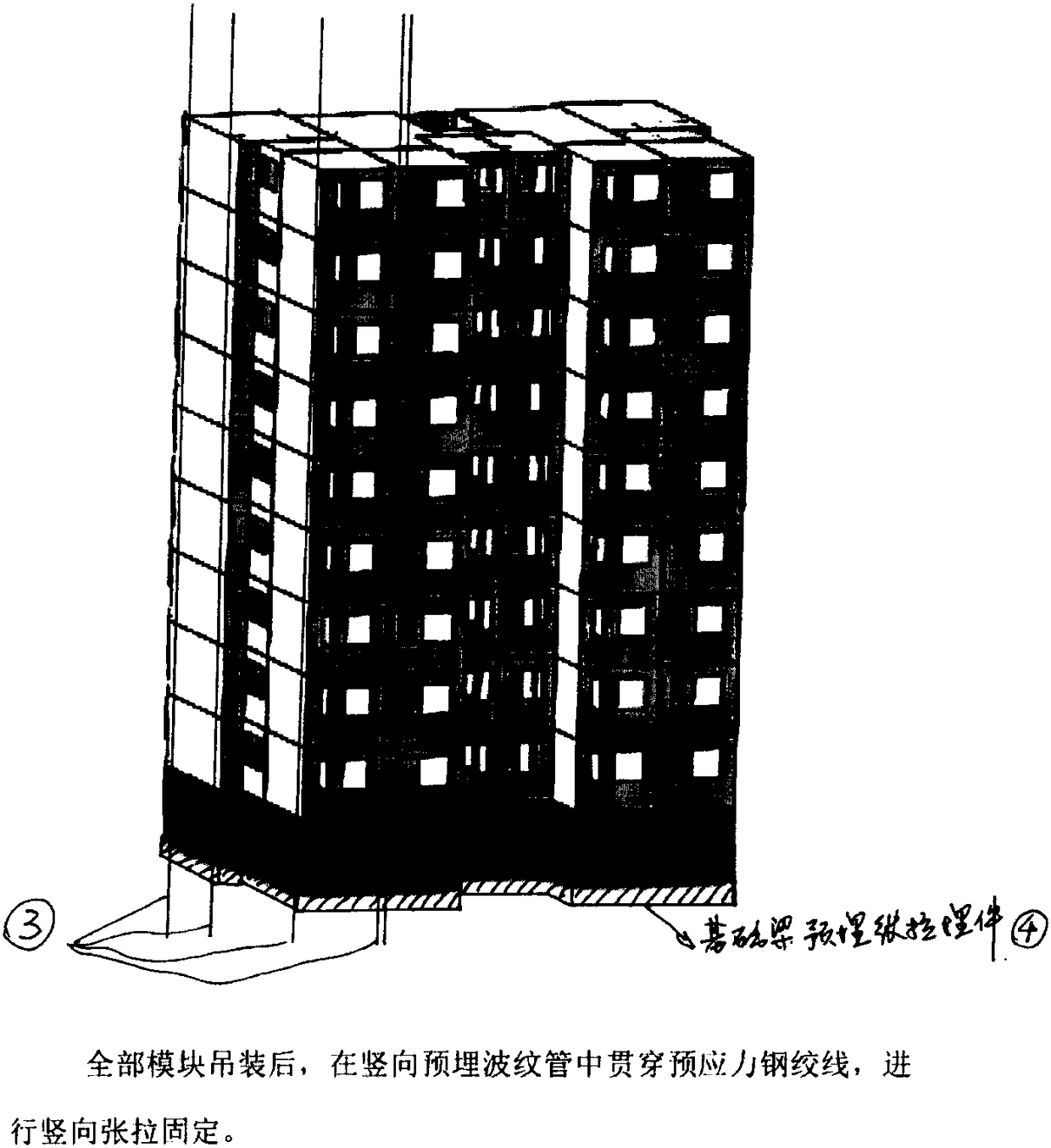

Medium high-rise concrete modularization building structure system

PendingCN108708462AHigh degree of industrializationBuild fastBuilding constructionsPre stressArchitectural engineering

The invention discloses a medium high-rise concrete modularization building structure system which mainly adopts a concrete room module and a steel strand pre-stressed post-tensioning and fixing method. According to the system, construction of a concrete building can be greatly accelerated, the current situation of a concrete assembled building is fundamentally changed, the industrialization levelof the building is improved, the construction cycle of the building is shortened, green construction is achieved, construction garbage and construction dust are omitted in the construction process, energy is saved, environments are protected, large-scale intensive production of the building is achieved, construction cost is reduced, and building quality is improved.

Owner:周圣勇

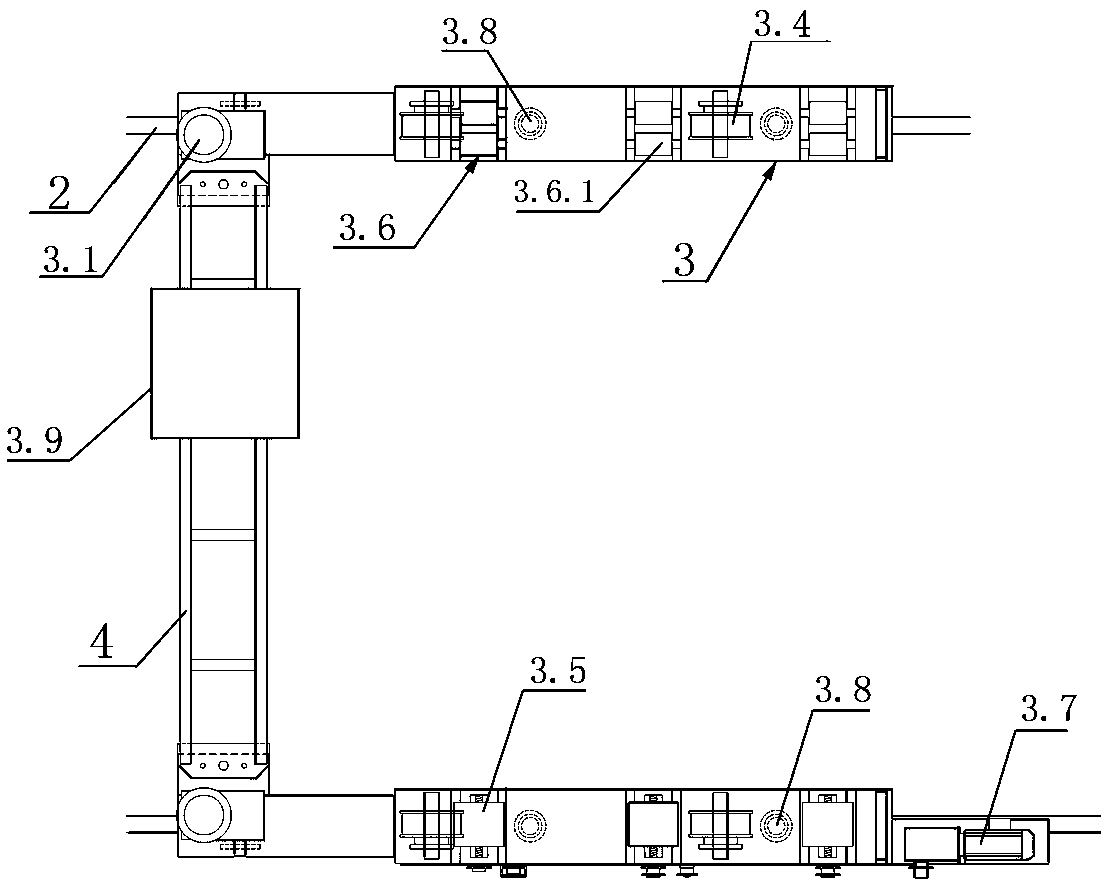

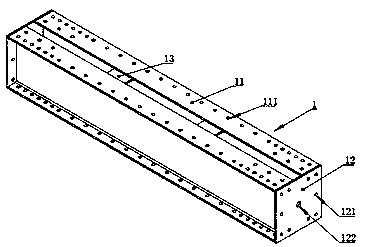

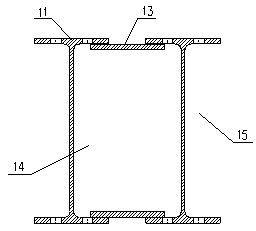

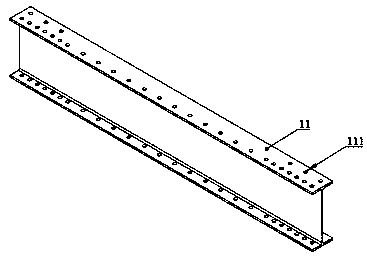

Combined type section steel support rod piece

PendingCN111218941AReduce the impact of human and weather factorsConstruction quality is reliableExcavationsStructure supportBatten

The invention relates to a combined type section steel support rod piece which adopts a pair of H section steel connected through a batten plate to form an integrity; the combined type section steel support rod piece is mainly used for horizontal support of a foundation pit; to facilitate transportation and installation, the combined type section steel support rod piece is manufactured by adoptingthe length of certain modulus; end plates are welded to the two ends of each support rod piece, and bolt holes are reserved in the two ends of the support rod piece; at the same time, the bolt holesare also reserved at certain intervals in a section steel flange plate; the support rod pieces are spliced through the end plates and the bolt holes reserved in the flange plate to realize steel structure prefabricated construction; the support rod piece is machined into a standard component in a factory, then, the standard component is transported to a building construction site, and onsite assembling and installation are realized through bolt connection, so that the construction efficiency of a foundation pit horizontal support structure can be greatly improved; and after the using period ofthe foundation pit horizontal support structure is finished, the support rod piece is dismantled and maintained for next engineering, so that environmentally-friendly construction is realized, and the construction cost is effectively reduced.

Owner:BEIJING ZHONGYAN DADI TECH CO LTD

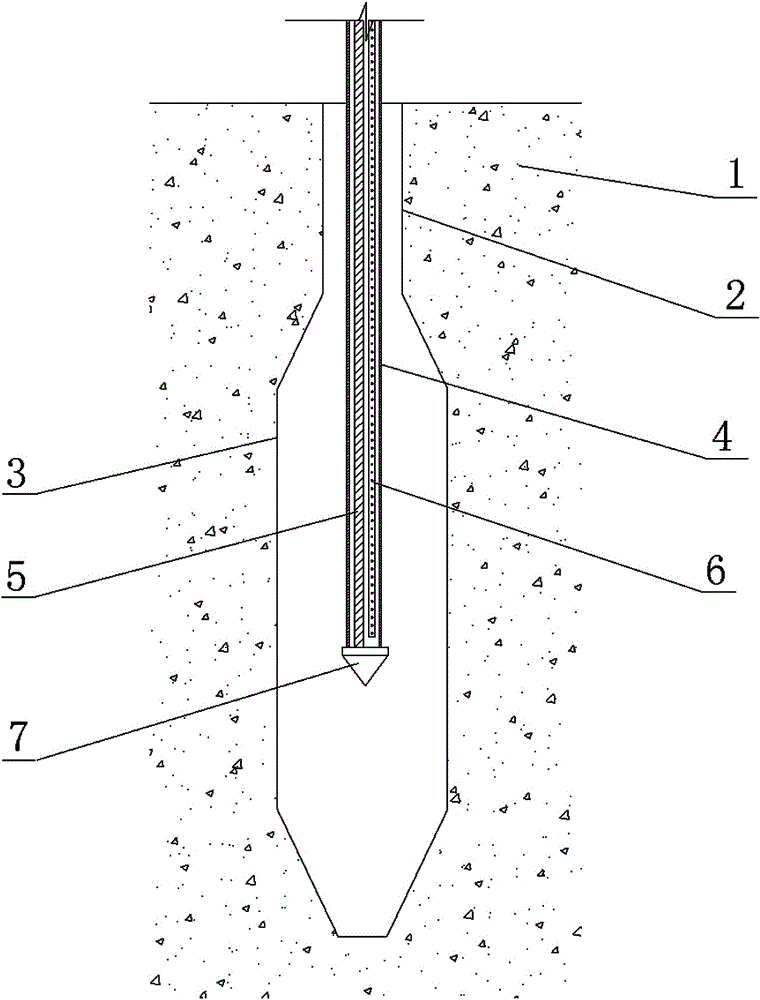

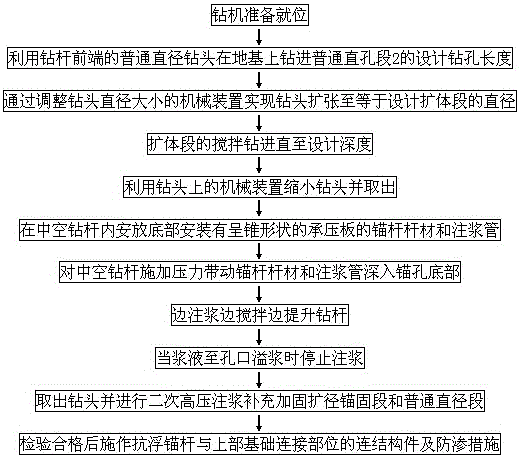

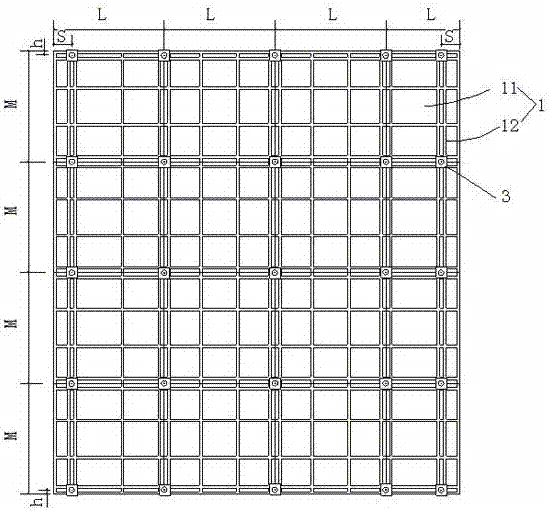

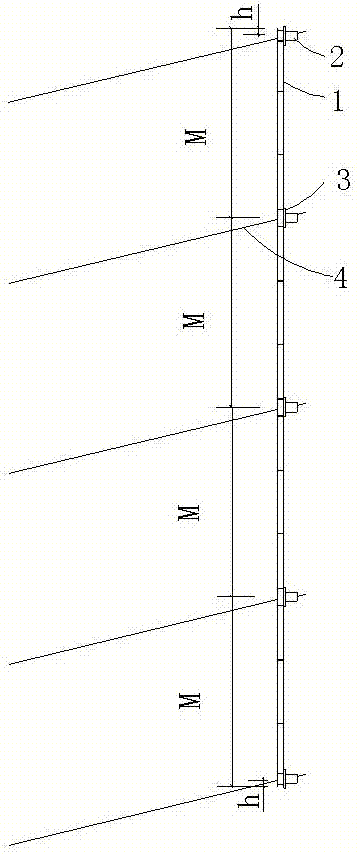

Mechanical agitation type body-expanding anti-floating anchor construction method

InactiveCN106284342AImprove pullout resistanceHigh strengthProtective foundationBulkheads/pilesDrill holeDrill bit

The invention discloses a mechanical agitation type body-expanding anti-floating anchor construction method. The mechanical agitation type body-expanding anti-floating anchor construction method comprises the following steps that S1, a drilling machine is prepared; S2, a drill hole, with the designed length, of an ordinary straight hole section is drilled in a foundation through an ordinary-diameter drill bit at the front end of a drill rod; S3, the drill bit is expanded through a mechanical device used for adjusting the diameter of the drill bit till the diameter of the drill bit is equal to the diameter of a designed body expanding section; S6, an anchor material with a conical pressure-bearing plate mounted at the bottom, and a grouting pipe are placed in the hollow drill rod; S7, pressure is applied to the hollow drill rod, so that the anchor material and the grouting pipe are driven to go deep into the bottom of an anchor hole; and S9, when grout reaches the hole orifice and overflows, grouting is stopped. The mechanical agitation type body-expanding anti-floating anchor construction method has the following characteristics that since stirring and grouting are conducted at the same time, an anchor body is uniform and reliable; and the bearing behavior of an ordinary tension type anchor is improved through diameter changing, the pulling resistance is improved, raising dust is avoided when stirring is conducted in the hole for hole formation, the earth outward transportation amount or waste grout treatment amount is reduced, the use amount of grout is reduced, and the construction cost of anti-floating projects is reduced.

Owner:SOUTHWESTERN ARCHITECTURAL DESIGN INST

Recoverable and modular deep foundation pit construction process, recoverable module and deep foundation pit support

The invention provides a recoverable and modular deep foundation pit construction process, a recoverable module and a deep foundation pit support and belongs to the technical field of deep foundation pit excavation and supporting. The process comprises the following steps that a foundation pit is dug down; a first anchor cable hole is formed, a first anchor cable is put in, and a grouting stop plug is installed for grouting; a second anchor cable hole is formed, a second anchor cable is put in, and a grouting stop plug is installed for grouting; modules and connecting fasteners are installed; a prestressing force is exerted to the first anchor cable and the second anchor cable to for a first layer of supporting; the operations are repeated to form multiple layers of supporting; modules, anchor cables and connecting fasteners of the last layer of supporting are recovered, soil is backfilled to the bottom surface of the second layer of supporting till the first layer of supporting is recovered. A soil body surrounding a deep foundation pit is supported and retained by adopting the modules and anchor cables jointly, the modules can be recycled, and materials waste and construction cost are reduced.

Owner:河北建科唐秦建筑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com