Combined type section steel support rod piece

A support rod and combined technology, used in excavation, construction, infrastructure engineering, etc., can solve the problems of difficulty in ensuring welding quality in foundation pit engineering, the gap between the load capacity of strong shaft and weak bearing, and the inability of material strength to fully exert. The effect of reducing the risk of foundation pit use, long turnaround period, and reducing the impact of human and weather factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, not to limit the present invention.

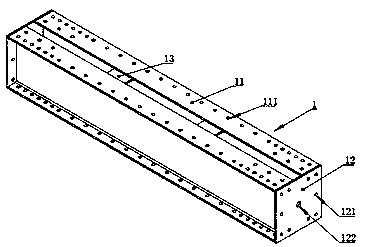

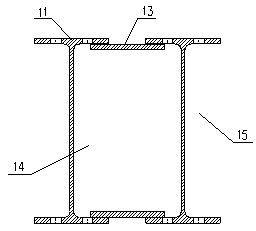

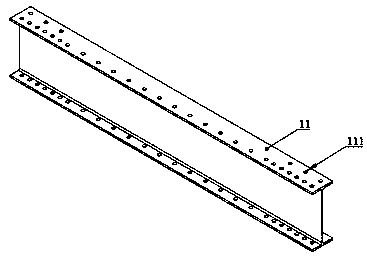

[0036] Such as figure 1 As shown, the combined section steel support bar 1 includes section steel 11 , end plate 12 and trim plate 13 . Such as figure 2 As shown, a pair of profiled steels 11 spliced into a combined profiled steel support bar 1 has a rectangular space 14 formed in its cross section and grooved spaces 15 on both sides. Such as image 3 As shown, the shaped steel 11 is an H-shaped steel, and bolt holes 111 are reserved in the flange plate. The end portion of the combined shaped steel support bar 1 is welded with an end plate 12, and the end plate 12 can comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com