Grouting sealing bag type dewatering well wall water stop structure

A technology for sealing bag type and dewatering wells, which is applied in infrastructure engineering, gaskets, buildings, etc. It can solve the problems of grout outflow, easy gaps, and failure to reach grouting pressure, etc., to achieve convenient batch installation and disassembly, and reliable quality , Construction quality and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

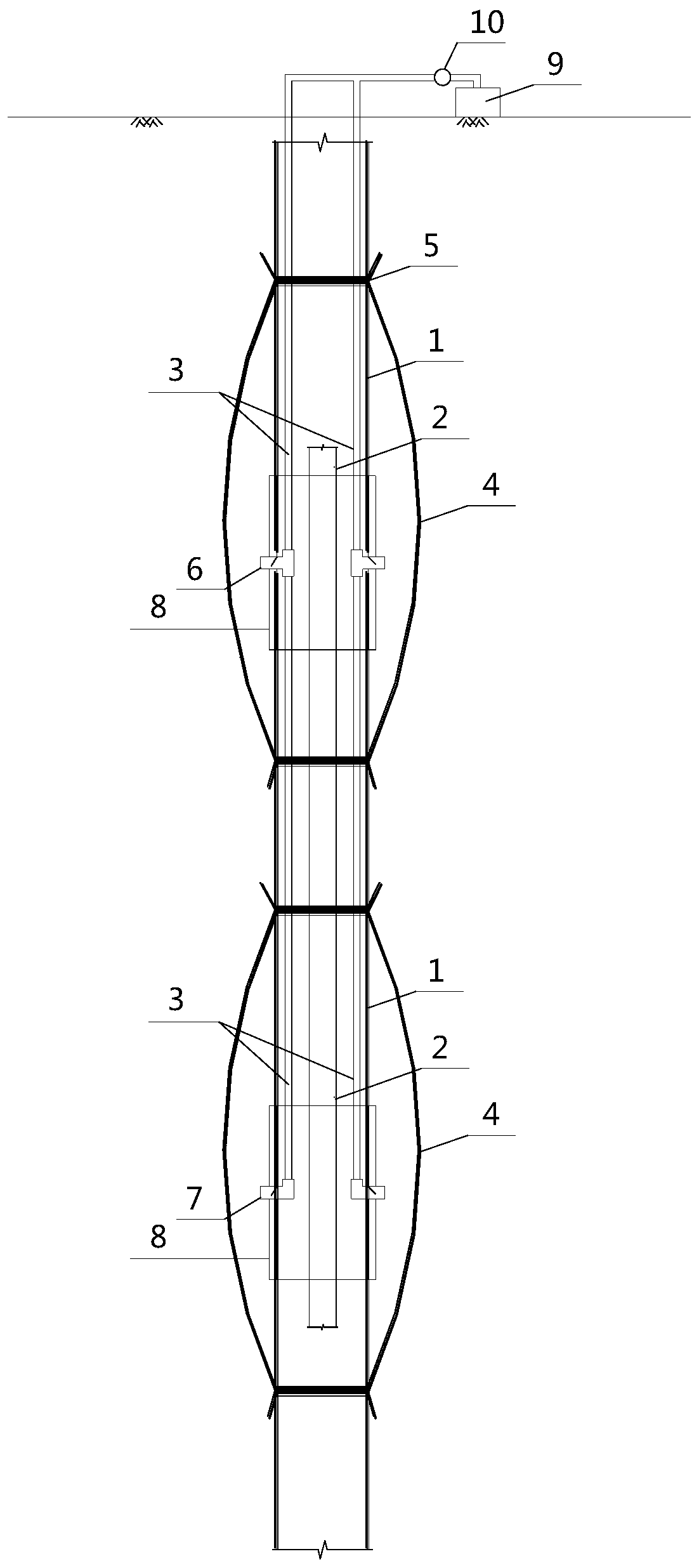

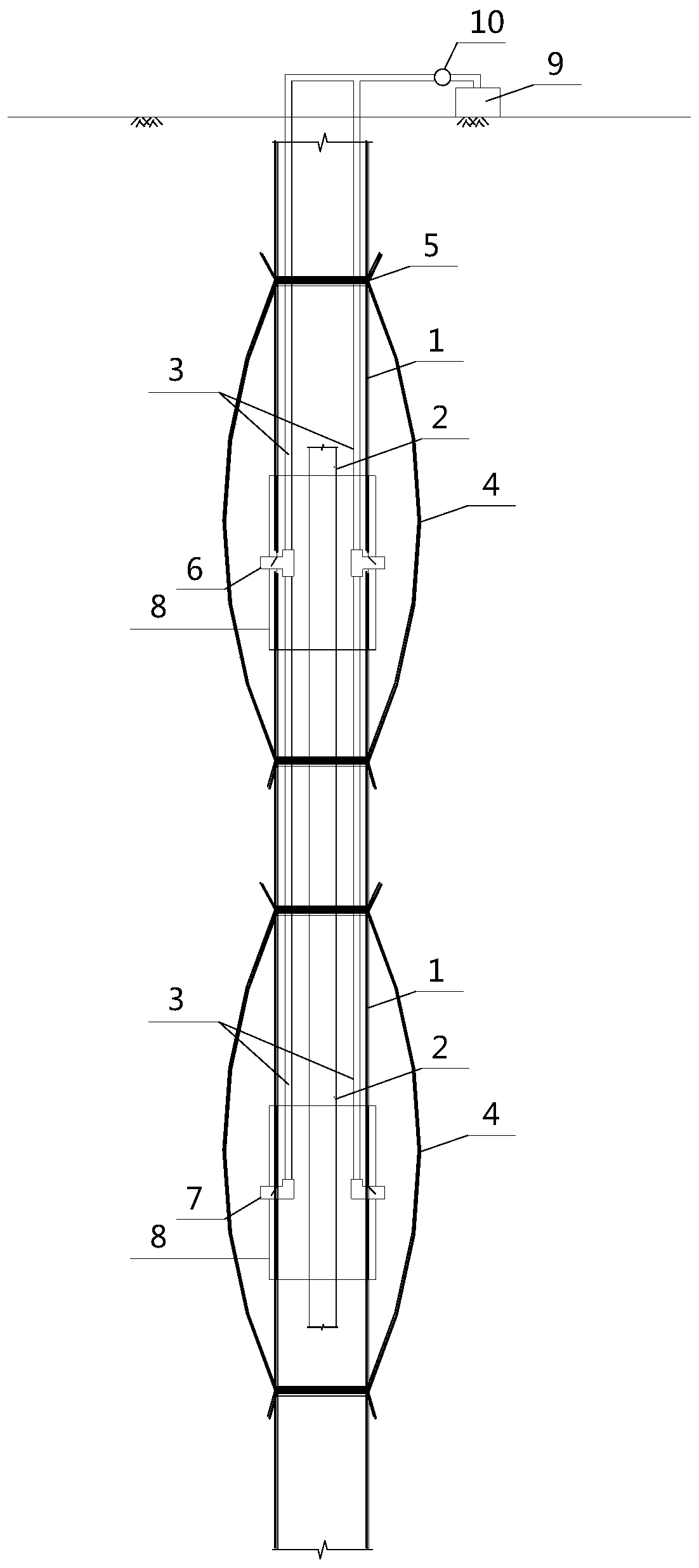

[0022] see figure 1 , a grouting sealed bag type dewatering well wall water-stop structure, at least one sealed bag 4 is fixed on the upper and lower ends of the well pipe 1; the well pipe extends into at least one grouting pipe 3 from the upper port, and the grouting pipe 3 passes through The bypass valve arranged on it traverses through the wall hole reserved on the well pipe 1 and communicates with the inside of the sealed bag 4 .

[0023] In this example, see figure 1 , the middle part of the well pipe is provided with a water outlet pipe 2, and the upper end of the water outlet pipe 2 extends outside the well pipe, and is used as a drainage channel for inflating and draining water into the well pipe. In the accompanying drawings, the upper end of the water outlet pipe 2 is omitted, and actually needs to extend out of the well pipe.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com