Production technology of wall cloth

A production process and technology of wall coverings, applied in the field of production process of wall coverings, can solve the problems of high cost, human health hazards, single function, etc., and achieve the effect of reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

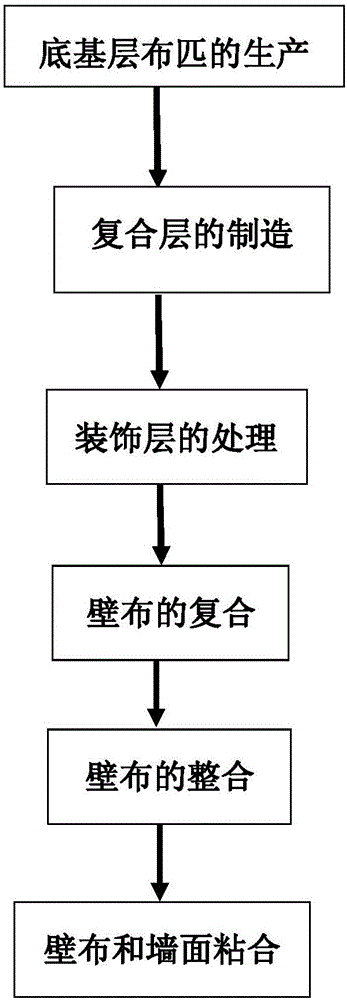

[0013] like figure 1 Shown, a kind of production process of wall covering, it is characterized in that, described production process comprises the following steps: The first step, the production of base layer cloth: adopt wide-width textile machine to produce, adopt nano-space cotton to weave and carry out It is obtained by shaping, finishing, decorative treatment and finishing; the second step is the manufacture of the composite layer: using a textile machine to weave the cloth and cotton, and performing shaping, finishing, decorative treatment and finishing on it; the third step , the treatment of the decorative layer: the surface of the decorative layer is dyed, shaped, arranged, decoratively treated and finished; the fourth step is the compounding of the wall covering: the above-mentioned base layer, decorative layer and compound layer are compounded by a compound machine, The base layer, the decorative layer and the composite layer are combined to obtain the wall covering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com