Oil bottom case oil discharge plug seat welding device

A technology of welding device and oil plug seat, applied in welding equipment, electrode support device, characteristics of welding rod, etc., can solve the problems of welding penetration, surfacing, air leakage, reducing production efficiency, high labor intensity of employees, etc., to achieve safety Good, reliable quality, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

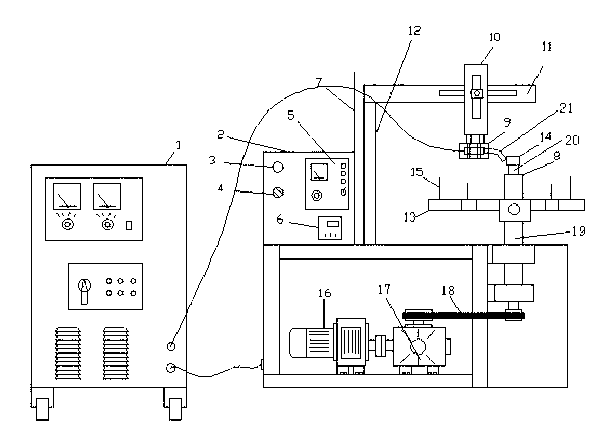

[0010] Such as figure 1 As shown, the present invention relates to a welding device for an oil drain plug seat of an oil pan, which is provided with a speed regulating motor 16, a reducer 17, a conveyor belt 18, a rotating shaft 19, a bracket 13, a limit block 15, a rotary mold 8, a pressing Mandrel 14, welding torch 21, angle adjuster 9, lift adjuster 10, left and right adjuster 11, support 12, protective plate 7, electric control box 2, welding machine 1, speed regulating motor 16 passes speed reducer 17, conveyer belt 18 and The rotating shaft 19 drives the bracket 13 to rotate, and the bracket 13 is horizontally installed on the rotating shaft 19. The bracket 13 is provided with several limit blocks 15, and the rotary mold 8 is installed on the limit block 15, and the workpiece 20 passes through the compression mandrel 14. Fixed on the rotary mold 8, and the welding ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com