Formwork-erecting-free self-heat-insulation brick wall construction method

A construction method and self-insulation technology, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of difficult control of construction quality, thick wall painting, hollowing, etc., and achieve shortened construction period and green construction , the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

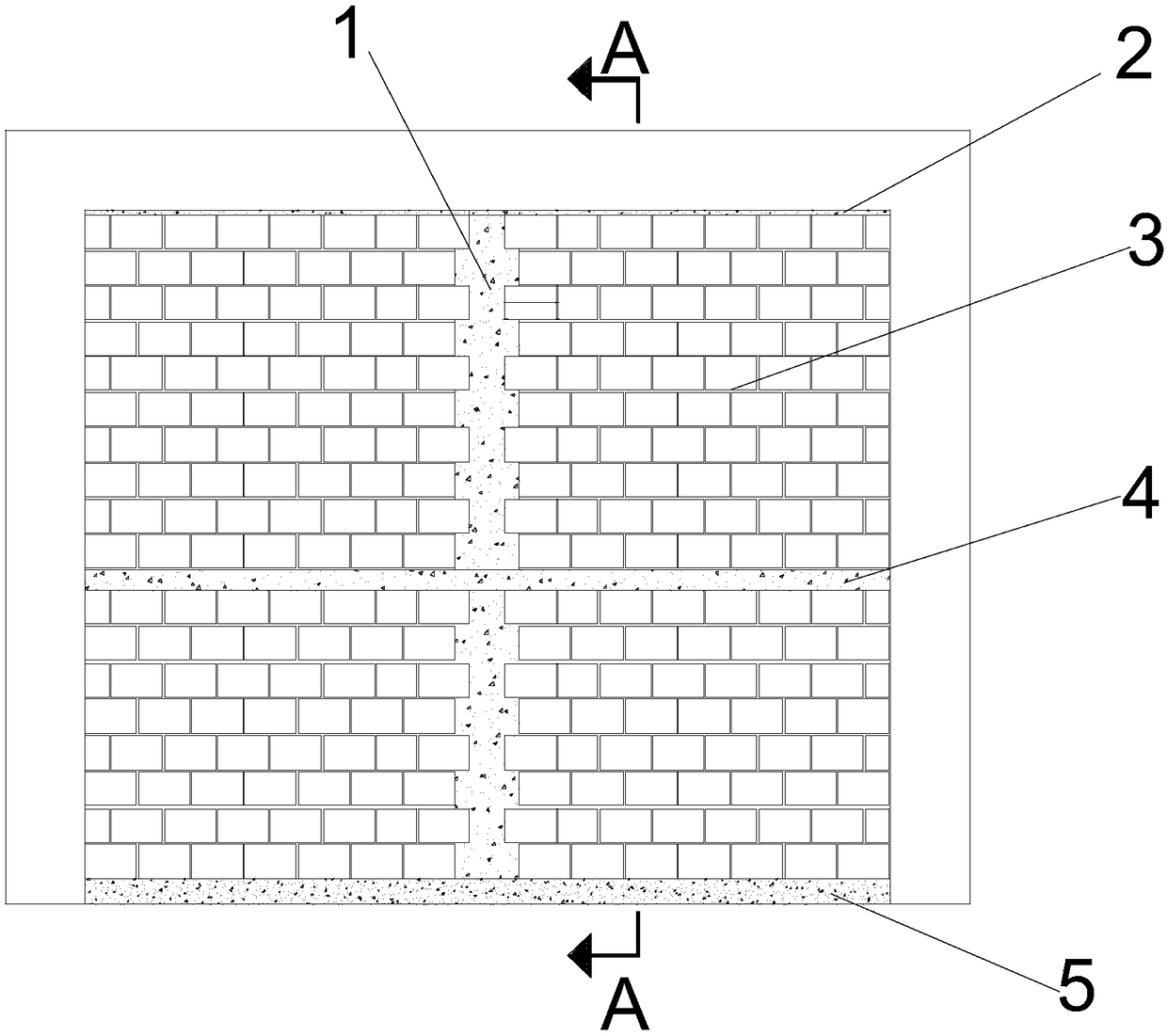

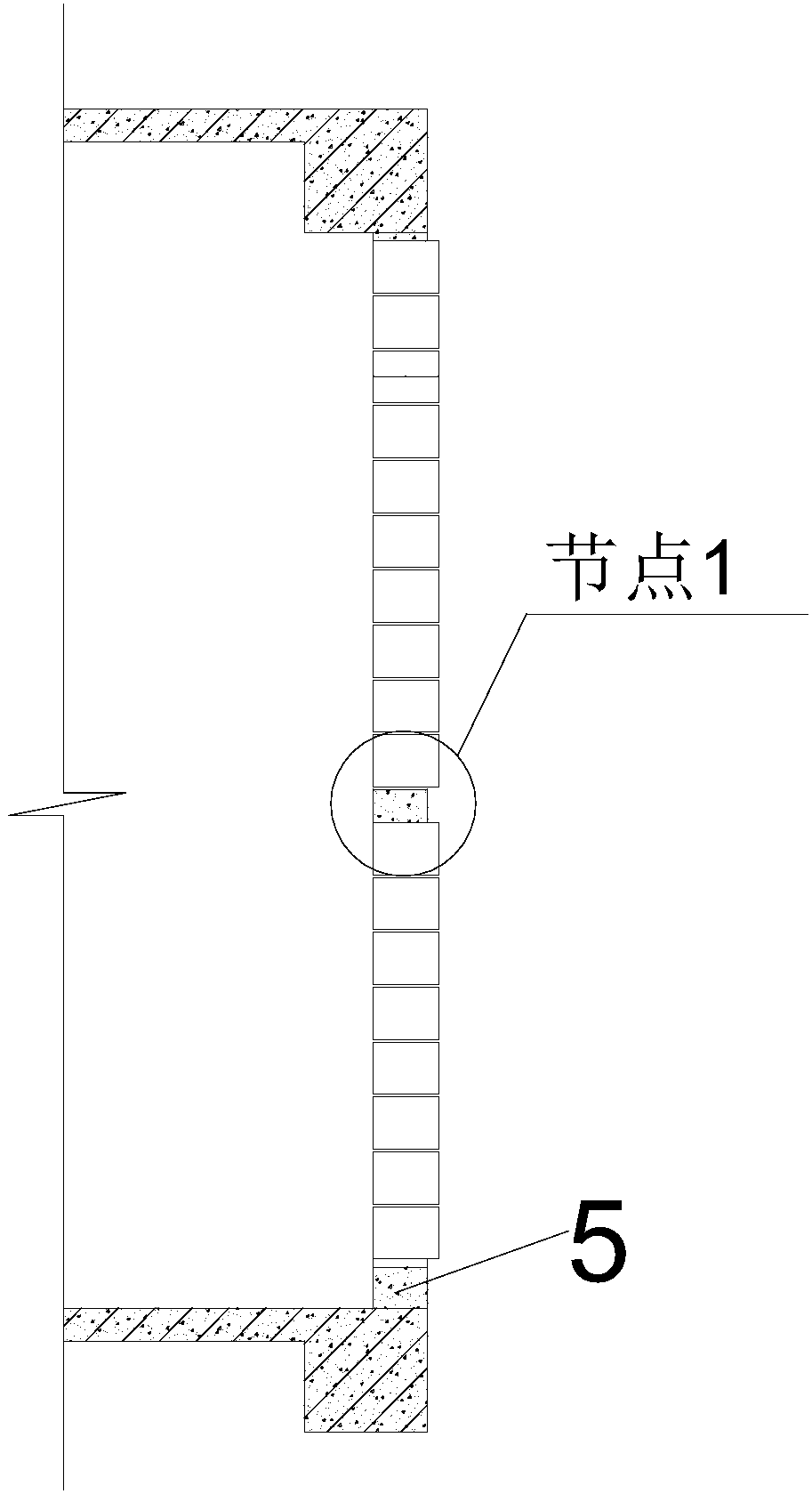

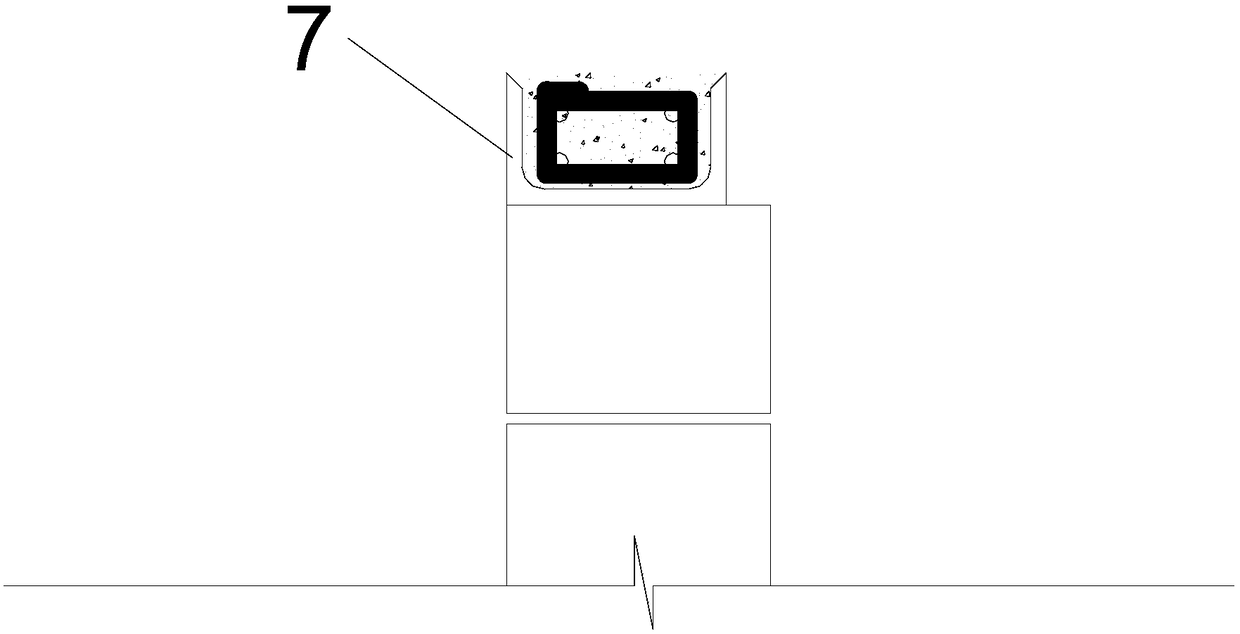

[0030] Example 1: See Figure 1-Figure 5 , the present invention provides a technical solution: a formwork-free self-insulating brick wall construction method, comprising the following steps:

[0031] (1) Play the main axis of the building and the masonry control sideline of the masonry according to the drawings, and plant reinforcement at the position where the structural column 1 is set according to the requirements of the specification;

[0032] (2) On the external wall or where there is a waterproof requirement, pour plain concrete flanging 5 with a height of 200 mm and the same level as the floor concrete. The width of the plain concrete flanging 5 is the thickness of the wall 3 minus the thickness of the insulation board 6 , and the inner wall of the plain concrete flange 5 is flush with the inner wall of the wall 3;

[0033] (3) Arrange the bricks on the wall 3 with a number rod, and plant reinforcements at the position of the waist beam 4;

[0034] (4) The lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com