Automatic dust removal system and excavator

An automatic dust removal and excavator technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, and the use of liquid separating agents, etc., can solve problems that affect the health of construction workers and a large amount of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

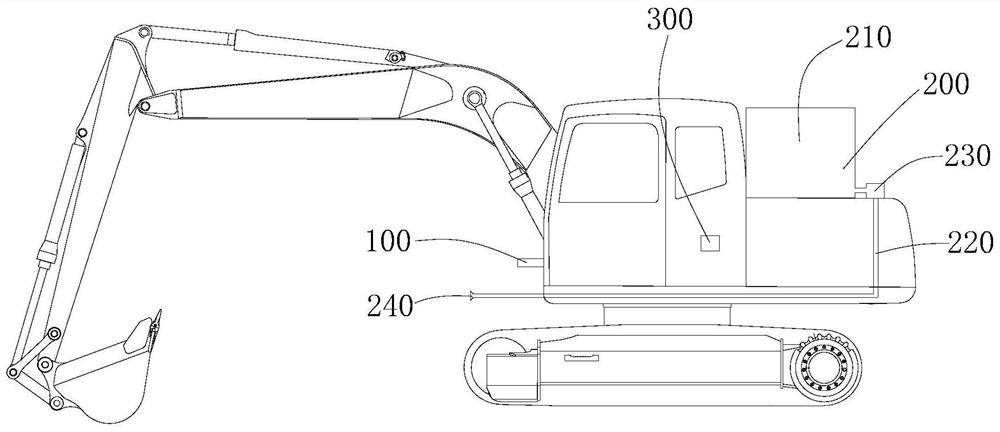

[0038] see figure 1 , this embodiment provides an automatic dust removal system, which is applied to an excavator, and includes a dust sensor 100 , a spray device 200 and a controller 300 .

[0039] Specifically, the dust sensor 100 is used to detect the dust concentration in the environment, the spray device 200 is used to spray the environment to reduce the dust concentration, and the controller 300 is connected to the dust sensor 100 and the spray device 200 respectively to obtain the dust concentration , and control the spraying device 200 to perform the spraying operation according to the dust concentration.

[0040] When the excavator is performing construction work, start the engine, and the dust sensor 100 starts to work to detect the dust concentration in the construction environment of the excavator in real time, and the dust sensor 100 transmits the dust concentration information detected in real time to the controller 300 in real time, and controls The controller ...

Embodiment 2

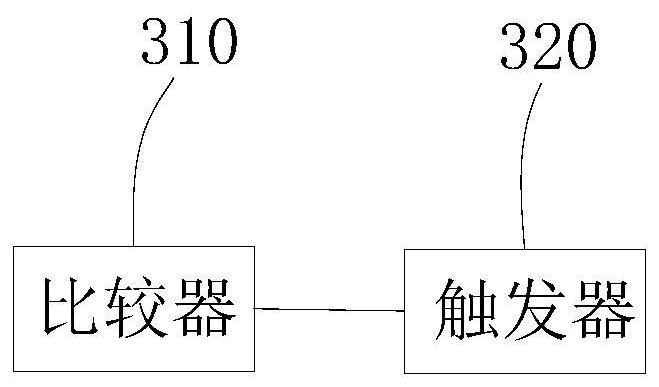

[0046] see figure 1 and figure 2, this embodiment provides an automatic dust removal system, which is applied to excavators. The automatic dust removal system provided by this embodiment is based on the automatic dust removal system provided by the first embodiment above, and some of the structures are improved. Compared with the automatic dust removal system provided in the first embodiment above, the specific improvements are as follows:

[0047] In the automatic dust removal system provided in this embodiment, the controller 300 includes a comparator 310 and a trigger 320, the comparator 310 is connected to the dust sensor 100, receives the dust concentration detected by the dust sensor 100 and compares it with the preset dust concentration threshold , the trigger 320 is connected to the comparator 310, and when the dust concentration exceeds the dust concentration threshold, the trigger 320 controls to start the spraying device 200.

[0048] Specifically, the dust conce...

Embodiment 3

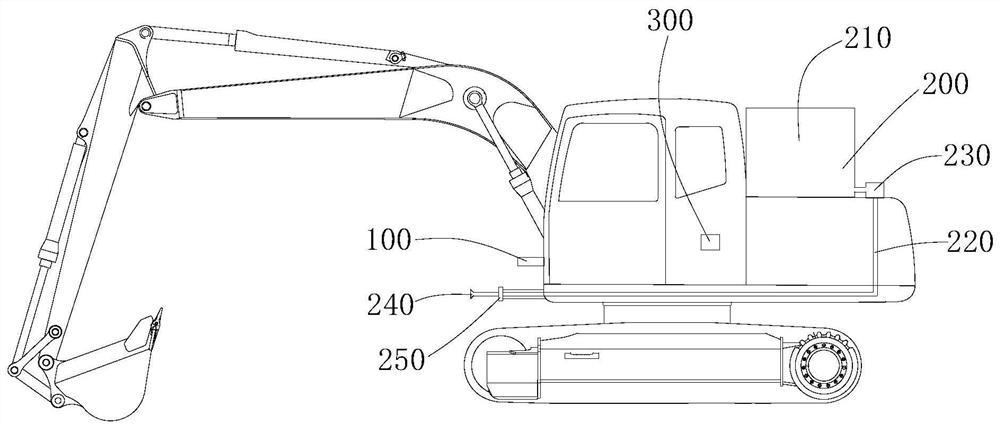

[0055] see figure 1 and figure 2 , this embodiment provides an automatic dust removal system, which is applied to excavators. The automatic dust removal system provided by this embodiment is based on the automatic dust removal system provided by the first or second embodiment above. Compared with the automatic dust removal system provided in the above-mentioned embodiment 1 or embodiment 2, the specific improvements are as follows:

[0056] In the automatic dust removal system provided in this embodiment, the spraying device 200 includes a water storage tank 210, a water delivery pipe 220, and a booster pump 230. One end of the water delivery pipe 220 is connected to the water storage tank 210, and the booster pump 230 is installed on the water delivery pipe 220. The booster pump 230 is connected to the controller 300 .

[0057] Specifically, the water storage tank 210 is a plastic water tank, and the water storage tank 210 is fixedly installed on the chassis at the rear si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com