Automatic spraying maintenance system for concrete vertical member employing circulating water supply

A vertical component, circulating water supply technology, applied in building construction, construction, building materials processing and other directions, can solve problems affecting the quality of plastering and bonding, difficulty in film removal, hollowing, etc., to avoid complaints and maintenance. Reinforcement, good economic and social benefits, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

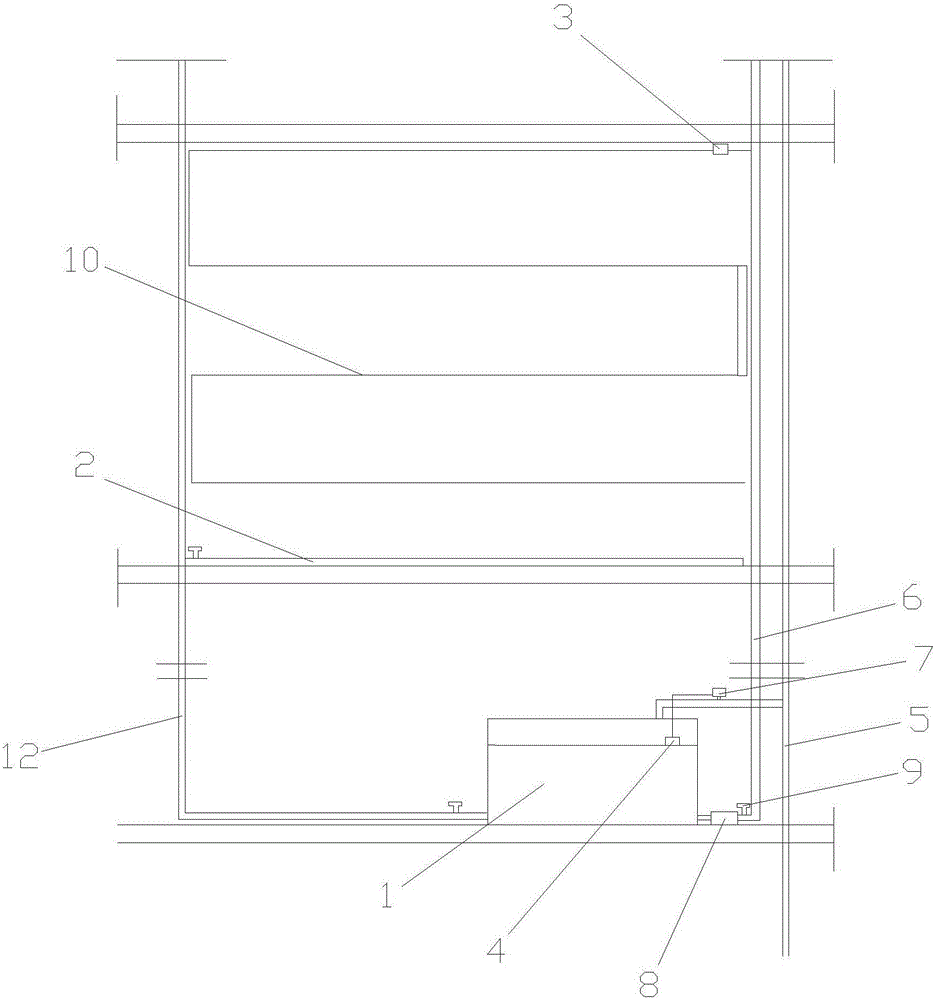

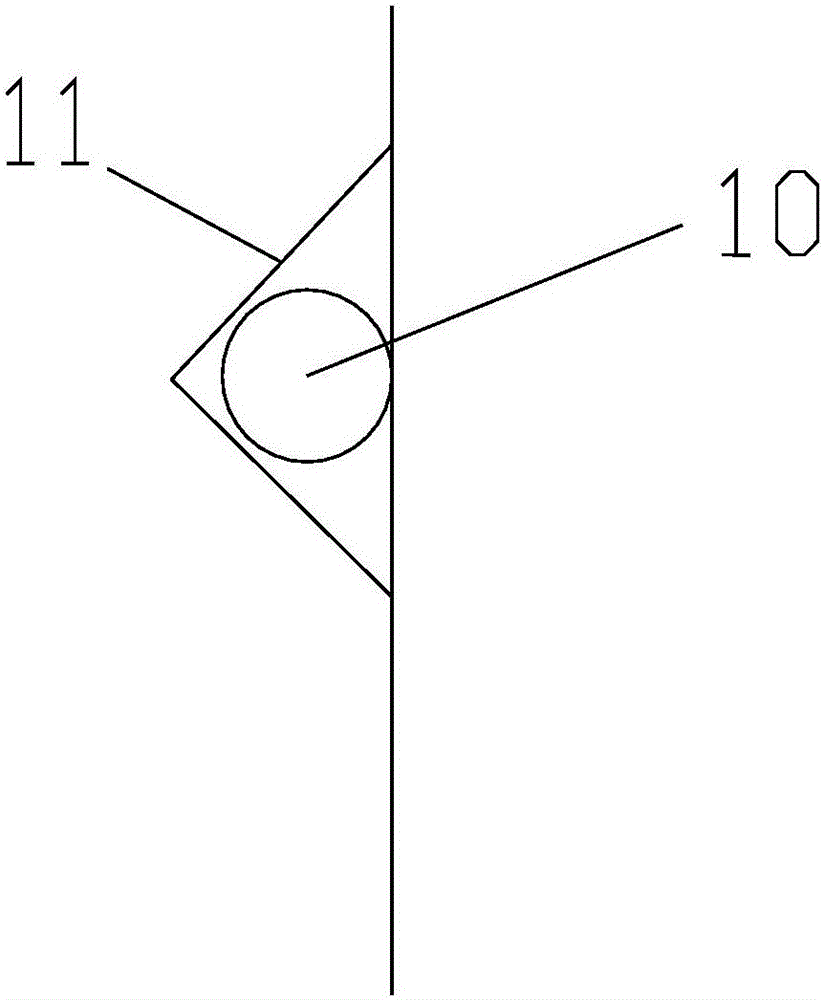

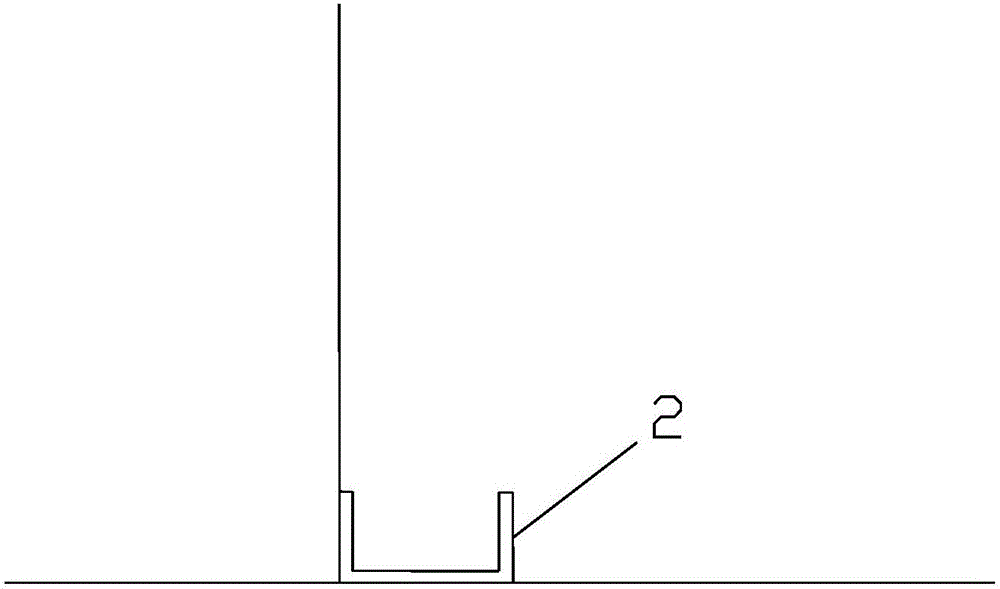

[0014] Such as Figure 1-3 As shown, a concrete vertical member circulating water supply automatic spraying maintenance system includes a water tank 1, a sump 2 and a timing control valve 3, the water tank 1 is provided with a water level sensor 4, and the water tank 1 is connected to a water supply trunk pipe 5 and the main water supply standpipe 6, the water level control valve 7 is installed on the water supply main pipe 5, the water level control valve 7 is connected with the water level sensor 4, when the water level is too low, the water level control valve 7 is automatically opened, To replenish water in the water tank 1, the main water supply standpipe 6 is provided with a water pump 8 and a check valve 9, the water pump 8 is connected with the timing control valve 3, and the main water supply standpipe 6 is connected with a spray pipe 10, so The spray pipe 10 is provided with more than one, the spray pipe 10 constitutes an S shape, through holes (not shown) are drille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com